Metal filament for 3d printer

Metallic 3D Printing Filament | MatterHackers

- Home

- Store

- 3D Printer Filament

- Metallic 3D Printing Filament

Which metallic filament is right for me?

Real Metal Filament - real stainless steel filament printed on your desktop 3D printer. This metal 3D printing filament can be debinded and sintered, leaving your 3D printed part solid 316L or 17-4 PH stainless steel metal. If you are looking for an affordable way to create one-off, custom metal parts, small-batch manufactured parts, or just want to finally print with real metal on your desktop printer, this is your best option.

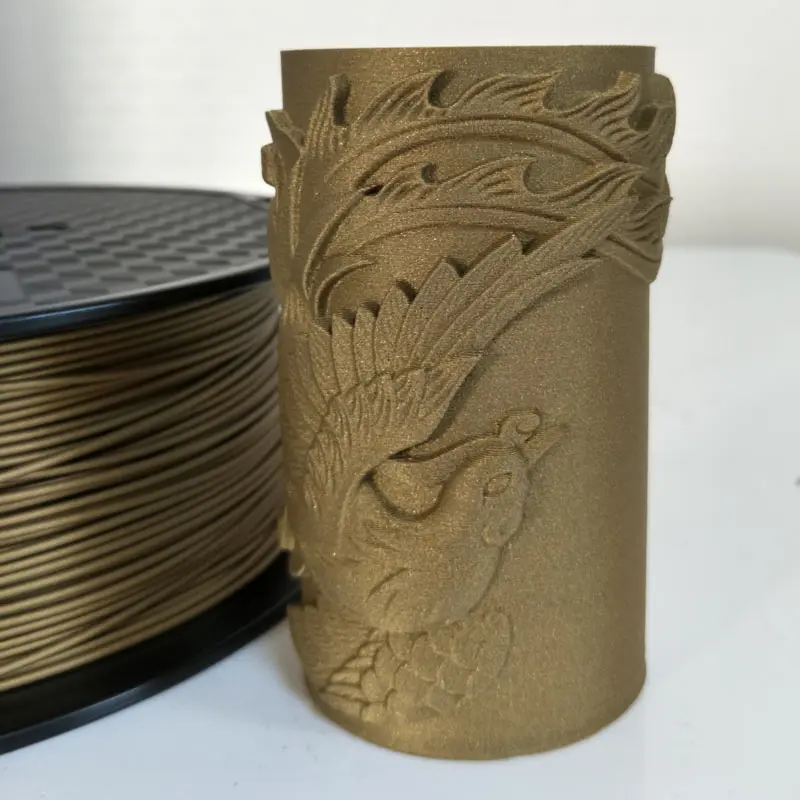

Metal Composite Filament - plastic filament infused with metal powders. These materials are still mostly PLA plastic and will have typical PLA filament characteristics. The metal powder (bronze, copper, or magnetic iron) provides aesthetic characteristics as opposed to their real metal properties. For example, printed parts in metal composite filament can rust/patina and even be sanded and polished to shine. So, if you are just searching for a metallic look, using a metal composite material is your best option.

Metallic 3D Printing Filament Collections

All Metallic 3D Printing Filament 3D Printer Filament

Metallic 3D Printing Filament

Metal 3D Printing Filament

Print with real metal on your desktop 3D printer.

The Virtual Foundry

If you can print plastic, you can print pure metal parts.

Metal Composite Filament

Plastic materials like PLA that are infused with metal powders

Guides & Articles

How to Succeed with 3D Printing Metal on a Desktop 3D Printer

The time is here to explore easy and affordable metal 3D printing. 3D printing with real metal on a desktop 3D printer is now possible using Ultrafuse Metal 3D printing filament from BASF Forward AM.

BASF Forward AM: A Look at One of Additive Manufacturing's Top Chemical Producers

BASF Forward AM is the production branch of BASF that creates a wide range of additive manufacturing materials for businesses and personal 3D printing.

3D Printer Filament Comparison Guide

There are many different kinds of 3D printer filament, and each one has it's own strengths for different projects. Knowing these differences is key to a successful 3D printing experience and so we have created a Filament Comparison Guide with everything you need to know about every type of filament available.

Stainless Steel Metal 3D Printing on Benchtop 3D Printers

A MatterHackers presentation on advanced materials and their rising presence in 3D printing and BASF Ultrafuse 316L, a composite filament that yields pure metal components

Casting Metal Parts From 3D Prints

Follow Sylatech as they transform legacy casting processes with 3D printing.

How to Succeed When 3D Printing With Metal PLA

Learn the best tips and tricks for 3D printing with metal-infused PLA 3D printing filament.

How To: Post Process Metal Filled Filaments

While 3D printing in true metal is still cost prohibitive to most people, 3D printing composite materials to achieve the look and feel of metal is easy, and all it takes is time.

Tech Breakdown: A Detailed Account of ColorFabb SteelFill Filament

An in-depth review of SteelFill 3D filament, the next great metallic PLA from ColorFabb that delights users with its metal characteristics and relatively easy printing.

