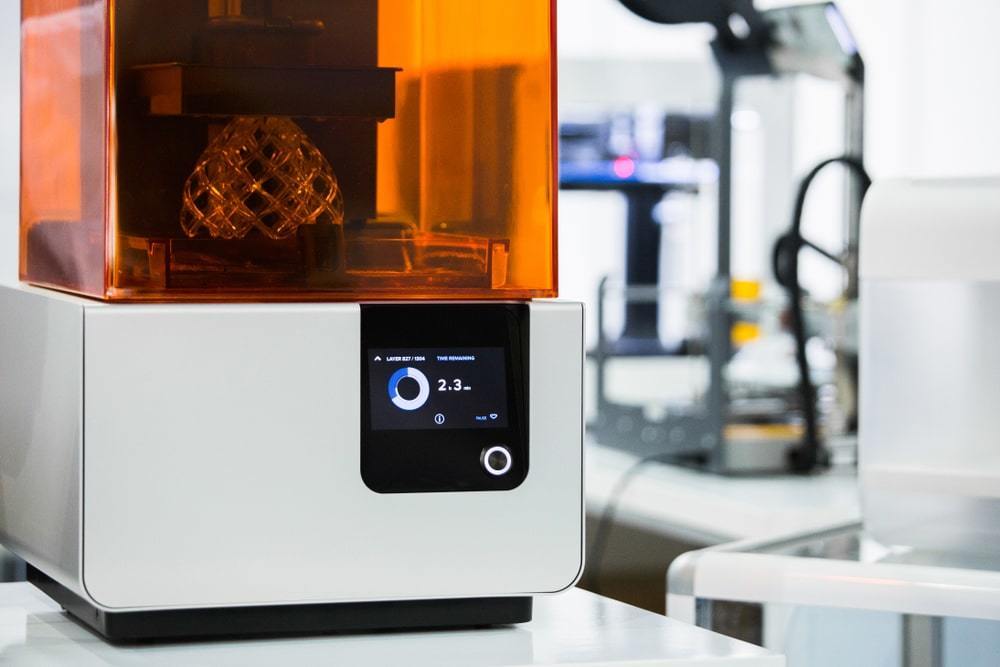

Desktop sla 3d printers

Guide to Stereolithography (SLA) 3D Printing

Stereolithography (SLA) 3D printing is the most common resin 3D printing process that has become vastly popular for its ability to produce high-accuracy, isotropic, and watertight prototypes and end-use parts in a range of advanced materials with fine features and smooth surface finish.

In this comprehensive guide, learn how SLA 3D printers work, why thousands of professionals use this process today, and how SLA printers can benefit your work.

White Paper

Looking for a 3D printer to realize your 3D models in high resolution? Download our white paper to learn how SLA printing works and why it's the most popular 3D printing process for creating models with incredible details.

Download the White Paper

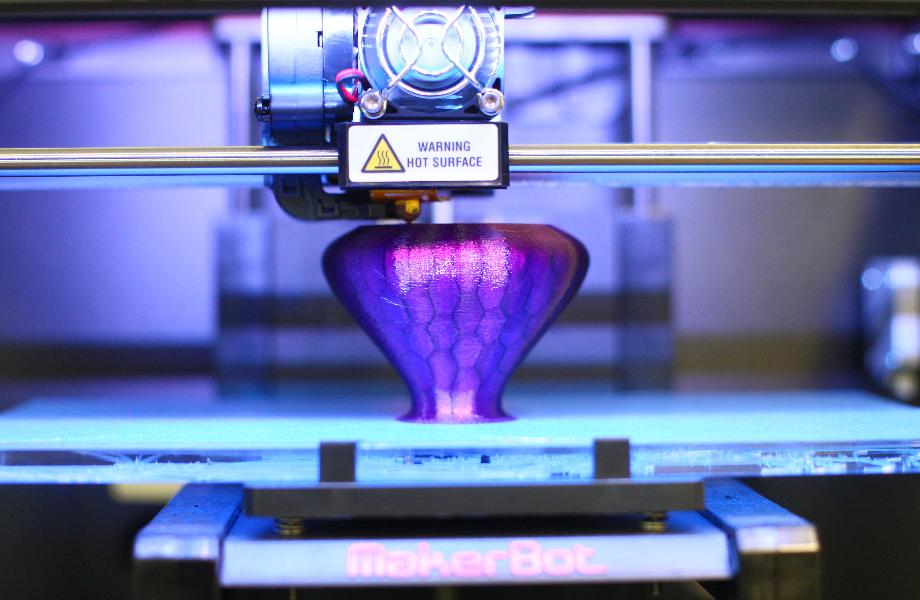

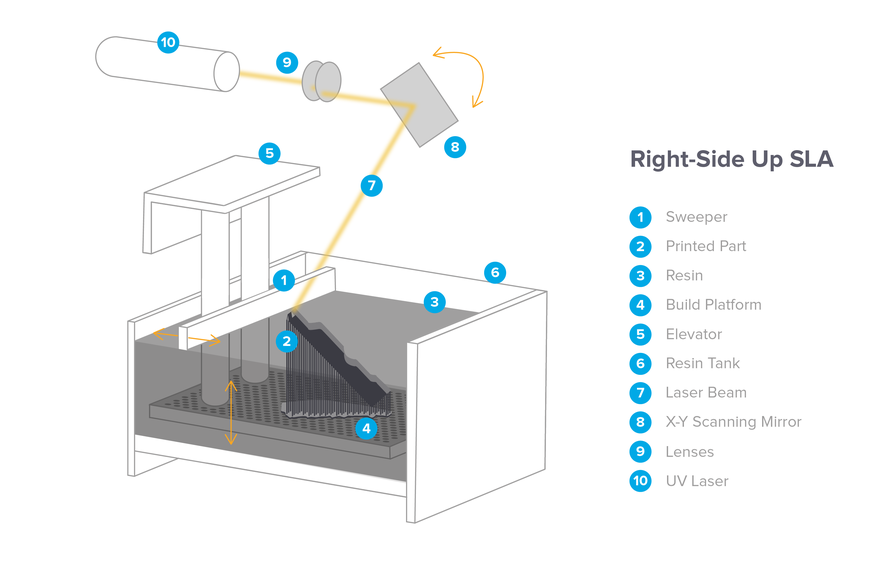

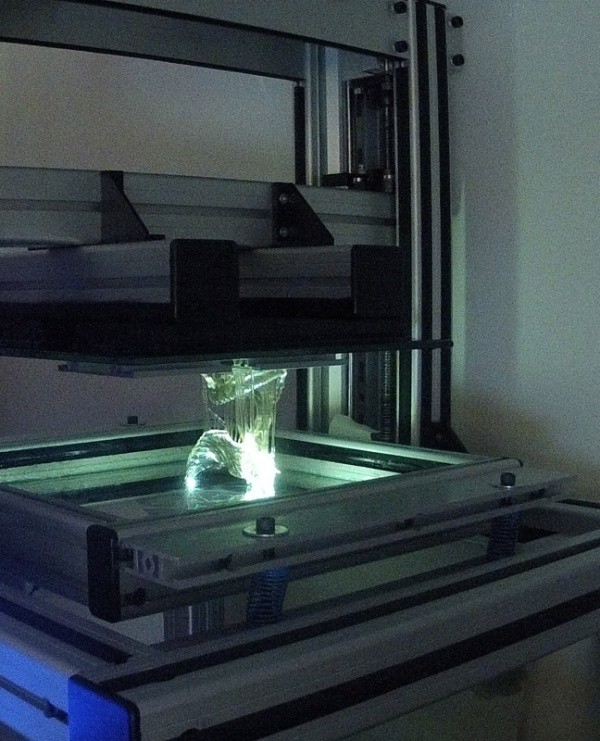

Stereolithography belongs to a family of additive manufacturing technologies known as vat photopolymerization, commonly known as resin 3D printing. These machines are all built around the same principle, using a light source—a laser or projector—to cure liquid resin into hardened plastic. The main physical differentiation lies in the arrangement of the core components, such as the light source, the build platform, and the resin tank.

Watch how stereolithography (SLA) 3D printing works.

SLA 3D printers use light-reactive thermoset materials called “resin.” When SLA resins are exposed to certain wavelengths of light, short molecular chains join together, polymerizing monomers and oligomers into solidified rigid or flexible geometries.

A graphic representation of the basic mechanics of stereolithography (SLA) 3D printing.

SLA parts have the highest resolution and accuracy, the sharpest details, and the smoothest surface finishes of all 3D printing technologies, but the main benefit of the stereolithography lies in its versatility.

Material manufacturers have created innovative SLA resin formulations with a wide range of optical, mechanical, and thermal properties to match those of standard, engineering, and industrial thermoplastics.

Advancements in 3D printing continue to change the way businesses approach prototyping and production. As the technology becomes more accessible and affordable and hardware and materials advance to match market opportunities and demands, designers, engineers, and beyond are integrating 3D printing into workflows across development cycles. Across industries, 3D printing is helping professionals cut outsourcing costs, iterate faster, optimize production processes, and even unlock entirely new business models.

