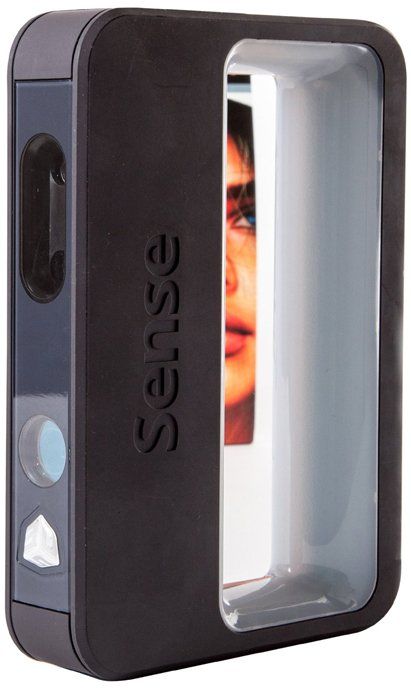

3D digitizer scanner

3D Measurement Scanners Information Request

Thank you for your interest in Creaform! Please fill out the form below. One of our agents will contact you shortly.

Step 1. Enter your contact info

The more we know about you, the better we will be at providing you with relevant answers.

Full name *

Company *

Country * Please select a country...AfghanistanAlbaniaAlgeriaAndorraAngolaAnguillaAntarcticaAntigua and BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBoliviaBosnia and HerzegovinaBotswanaBouvet IslandBrazilBritish Indian Ocean Terr.British Virgin IslandsBruneiBulgariaBurkina FasoBurundiCambodiaCameroonCanadaCape VerdeCayman IslandsCentral African RepublicChadChileChinaChristmas IslandCocos (Keeling) IslandsColombiaComorosCongoCongo, Democratic RepublicCook IslandsCosta RicaCôte d'IvoireCroatiaCubaCyprusCzech RepublicDenmarkDjiboutiDominicaDominican RepublicEast TimorEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEthiopiaFalkland IslandsFaroe IslandsFijiFinlandFranceFrench GuyanaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupe (French)GuatemalaGuineaGuinea-BissauGuyanaHaitiHeard and McDonald IslandsHondurasHungaryIcelandIndiaIndonesiaIranIraqIrelandIsraelItalyJamaicaJapanJordanKazakhstanKenyaKiribatiKuwaitKyrgyzstanLaosLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacauMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartinique (French)MauritaniaMauritiusMayotteMexicoMicronesiaMoldaviaMonacoMongoliaMontserratMoroccoMozambiqueMyanmarNamibiaNauruNepalNetherlandsNetherlands AntillesNeutral ZoneNew Caledonia (French)New ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorth KoreaNorthern Mariana IslandsNorwayOmanPacific Islands Trust TrPakistanPanamaPapua New GuineaParaguayPeruPhilippinesPitcairn IslandsPolandPolynesia (French)PortugalQatarRepublic of MacedoniaReunion (French)RomaniaRussiaRwandaS. Georgia S. Sandwich Is.Saint HelenaSaint Kitts and NevisSaint LuciaSaint Pierre and MiquelonSaint Vincent and the GrenadinesSamoaSan MarinoSão Tomé and PríncipeSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth KoreaSpainSri LankaSudanSurinameSvalbard and Jan Mayen Is.SwazilandSwedenSwitzerlandSyriaTaiwanTajikistanTanzaniaThailandTogoTokelauTongaTrinidad and TobagoTunisiaTurkeyTurkmenistanTurks and Caicos IslandsTuvaluUgandaUkraineUnited Arab EmiratesUnited KingdomUnited StatesUruguayUSA Minor Outlying IslandsUzbekistanVanuatuVatican CityVenezuelaVietnamWallis and Futuna IslandsWestern SaharaYemenZambiaZimbabwe

State * Please select a state...AlabamaAlaskaArizonaArkansasCaliforniaColoradoConnecticutDelawareFloridaGeorgiaGuamHawaiiIdahoIllinoisIndianaIowaKansasKentuckyLouisianaMaineMarylandMassachusettsMichiganMinnesotaMississippiMissouriMontanaNebraskaNevadaNew HampshireNew JerseyNew MexicoNew YorkNorth CarolinaNorth DakotaOhioOklahomaOregonPalauPennsylvaniaPuerto RicoRhodeIslandSouth CarolinaSouth DakotaTennesseeTexasU. S. Virgin IslandsUtahVermontVirginiaWashingtonWashington,DCWest VirginiaWisconsinWyoming