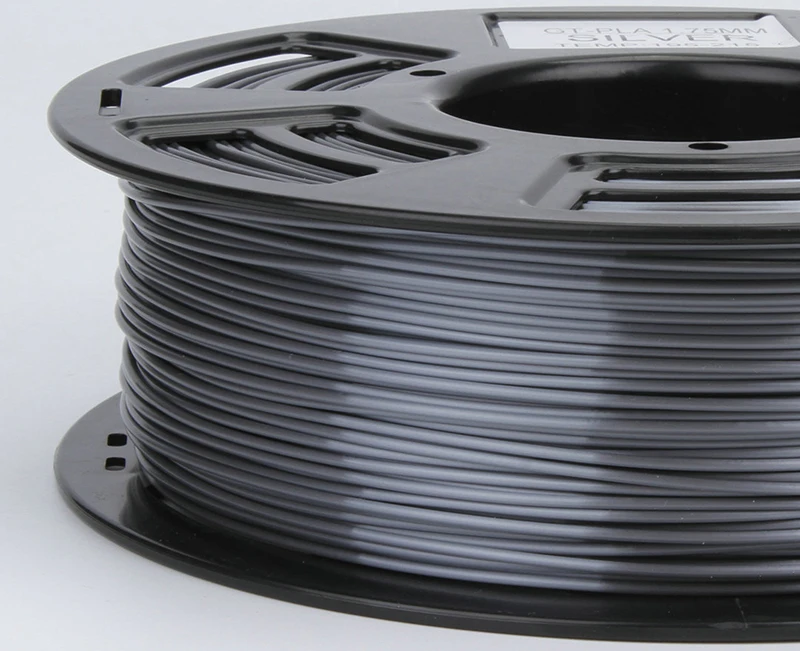

Ultimate Materials Guide - 3D Printing with Metal Filament

Overview

Metal filled filaments contain very fine metal powder such as Copper, Bronze, Brass, and Stainless Steel. The percentage of metal powder infused in each filament can vary depending on the manufacturer. The presence of this metal powder makes the filament much heavier than standard plastics. This means that the parts printed with metal-filled PLA will weigh significantly more than ones from the standard PLA, despite using the same settings and consuming the same amount of material. Metal filled filaments also tend to be very abrasive as they are extruded through the hotend. A standard brass nozzle will be too soft and will quickly wear down. Be sure to upgrade to a wear resistant nozzle in order to print this filament effectively. There are other metal-like filaments in the market that may just have metallic coloring added to the filament. These filaments do not contain any actual metal powder, so they do not share many of the same benefits of the true metallic filaments. This article will focus on materials that contain actual metal powders for a realistic metallic weight and feel.

This means that the parts printed with metal-filled PLA will weigh significantly more than ones from the standard PLA, despite using the same settings and consuming the same amount of material. Metal filled filaments also tend to be very abrasive as they are extruded through the hotend. A standard brass nozzle will be too soft and will quickly wear down. Be sure to upgrade to a wear resistant nozzle in order to print this filament effectively. There are other metal-like filaments in the market that may just have metallic coloring added to the filament. These filaments do not contain any actual metal powder, so they do not share many of the same benefits of the true metallic filaments. This article will focus on materials that contain actual metal powders for a realistic metallic weight and feel.

- Metallic finish is aesthetically appealing

- Does not need high-temperature extruder

- Heavier than standard filaments

- Requires a wear-resistant nozzle

- Printed parts are very brittle

- Very poor bridging and overhangs

- Can cause partial clogs over time

- Expensive

Hardware Requirements

Before 3D printing with metal filled filament make sure your 3D printer meets the hardware requirements listed below to ensure the best print quality.

Bed

Temperature: 45-60 °C

Heated Bed Optional

Enclosure Not Required

Build Surface

Painter’s Tape

Glue Stick

PEI

Extruder

Temperature: 190-220 °C

Requires Wear Resistant Hardened Steel Nozzle

Cooling

Part Cooling Fan Required

Best Practices

These tips will help you reduce the chances of common 3D printing issues associated with metal filled filaments such as clogging, the nozzle wearing down, poor bridging, and blobs left on the surface of the print.

Use Wear-Resistant Nozzles

Most 3D printers ship with brass nozzles that are relatively soft. Since metals can be abrasive in general, brass nozzles can easily wear out when used with metal filled filaments. Upgrading to a wear-resistant nozzle will help reduce the wear significantly. Another aspect to consider while upgrading is the nozzle size. Although it is possible to print with standard 0.4mm nozzles, metal particles tend to clump around the orifice and can cause clogging over extended periods of use. Nozzle sizes of 0.5 – 0.6 mm seem to work better for metal filled filaments. It is also good to periodically check the nozzle orifice for any visible wear. Worn out nozzles can otherwise result in inconsistent extrusion and reduced overall quality of the printed parts.

Nozzle sizes of 0.5 – 0.6 mm seem to work better for metal filled filaments. It is also good to periodically check the nozzle orifice for any visible wear. Worn out nozzles can otherwise result in inconsistent extrusion and reduced overall quality of the printed parts.

