How to make a 3d printer extruder

The Ultimate Guide to 3D Printer Extruder

Table of Contents

What makes a good extruder? How does it work?

The hotend has been accused quite often about being the source of a jam or clogging issue. Most of us have forgotten that it’s only part of the problem, where the extruder has its part of the blame too. The stepper motor might be clicking at very low torque, the driving teeth might be grinding the filament, or even the idler might be deforming the filament. These are very common problems of low-end extruders, where the design was optimized for cost, not for reliability and accuracy.

We’ll dive into this blog and see how important an extruder is. You’ll understand the challenges in designing a compact, powerful and durable extruder. We’ll also take a look at how we managed to improve our design by taking a deeper look into them.

How It Works

The principle is fairly simple, a motor drives one or more traction wheels. These wheels grip into the filament, a much softer material, and ensures the torque is converted to a force towards the hotend. Each step from the motor corresponds to a length of filament, thus a volume of polymer. The 3D printer controller accurately synchronized these small bits of extruded filament with the X and Y movement.

Single, Dual and Quad Driving

Extruders can be characterized as single drive, double drive, and more recently, quad drive. This nomenclature corresponds to the amount of motorized driving wheels in contact with the filament.

Despite what people think, the dual drive is an innovation that dates. One of the first FDM machines from Stratasys, the FDM series printer, was already using a dual drive system for both extruders.

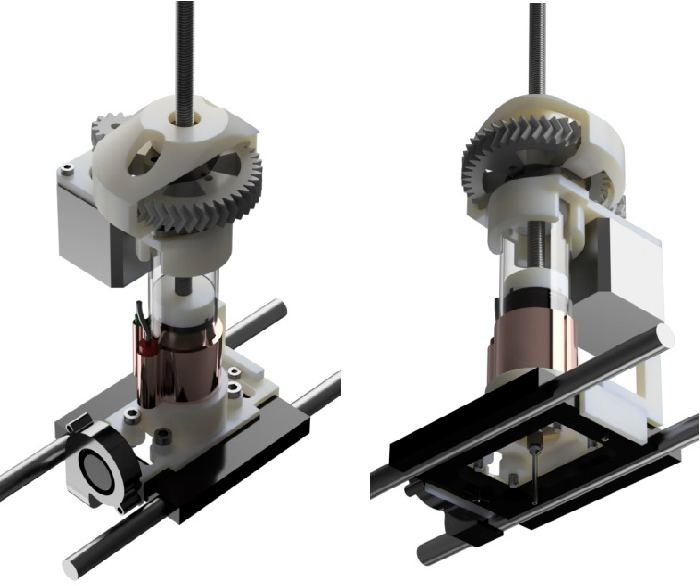

Dual Drive mechanism from FDM 2000 3D Printer from StratasysThe point of having more driving wheels is to increase contact with the filament, thus improving gripping and reducing slipping. Slipping is a general term used for describing the difference between the theoretical movement dictated by the driving wheel working pitch and the actual filament movement. It can be caused by either a bad traction, but also by filament deformation. This subject will be explained in further detail later.

It can be caused by either a bad traction, but also by filament deformation. This subject will be explained in further detail later.

The extrusion efficiency is the ratio of the actual length moved over the theoretical length sent to the extruder.

The graph below compares the extrusion efficiency between our legacy DyzeXtruder (single drive extruder), our current DyzeXtruder GT(dual drive extruder) and the Typhoon (quad drive extruder).

It can be seen that increasing the amount of traction wheels stabilize the output, meaning that you get closer to a constant volume extruded, no matter the speed. Also, having more traction wheels greatly helps reach faster speeds. As explained in our previous blog, increasing output flow will increase pressure. The driving wheels will have to push against this pressure. Without a firm grip, slipping occurs and speed can’t be reached.

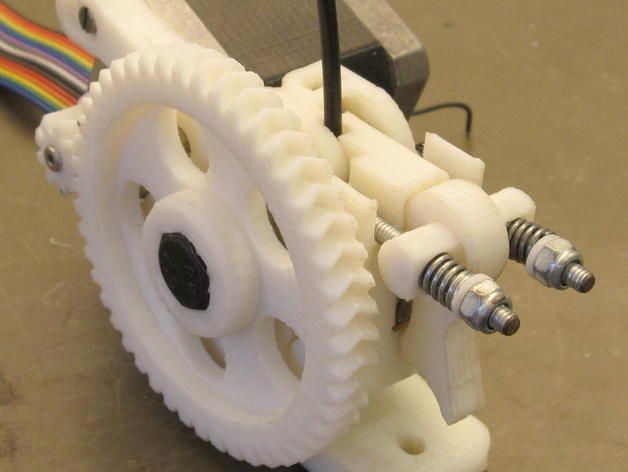

Gears

Extruders will greatly benefit from using one or more gear stages. Although the X and Y axis might be moving fast, the extruder might be slowly pushing the filament. Let’s take a typical case such as below:

Let’s take a typical case such as below:

Printing a 0.20 mm layer height, with a 0.65 mm line width (using a 0.40 mm nozzle) at 70 mm/s corresponds to an output volume of around 9 mm3/s.

Considering a driving wheel with a pitch diameter of 9 mm, using a filament of 1.75 mm, the extruder without gears needs to spin at about 0.42 rounds per seconds ( a full round corresponds to 21 mm3).

Taking a look at the torque curve of a NEMA17 stepper motor, you can see that the 0.42 RPS is far from using the motor at its maximum potential. With this current configuration, a gear reduction up to 10 could be achieved without suffering from the stepper torque decay.

STM17R-3NE motor torque curve from Applied MotionGear will increase output torque and resolution, two excellent factors when looking for great print quality. But it’s not only a matter of gear ratio.

Gears must be reliable, precise and strong. To drive 10 kg at the filament, the gears must endure quite a high stress. Since the first DyzeXtruder GT, we supplied quality heat treated gear steel to match our high reliability expectations. No brass gears or plastic gears could pass the torture tests. Even some untreated steel gear would show wear signs.

Since the first DyzeXtruder GT, we supplied quality heat treated gear steel to match our high reliability expectations. No brass gears or plastic gears could pass the torture tests. Even some untreated steel gear would show wear signs.

Not only gear material is critical: both gear lubrication and environment are two other critical factors. The gears should be fully enclosed, protected from the abrasive environment dust. Dust contains pollen, textile and paper fibers, but also minerals from outdoor soil, which can be very abrasive.

The DyzeXtruder GT and Pro have the gears enclosed and protectedTeeth Pattern

Many teeth patterns have been tested over the years. Hobbing is probably the most common type, derived from the manufacturing technique used for gears. We’ve seen knurls, standard gears with small modules, friction wheels, etc.

Comparison of extruder wheels from InstructableA good wheel pattern will provide enough grip to avoid shearing the filament while maintaining the filament shape. In fact, it’s quite easy to squeeze the filament as much as you can to get the best traction. However, after a few retracts, your filament will flatten and won’t fit inside you hotend anymore.

In fact, it’s quite easy to squeeze the filament as much as you can to get the best traction. However, after a few retracts, your filament will flatten and won’t fit inside you hotend anymore.

The sweet spot is a compromise between the indentation depth and the compression force. The new teeth pattern from the DyzeXtruder Pro is a good example, where the combination of groove shape and ball milled shape give a strong indentation in the filament, without changing its shape.

