Fast sla 3d printer

7 Fastest 3D Printers 2022 In Every Price Range

One of the major gripes with 3D printing is many consider it to be slow. However, over time both the speeds of FDM and resin printers have crept up — and there are now some super-fast options for both technologies.

For industrial printing, there are printers now reaching speeds competitive with traditional manufacturing, aiming to displace injection molding.

But what are the other fastest 3D printers in the world?

We have listed the world’s fastest 3D printers in every price range below, for both FDM and resin printers – but first, let’s explain the factors that affect the speed of 3D printing.

Do Bigger 3D Printers Print Faster?

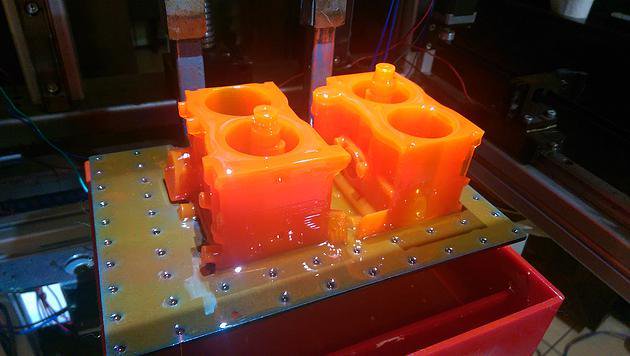

A bigger resin 3D printer does indeed print faster, but this is more in the sense of being more productive. A resin printer cures an entire layer on the XY axes, regardless of size, in one go. This means that the larger the printer, the more productive the printer is.

However, this isn’t the case for FDM printers, which need to deposit filament across the entire layer before moving on to the next.

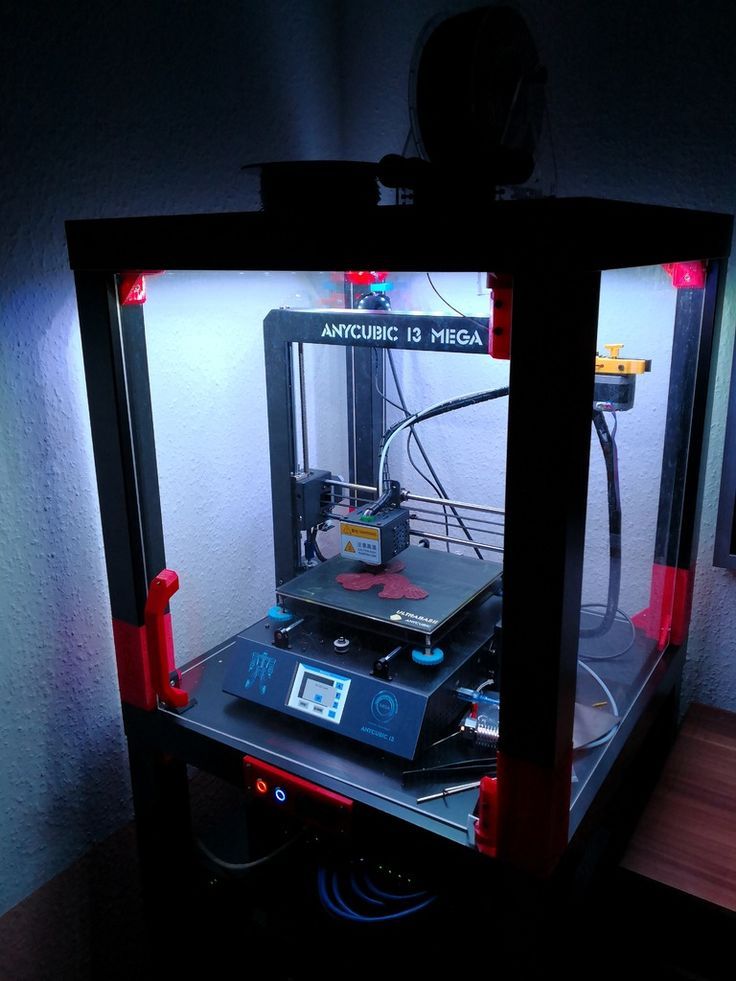

FAST FDM PICK

Flsun Super Racer200mm/s makes it one of the fastest FDM printers around

Comes 95% pre-assembled

Available at Amazon here

FAST RESIN PICK

Anycubic Photon M3 PlusSuper-fast 100mm/h speed

Larger resin build area for scalable minis prints or larger resin models

Available at Anycubic here Amazon here

SUPER-FAST PICK

Phrozen Sonic Mega 8KExtremely high-res 8K LCD screen

Enormous build area and 70mm/h speed

Available At Phrozen here Amazon here

How Fast is a 3D Printer?

As for the technologies and 3D printers we have now, simply stating the fastest possible 3D printing speeds is difficult.

That’s because – and I know it’s frustrating to read this – it depends on several factors:

Resolution of the 3D printed part: before you start printing, you need to slice your model into layers on a 3D slicer. The more layers, and the thinner each layer, the longer the part will take to print at the same speed. A part printed with 50-micron layers will have twice as many layers as the same part printed with 100-micron layers, and take twice as long at the same speed.

- We also have a guide to high resolution 3D printers.

Quality of print: theoretically you could run a budget 3D printer at an extremely high speed, and it would still print. But the results wouldn’t be anything like how it looked on your slicer. It would be a mess of filament hairs and blobs, because the speed settings were set too fast. Some 3D printers can handle high-speed 3D printing, some cannot.

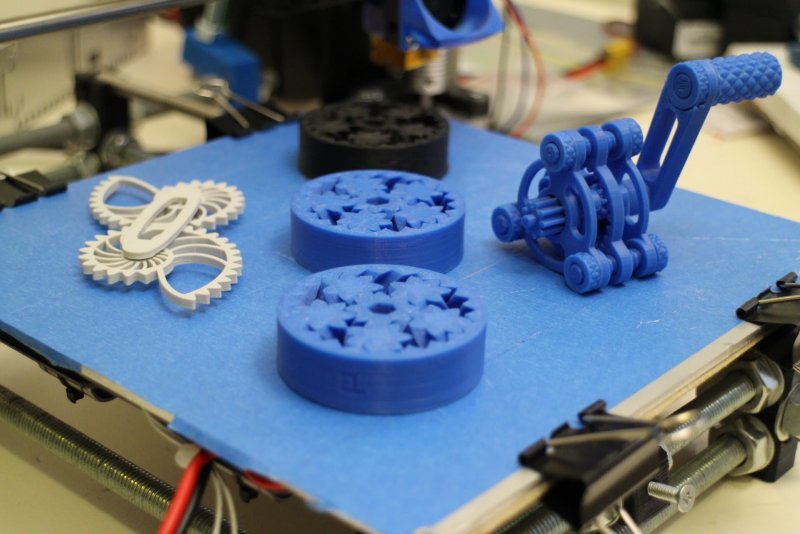

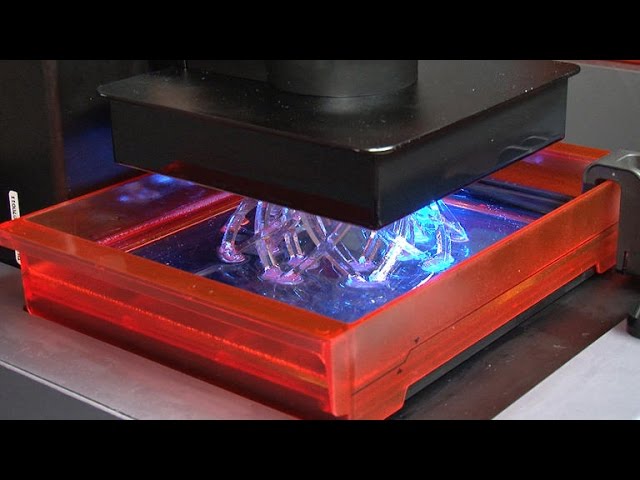

3D printing technology: how fast a 3D printer prints depends on the technology. Resin 3D printers are significantly faster than FDM 3D printers as they can cure entire layers at once, rather than depositing filament over each part of the layer. The fastest 3D printing technologies include Multi Jet Fusion and resin 3D printing technologies like MSLA.Resin 3D printing technologies are known for being faster than FDM.

Resin 3D printers are significantly faster than FDM 3D printers as they can cure entire layers at once, rather than depositing filament over each part of the layer. The fastest 3D printing technologies include Multi Jet Fusion and resin 3D printing technologies like MSLA.Resin 3D printing technologies are known for being faster than FDM.

Material: some materials are easier to print than others, putting less demand on the printer and leading to a slightly faster print.

Complexity of the model: You will be able to print a cube block far quicker than an intricate 3D printed jewelry piece. This is because you can print larger layers and at a faster print speed without a notable loss of quality, since the cube is a very simple shape with no details.

Size of print: fairly obvious, but a larger print will take far longer than a small one. A full-size vase will take around 12 hours to print in normal detail on most FDM 3D printers, but a small statue may take under an hour.

Nozzle size: for FDM 3D printing, smaller nozzles mean more intricate details can be printed more accurately, but larger nozzles can potentially print faster.

Will 3D printers get faster?

Almost certainly. We’ve already seen a number of major innovations that make 3D printers faster in the last decade. In 2012, the first delta 3D printers started to appear, which print significantly faster than previous Cartesian 3D printers.

Then, new resin 3D printer innovations such as Carbon 3D’s CLIP, and Uniz’s UDP technologies made SLA and DLP faster. Other significant speed innovations include HP’s Multi Jet Fusion technology, and also the huge advances being made in many metal 3D printers such as those by Desktop Metal and Markforged.