Be Aware of Bridging Limitations

Metal filled filaments are quite heavy, which has an impact on their bridging performance. When the molten plastic is extruded across either side of the bridge, it droops excessively and eventually breaks before it can complete the bridge. This means that parts with lots of large bridging regions will be very difficult to print.

Simplify3D Version 4.0 added several new features related to bridging, including one that allows you to completely customize the direction of this bridging fill. If you have a part that requires bridging and there is no way to avoid it, you might find that there is a specific fill angle that will work best for this material. The software also allows you to customize the exact speed and extrusion rate used for the bridges, so you can experiment to find what works best for your material. Other successful methods would be to add support structures to support any potential overhangs, or consider using a dual extrusion system with a dissolvable support structure such as PVA. Simplify3D includes a feature called Dense Supports, which allows you to use this PVA material very sparingly, only at the interface between the supports and the part, so this can be a great option as well.

Other successful methods would be to add support structures to support any potential overhangs, or consider using a dual extrusion system with a dissolvable support structure such as PVA. Simplify3D includes a feature called Dense Supports, which allows you to use this PVA material very sparingly, only at the interface between the supports and the part, so this can be a great option as well.

Check the Filament Path for Sharp Bends

Metal filaments are very brittle in general. This affects the final parts, but it also applies to the raw filament itself which needs to be pulled into the printer as it is extruded. If you follow the filament path from the spool, all the way to the extruder, check for any sharp angles or curves which may put too much stress on the filament. We found that many printers included sharp bends that had a tendency to cause the filament to snap in the middle of printing. You may notice this happens more as the toolhead moves around during the print, since different toolhead positions may put more stress on the filament as it bends to move to the new location. One great way to avoid this is the change the location where the filament spool is mounted. Start by mounting the spool on top of the printer and try to minimize the distance from the spool to the extruder.

One great way to avoid this is the change the location where the filament spool is mounted. Start by mounting the spool on top of the printer and try to minimize the distance from the spool to the extruder.

Additionally, a strong filament guide tube that limits the bend in the filament path will prevent most breakages.

Tune Your Retraction Settings

Like wood filled and other composites materials, retractions with metal filled filaments can be rather challenging. The presence of metal powder makes it difficult for the nozzle to contain the suction pressure in the melt chamber during retraction. This will frequently lead to blobs at the beginning and end of each printed segment, where the extruder was trying to start or stop the plastic extrusion. Simplify3D has several features that can be a big help in this situation. The first is a unique feature called Coasting, which will automatically reduce the pressure in the nozzle right before the end of a print segment. This greatly reduces oozing when moving to the next print segment, so it can be a great option to consider. You can also try setting the “extra restart distance” to a negative value of -0.1 or -0.2mm, as this can help with the blobs that may form at the start of each segment. For more tips on how to reduce these blobs, please refer to our Print Quality Guide: How to Reduce Blobs and Zits.

This greatly reduces oozing when moving to the next print segment, so it can be a great option to consider. You can also try setting the “extra restart distance” to a negative value of -0.1 or -0.2mm, as this can help with the blobs that may form at the start of each segment. For more tips on how to reduce these blobs, please refer to our Print Quality Guide: How to Reduce Blobs and Zits.

Pro-Tips

- To prevent the chances of clogging, you can greatly reduce the number of retractions in Simplify3D by enabling the “Only retract when crossing open spaces” option or disabling “Force retraction between layers”. Both of these settings can be found on the Advanced tab of your process settings.

- Due to the heavy nature of this material, metal filled filaments typically do quite poorly when printing overhangs or bridges. To reduce the number of overhangs required for your print, try reducing the layer height to 0.1 or 0.15mm. This can significantly improve overhang performance.

Get Started with Metal Filled Filaments

There are many unique applications for these specialty filaments. We’ve put together a list of common applications, sample projects, and even popular brands of filament to help you get started.

Common Applications

- Sculptures and Busts

- Replicas for Museums

- Jewelry

Sample Projects

- Bull

- Minerva

- Anvil

- Nefertiti

Popular Brands

- ColorFabb Brassfill, Bronzefill, Steelfill, CopperFil

- Protopasta Composite PLA – Magnetic Iron, Polishable Stainless steel

- FormFutura MetalFil

Ultrafuse 316L Metallic Filament for FDM (FFF) 3D Printing - SMARTPRINT

Composite Metallic Filament with Stainless Steel for FDM (FFF) 3D Printers

Ultrafuse® 316L is an innovative filament for the production of 316L stainless steel parts.