The DyzeXtruder Pro teeth shapeWheel size

The wheel radius is quite important too, theoretically. Having a bigger radius means that there is more contact between the teeth and the filament, thus leading to better grip. However, in practical terms, increasing the radius requires higher torque and bigger components. In the world of 3D printing, we prefer having a lightweight extruder and there is a limit to the size we can fit.

Power Loss in an Extruder

Starting from the electrical power sent to the motor, you’ll realize there are many losses in the system. This is perfectly normal for an electromechanical system, but we have control over some of them and things can be optimized in a way.

This is perfectly normal for an electromechanical system, but we have control over some of them and things can be optimized in a way.

First, the power loss in the motor is caused by the Eddy current loss and winding loss. Some motors are more efficient than others, but these parameters are hard to avoid. It’s possible, however, to change motor and gear combinations to ensure the motor is working at its peak efficiency. This is one of the reasons why both the DyzeXtruder GT and DyzeXtruder Pro have a weird gear ratio of 5.65 : 1. This gear ratio is the peak efficiency at printing speed, where torque and resolution are maximized.

DyzeXtruder GT gears in actionThen we have the gear loss, mostly caused by tooth friction, lubricant shear and bearings. The gear choice will highly affect the efficiency, where the worm gear starts with a 30% efficiency in worst cases, up to 98% with spur gear and helical gears.

Gear efficiency table by gear typesThe tooth indentation is all about the teeth pattern and pressure force. If you’re trying to indent a large slice into your filament, such as with the traditional hobbed design, you’ll need high-pressure force. Those two factors together end up requiring quite some torque with rigid filament, where the indentation strength is very high.

If you’re trying to indent a large slice into your filament, such as with the traditional hobbed design, you’ll need high-pressure force. Those two factors together end up requiring quite some torque with rigid filament, where the indentation strength is very high.

Finally, the loss in the filament after the teeth is mostly caused by the friction. Most rigid filaments won’t suffer much from friction. However, flexible filaments will highly be impacted by this factor. As the flexible material compresses and buckles, it’s effective diameter gets bigger and tries to grip the sides. This is one of the reasons why having a shorter distance between the driving gears and the melting zone is critical for flexible materials.

Troubleshooting an Extruder

Jamming used to be a very common problem, especially with PLA. The blame went all to the hotend, as the filament was stuck there (it makes sense after all). However, it wasn’t always the problem, the extruder also has its blame.

Problem Source

Too Little Torque

There are many factors that affect the torque:

- Too small motors: shorter motors tend to have less torque. However, winding can also affect both the torque and the maximum RPM.

- Low gear ratios: Up to a certain ratio (around 1:10 with a NEMA17), the extruder will benefit from having a higher reduction ratio.

- Low current: The motor will heat with over current, and will perform poorly with too little

Having too little torque means that you have less margin of error during retraction and extrusion. A weaker motor won’t be able to move the filament back into position after a retraction.

Bad Grip

Another very common problem is being unable to grip to the filament. Every filament type reacts differently to tooth patterns.

- Some are harder, thus difficult to penetrate, and will tend to slowly scratch until there is a groove in the filament.

Once this point is reached, the extruder won’t be able to push the filament anymore.

Once this point is reached, the extruder won’t be able to push the filament anymore. - Some softer filaments, such as flexible ones, will tend to avoid being gripped, and will simply avoid the driving wheel and slide over the teeth. With the Pro series extruder, we managed to see a big improvement in flexible filament extrusion with the new poke driving wheel design, and flexible filaments, once driven too hard, with start showing scales of shearing.

Filament Deformation

Based on the design, many extruders can squeeze the filament and make it flatter and larger. At some points, a bad combination of retraction amount and spring tension can lead to a filament larger than the filament path. Starting from this point, the extruder won’t be able to push the filament inside the hotend.

A good example from Rigid Ink where one side of the filament has been flattened by the extruderA bad slicer configuration can also be a part of this problem. Especially with Bowden setups, the retraction length is usually from 2 to 4 times the retraction used by direct drive users. For the same print, considering small parts are being printed with frequent retraction, the filament might be rolled over a few dozens of times with the Bowden setup, flattening the filament more each time.

Especially with Bowden setups, the retraction length is usually from 2 to 4 times the retraction used by direct drive users. For the same print, considering small parts are being printed with frequent retraction, the filament might be rolled over a few dozens of times with the Bowden setup, flattening the filament more each time.

The DyzeXtruder Pro has solved this issue. The new driving wheel is designed not to squeeze the filament, but rather to poke in it. No matter how much retraction, you won’t see any deformation in the filament.

Pressure Adjustment

Adjusting the spring tension has been quite a requested feature. There are many reasons why we decided not to include this in our extrusion systems. The key is repeatability:

- Precision: It’s very hard to adjust the spring twice at the same tension. Most of the time, the spring used is tiny, and only a preload difference of half-millimeter can make a huge difference on the filament. Also, most systems don’t have any precision scale.

Sometimes, the spring mechanism isn’t visible at all.

Sometimes, the spring mechanism isn’t visible at all. - Force and Torque: Changing the spring tension will change a lot of factors such as teeth indentation and total friction. The first element will reduce the risk of grinding the filament while the other will reduce the maximum output force.

- Error: After benchmarking a lot of filaments, you ended up with a different setting for each of them. It means that each time you change filament, you need to adjust another variable, leading to more errors like setting it wrong, or forgetting about it.

- Lever adjustment: Some high-tension settings compress the spring where the lever is unusable. To remove the filament, you need to undo your spring tension, move the lever, then readjust the spring tension.

- Extrusion: The spring tension will have a direct effect on the output flow. If you’re aiming for precision with your 3D printed parts, you need to make sure not to change the spring between two prints. This is impossible if you need to clear the lever by changing the spring tension.

As you can see, there are more downsides of adjusting the spring tension, and these are the reasons why we decided to opt for a better designed fixed spring.

Overheating

Another common problem is extruder overheating. This is one of the simplest problems to fix: reduce the current.

Each motor slot is precisely wound at an exact number of turns, using a precise copper magnet wire. Every motor runs many different tests at the factory for phase resistance and inductance. It’s very unlikely that the motor is overheating by being out of specs.

The main causes of error are:

- Poor stepper driver design: We’ve seen a lot of variations, and some very poor copies. Some stepper drives have the potentiometer wired wrong, making the adjustment in reverse. Others won’t provide a measuring point for voltage measurements. Some will have the wrong shunt (sense) resistors, making the current formula invalid.

- Poor measuring technique / tool : Sometimes, the wrong voltage is measured. You should always use the data sheet for validation. Using an improper tool will lead to results that are off. Make sure you use a measuring device with enough accuracy for small voltage.

Calibration

Calibration is underrated. Every polymer has a different rheology and will lead to different results. Depending on the slicer and the level of precision required, there might be better options.

For example, some slicers allow users to enter a percentage as flow adjustment, without any decimals. So only an adjustment with steps of 1% is possible. Sometimes with high flow rates, it can be bottlenecking.

Prusa Slicer allows as many decimals as you’d likeFilament Length Technique

The most common calibration technique involves the following steps:

- Preheat the hotend

- Mark the filament with a pen

- Note the distance between the mark and a reference point

- Extrude a known distance (usually around 100 mm)

- Measure the new distance between the mark and a reference point

- Calculate the new steps per millimeter

This technique is very straightforward, but has some limitations:

- The hotend has been hot for probably quite a while, thus it doesn’t represent a steady printing situation.

Having a “pre-molten” mass of polymer will make the first 20 mm easier to extrude than the rest, thus reducing the pressure at start.