The Fastest 3D printers 2022 in Every Price Range

| Name and brand | Build volume (mm) | Max speed | Price | Where to buy |

|---|---|---|---|---|

| Flsun Super Racer | 260 x 260 x 330 | 200mm/s | $499 | Amazon here |

| Anycubic Photon M3 Plus | 197 x 122 x 245 | 100mm/h | $699 | Anycubic here |

| Anycubic Photon M3 Max | 298 x 164 x 300 | 60mm/h | $1099 | Anycubic here |

| Phrozen Sonic Mega 8K | 330 x 185 x 400 | 70mm/h | $2199 | Phrozen here |

| Uniz Slash UDP | 293 x 122 x 200 | 600mm/h | $1,999 | Matterhackers here |

| WASP 2040 Pro Turbo | 200 x 200 x 400 | 500mm/s | $3,400 | Amazon here |

| HP Jet Fusion 5200 | 380 x 284 x 380 | 4115cm3/h | Quote |

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

When you buy through links on our site, we may earn an affiliate commission. Learn more

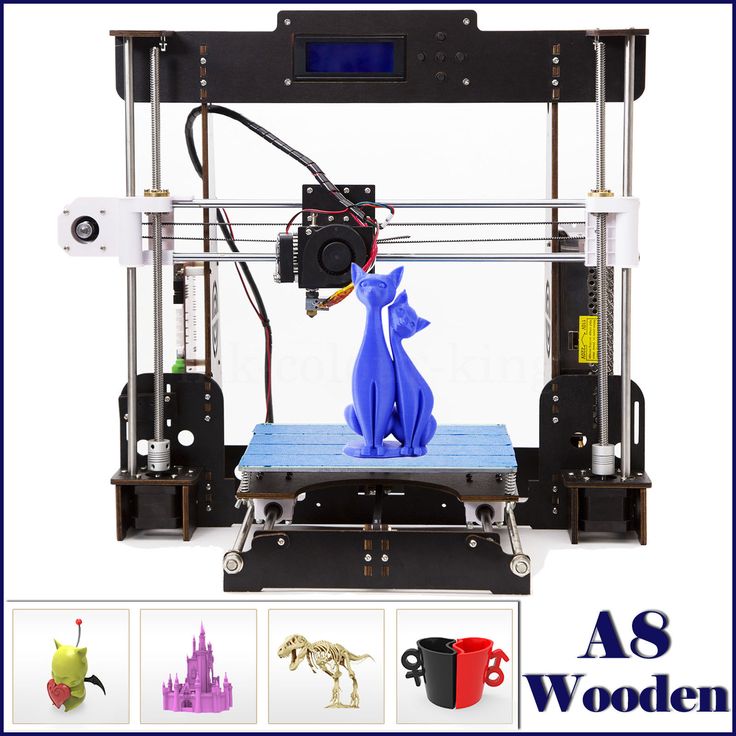

Flsun Super Racer – Fastest FDM 3D Printer Under $500

- Price — Check latest price at Amazon here

- Technology: FDM Delta

- Max Print Speed: 200 mm/h

- Build Volume: 260 x 260 x 330 mm

True to its speedy name, the Flsun Super Racer is a Delta FDM printer that absolutely gallops with a top print speed of 200 mm/h. It’s an upgraded version of Flsun’s QQ-S, which after some one-on-one time we found to be a competent, worthwhile printer for large projects.

Delta printers are known for offering higher speeds than their Cartesian brothers, but Flsun is pushing the boat out to new extremes with the Super Racer. Most standard FDM printers perform best at a comfortable 50-60 mm/h, while the Super Racer delivers solid quality prints at four times that.

With a decently-sized 260 x 260 x 330 mm build volume, the Super Racer is also big on vertical print capacity, ideal for those towering prints that exceed the dimensions of budget FDM printers. Throw in a thoughtful design, quality components, automatic bed leveling, breezy 20-minute assembly, a responsive, easy-to-navigate detachable touch screen, and the Super Racer comes awfully close to a speed freak’s dream 3D printer.

Throw in a thoughtful design, quality components, automatic bed leveling, breezy 20-minute assembly, a responsive, easy-to-navigate detachable touch screen, and the Super Racer comes awfully close to a speed freak’s dream 3D printer.

Now, all this speed does come with a trade-off. Delta printers, the Flsun Super Racer included, lack the accuracy and consistent print quality offered by Cartesian 3D printers. The difference is relatively negligible, but it’s a point to consider before buying for makers that favor quality over speed.

On the filament front, the Flsun Super Racer’s Bowden extruder setup works great for PLA but coughs up the usual Bowden-related jamming and clogging issues with flexibles. For example, if you’re working with TPU, you’re better off sticking to a classic Cartesian printer – ideally with a direct drive extruder.

Anycubic Photon M3 Plus/Max – Fastest Resin 3D Printers Under $1,000

- Price: $699 / $1,099 — M3 Plus Available here / M3 Max Available here

- Technology: MSLA Resin

- Max Print Speed: 100 mm/h / 60 mm/h

- Build Volume: 197 x 122 x 245 mm / 298 x 164 x 300 mm

More than simply an update to the long-running Photon series, the Anycubic Photon M3 machines are turning more than a few heads as the fastest resin 3D printer range around.

In particular, the Anycubic Photon M3 Plus proposes a top print speed of 100 mm/h. The beauty of resin printers is that they cure in layers, regardless of how much space on the build plate that layer takes. Those 100 mm/h apply whether you’re printing a single small miniature or a batch of twelve, which makes the Anycubic Photon M3 Plus exponentially more productive.

The Anycubic Photon M3 Max is no slouch either, offering a respectable 60 mm/h, but does this across a massive 298 x 164 x 300 mm. That’s the largest of any Anycubic resin printer and among the highest capacities found on consumer-grade printers, rubbing shoulders with the hulking Elegoo Jupiter and Phrozen Sonic Mega 8K.

Elsewhere, the Photon M3 duo stands out for offering excellent detail with 34 microns XY resolution on the Plus and 46 microns on the Max. The Max has a 7K LCD, one of the highest pixel counts on the market, while the Plus pushes a 6K LCD – higher than the standard 4K found on comparable printers. Both machines also ship with Anycubic excellent textured checkerboard build plate, which offers superb print adhesion.

Both machines also ship with Anycubic excellent textured checkerboard build plate, which offers superb print adhesion.

Read the full comparison: Anycubic Photon M3 vs M3 Plus vs M3 Max

Phrozen Sonic Mega 8K – Fastest High-Quality Resin 3D Printer

- Price: $2,199 — Available at Phrozen official here

- Technology: MSLA Resin

- Max Print Speed: 70 mm/h

- Build Volume: 330 x 185 x 400 mm

With the Phrozen Sonic Mega 8K, size and speed combine into arguably one of the most impressive mid-range professional resin printers on the market.

The 330 x 185 x 400 mm build volume is the largest available in this price range, and the Sonic Mega 8K darts across this printing expanse at a nippy 70 mm/h. No other printers manage to weave in such a large build volume with such high speeds; it’s always been one or the other.

The Phrozen Sonic Mega 8K allows makers to hone in on all the fine features and intricacies of even the most detailed models and minis thanks to a 43-micron resolution, propped up by a pixel-rich 15’’ 8K LCD. It’s a level of quality that simply isn’t currently available on any other printer in the same printer segment.

It’s a level of quality that simply isn’t currently available on any other printer in the same printer segment.

The build plate comes pre-calibrated, allowing you to print without delay once the Mega 8K lands on your doorstep. A clever dual linear rail design ensures the printer behaves and delivers those sharp details even high up into the upper reaches of the build area.

If you need a mammoth-format printer at a reasonable price to power a small business where time is of the essence, there’s little else out there that comes close to the Phrozen Sonic Mega 8K. If the build volume exceeds what you’ll conceivably ever need, a lower-cost resin printer such as the Anycubic Photon M3 Plus or even the standard M3 is likely a better use of your money. The Phrozen Sonic Mega 8K is a jumbo printer and will be far too much for most amateur makers.

Uniz Slash Plus UDP — Fastest desktop 3D printer

- Max print volume: 293 x 122 x 200 mm

- Price: $1,999 — Available on Matterhackers here

- Fastest 3D printer speed: 600mm/hour in UDP mode

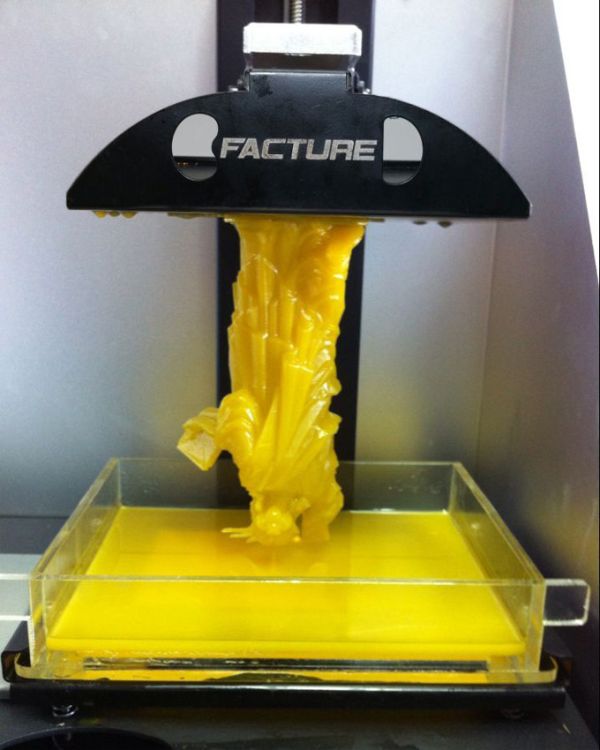

Uniz have made a big impact since their original Kickstarter campaign that raised over $500,000 to produce super-fast resin 3D printers at consumer prices. This quick 3D printer uses Uniz’s Uni-Directional Peel (UDP) technology to print far faster than its competitors, at up to 600mm/hour when in UDP mode.

