3D printing refill

REFILL | Cheap non-spool PLA & PETG 3D printing filament

REFILL | Cheap non-spool PLA & PETG 3D printing filament | FiberlogyREFILL

PRINT ECO

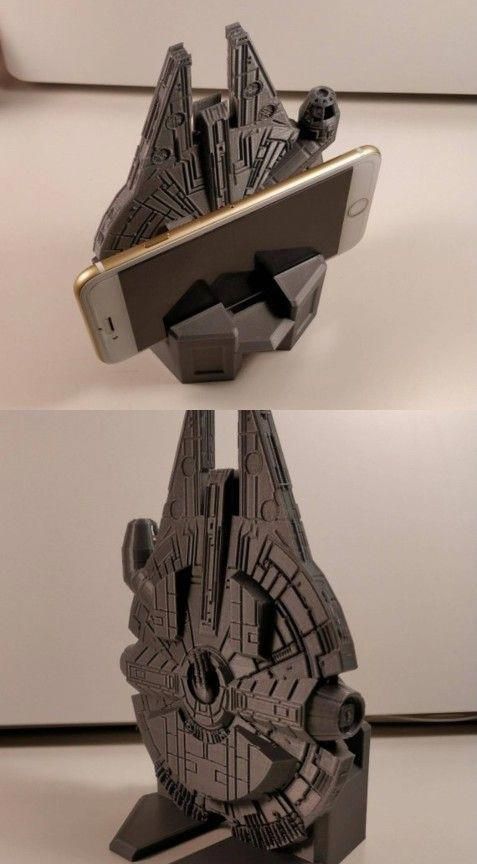

REFILL is a non-spool cartridge compatible with the reusable spool MASTERSPOOL standard, which anyone can print by themselves using the RichRap’s free and all-available project. This solution is more ecological and slightly cheaper in comparison to the filaments offered on disposable spools. Fiberlogy is one of the first few companies in the world that has decided to add the solution to its range.

APPLICATIONS:

APPLICATION:

The application is the same as in the case of filament spools. The only difference is that the refill does not have a spool. This makes it environmentally friendly and there is an extra win. Because the shipment is lighter it is also cheaper.

Masterspool to download: https://www.thingiverse.com/thing:2769823

REFILL ABS

| Diameter | Net weight | Colors |

|---|---|---|

| 1. | 0.85kg |

MSDS TDS Ask for a product

Expand the description

Find a store

Properties:

- high hardness

- high impact resistance

- resistance to high temperatures and abrasion

- can be processed mechanically and chemically

How to print?

The following parameters are only suggested print settings for this material. To ensure the best print quality, it is necessary to choose the appropriate settings for a specific printer and printing conditions.

| Nozzle Temperature | 250-265°C |

| Bed Temperature | 90-110°C |

| Closed chamber | recommended |

| Fan | 0-10% |

| Flowrate | 95-105% |

| Printing Speed | 35-60 mm/s |

| Surface | glass, kapton tape, ABS juice |

| Retraction (direct) | 2-3 mm |

| Retraction (bowden) | 4-6 mm |

| Retraction Speed | 20-45 mm/s |

| Drying conditions | 60°C / 4h |

| Diameter | Diameter tol | Oval tol | Printing temp | Table temp |

|---|---|---|---|---|

1. 75 mm 75 mm | +/- 0.02 mm | + 0.01 mm | 250-265 °C | 90-110°C |

Colors

Black

Graphite

Gray

White

REFILL EASY PET-G

| Diameter | Net weight | Colors |

|---|---|---|

| 1.75 mm | 0.85 kg |

MSDS TDS Ask for a product

Expand the description

Find a store

Properties:

- ease of printing

- high durability

- low susceptibility to shrinkage and flossing

- resistance to acids, salts, alkaline substances

- odorless

How to print?

The following parameters are only suggested print settings for this material. To ensure the best print quality, it is necessary to choose the appropriate settings for a specific printer and printing conditions.

| Nozzle Temperature | 220-250°C |

| Bed Temperature | 90°C |

| Closed chamber | not required |

| Fan | 0-25% |

| Flowrate | 95-105% |

| Printing Speed | < 100 mm/s |

| Surface | masking tape |

| Retraction (direct) | 2-3 mm |

| Retraction (bowden) | 3-5 mm |

| Retraction Speed | 20-45 mm/s |

| Drying conditions | 60°C / 4h |

| Notes | Due to the strong adhesion to the bed, it is not recommended to print directly on its surface or on glass. This can lead to damage. We recommend using a masking tape. |

| Diameter | Diameter tol | Oval tol | Printing temp | Table temp |

|---|---|---|---|---|

1. 75 mm 75 mm | +/- 0.02 mm | + 0.01 mm | 220-250°C | 90°C |

Colors

Black

Vertigo

Silver

Light Green Transparent

Burgundy Transparent

Orange Transparent

Graphite

Gray

White

Pure Transparent

REFILL EASY PLA

| Diameter | Net weight | Colors |

|---|---|---|

| 1.75 mm | 0.85 kg |

MSDS TDS Ask for a product

Expand the description

Find a store

Properties:

- biodegradability

- very good adhesion between the print layers

How to print?

