3D printer for furniture

Large Scale 3D Printers Big Enough to Print Furniture

Home / 3D Printers / Large Scale 3D Printers Big Enough to Print Furniture

Use Cases

Just like all types of 3D printing, XL 3D printing has its own strengths and tradeoffs. Users are constantly finding more applications for these gigantic machines so the XL 3D printing space is getting bigger and bigger. Let’s have a closer look.

Quick jump to:

- Request XL 3D printer quote

- Request XL service quote

When To Consider Large Scale 3D Printing

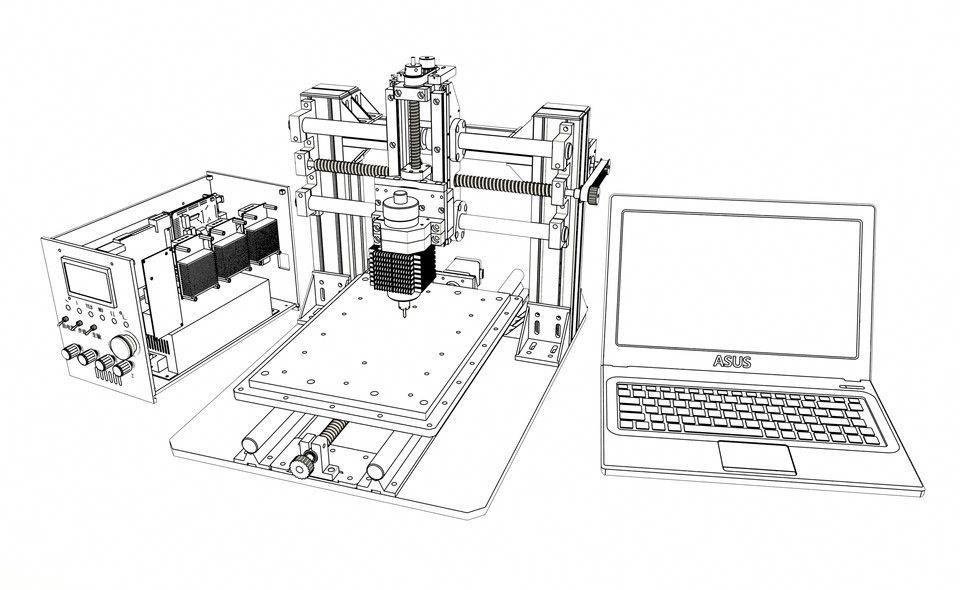

It takes a large scale 3D printer to print furniture, vehicle parts and architectural components. Obviously, size is the driving factor in choosing to use large-format printing but there’s more to it than that. Here’s a breakdown of some of the less-obvious considerations:

- Unibody Parts – Often, producers are already able to fabricate their large objects through traditional methods of assembly but those objects would perform better if they were produced as one solid piece, something only a large 3D printer can do efficiently.

- Weight Reduction – Large objects are usually made of wood, metal, or injection molded plastics. Printing the same objects in plastic will make them much lighter, especially when factoring that users can easily adjust the density infill of 3D printed objects. Consolidating large assemblies into single components also reduces weight by eliminating the need for fasteners like nuts and bolts.

- Faster Development – The larger an object, the longer it takes to create and setup the tooling to fabricate it through traditional means. With 3D printing, there are essentially no setup steps so large prototypes are significantly faster to print than to make them any other way. A large object may take a while to print, but by cutting out the time-consuming tooling step, it may also be faster to do production runs of large objects, depending upon the specifics.

- Reduced Cost – 3D printed large parts can be cost competitive with conventionally-made parts almost entirely because of the tooling costs of the latter.

Consolidated assemblies usually cost less as well because fewer materials have to be sourced from different places.

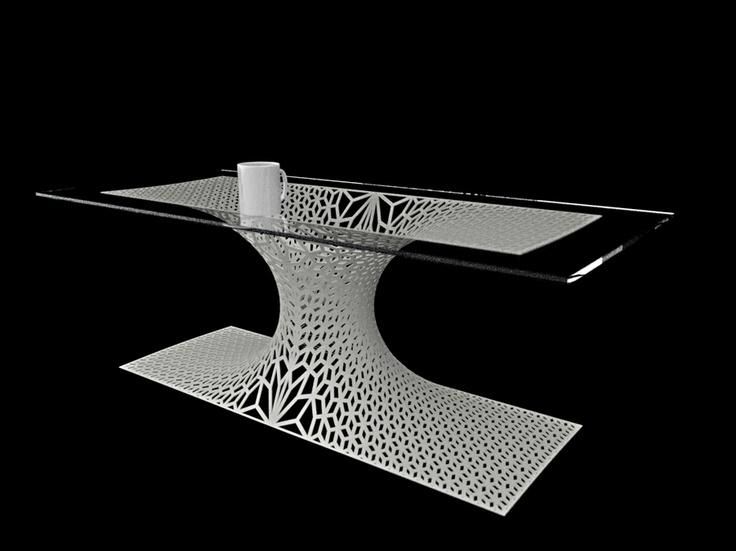

Consolidated assemblies usually cost less as well because fewer materials have to be sourced from different places. - Design Freedom – Using conventional manufacturing methods, many geometries are just not possible, such as internal channels and complex lattice structures. Many large objects, like furniture, benefit from such features and XL printers are the only way to realize those designs.