S. Virgin IslandsUtahVermontVirginiaWashingtonWashington,DCWest VirginiaWisconsinWyoming

Province * Please select a province...AlbertaBritish ColumbiaPrince Edward IslandManitobaNew BrunswickNova ScotiaNunavutOntarioQuebecSaskatchewanNewfoundland and LabradorNorthwest TerritoriesYukon

Province * Please select a province...AnhuiBeijingChinese TaipeiChongqingFujianGansuGuangdongGuangxiGuizhouHainanHebeiHeilongjiangHenanHong KongHubeiHunanJiangsuJiangxiJilinLiaoningMacaoNei MongolNingxiaQinghaiShaanxiShandongShanghaiShanxiSichuanTian JinXinJiangXizangYunnanZhejiang

Province * Please select a province...HokkaidoAomoriIwateMiyagiAkitaYamagataFukushimaIbarakiTochigiGunmaSaitamaChibaTokyoKanagawaNiigataToyamaIshikawaFukuiYamanashiNaganoGifuShizuokaAichiMieShigaKyotoOsakaHyogoNaraWakayamaTottoriShimaneOkayamaHiroshimaYamaguchiTokushimaKagawaEhimeKochiFukuokaSagaNagasakiKumamotoOitaMiyazakiKagoshimaOkinawa

State * Please select a state...AguascalientesBaja CaliforniaBaja California SurCampecheChiapasChihuahuaCoahuilaColimaDurangoFederal DistrictGuanajuatoGuerreroHidalgoJaliscoMexico StateMichoacánMorelosNayaritNuevo LeónOaxacaPueblaQuerétaroQuintana RooSan Luis PotosíSinaloaSonoraTabascoTamaulipasTlaxcalaVeracruzYucatánZacatecas

Province Please select a province. ..Andaman and Nicobar IslandsAndra PradeshArunachal PradeshAssamBiharChandigarhChhattisgarhDadar and Nagar HaveliDaman and DiuDelhiGoaGujaratHaryanaHimachal PradeshJammu and KashmirJharkhandKarnatakaKeralaLakshadeepMadya PradeshMaharashtraManipurMeghalayaMizoramNagalandOrissaPondicherryPunjabRajasthanSikkimTamil NaduTripuraUttaranchalUttar PradeshWest Bengal

..Andaman and Nicobar IslandsAndra PradeshArunachal PradeshAssamBiharChandigarhChhattisgarhDadar and Nagar HaveliDaman and DiuDelhiGoaGujaratHaryanaHimachal PradeshJammu and KashmirJharkhandKarnatakaKeralaLakshadeepMadya PradeshMaharashtraManipurMeghalayaMizoramNagalandOrissaPondicherryPunjabRajasthanSikkimTamil NaduTripuraUttaranchalUttar PradeshWest Bengal

State Please select a state...Australian Capital TerritoryNew South WalesNorthern TerritoryQueenslandSouth AustraliaTasmaniaVictoriaWestern Australia

State Please select a state...AcreAlagoasAmapáAmazonasBahiaCearáDistrito FederalEspírito SantoGoiásMaranhãoMinas GeraisMato Grosso do SulMato GrossoParáParaíbaParanáPernambucoPiauíRio de JaneiroRio Grande do NorteRio Grande do SulRondôniaRoraimaSanta CatarinaSão PauloSergipeTocantins

Province Please select a province...Amnat CharoenAng ThongBueng KanBuri RamChachoengsaoChai NatChaiyaphumChanthaburiChiang MaiChiang RaiChon BuriChumphonKalasinKamphaeng PhetKanchanaburiKhon KaenKrabiKrung Thep Maha NakhonLampangLamphunLoeiLop BuriMae Hong SonMaha SarakhamMukdahanNakhon NayokNakhon PathomNakhon PhanomNakhon RatchasimaNakhon SawanNakhon Si ThammaratNanNarathiwatNong Bua Lam PhuNong KhaiNonthaburiPathum ThaniPattaniPhangngaPhatthalungPhayaoPhetchabunPhetchaburiPhichitPhitsanulokPhra Nakhon Si AyutthayaPhraePhuketPrachin BuriPrachuap Khiri KhanRanongRatchaburiRayongRoi EtSa KaeoSakon NakhonSamut PrakanSamut SakhonSamut SongkhramSaraburiSatunSi Sa KetSing BuriSongkhlaSukhothaiSuphan BuriSurat ThaniSurinTakTrangTratUbon RatchathaniUdon ThaniUthai ThaniUttaraditYalaYasothon

