3D printing impact on society

Social Impact of 3D printing

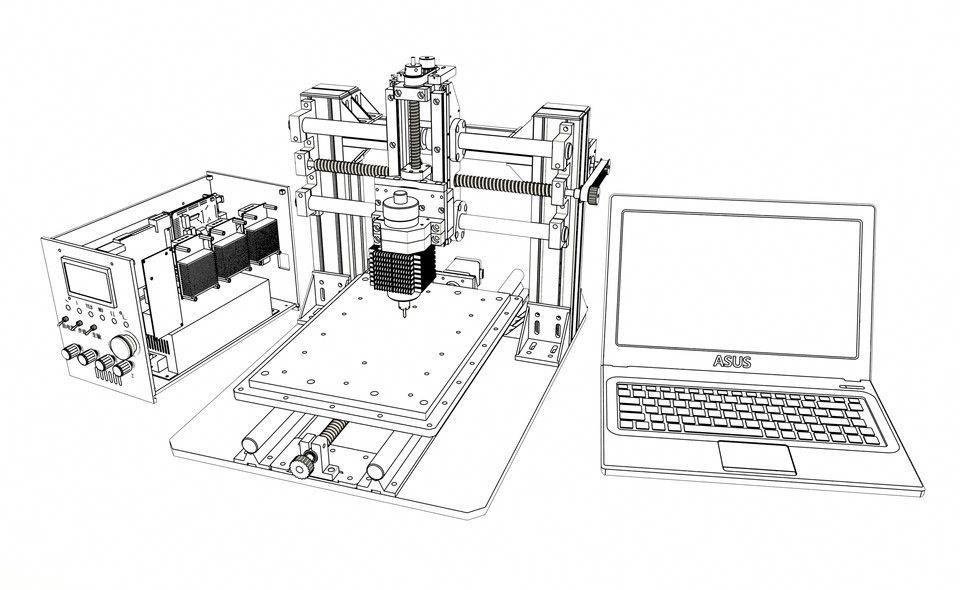

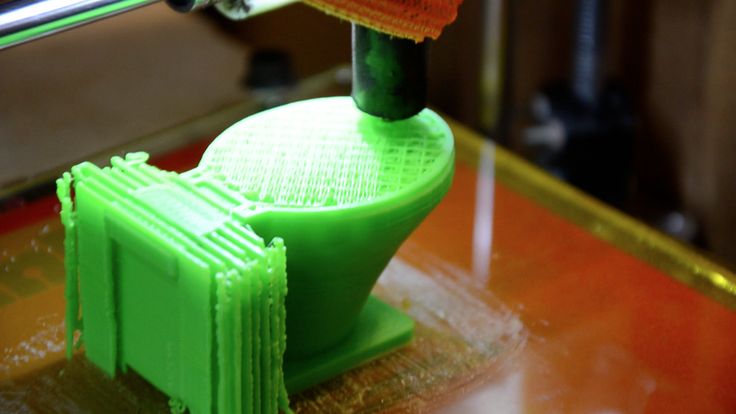

EOS produces systems for the Additive Manufacturing of components in both metal and polymers. Our customers include companies in the aerospace, medical technology, and toolmaking sectors as well as the automotive industry. Additive Manufacturing is a high-precision, 3D printing process for making a broad range of products and industrial components using digital 3D data that are directly transmitted to a “printer”. There, the powdered materials are melted with pinpoint accuracy via laser technology, thus creating highly complex parts layer by layer. The geometric possibilities of this technology are practically unlimited and therefore also its industrial applications. Structures no longer need to be limited to the capabilities of conventional production methods, but enjoy a great deal of design freedom. Even individual parts and small-scale batches can be profitably produced.

This complex technology has the potential to fundamentally change the industrial value chain and make a massive impact on the production scenarios of the future. Design freedom, customization, sustainability, rapid product developments, and the accompanying cost advantages are generating the impulses for the flexible manufacturing processes of the present day.

Component adaptations are both digitally and physically easy to implement, right from the product development stage – simply by adjusting the 3D data. Development cycles are therefore reduced to a minimum and sustainable product innovations can be rapidly implemented at lower cost.

Comprehensive functional integrations such as springs or hinge joints can be directly designed into the component. Complicated structures can be created without the need for tools and subcomponents can be reduced to a minimum.

For example, using EOS technology, ArianeGroup was able to reduce the injector head of a rocket engine powering the Ariane 6 from 248 individual parts to one single functionally integrated component. Created using Additive Manufacturing, the engine part is 25 percent lighter than its predecessor and production time was cut by a factor of 3, enabling ArianeGroup to reduce its costs by 50 percent.

The “maker” movement is gaining momentum through the endless implementation options that 3D printing offers. The barriers to market entry for this new manufacturing technology are low. Additive Manufacturing has proven to be profitable, even for small batches, and is enabling new business models. This technology is opening up a whole new world of possibilities for entrepreneurs, as the only things required are a good idea and internet access – everything else is freely accessible at any time via the World Wide Web. Software exists as freeware, while internet-based marketplaces and online shops serve as sales channels. Manufacturing capacities are available at any time via platforms that offer AM production services (such as Shapeways or Sculpteo).