This quick 3D printer uses Uniz’s Uni-Directional Peel (UDP) technology to print far faster than its competitors, at up to 600mm/hour when in UDP mode.

When not in UDP mode the maximum 3D printer speed is 200mm/hour, but this is still super fast. This is because not all parts are compatible, for example, any parts with cross sections, or fully enclosed parts cannot be printed in UDP mode; and no parts with solid infill can be printed either. You are also restricted as very tall prints cannot be printed in UDP mode, but if your part qualifies then you can print extremely quickly!

Not only is it an extremely fast 3D printer, but it’s also accurate. This SLA 3D printer has an XY resolution of 75 microns, and a minimum layer of thickness of just 10 microns. As a result, parts have very good surface finish and look almost like they have no layers at all. The printer can also calibrate itself, can be operated via your phone or table on the mobile app, and weighs just 12kg. It’s certainly one of the best speedy 3D printers for the price.

WASP 2040 PRO Turbo — Fastest 3D printer in the world

- Price: $3,400 — Available on Amazon here

- Max print volume: 200 x 200 x 400 mm

- Fastest 3D printer speed: 500mm/s recommend (some say it can print even faster!)

Delta 3D printers are known for their speed, and are the fastest FDM 3D printers in the world. The WASP 2040 PRO Turbo is a delta printer that is not only incredibly fast – at up to a recommend 500mm/s – but is also extremely accurate for an FDM printer. The resolution of up to 50 microns means very accurate and low cost prototypes and parts can be produced, and in record time. WASP claim they make the fastest 3D printers in the world for FDM.

WASP 3D printers are known for their reliability, with the Italian company ensuring the printers operate with workhorse-like consistency. It can print 3D printer filaments including ABS, PLA, PETG and Nylon, so if you want to print stronger parts from one of the tougher plastics you still can, and you can use third party filaments if you prefer – the WASP allows for these. and you can choose to buy the WASP 2040 as either a single or dual extruder 3D printer.

and you can choose to buy the WASP 2040 as either a single or dual extruder 3D printer.

Unlike most RepRap 3D printer deltas, the WASP 2040 Turbo comes fully assembled, so those who aren’t masters of DIY do not need to worry. You can also choose to order it either as a single or dual extruder 3D printer based on your printing needs.

It’s the world’s fastest 3D printer for FDM, and also accurate and reliable – what more could you want for under $5,000!

- It also has a variation designed specifically as a clay 3D printer.

HP 3D Jet Fusion 5200 — Fastest Industrial 3D printer

- Price: Requires a quote

- Max print volume: 380 x 284 x 380 mm

- Fastest 3D printer speed: 4115cm3/hour

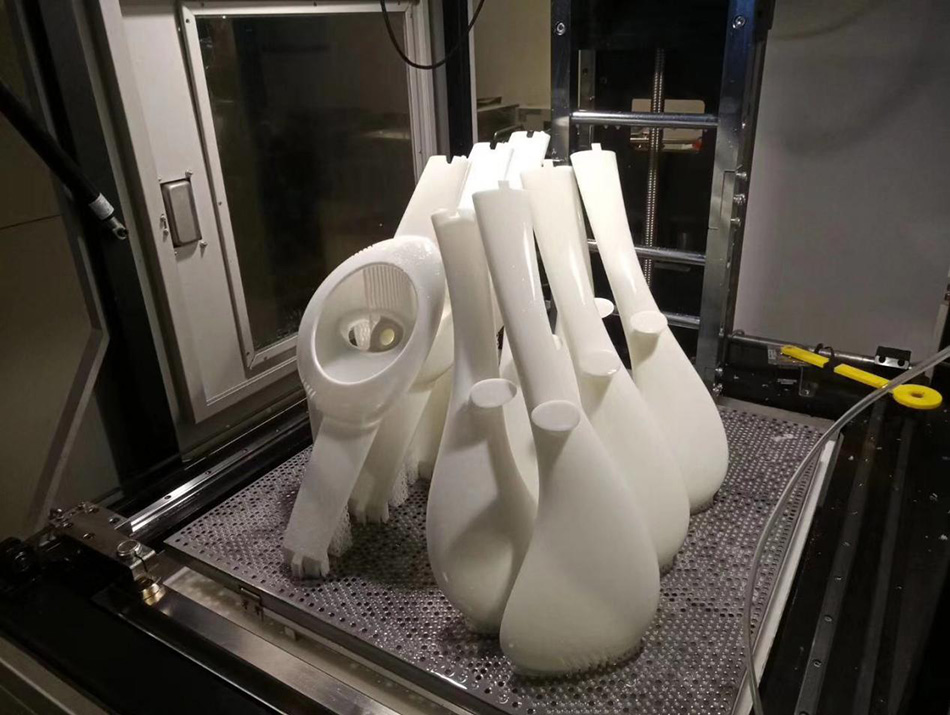

HP have only been actively involved in the 3D printing industry for the last few years, but have brought such technological advantages in that short space of time. The Jet Fusion 5200 epitomizes this, marking uncharted territory for 3D printing where it is now considered viable for mid-range production.

Multi Jet Fusion has always been known for its fast 3D printing speed, but the Jet Fusion is even faster than its predecessors. With speeds up to 4115cm3/hour, it’s faster than the Jet Fusion 4200 (4000cm3) and the 3200 (2800cm3) – and these were already some of the fastest 3D printers in the world. The high-quality 1200dpi print head resolution allows for extremely accurate parts with smooth surface finishes and crisp, sharp edges.

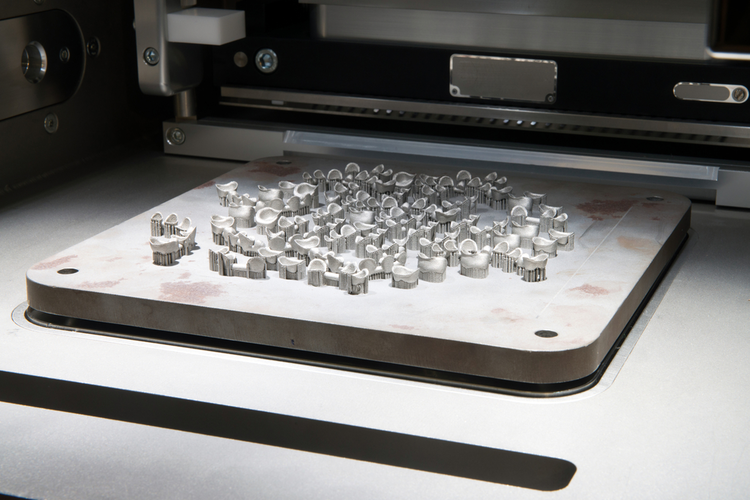

The Jet Fusion 5200 combines this astonishing speed with low part cost and scalability. Whole layers can be printed at once, rather than tracing each layer as with Selective Laser Sintering, meaning multiple parts can be printed at once without a drop off in productivity. Multi Jet Fusion isn’t known for its versatility of materials, but PA12, PA11 Nylons and TPU are strong materials with good properties for a variety of industries. It’s extremely fast, extraordinarily accurate, and a rare example of 3D printers being competitive in mid-volume part production – very exciting.

Do you really need a fast 3D printer?

Speed is always useful; nobody chooses to wait in a queue longer than they need to. However, with the quickest 3D printers, there are some cases where you can’t take advantage of this speed.

For FDM 3D printers, some materials become volatile and print with imperfections if you don’t slow right down, like PEEK, PC, and others. Printing at 150mm/s+ would just ruin your prints, so the speed is useless here.

Also, if you are printing a very simple object like a cube, speed becomes less useful as you can just use very large layer heights and print quickly anyway.

However, if your business depends on quick production, then absolutely go for a printer that can either print objects very quickly, or multiple objects simultaneously. The ability to rapidly prototype new designs and innovate quicker is invaluable, and other industries like 3D printed jewelry production or hearing aids need to be able to print custom designs at the highest speeds possible.

So, it depends. For hobbyists, speed is great for quality of life and printing all the cool things and useful 3D prints you can. For industry it can be more necessary, and businesses often opt for an industrial 3D printer than can meet their production speed requirements.

How Fast Can PLA Be 3D Printed?

The fastest FDM printers, such as the Flsun Super Racer, can print PLA up to 200 mm/h. However, the most common 3D printers, such as the Ender 3, can print PLA at around 50 to 80 mm/h without sacrificing print quality.

Related articles:

- Best large resin 3D printers (bigger = faster!)

- Best delta FDM 3D printers

- Best FDM 3D printers

Original Prusa SL1S SPEED | Original Prusa 3D printers directly from Josef Prusa

See the Original Prusa SL1S Speed in action!