Having a “pre-molten” mass of polymer will make the first 20 mm easier to extrude than the rest, thus reducing the pressure at start. - It’s very hard to measure the exact position of a drawn line of a filament. Using a ruler and a sharpie can easily lead to an error of +- 1 mm. It might not seem like a lot, but if you’re extruding only 100 mm, you have a 2% error right there.

- It’s very hard to choose the right extrusion speed. Should you set-it at 1 mm/s and wait about 2 minutes? Or 5 mm/s and wait less. Actually, each extrusion speed corresponds to a volumetric flow rate, thus different pressure level. If you’re setting it too fast, you’ll be calibrating with too much slipping. The resulting calibration will usually overflow by using slower extrusion speed.

- It’s impossible to use this technique with pellets.

Single Wall Thickness Technique

This technique is also very straightforward, but has many advantages over the previous technique.

Here are the steps:

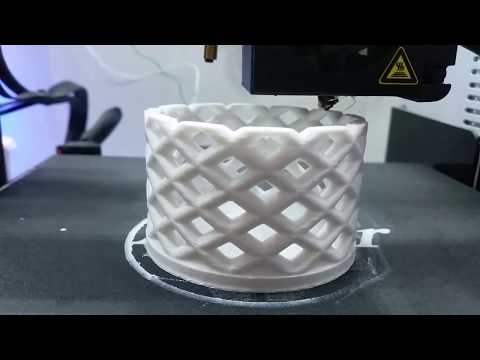

- Slice a small cube without infill (only one perimeter and no solid infill).

Use the same speed as your normal print settings

Use the same speed as your normal print settings- Small printers we usually print a 50 mm x 50 mm x 10 mm

- Medium printers with the Typhoon, we usually print 150 mm x 150 mm x 20 mm

- Large printers with the Pulsar, we usually print 250 mm x 250 mm x 30 mm

- Use a micrometer and measure the thickness of the wall, closer from the top. A vernier caliper will do, but is less precise.

- Calculate the new steps per millimeter

As mentioned before, here are the advantages:

- No variation caused by the idle time, bed temperature and other factors, since we measure the thickness of the last layers.

- Very precise measurements, based on your available tools, a digital micrometer can easily be found with a resolution of 1 µm.

- The speed is actually what you will use with a real print. There is no margin of error from this measurement to the actual print.

- This test works with both filament and pellets.

Structure and Ergonomics

The structure of your extruder is also very important. Many factors will be affected: total weight, rigidity, service temperature, etc. Let’s take a look at what should be carefully analyzed when choosing an extruder.

Many factors will be affected: total weight, rigidity, service temperature, etc. Let’s take a look at what should be carefully analyzed when choosing an extruder.

Materials

The housing material is critical. All the compressive loads used to pinch the filament are transferred from the bearings to the housing. Even though a plastic housing can be more affordable, you’re still pushing quite hard against the bearings to pinch the filament. With a heated environment, the plastic housing will get softer and won’t be of any use.

Competitor Extruder Cracking From the Applied LoadThe driving wheel material is also critical. Especially with filled filaments such as glass fibers and carbon fibers, each tooth will be in friction with this abrasive material. Choosing the right material is important, otherwise wear can happen pretty quickly.

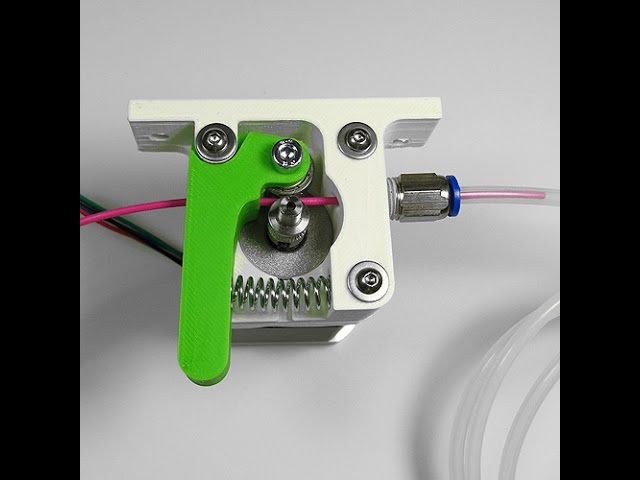

Updated version of DyzeXtruder Pro driving wheel: heat treated alloy steel with a hard coatingLatch

If you’re an experienced user, you know that you’ll be changing materials and filaments quite often. Some basic extruders don’t have any latch, others have one but you need to loosen the spring or even worse released in order to use it. To get the most out of a latch, we’re the only one to provide a “latch clip,” which holds the latch for you while you change filaments. It’s one of the most loved features from our users.

Some basic extruders don’t have any latch, others have one but you need to loosen the spring or even worse released in order to use it. To get the most out of a latch, we’re the only one to provide a “latch clip,” which holds the latch for you while you change filaments. It’s one of the most loved features from our users.

Groove Mount

Another vital feature you need to check is how to mount and remove the hotend. It’s highly possible that you’ll want to change the nozzle, clean the block, or adjust something. Some extruders are very impractical, and you need to remove the front housing (holding the gears and bearings) to remove the hotend. This is very impractical. Again, we did our best to make your life easier. A single screw can be loosened to remove the hotend, and not a single part needs to be removed. The biggest advantage is that the hotend can be removed along the filament axis. If you have a dry filament and it broke inside the extruder, you don’t need to worry; just pull out the hotend and the filament will follow.

Conclusion

I hope you liked this blog! We’ve seen how the extruder works, what’s inside, and what common problems people are having. Hopefully, it will be useful for you on your next upgrade or build.

3D Printer Nozzle Guide - Everything about 3D printer nozzles

When dealing with the topic of 3D printing, there is a lot to consider. Before you just start printing, you should look into the possibilities and settings of your 3D printer in order to achieve the best possible printing results and to preserve the service life of the device. An important and often underestimated part of the 3D printer is the printer nozzle, which is often given little attention. Even if the nozzle of a 3D printer is a very small component, it has a significant influence on the printing speed and quality.

In this comprehensive guide, we would like to explain to you what a 3D printer nozzle is, how different nozzle types differ and how to choose the right nozzle for your requirements.

Under this post you will also find our new YouTube video, in which we summarize the advantages and disadvantages of different nozzle types and show how you can easily and easily change the nozzle on your 3D printer.

What is a nozzle and what is it used for?

Nozzle are located on the hotend and it is through which the heated filament is printed on the printing platform. With most 3D printers, the nozzle can be exchanged. Depending on the requirements, changing the printer nozzle can be very worthwhile, so you should dare to try different nozzles.

How do 3D printer nozzles differ?

A basic distinction is made between 3D printer nozzles based on the following properties:

- Nozzle diameter

- Material

Depending on the material and nozzle diameter, the nozzle meets different print requirements.

Nozzle diameter

3D printer nozzles are available in different nozzle diameters from 0.1 to 2.0 mm. The diameter of a nozzle also determines the possible layer height and thus indirectly the printing speed, because:

Basically, it's about how much filament is extruded and how fast.

As a rule, the maximum layer height values should not exceed 80% of the nozzle diameter. For example, a 0.4 mm nozzle has a recommended maximum layer height of 0.32 mm.

If you want to know what maximum and minimum layer height you can print with your nozzle, use the following rule of thumb:

|

⇒ Maximum layer height = 0.75 * nozzle diameter ⇒ Minimum layer height = 0.25 * nozzle diameter |

0.4 mm nozzle as standard

For most 3D printers, the 0.4 mm nozzle has become the standard, as it is usually installed as standard and offers a good balance between resolution, precision and printing speed.