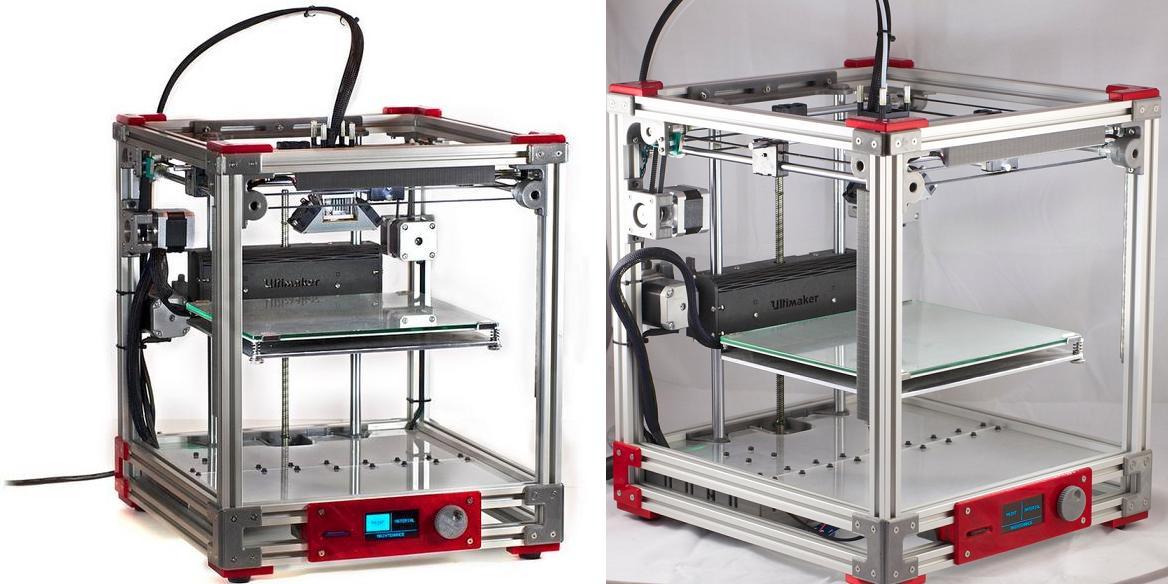

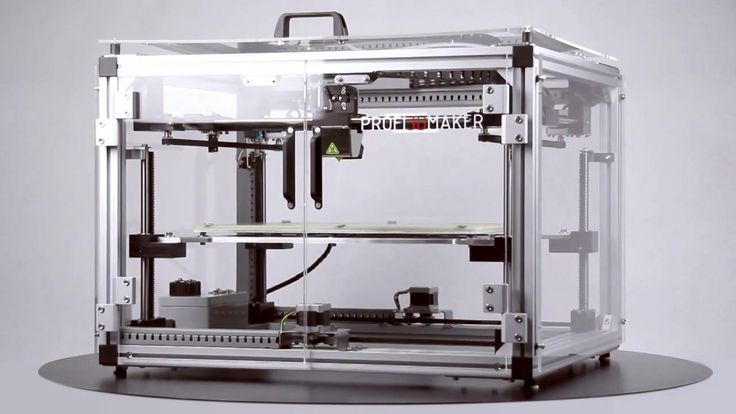

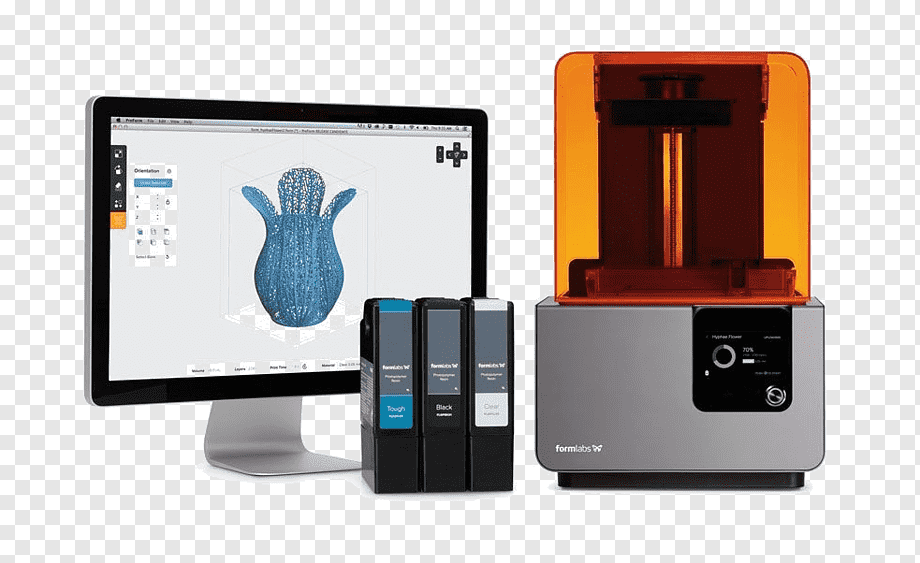

Stereolithography 3D printing in particular has undergone significant changes. Traditionally, SLA 3D printers have been monolithic and cost-prohibitive, requiring skilled technicians and costly service contracts. Today, small format desktop printers produce industrial-quality output, at substantially more affordable price points and with unmatched versatility.

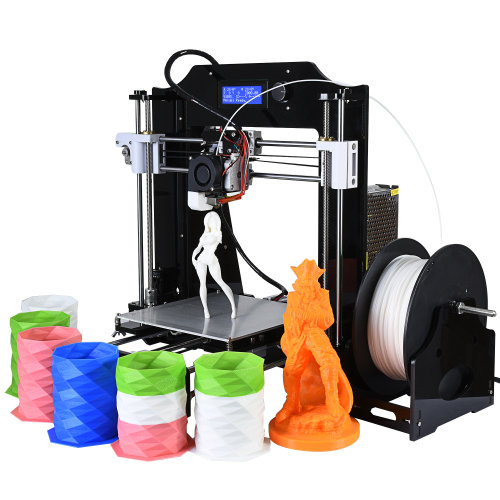

Compare stereolithography 3D printing to two other common technologies for producing plastic parts: fused deposition modeling (FDM) and selective laser sintering (SLS).

Sample part

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your office.

Request a Free Sample Part

See how to go from design to 3D print with the Form 3+ SLA 3D printer. This 5-minute video covers the basics of how to use the Form 3, from the software and materials to printing and post-processing.

Use any CAD software or 3D scan data to design your model, and export it in a 3D printable file format (STL or OBJ). Each SLA printer includes software to specify printing settings and slice the digital model into layers for printing. Once setup is complete, the print preparation software sends the instructions to the printer via a wireless or cable connection.

More advanced users may consider specifically designing for SLA, or taking steps like hollowing parts to conserve material.

After a quick confirmation of the correct setup, the printing process begins and the machine can run unattended until the print is complete. In printers with a cartridge system, the material is automatically refilled by the machine.

In printers with a cartridge system, the material is automatically refilled by the machine.

An online Dashboard from Formlabs allows you to remotely manage printers, materials, and teams.

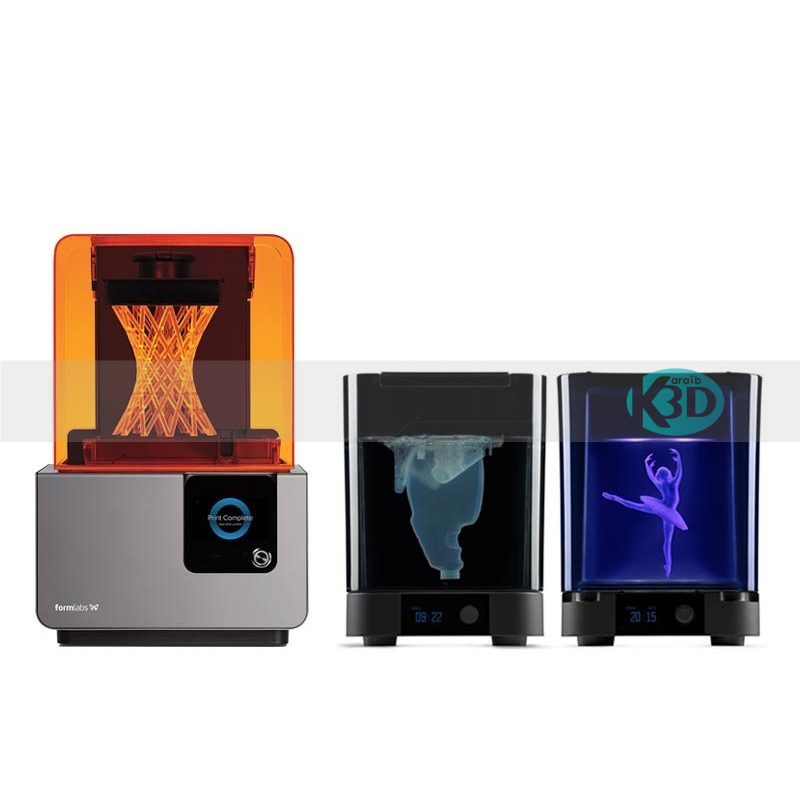

Once the printing is completed, parts require rinsing in isopropyl alcohol (IPA) to remove any uncured resin from their surface. After rinsed parts dry, some materials require post-curing, a process which helps parts to reach their highest possible strength and stability. Finally, remove supports from the parts and sand the remaining support marks for a clean finish. SLA parts can be easily machined, primed, painted, and assembled for specific applications or finishes.

Post-curing is particularly important for functional resins for engineering, and mandatory for some dentistry and jewelry materials and applications.

Webinar

In this webinar, Matt Lewis and Ricky Hopper walk you through an overview of the improved SLA line, and give a hands on demo of the new products.

Watch the Webinar Now

Engineers, designers, manufacturers, and more choose SLA 3D printing for its fine features, smooth surface finish, ultimate part precision and accuracy, and mechanical attributes like isotropy, watertightness, and material versatility.

Because 3D printing creates parts one layer at a time, completed prints may have variations in strength based on orientation of the part relative to the printing process, with different properties in X, Y, and Z axes.

Extrusion-based 3D printing processes like fused deposition modeling (FDM) are known for being anisotropic due to layer-to-layer differences created by the print process. This anisotropy limits the usefulness of FDM for certain applications, or requires more adjustments on the part geometry side to compensate for it.

Read our in-depth guide about FDM vs. SLA 3D printers to learn how they compare in terms of print quality, materials, applications, workflow, speed, costs, and more.

In contrast, SLA resin 3D printers create highly isotropic parts. Achieving part isotropy is based on a number of factors that can be tightly controlled by integrating material chemistry with the print process. During printing, resin components form covalent bonds, but layer to layer, the part remains in a semi-reacted “green state.”

While in the green state, the resin retains polymerizable groups that can form bonds across layers, imparting isotropy and watertightness to the part upon final cure. On the molecular level, there is no difference between X, Y, or Z planes. This results in parts with predictable mechanical performance critical for applications like jigs and fixtures, end-use parts, and functional prototyping.

SLA printed parts are highly isotropic compared to those produced with fused deposition modeling (FDM).

Because they are isotropic, SLA printed parts like this jig from Pankl Racing Systems can withstand the variety of directional forces they undergo during high stress manufacturing operations.

SLA printed objects are continuous, whether producing geometries with solid features or internal channels. This watertightness is important for engineering and manufacturing applications where air or fluid flow must be controlled and predictable. Engineers and designers use the watertightness of SLA printers to solve air and fluid flow challenges for automotive uses, biomedical research, and to validate part designs for consumer products like kitchen appliances.

OXO relies on the watertightness of SLA printing to create robust functional prototypes for products with air or fluid flow, like this coffee maker.

Industries from dental to manufacturing depend on SLA 3D printing to repeatedly create accurate, precise components. For a print process to produce accurate and precise parts, multiple factors must be tightly controlled.

Compared to machined accuracy, SLA 3D printing is somewhere between standard machining and fine machining. SLA has the highest tolerance of commercially available 3D printing technologies. Learn more about understanding tolerance, accuracy, and precision in 3D printing.

Learn more about understanding tolerance, accuracy, and precision in 3D printing.

The combination of the heated resin tank and the closed build environment provides almost identical conditions for each print. Better accuracy is also a function of lower printing temperature compared to thermoplastic-based technologies that melt the raw material. Because stereolithography uses light instead of heat, the printing process takes place at close to room temperature, and printed parts don't suffer from thermal expansion and contraction artifacts.

An example from the dental industry comparing a scanned component with the original CAD geometry, demonstrating the ability to maintain tight tolerances across an SLA printed part.

Low Force Stereolithography (LFS) 3D printing houses the optics inside a Light Processing Unit (LPU) that moves in the X direction. One galvanometer positions the laser beam in the Y direction, then directs it along across a fold mirror and parabolic mirror to deliver a beam that is always perpendicular to the build plane, so it is always moving in a straight line to provide even greater precision and accuracy, and allows for uniformity as hardware scales up to larger sizes, like Formlabs larger format SLA printer Form 3L. The LPU also uses a spatial filter to create a crisp, clean laser spot for greater precision.

The LPU also uses a spatial filter to create a crisp, clean laser spot for greater precision.

The characteristics of individual materials are also important for ensuring a reliable, repeatable print process.

