Zyxx 3d printer

High quality composite 3D printers for Professional use

ZYYX Labs AB is a Swedish company that develops, produces, and sells high quality composite desktop 3D printers for industrial customers world-wide.

ZYYX Labs AB has its focus on strong composite materials as well as both work environment and environmental issues in general. As a result of this, our products are designed to be OfficeSafe™, which means they are built in a closed design with air filters, and the 3D printing process is all nice and quiet, and of course fume-free. Our ZYYX materials ensures excellent surface quality.

Would you like more information on our printers or our materials? Don’t hesitate to hit the buttons below!

The New ZYYX Pro IIMaterials

The New ZYYX Pro II is an exceptionally quiet industrial-grade 3D printer. It is specifically developed to let professionals rapidly produce customized high-strength parts at their desk, for instance functional prototypes and end-use parts such as tools, jigs, and fixtures.

ZYYX Pro II has a closed design and clean room class air filtering system, perfectly suited for every office, classroom, makerspace, or workshop.

About ZYYX Pro II

More about Pro II

- OfficeSafe Whisper™ – Quiet by Design

- OfficeSafe Ultra™ - Clean and Fume-free Air

- ZYYX MagFlex™ - Easy-to-use spring-steel build-plate system

- proTect™ material system included - Complete system to secure material quality

- Automatic Levelling and Material Monitor - Automatic for each print

- Reliable - Robust all-metal design

- Controlled printing environment and Heated Chamber - Support for high-strength engineering grade materials

- Unique extrusion system

- Off-grid or Online – The choice is yours

- SwiftTool24™ - Quick nozzle change

The ZYYX+ is a Desktop 3D printer for the professional user. Its safety, reliability, and ease-of-use makes it the perfect choice for schools, product developers, and architects that quickly and easily need prototypes and concept models.

About ZYYX+

More about ZYYX+

- Reliable - Robust design

- Automatic Levelling - Auto-calibration of build-plate for each print

- Material Monitor - Pause for material problems

- OfficeSafe™ - Closed design with air filter system

- Simplify3D - The market leading software is included

- Open-material system - Compatible with all material brands (1.75 mm)

- Stand-alone - No computer needed during printing

- Cyber-safe - No internet connection needed (optional only)

The materials

The ZYYX user can choose from a line of carefully selected high-quality polymer materials that comes with plug-and-play profiles.

The ZYYX printers are also compatible with other material brands through their open-material system with all settings available for user tuning.

Learn more

38 dB

Exceptionally Quiet

The ZYYX printers are designed with a closed chamber, resulting in a quiet and OfficeSafe™ printing environment. The ZYYX Pro II printer is designed with carefully chosen components to be quiet as a Whisper at 38 dB.

The ZYYX Pro II printer is designed with carefully chosen components to be quiet as a Whisper at 38 dB.

Desktop

The desktop design allows for instant access, high productivity, and true agile development.

Fume free

With HEPA and active carbon filters that remove at least 96% of the ultrafine particles and odors from the outflow air, making the printers OfficeSafe™. The Pro II has an OfficeSafe Ultra™ HEPA h23 filter which removes at least 99.95% which makes it fume-free.

75 °C

ZYYX Pro II for Professionals

The hardened SwiftTool™ and 75°C chamber enable use of Engineering Grade materials to make functional prototypes and high-strength parts such as tools, jigs, and fixtures.

Workhorse

The ZYYX printers are reliable and robust, with previous customers referring to them as the office “Workhorse”.

Magnetic Flexibility

The MagFlex™ spring steel build-plate makes removal of the print easy to do by hand by gently bending the plate.

Sign up for our newsletter

ZYYX+ | our best, advanced desktop 3D printer

— an advanced desktop 3D printerAre you searching for that perfect smooth and easy-to-use desktop 3D printer?

