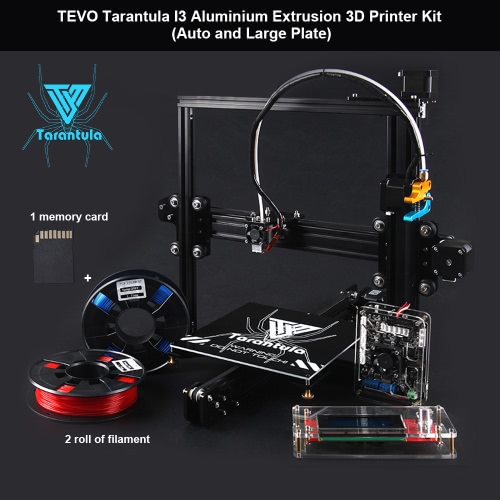

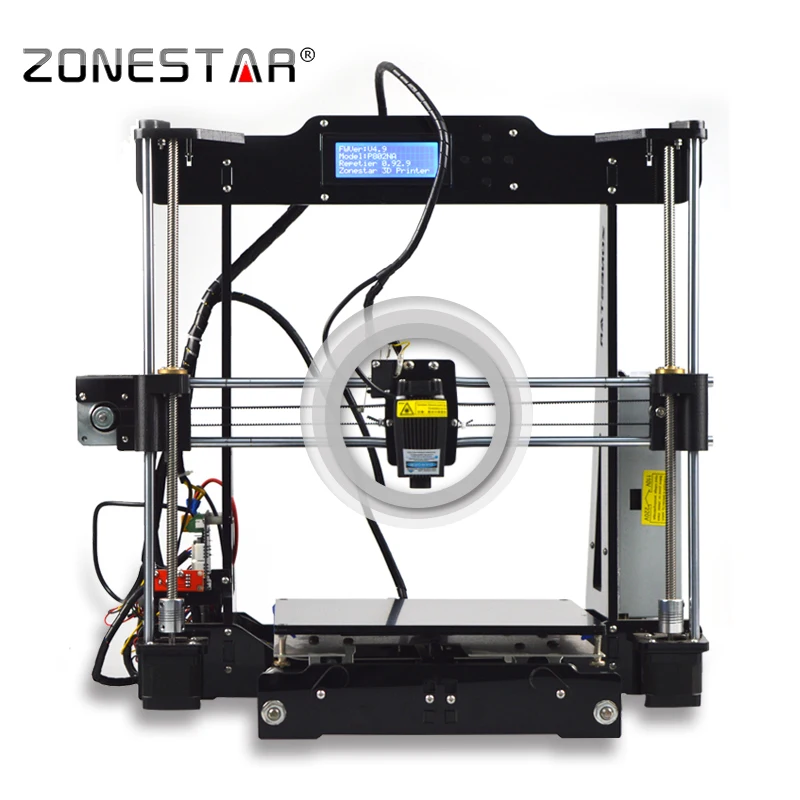

Zonestar p802qr2 3d printer diy kit

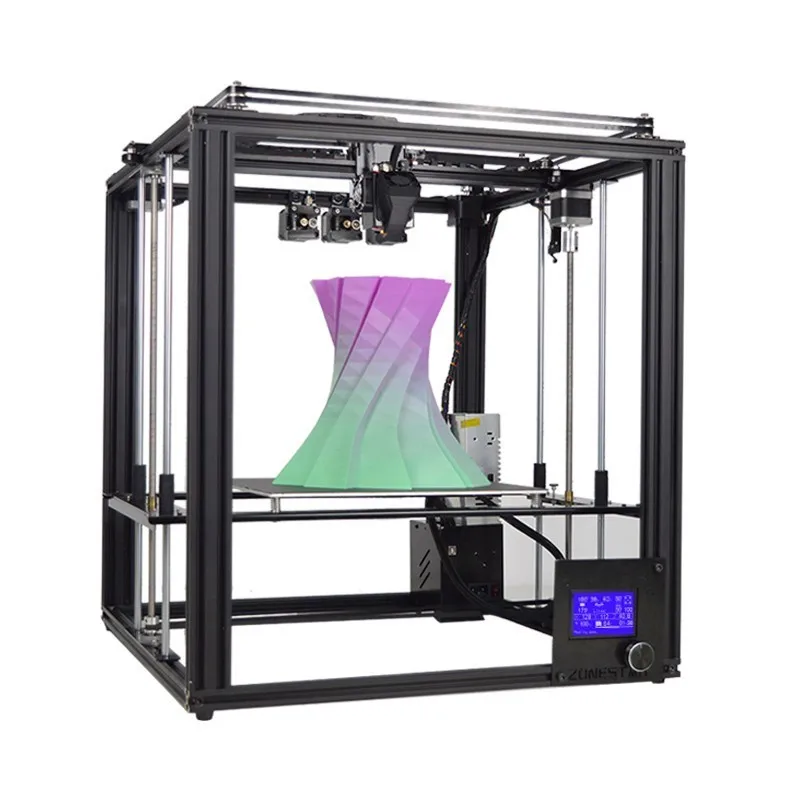

Zonestar P802QR2 Dual Extruder 3D Printer Kit (High Accurate, Smooth Stainless Steel Platform, Large Printing Volume)

₱21,908.79

Availability: 10 in stock.

SKU PB-TAIA-G904

Zonestar P802QR2 Dual Extruder 3D Printer Kit (High Accurate, Smooth Stainless Steel Platform, Large Printing Volume)

TAIA-G904 Highlights...