Large Scale 3D Printing Examples

- Restoration and replication – XL 3D printing has become rather popular among paleontologists as the technology allows them to both study and preserve the delicate fossils that they regularly handle.

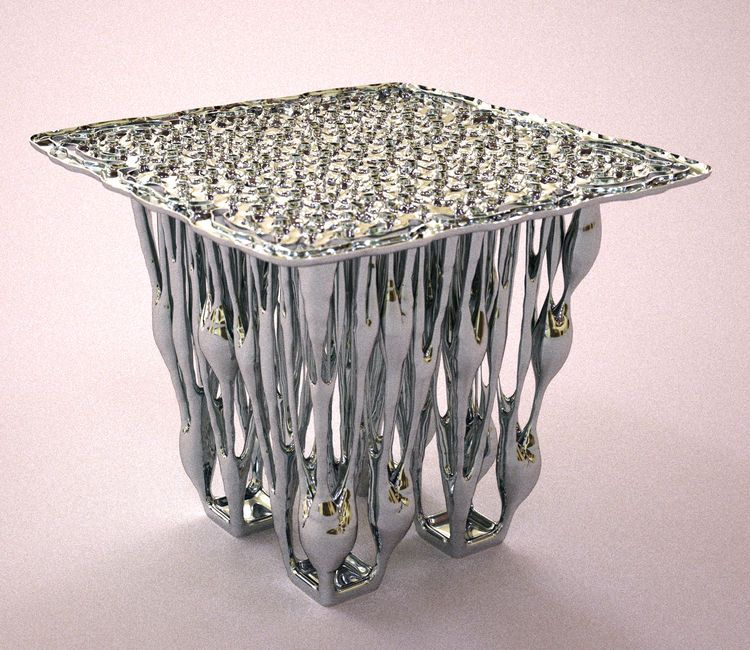

- Furniture – Thanks to large-scale 3D printers it is now possible to create complex functional designs within a fully digitized process chain. From full-size prototyping to production of 3D printed furniture.

- Display advertising – XL 3D printers are perfect for making high-quality, modern signage and lettering for retail stores, businesses and exhibitions.

- Props – With the introduction of large scale 3D printers, designers can now produce enormous set pieces – overnight. 3D printing can help designers quickly manifest their wildest imaginations into the physical reality, and the Film & TV industry has taken notice.

Pellet Extrusion

One of the differences between desktop-sized machines and XL printers is the possibility to utilize pellet extrusion systems on the large printers. Pellet extrusion doesn’t use spooled filament as feedstock but instead uses the same virgin plastic pellets that are used for injection molding, which are much cheaper than spooled filament. This makes it easy to mix different plastics to make custom polymer blends and colors. These systems can also take shredded plastics as feedstock, which enables users to directly recycle water bottles, milk jugs, and failed and unneeded prints into new objects. Such a degree of a circular ecosystem can not be achieved with any other form of manufacturing.

That’s all great but what compels most users to opt for pellet extrusion is its blazing speed as the technology enables output of several kilograms per hour. Printing times scale exponentially with part size so having a high extrusion rate is pretty important for large-format 3D printing. One drawback of pellet extrusion systems is that they struggle with retraction, a feature that filament extruders employ to improve surface finish by pulling back on the filament during non-extrusion travel moves; retraction reduces or eliminates blobs, dots, and stringing on prints. Some XL printers can operate with both filament and pellet extrusion systems, allowing users to choose the best toolhead for their specific application.

Get a Quote

Large Scale 3D Printers

Looking to implement large scale 3D printers in your production process? Get a quote from Modix or Industry

Modix BIG Meter

With the Modix BIG Meter, you are now able to manufacture objects as large as 1010 x 1010 x 1010 mm in one go!

$13,500Modix

Request a Quote

modix big meter

- Benefits

- Applications

- - DIY self-assembly kit

- - Print Volume: 1010 x 1010 x 1010 mm

- - Printer Dimensions: 1300 x 1470 x 1830 mm

- - Shipping Weight: 200kg

- - Included: Dual print head, E3D Aero & Volcano 1.

75mm

75mm - - Reprap Firmware developed and supported by Duet3D

- - 7 inch touchscreen made by Duet3D

- - E3D Titan Aero extruder with E3D Volcano hotend

- - Automatic bed tilt calibration

- - Power Requirements: 32A, single phase, 208-240V

Mold Making, Prototyping, Research and Development, Restoration

Industry MAGNUM

Hailing from Sweden, Industry is a company that has made major waves in the world of 3D printing. The new MAGNUM large scale pellet 3D printer enables you to print parts measuring 1500 x 1200 x 1200 mm.

A powerful E25 extruder manufactured to handle shredded material, granules or pellets. The MAGNUM handles nozzles between 2-8mm and has an average output between 1-8 kg / hour & a maximum output of 15 kg / hour.

MAGNUM offers powerful control features based on Bosch Rexroth MTX system control. It comes with a camera and mail/text module for external monitoring. A large touch screen display allows for easy setup and agile control.

€159,000Industry

Request a Quote

Industry MAGNUM

- Benefits

- Applications

- - Large scale pellet 3D printer

- - XL build size: 1500 x 1200 x 1200 mm

- - Granular extruder, which reduces material costs

- - Fast build rate: up to 15 kg per hour

- - Touch screen display

- - High quality linear motion modules from Bosch Rexroth MTX

Mold Making, Production, Prototyping, Research and Development, Restoration

Modix BIG-180X

The BIG-180X features a print volume of 1800 x 600 x 600 mm and comes at a competitive price of $12,000 USD. The unique extra width of the build chamber is designed per request of customers working in the automotive industry.