Formlabs Rigid Resin has a high green modulus, or modulus before post-curing, which means it’s possible to print very thin parts with precision and a lower chance of failure.

SLA printers are considered the gold standard for smooth surface finish, with appearances comparable to traditional manufacturing methods like machining, injection molding, and extrusion.

This surface quality is ideal for applications that require a flawless finish and also helps reduce post-processing time, since parts can easily be sanded, polished, and painted. For example, leading companies like Gillette use SLA 3D printing to create end-use consumer products, like 3D printed razor handles in their Razor Maker platform.

Leading companies like Gillette use SLA 3D printing to create end-use consumer products, like the 3D printed razor handles in their Razor Maker platform.

Z-axis layer height is commonly used to define the resolution of a 3D printer. This can be adjusted in between 25 and 300 microns on Formlabs SLA 3D printers, with a trade-off between speed and quality.

In comparison, FDM and SLS printers typically print Z-axis layers at 100 to 300 microns. However, a part printed at 100 microns on an FDM or SLS printer looks different from a part printed at 100 microns on an SLA printer. SLA prints have a smoother surface finish right out of the printer, because the outermost perimeter walls are straight, and the newly printed layer interacts with the previous layer, smoothing out the staircase effect. FDM prints tend to have clearly visible layers, whereas SLS has a grainy surface from the sintered powder.

The smallest possible detail is also much finer on SLA, given 85 micron laser spot size on the Form 3+, in comparison with 350 microns on industrial SLS printers, and 250–800 micron nozzles on FDM machines.

While FDM 3D printed parts tend to have visible layer lines and might show inaccuracies around complex features, parts printed on SLA machines have sharp edges, a smooth surface finish, and minimal visible layer lines.

SLA resins have the benefit of a wide range of formulation configurations: materials can be soft or hard, heavily filled with secondary materials like glass and ceramic, or imbued with mechanical properties like high heat deflection temperature or impact resistance. Material range from industry-specific, like dentures, to those that closely match final materials for prototyping, formulated to withstand extensive testing and perform under stress.

Rigid 10K Resin is a highly glass-filled material for industrial parts that need to withstand significant load without bending, including applications like injection molding.

In some cases, its this combination of versatility and functionality that leads to companies to initially bring resin 3D printing in-house. After finding one application solved by a specific functional material, it’s usually not long before more possibilities are uncovered, and the printer becomes a tool for leveraging the diverse capabilities of various materials.

For example, hundreds of engineers in the Design and Prototyping Group at the University of Sheffield Advanced Manufacturing Research Centre (AMRC) rely on open access to a fleet of 12 SLA 3D printers and a variety of engineering materials to support highly diverse research projects with industrial partners like Boeing, Rolls-Royce, BAE Systems, and Airbus. The team used High Temp Resin to 3D print washers, brackets, and a sensor mounting system that needed to withstand the elevated, and leveraged Durable Resin to create intricate custom springy components for a pick and place robot that automates composites manufacturing.

Engineers at the AMRC use a fleet of 12 SLA 3D printers and a variety of engineering materials to print custom parts for diverse research projects, like brackets for a pick and place robot (top), and mounts for sensors in a high-temperature environment (bottom).

Interactive

Need some help figuring out which 3D printing material you should choose? Our new interactive material wizard helps you make the right material decisions based on your application and the properties you care the most about from our growing library of resins.

Recommend Me a Material

SLA 3D printing accelerates innovation and supports businesses across a wide range of industries, including engineering, manufacturing, dentistry, healthcare, education, entertainment, jewelry, audiology, and more.

Rapid prototyping with 3D printing empowers engineers and product designers to turn ideas into realistic proofs of concept, advance these concepts to high-fidelity prototypes that look and work like final products, and guide products through a series of validation stages toward mass production.

Learn More

Manufacturers automate production processes and streamline workflows by prototyping tooling and directly 3D printing custom tools, molds, and manufacturing aids at far lower costs and lead times than with traditional manufacturing. This reduces manufacturing costs and defects, increases quality, speeds up assembly, and maximizes labor effectiveness.

Learn More

Digital dentistry reduces the risks and uncertainties introduced by human factors, providing higher consistency, accuracy, and precision at every stage of the workflow to improve patient care. 3D printers can produce a range of high-quality custom products and appliances at low unit costs with superior fit and repeatable results.

3D printers can produce a range of high-quality custom products and appliances at low unit costs with superior fit and repeatable results.

Learn More

Affordable, professional-grade desktop 3D printing helps doctors deliver treatments and devices customized to better serve each unique individual, opening the door to high-impact medical applications while saving organizations significant time and costs from the lab to the operating room.

Learn More

3D printers are multifunctional tools for immersive learning and advanced research. They can encourage creativity and expose students to professional-level technology while supporting STEAM curricula across science, engineering, art, and design.

Learn More

High definition physical models are widely used in sculpting, character modeling, and prop making. 3D printed parts have starred in stop-motion films, video games, bespoke costumes, and even special effects for blockbuster movies.

Learn More

Jewelry professionals use CAD and 3D printing to rapidly prototype designs, fit clients, and produce large batches of ready-to-cast pieces. Digital tools allow for the creation of consistent, sharply detailed pieces without the tediousness and variability of wax carving.

Learn More

Hearing specialists and ear mold labs use digital workflows and 3D printing to manufacture higher quality custom ear products more consistently, and at higher volumes for applications like behind-the-ear hearing aids, hearing protection, and custom earplugs and earbuds.

Learn More

Many companies start using 3D printing via outsourcing to service bureaus or labs. Outsourcing production can be a great solution when teams require 3D printing only occasionally, or for one-offs that require unique material properties or applications. Service bureaus can also provide advice on various materials and offer value-added services such as design or advanced finishing.

The main downsides of outsourcing are cost and lead time. Often, outsourcing is a gateway to bringing production in-house as needs ramp up. One of the greatest benefits of 3D printing is its speed compared to traditional manufacturing methods, which quickly diminishes when an outsourced part takes multiple days or even weeks to arrive. With growing demand and production, outsourcing also rapidly becomes expensive.

Because of the rise of affordable industrial-quality 3D printing, today, more and more companies choose to bring 3D printing in-house right away, vertically integrating into existing shops or labs, or in the workspaces of engineers, designers, and others who could benefit from translating digital designs into physical parts or who are involved in small batch production.

Small format, desktop SLA 3D printers are great when you need parts quickly. Depending on the number of parts and printing volume, investment into a small format 3D printer can break even within months. Plus, with small format machines, it’s possible to pay for just as much capacity as a business needs and scale production by adding extra units as demand grows. Using multiple 3D printers also creates the flexibility to print parts in different materials simultaneously. Service bureaus can still supplement this flexible workflow for larger parts or unconventional materials.

Plus, with small format machines, it’s possible to pay for just as much capacity as a business needs and scale production by adding extra units as demand grows. Using multiple 3D printers also creates the flexibility to print parts in different materials simultaneously. Service bureaus can still supplement this flexible workflow for larger parts or unconventional materials.

Interactive

Try our interactive ROI tool to see how much time and cost you can save when 3D printing on Formlabs 3D printers.

Calculate Your Savings

Fast turnaround time is a huge advantage to owning a desktop 3D printer. When working with a printing bureau, lead times, communication, and shipping all create delays. With a desktop 3D printer like the Form 3+, parts are in-hand within hours, allowing designers and engineers to print multiple parts in one day, helping to iterate faster and drastically reduce product development time and quickly test mechanisms and assemblies avoid costly tool changes.

Owning a desktop 3D printer results in significant savings over 3D printing service bureaus and traditional machining, as these alternatives rapidly becomes expensive with growing demand and production.

For example, to fulfill tight production deadlines, a process engineer and team at Pankl Racing Systems introduced SLA 3D printing to produce custom jigs and other low-volume parts directly for their manufacturing line. While in-house SLA was initially met with skepticism, it turned out to be an ideal substitute to machining a variety of tools. In one case, it reduced lead time for jigs by 90 percent—from two to three weeks to less than a day—and decreased costs by 80-90 percent.

| Cost | Lead Time | |

|---|---|---|

| In-House SLA 3D Printing | $9–$28 | 5–9 hours |

| CNC Machining | $45–$340 | 2–3 weeks |

| Outsourced 3D Printing | $51–$137 | 1–3 weeks |

Pankl Racing Systems significantly reduced lead times and costs by 3D printing custom jigs in-house.

With small format machines, it’s possible to pay for just as much capacity as a business needs and scale production by adding extra units as demand grows. Using multiple 3D printers also creates the flexibility to print parts in different materials simultaneously.

The Design and Prototyping Group at the University of Sheffield Advanced Manufacturing Research Centre (AMRC) runs an open-access additive manufacturing station with a fleet of 12 Form 2 stereolithography (SLA) 3D printers for hundreds of engineers working on diverse projects across the site.

Formlabs offers two high precision SLA 3D printing systems, a growing library of specialized materials, intuitive print preparation and management software, and professional services—all in one package.

To continue exploring SLA 3D printing, start with feeling the quality of SLA for yourself: Request a free sample 3D printed part in your choice of material to be mailed straight to your door.