Province Please select a province. ..AbruzzoAgrigentoAlessandriaAnconaAostaL'AquilaArezzoAscoli-PicenoAstiAvellinoBariBarletta-Andria-TraniBasilicataBellunoBeneventoBergamoBiellaBolognaBolzanoBresciaBrindisiCagliariCalabriaCaltanissettaCampaniaCampobassoCarbonia IglesiasCasertaCataniaCatanzaroChietiComoCosenzaCremonaCrotoneCuneoEmilia-RomagnaEnnaFermoFerraraFirenzeFoggiaForli-CesenaFriuli-Venezia GiuliaFrosinoneGenovaGoriziaGrossetoImperiaIserniaLa-SpeziaLatinaLazioLecceLeccoLiguriaLivornoLodiLombardiaLuccaMacerataMantovaMarcheMassa-CarraraMateraMedio CampidanoMessinaMilanoModenaMoliseMonza-BrianzaNapoliNovaraNuoroOgliastraOlbia TempioOristanoPadovaPalermoParmaPaviaPerugiaPesaro-UrbinoPescaraPiacenzaPiemontePisaPistoiaPordenonePotenzaPratoPugliaRagusaRavennaReggio-CalabriaReggio-EmiliaRietiRiminiRomaRovigoSalernoSardegnaSassariSavonaSiciliaSienaSiracusaSondrioTarantoTeramoTerniTorinoToscanaTrapaniTrentino-SüdtirolTrentoTrevisoTriesteUdineUmbriaVal d'osteVareseVenetoVeneziaVerbano-Cusio-OssolaVercelliVeronaVibo-ValentiaVicenzaViterbo

..AbruzzoAgrigentoAlessandriaAnconaAostaL'AquilaArezzoAscoli-PicenoAstiAvellinoBariBarletta-Andria-TraniBasilicataBellunoBeneventoBergamoBiellaBolognaBolzanoBresciaBrindisiCagliariCalabriaCaltanissettaCampaniaCampobassoCarbonia IglesiasCasertaCataniaCatanzaroChietiComoCosenzaCremonaCrotoneCuneoEmilia-RomagnaEnnaFermoFerraraFirenzeFoggiaForli-CesenaFriuli-Venezia GiuliaFrosinoneGenovaGoriziaGrossetoImperiaIserniaLa-SpeziaLatinaLazioLecceLeccoLiguriaLivornoLodiLombardiaLuccaMacerataMantovaMarcheMassa-CarraraMateraMedio CampidanoMessinaMilanoModenaMoliseMonza-BrianzaNapoliNovaraNuoroOgliastraOlbia TempioOristanoPadovaPalermoParmaPaviaPerugiaPesaro-UrbinoPescaraPiacenzaPiemontePisaPistoiaPordenonePotenzaPratoPugliaRagusaRavennaReggio-CalabriaReggio-EmiliaRietiRiminiRomaRovigoSalernoSardegnaSassariSavonaSiciliaSienaSiracusaSondrioTarantoTeramoTerniTorinoToscanaTrapaniTrentino-SüdtirolTrentoTrevisoTriesteUdineUmbriaVal d'osteVareseVenetoVeneziaVerbano-Cusio-OssolaVercelliVeronaVibo-ValentiaVicenzaViterbo

Province Please select a province. ..SeoulIncheonChungcheongbuk-doChungcheongnam-doJeonlabuk-doJeonlanam-doDaejeonGwangjuJeju-doGyeonggi-doGangwon-doGyeongsangbuk-doGyeonsangnam-doDaeguUlsanBusanSejong

..SeoulIncheonChungcheongbuk-doChungcheongnam-doJeonlabuk-doJeonlanam-doDaejeonGwangjuJeju-doGyeonggi-doGangwon-doGyeongsangbuk-doGyeonsangnam-doDaeguUlsanBusanSejong

State *

City *

Postal Code *

Phone *

Department *

Email *

Sector * Please select a sector...Industrial / Manufacturing (Product Development)Industrial / Manufacturing (Quality Control)NDT / Pipeline & Aircraft Damage AssessmentEducationalHealthcare / Body ScanningEntertainment, Heritage, Arts, Other

Interest * Please select the Creaform product/service you are interested in...Portable 3D scannerPortable CMM (Probe)Complete Measurement Solution (3D Scanner + Probe)Automated Inspection (Robot Mounted 3D Scanner)Robot calibration and Dynamic TrackingEngineering Services (Design, CAD, FEA, CFD)Metrology Services (3D Scanning, RE, Inspection)Photogrammetry / Optical Coordinate Measuring System

Interest * Please select the Creaform product/service you are interested in. ..Portable 3D scannerPortable CMM (Probe)Complete Measurement Solution (3D Scanner + Probe)Automated Inspection (Robot Mounted 3D Scanner)