[button target="_blank" hover_type="default" text="Buy Ultrafuse® 316L 1. 75mm" margin="15px 0px 0px 0px" link="https://3dsmart.com.ua/shop/materials/basf- ultrafuse-316l-175″][button target="_blank" hover_type="default" text="Buy Ultrafuse® 316L 2.85mm" margin="15px 0px 0px 0px" link="https://3dsmart.com.ua /shop/materials/basf-ultrafuse-316l-285″]

75mm" margin="15px 0px 0px 0px" link="https://3dsmart.com.ua/shop/materials/basf- ultrafuse-316l-175″][button target="_blank" hover_type="default" text="Buy Ultrafuse® 316L 2.85mm" margin="15px 0px 0px 0px" link="https://3dsmart.com.ua /shop/materials/basf-ultrafuse-316l-285″]

Material Details

[icons size=" custom_size=" icon='fa-download' type='normal' position=" border='yes' border_color=" icon_color=" background_color=" margin=" icon_animation= » icon_animation_delay=» link=» target='_self'] Product Brochure

[icons size=" custom_size=" icon='fa-download' type='normal' position=" border='yes' border_color=" icon_color =" background_color=" margin=" icon_animation=" icon_animation_delay=" link=" target='_self'] Datasheet

[icons size=" custom_size=" icon='fa-download' type='normal' position=" border='yes' border_color=" icon_color=" background_color=" margin=" icon_animation=" icon_animation_delay=" link= » target='_self'] User Manual

[icons size=" custom_size=" icon='fa-download' type='normal' position=" border='yes' border_color=" icon_color=" background_color=" margin= » icon_animation=» icon_animation_delay=» link=» target='_self'] Debinding Simulation Guide

[icons size=" custom_size=" icon='fa-download' type='normal' position=" border='yes' border_color=" icon_color=" background_color=" margin=" icon_animation=" icon_animation_delay=" link=" target='_self'] Processing Guide

Description

It is designed for maximum ease of use on conventional 3D printers with FFF (Fused Filament Fabrication) technology. The BASF Ultrafuse® 316L combines greater design freedom with a lower total cost of ownership—printing metal parts is easier, faster and more affordable. Parts printed with Ultrafuse® 316L develop their final properties, including hardness and strength, through a catalytic debinding and sintering process. The catalytic debinding technology was developed and implemented by BASF and has become the industry standard. nine0005

The BASF Ultrafuse® 316L combines greater design freedom with a lower total cost of ownership—printing metal parts is easier, faster and more affordable. Parts printed with Ultrafuse® 316L develop their final properties, including hardness and strength, through a catalytic debinding and sintering process. The catalytic debinding technology was developed and implemented by BASF and has become the industry standard. nine0005

Benefits at a Glance

=» icon_animation_delay=» link=» target='_self'] Simple and Affordable Metal 3D Printing

[icons size=" custom_size=" icon='fa-check' type='normal' position=" border='yes' border_color=" icon_color=" background_color=" margin=" icon_animation=" icon_animation_delay=" link=" target='_self'] Fast material change and easy handling

[icons size=" custom_size=" icon='fa-check' type='normal' position=" border='yes' border_color=" icon_color=" background_color=" margin=" icon_animation=" icon_animation_delay=" link=" target='_self'] For all open source FFF printers

[icons size=" custom_size=" icon='fa-check' type='normal' position=" border='yes' border_color=" icon_color=" background_color =" margin=" icon_animation=" icon_animation_delay=" link=" target='_self'] Produces 316L stainless steel parts. nine0035 [icons size=" custom_size=" icon='fa-check' type='normal' position=" border='yes' border_color=" icon_color=" background_color=" margin=" icon_animation=" icon_animation_delay=" link=" target='_self'] Uniform particle distribution improves mechanical properties

nine0035 [icons size=" custom_size=" icon='fa-check' type='normal' position=" border='yes' border_color=" icon_color=" background_color=" margin=" icon_animation=" icon_animation_delay=" link=" target='_self'] Uniform particle distribution improves mechanical properties

[icons size=" custom_size=" icon='fa-check' type='normal' position=" border='yes' border_color=" icon_color=" background_color=" margin=" icon_animation=" icon_animation_delay=" link=" target='_self'] The high flexibility of the filament allows it to print successfully on any FFF printer. nine0035 [icons size=" custom_size=" icon='fa-check' type='normal' position=" border='yes' border_color=" icon_color=" background_color=" margin=" icon_animation=" icon_animation_delay=" link=" target='_self'] Compatible with both Bowden and direct drive extruders

Use Cases

[icons size=" custom_size=" icon='fa-check' type='normal' position=" border='yes' border_color=" icon_color=" background_color=" margin=" icon_animation=" icon_animation_delay=" link=" target='_self'] Snap

[icons size=" custom_size=" icon='fa-check' type='normal' position=" border='yes' border_color=" icon_color=" background_color=" margin=" icon_animation=" icon_animation_delay=" link= » target='_self'] Fixtures & Fixtures

[icons size=" custom_size=" icon='fa-check' type='normal' position=" border='yes' border_color=" icon_color=" background_color=" margin =" icon_animation=" icon_animation_delay=" link=" target='_self'] Function Prototypes

[icons size=" custom_size=" icon='fa-check' type='normal' position=" border='yes' border_color =" icon_color=" background_color=" margin=" icon_animation=" icon_animation_delay=" link=" target='_self'] Limited edition

Process Brief

Easy and cost-effective 3D printing of metal parts with Ultrafuse® 316L

We have developed Ultrafuse® 316L to produce high quality metal parts and high productivity. This state of the art metallic filament is suitable for use with any conventional Fused Filament Fabrication (FFF) printer. Once printed, the final properties of the part are achieved through a debinding and sintering process developed by BASF that has become the industry standard. nine0035 Ultrafuse® 316L is economical, easy to process and meets MIM industry standards for catalytic debinding and sintering. This innovative industrial metal-polymer composite supports a wide range of applications, including tools, fixtures and fixtures, small-scale production, functional parts, prototypes, and even jewelry.