The ZYYX+ is an advanced desktop 3D printer for the professional user. Its safety, reliability, and ease-of-use makes it the perfect choice for schools, product developers and architects in need of quick and easy prototypes and concept models. And of course: it is totally OfficeSafe™ – both fume free and quiet.

What else do you need your professional 3D printer to be, if not:- Reliable

- Easy to use

- Producer of professional prints

- Quiet and fume-free

The ZYYX+ desktop 3d printer is equipped with auto-calibration of build-plate for each print. The build-plate is probed before every print and the print plane is adjusted during the print in order to keep your models safely on the plate.

The ZYYX+ desktop 3d printer monitors the print and if something goes wrong it pauses the print automatically. You can then identify the problem and in many cases even resume printing, when issue is solved.

ZYYX Filament MonitorThe ZYYX+ detects if you run out of filament or if the filament gets tangled. If so, it pauses the print so you can fix the problem and resume printing.

Maintenance Made EasierThe design of the print head allows for an easy access of the feeder mechanism for keeping it in top condition.

The Reliable ZYYX ExtruderFilament jams are rare with the ZYYX+ desktop 3d printer, because it is equipped with the ZYYX extruder: The hot end is thermally isolated from the feeder mechanism by a custom designed “hot end holder” in PEEK plastic. The filament is also isolated by a PTFE tube all the way down to the melt zone of the hot end.

The surface characteristics of the ZYYX build-plate is designed for optimal adhesion between model and plate. Together with the closed chamber and our ZYYX-ABS this reduces warp when printing ABS.

ZYYX+ is Easy to UseProfessional Grade Print Software

The ZYYX+ desktop 3d printer comes with the Simplify3D Integrated 3D Printing Software, an all-in-one software suite with fully customized profiles for the ZYYX+ and ZYYX Filaments. This advanced 3d printer needs no computer connection during printing.

ZYYX Build-Plate SystemThe Auto-Leveling functionality of the ZYYX+ eliminates the need for tedious adjustments of the mechanics before every print. Furthermore; to make it easy for you to remove the finished model the build-plate can be lifted out of the printer. This is facilitated by the use of magnets which hold the build-plate in position during the print.

ZYYX+ Produces Professional PrintsState-of-the-art AlgorithmsThe motion planner algorithm and the extrusion algorithms are optimized for removing vibrations and improving retractions. The result is smoother surfaces and a higher quality of finer details.

The result is smoother surfaces and a higher quality of finer details.

The moving parts around the print-head are all aluminum, which increases stability and reduces vibrations. This will improve the print quality as well as extending the lifetime of the printer.

State-of-the-art Print FanThe powerful print fan will cool the plastic at the extrusion point to prevent curling. Furthermore; the print fan speed can be adjusted in Simplify3D to tune the cooling power to different filament types.

Enclosed ChamberThe enclosed printing space keeps the print environment draught free and maintains a stable temperature in the build chamber. This will keep your prints free from tensions and other print defects. Together with the ZYYX build-plate and the ZYYX-ABS this reduces warp when printing ABS.

ZYYX+ is Quiet and Fume FreeFume FreeThe ZYYX+desktop 3d printer has a closed design with an air filter system. The enclosed chamber with its negative pressure will contain any odour. The outgoing air then passes through an active carbon filter to remove any fumes.

The enclosed chamber with its negative pressure will contain any odour. The outgoing air then passes through an active carbon filter to remove any fumes.

The optimized motion algorithms, the robust design and the enclosed chamber keeps the sound to a minimum.

Technical SpecificationPrint Technology Fused Filament Fabrication(FFF)

Build Volume 265x225x195 mm

Filament diameter 1.75 mm

Nozzle diameter 0.4 mm

Max Resolution 50 µm layer thickness, 11 µm XY positioning

Speed up to 200 mm/s print speed

Printing temperature 100-265 °C

Filament type PLA, ABS, and TPU are supported by ZYYX profiles. ABS sizes may be limited due to the heavy material shrinkage.