..Portable 3D scannerPortable CMM (Probe)Complete Measurement Solution (3D Scanner + Probe)Automated Inspection (Robot Mounted 3D Scanner)

Interest * Please select the Creaform product/service you are interested in...Portable 3D scannerPortable CMM (Probe)Complete Measurement Solution (3D Scanner + Probe)Automated Inspection (Robot Mounted 3D Scanner)Robot calibration and Dynamic TrackingEngineering Services (Design, CAD, FEA, CFD)Metrology Services (3D Scanning, RE, Inspection)Photogrammetry / Optical Coordinate Measuring System

Interest * Please select the Creaform product/service you are interested in...Portable 3D scannerPortable CMM (Probe)Complete Measurement Solution (3D Scanner + Probe)Automated Inspection (Robot Mounted 3D Scanner)Robot calibration and Dynamic TrackingEngineering Services (Design, CAD, FEA, CFD)Metrology Services (3D Scanning, RE, Inspection)Photogrammetry / Optical Coordinate Measuring System

Purpose of request * Please select an option. ..General inquiry about the technology / serviceLooking to acquire a measurement technology / service in the near futureLooking to acquire a measurement technology / service eventually

..General inquiry about the technology / serviceLooking to acquire a measurement technology / service in the near futureLooking to acquire a measurement technology / service eventually

Step 2. Tell us about your project or application (optional)

Please tell us about your project or application, so that we can analyze it, target your needs and provide valuable, customized information for your business.

The Creaform portable 3D measurement technologies start at US$21 900.

How to Choose the Best 3D Scanner to Use With Your 3D Printer

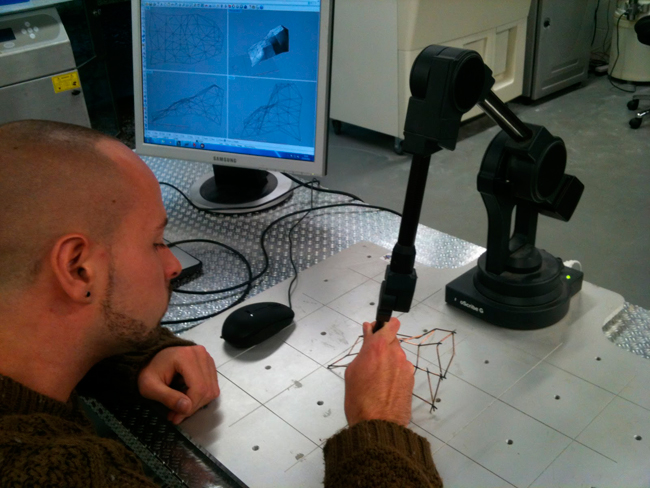

3D scanning has an important place at the beginning and end of 3D fabrication workflows. Engineers, product designers, and researchers use 3D scanners as a faster and more efficient way to start constructing digital models, whether by incorporating existing designs via reverse engineering, digitizing hand-sculpted clay designs, or referencing the exact shape of the human body.

After fabrication, 3D scanning can support quality control and help to verify the accuracy of a 3D printed part, or, after the part has been used, a scanner can reveal how it’s performed—a scan of a deformed part can show you where to reinforce the design in the next revision.

With such a wide range of product options from handheld 3D scanners to desktop 3D scanners, it can be difficult to choose the best 3D scanning system that’s right for your application and budget. In this post, we explore the most important factors to consider when purchasing a 3D scanner and showcase some of the key applications that are empowered by combining 3D scanning and 3D printing.

White Paper

3D scanning and 3D printing workflows can be applied to replication and restoration, reverse engineering, metrology, and more. Download our white paper to explore these applications and learn how to get started.

Download the White Paper

There are multiple scanning technologies currently on the market, all offering their own advantages and weaknesses.

Laser triangulation uses light projected onto the object to take up to millions of measurements (dots) per second. The light reflected from the dots back into the scanner’s sensor to help it capture the geometry of the object. These types of scanners are often the most accurate, and are great for highly detailed parts that have opaque surfaces.

These types of scanners are often the most accurate, and are great for highly detailed parts that have opaque surfaces.

Laser triangulation scanners do have limitations. For example, this technology is not used in most portable scanners because the laser dots need to project from a stable source, and the source has to be kept a close distance from the scanned object. Laser triangulation scanners don’t always work on transparent or shiny surfaces either. Typically, they require reflective markers to be applied onto the object, which need to be removed after use and can be an obstacle depending on the object being scanned.