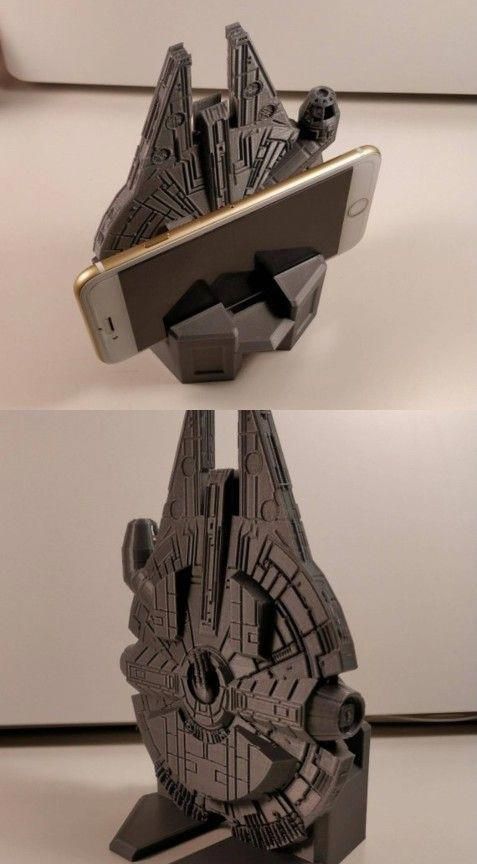

Affordable 3D printer lets you create all your mind can imagine

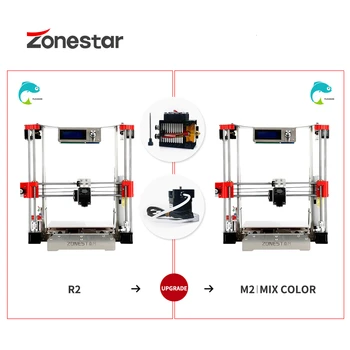

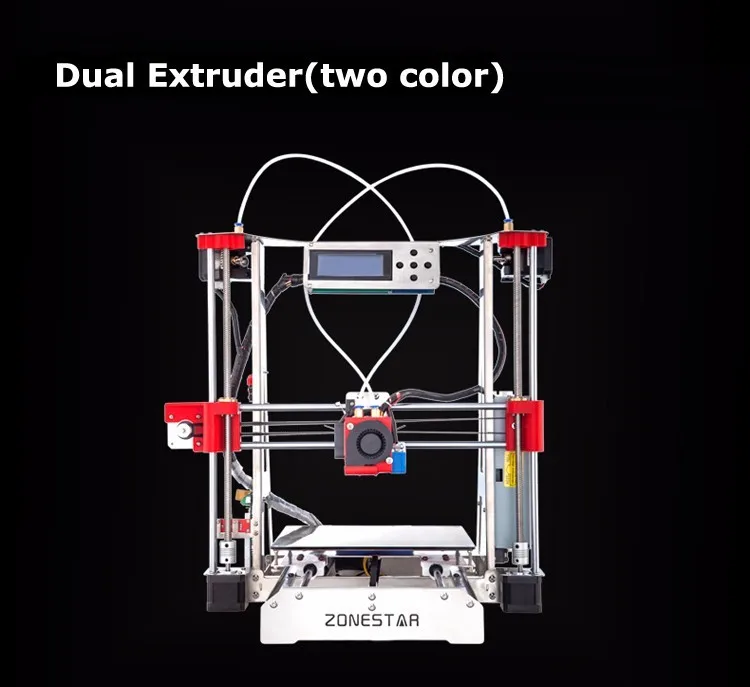

Dual extruders for multi-color printing

Supports a wide range of different filaments

Highly accurate and large 220x220x240mm printing volume

Zonestar P802QR2 3D Printer Kit

If you've always dreamt of entering the world of 3D printing, the Zonestar P802QR2 3D Printer is the gadget that you've been waiting for. This cheap DIY 3D printer can be easily built-up and used by anybody out there....

Quantity:

-

+

wishlist

Type 3D Printer + Accessories

Vendor Generic

- Product Description

- Customer Review

Zonestar P802QR2 Dual Extruder 3D Printer Kit (High Accurate, Smooth Stainless Steel Platform, Large Printing Volume)

TAIA-G904 Highlights. ..

Affordable 3D printer lets you create all your mind can imagine

Dual extruders for multi-color printing

Supports a wide range of different filaments

Highly accurate and large 220x220x240mm printing volume

Zonestar P802QR2 3D Printer Kit

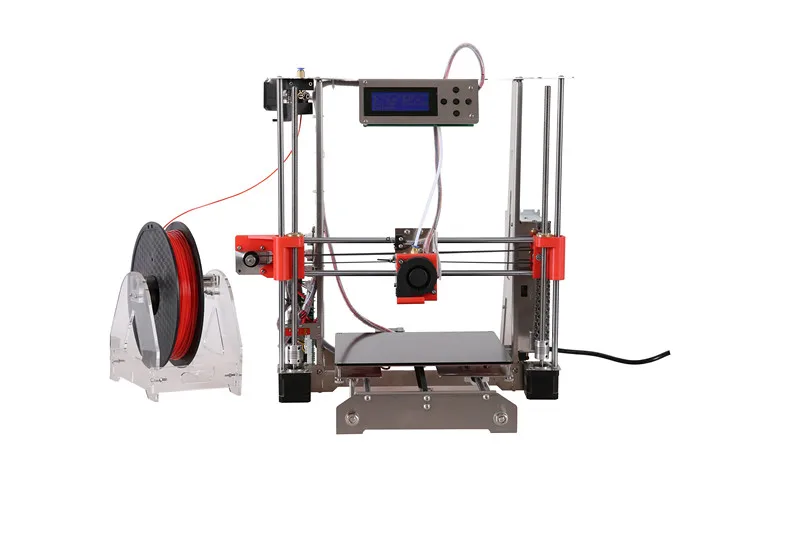

If you've always dreamt of entering the world of 3D printing, the Zonestar P802QR2 3D Printer is the gadget that you've been waiting for. This cheap DIY 3D printer can be easily built-up and used by anybody out there. Once assembled, it allows you to print anything your mind can imagine. Simply insert your file, press print, and your 3D printer will do its job. With its simple design and large LCD display, this 3D printer kit is easy to operate. It features printing speeds up to 150mm/s and a large printing volume of 220x220x240mm. This makes your 3D printer perfect for printing larger sized objects. By supporting a wide range of filaments, this gadget is great for any type of artist, hobbyist, teacher, and 3D printing enthusiast.