FFF vs SLA Basic Comparison

Original Prusa i3 MK3S+ (FFF printer)

Prints 3D objects by extruding melted plastic, compatible with materials such as PLA, PETG, ABS, flexible filaments and many more

Layer height 0. 05 mm - 0.15 mm

05 mm - 0.15 mm

Maximum print area size 25 x 21 x 21 cm (9.84 x 8.3 x 8.3 in)

Great for: prototyping, printing toys, RC models or mechanical parts

Post-processing: possible, depends on the type of used materials. Possible sanding, gluing, painting

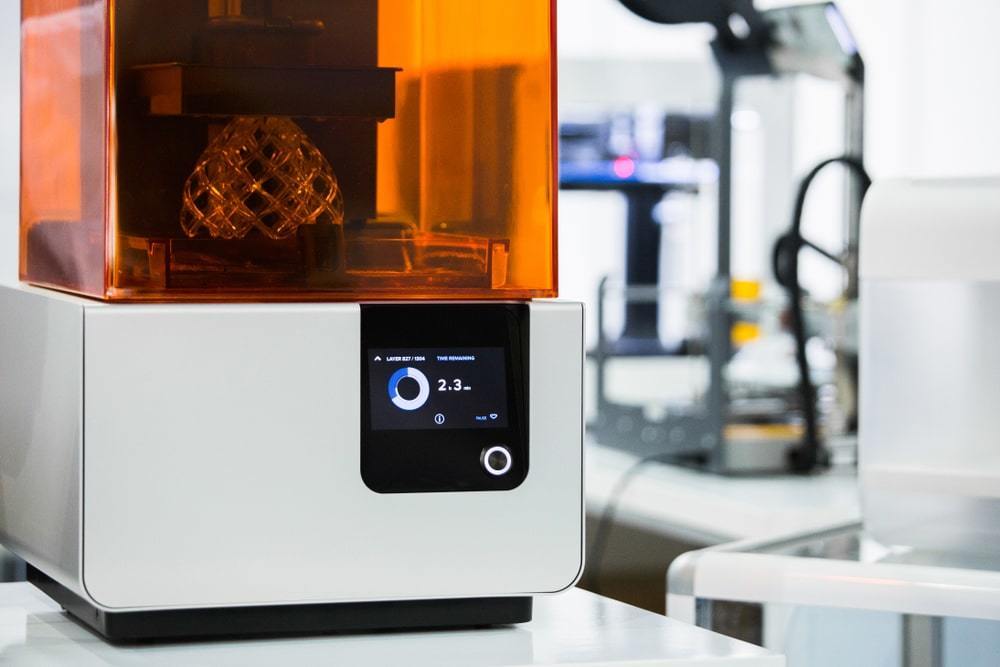

Original Prusa SL1S (SLA printer)

Uses UV light pattern to cure layers of resin. Photo polymers are cured layer by layer to create the final object

Min layer height: 0.01 mm, recommended layer height: 0.025 - 0.1 mm

Maximum print area size: 127 × 80 × 150 mm (5 × 3.14 × 5.9 in)

Great for: prototyping, jewelry, art models, medical use (e.g. dental molds for casting)

Post-processing: easy, models can be glued, sanded and painted

Main Features

Great Print Quality

The SL1S features a new 5.96'' monochrome LCD with a physical resolution of 2560×1620p. Taking advantage of the completely reworked optics and the new monochrome display technology, the SL1S offers a vastly improved print quality compared to its predecessor.

Our Fastest Printer Ever

Configure your 3D printer with ease and see previews of sliced models before you start printing! Thanks to the 2.8’’, 240×320 LCD screen with 65.000 colors, every option is just a few clicks away.

Touch Controls and Network Features

Upload your print files over network and perform over-the-air firmware updates. The SL1S comes packed with modern technologies that make 3D printing easier, safer and more convenient than ever before. On-screen wizard will guide you through the whole setup process. You will be ready to print in no time!

25% Bigger Print Area

The SL1S features a 25% bigger print area compared to the SL1. The largest object that fits in the 127×80×150mm print area can finish under 4 hours (0.05mm layer height) or in 2 hours with 0.1mm layer height. This is also possible thanks to the nearly three times faster tilt compared to the SL1.

For Newcomers and Professionals

The SL1S is more than just a machine for producing figures and statues. With professional-level print quality, extensive documentation, low running costs and 24/7 tech support, the SL1S is perfect for newcomers and professionals alike. Its predecessor, the SL1, already found its way to hospitals and industrial companies.

With professional-level print quality, extensive documentation, low running costs and 24/7 tech support, the SL1S is perfect for newcomers and professionals alike. Its predecessor, the SL1, already found its way to hospitals and industrial companies.

High-Quality Materials and Rigid Body

We have built the Original Prusa SL1S 3D printer around a rigid, heavy aluminum body, which minimizes vibrations and ensures the best possible printing performance even when printing thin and highly detailed geometry. The SL1S features a quick-release mechanism, which maintains the Z-axis calibration.

Smart Resin Tank

The new tank from high-quality graphite-reinforced PA6 composite comes with a practical opaque lid that protects the resin from being cured by daylight. Automatic Resin Sensor prevents resin from overflowing or running out mid-print.

Slice with PrusaSlicer

The SL1S is fully supported in the latest releases of PrusaSlicer, our internally developed and regularly updated slicing software. Take advantage of hollowing, automatic support generation, easy object manipulation and many other tools. PrusaSlicer also contains factory-tested profiles for dozens of resins.

Take advantage of hollowing, automatic support generation, easy object manipulation and many other tools. PrusaSlicer also contains factory-tested profiles for dozens of resins.

Original Prusa Curing and Washing Machine CW1S

CW1S is a post-processing device for resin-based 3D prints. The CW1S is a 4-in-1 device, which makes the otherwise long and messy process a breeze. What it can do?

Washing

The finished print has to be washed to remove the uncured resin from its surface. CW1S uses a stainless steel tank for isopropyl alcohol and a magnetic propeller. This method is less aggressive compared to ultrasonic cleaning and works very well even with very small objects.

Drying

Drying a washed model is yet another feature of the multipurpose CW1S. Before the washed model is cured with UV-light, it has to be dried in order to avoid resin residue stains.

Curing

Curing the model with UV-light is an essential part of the resin printing process. Printed objects are usually soft, so treating them with UV light gives them optimal surface properties.

Printed objects are usually soft, so treating them with UV light gives them optimal surface properties.

Resin Pre-heat

CW1S can preheat the resin before printing it, thus getting it to the ideal printing temperature and state for the best performance of the SL1S and the resin itself.

Order CW1S in bundle with SL1S Order stand-alone CW1S

Case Studies

Medicine (Surgery)

Neu3D Laboratories, based in Lefkosa, TRNC, operates under the Experimental Medical Research Centre of Near East University. The institute uses 3D printing to advance surgery methods. The SL1 is used to print test models for flexible bronchoscopy simulation.

Medicine (Dental)

Asana Dental uses a special suction system designed by Dr. Vit Payma and Lukas Pekarek. The system is printed on the SL1 and helps dentists to reduce risks during the Covid-19 pandemic by eliminating potentially hazardous aerosol.

Professional Models

Professional-grade miniatures by David Damek are wonderful recreations of their real-life counterparts. Intricate details and high print quality are an absolute must. "Printing with the SL1 made my work much easier and opened doors to unlimited creativity," Damek says.

Intricate details and high print quality are an absolute must. "Printing with the SL1 made my work much easier and opened doors to unlimited creativity," Damek says.

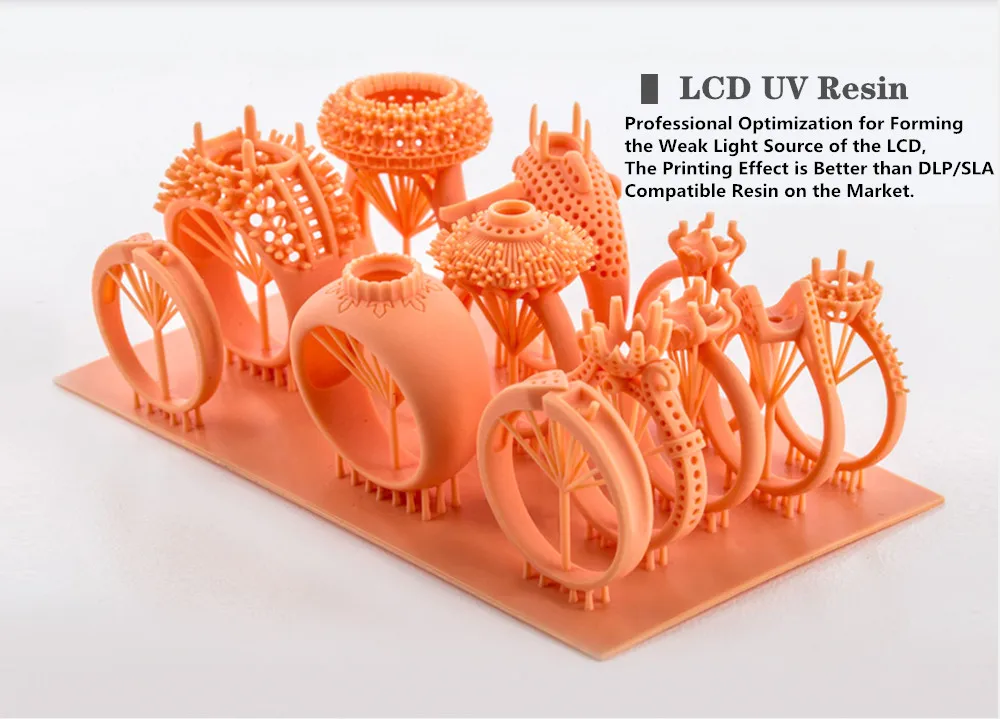

Jewelry

SLA printers are precise enough to print even the smallest details. This makes them useful for the process of designing and manufacturing casting jewelry models. SL1S is a perfect match for jewelry professionals all around the world.

Sample Prints

Reviews

Awards

Our printers continue to collect great reviews and awards all around the world. Original Prusa i3 MK3/S is the best 3D Printer in the Ultimate Guide to Digital Fabrication by MAKE: Magazine and our printers also received several editor's choices and awards from respected media outlets like All3DP, PC Mag, Tom's Hardware, TechRadar, Forbes, WireCutter, Windows Central and many more!

Get the Original Prusa SL1S Speed now!