Finally, the laser dots can be harmful to human eyes, so it is important to use extra safety precautions when scanning body parts with a laser triangulation system, or to check with your scanner manufacturer to make sure the device is eye-safe.

Structured light scanners (also known as white light scanners or blue light scanners) generally use a projector with two cameras at angles on either side. A pattern of light is projected and laid over the component being scanned, the cameras capture the ways in which the object deforms the light pattern, and then multiple images are integrated into a single 3D snapshot.

A pattern of light is projected and laid over the component being scanned, the cameras capture the ways in which the object deforms the light pattern, and then multiple images are integrated into a single 3D snapshot.

Structured light scanners are available in both stationary and portable format—the technology is the most commonly used process for handheld 3D scanners. Structured light scanners are far more common in medical applications, since it is safe to use on both humans and animals and excels when an object is not perfectly still. Traditional white light scanners have been slower to scan than laser triangulation scanners.

Structured light scanning is the most commonly used technology in handheld 3D scanners.

Depth-sensing cameras project a field of dots in infrared (IR) to sample a 3D scene. Depth-sensing cameras are simple to use and are the least expensive scanning option, but their accuracy and resolution are low, and fine details are sometimes lost. Large objects may be captured with depth-sensing cameras, but accuracy declines with increased distance from the subject and at steeper angles to the camera.

Large objects may be captured with depth-sensing cameras, but accuracy declines with increased distance from the subject and at steeper angles to the camera.

Photogrammetry means the act of deriving precise measurements from photographs. It involves taking a set of overlapping photos of an object, building, person, or environment, and converting them into a 3D model using a number of computer algorithms. This is the most commonly used method when creating a 3D scan with a smartphone, since modern phone cameras are capable of capturing and combining a large numbers of photos. Photogrammetry should be considered the least expensive and least accurate method for creating 3D prints, and is not suitable for serious business applications.

LiDAR (light detection and ranging) sensors can be found on some higher-end smartphones and tablets, such as the latest versions of the iPhone Pro and the iPad Pro. This has made the iPhone and iPad viable scanners for those with only occasional scanning needs, offering performance a step above devices that only have access to photogrammetry. Applications that generate 3D mesh files via your smartphone’s or tablet's camera should be seen as the floor for entry-level scanning; users should expect additional work in their CAD software to remove gaps in meshes and improve the 3D model for applications like sending it to a 3D printer. Smartphones use fewer light points when scanning objects, resulting in less detail than a true, stand-alone scanner. iPhones are good substitutes for scanners if you have significant CAD design ability or need to transfer basic models into a digital space.

Applications that generate 3D mesh files via your smartphone’s or tablet's camera should be seen as the floor for entry-level scanning; users should expect additional work in their CAD software to remove gaps in meshes and improve the 3D model for applications like sending it to a 3D printer. Smartphones use fewer light points when scanning objects, resulting in less detail than a true, stand-alone scanner. iPhones are good substitutes for scanners if you have significant CAD design ability or need to transfer basic models into a digital space.

WEBINAR

Watch this webinar with Peel 3D to explore how to integrate 3D scanners into your 3D printing workflow to elevate your product development process.

Watch the Webinar Now

Scan accuracy varies considerably between scanner technologies, and higher accuracy generally comes at a higher cost. The required tolerances of your final part can be a helpful guide for determining your accuracy requirements for a 3D scanner.

| High Price, Highest Accuracy ($15,000 and more) | More Affordable, High Accuracy ($12,000 and under) | Low price, Low Accuracy |

|---|---|---|

| Zeiss T-Scan Hawk Scantech Simscan EviXscan Optima+ M Creaform HandyScan 307 Silver Series | peel 3d peel 1, peel 2 & peel 2-S FARO Freestyle 2 Polyga Compact S1 | iPhone Pro and iPad Pro Structure Sensor Matter and Form 3D Scanner V2 Revopoint POP |

With accuracy in the range of 0.1 mm or better, laser and structured light scanners are a good fit for professional applications and alongside high-resolution 3D printers. Formlabs stereolithography (SLA) 3D printers (such as the Form 3+) produce parts at a similar accuracy, and with a similar printable area, to the scan volume of many desktop 3D scanners.

Besides the accuracy between measured points and their actual location, scanners also vary in terms of resolution, which is the distance between captured points at a given scan distance. This means that details on the scanned object that are smaller than the scanner’s resolution won’t be captured. For example, a highly accurate 3D scanner with a lower resolution might detect the general shape of jewelry on a statue, but not clearly show individual details on a ring or necklace. Depending on your project requirements, this may or may not be a dealbreaker.