Request a Free Sample Part

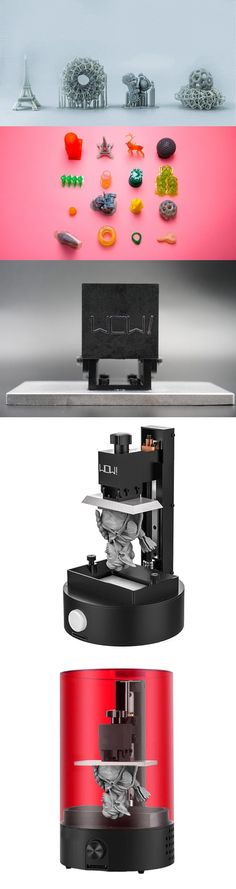

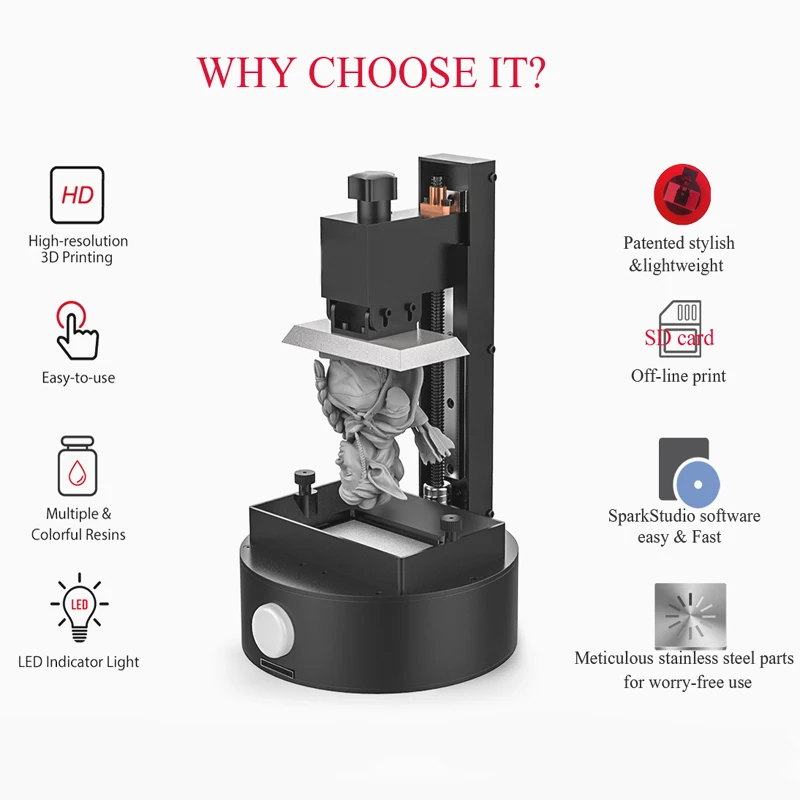

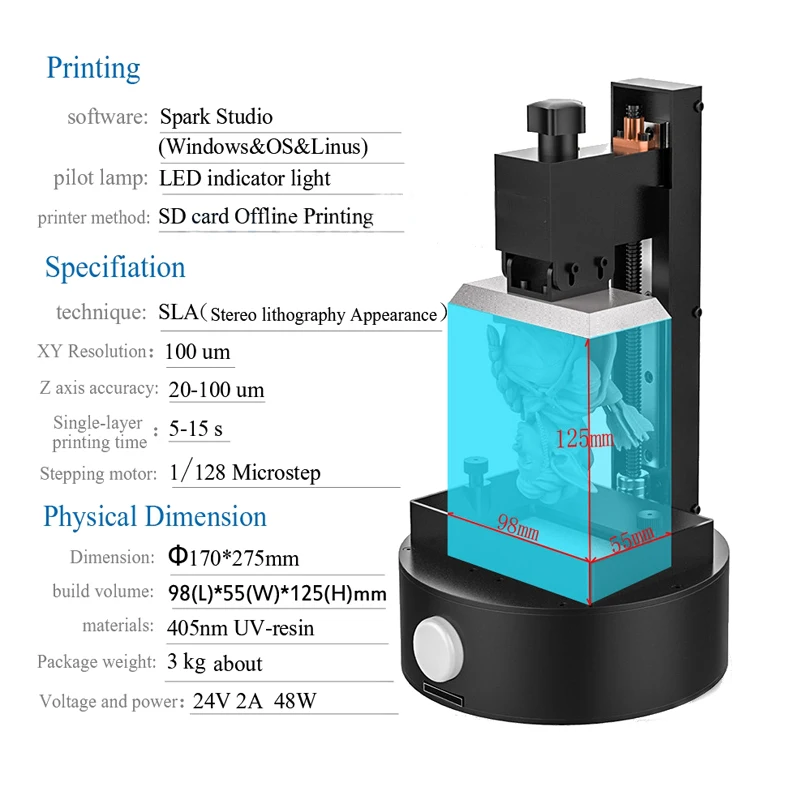

SLA 3D Printers - 10 Best of 2022

SLA 3D printers are used in various industries, from jewelry to dentistry to several companies, at affordable prices. We’ve compiled a list of the ten leading SLA 3D printers based on our research. Before that, let’s refresh what we know about SLA.

We’ve compiled a list of the ten leading SLA 3D printers based on our research. Before that, let’s refresh what we know about SLA.

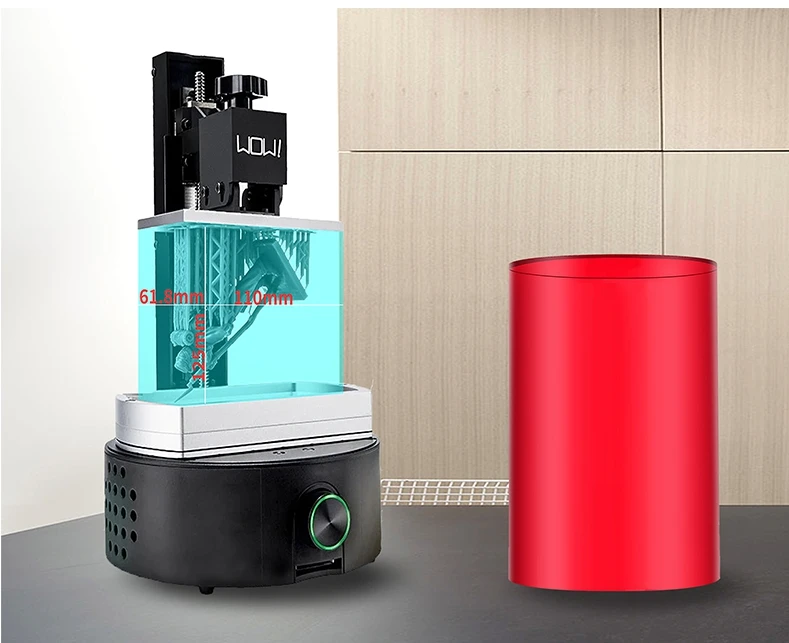

Stereolithography is also known as SLA. This method uses a UV laser and mirrors (galvanometers) to cure the photosensitive resin. It was one of the very first additive printing methods. SLA 3D printers were first invented in 1986 by Chuck Hull.

After SLA, many similar improvised processes emerged, such as DLP. However, SLA has not lost its significance over time. It’s used in the jewelry, automobile, and aerospace industries to make prototypes and functional parts.

The Advantages of SLA 3D PrintingSLA 3D printers have numerous advantages. These are some of them:

- 3D prints that are extremely precise

- Finished with a smooth surface

- A wide range of materials

- Low-cost

- High-volume production stiffness and strength

- Resistant to chemicals

- Prints with a high resolution

Purpose

One of the first things you should consider when purchasing a 3D printer is what you intend to make with it. This can significantly impact the type of machine you should buy.

This can significantly impact the type of machine you should buy.

Printer Style

There are a few different printer styles available on the market that you should consider. What you choose will, once again, influence the types of things you can make with the printer.

Quality

Before you buy, you should evaluate the printer’s overall quality. Naturally, print quality is determined by two factors: print resolution and print speed.

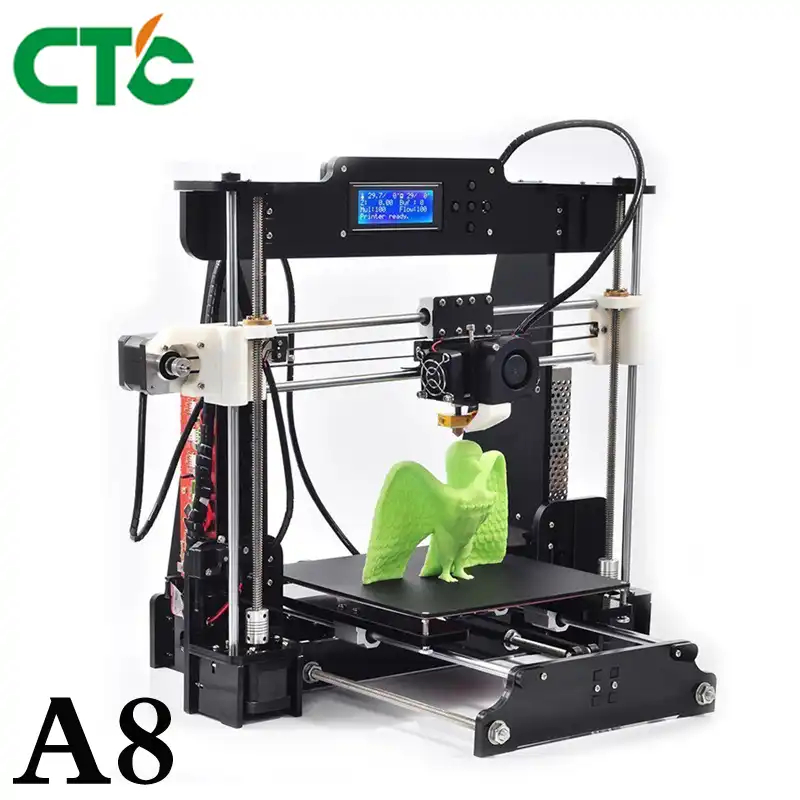

Now, let’s discuss the choicest SLA printers with their characteristic attributes and prices.

Top 10 SLA 3D Printers of 2022There are hundreds of SLA 3D printers available in the market. If you want to buy one for your company, screening out each 3D printer that meets your requirements is time-consuming and exhausting, especially if you have no prior experience.

The detailed comparison of the following best 10 SLA 3D printers will make selecting one that meets your printing goals and demands easier.

XYZPrinting Nobel 1.0 A: Image Source: 3dprima.com

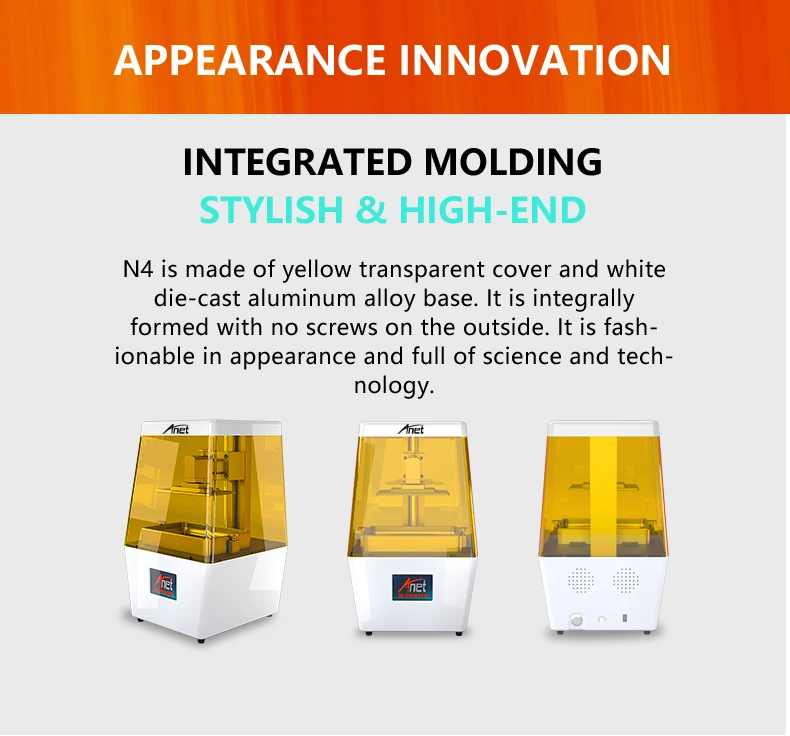

XYZPrinting is well-known for producing high-quality SLA 3D printers. The company began by manufacturing low-cost FDM 3D printers, but as demand for SLA printers grew, it expanded to include resin 3D printers.

The advanced version of Nobel 1.0 is Nobel 1.0 A. The letter ‘A’ stands for ‘Advanced.’ It has a print volume of 128 x 128 x 200 mm and runs on user-friendly XYZ Ware Nobel Software. The STL files can be uploaded for 3D printing using a USB cable or key.

The machine is reasonably priced at $1995.95 and is a good choice for long-term 3D printing.