$15,500Modix

Request a Quote

modix 180

- Benefits

- Applications

- - DIY self-assembly kit

- - Print Volume: 1800 x 600 x 600 mm

- - Printer Dimensions: 2170 x 1060 x 1430 mm

- - Shipping Weight: ~240kg

- - Included: Dual print head, E3D Aero & E3D Volcano 1.

75mm

75mm - - Reprap Firmware developed and supported by Duet3D

- - 7 inch touchscreen made by Duet3D

- - E3D Titan Aero extruder with E3D Volcano hotend

- - 4 X Z axis motors are controlled individually providing automatic bed tilt calibration.

- - Minimal Electricity requirements: 32A, single phase, 208-240V

Prototyping, Research and Development, Restoration

Modix BIG-120Z

The closed enclosure of the BIG-120Z is made of aluminum composite panels and polycarbonate doors. It incorporates a premium motion system including HIWIN motion rails, Gates timing belts and IGUS signal cables. This is a smart 3D printer providing several key reliability features including power-off resume, filament runout sensor, 120 probing points based automatic bed leveling, stall detection and more. The manufacturer offers an active air filter device as an add-on.

$7,500Modix

Request a Quote

BIG-120Z

- Benefits

- Applications

- - DIY self-assembly kit

- - XL print volume of 600 x 600 x 1200 mm

- - Z axis guides, HIWIN MGW Linear Rails

- - Duet 2 Wifi, 32Bit controller developed by Duet3D

- - Reprap Firmware developed and supported by Duet3D

- - 7 inch touchscreen made by Duet3D

- - Dual print head

- - E3D Titan Aero extruder with E3D Volcano hotend

Displays, Fashion, Mold Making, Prototyping

Modix BIG-120X

Modix BIG-120X Version 3 represents a major leap forward with regards to the printer reliability, print quality, ease of assembly and readiness to future advanced updates. Since Modix big60 and 120X share the same core design the new update is benefiting both models.

Since Modix big60 and 120X share the same core design the new update is benefiting both models.

$7,500Modix

Request a Quote

BIG-120X

- Benefits

- Applications

- - DIY self-assembly kit

- - XL print volume of 1200 x 600 x 660 mm

- - Duet 2 Wifi, 32Bit controller developed by Duet3D

- - Reprap Firmware developed and supported by Duet3D

- - 7 inch touchscreen made by Duet3D

- - E3D Titan Aero extruder with E3D Volcano hotend

- - Closed loop motion system (optional)

Mold Making, Prototyping, Research and Development, Restoration

Get a Quote

XL 3D Print Service

3D printing is a viable option for display advertising, large scale concept models, car parts, furniture, molds & tooling. We offer both cost effective solutions with thick layers and rough surfaces for rapid prototyping as well as highly detailed & post-processed end-use objects. Please contact — [email protected] — for any questions or complete the form below and we’ll answer you as soon as possible.

Please contact — [email protected] — for any questions or complete the form below and we’ll answer you as soon as possible.

- Technologies: FDM, SLA, GDP

- Materials: From PLA to CF composites & more

- Maximum print size: 1450 x 1100 x 1800 mm

- Post-processing: Spray paints, metal coatings, assembly & many more

How 3D Printing Is Turning the Furniture Business Upside Down

NATHANIEL BERMAN IS FOUNDER OF HOUSELY, A DESIGN AND REAL ESTATE BLOG TRACKING TRENDS IN DOMESTIC ARCHITECTURE. HERE, HE LOOKS AT EXAMPLES OF 3d-printed furniture and the technology’s impact on furniture manufacturing.

Pizza, working cars, entire office buildings, tiny power tools — is there anything that can’t be made with a 3D printer? Over the last several years the world has seen 3D printing shake up a number of industries. It seems as if there’s nothing one can’t have printed these days, and now this technology is changing the world of furniture, too. Lamps, chairs, tables and decorative hardware are now being printed, and it’s quickly changing how companies produce pieces as well as increasing the options available to consumers.

Lamps, chairs, tables and decorative hardware are now being printed, and it’s quickly changing how companies produce pieces as well as increasing the options available to consumers.

Cohda’s Binary Furniture

Changing the Design Process

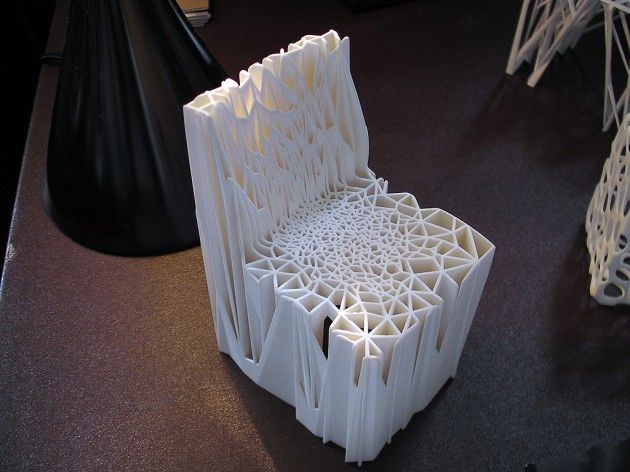

One part of the furniture business that has traditionally required significant time and financial investment is the design process. Prototypes have to be made, models tested and pieces reworked to reach a final product. 3D printing streamlines, simplifies and reduces the cost of designing furniture. Being able to create lightweight furniture prototypes quickly and inexpensively with 3D printing enables designers to test their creations more thoroughly and maximize the beneficial features in the finished product. UK design firm Cohda collaborated with 3D printer Freedom of Creative to produce the Binary Furniture Collection. It’s styled to resemble designs made by an old school Spirograph, and being able to electronically sketch and then print each piece has made the collection affordable for the business and its customers.