This state of the art metallic filament is suitable for use with any conventional Fused Filament Fabrication (FFF) printer. Once printed, the final properties of the part are achieved through a debinding and sintering process developed by BASF that has become the industry standard. nine0035 Ultrafuse® 316L is economical, easy to process and meets MIM industry standards for catalytic debinding and sintering. This innovative industrial metal-polymer composite supports a wide range of applications, including tools, fixtures and fixtures, small-scale production, functional parts, prototypes, and even jewelry.

Ultrafuse® 316L contains thermoplastic binders with 90 weight percent fine metal particles. Our filament has a non-slip surface that allows it to be used in most Bowden or direct drive extruders. Due to its high flexibility, it can be fed through sophisticated idlers and multiple filament transport systems in printers – no additional drying required. Metal-polymer composite as a filament does not have any of the production hazards and safety risks associated with handling fine metal powders, making 3D printing of stainless steel parts affordable, simple and safe. nine0005

nine0005

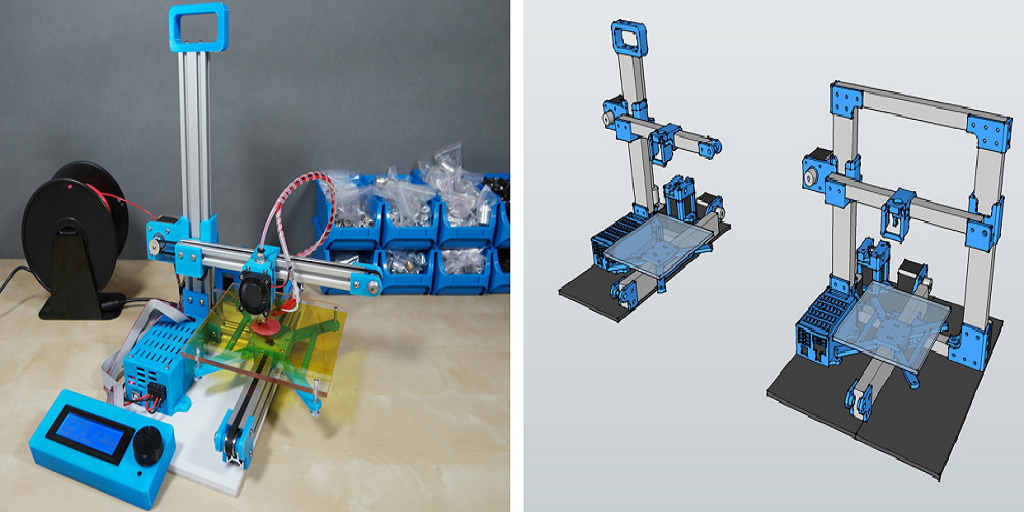

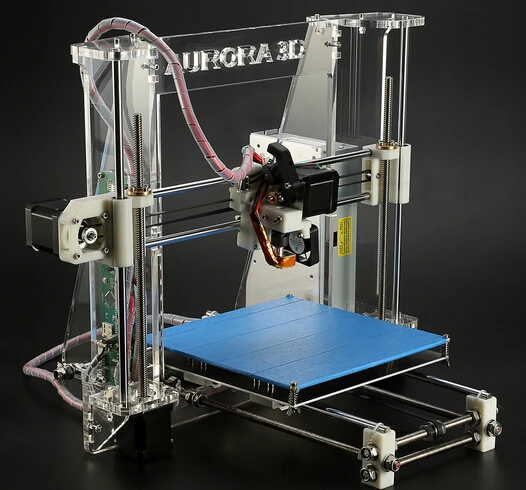

Which 3D printers should I use with the Ultrafuse® 316L?

Ultrafuse® 316L, designed for safe and easy use with conventional FFF printers, has a wide processing window. To help you succeed in metal 3D printing, we provide printer processing instructions, including Ultrafuse® 316L presets. In addition, on-site consultation and support is available to ensure that the material will work on your printer. nine0005

Would you like a 3D printing and/or post-processing service for your Ultrafuse® 316L part?

Your name (required)

Your e-mail (required)

Your phone number (required)

Your message

Attach a file (up to 10 mb)

Steel 3D Printing - A Quick Guide nine0005

Any metal 3D printing technology can print with steel. This is the most popular material. But which steel grades and which technology is best for your application? Will printed steel parts really be as strong and durable as traditionally made parts?