Small nozzles <0.4 mm

Small nozzles are ideally suited for the production of objects with very fine, precise details and barely visible layer traces.

Since the nozzle diameter is so small, the printing times are longer than, for example, with a 0. 4 mm nozzle. In addition, special materials, such as filaments with particles, cannot be processed with small nozzles. The risk of clogging the nozzle is also much higher than with larger nozzles.

4 mm nozzle. In addition, special materials, such as filaments with particles, cannot be processed with small nozzles. The risk of clogging the nozzle is also much higher than with larger nozzles.

Large nozzles> 0.4 mm

Large printer nozzles ensure a higher material flow, thicker layer heights and reduced printing times. The wider extrusion and the higher layers give the printed models more stability, but they are not as finely printed and are not rich in detail. In addition, wider nozzles hardly clog and are therefore ideal for special materials such as wood, carbon fibre or glow-in-the-dark filaments.

Due to the fast possibility of printing, large nozzles are particularly recommended for rapid prototyping.

|

⇒ Fact: When printing with a layer height of 0.4 mm, the printing time is almost halved compared to a layer height of 0.2 mm. |

Nozzle materials

Due to their relatively high thermal conductivity, 3D printer nozzles are made of different metals that influence the 3D printing process in different ways. Since some filaments have abrasive properties and therefore certain types of metal wear out faster than others, the nozzle material should be selected accordingly.

Since some filaments have abrasive properties and therefore certain types of metal wear out faster than others, the nozzle material should be selected accordingly.

In the following, we will list the different nozzle materials with their advantages and disadvantages in order to create an overview of their abilities.

- Brass nozzles

→ max 300 ° C.

Brass is the most commonly used material for 3D printer nozzles. It offers excellent heat transfer at a relatively low cost. When processing abrasive special filaments with wood, carbon or metal fibres, however, a brass nozzle wears out very quickly and becomes imprecise.

In order to protect the relatively soft nozzle material from excessive abrasion and to reduce the friction between the filament and the nozzle, a brass nozzle can be coated with nickel or chrome.

Advantages

- Low cost

- High thermal conductivity

Disadvantages

- Low wear resistance

- Not suitable for highly abrasive materials

- Coated nozzles

→ max 500 ° C.

In order to protect relatively soft nozzle material from excessive abrasion and to reduce the friction between the filament and nozzle, brass or copper nozzles are also available with a nickel or chrome coating.

In addition to the improved scratch resistance, a coating also significantly increases the temperature resistance of the nozzle.

Advantages

- Higher wear resistance than normal brass or copper

- Perfect all-rounder

- High-temperature resistance

- High thermal conductivity

Disadvantages

- Not as hard as hardened steel

- Not suitable for permanent use with abrasive materials

- Stainless steel nozzles

→ max 500 ° C.

Steel is another popular material for nozzles because it offers slightly better wear resistance than brass nozzles. They also, to some extent, prevent molten plastic from sticking to its surfaces and contaminating the print with lead, which is often the case with brass nozzles. Steel nozzles are therefore theoretically suitable for food-safe materials.

Steel nozzles are therefore theoretically suitable for food-safe materials.

Steel allows a wider range of filaments to be processed but is not recommended if abrasive filaments are used frequently. It is also less heat-conductive compared to brass.

Advantages

- Better wear resistance than brass

- Can be used for food-safe filaments

Disadvantages

- Lower thermal conductivity than brass

- Lower wear resistance than hardened steel

- Hardened Steel Nozzles

→ max 500 ° C.

Hardened steel nozzles are a useful 3D printer upgrade as they are tough enough for frequent use of abrasive materials (10 times more wear-resistant than brass nozzles) and literally offer years of use without replacement.

However, this material has an even lower thermal conductivity than the two previous materials and is more expensive to purchase. Since the inner surface of the nozzle is not as smooth as other “softer” nozzle materials, this can result in poor print quality.

Since the inner surface of the nozzle is not as smooth as other “softer” nozzle materials, this can result in poor print quality.

Advantages

- High wear resistance

- Very durable

- Suitable for abrasive materials

Disadvantages

- Lower thermal conductivity

- Lower print quality

- Higher cost

- Ruby Nozzles / Brass Ruby Nozzles

→ max 550 ° C.

Nozzles with ruby tips belong to the luxury class of 3D printer nozzles. As a rule, ruby nozzles are brass nozzles with or without a coating that have a ruby on the tip. Since the hole in the ruby can be made very precisely, there are only small diameter tolerances.

The ruby tip of the nozzle ensures additional wear resistance, which is particularly useful when processing special filaments. Compared to the other types of nozzles, the ruby nozzle is the most expensive.

Advantages

- High thermal conductivity due to the brass body

- High wear resistance

- High-temperature resistance

Disadvantages

- Higher cost

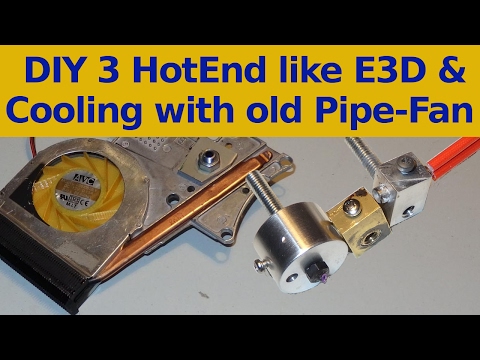

Changing the 3D printer nozzle - this is how it works

Would you like to exchange your 3D printer nozzle? In our video we show you exactly what to look out for when replacing the 3D printer nozzle.

We would be happy if you visit us on YouTube and leave a like or comment. If you want to see something specific on our channel in the future, please let us know in the comments!