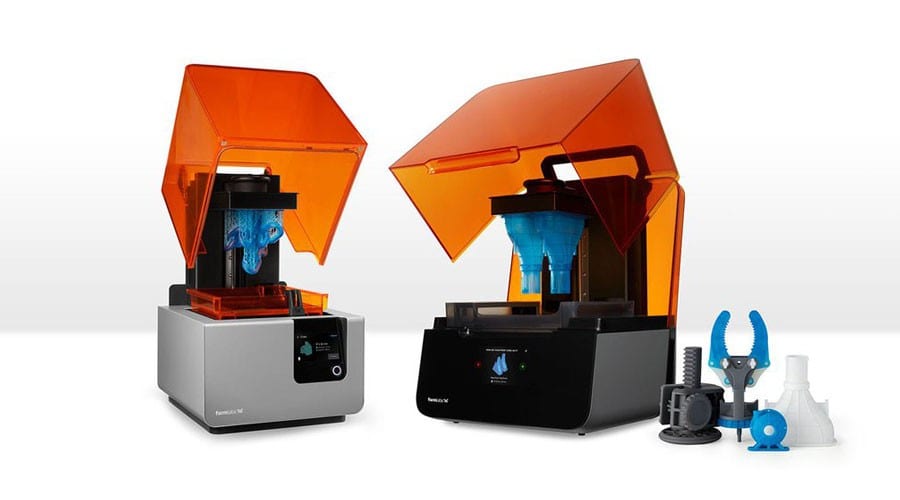

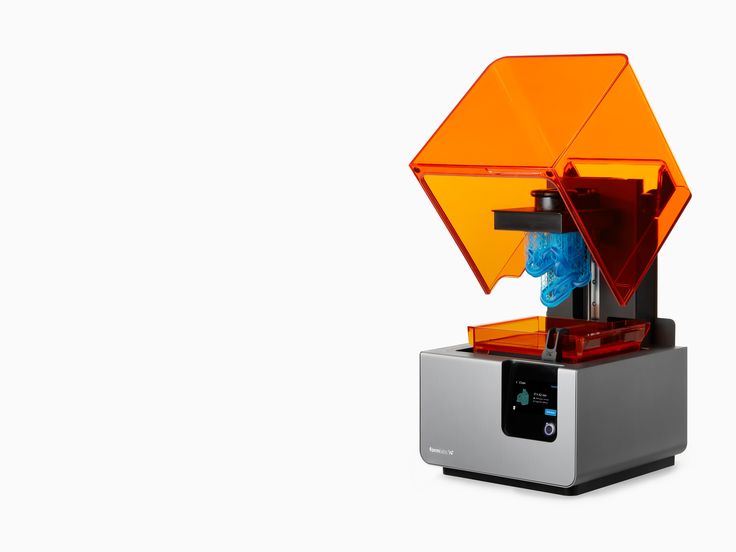

The Complete Guide to Stereolithographic (SLA) 3D Printing

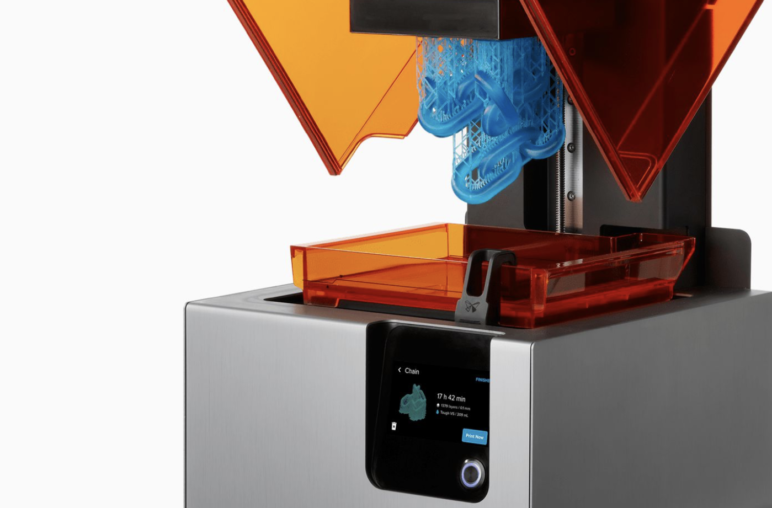

Stereolithographic (SLA) 3D printing is gaining immense popularity due to its ability to produce highly accurate, isotropic and waterproof prototypes and models with fine details and smooth surfaces from various modern materials.

This comprehensive guide explains how SLA printing technologies work, why thousands of professionals use them today, and how this 3D printing technology can be useful in your work. nine0003

White Paper

Download our white paper to find out how SLA printing works, why thousands of people use it today, and how this 3D printing technology can help your work.

Download white paper

The development of 3D printing technology continues to influence how companies approach prototyping and manufacturing. This technology is becoming more accessible, and equipment and materials are developing in accordance with the possibilities and requirements of the market. That's why today designers, engineers and others are integrating 3D printing into workflows at all stages of development. nine0003

3D printing is helping professionals across industries reduce recruitment costs, accelerate iteration, streamline manufacturing processes, and even discover entirely new business models.

Stereolithographic 3D printing technology has evolved significantly. In the past, resin 3D printers were monolithic and costly, requiring skilled technicians and costly service contracts to operate. Today's small desktop printers are highly flexible and produce industrial-quality products at a much lower cost. nine0003

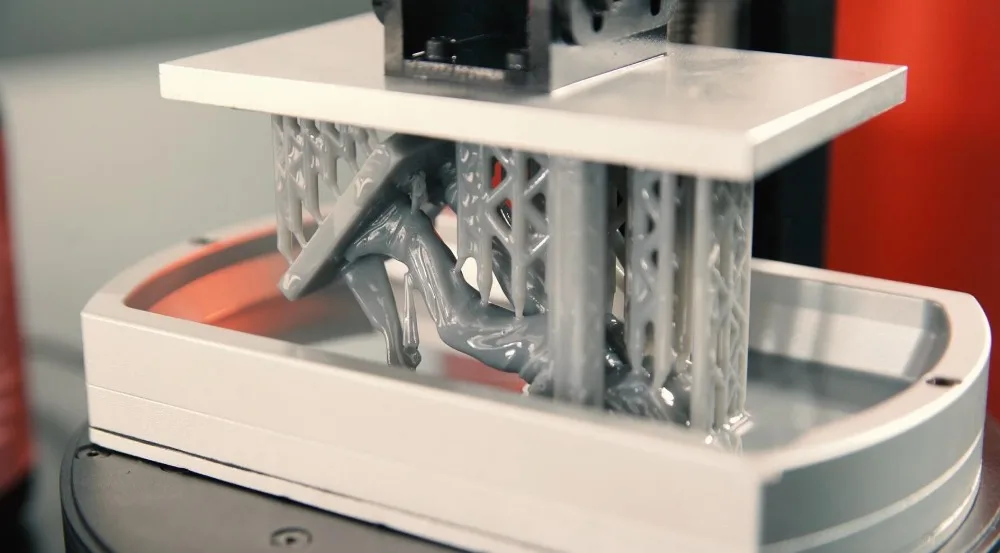

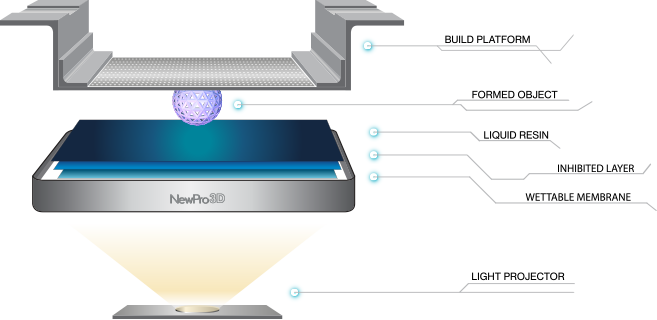

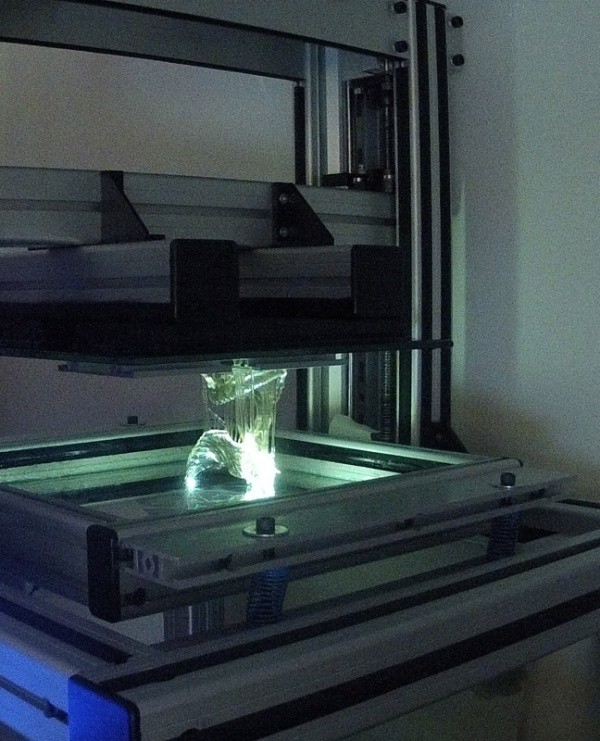

Stereolithography is a type of additive manufacturing. It is also known as photopolymerization in the bath or 3D printing using polymer resin. Devices that use this technology have a common principle of operation: under the influence of a light source (laser or projector), a liquid polymer turns into a solid plastic. The main differences are in the location of the main components such as the light source, work platform and resin tank.

See how stereolithography 3D printing is done.

Stereolithographic 3D printers use light-sensitive curable materials called "polymers". When stereolithographic polymers are exposed to specific wavelengths of light, short molecular chains join together causing the monomers and oligomers to polymerize into either rigid or flexible patterns.