Let's see how a 3D printed steel part is revolutionizing manufacturing and opening doors to new applications in aerospace, medical equipment, automotive, tool making, heavy industry, architecture and more. In addition, more affordable desktop printers are expanding the scope and scope of real steel 3D printed parts. nine0005

In addition, more affordable desktop printers are expanding the scope and scope of real steel 3D printed parts. nine0005

Strength of steel printed parts.

Cast steel part (left), 3D printed version (center). On the right, a fully 3D printed hinge requires no assembly. (Source: Desktop Metal)The most common question when it comes to a 3D printed metal model is "Will it be as strong as a forged or cast part?" ?". The short answer is yes... and no.

3D printed steel parts can be just as strong, and sometimes stronger, than traditionally made ones. It depends on many factors such as: end use, type of steel, choice of 3D printing method, post-processing and shape of the part. Also, the comparison depends on which of the strength characteristics you focus on: tensile strength, static load strength, fatigue strength, etc. nine0005

Printed steel parts are used in the aerospace industry, the military, and for example the footbridge shown below. Therefore, the strength of printed products is beyond doubt, but let's take a closer look.

A 3D printed or laser powder sintered (LPBF) steel part has a finer grain structure than cast metal products. This provides better tensile strength characteristics, but in other respects the cast parts are currently still stronger. Most often, LPBF 3D printing is used to replace cast components, but in some cases, 3D printed components can replace forged parts. nine0005

One study showed that, under certain conditions, stainless steel parts made using LPBF 3D printers were three times stronger than parts made from the same steel using the traditional method.

In an experiment comparing 3D printed steel parts to traditionally made steel parts, researchers create identical parts using two methods and compare their performance. However, head-to-head comparison of details is only part of the big picture. nine0005

The main advantage of printing with steel is not only its strength, but also the unique ability to create internal channels and lattice fillings in parts, which is impossible with traditional manufacturing methods. Metal 3D printing makes it possible to produce parts faster than traditional production, since this method does not require the use of special equipment and tools, it allows you to create assemblies as a whole, eliminating the need for subsequent assembly and welding. Designing a printed part usually means that less metal is needed to make it, and therefore less weight, for the same strength. nine0005 MX3D Wire Arc Additive Manufacturing (WAAM) printed steel architectural support (Source: MX3D)

Metal 3D printing makes it possible to produce parts faster than traditional production, since this method does not require the use of special equipment and tools, it allows you to create assemblies as a whole, eliminating the need for subsequent assembly and welding. Designing a printed part usually means that less metal is needed to make it, and therefore less weight, for the same strength. nine0005 MX3D Wire Arc Additive Manufacturing (WAAM) printed steel architectural support (Source: MX3D)

Steel 3D printing is also more stable and cost effective as it reduces waste. When using subtractive manufacturing methods, such as CNC machining, you make a part by cutting it out of a large one, with a lot of waste. With additive manufacturing, you only use the material you need to make the finished product. nine0005

Steel 3D printing is not intended to replace traditional methods in all areas, but it may be a better choice for a wide range of applications. Particularly when the required parts are unique and designed for specific applications, such as rocket engines, racing cars or the oil and gas industry. 3D printing is the fastest and most flexible technology for mass production and prototype production. For military and industrial applications, steel 3D printing is a faster and more efficient way to create individual parts for vehicles and machines. Stainless steel 3D printing is rapidly finding applications in medicine to create unique surgical instruments and implants. nine0005

3D printing is the fastest and most flexible technology for mass production and prototype production. For military and industrial applications, steel 3D printing is a faster and more efficient way to create individual parts for vehicles and machines. Stainless steel 3D printing is rapidly finding applications in medicine to create unique surgical instruments and implants. nine0005

If you know what characteristics your final product should have (tensile strength, compressive strength, hardness, density, etc.), then all these parameters can be incorporated into the product at the production stage.

Types of steel for 3D printing

Metal powder is the most used metal material for 3D printing (Source: GKN Additive) There are thousands of different grades of steels and alloys with different mechanical properties, used in traditional manufacturing but in 3D printing there are only a few dozen of them, and some of them are unique, created specifically for this technology. Among the steel options, the following can be distinguished:

Among the steel options, the following can be distinguished:

-

Stainless steel (316L, 304L , 17-4PH, 15-5PH, 420, 254, Ph2, GP1, 630, 410).

-

Tool steel (D2, M2, h23, h21, MS1, 1.2709).

-

Low alloy steel (4140).

-

Structural alloyed (20MnCr5).

Recently, unique alloys have been developed specifically for 3D printing, designed to solve the problems that occur with classical production methods. nine0005

For example, 3D printer manufacturer Desktop Metal released a patented stainless steel in 2022 that the company says combines the tensile strength, ductility, and corrosion resistance of 13-8 PH stainless steel, combined with the hardness low alloy steel like 4140. The company says customers can go to market with this material and skip the galvanizing step to protect products from corrosion.

ExOne offers two special blends of steel and bronze that the company says allows 3D printed steel parts to achieve increased corrosion resistance while being easy to machine and polish. nine0005

nine0005

While most of the metal powders used in 3D printing are similar to those used for other manufacturing methods, their numbers are on the rise as more companies adopt the technology. Some metal powder manufacturers, such as GKN, also make custom powders for specific 3D printing applications.