An easy way to remember these metrics is: accuracy is the measurement error between the part and digital value. Resolution refers to the density of measurements.

Accuracy can mean slightly different things depending on the manufacturer and 3D scanning technology. For example, the accuracy of handheld scanners depends on the distance to the subject and the quality of scan reconstruction, while desktop scanners have consistent accuracy within the constrained scan volume. If you are considering buying a 3D scanner for precise measurement, make sure to compare like to like.

In general, structured light scanning provides the best resolution and accuracy when compared to laser scanning. For some artistic use-cases for 3D scanning you may need a lot of detail, while overall accuracy is less important—especially if you don’t require your part to fit precisely with other parts in an assembly. In these cases, photogrammetry is an excellent low-cost option to explore.

For some artistic use-cases for 3D scanning you may need a lot of detail, while overall accuracy is less important—especially if you don’t require your part to fit precisely with other parts in an assembly. In these cases, photogrammetry is an excellent low-cost option to explore.

Both depth-sensing cameras and photogrammetry are a good solution for scanning large objects in order to create 3D printed scale models and also offer enough accuracy for capturing the shape of the human body.

Several entry-level laser scanners are available using technology similar to higher-end systems. These scanners are a great way to start replicating small objects at 1:1 scale. As one would expect, the accuracy of entry-level laser 3D scanners is lower than a high-end scanner, but they can easily provide enough detail to replicate small decorative objects and figures where accuracy is not critical.

If you only have occasional 3D scanning needs, digitization services can scan your object, as well as perform CAD translation and accuracy inspection.

The area that a 3D scanner can capture varies significantly between scanners. Find a scanner that fits your size and resolution requirements without too much overhead, as cost typically increases with scan volume.

Handheld scanners can be manually moved around the object and have fewer size constraints than desktop models. Most inexpensive handheld scanners can capture objects from the size of a basketball to an entire room. High-end handheld scanners have an even wider range, and fill the niche for all objects that require precise measurements, but cannot fit in a desktop scanner. Handheld scanners are also able to capture objects nearly instantaneously, which makes them well-suited for taking human measurements (where the subject is not perfectly still) for ergonomics and medical applications.

If the area of the model can’t be seen by the scanner, it will cause a gap in the model. You can automatically repair small missing sections with most scan software programs to create a 3D printable model. However, repaired holes are rarely accurate to the original object. For parts that demand close to perfect accuracy, auto-repair of gaps or holes will not be sufficient. Read our MeshMixer tutorial for advanced tips to edit and repair 3D files for 3D printing.

However, repaired holes are rarely accurate to the original object. For parts that demand close to perfect accuracy, auto-repair of gaps or holes will not be sufficient. Read our MeshMixer tutorial for advanced tips to edit and repair 3D files for 3D printing.

Many scanners use turntables to increase what the scanner can see. The sophistication of a scanner’s turntable affects how easily and completely the object is captured: some scanners have the ability to move the object around multiple axes, imaging the object from more angles. This feature is important when reverse engineering plastic parts with deep recesses and ribs, which are impossible to capture from a single angle.

Scanners may rotate the object to capture occluded areas. Red regions are occluded and will be missing in the scan. Areas with deep relief are difficult for a single axis turntable to fully capture due to occlusion.

Cost concerns are straightforward; how much you are willing to spend on a scanner will reflect your business’s budget and how often the scanner is going to be used. Higher cost scanners will be able to capture small objects and create highly-detailed meshes that don’t require significant touch-ups in CAD software. Handheld scanners are also often on the higher end of the price range, due to their portable nature. The low-cost scanning market offers a wide range of options, but you have to know what to look for.

Higher cost scanners will be able to capture small objects and create highly-detailed meshes that don’t require significant touch-ups in CAD software. Handheld scanners are also often on the higher end of the price range, due to their portable nature. The low-cost scanning market offers a wide range of options, but you have to know what to look for.

Use this flowchart to determine what scanner you need based on accuracy, scan volume, and budget.

Download the high-resolution version of this infographic here.

A 3D scanner expands the capabilities of a 3D printer, allowing you to replicate the shape of almost any object. Together, the two technologies create a powerful, digital workflow that can simplify and sophisticate processes in a range of industries.

The output from a 3D scanner is a mesh of triangles representing the surface of an object at a real-world scale. In some cases, the scan can be used directly to replicate objects without any CAD work. A hybrid workflow can also be powerful, where solid CAD models are combined with scanned 3D models. For example, customized ergonomics capture a physical imprint of a part of the human body, and integrate them with a mechanical design.