Interfaces SD Card, USB for firmware updates

Stepper Motor type 1.8° Step angle, 1/16 micro stepping

Build-Plate Glass build-plate with ZYYX 3D Print-Sheet top layer

Firmware Custom Sailfish Open Source FW

Desktop Software Simplify3D

Computer Requirements Intel Pentium 4 or higher processor, 4 GB or more of RAM, Windows 7 or later (32- or 64-bit), MacOS X 10. 7 or later, Ubuntu Linux 14.04 LTS or later. OpenGL 2.0 capable system

7 or later, Ubuntu Linux 14.04 LTS or later. OpenGL 2.0 capable system

Supported file types STL, X3G, 3MF

Product size 43x54x45.5(WxHxL) cm

Product weight 19 kg

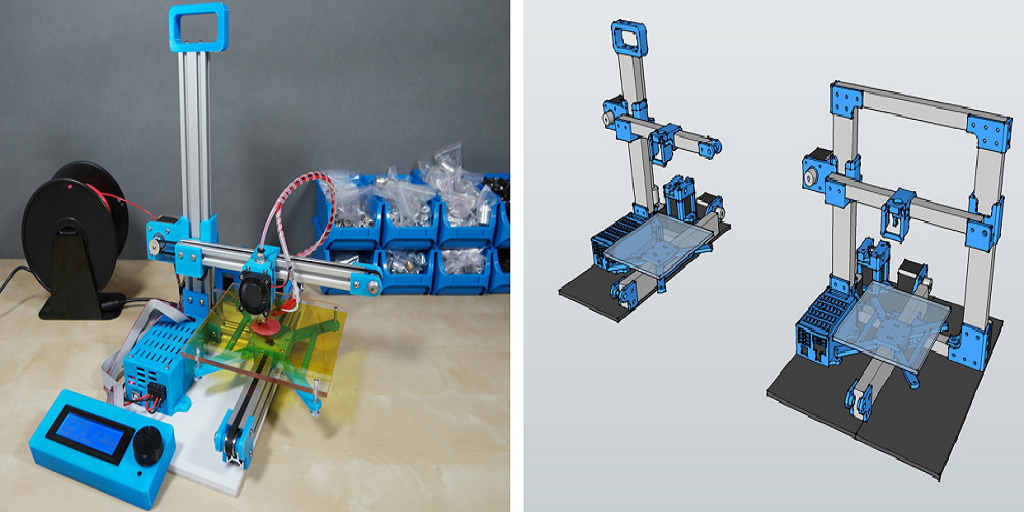

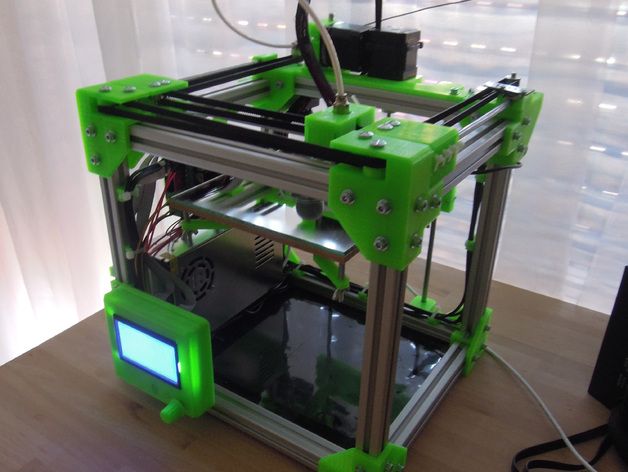

Zmorph is the most multi-head 3D printer. Investigation from REC.

Hello everyone! Not so long ago, we got to see the unique multifunctional Zmorph platform. This article will tell you about our experience, observations and technical aspects revealed during 3D printing. However, since the Zmorph is not just a simple single extruder 3D printer, there will be additional articles about each interchangeable head describing the work, nuances and results.