How to print with steel

The strength, properties, and applications of 3D printed steel products largely depend on which 3D printing technology you use. Some methods produce stronger parts, other methods provide better hardness or abrasion resistance, and some technologies are simply very fast. nine0005

Below are the main metal 3D printing methods, their properties and some of the most common application examples.

Fused Deposition Printing (FDM)

BCN3D's Epsilon printer extrudes metal filament from stainless steel (Source: BCN3D) as more printer manufacturers certify metallic filaments for use on their printers, such as Ultimaker, BCN3D, Makerbot, Raise3D. Raise3D has recently released a complete metal printing suite - Metalfuse (3D printer, debinding oven and sintering oven). This method is still much more popular for printing plastics, but with new plastic filaments filled with stainless steel powder, strong metal parts can be produced. nine0005

Raise3D has recently released a complete metal printing suite - Metalfuse (3D printer, debinding oven and sintering oven). This method is still much more popular for printing plastics, but with new plastic filaments filled with stainless steel powder, strong metal parts can be produced. nine0005 FDM media was once limited to thermoplastics. Companies like BASF Forward AM and The Virtual Foundry now offer metal filaments that can be used on almost any FDM printer as long as it has a hardened steel nozzle for abrasive media.

These materials are approximately 80% metal and 20% plastic. After printing, the post-processing process removes the plastic, resulting in 100% metal parts. nine0005

Due to the removal of the bonding plastic, FDM metal parts shrink during post-processing. The amount of shrinkage is constant and can be taken into account in CAD systems, which allows to obtain relatively accurate finished parts.

Forward AM's 316L Stainless Steel Ultrafuse filament produces finished parts with material properties that the company claims are comparable to injection molded metal parts. nine0005 (Source: BCN3D)

nine0005 (Source: BCN3D)

While 3D printing with metallic materials may not be suitable for demanding applications such as aerospace, the economics of producing simple metal components without critical loads on an affordable FDM printer can outweigh the impossibility of applying them in some areas.

Ideal use cases for this technology are metal prototype parts and finished parts that will not be subjected to extreme stress. nine0005

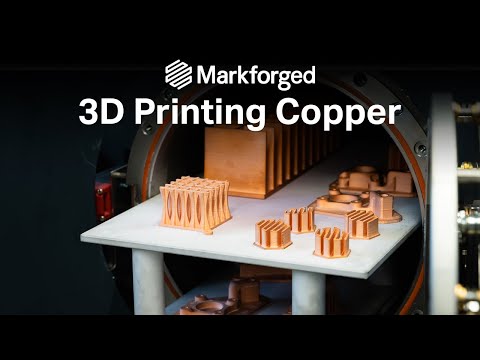

Bound Metal Deposition (BMD)

Desktop Metal's Studio System 3D printer used bonded metal bars that were extruded layer by layer to form a metal part. Metal mesh deposition method (BMD) or bonded powder extrusion (BPE) is a 3D printing process based on extrusion. This method uses bonded metal rods or bonded powdered metal filaments, which consist of a much higher percentage of metal powder than the filaments used in FDM. As with FDM, post-treatment to remove the binder and heat treatment in a final sintering oven are required. nine0005 There are only a few 3D printers using this method such as Desktop Metal, Markforged and more recently 3DGence, but more companies are entering this market, so stay tuned. These printers are valued as a convenient solution for office 3D metal printing, they are more expensive than most FDM printers, but cheaper than the powder-based metal 3D printing technologies described below.

These printers are valued as a convenient solution for office 3D metal printing, they are more expensive than most FDM printers, but cheaper than the powder-based metal 3D printing technologies described below.

These printers use their own proprietary filament. Desktop Metal and Markforged offer four types of steel. nine0005

Ideal niches for this technology are metal prototype parts, where it is necessary to test the functionality of a part before mass production using traditional methods. Popular applications are molds, punching dies, nozzles, impellers, fasteners and heat exchangers.

For example, Shukla Medical uses Markforged's Metal X printer to print steel prototypes of its orthopedic implant removal tools. nine0005

Laser powder sintering.

Laser powder sintering technology uses one or more lasers to melt powdered metal into a desired shape layer by layer (Source: GE Additive) metal printing. This technology is used by 80% of all metal 3D printers on the market.

This method uses powerful lasers to selectively sinter metal powder layer by layer. nine0005

LPBF 3D printers come in a wide range of sizes, prices and laser powers. These and other characteristics affect the properties of the finished part, print speed and other parameters of the finished products.

Steel and steel alloys are the most popular material for LPBF equipment and, unlike FDM and BMD, metal powders are commercially available as they are most commonly used in traditional production methods.

LPBF is a technology that maximizes the quality of a 3D printed part. Applications include aerospace components such as monolithic thrust chambers, rocket engine components and heat exchangers, molds, tools and other applications, as well as high wear parts and surgical instruments. nine0005

Binder Jetting

Binder 3D printing technology uses powdered metal and a binder to form metal parts (Sorrce: ExOne) binder, and not with a laser. During post-processing, the binder is removed.