Patrick Jouin’s One Shot Stool

A rapidly growing number of furniture design firms are experimenting with 3D printing, and the results have been quite creative. With less production and design expenses, 3D printing lets companies develop furniture that is as beautiful to look at as it is functional. The One Shot stool, designed by Patrick Jouin, is a 3D-printed piece that folds up to save space when not in use and elegantly fans out when an extra seat is needed. Its aesthetic is unlike that of most other stools, and that’s what makes the One Shot’s design so attractive to those who like modern furniture.

Patrick Jouin’s One Shot Stool

Patrick Jouin also designed a light, called Bloom, for Materialise that is an articulated lamp produced via 3D printing. The shade opens and closes, resembling a lotus flower. Incredibly, Bloom is printed in one piece and requires no assembly at all. It’s just one of a number of innovative pieces that are coming to the furniture market and expanding consumer options like never before.

Patrick Jouin’s Bloom

Manufacturing Revolution

In addition to giving designers the ability to create furniture that’s simply not possible to make by traditional methods, 3D printing has made it cheaper for new businesses to enter the furniture game. Less design and production expenses equates to furniture that can quickly be made available to consumers at a lower price on both ends. It’s truly a win-win for designers, manufacturers and people who want awesome furniture without spending an arm and a leg.

Since its inception, the 3D printing industry as a whole has grown over 45 percent each year. In 2013 the market was valued at $2.5 billion, and the projected value is estimated to reach $16 billion by the year 2018. This technology allows furniture design firms and retailers of home goods to increase their bottom lines, waste significantly less resources and energy and make production much more efficient.

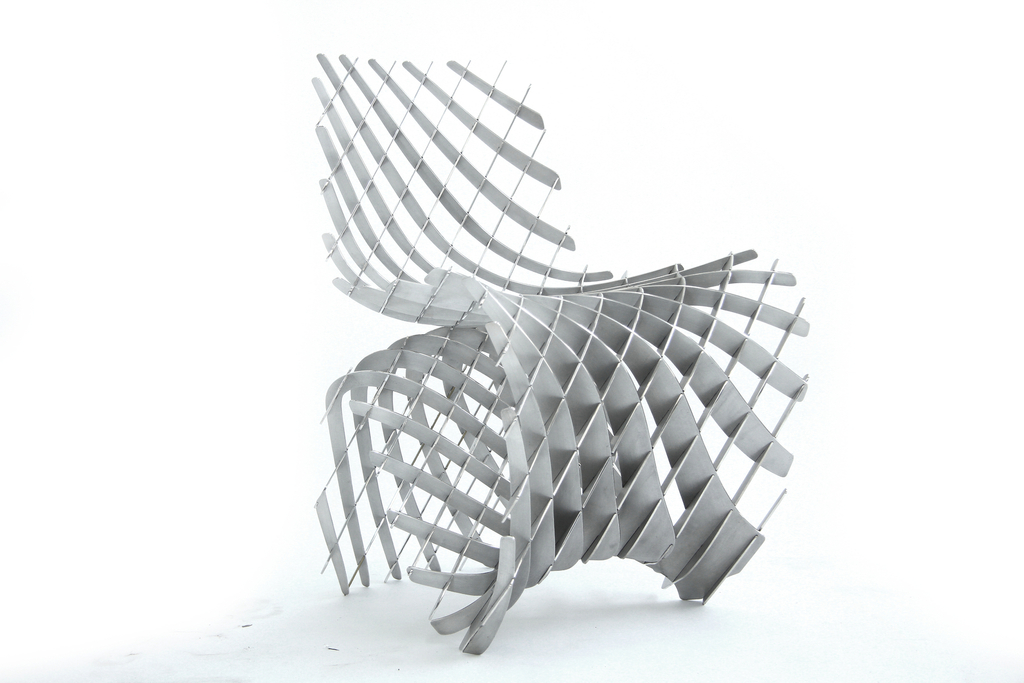

Dirk Vander Kooij’s Endless Pulse Chair

3D printing is not only more cost effective for companies, it’s much more environmentally friendly and sustainable than most traditional means of creating furniture. Dirk Vander Kooij’s Endless Pulse Chair is made via 3D printing and comprised of discarded refrigerators that have been melted down. The result is a piece that’s durable and strong yet lightweight. As an eco-conscious bonus, the Pulse Chair itself can be recycled.

Dirk Vander Kooij’s Endless Pulse Chair is made via 3D printing and comprised of discarded refrigerators that have been melted down. The result is a piece that’s durable and strong yet lightweight. As an eco-conscious bonus, the Pulse Chair itself can be recycled.