General information about the device. nine0006

1. External dimensions - 530 mm x 555 mm x 480 mm.

2. Printable area - 250mm x 235mm x 165mm.

3. Number of printheads - 1

4. Weight is ~ 25 kg.

5. The printer is equipped with a thermal table, card reader, ethernet port and touch monitor.

6. Maximum nozzle temperature: ~260

7. Nozzle diameter: 0.4 mm, resolution: 200 to 70 microns

8. Build speed 60-150 mm/s

9. Printing materials declared by the manufacturer: PLA, ABS, PETG, Laywood, nylon, rubber, etc.

10) Features - the main bonus of this printer is interchangeable heads. In our kit there are 1.75 single extruder head, 1.75 double extruder head, milling cutter, laser and extruder-syringe,

11) The printer has its own software, called Voxelizer. The program provides all the options for the heads of this device and has many settings.

Review

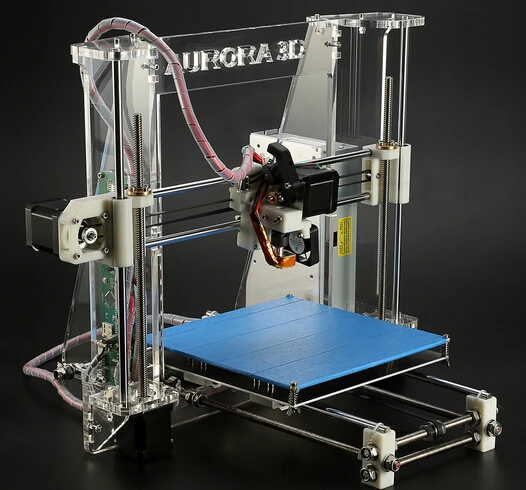

The printer itself looks quite serious, thanks to the metal and transparent plastic, it evokes the feeling of some kind of device from sci-fi films, although in principle we see a Prusa i2, but with a very rigid body.

The extruder looks serious, the carriage itself is assembled from metal and a small number of printed parts. The airflow of the model is attached with magnets, which is very convenient.

The airflow of the model is attached with magnets, which is very convenient.

Thermotable moves on two belts and rails, adjustable with 3 screws. Fastening is realized through magnets. nine0003

The axle guides are also made of sheet metal. No backlash, everything is very rigid.

The printer has a nice touch screen display with its own menu.

Cable management is perfectly arranged in the printer body itself. All wires are perfectly protected from breaking and bending. All connectors that the user will have to work with are signed and marked.

The printer has an interesting implementation of the spool attachment mechanism and the filament channel.

This is how 0 is implemented on the Z axis.

Very pleased with the highlighting and marking of important elements on a 3D printer. There is a feeling of working with an expensive industrial device.

There is a feeling of working with an expensive industrial device.

Diode illumination of the printed model is a very nice element.

Like many other units, the outer protective case is also attached with a magnet.

Software

Voxilaser looks like this

this is the first menu of transformations and settings, here we place objects, set their sizes, and also select the work area. In this case, workflow costs as 3D printer. nine0003

press voxilase and go to voxel editor. It has the usual print settings for all of us.

after we click generate g-code

here we see the generated task, it remains to press play

save it to a USB flash drive and print it.

Print.

First print on a ZMorph 3D printer. A single extruder print head is used. Material natural REC PLA. Before printing, I had to calibrate the table.

A single extruder print head is used. Material natural REC PLA. Before printing, I had to calibrate the table.

Model can be found here: https://www.thingiverse.com/thing:1803617

Material red REC PLA plastic, print speed 90 mms

Material red REC PLA plastic, print speed 70 mms. (outer wall)

Relax

Material natural REC RELAX plastic, print speed 60 mm with 0.4 mm nozzle and 0.2 mm layer.

Bicycle pedals made of natural and white REC RELAX plastic. Layer height 0.15 mm, speed 30. In total, it took 48 hours to print, the result is stable.