Binder application stands out for its high printing speed compared to other 3D printing methods or traditional manufacturing, and metal parts made with this technology have material properties equivalent to those made by metal injection molding. nine0005

The number of manufacturers producing metal-bonded inkjet 3D printers is much smaller than that of LPBF machines. Leading manufacturers include ExOne, Desktop Metal, Digital Metal, GE Additive and HP.

Binder blasting is ideal for medium to high volume production of metal tools and spare parts.

In fact, HP claims that its Metal Jet 3D printer was designed specifically for mass production of 316L stainless steel products. HP has partnered with Parmatech to produce metal parts for the medical industry. Pennsylvania-based ExOne uses this technology to manufacture hard metal cutting tools and tool steels. nine0005

Electron Beam Melting (EBM)

(Source: GE Additive) Electron Beam Melting (EBM) is another powder cladding technology. It works in a similar way to selective laser melting (SLM), but instead of using a laser as the energy source, it uses a much more powerful beam of charged particles.

It works in a similar way to selective laser melting (SLM), but instead of using a laser as the energy source, it uses a much more powerful beam of charged particles.

The recoater moves the powder onto the printing plate and an electron beam selectively melts each layer of powder. After each layer is printed, the plate is lowered and another one is applied on top of the previous layer. nine0005

EBM can be much faster than SLM, but SLM produces smoother and more accurate pieces. The electron beam is wider than the laser beam, so EBM cannot produce the same precise parts as SLM. Another difference is that the manufacturing process takes place in a vacuum chamber, which reduces the amount of impurities in the material that can lead to defects. That is why EBM is often chosen for printing components for the aerospace, automotive, defense, petrochemical and medical implant industries. nine0005

Titanium is the most popular metal for most EBM applications, however steel can be used.

Cold Spray

(Source: Impact Innovations)Cold spray 3D printing is done by injecting metal powders through a jet nozzle into a supersonic stream of pressurized gases such as air, nitrogen, or helium. The process is called "cold" because the metal particles do not melt, but hit the metal substrate and adhere to its surface during the so-called plastic deformation. nine0005

Cold spray printed products are not prone to porosity, thermal cracking and other defects associated with melt-based technologies. This method has several advantages over other production methods. The technology is used in the military and aerospace industries around the world. For example, the US Army uses cold spray to repair the mounts of a worn Bradley 25mm steel turret gun.

In the automotive industry, cold spray steel is used for post-accident repairs because high-strength steel substrates in automobiles can be susceptible to thermal repair methods such as welding. nine0005

Direct Energy Deposition (DED) and Wire Arc Additive Manufacturing (WAAM)

MX3D WAAM Steel Parts (Source: MX3D) Direct Energy Deposition (DED) uses welding powder or wire that enters through a nozzle and is fed into the power source to melt the metal. A melt region is created and applied to the substrate. DED is a new process, reminiscent of an old building technology known as "cladding", in which a coating is applied to a substrate, often for thermal insulation or weather resistance. DED is useful for fabricating large objects as a whole, as well as complex geometries that require extensive machining. DED can get such parts much closer to finished than traditional CNC machining. nine0005

A melt region is created and applied to the substrate. DED is a new process, reminiscent of an old building technology known as "cladding", in which a coating is applied to a substrate, often for thermal insulation or weather resistance. DED is useful for fabricating large objects as a whole, as well as complex geometries that require extensive machining. DED can get such parts much closer to finished than traditional CNC machining. nine0005

Because DED uses a coating process, it can be used to add complex geometries to existing steel parts, thus combining complexity with cost reduction. For example, the French company AddUp advertises a rocket nozzle that uses a preformed large 304 stainless steel hopper cone printed with an isogrid structure, usually made from a larger piece by traditional methods.

A technology related to DED is wire-arc additive manufacturing (WAAM). Instead of powder, WAAM uses a metal wire that is melted by an electric arc. The process is controlled by robotic arms. WAAM is also capable of producing large-sized metal parts, as demonstrated by the Dutch company MX3D and its nine thousand-pound 41-foot stainless steel bridge in Amsterdam, as well as an oil and gas equipment repair part, proving that parts can be made in the field. nine0005

WAAM is also capable of producing large-sized metal parts, as demonstrated by the Dutch company MX3D and its nine thousand-pound 41-foot stainless steel bridge in Amsterdam, as well as an oil and gas equipment repair part, proving that parts can be made in the field. nine0005

Micro 3D printing

Micro parts printed from steel (Source: 3D MicroPrint)Micro scale additive manufacturing, or micro 3D printing, can produce products with a resolution of a few microns (or less). There are three micro 3D printing methods to produce metal parts.

LMM (lithography-based metal fabrication) is a light-based technology that creates tiny parts from raw materials, including stainless steel, for applications such as surgical instruments and micro-mechanical parts. nine0005

Electrochemical deposition is the latest micrometal 3D printing process developed by the Swiss company Exaddon. In this process, the printing nozzle applies liquid with metal ions, creating details at the atomic level.