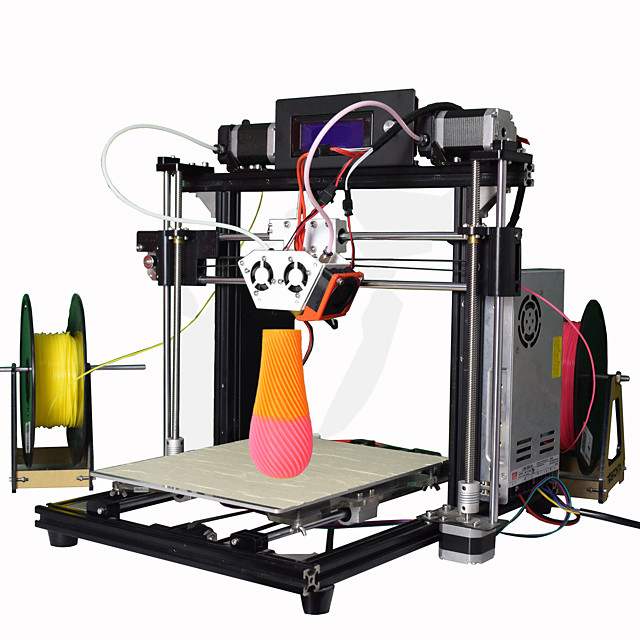

The Zonestar P802QR2 3D printer comes with smooth stainless steel parts for extra stability. It features an extremely high accuracy to make sure all your printing projects look absolutely stunning. Thanks to its dual extruders, this DIY 3D printer can print multiple colors and different filaments at once. This will significantly increase your artistic capabilities while working on your upcoming art projects. Whether you're a teacher, artist, engineer, or beginning 3D enthusiast - this cheap and simple to use 3D printer is sure to meet your demands.

Product Specifications

General

Frame Material: Steel

SD Card Slot

LCD Monitor Screen

Filament Materials: PLA, ABS, HIPS, Wood, PC, Nylon

Filament Diameter: 1.75mm

XY Axis Positioning Accuracy: 0.012mm

Z Axis Positioning Accuracy: 0.0025mm

Extruder Quantity: 2

Print 2 Colors

Extruder Diameter: 0.4mm

Layer Thickness: 0.1-0.36mm

Printing Speed: 20-150mm/s

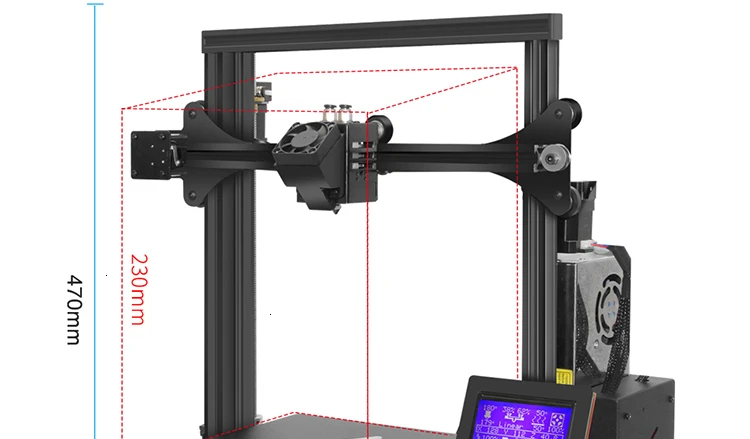

Maximum Print Size: 220x220x240MM

Nozzle Temperature Recommended: 170 degrees Celsius, Maximum 250 degrees Celsius

Hot Bed Temperature Recommended: max 110 degrees Celsius

Data Format: STL, OBJ, G-Code

Compatible Computer: Windows, MAC

3D Printing Software: Repetier-Host

Power Consumption: 140W

Power Supply: 110V-240V

Power Supply: DC 12V/20A

Language: English, Chinese, Spanish, Portuguese

Auto leveling function

Automatic platform leveling and height detection

EM4 Bowden extruder

500mW - 2500mW selectable upgradable laser engraver

Ports

USB Line In

SD Car Slot Up To 32GB

Dimensions

Main Product Dimensions: 460 x 420 x 420mm (L x W x D)

Main Product Weight: 9000 g

Weight/dimension is for the main item of this boxed product, to help you compare product sizes before buying: please do not base your shipping calculations on this price - shipping prices depend on your cart contents, shipping destination, and shipping method: please use the checkout to select options and preview shipping price for your total order.

Package Details

Zonestar P802QR2 3D Printer DIY Kit

{aioChoose_file_btn_heading}

{aioChoose_file_btn_heading}

`; var aio_review_html = `

{aioScore}:

{aioTitle}:

{aioReviews}:

{aio_enable_images_text}{aioName}:

{aioTxt_submit_review_button}

Zonestar P802QR Review (2023)

A few days ago I looked for a 3D printer at Gearbest. A printer with a dual extruder would be nice so that we also have a little something for our readers to demonstrate. You then have the option of printing with two different colors at the same time, or using water-soluble filament for support struts, etc.

A printer with a dual extruder would be nice so that we also have a little something for our readers to demonstrate. You then have the option of printing with two different colors at the same time, or using water-soluble filament for support struts, etc.

At Gearbest there is the possibility to buy fully assembled printers, or so-called KITs, which then have to be assembled by yourself with a PDF / Youtube manual and are a few euros cheaper.

The Zonestar P802QR2 is one of these DIY KITs and comes to Germany for just 226 euros. The price is understandably so low because the printer has to be screwed together and that can take 3 to 4 hours.

A few details about the Zonestar P802QR2

-

- 2 extruders and can therefore print in two colors

- Metal case

- Memory card and USB port for data transfer

- Chinese, English, Portuguese, Spanish and German

- Supported Material: ABS, Flexible PLA, PETG, PLA, PVA, Wood

- Print size: 220 x 220 x 240 mm

- Weight: approx.

9 kg

9 kg - Based on the Preprap Prusa I3

In my case, the package was sent via London. That’s why I probably didn’t have to give myself a customs whiz, but I just had to wait 21 days for shipping. More than half the time the package was lying around in London without any further information in the tracking app as to what is going on with it.

I suspect they are waiting until several parcels are going to Germany in order to save shipping. But if you plan that right from the start, the waiting time is fine.

The videos on the net of the assembly of a printer are often recorded in the form of a time lapse and give the impression that everything is very simple. A first unpacking of the parts makes your heart slip a bit:

Well what the heck – let’s go! Absolutely all tools for assembly are included in the package. Pliers, screwdriver, tweezers, Allen key, cable tie etc. On the SD card, which can later be used to transfer the print data, there are instructions in the form of PDFs, demo files to test the printer later and much more .