Source: EOS

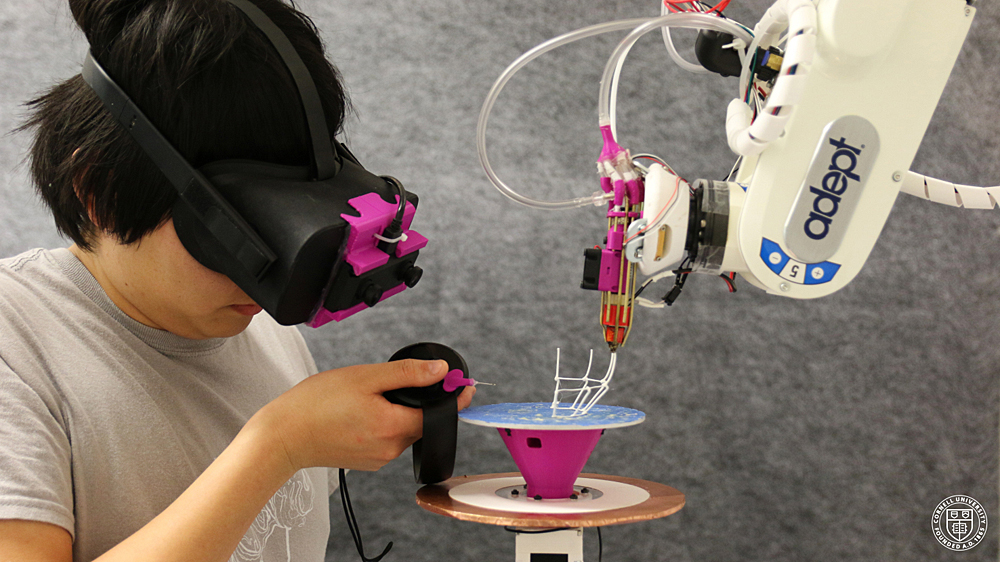

Industrial 3D printing is a key element for the factory of the future

3D printing is an essential part of Industry 4. 0, i.e. the buzzword that describes technology and production in the era of the digital revolution. Like every industrial revolution, the fourth stage is also causing job profiles to change. Whether 3D printing, robotics, Artificial Intelligence, or technology convergence – the increasingly interconnected digital world is opening up new opportunities, changing the existing, and creating the new. The cutting out of various intermediate stages and the shift from physical manpower to digital processes is having a long-term influence on the structures and working conditions of the future. These far-reaching changes will mean fewer uses for some types of work relating to conventional production, but new jobs will be created in the digital field, in IT, in design, or in completely new fields of activity. As this technology is making it possible to establish companies without a great deal of investment, 3D printing will play its part in counteracting the trend towards workforce reduction caused by digitalization.

0, i.e. the buzzword that describes technology and production in the era of the digital revolution. Like every industrial revolution, the fourth stage is also causing job profiles to change. Whether 3D printing, robotics, Artificial Intelligence, or technology convergence – the increasingly interconnected digital world is opening up new opportunities, changing the existing, and creating the new. The cutting out of various intermediate stages and the shift from physical manpower to digital processes is having a long-term influence on the structures and working conditions of the future. These far-reaching changes will mean fewer uses for some types of work relating to conventional production, but new jobs will be created in the digital field, in IT, in design, or in completely new fields of activity. As this technology is making it possible to establish companies without a great deal of investment, 3D printing will play its part in counteracting the trend towards workforce reduction caused by digitalization. The new possibilities are giving people with good ideas the chance to start an enterprise with a relatively low level of seed capital, regardless of where they are located.

The new possibilities are giving people with good ideas the chance to start an enterprise with a relatively low level of seed capital, regardless of where they are located.

Industrial 3D printing is making the localized “on-demand” manufacturing of components and spare parts economically viable, as it is becoming possible to produce the parts right where they are needed. The technology enables production to be decentralized, as components can be produced directly and locally, cutting logistics costs and reducing carbon emissions at the same time.

The manufacturing process itself also requires far fewer resources. In conventional production operations such as milling, 85 percent of the blank is simply cut away, generating a great deal of expensive waste. Industrial 3D printing, however, is quite the opposite as most of the residual powdered material can be reused. Both the systems and the components they manufacture have a highly positive impact on preserving valuable resources. Energy-efficient machines produce components that save a considerable volume of resources and promote the sustainable use of raw materials due to their design freedom, functional integration, and lightweight construction options. The simplification of designs and improved material characteristics made possible through additive technology can, for instance, mean that the wall thicknesses of components is greatly reduced without losing any of their robustness. The weight reduction achieved using this technology additionally generates savings in terms of lower fuel consumption.

Energy-efficient machines produce components that save a considerable volume of resources and promote the sustainable use of raw materials due to their design freedom, functional integration, and lightweight construction options. The simplification of designs and improved material characteristics made possible through additive technology can, for instance, mean that the wall thicknesses of components is greatly reduced without losing any of their robustness. The weight reduction achieved using this technology additionally generates savings in terms of lower fuel consumption.