Bonus

And now an unexpected bonus - ABS + HIPS printing test on the Dual PRO head. nine0003

It differs from the previous one by the ability to print two materials through one nozzle.

The slicing is not much different, all you need to do is set extruder 2 in some places. Thanks to the software, the head is able not only to create supports from another material or to imprint parts from different materials into each other, but also to mix them. nine0003

Thanks to the software, the head is able not only to create supports from another material or to imprint parts from different materials into each other, but also to mix them. nine0003

Now let's look at "two-color" printing.

The algorithm of actions is described here, but in general, it's very simple.

The result is just wonderful.

Now let's try blending. Let's fiddle a little with the settings again.

This tutorial describes how to do it.

Looking at the result

Unfortunately we overlooked the amount of pink ABS and ran out of it during the printing process, leaving most of the vase under extruded, but the resulting part shows that the mixing occurs without any problems according to the given program. nine0003

Anyway, we did it again.

And now the result:

Conclusions.

Pros:

- Rigid frame, good design and very high quality assembly and components.

- Very precise kinematics.

- The ability to quickly remove and put on additional elements such as protective screens, a model air cooler, a working head and even a heating table.

- Easy-to-learn software with lots of settings and features.

- Convenient printable area.

- The printer has all the necessary warnings and markings, heated table, extruder and powered Z and X axes are illuminated by diodes. The printed object itself is also illuminated, which helps to keep track of the printing process.

- User-friendly interface with a set of useful features. Fine-tuning printing is easy enough, all the icons are unambiguous and large enough not to miss them.

- The printer produces excellent results at low to medium speeds from PLA and RELAX

Cons:

- It is very easy to calibrate the table because of the magnetic mount, you will not only have to level the table plane but also very likely to set zero on the Z axis, after removing the part or detaching the table.

- This printer is conceived and designed as an MFP, not as a 3D printer, so it has a high margin of safety and rigidity, while at the expense of print speed there may be traces of underextrusion or, conversely, excessive drops on the surfaces of models, especially when it comes to a large number of retracts. nine0129

- The spool mounting on the printer is interesting, but practice has shown that the filament supply channels can get stuck in the case, stretch and thereby interfere with the plastic supply.

- The software calculates the print time very accurately, but not the amount of plastic required.

- Printing with flexible materials is difficult, again due to thermal distribution, difficulty in feeding the plastic through the tube, and too much pressure that compresses the bar.

Pro Dual PRO

This head has been tested for the main tasks conceived in the design. This system is capable of printing solvent-based supports in PLA+PVA and ABS+Hips combinations, and also allows two-color printing. and The ability to mix colors with a gradient comes as a special feature.

and The ability to mix colors with a gradient comes as a special feature.

Plug&play head, we installed it, filamented it, and started the job. Slicing in Voxeliser, even for this mode, is very simple and intuitive. If you don’t figure it out yourself, there are good tutorials on working in text and video format on the manufacturer’s website. nine0003

Conclusion.

Zmorph is a unique platform with many possibilities. Our practice of using it as a 3D printer has shown that this device requires very thoughtful use. This is also due to the software, in which the interface is very clear, but overloaded with elements, which makes it easy to miss something in the settings. It is worth noting a very tough and thoughtful case filled with useful features, markers and indicators. Despite its robust and simple design, the Zmorph printer is not one of the best offerings on the market, as it is built solidly and reliably to handle a range of versatile tasks, not just printing. Therefore, the printer is quite reliable, but not very fast in the additive manufacturing of objects. nine0003

Therefore, the printer is quite reliable, but not very fast in the additive manufacturing of objects. nine0003

At the same time, working with Zmorph is very simple, in order for the device to behave like a plug and play you just need to remove the printed models very carefully, trying not to pull the table off its mounts and thereby violate its calibration.