Do a little browsing on YouTube and you’ll find a few more videos in which the printer is screwed together. We also set the cell phone to timelapse and recorded the following video (4 minutes from 4 hours of handicraft work).

For the sake of order, it must be said that there were two of us and that the last hour was spent on optional cable management (color coding of the cables using adhesive tape). The printer could very well have been assembled in just over two hours.

Zonestar P802QR2 assembly in the video

https://www.youtube.com/GdyldvC3F9Y

On the video you can see briefly that I had not only used the PDF instructions, but also googled with my mobile phone and looked for instructions on YouTube. The enclosed PDF instructions are very detailed, but here and there one or the other part is missing.

For example, the bags are labeled with letters and numbers, but the instructions don’t mention one of these names for a second. Then the stepper motors are almost all the same, but two of them have a shorter drive shaft. Neither in the videos nor in the PDF could I see where these motors should be located. So just try.

Neither in the videos nor in the PDF could I see where these motors should be located. So just try.

A few parts have also been created with a 3D printer. Unfortunately one of them already had a hairline crack in my case. When threading through one of the axes that guides the print head, the page is then almost completely torn. Nothing that a bit of superglue can’t save, but it’s a bit annoying.

The DIY or KIT printers are nerd objects in my eyes and in no way comparable to printers such as the Dremel .

The power supply is simply screwed to the side and has a CE mark and a flap that covers the connections, but basically 220V goes through there and I don’t think that would go through the authorities with us .

But keep going … First the stepper motors are provided with the appropriate ends. One to transport a V-belt, the other to transport the filament, etc.

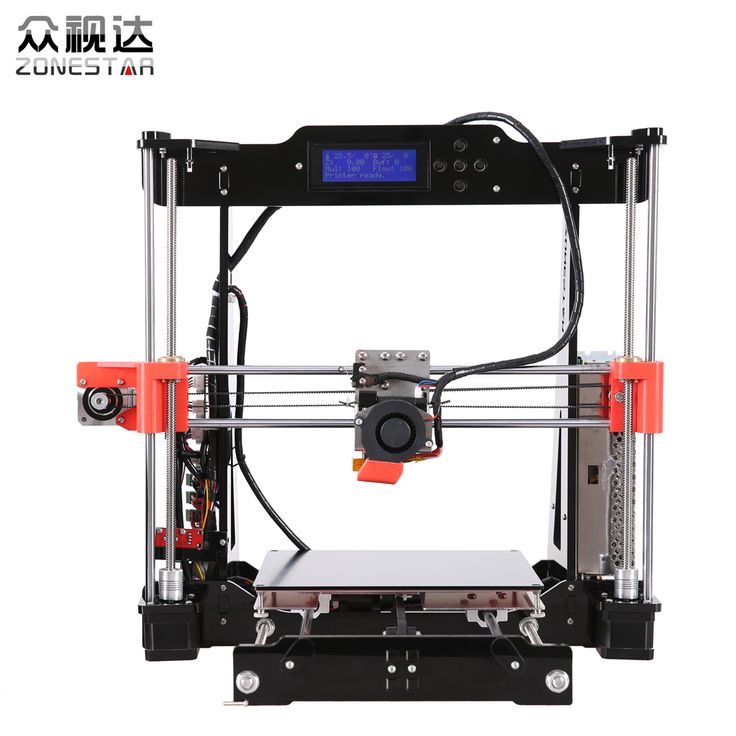

Then the display is screwed into the socket and the frame of the printer screwed together. Next to the display is a 5-way control pad which guides you through the printer’s menu. The same is kept simple, can even be set in German and is by and large self-explanatory.

Next to the display is a 5-way control pad which guides you through the printer’s menu. The same is kept simple, can even be set in German and is by and large self-explanatory.

The following picture shows the display with the information shown during the printing process. E1 and E2 stand for extruder, followed by the corresponding temperatures and below that the printing progress.

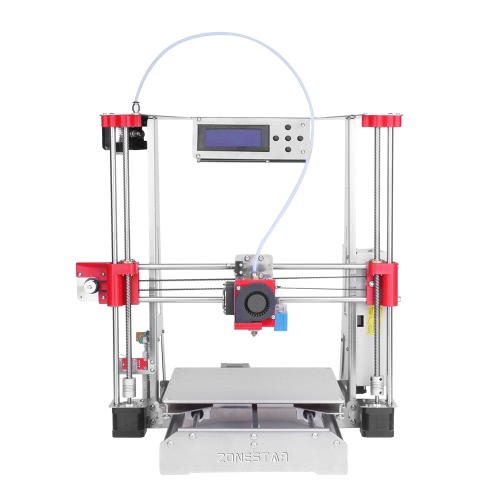

The frame is one of the advantages of this printer, by the way. The printer is based on the Preprap Prusa i3 and has a metal housing instead of the plastic housing that is often used. This is much more stable and less prone to twisting.

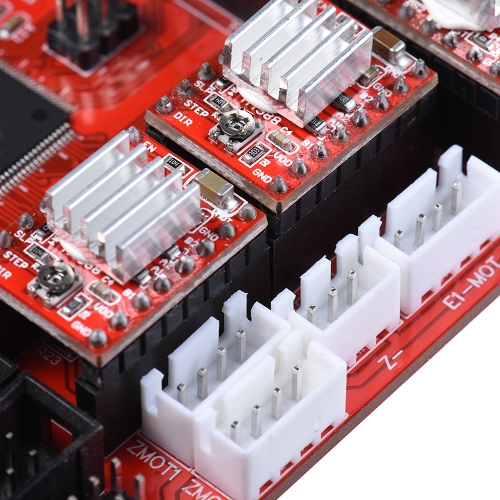

Once the motors are installed and the frame screwed together, the wiring is basically done. Screw the power pack to the housing, screw the circuit board to the housing, screw the emergency stop sensors for the respective axes and screw the printhead together with the corresponding temperature sensors.

Connect everything to the board and off you go the first attempt. We started out on the terrace for the first time because it was a bit strange feeling with the cables and the power supply, etc. In the end it turned out that everything in terms of electronics worked.

We started out on the terrace for the first time because it was a bit strange feeling with the cables and the power supply, etc. In the end it turned out that everything in terms of electronics worked.