2. Anycubic Photon SAnycubic Photon S: Image Source: amazon.in

Anycubic, a Chinese company, created the Proton S, the cheapest SLA 3D printer. It provides complex 3D prints. It’s a better version of the original Proton. The plastic resin is cured using a UV lamp.

It comes with a 5.2-inch 2K LCD screen for monitoring the printing process. The printing quality is outstanding.

The printing speed is 15 to 18 mm per second, industrial-grade. It’s an excellent material for making jewelry, figurines, and other small models.

The printer has a 115 x 65 x 65 mm print volume and costs $419. It comes with a one-year warranty and a three-month warranty on the LCD screen.

3. Original Prusa SL1Original Prusa SL1: Image Source: top3dshop.com

Prusa SL1, a magnetically appealing 3D printer, is a well-designed and ideal machine for producing high-quality 3D prints with minimal effort.

UV-sensitive liquid resin with a wavelength of 405 nanometers is supported by the printer.

The machine’s built volume is 120 x 68 x 150 mm, with a 0.025 to 0.1 mm layer resolution.

The printer costs $1399 unassembled and $1699 fully assembled. It is primarily used in the aerospace, medical, and jewelry industries to create functional prototypes and parts.

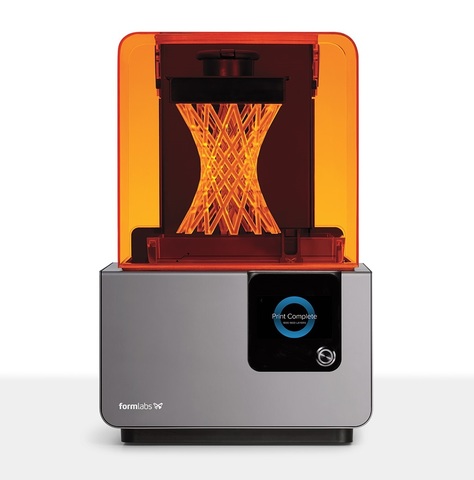

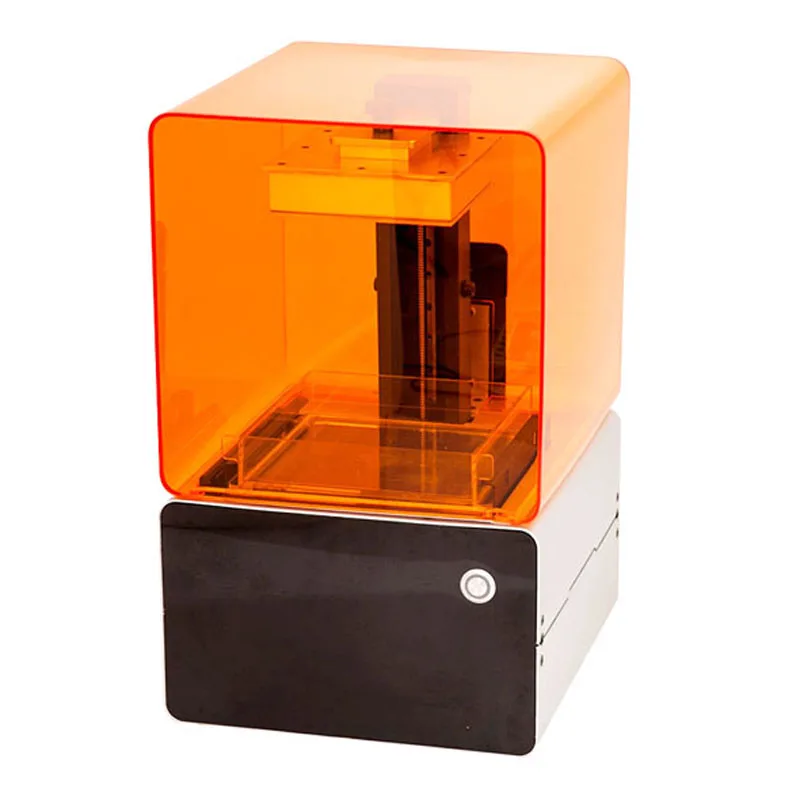

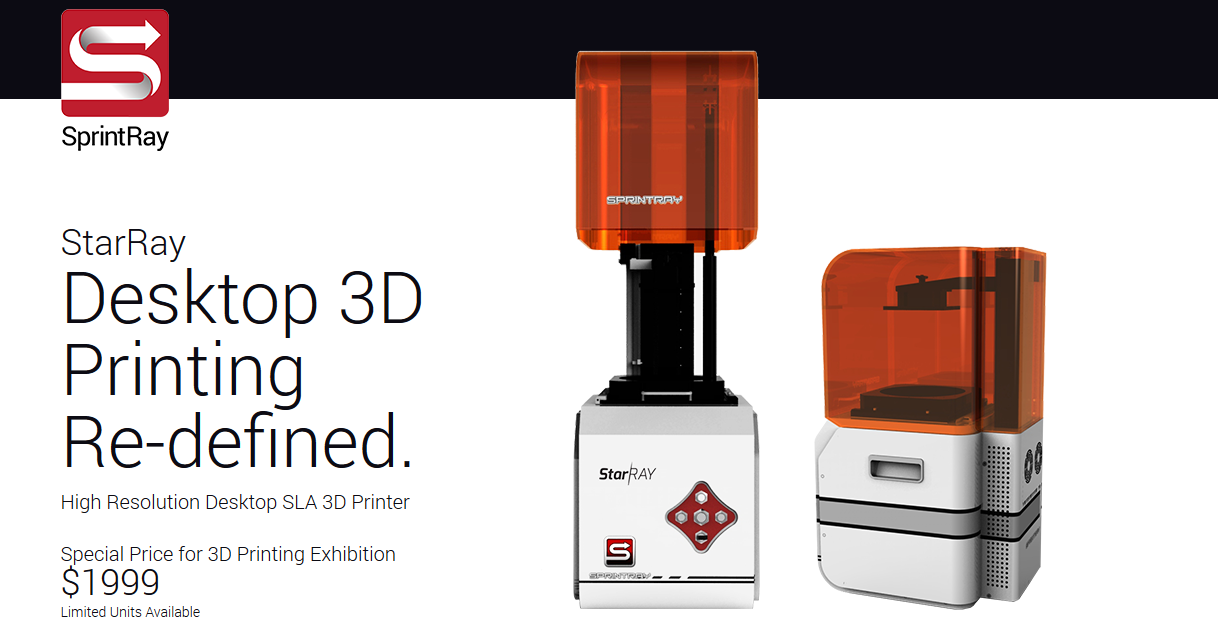

Formlabs Form 3: Image Source: formlabs.com

Form 3 is a more sophisticated version of Form 2. Low Force Stereolithography is used, which is superior to SLA. The built-in volume of the printer is 145 x 145 x 185 mm. The layer resolution is set to 25 microns.

It works with 20 different materials and is simple to set up by following the manufacturer’s instructions.

The machine’s body is black with an orange hood. The basic printer package costs $3499, while the full package costs $5999 and includes post-processing tools (one form wash, 1 L of resin, pro service plan, and one form cure).

Choose the package that is most cost-effective for you.

5. EnvisionTEC D4K ProEnvision TEC D4K Pro: Image Source: envisiontec.com

Envision TEC D4K Pro, one of the large 3D printers, has a print volume of 148 x 83 x 110 mm. It allows for the faster production of large-scale models without sacrificing print quality.

The user can employ a variety of castable resins, such as PIC100, WIC100G, and QView, among others.

The XY and Z-axis resolutions are 25 microns and 1 micron, respectively. Its primary applications are in the dental and jewelry industries.

6. 3D Systems FabPro 10003D Systems FabPro 1000: Image Source: 3dprintingindustry.com

3D Systems produced the FabPro 1000, an entry-level industrial 3D printer. It has excellent print quality but comes at a high cost. It specializes in the low-volume production of small parts and prototypes.

The build volume is 125 x 75 x 120 mm, with a print speed of 21 millimeters per hour. Layer resolution ranges between 30 and 50 microns.

For 3D printing, the printer employs DLP StereoLithography technology. Engineering, manufacturing services, dentistry, and jewelry are among the industries that use it the most.

The cost of the machine is $4126.

It comes with a slew of extras. A print tray, two print platforms, a resin tank kit, and a post-processing kit are included.

Zortrax Inkspire: Image Source: amazon.in

The vat polymerization process is used in Inkspire. To come up with the best design, a research team was assigned for at least two months.

It can print eight times faster and nine times more precisely than other 3D printers, as per the company.

Users in the automotive and consumer electronics industries were taken aback by this.

The layer height is a minimum of 25 microns, and the x-y resolution is 50 x 50 microns. The print volume is 74 x 132 x 175 mm, with a print speed of 20 to 36 mm per hour.

Aerospace, medical, jewelry, and automotive industries all use the printer.

Around $2699 is the price of the machine.

8. DWS XFAB 2000DWS XFAB 2000: Image Source: sundonull.com

DWS Systems, an Italian company, created XFAB 2000 specifically for the jewelry and fashion industries. It claims that the XFAB 2000 is the best 3D printer for the money of its time.

Its dimensions are 180 x 180 x 180 mm. For greater precision, the layer thickness ranges from 10 to 100 microns.

The cost of the machine is $7540. The printer is also used to make fashion accessories like eyewear, keychains, studs, zip pullers, brooches, and cufflinks, among other things.

It’s a good option for those with long-term 3D printing goals.

9. Uniz Slash ProUniz Slash Pro: Image Source: aniwaa.com

Uniz, a California-based company, created Slash Pro for professional use. For 3D printing, it is based on LCD technology. It has a build volume of 192 x 120 x 400 mm and can be used with any of the five resin types.

Layer resolutions of 10, 25, 50, 100, 150, 200, and 300 micrometers are available on the printer.

The machine has two modes of operation. The printer uses standard resins in the usual way. It uses special resins established by the company in UDP (Uni-Directional Peel) mode.

The light source is an LCD that is kept in the tank. The UDP mode prints at 600mm per hour, while the standard mode prints at 200mm per hour.

The UDP mode prints at 600mm per hour, while the standard mode prints at 200mm per hour.

The printer cost is $4499. The printer is delivered fully assembled by the manufacturer. Uniz has excellent customer service. You can watch instructional videos on the brand’s website for more information.

10. Phrozen Shuffle XLPhrozen Shuffle XL: Image Source: top3dshop.com

Phrozen Shuffle XL, as the name suggests, allows for the 3D printing of large models without sacrificing quality. It can print full-size mechanical parts and precise medical equipment, jewelry, and automobiles for the aerospace industry.

LCD masked StereoLithography technology is used in the printer. It’s compatible with nanometer-sized resins.

It has a print area of 190 x 120 x 200 mm, a resolution of 85 microns on the X and Y axes, 10 microns on the Z-axis, and a print speed of 35 mm per hour.

The machine costs $1399 and is delivered fully assembled. A one-year warranty is also included.

3D Printing Software – “SelfCAD”: Image Source: 3dwithus.com

SelfCAD is a free online 3D modeling and STL editor software for beginners and advanced 3D printer users. The user interface of this 3D printing software is very simple. Compared to other programs, the average number of available tools has been drastically reduced, with only the most commonly used tools included. SelfCAD is one of the programs whose devices can be easily mastered because the available tools can be reused. It’s the only 3D modeling software that combines artistic, technical, rendering, and 3D printing capabilities into a single package!