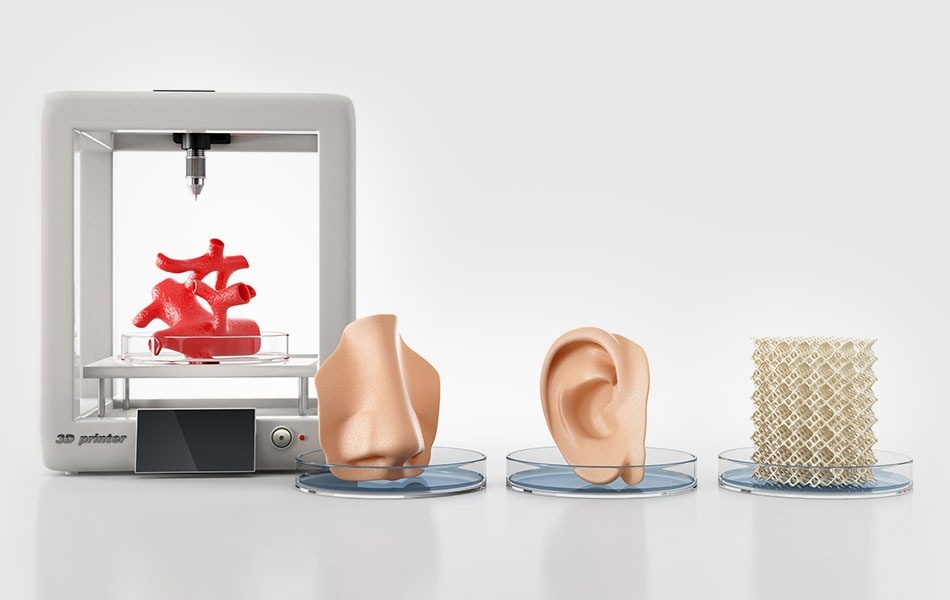

One field in particular where 3D printing truly is having the most noticeable impact, is that of medical technology. Although it has been possible to manufacture components such as dental implants, joints, artificial limbs, and parts of the skull in the past, they were only available as standard products. However, people differ greatly in terms of physique and their bodies also change as they age. Here, the customized shapes and sizes made possible by 3D printing can have an immense influence on people’s quality of life, as this technology can be used to manufacture made-to-measure prosthetic devices and dental implants that are precisely created to match the anatomy of each patient, significantly encouraging the healing process and therefore each patient’s chances of recovery.

Here, the customized shapes and sizes made possible by 3D printing can have an immense influence on people’s quality of life, as this technology can be used to manufacture made-to-measure prosthetic devices and dental implants that are precisely created to match the anatomy of each patient, significantly encouraging the healing process and therefore each patient’s chances of recovery.

For example, the UK startup company Andiamo uses EOS systems to produce tailor-made orthoses for children, which are otherwise conventionally created by using plaster casts. The process is painstaking, elaborate and the resulting product is less adjustable to the individual. Particularly young patients who are still growing are obliged to repeatedly undergo this procedure. They are often required to wait for up to six months for an orthosis that often no longer fits by the time it is delivered. Additive Manufacturing reduces this waiting time to a minimum. A 3D body scan is used as the basis for manufacturing a precisely fitting orthosis that can be delivered within one week.

Source: EOS

Additive manufacturing in the medical industry: 3D-printed concept of a hand orthosis

The possible applications for 3D printing are practically unlimited, as it is capable of producing flexible, light, and yet stable designs that only use as much raw material as required to make the product. The process is revolutionizing industrial manufacturing processes and helping create new business models. Its application in medical technology is facilitating healing processes and simultaneously improving patients’ quality of life.

The integration of industrial 3D printing in both existing and future production scenarios is a catalyst for innovative product design, marketing, and the sustainable use of resources.