Graphical representation of the main mechanisms of stereolithographic 3D printing. nine0003

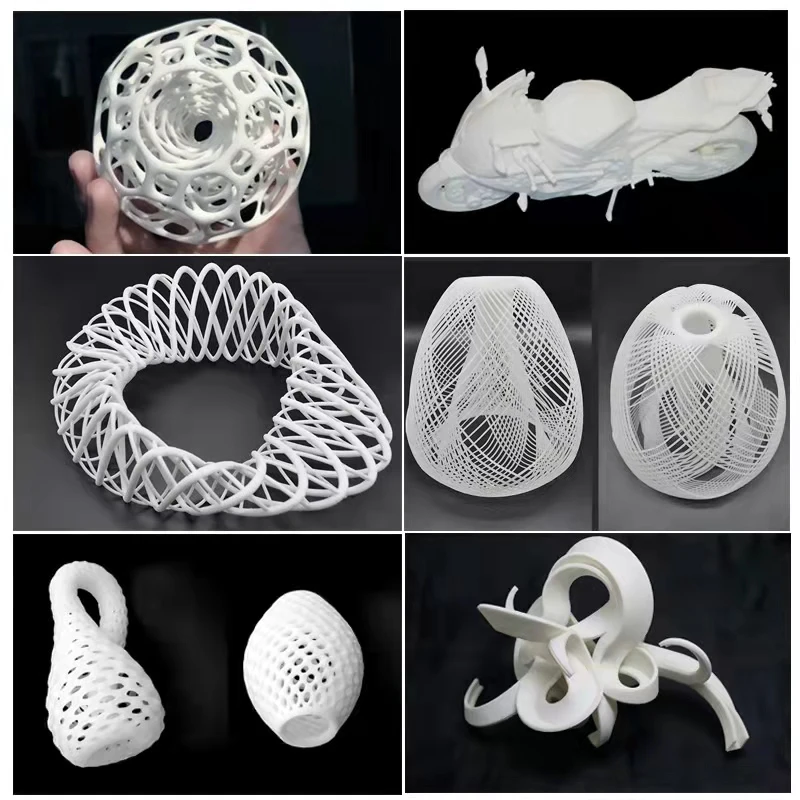

Models printed on SLA printers have the highest resolution and accuracy, the finest detail, and the smoothest surface of any 3D printing technology, but the main advantage of this method is its versatility.

Materials manufacturers have developed innovative formulas for stereolithographic polymers with a wide range of optical, mechanical and thermal properties similar to standard, engineering and industrial thermoplastic resins. nine0003

Comparison of 3D stereolithography with two other common plastic modeling technologies: Fused Deposition Modeling (FDM) and Selective Laser Sintering (SLS).

Sample

Experience the quality of 3D stereolithography for yourself. We will send a free sample of the printed model directly to your office.

Request a Free Print Sample

Learn how to go from design to 3D printing with a Form 3 3D printer. Watch this 5-minute video to learn the fundamentals of using a Form 3 printer, from software and materials to processes printing and post-processing. nine0022

Watch this 5-minute video to learn the fundamentals of using a Form 3 printer, from software and materials to processes printing and post-processing. nine0022

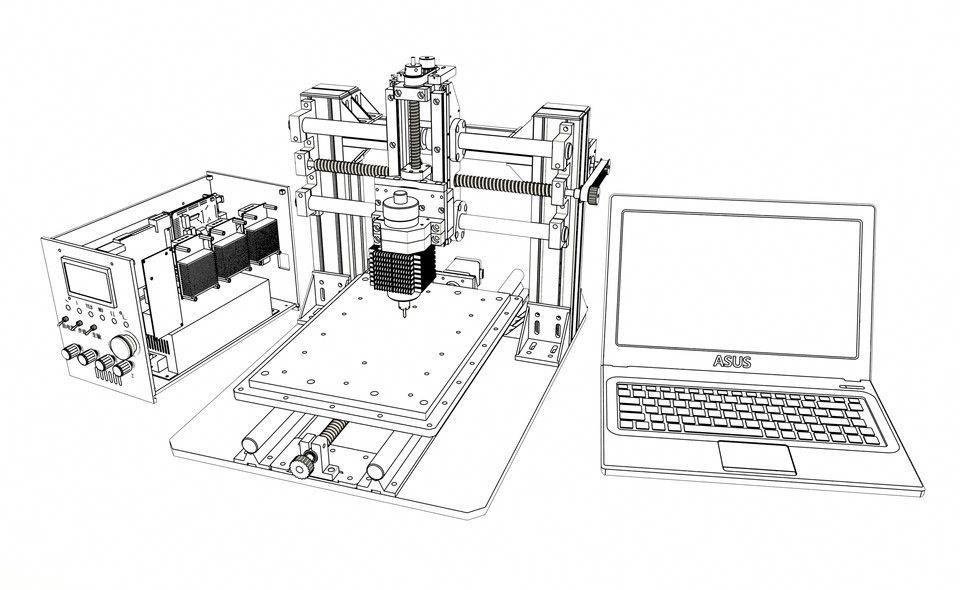

Use any CAD software or 3D scan data to design the model and export it to a 3D print file format (STL or OBJ). All printers based on SLA technology work with software that allows you to set print parameters and separate the digital model into layers. After the settings are complete, the model preparation software sends instructions to the printer via a wireless or cable connection.

More advanced users can design directly for SLA technology or, for example, print models with voids to save materials.

After a quick check of the settings, the printing process starts. The printer may run unattended until printing is complete. In printers with a cartridge system, material is replenished automatically.

Formlabs' online Dashboard allows you to remotely manage printers, resins, and employee access. nine0022

nine0022

After printing is complete, models should be rinsed with isopropyl alcohol to remove resin residue from their surface. After the washed models have dried, some materials require final polymerization, a process that ensures the best possible strength and stability of the parts. Finally, remove the support structures from the models and sand down the remaining traces of the supports for a clean finish. Models produced with SLA technology can be machined, primed, painted or assembled depending on the intended use. nine0003

Final polymerization is particularly important for functional polymer resins used in engineering, dentistry and jewellery.

Engineers, designers, fabricators and others choose 3D stereolithography because it provides excellent detail, smooth surfaces, superior model fidelity, isotropy, and water resistance. In addition, it allows you to work with various materials. nine0003

Because 3D printing builds models layer by layer, the strength of finished parts can vary depending on the orientation of the part relative to the printing process: the X, Y, and Z axes will have different properties.

Extrusion-based 3D printing processes such as deposition filament modeling (FDM) are anisotropic due to a special approach to creating different layers during the manufacturing process. This anisotropy limits the application of FDM technology or requires additional changes in the design of the model to compensate for it. nine0003

Check out our detailed guide comparing FDM vs. SLA 3D printers to see how they differ in terms of print quality, materials, application, workflow, speed, cost, and more.

Stereolithographic 3D printers, on the other hand, allow the production of highly isotropic models. Achieving detail isotropy relies on a number of factors that can be tightly controlled by integrating the chemical composition of materials with the printing process. During printing, the components of the polymers form covalent bonds, but when creating subsequent layers, the model remains in an "immature" state of partial reaction. nine0003

When immature, the resin retains polymerizable groups that can form bonds between layers, giving the model isotropic and waterproof properties after final curing. At the molecular level, there are no differences between the X, Y, and Z planes. This results in models with predictable mechanical characteristics critical for applications such as jigs and fixtures and finished parts, as well as functional prototyping. nine0003

At the molecular level, there are no differences between the X, Y, and Z planes. This results in models with predictable mechanical characteristics critical for applications such as jigs and fixtures and finished parts, as well as functional prototyping. nine0003

SLA printed parts are highly isotropic compared to FDM parts.

Due to its isotropic nature, stereolithographic printed models, such as this jig for Pankl Racing Systems, can withstand directional loads during the manufacturing process.

SLA printed objects are continuous, whether they are solid or have internal channels. Watertightness is important when it is necessary to control and predict the impact of air or liquid flows. Engineers and designers are using the water resistance of stereolithography printers for air and fluid flow applications in the automotive industry, biomedical research, and to test the design of parts in consumer products such as kitchen appliances. nine0003

OXO relies on the water resistance of stereolithographic printed models to create durable working prototypes of air and liquid products such as coffee makers.

Stereolithographic 3D printing is used to produce precise, reproducible components in a variety of industries, including dentistry and manufacturing. In order to produce accurate models during the printing process, many factors must be strictly controlled. nine0003

The quality of stereolithographic 3D printing is between standard and precision machined. SLA has the highest tolerance compared to other commercial 3D printing technologies. Learn more about tolerances, accuracy and precision in 3D printing.

The heated resin tank combined with the closed working environment provide virtually the same conditions for every model. The higher accuracy also depends on the lower printing temperature compared to thermoplastic-based technologies in which the raw material is melted. Because stereolithography uses light instead of heat, it prints at close to room temperature and models are not subject to thermal expansion and contraction. nine0022

Dental example (comparison of a scanned component with the original CAD model) demonstrating the ability to maintain tight tolerances for the entire stereolithographic model.

LFS stereolithography 3D printing involves an optic in a Light Processing Unit (LPU) that moves along the x-axis. parabolic mirrors so that it is always perpendicular to the plane of the platform, so it always moves in a straight line, ensuring maximum precision and accuracy. This allows consistency to be achieved as the size of the equipment increases, for example, when working with a large-sized Formlabs Form 3L stereolithography printer. The LPU also uses a spatial filter, which forms a clear laser spot. nine0003

The characteristics of the individual materials also play an important role in ensuring the reliability and reproducibility of print results.

Formlabs Rigid Resin has a high green modulus, or modulus of elasticity, before final polymerization, allowing you to print very thin models with high precision and reliability.

Stereolithography printers are considered the best 3D printers due to the smooth surface of the produced models, the appearance of which is comparable to parts produced by traditional methods such as machining, injection molding and extrusion. nine0022

nine0022

This surface quality is ideal when a perfect finish is needed and also helps reduce post-processing time because these models are easy to sand, polish and paint. For example, large companies like Gillette use stereolithography 3D printing to create finished products such as razor handles in their Razor Maker platform.

Large companies like Gillette use stereolithography 3D printing to create finished products such as razor handles in their Razor Maker platform. nine0022

The Z layer height is often used to determine the resolution of a 3D printer. On Formlabs stereolithographic 3D printers, it can be adjusted from 25 microns to 300 microns to trade off speed and print quality.