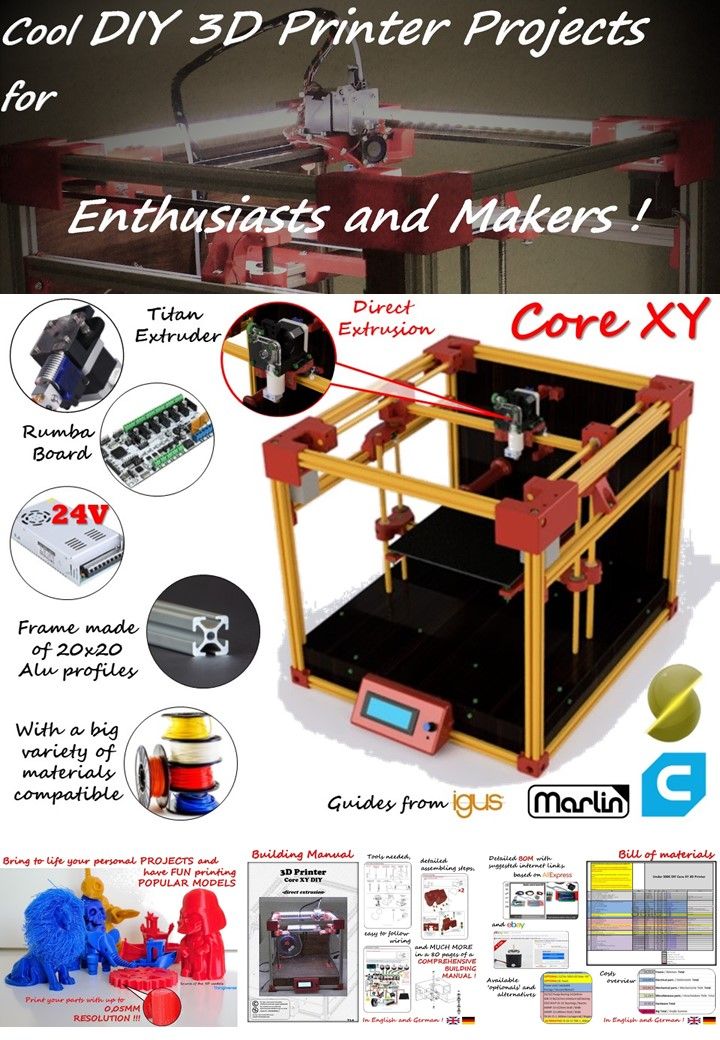

DIY 3d printer extruder, 3d printer extruder device - 3dprofy

Turch April 2nd, 2015

Each 3D printer has its own design features. The main role in any device is played by the 3d extruder, the second name of which is the print head. The essence of her work is simple: she squeezes plastic through a special nozzle, thanks to which a three-dimensional pattern is formed.

Design Features

The 3D printer uses several types of filamentary plastic, but ABS and PLA are the most commonly used. And despite the variety of consumables, all printheads are created according to the same principle and differ little from each other. nine0009 The device of the extruder of the 3d printer is as follows:

- The cool-end unit feeds the filament. It includes gears and a drive from an electric motor, as well as a clamping mechanism. Under the influence of the rotation of the gear, a plastic thread is removed from the coil, passed into the heater, where, under the influence of high temperature, the plastic becomes viscous. This structure makes it possible to extrude the thread through the nozzle to give it the desired shape.

- hot-end block is a nozzle with a heater. To create it, brass or aluminum are used, which are characterized by high thermal conductivity. The composition of the heating element also includes a spiral of nichrome wire, a pair of resistors, thermocouples that regulate the temperature.

During operation, the hot-end heats up, due to which the plastic melts. An important role is played by the timely cooling of the working platform, which is provided by a special thermal insulating insert between the hot-end and cool-end. nine0016

During operation, the hot-end heats up, due to which the plastic melts. An important role is played by the timely cooling of the working platform, which is provided by a special thermal insulating insert between the hot-end and cool-end. nine0016

A variation of the printhead is the bowden extruder, which differs in that the hot-end and cool-end are spaced apart in terms of location: the heater with the nozzle is located on the industrial printing press, while the feeder is located on the printer frame. The plastic thread is fed through a long Teflon tube. Its main purpose is to protect the thread from possible bends so that it is fed into the hot-end with optimal speed and pressure. The Bowden extruder is good because it allows you to make the print head smaller and lighter, but on the other hand, the transfer of plastic to the nozzle is not so reliable. nine0003

How to choose an extruder?

An extruder for a 3d printer must be chosen correctly, taking into account several important points:

- Material .

modern printheads are equipped with cast elements or created on the basis of 3d printing. Of course, cast modifications are durable, which is especially important for areas that have a large load. On the other hand, 3D printed parts are much cheaper.

modern printheads are equipped with cast elements or created on the basis of 3d printing. Of course, cast modifications are durable, which is especially important for areas that have a large load. On the other hand, 3D printed parts are much cheaper. - Filament supply . The quality of this mechanism plays an important role, since the thread must be fed to the heater constantly and accurately. This is the only way to ensure trouble-free printing. The plastic can get tangled on its way to the nozzle, so choose printers with a high power electric motor to minimize tangles.

- Feed roll type . Very often, as a result of poor adhesion of the material to the feed roller, the thread begins to slip. Especially often such situations arise when using nylon thread on those devices where only ABS or PLA plastic can be used. nine0016

- Nozzle size . The extruder can be equipped with nozzles of different diameters. An important role in the choice is played by the purpose of the products themselves.

For example, if objects must be carefully and detailed drawn, then the nozzle is selected with a smaller diameter. The smaller the nozzle, the higher the likelihood of clogging, so the best plastic extrusion is provided with a powerful electric motor.

For example, if objects must be carefully and detailed drawn, then the nozzle is selected with a smaller diameter. The smaller the nozzle, the higher the likelihood of clogging, so the best plastic extrusion is provided with a powerful electric motor.

How to make your own hands

To make an extruder for a 3D printer, an extruder with your own hands, you will need to choose a stepper motor. However, motors from old scanners or printers can also be used in this capacity. To mount the engine, you will need a housing, a pressure roller and a hot end. The case is created from different materials, while its design can be very different. The pressure roller must be adjusted by a spring because the bar thickness is not always ideal. The material engages with the feed mechanism, but the adhesion must not be too strong or pieces of plastic will break off. nine0003

You can buy a hot end (the purchase will cost about $ 100), or you can download drawings and create it yourself. The radiator is made of aluminum and is needed in order to remove heat from the barrel of the hot end. This will prevent the media from heating up prematurely. A good solution is an LED radiator, and the cooling is done by a fan. The barrel of the hot end is made from a hollow metal tube that connects the heatsink and the heating element. nine0003

The radiator is made of aluminum and is needed in order to remove heat from the barrel of the hot end. This will prevent the media from heating up prematurely. A good solution is an LED radiator, and the cooling is done by a fan. The barrel of the hot end is made from a hollow metal tube that connects the heatsink and the heating element. nine0003

The thin part of the tube is a thermal barrier that prevents heat from entering the top of the extruder. The main thing in the hot end is to ensure that the filament does not melt ahead of time, which will lead to clogging of the nozzle.

Do-it-yourself heating element in a 3d extruder is created from an aluminum plate. A hole is drilled in it for fastening the barrel of the hot end, then more holes are drilled for the fastening bolt, resistors, thermistor. The plate is heated by a resistor, and the task of the thermistor is to regulate the operating temperature. The nozzle can be created from a blind nut with a rounded end. It is better if the nut is brass or copper - these metals are easy to process. A bolt is fastened in a vice, then a nut is screwed onto it, and a hole is drilled in the center. Thus, an extruder is easily created at home. nine0003

It is better if the nut is brass or copper - these metals are easy to process. A bolt is fastened in a vice, then a nut is screwed onto it, and a hole is drilled in the center. Thus, an extruder is easily created at home. nine0003

Some printer models are equipped with dual extruders - this allows you to print two-color objects or create support structures from soluble polymer. That is, two types of plastic can be used simultaneously on such a device. True, simultaneous printing is still impossible, so each extruder is activated if necessary.