The printing process itself was still a bit of a challenge. We had postponed this part to the next morning because after 4 hours of screwing there was simply no longer the necessary rest for adjustment work etc.

Since, as mentioned before, we weren’t sure whether we had installed the stepper motors correctly, we rebuilt them a total of three times until we finally got everything back to the beginning and the printer finally worked.

We are super happy and proud that it prints so delicately and actually even that it prints at all. You’re not so sure when you screw it together for the first time. 🙂

But everything worked out! In the meantime, the first objects have already been printed out and tested and we are currently trying out which slicer software we will use in the future and which are the best settings for a beautiful print.

As with the Dremel 3D printer , there will be a few more articles on the topic here in the blog. I am currently thinking of reports about printing with 2 filaments at the same time, possibly about different filaments (wood, water-soluble, etc.) and again about corresponding software that has to be used to create and slice. Stay tuned!

Zonestar P802QR2. Results of the first month.

So. It's been a month since I bought my first 3D printer. I wanted to tell you more about what has been done and get advice from veterans of 3DE printing. Many thanks to everyone on the portal who share their knowledge and skills. Much of what has been done is taken from here and from the same forums. Also, please don't throw shoes at me. Because the Chukchi is more of a reader than a writer. And I write to make it easier for those who follow. Everything is on the network, but finding what you need and trying it out - you have to kill a lot of time. nine0003

nine0003

I took the printer from Ali here. Delivery from a warehouse in Russia. That is, without customs clearance and faster. But it worked out as usual. After payment, it turned out that the warehouse was empty and waiting for a ship with fresh printers. In general, it turned out in time as from China, but bypassing customs. Everything came well packed, everything was in place and after assembly there was a bunch of bolts, a thermistor and a cable to the motor. The seller is sociable and likes to joke. In a good way. Download links for

printer 1. User manuals 2. Errors and Troubleshooting 3. Firmware 4. Certificates 5. Facebook group 6. Channel on YoutubeThe printer took, because the topic of CNC became interesting, as well as to expand the home workshop. I plan to assemble a laser engraver and maybe a milling cutter. For the milling cutter, you just need a separate room. But this is how it goes. Up to this point, the 3D theme is a complete zero. The only experience is the creation in 3D Max of the first versions of intros for home video. And that was a long time ago and is no longer true. I decided to take it with two extruders at once. And did not regret. There are many more possibilities than with one. There are also disadvantages, but they disappear by twisting the second extruder. You can unscrew the nozzle (hot!) And in the settings indicate that only one is available. Business for 5 minutes. Disadvantages - the second one scratches what the first one prints and vice versa. Surfaces are glossy and matt. But these are trifles. Well, snot from one color falls on the second. Still more merit. I thought to put a dual extruder with one nozzle like this. But if you print with different plastics, who knows what kind of reaction can go there. Yes, temperatures are different. And it's harder to clean. nine0003

And that was a long time ago and is no longer true. I decided to take it with two extruders at once. And did not regret. There are many more possibilities than with one. There are also disadvantages, but they disappear by twisting the second extruder. You can unscrew the nozzle (hot!) And in the settings indicate that only one is available. Business for 5 minutes. Disadvantages - the second one scratches what the first one prints and vice versa. Surfaces are glossy and matt. But these are trifles. Well, snot from one color falls on the second. Still more merit. I thought to put a dual extruder with one nozzle like this. But if you print with different plastics, who knows what kind of reaction can go there. Yes, temperatures are different. And it's harder to clean. nine0003

1. Assembly.

In general, instructions and assembly video are attached on a USB flash drive to the printer. I did not experience any particular difficulties. But there are a few things to note. There is no mention of how to tighten the belts at all. There is not even a hint of how to lay the wires. Full freedom.

There is no mention of how to tighten the belts at all. There is not even a hint of how to lay the wires. Full freedom.

Belt tensioner. We loosen the roller and the motor mount along the Y axis (loosening only the roller is enough). We tighten the belt and then we fasten the roller and the motor. There are fewer options along the X axis - you can loosen the motor there, but you also need to tighten the belt. The main thing is without fanaticism. The belt should not sag, but it should not ring like a string either. You can get X on the racks along the Z axis. The plans were to print tensioners in X and Y, but somehow I got used to it and the need disappeared. Maybe when there is nothing to do at all, I will do it. nine0003

Wires. After assembling the mechanics, I want to start the unit faster and the wires seem to be wired neatly, but in the end I got what I got.

The main work. The first picture shows that this disgrace is no longer there.

Only one spool holder was included with the printer. The issue of printing the second became acute. I really liked this one and this one. I printed both. But I've only used the first one so far. You can see it on the left in the first picture. The bar gives off with some effort, but it is always taut and does not twist. Compact and convenient. It's good that the bearings were already in stock. nine0003

Extruder clogged for the first time while printing. I printed the PLA that came with the printer. Horrified. What to grab and where to poke? I found it here on the forum. We take out the filament on a hot one, unscrew the tube and gently clean the top with a toothpick. And from below a wire from a stranded wire. All on heat.

After cleaning, take a piece of bar and carefully feed it by hand. If it doesn’t go, we clean further and so on until it goes easily and naturally. It turns out that it is necessary to put dust filters on the bar. I printed these. Since then there have been no blockages. There were difficulties with PLA residues when switching to SBS. The remains crystallized from the higher temperature and had to be carefully cleaned out. Again, nowhere without a toothpick. To make it easier to clean, you can print this holder. Hands do not burn so much and you can stick the wand further. nine0003

Since then there have been no blockages. There were difficulties with PLA residues when switching to SBS. The remains crystallized from the higher temperature and had to be carefully cleaned out. Again, nowhere without a toothpick. To make it easier to clean, you can print this holder. Hands do not burn so much and you can stick the wand further. nine0003

By that time I had received a bar from FDPlast HIPS and SBS. Decided not to mess with ABS yet. After all, I did not know that HIPS is almost the same ABS. It sticks to the table just as hard and the temperature is even a little higher. And warps, though less, but almost the same.

The printer does not have an off button. We print this box, and twist the connector and switch from a faulty power supply from the printer. Well, or buy in the store. I just had a couple of blocks lying around on a stash. Came like family.