Dirk Vander Kooij’s Endless Pulse Chair

Consumer Benefits

Custom designed furniture has historically been cost prohibitive because of the costs involved on the business end, but printed furniture eliminates some of that burden. Not only is designing prototypes made easier with this technology, getting finished pieces to customers is as well. They can choose their preferred colors, styles, and other customized options and it won’t add any additional cost to the printing process.

While 3D printing will change many segments of the furniture industry, it won’t replace traditional manufacturing or upholstery entirely. Those who prefer classic designs or pieces crafted of exotic woods and materials are unlikely to start favoring the very modern style of furniture that 3D printing produces. However, consumers who want their furniture to look like a trendy Pinterest board, custom artwork, or minimalist piece will find it very easy to love 3D printed furniture.

However, consumers who want their furniture to look like a trendy Pinterest board, custom artwork, or minimalist piece will find it very easy to love 3D printed furniture.

© Studio Leyssen Photograph

Peter Donders’s Batoidea Chair

Peter Donders is a Belgian furniture designer who developed the Batoidea Chair and creates each one with the aid of 3D printing. It’s an airy piece of furniture with attractive twists and curves, and it can be printed in various colors. Similar chairs made of metal cost many times more than Donders’ printed design, and he says that without additive manufacturing, creating the Batoidea Chair would result in a great amount of waste.

Peter Donders’s Batoidea Chair

In addition to having a much wider array of designs to choose from and the ability to easily obtain custom pieces, 3D printed furniture is easier on the wallet than traditionally manufactured furniture. Whereas a custom table would cost thousands of dollars, a printed one would cost a few hundred, if that. It’s much quicker to actually get the furniture in hand as well. Designer Dirk Vander Kooij can create furniture with his 3D printer, dubbed Furoc, within a three hour time span. That’s incredibly faster than the time it takes to make non-printed furniture, and it’s even 40 times faster than most 3D printers.

Whereas a custom table would cost thousands of dollars, a printed one would cost a few hundred, if that. It’s much quicker to actually get the furniture in hand as well. Designer Dirk Vander Kooij can create furniture with his 3D printer, dubbed Furoc, within a three hour time span. That’s incredibly faster than the time it takes to make non-printed furniture, and it’s even 40 times faster than most 3D printers.

This speed will change furniture shopping as consumers have come to know it. In the very near future, customers will be able to go to locations nearest them and get their chairs, tables, and fixtures 3D printed on the spot. Imagine being able to look at a piece of furniture online, have it printed, and then pick it up the same day — it’s a very real possibility, and shoppers and retailers can expect it to become reality in just a few years. Lower production costs, endless design possibilities, happy consumers — it’s no wonder 3D printing is taking the furniture industry by storm.

Originally posted on housely.com.

Read more articles by Nathaniel

As part of our new tech section, Architizer presents an overview of apps that can benefit architects and designers throughout the lifetime of a project, from concept to completion. In the field of architecture, time is always of essence. Drafting a field report during or after a site visit is often a time-consuming and tedious…

Thonon-les-Bains, France

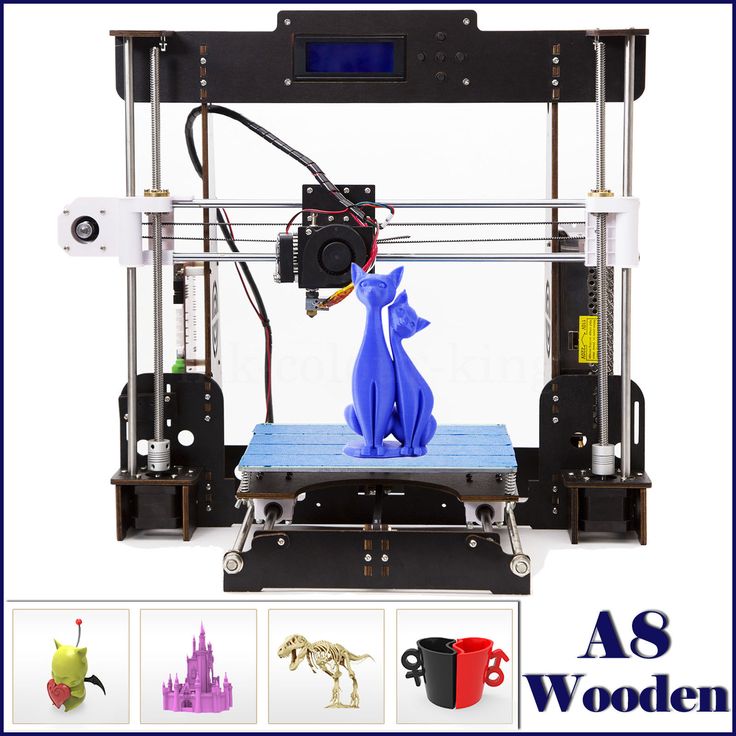

3D printers for furniture printing. Large build chamber.

We are all used to factory furniture. However, designer furniture is valuable. 3D furniture printers make it possible to turn very original objects into reality: chairs, tables, lamps, vases, etc.

3D printers use different materials to print furniture. Most often it is high-strength plastic, although a printer has been created in America that prints wooden furniture. To do this, small chips and sawdust are taken, pressed and mixed with a polymer material. Thus, additive technologies make it possible to manufacture furniture from different materials. It remains only in a special program to develop the design of future furniture. nine0003

Thus, additive technologies make it possible to manufacture furniture from different materials. It remains only in a special program to develop the design of future furniture. nine0003

Almost every layman mistakenly believes that 3D printing is one of the benefits that the volatile 21st century has brought to our lives. However, this is a big misconception. A patent for this invention was registered in the mid-80s of the last century.