.docx

Expert Article: Social Impact 3D Printing

Source: EOS

Original

1. 010,6 KB

010,6 KB

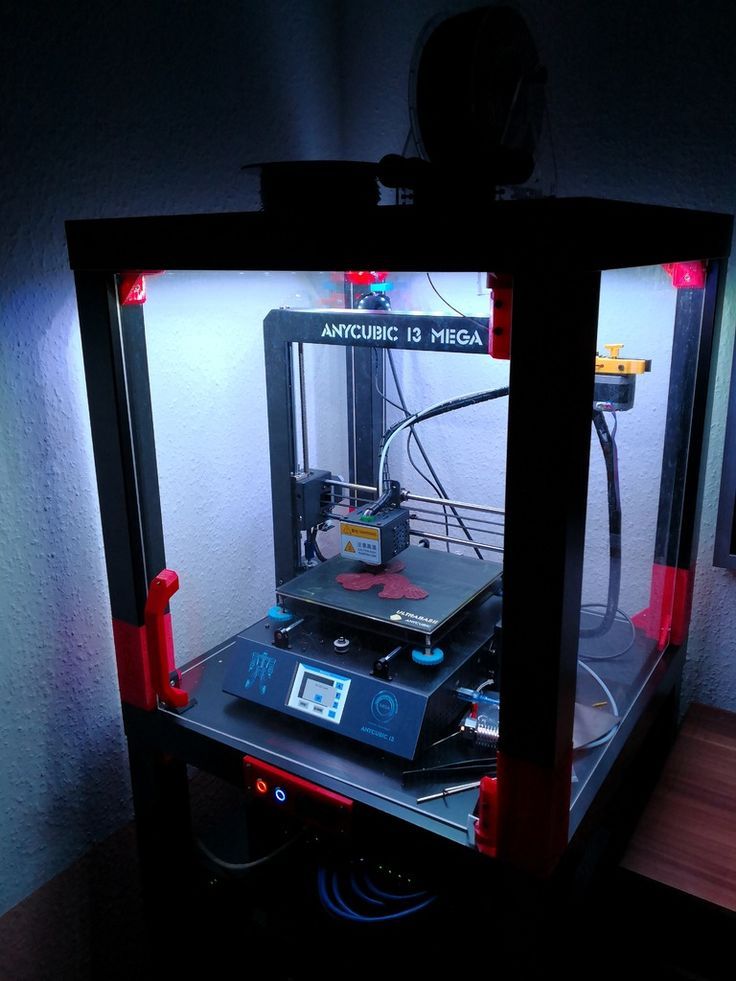

.jpg

Additive manufacturing in the medical industry: 3D-printed concept of a hand orthosis

Source: EOS

Original

233,0 KB Big

166,9 KB Web

65,5 KB

.png

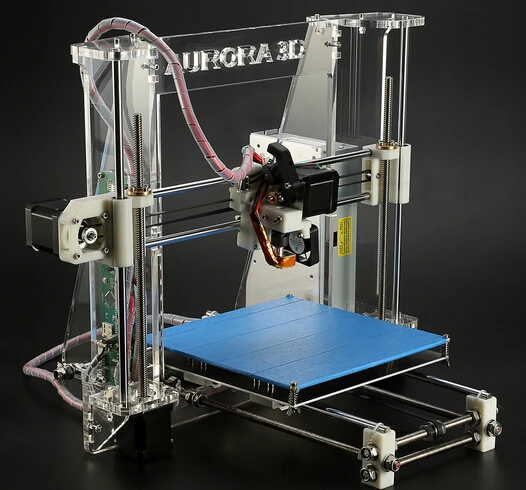

Industrial 3D printing is a key element for the factory of the future

Source: EOS

Original

1,0 MB Big

105,7 KB Web

105,7 KB

. jpg

jpg

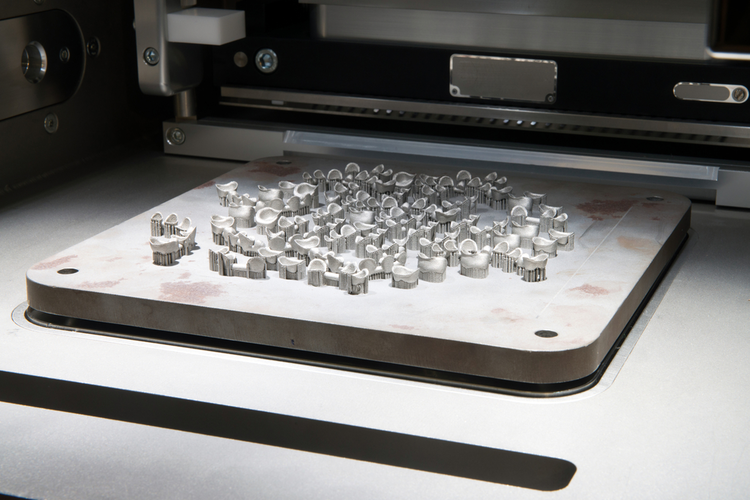

Industrial 3D printing with metal

Source: EOS

Original

1,9 MB Big

461,2 KB Web

104,3 KB

-- loading ... --

Be inpired. Stay up to date.

Join our Monthly Newsletter Now!