Printer without base. With each move, the geometry changes and must be reconfigured. I chose plywood more even than 5 mm and cut out a 50x50 square. Chipboard would be better. But it will do for now. Covered with varnish. Dried up. I printed this fastener. The main thing to pay attention to is the rear mount near the Y-axis motor. The base needs to be slightly adjusted in height. The rest comes right away. I printed SBS with HIPS infill. It turned out cool. HIPS gives rigidity, and SBS absorbs vibration like rubber. Above in the photo is a box for a switch (PLA) and part of the attachment to plywood. Further according to the plans - to remove the cosmic wires and make the brain cool. nine0003

I chose plywood more even than 5 mm and cut out a 50x50 square. Chipboard would be better. But it will do for now. Covered with varnish. Dried up. I printed this fastener. The main thing to pay attention to is the rear mount near the Y-axis motor. The base needs to be slightly adjusted in height. The rest comes right away. I printed SBS with HIPS infill. It turned out cool. HIPS gives rigidity, and SBS absorbs vibration like rubber. Above in the photo is a box for a switch (PLA) and part of the attachment to plywood. Further according to the plans - to remove the cosmic wires and make the brain cool. nine0003

By that time I had run out of scotch tape and I started to buy mirrors for the table. Went to a mirror company. They didn't have anything less than 4. I ordered 2 pieces. It took 2 days to complete. load, you know. I went to Uncle Vasya's market.))) Uncle Vasya's like in Greece - he found me a moisture-resistant mirror 3 mm, cut it to size and polished it. Delov for 10 minutes . .. Now I have a stack of mirrors for all occasions.

.. Now I have a stack of mirrors for all occasions.

I took the CPU cooler from here - it's beautiful though. And my first print with supports and different plastics. It turned out not the first time and not without jambs, but it turned out ...

Printed on a mirror with a pencil. Only thanks to SBS (red), which sticks to everything, HIPS (yellow) somehow held on. It became a little better with PVA, even better with Moment Joiner. But finally HIPS agreed only on BF-2 with a skin. And then at 75 C it flies off the table with a crunch. But that will be later. How I was looking for this cherished BF-2 (originally from pioneer childhood). Rarity in one word. But found! And when I opened and sighed its fragrance - a bunch of memories of my modeling youth flooded in. The smoker lives! And so without SBS it was possible to print only small details from pure HIPS. nine0003

Disconnected the wires and twisted them into bundles. I tried to collect as much as possible into the bus and wrapped it with a complete spiral cable channel. In the end, it kind of worked out. I bought a 92mm cooler from a store. Connected directly to power. Total what happened below in the photo.

In the end, it kind of worked out. I bought a 92mm cooler from a store. Connected directly to power. Total what happened below in the photo.

SBS is translucent and the LEDs illuminate the box from the inside during operation. It's beautiful at night. Of course, it didn’t work out perfectly, but the first pancake. Yes, and printed almost 12 hours.

Now a few words about settings and programs

I used this model to adjust the offset of the extruder nozzles. Enough to print twice. The first time is rough. The second time is final. How to enter into EEPROM in the instructions for the printer is described in detail.

I mainly use the Repitier-Host slicer. How to set up is also in the instructions. The only thing to do is to increase the flow in the filament settings to 1.1. By default, the feed is not enough and because of this, the vertical layers do not sinter together well. Cura versions prior to 1.6 also work. They don’t see the printer above, as they didn’t go out of their way. Cura throws firmware well. In the Repeater, I could not go to the server page in any way. It turns out there is a glitch in the localization files for the Russian language. The solution to the problem is here. It’s strange what version has already been released, but they didn’t remember about us. Now I have a server configured and I can print from any computer and control the work via the Internet. I also connected the webcam - everything shows. I put it on print and went about my business - through smart, you can periodically see how work is going there. And if that stop remotely. nine0003

Cura throws firmware well. In the Repeater, I could not go to the server page in any way. It turns out there is a glitch in the localization files for the Russian language. The solution to the problem is here. It’s strange what version has already been released, but they didn’t remember about us. Now I have a server configured and I can print from any computer and control the work via the Internet. I also connected the webcam - everything shows. I put it on print and went about my business - through smart, you can periodically see how work is going there. And if that stop remotely. nine0003

Now about the fucking drygost. It's impossible to set up perfectly, or just so that it's impossible. Included is an auto level sensor. Initially, after turning on the printer, it worked on the strength of about 15 minutes and that's it. Then it just ignites and burns, regardless of the presence or absence of metal next to it. Now it won't turn off at all. Well, people live without sensors, however. But after turning off the auto level in the panel, setting the table is another adventure. Here people write that the springs must be thrown out and the table fastened firmly and forever. But does anything happen? If the extruder pokes into the table, the spring will somehow soften the blow. In general, I set myself specific springs and printed lambs more abruptly than regular ones. Only in this way could I set the table so that the first layer would somehow come out. It is necessary to think about the sensor something and about the mechanics of the table. I don't like her. What is the best sensor to install? Wouldn't this be better? There are not many options. There is also a retractable probe. But there are five wires and it is not clear where to stick them. For the source codes for the firmware are given individually and on special occasions. You can pour in the 'left'. But I haven't matured yet. nine0003

But after turning off the auto level in the panel, setting the table is another adventure. Here people write that the springs must be thrown out and the table fastened firmly and forever. But does anything happen? If the extruder pokes into the table, the spring will somehow soften the blow. In general, I set myself specific springs and printed lambs more abruptly than regular ones. Only in this way could I set the table so that the first layer would somehow come out. It is necessary to think about the sensor something and about the mechanics of the table. I don't like her. What is the best sensor to install? Wouldn't this be better? There are not many options. There is also a retractable probe. But there are five wires and it is not clear where to stick them. For the source codes for the firmware are given individually and on special occasions. You can pour in the 'left'. But I haven't matured yet. nine0003

In general, in the intermediate result I have such a printer.

Fits perfectly on the shelf above my computer. Above is a bookshelf.

Above is a bookshelf.