The 3D prototyping technology was copyrighted by Charles Hull. It was he who founded the company 3D Systems, which still holds a leading position in the production and sale of equipment for 3D printing. Their printers, such as the Cube Pro Trio or CubeX Duo, create great products that are accurate and durable. nine0003

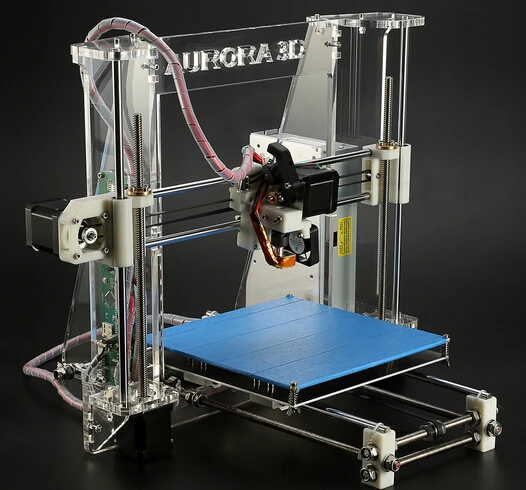

With the light hand of this man, 3D printing later began to spread and many other companies appeared that produce equipment aimed at creating a variety of objects. Some 3D printers may well settle down even at home. For example, there is a 3D Quality company based in Russia. In its assortment there are many names like Prism Mini V2, Prism Uni or Prism Pro, among which everyone can find the right one for him.

In recent years, more and more designers are taking on the creation of furniture on 3D devices. It has a number of undeniable advantages:

- It is possible to create a unique design. You can even arrange everything in such a way that not a single item produced will be similar to the previous one.

- The designer's fantasy is not constrained by any conventions, such as the complexity of manufacturing. Any figment of the imagination can be brought to life.

- Anything can be printed, from lamp shades to tables and chairs. nine0020

For all its advancement, furniture made using 3D printing is still available only to a few. And the point here is not at all the prevalence of such printers, but the cost. The furniture is really exclusive. The concern of many specialists in this field at the moment is to find ways to reduce the cost of production.

However, for those who have a printer on hand, I can give you a piece of advice: you can't furnish your apartment just yet, but a doll house for children can acquire a unique style and sparkle with a unique design. You can call it layouts. Science does not stand still, and soon you will be sitting on chairs printed by 3D printers. nine0003

Already, many online stores offer designer furniture printed on a 3D printer. Would you like to prove yourself as a furniture and interior designer? You only need to buy 3D printers for printing furniture and everything will become real. And you can easily do this in our 3DMall online store.

Furniture on a 3D printer: 3D printing

In this article we talk about making furniture using additive technologies - 3D printing - about the advantages and examples of using this approach in practice and what technique is best to use. nine0003

In preparing the article, a publication from the 3dsourced. com website was used, which was translated and supplemented for you by the Top 3D Group.

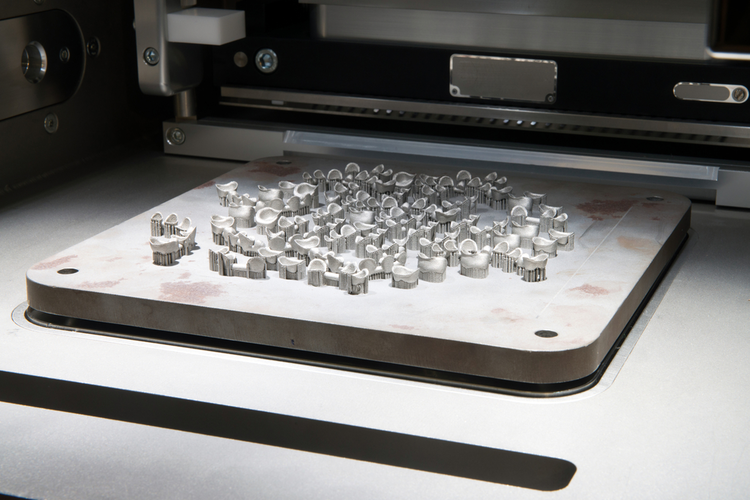

You may have once had the idea to use 3D printing in the manufacture of furniture for your home, but you dismissed it, considering this idea too laborious, time consuming or expensive. After all, large industrial 3D printers with a huge print area, like the Farsoon SS403P 3D printer, are usually needed to create large pieces of cabinet furniture, right? nine0003

That used to be true, but now there are ways to use 3D printing in the interior without the need for large-format industrial machines.

Read on - we'll take a look at some of these applications with real examples.

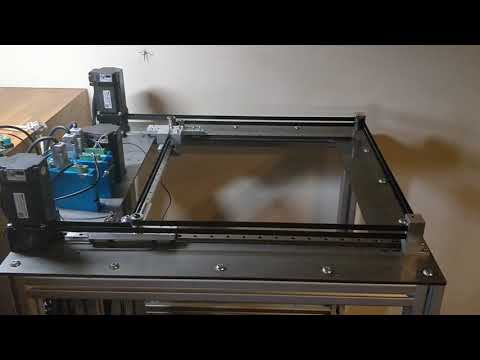

Option 1: Build furniture with the Hangprinter

Designed by Torbjørn Ludwigsen, the Hangprinter is a cable-suspended and movable print unit designed to print large objects as cheaply as possible. The Hangprinter doesn't fit in a case, its print chamber is the entire room. nine0003

nine0003

Hoping to inspire others to try frameless 3D printing, Thorbjörn has made the software files for this printer open and free for everyone to copy, use and further refine. Most parts of the Hangprinter can be 3D printed, and the cost of building one yourself is estimated to be as low as $250.