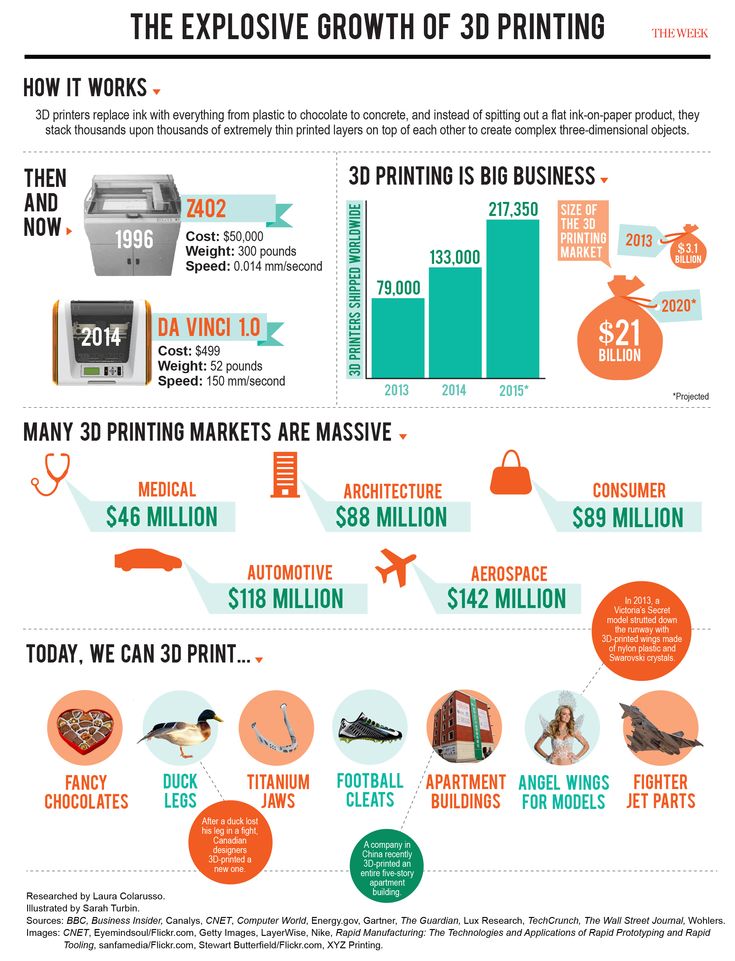

The Positive Effects of 3D Printing Accessibility on Society

In layman’s terms, 3D printing is the process of processing and printing materials such that they have a tangible, physical presence—i.e., with length, width, and depth (three-dimensional). As opposed to conventional printing which uses paper and ink, materials used in 3D printing can be sandstone, ABS plastic, nylon, or even metals. This variety of materials used means that 3D-printed creations can be applied in almost every aspect of our lives. Below are five positive effects of 3D printing on our society:

This variety of materials used means that 3D-printed creations can be applied in almost every aspect of our lives. Below are five positive effects of 3D printing on our society:

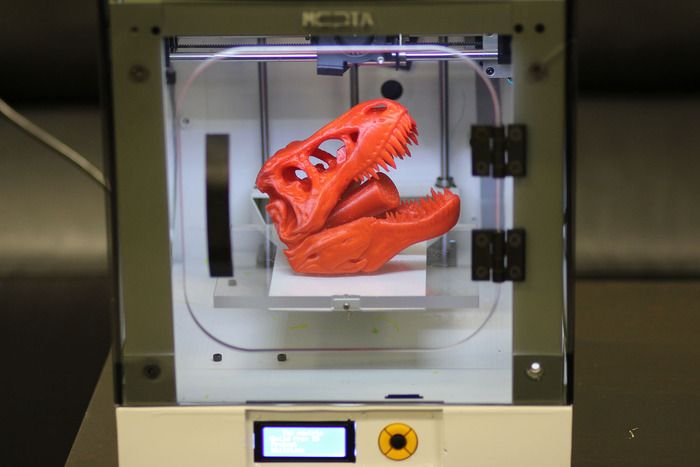

3D Printing Innovations Will Revolutionize Manufacturing

With widespread access to 3D printing equipment will come the ability to purchase and print items from the internet in real time. For instance, if you need a custom-made cover for your smartphone, all you will need to do is visit an online store selling the same and get its technical prints. Then, you can choose the color you want (maybe putting your name on it for good measure), download the final design to your computer, and subsequently print it out.

Currently, most companies charge for their designs, but it’s not as much as you would have to pay if you bought it via retail with the accompanying shipping costs. Notably, objects like smartphones and TV sets won’t be printable, but most household items will; this means that manufacturers will have to change their production systems.

3D printing has opened a customization industry. Engineers can create specialized prototypes and products for exact use cases.

Increased Mass Personalization of Products

As 3D printing innovations become more diverse with continuous advancements in technology, companies will be able to personalize products to suit the individual needs of their customers. As with the aforementioned phone covers, this mass personalization will take place without any corresponding labor costs as customers will be in charge of customization. Consequently, manufacturers will spend less on design and prototypes as these functions will be partially transferred to the customers’ home offices.

Nonetheless, some may argue—and rightly so—that mass personalization due to widespread 3D printing will lead to unemployment, so it’s not a good thing on all fronts.

Cheaper Medical Care

The use of 3D printing in the medical field has grown over the last decade, and the future looks even brighter. Very soon, scientists will be bioprinting blood vessels if researchers at Harvard University have their way. If this happens, it will open the door to the printing of body tissues and skin cells that will go a long way towards alleviating the suffering of millions of patients with blood diseases.

Very soon, scientists will be bioprinting blood vessels if researchers at Harvard University have their way. If this happens, it will open the door to the printing of body tissues and skin cells that will go a long way towards alleviating the suffering of millions of patients with blood diseases.

Additionally, researchers from the University of Toronto are working on the necessary infrastructure to allow 3D printing of prosthetic sockets. If this goes through, it will lead to reduced prosthetic prices—a relief for those who wear them.