SelfCAD is 3D printing optimized in several ways. There’s a Magic Fix tool that ensures the model’s geometry is stable. An in-built slicer assists you in slicing your models and generating G-Code for your 3D printer.

It’s the most cost-effective professional 3D printing tool available, and both beginners and experts use it. You can sign up for a free account and use it to test out the program before upgrading to the premium version if you like it.

You can sign up for a free account and use it to test out the program before upgrading to the premium version if you like it.

SLA 3D Printers –

ConclusionSLA 3D printers can produce high-quality prints, and their prices have dropped significantly in recent years. Both personal users and businesses can afford them.

Finding the right one isn’t as simple as buying the first 3D printer you come across; there are several factors to consider first.

This is why we compiled this list to show you the best SLA 3D printers on the market, but you must choose one, or you can also try our SelfCAD 3D Modeling and Printing software.

The Complete Guide to Stereolithographic (SLA) 3D Printing

Stereolithographic (SLA) 3D printing is gaining immense popularity due to its ability to produce highly accurate, isotropic and waterproof prototypes and models with fine details and smooth surfaces from various modern materials.

This comprehensive guide explains how SLA printing technologies work, why thousands of professionals use them today, and how this 3D printing technology can be useful in your work. nine0003

nine0003

White Paper

Download our white paper to find out how SLA printing works, why thousands of people use it today, and how this 3D printing technology can help your work.

Download white paper

The development of 3D printing technology continues to influence how companies approach prototyping and manufacturing. This technology is becoming more accessible, and equipment and materials are developing in accordance with the possibilities and requirements of the market. That's why today designers, engineers and others are integrating 3D printing into workflows at all stages of development. nine0003

3D printing is helping professionals across industries reduce recruitment costs, accelerate iteration, streamline manufacturing processes, and even discover entirely new business models.

Stereolithographic 3D printing technology has evolved significantly. In the past, resin 3D printers were monolithic and costly, requiring skilled technicians and costly service contracts to operate. Today's small desktop printers are highly flexible and produce industrial-quality products at a much lower cost. nine0003

Today's small desktop printers are highly flexible and produce industrial-quality products at a much lower cost. nine0003

Stereolithography is a type of additive manufacturing. It is also known as photopolymerization in the bath or 3D printing using polymer resin. Devices that use this technology have a common principle of operation: under the influence of a light source (laser or projector), a liquid polymer turns into a solid plastic. The main differences are in the location of the main components such as the light source, work platform and resin tank.

See how stereolithography 3D printing is done.

Stereolithographic 3D printers use light-sensitive curable materials called "polymers". When stereolithographic polymers are exposed to specific wavelengths of light, short molecular chains join together causing the monomers and oligomers to polymerize into either rigid or flexible patterns.

Graphical representation of the main mechanisms of stereolithographic 3D printing. nine0003

nine0003

Models printed on SLA printers have the highest resolution and accuracy, the finest detail, and the smoothest surface of any 3D printing technology, but the main advantage of this method is its versatility.

Materials manufacturers have developed innovative formulas for stereolithographic polymers with a wide range of optical, mechanical and thermal properties similar to standard, engineering and industrial thermoplastic resins. nine0003

Comparison of 3D stereolithography with two other common plastic modeling technologies: Fused Deposition Modeling (FDM) and Selective Laser Sintering (SLS).

Sample

Experience the quality of 3D stereolithography for yourself. We will send a free sample of the printed model directly to your office.

Request a Free Print Sample

Learn how to go from design to 3D printing with a Form 3 3D printer. Watch this 5-minute video to learn the fundamentals of using a Form 3 printer, from software and materials to processes printing and post-processing. nine0022

nine0022

Use any CAD software or 3D scan data to design the model and export it to a 3D print file format (STL or OBJ). All printers based on SLA technology work with software that allows you to set print parameters and separate the digital model into layers. After the settings are complete, the model preparation software sends instructions to the printer via a wireless or cable connection.

More advanced users can design directly for SLA technology or, for example, print models with voids to save materials.

After a quick check of the settings, the printing process starts. The printer may run unattended until printing is complete. In printers with a cartridge system, material is replenished automatically.

Formlabs' online Dashboard allows you to remotely manage printers, resins, and employee access. nine0022

After printing is complete, models should be rinsed with isopropyl alcohol to remove resin residue from their surface. After the washed models have dried, some materials require final polymerization, a process that ensures the best possible strength and stability of the parts. Finally, remove the support structures from the models and sand down the remaining traces of the supports for a clean finish. Models produced with SLA technology can be machined, primed, painted or assembled depending on the intended use. nine0003

After the washed models have dried, some materials require final polymerization, a process that ensures the best possible strength and stability of the parts. Finally, remove the support structures from the models and sand down the remaining traces of the supports for a clean finish. Models produced with SLA technology can be machined, primed, painted or assembled depending on the intended use. nine0003

Final polymerization is particularly important for functional polymer resins used in engineering, dentistry and jewellery.

Engineers, designers, fabricators and others choose 3D stereolithography because it provides excellent detail, smooth surfaces, superior model fidelity, isotropy, and water resistance. In addition, it allows you to work with various materials. nine0003

Because 3D printing builds models layer by layer, the strength of finished parts can vary depending on the orientation of the part relative to the printing process: the X, Y, and Z axes will have different properties.

Extrusion-based 3D printing processes such as deposition filament modeling (FDM) are anisotropic due to a special approach to creating different layers during the manufacturing process. This anisotropy limits the application of FDM technology or requires additional changes in the design of the model to compensate for it. nine0003

Check out our detailed guide comparing FDM vs. SLA 3D printers to see how they differ in terms of print quality, materials, application, workflow, speed, cost, and more.

Stereolithographic 3D printers, on the other hand, allow the production of highly isotropic models. Achieving detail isotropy relies on a number of factors that can be tightly controlled by integrating the chemical composition of materials with the printing process. During printing, the components of the polymers form covalent bonds, but when creating subsequent layers, the model remains in an "immature" state of partial reaction. nine0003

When immature, the resin retains polymerizable groups that can form bonds between layers, giving the model isotropic and waterproof properties after final curing. At the molecular level, there are no differences between the X, Y, and Z planes. This results in models with predictable mechanical characteristics critical for applications such as jigs and fixtures and finished parts, as well as functional prototyping. nine0003

At the molecular level, there are no differences between the X, Y, and Z planes. This results in models with predictable mechanical characteristics critical for applications such as jigs and fixtures and finished parts, as well as functional prototyping. nine0003

SLA printed parts are highly isotropic compared to FDM parts.

Due to its isotropic nature, stereolithographic printed models, such as this jig for Pankl Racing Systems, can withstand directional loads during the manufacturing process.

SLA printed objects are continuous, whether they are solid or have internal channels. Watertightness is important when it is necessary to control and predict the impact of air or liquid flows. Engineers and designers are using the water resistance of stereolithography printers for air and fluid flow applications in the automotive industry, biomedical research, and to test the design of parts in consumer products such as kitchen appliances. nine0003

OXO relies on the water resistance of stereolithographic printed models to create durable working prototypes of air and liquid products such as coffee makers.

Stereolithographic 3D printing is used to produce precise, reproducible components in a variety of industries, including dentistry and manufacturing. In order to produce accurate models during the printing process, many factors must be strictly controlled. nine0003

The quality of stereolithographic 3D printing is between standard and precision machined. SLA has the highest tolerance compared to other commercial 3D printing technologies. Learn more about tolerances, accuracy and precision in 3D printing.

The heated resin tank combined with the closed working environment provide virtually the same conditions for every model. The higher accuracy also depends on the lower printing temperature compared to thermoplastic-based technologies in which the raw material is melted. Because stereolithography uses light instead of heat, it prints at close to room temperature and models are not subject to thermal expansion and contraction. nine0022

Dental example (comparison of a scanned component with the original CAD model) demonstrating the ability to maintain tight tolerances for the entire stereolithographic model.

LFS stereolithography 3D printing involves an optic in a Light Processing Unit (LPU) that moves along the x-axis. parabolic mirrors so that it is always perpendicular to the plane of the platform, so it always moves in a straight line, ensuring maximum precision and accuracy. This allows consistency to be achieved as the size of the equipment increases, for example, when working with a large-sized Formlabs Form 3L stereolithography printer. The LPU also uses a spatial filter, which forms a clear laser spot. nine0003

The characteristics of the individual materials also play an important role in ensuring the reliability and reproducibility of print results.

Formlabs Rigid Resin has a high green modulus, or modulus of elasticity, before final polymerization, allowing you to print very thin models with high precision and reliability.

Stereolithography printers are considered the best 3D printers due to the smooth surface of the produced models, the appearance of which is comparable to parts produced by traditional methods such as machining, injection molding and extrusion. nine0022

nine0022

This surface quality is ideal when a perfect finish is needed and also helps reduce post-processing time because these models are easy to sand, polish and paint. For example, large companies like Gillette use stereolithography 3D printing to create finished products such as razor handles in their Razor Maker platform.

Large companies like Gillette use stereolithography 3D printing to create finished products such as razor handles in their Razor Maker platform. nine0022

The Z layer height is often used to determine the resolution of a 3D printer. On Formlabs stereolithographic 3D printers, it can be adjusted from 25 microns to 300 microns to trade off speed and print quality.

FDM and SLS printers typically print Z-axis layers between 100 and 300 microns wide. At the same time, a part printed with 100 micron layers on an FDM or SLS printer is very different from a part printed with 100 micron layers on an SLA printer. Models printed on a stereolithographic printer have a smoother surface immediately after printing, because their outer walls are straight, and each new printed layer interacts with the previous one, smoothing out the effect of the stairs. When printed on an FDM printer, layers are often visible in models, and the surface of models printed on an SLS printer has a grainy structure due to sintered powder. nine0022

Models printed on a stereolithographic printer have a smoother surface immediately after printing, because their outer walls are straight, and each new printed layer interacts with the previous one, smoothing out the effect of the stairs. When printed on an FDM printer, layers are often visible in models, and the surface of models printed on an SLS printer has a grainy structure due to sintered powder. nine0022

In addition, the stereolithography printer can print fine details: the Form 3 laser spot size is 85 microns, while industrial SLS printers have a laser spot size of 350 microns, and FDM-based devices use nozzles with a diameter of 250– 800 microns.

Models printed on FDM printers often show layer lines and may have inaccuracies around complex features. Models printed on stereolithography printers have sharp edges, a smooth surface, and almost imperceptible layer lines. nine0003

The advantage of SLA polymers lies in a wide range of formulations offering a variety of characteristics: they can be soft or hard, contain additives such as glass and ceramics, or have special mechanical properties such as high bending temperature under load or impact resistance. Materials can be designed for a particular industry, such as dentures, or have properties close to those of final materials to create prototypes that can be tested and run under stress. nine0003

Materials can be designed for a particular industry, such as dentures, or have properties close to those of final materials to create prototypes that can be tested and run under stress. nine0003

Ceramic Resin can be 3D printed with a stone-like texture and then fired to create a ceramic product.