Chris Riley Stool

Introduced in mid-2017, Hangprinter printing immediately began to be tested in the creation of large objects. In the video below - one of the very first examples - Chris Riley's bar stool. nine0003

These videos showed the strengths and weaknesses of Hangprinter, such as the ability to create really large objects for relatively very little money and the possible delamination due to the lack of a closed camera.

Chris Riley's Stool printed with offset layers and delamination, and it also took two weeks to print because the Hangprinter was so loud it couldn't be used at night and only had to be printed during the day. nine0003

nine0003

Building and operating the Hangprinter requires familiarity with 3D printers, an understanding of the mechanics of how they work, skills in working with electronics and debugging devices, but there are also detailed instructions for beginners, as well as a small but growing community of other Hangprinter users who can be contacted for help.

For those who are willing to put up with the disadvantages described above, or are confident that they can avoid them, Hangprinter remains the most affordable and affordable way to create fully 3D printed furniture. nine0003

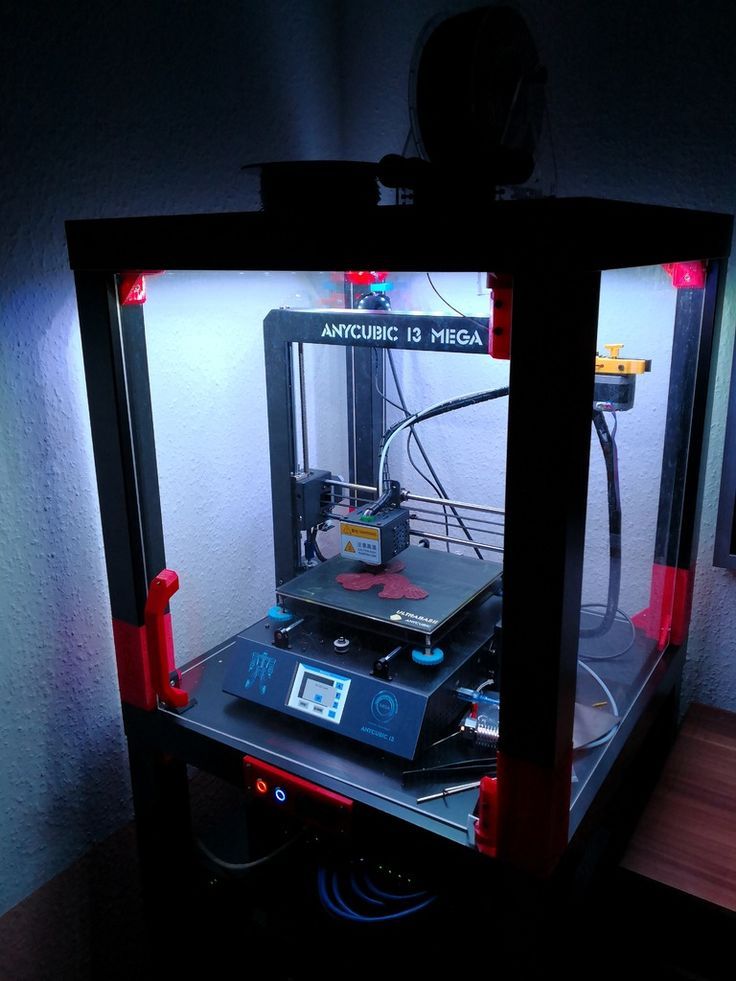

Option 2: 3D printed furniture on a large 3D printer

3D printed furniture from the “Print Your City” project. This model may not fit in your desktop printer.

The second method is to use a stationary 3D printer with a really large print chamber

Print Your City

The “Print Your City” project, for example, uses a 3D printer to print street furniture and other small architectural forms, consisting of a robot and a fenced indoor area equipped with a special printing platform. nine0003

nine0003

Last but not least, plastic for printing is made from recycled waste.

Despite the simplicity of the idea itself, this method of manufacture is beyond the reach of most people. Large 3D printers not only take up a lot of space, sometimes entire rooms, but are also incredibly expensive. Large industrial 3D printers like the Farsoon HT1001P can still cost hundreds of thousands of dollars.

Because of this, very few furniture projects are carried out by individuals, usually by businesses or very passionate enthusiasts, and the Wilkhahn Printstool stool shown below is an example of both. nine0003

Wilkhahn Printstool One

Designed by Thorsten Frank and produced by Wilkhahn, this 3D stool was produced on an industrial 3D printer and is available as part of Wilkhahn's premium office furniture range.

Wilkhahn is a German furniture manufacturer that strives to differentiate itself from its competitors.

“Unlike almost any other office furniture manufacturer, Wilkhahn stands for designs made in Germany all over the world. It offers high-quality office and dynamic conference furniture that sets the benchmark for the entire industry,” the company says. nine0003

Printstool One is one of the few 3D printed pieces of furniture available commercially. It takes several hours to create and assemble, including 3D printing the base and attaching the seat. The base is printed with lignin, an organic biopolymer that decomposes in nature.