For example, customized ergonomics capture a physical imprint of a part of the human body, and integrate them with a mechanical design.

3D scanners are also valuable tools for measuring the accuracy of manufactured objects. Many factors affect 3D print accuracy, and metrology-grade 3D scanners provide a clear picture of how a material performs for demanding applications.

A variety of powerful workflows are enabled by combining a 3D printer and a 3D scanner:

- Reverse engineering to create replacement parts, products with custom ergonomics, and more.

- Replication and restoration of parts, especially in art and jewelry.

- Consumer audio for creating custom earpieces.

- Dental and medical applications, and how 3D scanning is enabling patient-specific workflows.

- Metrology to validate and measure the accuracy of manufactured objects.

Webinar

Watch this webinar for a detailed look at how to start using 3D scanning to improve part design and production when paired with reverse engineering CAD and 3D printing.

Watch the Webinar Now

3D scanners and 3D printers are essential parts of digital workflows across industries. Download our white paper or watch our webinar to get a detailed look into how to start using 3D scanning to improve part design and production and learn how to pair 3D printing and 3D scanning to empower a variety of workflows in engineering, product design, and more.

Learn more about the 3D printer side of the equation: get to know stereolithography (SLA) and selective laser sintering (SLS) 3D printing technologies and see Formlabs advanced 3D printing materials for yourself with a free sample 3D printed part.

Explore Formlabs 3D PrintersRequest a Free Sample Part

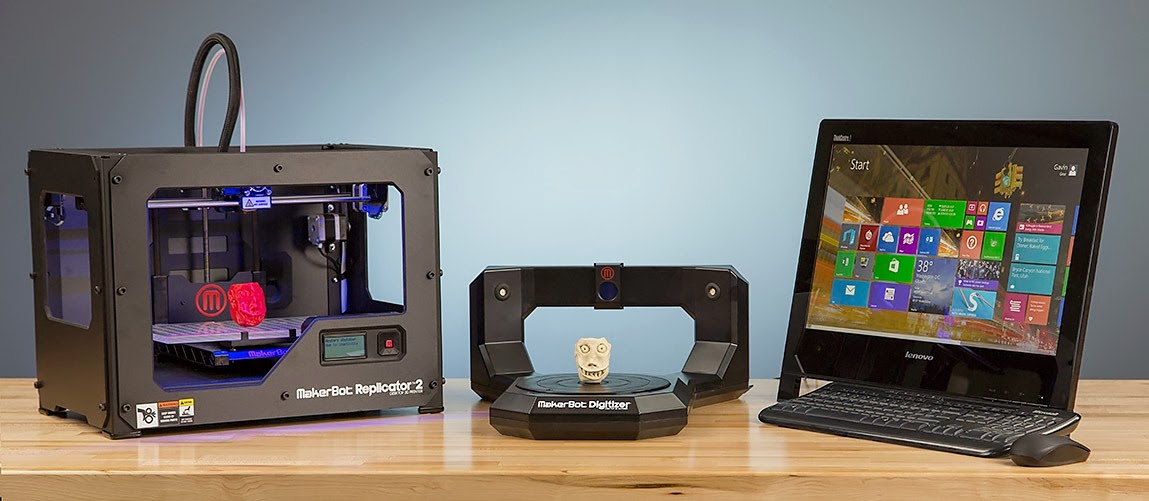

MakerBot Digitizer Desktop 3D Scanner at an Affordable Price

Description

MakerBot Digitizer Desktop 3D Scanner

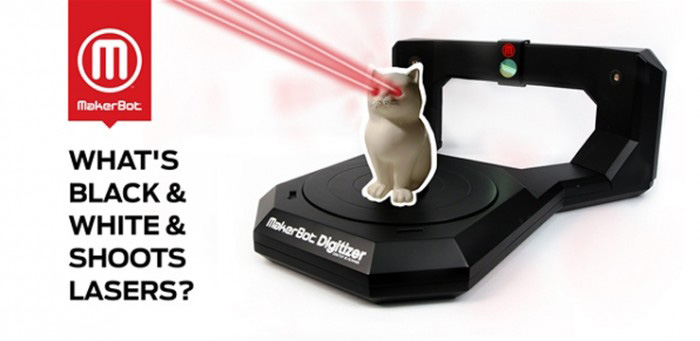

The compact MakerBot Digitizer Desktop 3D Scanner is great for scanning small, stationary objects. The device works on the technology of laser 3D scanning and allows you to get detailed 3D models of high quality. The digital data obtained as a result of the work requires minimal post-processing and is suitable for reproduction in volume using a 3D printer. On average, a 3D scan takes about 12 minutes. This is enough to obtain an accurate and high-quality 3D model.