In some cases, it is this combination of versatility and functionality that is leading businesses to use polymer-based 3D printing in-house. After solving existing problems through the use of a certain functional polymer, other applications are usually quickly discovered. In this case, the printer becomes a tool for discovering the various properties of various polymers. nine0022

For example, hundreds of engineers in the Design and Prototyping group at the Advanced Manufacturing Equipment Research Center (AMRC) at the University of Sheffield have access to 12 stereolithographic 3D printers and various construction materials that they use in numerous research projects for these partner companies like Boeing, Rolls-Royce, BAE Systems and Airbus. They printed High Temp Resin washers, brackets, and a mounting system for a sensor that must operate in high temperature conditions, and used Durable Resin to create complex spring components for a material handling robot as part of a composite manufacturing automation system. nine0022

They printed High Temp Resin washers, brackets, and a mounting system for a sensor that must operate in high temperature conditions, and used Durable Resin to create complex spring components for a material handling robot as part of a composite manufacturing automation system. nine0022

AMRC engineers have access to 12 stereolithographic 3D printers and various construction materials, allowing them to create custom-designed parts for a variety of research projects, such as arms for a stacking robot (above) and mounts for an environmental sensor high temperature (below).

Material selection

Need help choosing a 3D printing material? Our new interactive material wizard will help you make the right material decision based on what you're going to use it for and the properties you care most about in our growing range of polymers. nine0003

Get material recommendations

Stereolithographic 3D printing makes it easier for businesses across industries to innovate. Such industries include engineering, manufacturing, dentistry, healthcare, education, entertainment, jewelry, and audiology.

Such industries include engineering, manufacturing, dentistry, healthcare, education, entertainment, jewelry, and audiology.

Rapid prototyping with 3D printing enables engineers and developers to turn ideas into working proofs of concept, transform concepts into high-quality prototypes that look and work like final products, and take products through testing phases to launch into mass production. nine0003

Find out more

By creating the necessary prototypes and 3D printing special tools, molds and production aids, manufacturing companies can automate production and optimize workflows at a much lower cost and in much faster time than traditional manufacturing. Thus, production costs are reduced and defects are prevented, quality is improved, assembly is accelerated and labor productivity is increased. nine0003

Find out more

Digital Dentistry reduces the risks and uncertainties associated with human error, enabling consistent quality and precision at every step of the workflow, and improving patient care. 3D printers can produce a range of high quality custom products at low cost, providing exceptional fit and reproducible results.

3D printers can produce a range of high quality custom products at low cost, providing exceptional fit and reproducible results.

Learn more

3D printers are multifunctional tools for creating immersive learning and research environments. They stimulate creativity and introduce students to professional-level technology, enabling the implementation of the STEAM method in the fields of science, technology, art and design. nine0003

Find out more

Affordable, professional-grade desktop 3D printers help clinicians produce medical devices that meet individual needs and improve patient outcomes. At the same time, the organization significantly reduces time and money costs: from laboratories to operating rooms.

Learn more

High resolution printed physical models are widely used in digital sculpting, 3D character modeling and prop making. 3D-printed models have been featured in animated films, video game characters, theatrical costumes, and even special effects for blockbuster films. nine0003

nine0003

Learn more

Professional jewelers use the power of CAD and 3D printing to rapidly prototype, customize jewelry to customer specifications and produce large batches of blanks for casting. Digital tools allow you to create dense, highly detailed models without the tedious, error-prone production of stencils.

Learn more

Hearing professionals and hearing care labs use digital workflows and 3D printing to simplify the production of high-quality custom and hearing aids, as well as to mass-produce behind-the-ear hearing aids, hearing protectors, custom earmolds and headphones . nine0003

Find out more

Many companies are starting to use 3D printing technology through service bureaus and laboratories. Outsourcing can be a great solution when the need for 3D printing is infrequent or you need to do one-off jobs using materials that have unique properties or produce special models. Service bureaus can also provide advice on various materials and offer additional services such as design or improved finishes. nine0003

nine0003

The main disadvantages of outsourcing are the high cost and duration of production. Often, outsourcing becomes a step on the way to in-house production as needs grow. One of the main advantages of 3D printing is its speed compared to traditional production methods. But it is noticeably reduced when the delivery of the model produced by the involved organization takes several days or even weeks. As demand and production capacity increase, the costs of outsourcing are rising rapidly. nine0003

With the increasing availability of industrial quality 3D printing today, more companies are opting to bring 3D printing into their factory right away, vertically integrating it into existing workshops or labs, or providing printers to engineers, designers and other professionals who benefit from digital transformation. projects into physical models or are engaged in the production of products in small batches.

Compact desktop stereolithography 3D printers are an excellent solution for rapid model production. Depending on the number of parts needed and the volume of prints, the investment in a compact 3D printer can pay for itself in just a few months. In addition, compact appliances allow you to purchase just the amount of equipment you need to run your business and scale your production by adding more units as demand grows. Using multiple 3D printers also allows you to print models from different materials at the same time. And when the need arises for the production of large parts or the use of non-standard materials, service bureaus can come to the rescue. nine0003

Depending on the number of parts needed and the volume of prints, the investment in a compact 3D printer can pay for itself in just a few months. In addition, compact appliances allow you to purchase just the amount of equipment you need to run your business and scale your production by adding more units as demand grows. Using multiple 3D printers also allows you to print models from different materials at the same time. And when the need arises for the production of large parts or the use of non-standard materials, service bureaus can come to the rescue. nine0003

INTERACTIVE

Try our interactive ROI tool to see how much time and money you can save by printing with Formlabs 3D printers.

Calculate your savings

High production speed is an important reason to buy a desktop 3D printer. When working with a print bureau, there are delays related to the speed of production, communication and delivery. A desktop 3D printer like the Form 3 delivers models in hours, allowing designers and engineers to print multiple parts a day. This contributes to faster iterations and significant time savings in product development, as well as rapid testing of mechanisms and assemblies, avoiding costly tool changes. nine0003

This contributes to faster iterations and significant time savings in product development, as well as rapid testing of mechanisms and assemblies, avoiding costly tool changes. nine0003

Purchasing a desktop 3D printer saves a lot of money by eliminating bureau services and traditional processing methods, as their cost rises sharply with increasing demand and production volumes.

For example, the production engineer and others at Pankl Racing Systems used stereolithographic 3D printing technology to produce products on a tight schedule. This allowed them to independently manufacture custom-designed jigs and other small-sized components for the production line. While stereolithography was initially viewed with skepticism, this technology proved to be an ideal solution to replace the machining of a number of tools. In one of the cases, it made it possible to reduce the manufacturing time of conductors by

By 3D printing custom-designed jigs, Pankl Racing Systems has significantly reduced both order preparation time and production costs.

Compact units allow you to purchase just the amount of equipment you need to run your business and scale your production by adding new units as demand grows. Using multiple 3D printers also allows you to print models from different materials at the same time. nine0003

The University of Sheffield's Manufacturing Advanced Research Center (AMRC) has an additive manufacturing station with 12 Form 2 stereolithography (SLA) 3D printers that hundreds of engineers working on various projects have access to.

Formlabs offers two high-precision stereolithographic 3D printing systems, an ever-growing range of specialty materials, intuitive print preparation and process management software, and professional services, all in one solution. nine0003

To learn more about 3D stereolithography, experience it for yourself: request a free printed sample in your choice of material, delivered right to your door.

Request a print sample

3D printer comparison in 2020

A variety of 3D printing technologies are available on the market today. Getting to know the nuances of each helps you understand what you can expect from the final models and decide which technology is right for you. nine0003

Getting to know the nuances of each helps you understand what you can expect from the final models and decide which technology is right for you. nine0003

Stereolithography (SLA) and digital light processing (DLP) are the two most common 3D printing technologies using resins. 3D printers that use resin as consumables have become very popular due to their ability to produce highly accurate, isotropic and waterproof prototypes and models with high detail and smooth surfaces.

While these technologies used to be complex and prohibitively expensive, today's compact desktop SLA and DLP printers produce industrial quality parts at an affordable price and offer tremendous application flexibility through a wide range of materials. nine0003

Both of these processes selectively expose the liquid polymer to a light source: an SLA laser, a DLP projector, forming very thin, hard layers of plastic that fold into a solid object. Although the principle of operation of these technologies is very similar, they can give significantly different results.

In this detailed guide, we will explain the features of these two 3D printing processes and see how they differ in terms of resolution, accuracy, print volume, speed, workflows, etc.

sample print

Experience the quality of stereolithography for yourself. We will send a free sample of the Formlabs stereolithographic 3D printed model directly to your office.

Request a free print sample

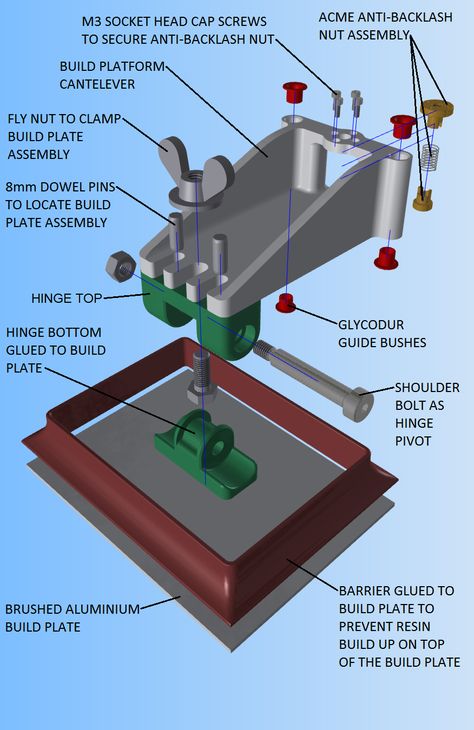

Desktop stereolithography 3D printers contain a resin tank with a transparent bottom and a non-adhesive surface that serves as a base for the liquid polymer to cure, allowing newly formed layers to be carefully separated. nine0003

The printing process begins with the platform lowered into the resin tank, leaving a free space corresponding to the height of the layer between the platform or the last finished layer and the bottom of the tank. The laser beam is fed to two mirror galvanometers, with the help of which it enters the desired coordinates on a series of mirrors. This allows a focused beam of light to be fed upwards through the bottom of the tank, under the influence of which the polymer layer hardens.

This allows a focused beam of light to be fed upwards through the bottom of the tank, under the influence of which the polymer layer hardens.

Then the hardened layer is separated from the bottom of the tank, and the platform rises higher, and liquid polymer enters the vacated space. This process is repeated until printing is complete. nine0003

The Form 3 and Form 3L Low Force Lithography (LFS) stereolithography technology is a new step in the development of stereolithographic 3D printing.

In LFS-based 3D printers, the optical components are located in the Light Processing Unit (LPU). Inside the LPU, a galvanometer positions the high-density laser beam in the y-direction, passes it through a spatial filter, and directs it into a deflecting and parabolic mirror to ensure that the beam always remains perpendicular to the plane of the platform, ensuring print accuracy and reproducibility. nine0003

As the LPU moves in the X direction, the printed model is gently separated from the flexible bottom of the tank, which greatly reduces the forces on the models during the printing process.