DIY 3D printer extruder

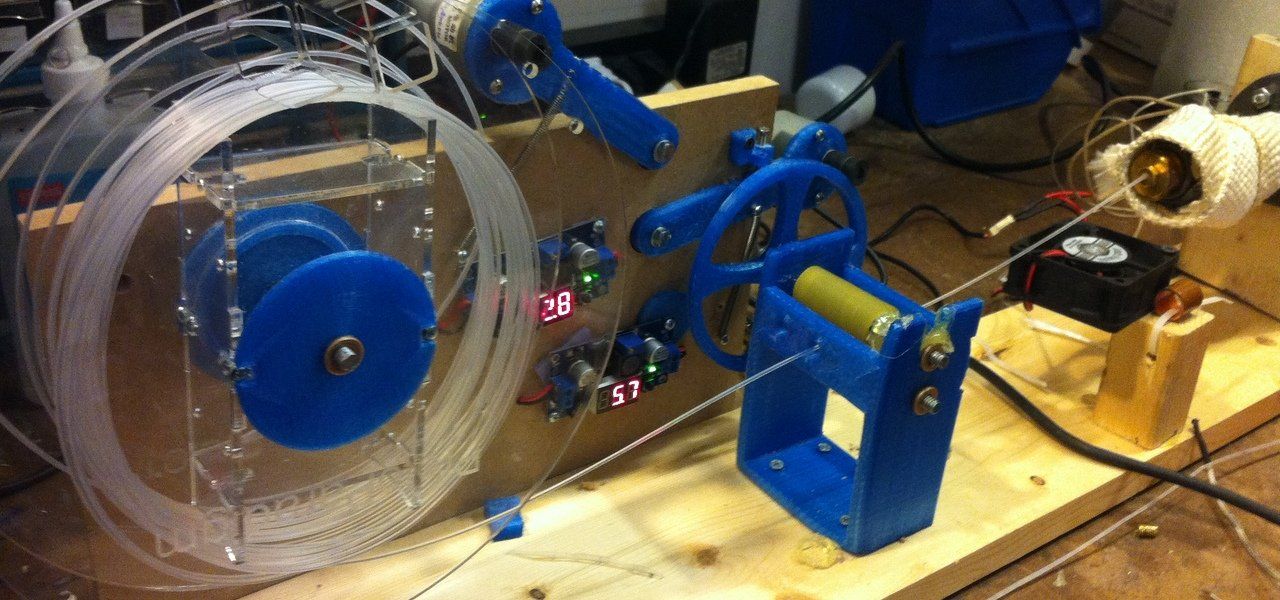

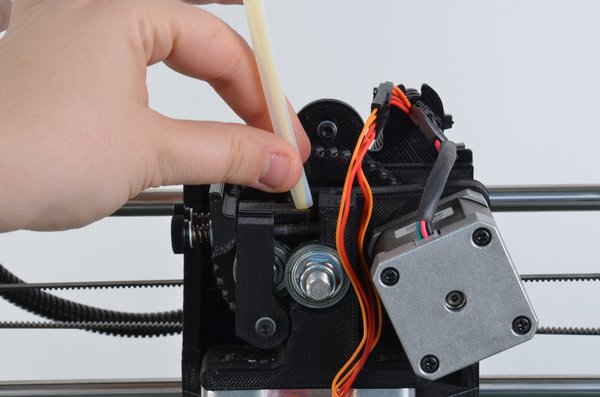

Parts for assembling an extruder How to assemble a Mosaic printer from a set of parts from MakerGear is described in the article Assembling a 3D printer with your own hands. You probably noticed that the device of a 3D printer is considered in detail there, but we are not talking about the print head. This is the topic of today's conversation.

You probably noticed that the device of a 3D printer is considered in detail there, but we are not talking about the print head. This is the topic of today's conversation.

We will look at the types of extruders and how to make individual parts of this complex mechanism in order to understand how to make an extruder with your own hands (video about drilling a nozzle at the end of the article). nine0003

How it works and varieties

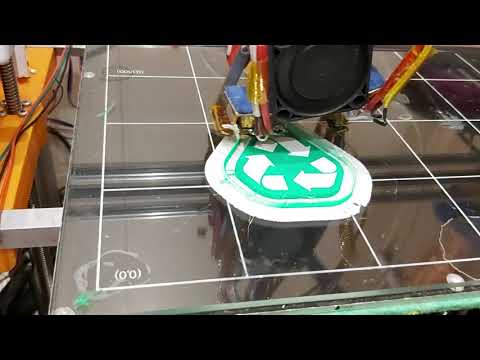

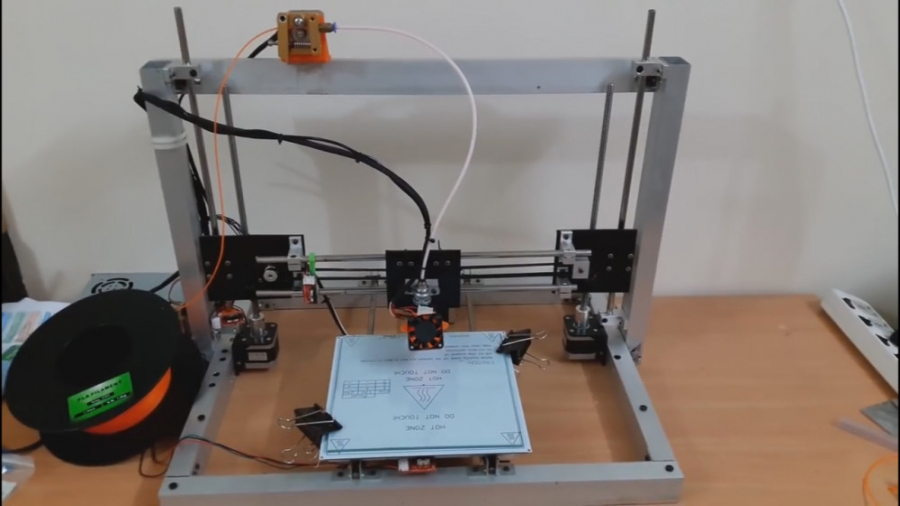

The print head of a 3-D printer pulls a plastic rod, heats it up and pushes the hot mass through the nozzles.

Wade extruder

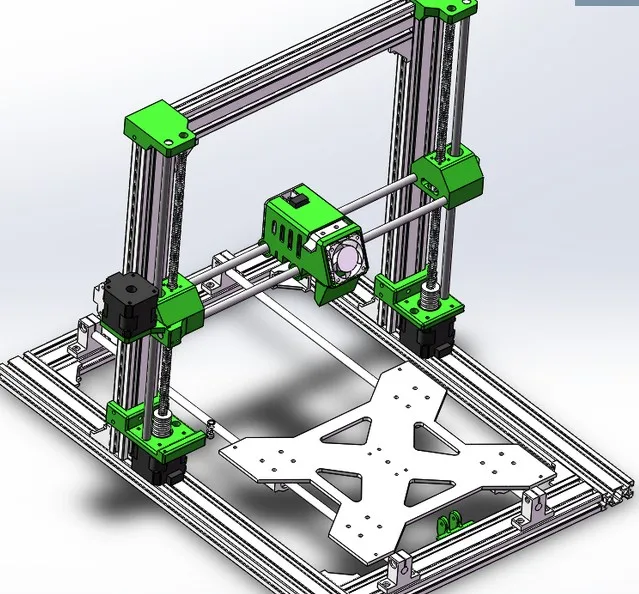

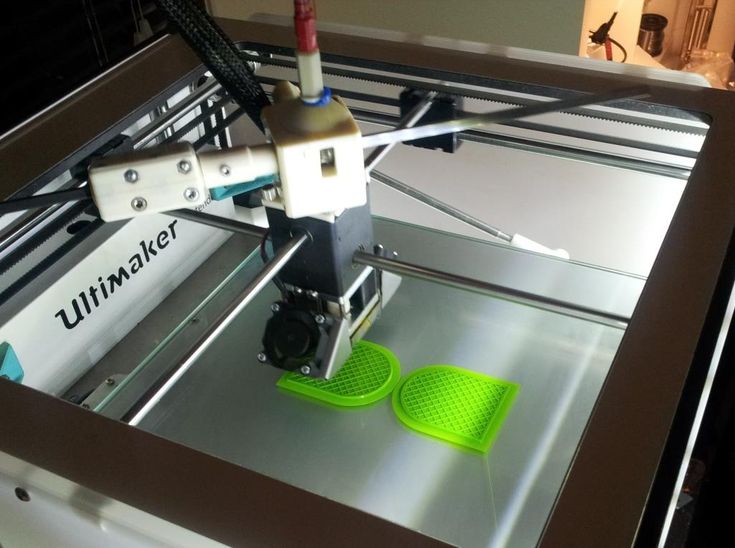

Extruder designThe picture shows a simplified diagram of the Wade type extruder. The device consists of two parts. At the top is the cold-end (cold end) - the mechanism that feeds the plastic, at the bottom - the hot-end (hot end), where the material is heated and squeezed out through the nozzle.