In general, the printer produced the best results at speeds from 30 to 70 mm s (infill and outer contour, travel from 120 to 180 mm s) with REC PLA and REC RELAX plastics. When printing ABS and ETERNAL, it is necessary to install protective screens, as they are enough to avoid delamination of the object. nine0003

Summing up, we note that Zmorph is a unique machine that will give the user great opportunities, and in return they will only ask you to follow the instructions. This device will find its well-deserved place in various workshops, design bureaus, and especially in educational institutions.

If you have any questions, write comments, call, contact us in the social. networks or by mail, we are always ready to answer. And don't forget that we welcome guests in our office.

networks or by mail, we are always ready to answer. And don't forget that we welcome guests in our office.

Website: https://rec3d.ru/Phone: +7 (800) 775-7331 (free of charge from anywhere in Russia)

http://www.viber.com/rec3d https://telegram.me/Rec3d_bot https://vk.com/rec3dcompanyhttps://www.instagram.com/rec3dcompany/Office: Moscow, st. Godovikova d. 9, building 1, entrance 1.19, office 2.3. Technopark "Caliber".

Thank you for your attention and happy printing!

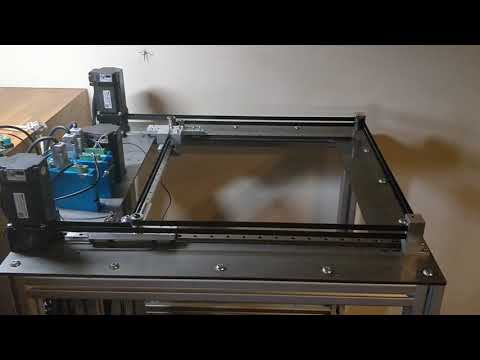

Best Budget - Infinite-Z 3D Printer

Known for its quality desktop 3D printers and high market share in the 3D printing industry, Creality 3D launched the revolutionary Infinite-Z 3D printer, 3DPrintMill, on Kickstarter on November 19, 2020. nine0003

More information about the campaign: https://www.kickstarter.com/projects/3dprintmill/creality-infinite-z-axis-build-volume-printer-3dprintmill?ref=1dse7g

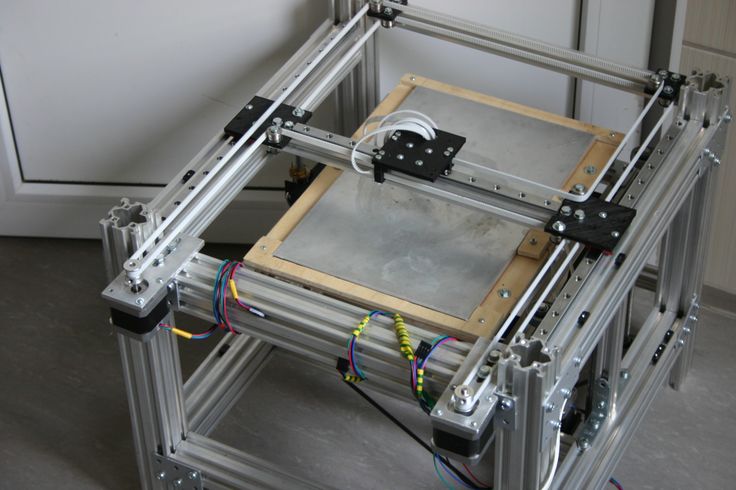

Simply put, 3DPrintMill is something between a traditional 3D printer and a conveyor belt. This means two things:

This means two things:

Continuous, maintenance-free printing of parts. The parts are 3D printed, the heated ribbon moves forward, the parts come off and fall into the tray. There is no need to constantly remove parts from a heated bed and start the printing process again. 3DPrintMill can turn a whole roll of plastic filament weighing 1, 5 or 10 kilograms into precisely sized plastic parts without any human control. nine0003

Very long 3D prints (theoretically "infinite" along the Z axis). By tilting the hot end 45 degrees, the back of the printed object slides out of the 3D printer while the front remains printed inside the printer. The longest 3DPrintMill print to date is a 20ft, 6m bar all in one piece made by a machine only 66cm long. The maximum length of a structure is no longer an obstacle. The hot end is also adjustable to 15°, 25° and 35° with accessories. nine0003

Conveyor belt combined with 45° hot section for endless prints. The printed design will eventually come out of the belt. Users can leave the printer unattended until it finishes printing. All prints can be collected at the collection area at the end.