What do we have in the next step? Correctly! The printer is, something like prints. What does it print? Any left. And you need your own, dear. So I became preoccupied with studying the vast topic of 3DE modeling. It was generally easy for me. I didn't know shit at all in this area. Therefore, the look is not blurry and clean. Generally began to poke back and forth. Pure intuition - and trample or not trample. I tried a bunch of CADs more difficult and simpler. Tutorials on YouTube and more. The only package where I flooded - Solidworks. After the 3rd lesson, it went and went and went. I do not want to offend any software package for IMHO. Either there is or not. Of course, I understand that I will never be a professor there, but now I can draw something and it turns out exactly as I need it. And this is the main point. I still keep blender and Rhinoceros in mind. I made my first model in a couple of hours. My daughter asked me to buy an organizer, but why do I need a printer then? Posted what happened here. There is also an abstract model on the theme of the pyramid of Cheops. In general, the process has begun. And there you will see. nine0003

There is also an abstract model on the theme of the pyramid of Cheops. In general, the process has begun. And there you will see. nine0003

A little about spare parts. I took care of spare parts and purchased from Ali a few nozzles of different diameters, thermistors, heaters and other consumable small things. Let it be than to wait months for the ship.

Including bronze linear bearings. Until I change. The balls are still running and there is no backlash. I wanted to ask which ones should be changed first? Z doesn't seem to make sense at all. Dragostals will be erased most quickly. Then the X axis.

Printer ZONESTAR P802QSU - samopal.pro

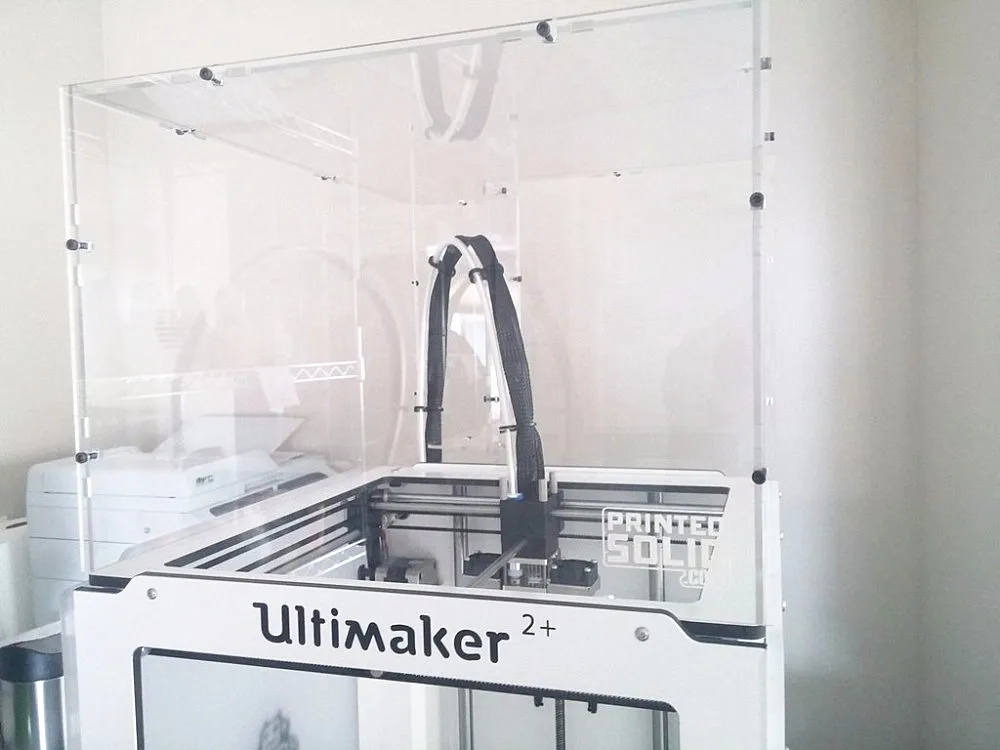

This article is an overview of the ZONESTAR P802QSU printer, a Prusa I3 clone with a steel frame. An inexpensive printer was needed to print a prototype case for various devices.

The first thought was to assemble it myself. After all, I already had experience in designing and assembling a CNC machine. But studying RepRap.org and marking some projects, as well as reading specialized forums and sites, showed the following

But studying RepRap.org and marking some projects, as well as reading specialized forums and sites, showed the following

- Savings when buying individual parts are very small (if any) than buying similar ready-made kits for assembly

- Self-assembly of your first printer can take several months

- The quality of the self-assembly printer model is a function of so many unknowns

Therefore, it was decided to buy a ready-made kit. The choice fell on the ZONESTAR P802 printer for the following reasons -

is a clone of the "folk" Prusa i3 model, well run in and out.

- A manufacturer with its own website and model range.

- Steel frame, heated table, Bowden extruder, table auto leveling function. nine0070

- In addition, the printer was sold from the Moscow warehouse.

The cost of the printer at the time of the review was $ 200 (there was a discount)

CDEK brought the printer in 5 days. The packaging is a nondescript box weighing 10 kg

Inside the box, the designer is a childhood dream. In addition to the printer itself, the kit included two rolls of PLA plastic 250g each, a plastic holder, a 512MB memory card, an assembly tool (screwdriver, hex keys, plastic tweezers, wire cutters), a set of nozzles 0.2, 0.3 and 0.4 (+ nozzle 0.4 on the hot end) , wires for cleaning nozzles of different diameters, a piece of white masking tape. nine0003

In addition to the printer itself, the kit included two rolls of PLA plastic 250g each, a plastic holder, a 512MB memory card, an assembly tool (screwdriver, hex keys, plastic tweezers, wire cutters), a set of nozzles 0.2, 0.3 and 0.4 (+ nozzle 0.4 on the hot end) , wires for cleaning nozzles of different diameters, a piece of white masking tape. nine0003

Kit specification

The frame consists of prefabricated elements of (I hope) stainless steel 1.5mm thick (table mount 2mm) with places for reinforcement with a profile bend. All steel elements are machined.

The frame elements are threaded. It assembles easily and simply. All screws included are for hex sockets, which are also included in the set

Mechanics - SC8UU linear bearings (LM8UU in Z axis), polished shafts 380mm with end threads, leadscrews (Z) - 8mm trapezoid with 2mm pitch / turn 345mm long , belts (X and Y) GT2 6mm with matching pulleys. nine0003

SL42STh50-1684A (NEMA 17) motors with 40mm length, 1. 8 degree pitch, 1.68A current, and 4kg/cm holding torque , and on the frame with the supply of plastic through a fluoroplastic flexible tube. I am glad that the mechanism is “factory”, and not printed on a printer.