FDM and SLS printers typically print Z-axis layers between 100 and 300 microns wide. At the same time, a part printed with 100 micron layers on an FDM or SLS printer is very different from a part printed with 100 micron layers on an SLA printer. Models printed on a stereolithographic printer have a smoother surface immediately after printing, because their outer walls are straight, and each new printed layer interacts with the previous one, smoothing out the effect of the stairs. When printed on an FDM printer, layers are often visible in models, and the surface of models printed on an SLS printer has a grainy structure due to sintered powder. nine0022

Models printed on a stereolithographic printer have a smoother surface immediately after printing, because their outer walls are straight, and each new printed layer interacts with the previous one, smoothing out the effect of the stairs. When printed on an FDM printer, layers are often visible in models, and the surface of models printed on an SLS printer has a grainy structure due to sintered powder. nine0022

In addition, the stereolithography printer can print fine details: the Form 3 laser spot size is 85 microns, while industrial SLS printers have a laser spot size of 350 microns, and FDM-based devices use nozzles with a diameter of 250– 800 microns.

Models printed on FDM printers often show layer lines and may have inaccuracies around complex features. Models printed on stereolithography printers have sharp edges, a smooth surface, and almost imperceptible layer lines. nine0003

The advantage of SLA polymers lies in a wide range of formulations offering a variety of characteristics: they can be soft or hard, contain additives such as glass and ceramics, or have special mechanical properties such as high bending temperature under load or impact resistance. Materials can be designed for a particular industry, such as dentures, or have properties close to those of final materials to create prototypes that can be tested and run under stress. nine0003

Materials can be designed for a particular industry, such as dentures, or have properties close to those of final materials to create prototypes that can be tested and run under stress. nine0003

Ceramic Resin can be 3D printed with a stone-like texture and then fired to create a ceramic product.

In some cases, it is this combination of versatility and functionality that is leading businesses to use polymer-based 3D printing in-house. After solving existing problems through the use of a certain functional polymer, other applications are usually quickly discovered. In this case, the printer becomes a tool for discovering the various properties of different polymers. nine0022

For example, hundreds of engineers in the Design and Prototyping group at the Advanced Manufacturing Equipment Research Center (AMRC) at the University of Sheffield have access to 12 stereolithographic 3D printers and various construction materials that they use in numerous research projects for these partner companies like Boeing, Rolls-Royce, BAE Systems and Airbus. They printed High Temp Resin washers, brackets, and a mounting system for a sensor that must operate in high temperature conditions, and used Durable Resin to create complex spring components for a material handling robot as part of a composite manufacturing automation system. nine0022

They printed High Temp Resin washers, brackets, and a mounting system for a sensor that must operate in high temperature conditions, and used Durable Resin to create complex spring components for a material handling robot as part of a composite manufacturing automation system. nine0022

AMRC engineers have access to 12 stereolithographic 3D printers and various construction materials, allowing them to create custom-designed parts for a variety of research projects, such as brackets for a stacking robot (above) and mounts for an environmental sensor. high temperature (below).

Material selection

Need help choosing a material for 3D printing? Our new interactive materials wizard will help you make the right material decision based on what you're going to use it for and the properties you care most about in our growing range of polymers. nine0003

Get material recommendations

Stereolithographic 3D printing makes it easier for businesses across industries to innovate. Such industries include engineering, manufacturing, dentistry, healthcare, education, entertainment, jewelry, and audiology.

Such industries include engineering, manufacturing, dentistry, healthcare, education, entertainment, jewelry, and audiology.

Rapid prototyping with 3D printing enables engineers and developers to turn ideas into working proofs of concept, transform concepts into high-quality prototypes that look and work like end products, and take products through testing phases to launch into mass production. nine0003

Find out more

By creating the necessary prototypes and 3D printing special tools, molds and production aids, manufacturing companies can automate production and optimize workflows at a much lower cost and in much faster time than traditional manufacturing. Thus, production costs are reduced and defects are prevented, quality is improved, assembly is accelerated and labor productivity is increased. nine0003

Find out more

Digital Dentistry reduces the risks and uncertainties associated with human error, enabling consistent quality and precision at every step of the workflow, and improving patient care. 3D printers can produce a range of high quality custom products at low cost, providing exceptional fit and reproducible results.

3D printers can produce a range of high quality custom products at low cost, providing exceptional fit and reproducible results.

Learn more

3D printers are multifunctional tools for creating immersive learning and research environments. They stimulate creativity and introduce students to professional-level technology, enabling the implementation of the STEAM method in the fields of science, technology, art and design. nine0003

Find out more

Affordable, professional-grade desktop 3D printers help clinicians produce medical devices that meet individual needs and improve patient outcomes. At the same time, the organization significantly reduces time and money costs: from laboratories to operating rooms.

Learn more

High resolution printed physical models are widely used in digital sculpting, 3D character modeling and prop making. 3D-printed models have been featured in animated films, video game characters, theatrical costumes, and even special effects for blockbuster films. nine0003

nine0003

Learn more

Professional jewelers use the power of CAD and 3D printing to rapidly prototype, customize jewelry to customer specifications and produce large batches of blanks for casting. Digital tools allow you to create dense, highly detailed models without the tedious, error-prone production of stencils.

Learn more

Hearing professionals and labs use digital workflows and 3D printing to simplify the production of high-quality custom and hearing aids, as well as to mass-produce behind-the-ear hearing aids, hearing protectors, custom earmoulds, and headphones . nine0003

Find out more

Many companies are starting to use 3D printing technology through service bureaus and laboratories. Outsourcing can be a great solution when the need for 3D printing is infrequent or you need to do one-off jobs using materials that have unique properties or produce special models. Service bureaus can also provide advice on various materials and offer additional services such as design or improved finishes. nine0003

nine0003

The main disadvantages of outsourcing are the high cost and duration of production. Often, outsourcing becomes a step on the way to in-house production as needs grow. One of the main advantages of 3D printing is its speed compared to traditional production methods. But it is noticeably reduced when the delivery of the model produced by the involved organization takes several days or even weeks. As demand and production capacity increase, the costs of outsourcing are rising rapidly. nine0003

With the increasing availability of industrial quality 3D printing today, more companies are opting to bring 3D printing into their factory right away, vertically integrating it into existing workshops or labs, or providing printers to engineers, designers and other professionals who benefit from digital transformation. projects into physical models or are engaged in the production of products in small batches.

Compact desktop stereolithography 3D printers are an excellent solution for rapid model production. Depending on the number of parts needed and the volume of prints, the investment in a compact 3D printer can pay for itself in just a few months. In addition, compact appliances allow you to purchase just the amount of equipment you need to run your business and scale your production by adding more units as demand grows. Using multiple 3D printers also allows you to print models from different materials at the same time. And when the need arises for the production of large parts or the use of non-standard materials, service bureaus can come to the rescue. nine0003

Depending on the number of parts needed and the volume of prints, the investment in a compact 3D printer can pay for itself in just a few months. In addition, compact appliances allow you to purchase just the amount of equipment you need to run your business and scale your production by adding more units as demand grows. Using multiple 3D printers also allows you to print models from different materials at the same time. And when the need arises for the production of large parts or the use of non-standard materials, service bureaus can come to the rescue. nine0003

INTERACTIVE

Try our interactive ROI tool to see how much time and money you can save by printing with Formlabs 3D printers.

Calculate your savings

High production speed is an important reason to buy a desktop 3D printer. When working with a print bureau, there are delays related to the speed of production, communication and delivery. A desktop 3D printer like the Form 3 delivers models in hours, allowing designers and engineers to print multiple parts a day. This contributes to faster iterations and significant time savings in product development, as well as rapid testing of mechanisms and assemblies, avoiding costly tool changes. nine0003

This contributes to faster iterations and significant time savings in product development, as well as rapid testing of mechanisms and assemblies, avoiding costly tool changes. nine0003

Purchasing a desktop 3D printer saves a lot of money by eliminating bureau services and traditional processing methods, as their cost rises sharply with increasing demand and production volumes.

For example, the production engineer and others at Pankl Racing Systems used stereolithographic 3D printing technology to produce products on a tight schedule. This allowed them to independently manufacture custom-designed jigs and other small-sized components for the production line. While stereolithography was initially viewed with skepticism, this technology proved to be an ideal solution to replace the machining of a number of tools. In one of the cases, it made it possible to reduce the manufacturing time of conductors by

By 3D printing custom-designed jigs, Pankl Racing Systems has significantly reduced both order preparation time and production costs.

Compact units allow you to purchase just the amount of equipment you need to run your business and scale your production by adding new units as demand grows. Using multiple 3D printers also allows you to print models from different materials at the same time. nine0003

The University of Sheffield's Manufacturing Advanced Research Center (AMRC) has an additive manufacturing station with 12 Form 2 stereolithography (SLA) 3D printers that hundreds of engineers working on various projects have access to.

Formlabs offers two high-precision stereolithographic 3D printing systems, an ever-growing range of specialty materials, intuitive print preparation and process management software, and professional services, all in one solution. nine0003

To learn more about 3D stereolithography, experience it for yourself: request a free printed sample in your choice of material, delivered right to your door.