The digital data obtained as a result of the work requires minimal post-processing and is suitable for reproduction in volume using a 3D printer. On average, a 3D scan takes about 12 minutes. This is enough to obtain an accurate and high-quality 3D model.

This 3D scanner is suitable for a wide range of applications. It can be used both in prototyping and for various engineering and creative projects. The MakerBot Digitizer Desktop 3D Scanner is an indispensable tool for small-scale production, small businesses, offices and workshops. Also it will find application in the household and educational purposes.

MakerBot Digitizer Desktop 3D Scanner Guidelines

Each instrument has specific operating guidelines, limits, and limits. The MakerBot Digitizer Desktop 3D scanner is no exception, and below we list the features of working with it.

The MakerBot Digitizer Desktop 3D Scanner is perfect for scanning:

- Objects larger than 50x50mm and up to 203x203mm;

- Objects weighing up to 3 kg;

- Fixed objects;

- Opaque objects.

You may have difficulty scanning transparent, bright, or reflective objects. It can also be difficult to work with very dark objects, and objects with a hairy surface.

Specifications

| Scan technology | Laser triangulation |

| Housing material | PC ABS |

| Scan area | 203×203 mm, cylindrical |

| Operating ambient temperature | 0 - 32°C |

| Scan speed | ~12 minutes |

| Detail resolution | 0.5 mm |

| Precision | ±2.0 mm |

| Interface | USB |

| Software package | MakerBotMakerWare™ for Digitizer |

| File types | STL, Thing |

| Supported operating systems | Windows (7+) Mac OSX (10. 7+) Ubuntu Linux (12.04+) 7+) Ubuntu Linux (12.04+) |

| Dimensions | 474.5 mm*412.0 mm*203.9 mm |

| Weight | 2.1 kg |

| Packing box | 521 (L) x 244 (H) x 470 (W) mm |

| Power consumption | 100 - 240 V, ~2 A, 50 - 60 Hz |

| Power requirement | 12V, 2.08A DC |

| Connection: | USB |

| Lasers | 2 class 1 emitting laser elements (line shape) |

| Sensor | 1.3 MP CMOS image sensor |

| Central bearing: | Chrome/chrome shielded ball bearing |

| Stepper motor | Pitch angle 0.9° with step division by 16 |

Contents

- MakerBot Digitizer Scanner

- Calibration tables

- Adjusting key

- Power supply

- USB cable

- Network cable

Back to main page

Document Center Tver, 3d printing, laser cutting, layout making, industrial design, 3d printer

- Internet shop

Discount up to

20%

design bureau

Courier

delivery!

Technopolis

Document Center

Printing documents

Printing drawings

Posters and photos

Advertising printing

Read more Order a print!

Discount up to

20%

developers

Case

is free!

Dummy

Workshop

Production of models of any complexity

Architectural layouts

Industrial and production layouts

Macakets of houses and churches

Landscape modes

6 Makers0029

More Order a layout!

3D printing

from 10 rubles/g

PLA plastic

3D printing

55 rub./cm 3

plaster

Technopolis

3D printing center

3D scanning

3D modeling

3D printing

Order 3D printing!

Our services

Technopolis provides comprehensive solutions for 3D technologies, engineering and operational printing. We use a new approach to the implementation of a full cycle of engineering services.

We use a new approach to the implementation of a full cycle of engineering services.

Our advantages

Technopolis is a large-scale platform where a team of specialists is engaged in rapid prototyping and manufacturing of final products.

A team of professionals

The high qualification and personal qualities of employees allow the company to consistently ensure conscientious and timely fulfillment of its contractual obligations.

Accumulated experience

Accumulated experience in creating engineering solutions of various levels of complexity.

Modern production site

Today, more than thirty units of modern equipment are concentrated at the Technopolis premises.

Press about us

Our company often becomes the object of attention of the local media. Every year Technopolis takes an active part in construction exhibitions and competitions. On the basis of our center, events are held with the participation of specialists from various fields.

Ren TV Pilot

Vesti Tver

Vesti Tver

university university

Technopolis team winner of the Interregional Inzhpromfest Competition 2016.

Read more

Etver

City of Technics. A center for young engineers has opened in Tver.

Read more

Complex of engineering services

Project development stages

- Sketch project

- Design

- Tests

- Launch of the series

Sketch project

Testimonials from our customers

We were chosen

Have an idea? Give her a shape!

Leave a request!

© 2012 - 2022 tver3dprint.