Healthcare has changed dramatically under 3D printing. Doctors can turn advanced image scans into pre-op planning tools. The image above is of a hip that can be used for educational medical purposes.

The Rise (and Rise) of Open-Source Designs

3D printing uses Computer Aided Design (CAD) software, which requires human input both in the back and front ends. Of course, for you to print an item on your home 3D printer, someone has to create the basic designs which are typically stored in the CAD file. Currently, manufacturers and designers sell their CAD files to interested individuals who are, in fairness, not numerous.

Currently, manufacturers and designers sell their CAD files to interested individuals who are, in fairness, not numerous.

However, there are some sites, such as Thingiverse, that bring together creatives and designers under open-source principles. There, users share their print designs, and the rights to use them, to other users on the cheap—way cheaper than major companies charge. As a result, members save lots of time as they don’t have to learn the basics of 3D printing before they can customize and print the items they need. We expect more and more open-source communities to pop up in the future as 3D printing gains more mainstream acceptance and popularity.

Reduction of Environmental Pollution

As things currently stand, goods are manufactured in totally different places from where they are consumed—sometimes on different continents altogether. To get to the end users, these goods have to be transported, whether via plane, ship, train, or road, all of which use fuels and cause emissions that are harmful to the environment.

With widespread 3D printing, most goods will be designed on computers and “manufactured” in the homes of consumers, thus reducing both the costs and environmental impacts of transportation. Admittedly, 3D printing prices are quite high at this time, but they won’t stay that way forever. Soon enough, the prices of 3D printers and materials will fall as the demand and supply increase.

It is a fact that universal use of 3D printing technologies won’t happen soon, what with the natural human opposition to change. However, all signs are that we are headed that way, so if you're interested, now is the time to enroll in a 3D course. You may be lucky to land a 3D printing job worth hundreds of thousands per year in the near future.

And that's all we have about 3D printing, folks. But of course, the discussion doesn’t end there. Chip in with your two cents in the comments.

Lucas M. Cappel is a human culture educator from New York City who enjoys modern-day technologies. Learn more by checking out his website: Besttechexpert.guide.

Learn more by checking out his website: Besttechexpert.guide.

3D printers. 3D printing technologies and their impact on society and the economy

3D printers. 3D printing technologies and their impact on society and the economy- Main

- Articles

- 3D printers. 3D printing technologies and their impact on society and the economy

UDC: 338.27:004

Kushnir N. V. Kuban State Technological University, Krasnodar

Kushnir A. V. Kuban State Technological University, Krasnodar

Gerashchenko A. M. Kuban State Technological University, Krasnodar

Teryakin V. A. Kuban State Technological University, Krasnodar

Key words: 3D printers, three-dimensional printing (3D printing), stereolithography (SLA), fusing deposition (FDM)

This article is devoted to the analysis of such a product of the development of innovative technologies as 3D printers. The paper describes the basic technologies of three-dimensional printing (3D-printing). Particular attention is paid to various aspects of the impact that this technology can have on society and the economy.

The paper describes the basic technologies of three-dimensional printing (3D-printing). Particular attention is paid to various aspects of the impact that this technology can have on society and the economy.

Literature:

1. Encyclopedia of 3D printing [Electronic resource]. — Access mode: http://3dtoday.ru/wiki/ (Date of access: 20.05.2015).

2. Sychev V. Signed for publication. The American authorities were afraid of the pistol "from the printer" [Electronic resource]. — Access mode: http://lenta.ru/articles/2013/05/13/printed/ (Date of access: 05/20/2015).

3. The Americans "printed" an army pistol from metal [Electronic resource]. — Access mode: http://lenta.ru/news/2013/11/08/gun1911/ (Date of access: 20.05.2015).

4. 3D printers in medicine, their present and future [Electronic resource]. — Access mode: http://medicena.ru/blogpost/3d-printeryi-v-meditsine-ih-nastoyashhee-i-budushhee/ (Date of access: 05/20/2015). nine0011

5. Baranovskaya T. P., Loiko V. I., Semenov M. I., Trubilin A. I. Computing systems, networks and telecommunications: Electronic textbook. - Krasnodar: KubGAU, 2011. - 292 p.

Baranovskaya T. P., Loiko V. I., Semenov M. I., Trubilin A. I. Computing systems, networks and telecommunications: Electronic textbook. - Krasnodar: KubGAU, 2011. - 292 p.

6. Zalogova L. A. Computer graphics. Elective course: Proc. allowance. — M.: Binom. Knowledge Laboratory, 2009. - 216 p.

7. Zalogova L. A. Computer graphics. Elective course: Practicum. — M.: Binom. Knowledge Laboratory, 2009. - 245 p.

8. Kotsuba E. V., Evseev A. V., Kamayev S. V., et. al. Operative fabrication of plastic copies of objects using x-ray tomography data // Proc. of 8th European Stereolithography User Group Meeting. — 7–8 October 1996, Darmstadt, Germany.