The printhead with hotend was already assembled.

Steel holder, two fans, detachable design - radiator, heater and nozzle. The X limit switch and the non-contact sensor for auto-leveling are also attached here. nine0003

Aluminum table MK3 of our own production, as evidenced by the logo on the back.

Size 220×220 thickness 3mm. The heater is 12V, 140W, has a built-in NTC100 thermistor.

PLA plastic adheres perfectly to the glue stick.

Electronics:

Self-produced four-line text display + 5 control buttons and an SD card slot82 compatible with RAMS 1.4

As I already wrote, the controller is designed for 6 motors, 3 temperature sensors, three fans and two heaters, which in the future may allow the use of a double extruder.

Power supply 12V 20A with forced cooling. There is a panel with a switch and a power socket IEK 320

Plastic spool holder made of 3mm black acrylic is designed for large 1kg spools

0077 NPN type. Works well on a metal table. The inscription 8mm should also be taken through the glass.

The printer is running Repetier 0.92.9 firmware. Moreover, the assembly and configuration from ZONESTAR.

I will not describe the assembly of the printer. The manufacturer did this for me, and in such detail that I, a beginner, practically did not have to surf the Internet during assembly. On the memory card that came with the kit, there was a whole wealth:

- Specification of the kit in PDF format

- Illustrated Oven Troubleshooting Guide

- Firmware binaries of different versions for different models with instructions on how to download.

- Empty "Source" directory. I asked the seller - I immediately received the source code for firmware

- Detailed assembly instructions with illustrations in PDF

- Printer manual in PDF and two demo videos

- Instructions for leveling the table in PDF with illustrations in PDF

- PDF manual for table level sensor and video link

- Test models

- USB drivers for Windows, Linux and MAC OS

- Printer profiles for Cure and Simplify3d

All documentation in English, with explanatory files and internet links. Just a balm for the soul of an engineer!

Just a balm for the soul of an engineer!

Let's get down to business or the difficult path of a beginner

Well, the printer is assembled, all the wires are connected and even more or less tidied up with ties and braids. The table is somehow leveled and the plastic is filled.

Slowly mastering the online 3D editor tinkercad and the CURA slicer, I am trying to create something.

The first pancake was lumpy The first test cube came out crooked.

It turned out that the pulley was not tightened well along Y. We tightened it - it got better

Next came the beginner's jambs - the model does not stick to the table, the edges are raised, some threads are all around. Half of the test coil went to the marriage. The next day I bought it in the domestic BESTFILAMENT (It turns out that in Perm you can easily buy different plastic with delivery to the office, starting from Technopoint, ending with various specialized offices). And things went. To stick the plastic to the table, I used an ordinary stationery glue stick (the main purpose, as I understand it, is that the finished product can be torn off the table without damaging it). nine0003

To stick the plastic to the table, I used an ordinary stationery glue stick (the main purpose, as I understand it, is that the finished product can be torn off the table without damaging it). nine0003

The auto level sensor proved to be easy and convenient to use. The corresponding menu item is launched on the display

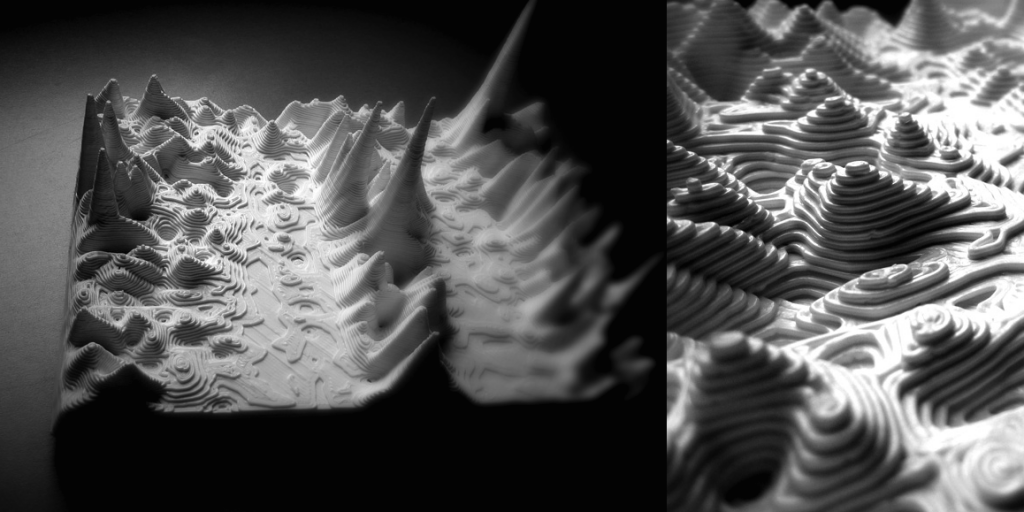

A few print results

about the first, for printing test cubes. It's scary to think how much plastic goes into these cubes. Much like evolution. I have nothing to improve so far, but cleaning for the filament can be done. nine0003

Something broken can be fixed. I lost a platform from a Chinese clone of a gorillapod. I printed a new pad and a 1/4″ screw (it’s hard to buy this in a store). True, the screw turned out to be quite fragile, but as a temporary option, while the steel screws are moving, it is quite possible to carefully use the printed ones

Printing a broken corner for an old kitchen hood. True, the model in thinkcad turned out to be “faceted” and a snot of an old plastic of a different color dripped into the plastic. It is necessary to sort out the hot end so that the plastic snot does not climb through all the cracks. nine0003

True, the model in thinkcad turned out to be “faceted” and a snot of an old plastic of a different color dripped into the plastic. It is necessary to sort out the hot end so that the plastic snot does not climb through all the cracks. nine0003

And this is an adapter from a Chinese socket to ours. It remains to solder the round legs of the euro plug directly to the Chinese flat plates. (First photo from the author's website)

Well, that's what the printer actually took on for - printing small-scale instrument cases and developing prototypes.

Case for Orange PI ZERO taken from the Internet and slightly modified by me

Most importantly, you can meditate for hours on how it prints

The main thing that I understood for myself is that there is no need to rush anywhere.