Users can leave the printer unattended until it finishes printing. All prints can be collected at the collection area at the end.

Silent 32-bit motherboard for the desired printing environment. Users no longer have to look for another way to eliminate engine noise. nine0003

Filament sensor. It is a necessary component for endless or repeated identical prints. It will pause printing if the filament runs out or breaks to prevent possible printing failure.

Proprietary 350 W power supply. It is able to provide sufficient power of the thermal layer. The heating layer is located at the back of the tape, next to the hot spot. The model cools by slowly moving away from the heated area and then detaches from the belt into the collection area. nine0003

3DPrintMill's unique triangular structure gives it perfectly balanced strength and superior rigidity. The moving belt allows the mass production of an identical object or purlins, which are usually located outside the building slab.

The 3DPrintMill triangular frame is built using a Core-XY structure that provides precision, speed and stability.

Creality will provide the special slicer version required to match the unique structure of this printer. It allows users to select the number of copies for a single part, or use the infinite Z-axis to create a long print. nine0003

This campaign was launched on Kickstarter at 12 noon on November 19 (GMT +8), 3DPrintMill is available for order from November 19 to December 19 on Kickstarter, shipping in March 2021. The regular retail price of 3DPrintMill is $999. You can save up to $461 with the flash sale. Super Early Birds also save up to $411. The sooner you join the program, the more benefits you will receive.

Special price per piece:

Urgent sale price - $538

Early Booking Price - $588

Early Booking Price - $688

Kickstarter Special Price - 738

Special Multipack Price:

2 pieces for $1363

3 pieces for 1998

3DPrintMill is the most affordable 3D printer -Z ever created. Similar strip printers currently on the market are for industrial use and cost about 10,000 euros.

Similar strip printers currently on the market are for industrial use and cost about 10,000 euros.

3DPrintMill will be available at about 1/10 of our competitor's price. In addition, when buying on the Kickstarter platform, you can save up to 50%. It will not be available elsewhere until the Creality Kickstarter campaign completes all backer orders. nine0003

Creality was inspired by the open source design and collaborated with those who developed it. By combining these ideas with our hardware design team over the past few months, we have been able to create a configuration that is both high performance and low cost.

Creality releases this product at such an affordable price for the following reasons: Creality is a manufacturer and distributor, there are no intermediaries. Our products are distributed by word of mouth, which saves on advertising. We are grateful to all Creality users. We want to thank our users with this innovative and revolutionary product at the most affordable price on the occasion of Creality's 6th Anniversary. nine0003

nine0003

Since its founding in 2014, Creality 3D has grown rapidly to become a well-known and trusted name in the 3D printing community. Creality 3D is headquartered in Shenzhen, with branch offices in Beijing, Shanghai, and Wuhan that include R&D, manufacturing, and after-sales divisions. With a total area of 30,000㎡ factory and research space, a team of more than 1,000 employees, and a sales volume of more than half a million 3D printers per year, our ability to meet production deadlines is guaranteed. Creality 3D is proud of its major R&D facility, the Creality 3D Printing Labs and Research Institute. It is this drive to innovate - to develop and improve open source designs - that led to the creation of 3DPrintMill. nine0003

The spirit of preaching, enabling thousands of families to enjoy the convenience that technology brings, is the mission of Creality. 3DPrintMill is a powerful continuous printing and mass production 3D printer for your micro factory that really offers simple and very affordable 3D printing solutions.