Today it is difficult to imagine a person without modern technology used in all areas of our society. Various new technologies are constantly emerging, which in the shortest possible time become of tremendous importance. A striking example of this are three-dimensional technologies, often referred to as "3D technologies" (from the English 3D - three-dimensional, i. e. "three-dimensional"). One of the options for their application is three-dimensional printing (3D printing), which is a modern, promising way to create three-dimensional objects. The devices used to carry out this kind of printing are called 3D printers, or fabbers. nine0011

e. "three-dimensional"). One of the options for their application is three-dimensional printing (3D printing), which is a modern, promising way to create three-dimensional objects. The devices used to carry out this kind of printing are called 3D printers, or fabbers. nine0011

The development of these technologies was dictated by the desire to reduce the cost and simplify production. Small-scale production required a lot of effort to create the appearance and main components of each product. Expenses for sketches, drawings, patterns, prototypes, models, etc. were significant. In this regard, machine devices began to appear, which created the necessary models in a short time and with great accuracy. The main constructor of these machines was an integrated software control. With the same success, they are now used in many enterprises. The 3D printer is the direct successor of such units. 1995, when Solidscape introduced a dedicated multifunctional inkjet printer to create a 3D image. With this event, in fact, the emergence of such concepts as "3D printing" and "3D printer" is connected.

With this event, in fact, the emergence of such concepts as "3D printing" and "3D printer" is connected.

There are a large number of 3D printing technologies, the basic ones being stereolithography and fusing.

Consider the history and essence of both of these methods. The appearance of stereolithography is associated with the name of Charles Hull, at 1986, who patented it as a method and device for creating solid physical objects (in particular, 3D prototypes). Stereolithography (stereolithography, abbreviated as SLA or SL) is a technology for the additive (total) production of models, prototypes and finished products from liquid photopolymer resins, brought to a state of hardening by irradiation with an ultraviolet laser or other similar energy sources. The main advantage of stereolithography over other technologies is the greater accuracy of printed objects. The existing technology makes it possible to apply layers with a thickness of about 15 microns, which is many times thinner than a human hair. Such accuracy seems to be quite satisfactory in the manufacture of prototypes of dental prostheses and even jewelry. Given the high resolution of such objects, the printing speed can be considered relatively high: building one model can take only a few hours, although it ultimately depends on the size of the model and the number of laser heads simultaneously used by the device. Relatively small desktop devices can provide a build area of 50 to 150 mm in one dimension. There are also industrial installations that provide the ability to print large objects, already measured in meters. Finished products exhibit various mechanical properties determined by the inherent characteristics of the photopolymer. Already now there is a sufficient number of imitators of solid thermoplastics, rubber and a number of other materials. Stereolithography makes it possible to create details of high complexity, which is undoubtedly the advantage of the method. The disadvantage of this technology at the moment is its high cost, due to the rather high price of consumables.

Such accuracy seems to be quite satisfactory in the manufacture of prototypes of dental prostheses and even jewelry. Given the high resolution of such objects, the printing speed can be considered relatively high: building one model can take only a few hours, although it ultimately depends on the size of the model and the number of laser heads simultaneously used by the device. Relatively small desktop devices can provide a build area of 50 to 150 mm in one dimension. There are also industrial installations that provide the ability to print large objects, already measured in meters. Finished products exhibit various mechanical properties determined by the inherent characteristics of the photopolymer. Already now there is a sufficient number of imitators of solid thermoplastics, rubber and a number of other materials. Stereolithography makes it possible to create details of high complexity, which is undoubtedly the advantage of the method. The disadvantage of this technology at the moment is its high cost, due to the rather high price of consumables. For example, the cost of one liter of photopolymer resin can vary from $80 to $120, while the price of the devices themselves can range from $10,000 to $500,000 [1]. It is obvious that such costs are unbearable for most enterprises, in particular, in our country. nine0011

For example, the cost of one liter of photopolymer resin can vary from $80 to $120, while the price of the devices themselves can range from $10,000 to $500,000 [1]. It is obvious that such costs are unbearable for most enterprises, in particular, in our country. nine0011

For Citation:

Kushnir N. V., Kushnir A. V., Gerashchenko A. M., Teryakin V. A., 3D printers. 3D printing technologies and their impact on society and the economy. Design department. 2016;2.

The full version of the article is available to subscribers of the journal

For Citation:

N. V. Kushnir, A. V. Kushnir, A. M. Gerashchenko, V. A. Teryakin, 3D printers. 3D printing technologies and their impact on society and the economy. Design department. 2016;2. nine0011

full name

Your e-mail

Your telephone number is

By clicking the "Get access" button, you consent to the processing of your personal data

Your name

Your last name

Your e-mail

Your phone number

Create a password

Password again

Remember me

Inform me about all the news and special offers by mail nine0011 A confirmation code has been sent to the phone number you provided.

It will be possible to request the code again in seconds.

Confirmation code

A confirmation code has been sent to the phone number you provided.It will be possible to request the code again in seconds.