Although the Printstool One is a commercial product, it is not easy to obtain. It is not part of the main Wilkhahn catalog and was released in a limited edition of 500 pieces.

The price for this stool has not been disclosed and probably depends on options, seat material, for example. But given that regular stock stools in this manufacturer's catalog range from $266 to $660, it's safe to assume that the Printstool One costs at least $500, making it quite an expensive plastic stool. However, overpayment for exclusive furniture is a quite common phenomenon. nine0003

However, overpayment for exclusive furniture is a quite common phenomenon. nine0003

In recent years, 3D printing has become more and more accessible. Most likely, this will also affect its large-format sector.

RH Engineering & ManoFigura - home furnishings

Magna Patero Ortus - 3D printed sink RH Engineering & Manofigura .

In mid-2020, this pair of German designers broke into the luxury furniture and interiors segment with their signature Manoveneer finishing technology and large-scale 3D printing. nine0003

Their favorite printer is the BigRep One, large enough to print furniture, with a 1005 mm³ displacement, and costs around $39,000, depending on specifications.

The production process begins with 3D printing of craft furniture based on the client's design, then the ManoVeneer branded coating is applied to the product. What Manoveneer is made of is a company secret, it is only known that the coating is waterproof, can imitate the texture of natural stone and weighs very little.

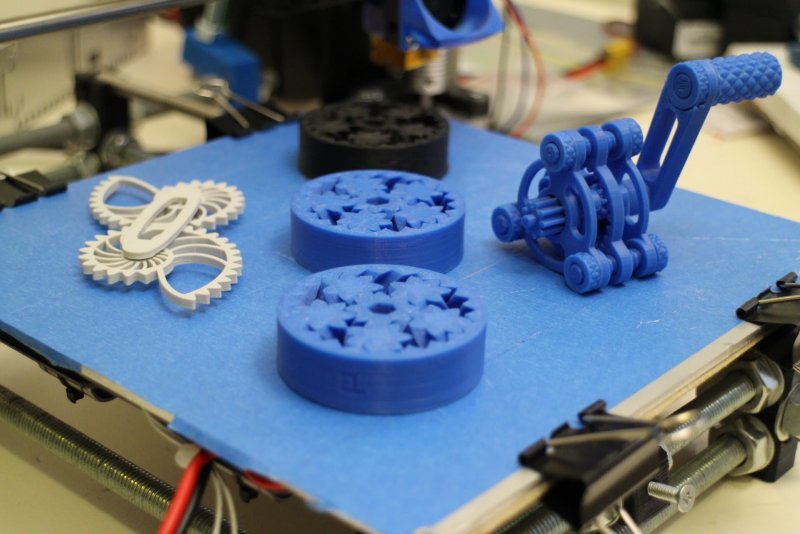

Option 3: modular printing on a small 3D printer

Large 3D printers will always be a barrier to furniture 3D printing due to their sheer size and cost, prompting designers to look for ways to stop using them, turning to smaller 3D printers and printing smaller parts for assembly.

Supermod 3D printed wall

3D printed Supermod wall.

Designed by the founders of Simplus Designs, the Supermod shelving wall consists of individually printed modules that fit together. nine0003

Supermod was created for decoration, visual division of the room into zones and storage of small things in cells. As a modular system, Supermod bypasses the need for large scale 3D printers. While the assembled wall may be taller than most people, each module can be printed on an affordable desktop 3D printer.

The next method involves using 3D printed parts in combination with conventional ones, such as a table top shield or wooden legs, giving the 3D printed components the role of fasteners and framing elements. This is the most accessible way for a wide range of makers to use 3D printing in the creation or repair of furniture. nine0003

This is the most accessible way for a wide range of makers to use 3D printing in the creation or repair of furniture. nine0003

Option 4: 3D printed parts as accessories

John Christie Saul Dining Table and Chairs

John Christie, who has been designing custom-made furniture for over 20 years, returned to university at 40.

“During my studies, I became interested in 3D printing and how I could integrate it into the traditional furniture making process. In my projects, I studied how 3D printed parts can be used in the production of furniture.”

John is best known for his Saul Dining Table and Chairs. The table is a handcrafted piece of wood with 3D printed connections.

The author suggested that his connection system would provide "greater customization, reduced production time and waste" when applied to existing pieces of furniture.

This furniture set was exhibited at the Royal Academy of Arts in Edinburgh in 2016. nine0003

This is a craft project to sell products, but similar technology has been used by amateur authors as well.

Alexandre Chappelle Furniture

Designer and YouTuber Alexandre Chappelle has documented the process of making his own wooden table with 3D printed connections. As with John Christie's project, the only 3D printed parts on this table were the articulations, while the rest of the table's parts were made from wood using conventional hand tools. nine0003

The chair is another creation of Alexandre Chappelle.

The author has posted the STL files and instructions on his personal website, where they are available for as little as $5.

This is perhaps the most affordable way to 3D print your own furniture, although the fact that John and Alexander's designs are mostly made of wood begs the question: is using 3D printed fittings 3D printed furniture?

Which technique should be used to 3D print furniture? nine0047

So which of these methods can you use for your own furniture project?

If you are a professional studio or independent designer with the necessary funds and you have a project that needs to be printed reliably and with high quality, then a large 3D printer will be the best option.