Request a Print Sample

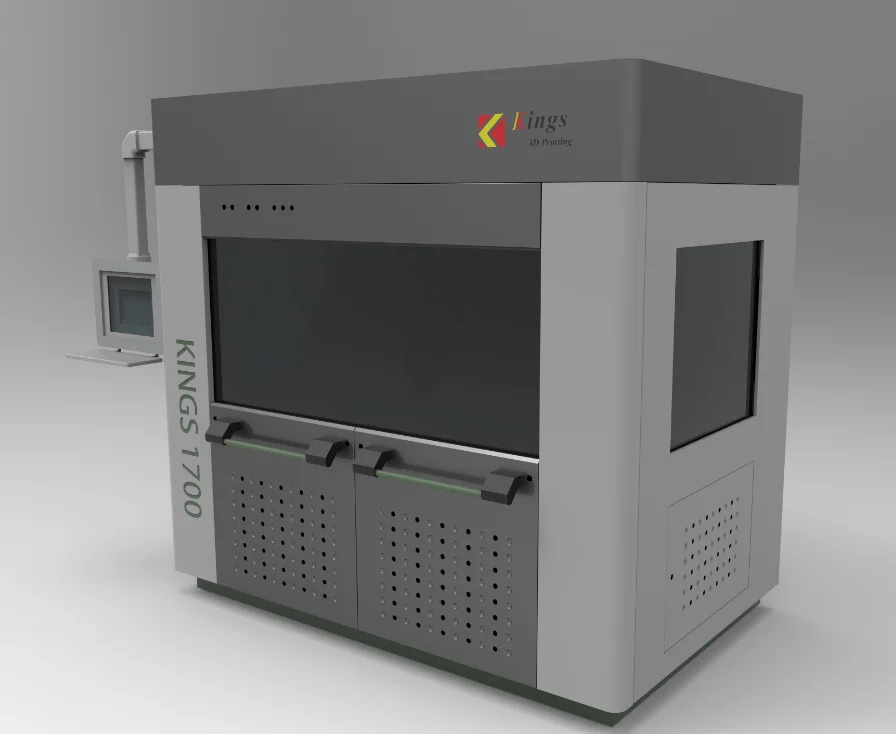

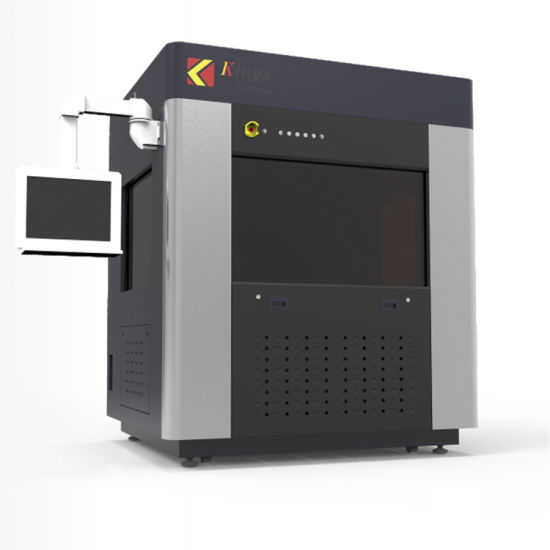

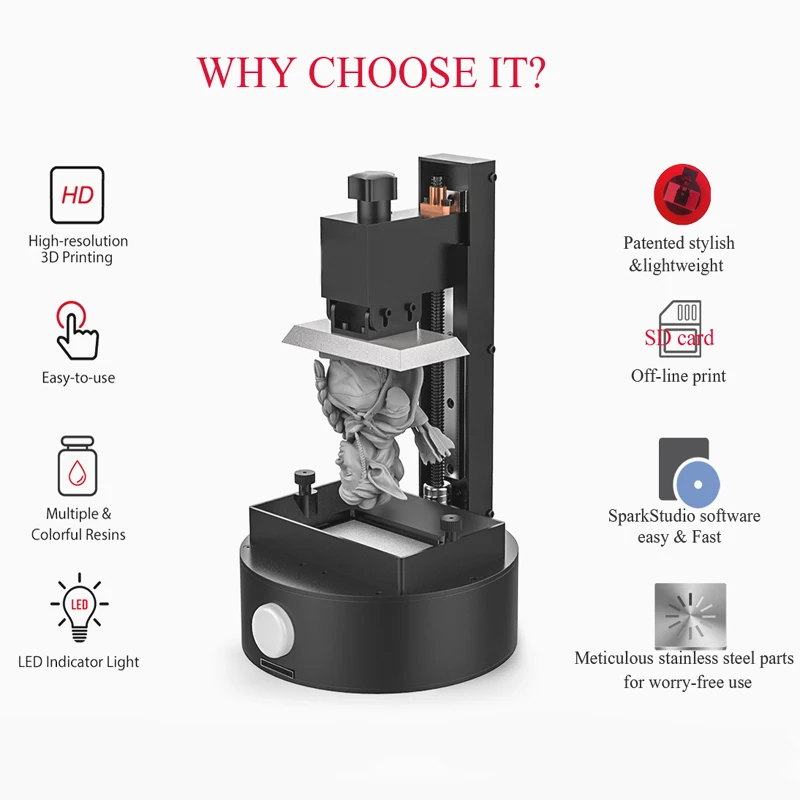

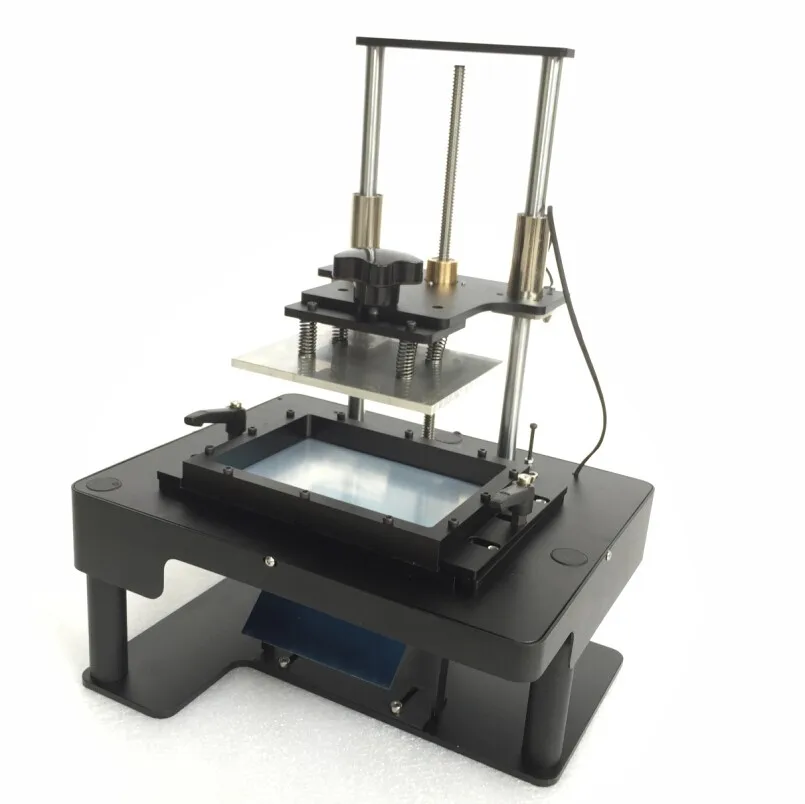

Fastest SLA 3D Printer - SLASH 3D Printer

Description

Fastest 3D Printer

The SLASH 3D printer is a novelty that has shaken up the 3D printing market. What is special about this device? Quite simply, this is the fastest SLA 3D printer available today. Let's list its features:

What is special about this device? Quite simply, this is the fastest SLA 3D printer available today. Let's list its features:

High print speed . Just imagine, this desktop 3D printer allows you to create products at a speed of up to 200 mm/hour;

High Precision Printing . The fastest 3D printer SLASH did not let us down with the accuracy of 3D printing. The minimum available layer thickness is 10 microns, which not all professional devices can boast of;

Large plot area . This 3D printer also features a large build area for equipment in its class - as many as 192x120x200 mm. This is not just enough, it is more than enough even for non-standard tasks;

Powerful software . Specialized software turns the fastest 3D printer into one of the most functional 3D printers due to numerous flexible 3D printing settings;

Large selection of materials available. Manufacturers have developed a range of specialized photopolymers to work with the fastest 3D printers. With them, each user will be able to realize any ideas. nine0003

Manufacturers have developed a range of specialized photopolymers to work with the fastest 3D printers. With them, each user will be able to realize any ideas. nine0003

3D printer SLASH

SLASH 3D printers are a revolutionary development of UNIZ in the field of volumetric printing, which uses stereolithography technology to build objects from photopolymer resin. As a polymerization factor, the printer uses light from the LED array and the LCD module that forms the layer mask. Incredible print speed in the printers of this series became possible due to the implementation by the company's engineers of a unique cooling system for the print area. The construction zone is cooled using a special liquid module - a heat exchanger. To fully exploit the unique capabilities of SLASH and SLAH+ printers, UNIZ has developed a series of unified photopolymer formulations. The SLASH model, thanks to its patented technological innovations, has reduced the cost of printing equipment to the level of 3D printers using FDM technology, and even surpassed them in terms of the speed of building objects. nine0003

nine0003

Features:

- The relatively low price of this series of printers is comparable to FDM printing equipment.

- The use of a unique combination of LED array and LCD module provides a faster build speed than FDM printers and the quality inherent in stereolithography.

- Unique resin cartridge system for economical resin usage and easy storage.

- Steel-reinforced frame to ensure that the build area is dimensionally stable and that the device does not deform, which could affect print quality. nine0325

SLASH 3D printer

Specifications

| 3D printing technology | LCD Stereolithography |

| Construction area | 192 x 120 x 200 mm |

| XY Resolution | 75 micron, WQXGA [2560 × 1600] |

| Precision | 50 micron |

| Layer thickness (Z-axis) | 10, 25, 50, 75, 100, 150, 200, 300 micron (adjustable) |

| 3D printing speed | Up to 200 mm/h Up to 1000 cm 3 /h |

| Resin level control | Automatic |

| Assembly | Fully enclosed body, adjustable build platform |

| Optical system | Blue LED array (5000 Lux blue LED array) Liquid cooling |

| 3D printer bath cover | Original polymer coating, up to 100 times stronger than PDMS |

| Operating temperature | 18-28°C |

| Interface | USB, WiFi, Ethernet |

| System requirements | nine0237 Windows 7 sp1 or higher (64-bit only), Mac OS X 10.