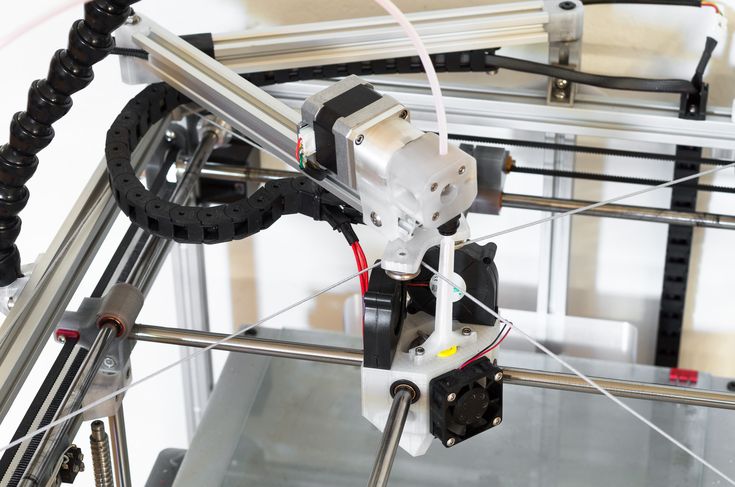

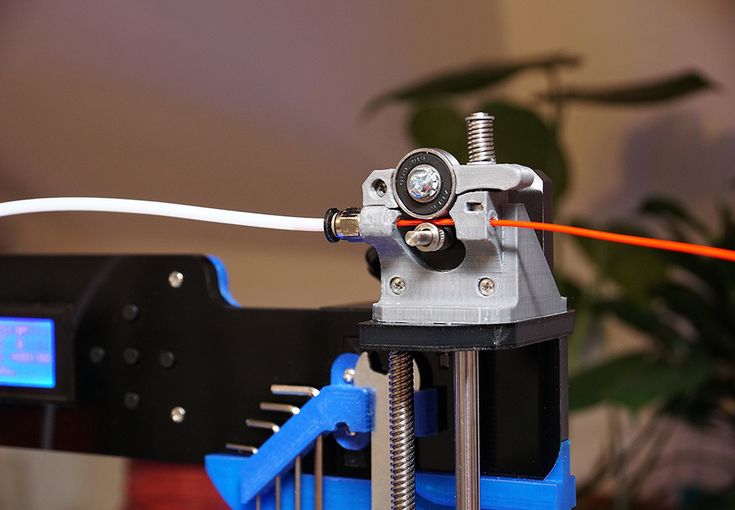

Bowden extruder

There is another design of the device, where the cold and hot parts are separated, and the plastic enters the hot-end through a Teflon tube. Such a model, where the cold end is rigidly fixed to the printer frame, is called the Bowden extruder.

Such a model, where the cold end is rigidly fixed to the printer frame, is called the Bowden extruder.

Its undoubted advantages include the following:

- the material does not melt ahead of time and does not clog the mechanism;

- The print head is significantly lighter, allowing for faster printing. nine0016

However, there are also disadvantages. The plastic thread at such a large distance can be twisted and even tangled. The solution to this problem may be to increase the power of the coldend engine.

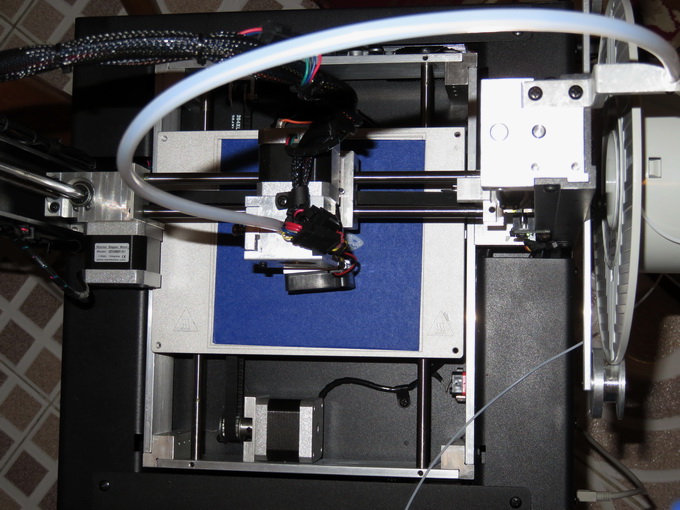

Cold end

E3D-v6 completeThe filament rod is pushed down by a gear driven by a gear motor. The feed wheel is rigidly mounted on the motor shaft, while the pressure roller is not fixed, but is in a floating position and, thanks to the spring, can move. This design allows the plastic threads not to get stuck if the diameter of the rod in some areas deviates from the specified size. nine0003

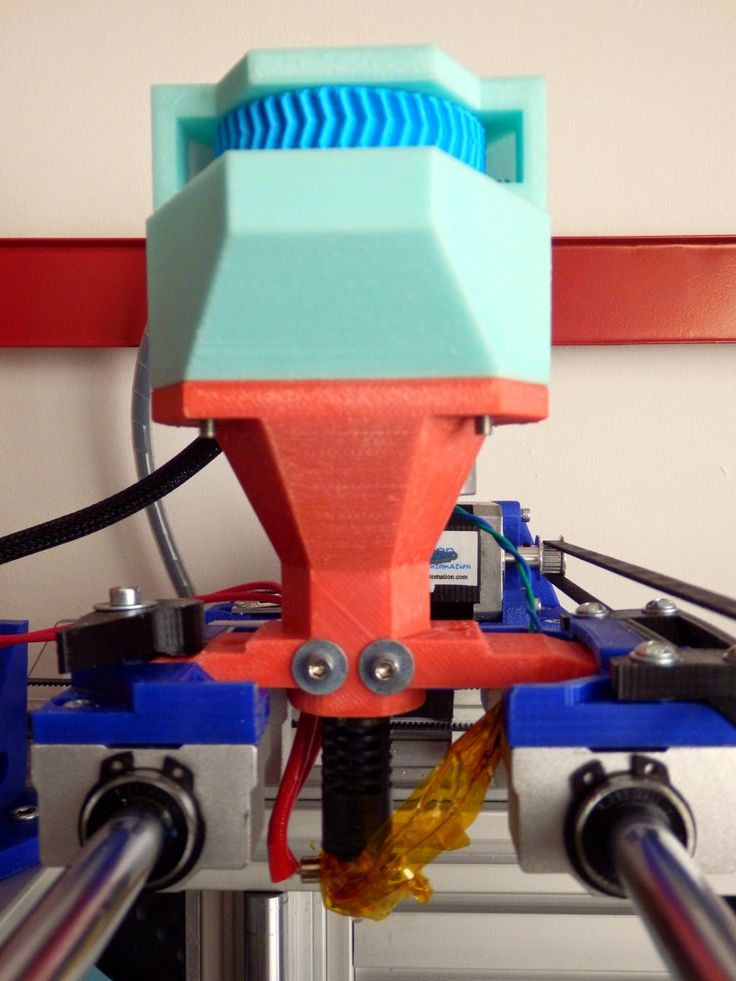

Hot-end

Plastic enters the bottom of the extruder through a metal tube. It is here that the material is heated and flows out in liquid form through the nozzle. The heater is a nichrome wire coil, or a plate and one or two resistors, the temperature is controlled by a sensor. The upper part of the mechanism should prevent early heating of the filament and prevent heat from passing up. Heat-resistant plastic or a radiator is used as insulation.