Confirmation code

A confirmation code has been sent to the phone number you provided.It will be possible to request the code again in seconds. nine0010 Confirmation code

Login

Password

Your name:

Your e-mail:

Your phone:

Message:

The site uses reCAPTCHA spam protection and applies Terms of Use and Google Privacy

nine0109 Use this device? Only one device is allowed to use one account at a time.

It will be possible to request the code again in seconds.

Confirmation code

×

We have translated you to the Russian version of the site nine0119

You have been redirected to the English version

We use cookies

Impact of 3D printing on society

Extra-curricular event in English in grades 8-9 Topic: "The impact of 3D printing on society"

Teacher: Margarita Dmitrievna Strigunkova

School: MBOU "Secondary School No. 59", Kursk.

Lesson time: 45-60 minutes.

Lesson Objective: Evaluate the pros and cons of 3D printing and determine if 3D printers should be widely available.

Tasks:

Developing: development of the basic techniques of logical thinking, memory, imagination, language skills and communication skills, as well as the skills and abilities associated with finding the necessary information and conducting research.

Educational: activation of vocabulary and grammar on the topic and the use in practice of the learned material in all types of speech activity.

Cognitive: acquaintance with the possibilities of 3D printing, its pros and cons, expanding the information, communication and socio-cultural competence of students.

Educational: increasing motivation for learning, fostering a culture of behavior during conversations and debates.

Methods and techniques: method "Six Thinking Hats", visual (presentation, posters), interactive (quiz), reflection "Everything is in your hands".

Materials needed: computer, projector, hats in 6 colors (white, black, yellow, green, red, blue), ppt presentation, internet access / printout of articles about the benefits and harms of 3D printing.

Students are encouraged to study the vocabulary on the topic in advance ( https://lingualeo.com/ru/glossary/28934?utm_source=britishcouncil&utm_medium=pr ) and the following materials online or in print:

https :// en . wikipedia . org / wiki /3 D _ printing

https ://3 dprinting . com / what - lesson

-

Organizational stage

-

Goal-setting stage.

-

Stage of mobilization (inclusion of students in active intellectual activity)

-

Stage of communication (debate)

-

Stage of reflection

-

Stroke lesson

-

Organizational stage

The teacher welcomes the class, sets up for learning activities.

-

Stage goal-setting

The teacher asks questions about the topic of the lesson:

- How often do you use a printer?

- What do you usually print out?

- How many of you have heard of 3D printing?

- Would you like to know more about this? (Think about what exactly you would like to know about it, write down 2-3 questions). nine0011

Watch a short video about how the 3D printer works ( www.youtube.com/watch?v=fv6yaWnopls ) and write down your questions.

-

Mobilization stage

Students are divided into the following groups:

- 5 people (Optimists) with a yellow hat (their task is to talk about the main advantages and bright prospects of using a 3D printer) 9001 9001 a person (Critics) who has a black hat (their task is to find flaws, express their concerns)

- 5 people (Creatives) who wear a green hat (their task is to find new creative ideas that break stereotypes that are related to the topic of debate)

- 2 people (Scientists) who wear a white hat (their task is to report all the information on the topic: facts, statistics, graphs - basic data, no emotions)

- 1 person (Head) who has a blue hat (his task is to coordinate the work of the others, determine what needs to be done at the beginning of the work, record the results of the study at the end and identify tasks for the future)

- 3 people (Artists) who have a red hat (their task is to express what they feel and experience during the discussion, what intuition tells them).

The Blue Hat invites you to discuss the benefits and harms of 3D printing and, at the end of the session, decide on the availability of 3D printers to the general public.

Next, 2 people present the white hat.

-

Communication stage (debate)

5 yellow hat people report the benefits and benefits of using 3D printers with their Pros of 3D printing poster.

5 Black Hat Critics enter the discussion. They report on the cons of 3D printing, possible risks and threats, express their concerns and show their Cons of 3D printing poster.

Next comes the green hat group. They offer videos of 17 incredible 3D printed items ( www.youtube.com/watch?v=FSu19nz7NlE ) and each of them talks about one amazing use of a 3D printer not mentioned here, showing a model in a photo (They prepare this material in advance. Source - 20 Incredible Ideas www.hongkiat. com/blog/3d-printings/ )

-

Reflection stage

3 people (Artists) wearing a red hat express their emotional attitude to what they heard and saw. They summarize the idea in three words characterizing the received information.

They summarize the idea in three words characterizing the received information.

The leader ("Blue Hat") invites everyone to evaluate the quality of this debate using the reflection technique "Everything is in your hands."

Students trace their left hand on a piece of paper. Each finger is a SOMETHING position on which you need to express your opinion. Students fix positions on their fingers that correspond to their inner feeling.

THUMB – a lot of things were important and interesting for me. nine0011

INDICATOR - I received a specific recommendation on this matter.

MEDIUM - I had a hard time (didn't like it).

UNNAMED - a positive assessment of the psychological atmosphere.

LITTLE FINGER - this information was not enough for me.

Finally, the teacher asks the students to go back to the questions they wrote down at the beginning of the lesson and asks if they got answers to their questions.