LFS-based 3D printing greatly reduces the stress placed on parts during the printing process by using a flexible reservoir and linear illumination for incredible surface quality and print accuracy.

This advanced stereo lithography technology features higher surface quality and print accuracy. The lower print tear force also allows the creation of lightweight support structures that can be detached without force, and the method itself opens up great opportunities for the further development of advanced production-ready materials. Learn more about stereolithographic 3D printing

White Paper

Download our in-depth white paper to learn how SLA printing works, why thousands of professionals use it today, and how this 3D printing technology can help your work.

Download white paper

Desktop DLP printers use a transparent bottom resin tank and a platform that descends into the tank to layer upside down models. In this they are no different from stereolithographic 3D printers. nine0003

In this they are no different from stereolithographic 3D printers. nine0003

The difference between them is the light source. DLP-based 3D printers use a digital screen to project the image of the layer onto the entire platform, causing all the desired dots to solidify at the same time.

Light is reflected on a digital micromirror screen (DMD), a dynamic mask consisting of microscopic mirrors that are located in a matrix on a semiconductor chip. The rapid switching of these tiny mirrors between lenses that direct light to the bottom of a tank or radiator determines the coordinates at which the liquid polymer must solidify in order to form the current layer. nine0003

Because the projector is a digital screen, each layer's image is made up of square pixels, resulting in a three-dimensional layer of rectangular cubes called voxels.

When it comes to 3D printer specifications, resolution is the focus, but it often leads to confusion. The basic units of the SLA and DLP processes are different forms, making it difficult to compare printers by numbers alone.

In 3D printing, there are three dimensions to consider: two planar 2D dimensions (X and Y) and a third vertical Z dimension, which is used for 3D printing. nine0003

The resolution of the Z measurement is determined by the thickness of the layer that the 3D printer can print. Printers based on SLA and DLP technology have one of the best Z resolutions of any other process, allowing you to print layers with minimal thickness. Typically, users can set the layer height to between 25-300µm, allowing developers to trade-off between level of detail and speed.

In DLP printers, XY resolution is determined by the pixel size, the smallest detail that the projector can reproduce in a single layer. It depends on the resolution of the projector (the most common is Full HD (1080p)) and its distance from the optical glass. Therefore, most desktop DLP printers have a constant XY resolution of 35 to 100 microns. nine0003

In stereolithographic 3D printers, the XY resolution is determined based on the size of the laser spot and the number of steps that can be used to control the beam. For example, a Form 3 3D printer based on LFS technology has a laser with a spot size of 85 μm, but due to the constant line scanning process, the laser can move at a smaller step, and the printer can consistently print models with an XY resolution of 25 μm.

For example, a Form 3 3D printer based on LFS technology has a laser with a spot size of 85 μm, but due to the constant line scanning process, the laser can move at a smaller step, and the printer can consistently print models with an XY resolution of 25 μm.

Resolution itself is often only an indicator of vanity. It gives some idea of the performance, but does not necessarily directly correspond to the accuracy and quality of the print. nine0003

Learn more about resolution in 3D printing in our detailed guide.

Since 3D printing is an additive process, violations can potentially occur in every layer. The process of forming layers affects the level of accuracy and correctness of each layer. Accuracy and accuracy depend on many factors: 3D printing process, materials, software settings, post-processing, etc.

In general, SLA and DLP printers are among the most accurate. Differences in print accuracy are often more noticeable between printers from different manufacturers than between the technologies themselves. nine0003

nine0003

For example, entry-level SLA or DLP printers may use off-the-shelf projectors, lasers, or galvanometers, and their manufacturers strive to achieve optimum performance from these parts. Professional SLA and DLP printers (such as Formlabs Form 3) have a special optical system that is adjusted according to the needs of users.

Precision is critical for parts such as mouth guards (left) and surgical guides (right). nine0022

Precision is critical for parts such as mouth guards (left) and surgical templates (right).

Equally important is the calibration. When using DLP projectors, manufacturers face uneven distribution of light on the platform and optical lens distortion, which means that the size and shape of the pixels in the middle and at the edges are different. Stereolithographic 3D printers use the same light source for all parts of the model, ensuring uniformity, but they still need to be carefully calibrated to avoid distortion. nine0003

Even a 3D printer with the best components and the best degree of calibration can produce different results depending on the consumables used. Resin parameters have to be changed to ensure the best quality, but they may not be available for new materials that have not been properly tested with the appropriate 3D printer model.

Resin parameters have to be changed to ensure the best quality, but they may not be available for new materials that have not been properly tested with the appropriate 3D printer model.

What conclusion can be drawn from this? Knowing only the technical characteristics, it is impossible to get a complete picture of the quality. The best way to evaluate a 3D printer is to study the models printed on it or ask the manufacturer to make a test model for your project. nine0003

DLP printers have an inverse relationship between resolution and working volume. The resolution depends on the projector, which determines the number of pixels/voxels available. If you move the projector closer to the optical glass, the pixels will become smaller and the resolution will increase, but the working area will be limited.

Some manufacturers install multiple projectors side by side or use a 4K high-definition projector to increase the working area, but this increases the cost significantly. The price of such models is much higher than other desktop 3D printers. nine0003

The price of such models is much higher than other desktop 3D printers. nine0003

Therefore, DLP printers are usually optimized for specific purposes. Some of them have a smaller workspace and allow you to produce in high resolution such small and detailed models as jewelry, while others can print larger parts, but with a lower resolution.

The stereolithography process is inherently more scalable because the print volume of an SLA printer is independent of model resolution. A single model can be of any size and resolution, and can be placed anywhere on the workspace. This allows you to print large high-resolution 3D models or large batches of finely detailed models to increase printer performance. nine0003

Another hurdle to increasing print volume in both SL and DLP printers is the release force. When printing large models, the forces applied to them increase exponentially as the cured layer separates from the reservoir.

With LFS printing, the flexible film at the base of the resin reservoir gently peels off when the platform pulls the model up, greatly reducing stress on the model. This unique feature has dramatically increased print volume in the first affordable large-format stereolithography printer, the Form 3L. nine0003

This unique feature has dramatically increased print volume in the first affordable large-format stereolithography printer, the Form 3L. nine0003

Form 3L is the first affordable 30 x 33.5 x 20cm large format 3D lithography 3D printer. compared to solutions based on other technologies. When we talk about differences, in most cases they are only visible on very small parts and models with a high degree of detail.

Because 3D printers print in layers, finished models often have noticeable horizontal lines. And due to the fact that digital light processing technology uses rectangular voxels, the effect of vertical lines can also be observed. nine0003

DLP printers use rectangular voxels to render images, which can result in vertical lines. In this image, the vertical voxel lines are shown as they appear when printed (left), highlighted for better visibility (right).

Since voxels are rectangular, they affect the shape of the curved edges. Let's draw an analogy with creating a round shape from a LEGO constructor - the edges will have a stepped shape both along the Z axis and on the X-Y plane. nine0003

nine0003

The rectangular shape of the voxels makes the curved edges appear jagged. Removing visible voxels and layer lines requires post-processing such as sanding.

Layer lines are virtually invisible when printed with LFS-based 3D printers. As a result, surface roughness is reduced, resulting in a smooth surface, and when using transparent materials, models with greater transparency.

When talking about the speed of 3D printing, it is important to consider not only the printing speed itself, but also the productivity. nine0003

The overall print speed of 3D printers based on SLA and DLP technologies is approximately the same. Since the projector exposes each layer as a whole, the speed of DLP 3D printing is uniform and depends only on the height of the model, while SLA 3D printers laser shape each part. As practice shows, as a result, stereolithographic 3D printers become comparable in speed or even faster when printing one small or medium model, while DLP printers are faster at printing large solid models or several models that almost completely fill the space of the platform. nine0003

nine0003

But do not forget that in printers based on DLP technology, there is an inverse relationship between resolution and working volume. A small DLP printer can quickly print small models or high-resolution (small) batches of small models, but print volume limits model size and device performance. Another high volume device can produce larger models, or batches of smaller models, faster but at lower resolution than a stereolithographic printer. nine0003

With a stereolithographic 3D printer, all this can be done on one machine. At the same time, users can decide what they want to optimize in each case: resolution, speed or performance.

DLP printers use rectangular voxels to render images, which can result in vertical lines. In this image, the vertical voxel lines are shown as they appear when printed (left), highlighted for better visibility (right). nine0022

Stereolithographic 3D printers have higher print volumes, batch production, and overnight prints for increased productivity.

| 100 microns | 200 microns |

|---|---|

| | |

| nine0418 Grey Resin 100 microns | 200 microns |

|---|---|

| | |

| 100 Microns | |

|---|---|

| | |

Stereolithographic 3D printers have higher print volumes, batch production, and overnight printing of models, increasing productivity.

INTERACTIVE

Try our interactive ROI tool to see how much time and money you can save by printing with Formlabs 3D printers.

Calculate savings

As with accuracy, differences in workflows and available materials are more printer dependent than technology. nine0003

Most SLA and DLP printers are plug and play and allow easy replacement of platforms and resin tanks. Some more sophisticated models come with a cartridge system to automatically refill the reservoir with liquid resin, requiring less attention and making it easier to print at night.

Some printers come with their own software for preparing 3D models for printing (for example, PreForm for Formlabs stereolithographic 3D printers), while other manufacturers offer ready-made standard solutions. Different software tools have different features, such as PreForm allows you to customize the printing process with one click, powerful tools for optimizing the density and size of supporting structures, adjustable layer thickness, and features to save materials and time. Fortunately, the software can be downloaded and tested before purchasing a 3D printer. nine0003

Fortunately, the software can be downloaded and tested before purchasing a 3D printer. nine0003

As with precision, differences in workflows and available media are more printer dependent than technology.

3D printers can work with a wide range of polymer materials for different applications.

One of the main advantages of polymer-based 3D printing is the large number of materials from which models can be made for various purposes. Polymers with different compositions have a variety of characteristics: they can be soft or hard, contain additives such as glass and ceramics, or have special mechanical properties such as high bending temperature under load or impact resistance. nine0003

But at the same time, the range of supported materials depends on the specific model of the 3D printer, so we recommend that you check this information with the manufacturer before making a purchase.

SLA and DLP prints require post-processing after printing. First, the models must be washed in solvent to remove excess resin. In some cases, such as models made from engineering and biocompatible materials, final polymerization is also required. For stereolithographic 3D printers, Formlabs offers solutions to automate these steps, saving you time and effort. nine0003

In some cases, such as models made from engineering and biocompatible materials, final polymerization is also required. For stereolithographic 3D printers, Formlabs offers solutions to automate these steps, saving you time and effort. nine0003

Finally, 3D models printed on supporting structures require the removal of such structures. This must be done manually - the process is similar for both SLA and DLP printers. LFS-based 3D printers use lightweight support structures with very small contact points, allowing for easy release with minimal marks.

Interactive

Need some help figuring out which 3D printing material you should choose? Our new interactive material wizard helps you make the right material decisions based on your application and the properties you care the most about from our growing library of resins. nine0003

Recommend Me a Material

We hope that after understanding the differences in technologies and print results, it will be much easier for you to choose the 3D printer that best suits your needs and workflow.