It is here that the material is heated and flows out in liquid form through the nozzle. The heater is a nichrome wire coil, or a plate and one or two resistors, the temperature is controlled by a sensor. The upper part of the mechanism should prevent early heating of the filament and prevent heat from passing up. Heat-resistant plastic or a radiator is used as insulation.

Feeder

Schematic diagram of aunipolar stepper motor

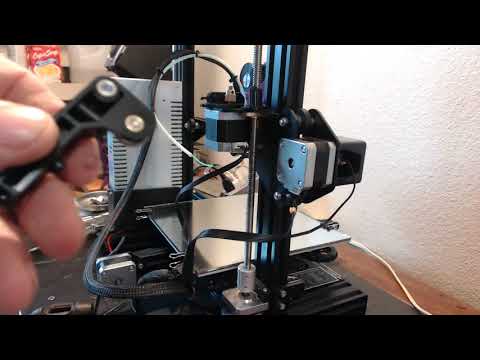

First of all, you need to choose a stepper motor. It is best to buy an analogue of Nema17, but motors from old printers or scanners, which are sold very cheaply on radio markets, are also quite suitable. For our purpose, we need a bipolar motor with 4 outputs. Actually, you can use unipolar, its circuit is shown in the figure. In this case, the yellow and white wires will simply remain unused, they can be cut off.

Printer motors are generally weak, but the EM-257 (Epson), as shown below, with a shaft torque of 3.2 kg/cm, is fine if you are going to use Ø 1. 75 mm filament. nine0003

75 mm filament. nine0003

For bar Ø 3 mm, or with a weaker motor, a gearbox is also required. It can also be picked up from dismantled old tools, for example, a planetary gearbox from a screwdriver.

Engines from printersAlteration will be needed to put the screw driver motor gear on the stepper, to align the axis of rotation of the motor with the gearbox. And the cover for the output shaft bearing also needs to be made. A gear is installed on the output axis, which will feed the plastic bar into the heating zone. nine0003

The extruder body is used to mount the motor, pressure roller and hot end. One of the options is shown in the figure, where a red filament rod is clearly visible through a transparent wall.

You can make a case from different materials, come up with your own design, or, taking a ready-made kit as a sample, order printing on a 3-d printer.

Transparent body extruder The main thing is that the pinch roller is adjustable by a spring, as the bar thickness is not always ideal. The adhesion of the material to the feeder should not be too strong, in order to avoid breaking off pieces of plastic, but sufficient to push the filament into the hot-end. nine0003

The adhesion of the material to the feeder should not be too strong, in order to avoid breaking off pieces of plastic, but sufficient to push the filament into the hot-end. nine0003

It should be noted that when printing with nylon, it is better to use a feed gear with sharp teeth, otherwise it simply will not be able to hook the bar and will slip.

All-metal hotend

E3D hotends are widespread and popular. You can buy it on ebay.com for $92 (without shipping) or download drawings that are freely available on the company's official website (http://e3d-online.com/), which you can use to make a decent savings. nine0003 hot end device

The heatsink is made of aluminum and serves to remove heat from the hot end barrel and prevent premature heating of the print material. An LED radiator is quite suitable, to enhance the cooling effect, you can also send a small fan to it.

Hot end shaft - a hollow metal tube connecting the radiator and the heating element. It is made of stainless steel due to its low thermal conductivity.

This is how the part looks in section and its drawing with dimensions for a bar Ø 1.75 mm. nine0003

The thin part of the tube acts as a thermal barrier and prevents heat from spreading to the top of the extruder. It is important that the filament does not begin to melt prematurely, because in this case the rod will have to push too much viscous mass. As a result, the friction force increases and the tube and nozzle become clogged.

It is not only the authors of self-made constructions who face the problem. This often happens in all-metal hot ends, even if the extruder is manufactured in production. nine0003 Additional thermal barrier

If you drilled the part yourself, you need to polish the barrel hole. For rough grinding, fine sandpaper “zero”, fixed with tape on a drill of a smaller diameter, is suitable.

Fine polishing to a mirror shine is required (with thread and paste GOI No. 1), then it is useful to fry the hole with sunflower oil to reduce friction. To prevent the plastic from heating up too early, you can cover the bottom of the tube located in the radiator with a thin layer of thermal paste. nine0003

To prevent the plastic from heating up too early, you can cover the bottom of the tube located in the radiator with a thin layer of thermal paste. nine0003

Another possible problem is that melted plastic under the pressure of the incoming bar can seep up and cool in the cooling zone, causing the barrel to clog and stop printing. You can fight this with the help of a Teflon insulating tube, which is inserted into the barrel of the hot end to the zone where the filament begins to heat up.

Heater

Heater plateThe heating element uses an aluminum plate. If you are unable to find a suitable thick bar, a 4 mm thick aluminum strip, which can be purchased at building materials stores, is quite suitable. In this case, the heating element will consist of two parts. It is necessary to drill a central hole for the hot end barrel, and after twisting it with a bolt, clamp the entire structure in a vise. Then drill the required number of holes for the constituent elements of the heater:

- mounting bolt,

- two resistors,

- thermistor.

A 12v ceramic heater or a 5 ohm resistor can be used to heat the plate. But for our block, two 10 ohm resistors are better, since they are much smaller in size, and connecting in parallel will just give the desired resistance of 5-6 ohms.

Heating element assemblyThe temperature will be controlled by a B57560G104F 100 kΩ NTS thermistor, with a maximum operating temperature of 300°C. Thermistors with a lower resistance cannot be used, they, as a rule, have a large error at high temperatures. nine0003

It is necessary to ensure a tight connection of the resistors with the plate, since the air gap inhibits heating. It is important to choose the right sealant here. It is best to use ceramic-polymer pastes (CPPT), the operating temperature of which is at least 250 °C. For additional thermal insulation, it's a good idea to wrap the entire hot-end with fiberglass.

Nozzle

Nozzle drill fixture Cap nut with round end is ideal for making a nozzle. It is better to take a part made of copper or brass, since these metals are relatively easy to work with. It is necessary to fix the bolt in a vice, screw the nut onto it and drill a hole of the desired diameter in the center of the rounding. nine0003

It is necessary to fix the bolt in a vice, screw the nut onto it and drill a hole of the desired diameter in the center of the rounding. nine0003

You can do it this way: on a drill clamped in a conventional drill, fasten a collet chuck with a drill of the desired diameter. It turns out an interesting design.

The 0.4 mm hole is considered the most successful, since a smaller diameter slows down the speed, and a larger diameter suffers from print quality.

Here is another way to drill a nozzle (English video).

As you can see, making an extruder for a 3-d printer with your own hands is quite difficult. But if you know that it will not be possible to make some part on your own due to the lack of necessary materials or tools, it is not necessary to purchase a complete kit, you can buy any part of the extruder separately and continue working.