The following parameters are only suggested print settings for this material. To ensure the best print quality, it is necessary to choose the appropriate settings for a specific printer and printing conditions.

| Nozzle Temperature | 200-230°C |

| Bed Temperature | 50-70°C |

| Closed chamber | not required |

| Fan | 75-100% |

| Flowrate | 90-100% |

| Printing Speed | < 100 mm/s |

| Surface | glass, masking tape |

| Retraction (direct) | 2-3 mm |

| Retraction (bowden) | 4-6 mm |

| Retraction Speed | 20-45 mm/s |

| Drying conditions | 50°C / 4h |

| Notes | Easy PLA White – due to the dye, the suggested minimum printing temperature is 230°C |

| Diameter | Diameter tol | Oval tol | Printing temp | Table temp |

|---|---|---|---|---|

1. 75 mm 75 mm | +/- 0.02 | + 0.01 | 200-230°C | 50-70°C |

Colors

Black

Vertigo

Inox

Light Green

Blue

Orange

Graphite

Gray

White

REFILL PCTG

| Diameter | Net weight | Colors |

|---|---|---|

| 1.75mm | 0.75 kg |

MSDS TDS Ask for a product

Expand the description

Find a store

Properties:

- high impact strength (up to 20 times greater than PET-G)

- high chemical resistance

- high optical transparency

- easy to print – dimensional stability and low shrinkage

- suitable for contact with food – BPA free

How to print?

The following parameters are only suggested print settings for this material.

To ensure the best print quality, it is necessary to choose the appropriate settings for a specific printer and printing conditions.

To ensure the best print quality, it is necessary to choose the appropriate settings for a specific printer and printing conditions.

| Nozzle Temperature | 250-270°C |

| Bed Temperature | 90-110°C |

| Closed chamber | not required |

| Fan | 0-25% |

| Flowrate | 90-100% |

| Printing Speed | < 100 mm/s |

| Surface | masking tape, PVA glue, hairspray |

| Retraction (direct) | 1-2 mm |

| Retraction (bowden) | 4-6 mm |

| Retraction Speed | 20-45 mm/s |

| Drying conditions | 60°C / 4h |

| Notes | Due to the strong adhesion to the bed, it is not recommended to print directly on its surface or on glass. This can lead to damage. We recommend using a masking tape. |

Fiberlogy PCTG has been positively assessed in the Open Filament Program (OFP) project run by Raise3D:

- Raise3D Pro3

| Diameter | Diameter tol | Oval tol | Printing temp | Table temp |

|---|---|---|---|---|

| 1.75mm | +/- 0.02 mm | + 0.01 mm | 250-270°C | 90-110°C |

Colors

Black

Graphite

White

Pure Transparent

REFILL R ABS

| Diameter | Net weight | Colors |

|---|---|---|

| 1.75 mm | 0.75 kg |

MSDS TDS Ask for a product

Expand the description

Find a store

Properties:

- high hardness

- high impact resistance

- resistance to high temperatures and abrasion

- can be processed mechanically and chemically

How to print?

The following parameters are only suggested print settings for this material.

To ensure the best print quality, it is necessary to choose the appropriate settings for a specific printer and printing conditions.

To ensure the best print quality, it is necessary to choose the appropriate settings for a specific printer and printing conditions.

| Nozzle Temperature | 250-265°C |

| Bed Temperature | 90-110°C |

| Closed chamber | recommended |

| Fan | 0-10% |

| Flowrate | 95-105% |

| Printing Speed | 35-60 mm/s |

| Surface | glass, kapton tape, ABS juice |

| Retraction (direct) | 2-3 mm |

| Retraction (bowden) | 4-6 mm |

| Retraction Speed | 20-45 mm/s |

| Drying conditions | 60°C / 4h |

| Diameter | Diameter tol | Oval tol | Printing temp | Table temp |

|---|---|---|---|---|

1. 75 mm 75 mm | +/- 0.02 mm | + 0.01 mm | 250-265°C | 90-110°C |

Colors

Anthracite

Find a store

Fourth dimension

of printing

Refill PLA | Filament2Print

> Filaments>SPECIAL PLA>Refill PLA

Accessories

30 other products in the same category:

-

SOFT PLA-Flexible

38,62 €

-

PLA 3D850 Natural

24,45 €

-

PLA Textura

42,29 €

-

PLA Textura™ Flare

50,16 €

-

PLA Purifier

39,25 €

-

Smartfil GLACE

38,26 €

-

PolySmooth

43,97 €

-

PLA XRS

46,35 €

-

PLA Flax

32,31 €

-

PLA EF

22,91 €

-

HR-PLA 3D870

29,69 €

-

Thermoactive PLA

16,67 €

-

PLA Iris

29,50 €

-

ZERO WARP PLA (PLA-45)

41,53 €

-

Natural PLA-90 PREMIUM

41,53 €

-

Reflect-o-Lay

39,15 €

-

Silk Gloss PLA

34,41 €

-

NonOilen

39,33 €

-

Laser Marking PLA

49,12 €

-

LW-PLA

44,21 €

-

Olive PLA

42,25 €

-

PLA Corkfill (cork)

39,29 €

-

Stonefil PLA

34,41 €

-

EasyWood PLA

34,41 €

-

EasyCork PLA

34,41 €

-

Entwined - Hemp PLA

55,63 €

-

Buzzed - Beer PLA

48,37 €

-

Wound Up - Coffee PLA

48,37 €

-

Landfillament - Waste PLA

48,37 €

-

Mussel PLA

41,59 €

Choice of plastic for the 3D pen.

ABS or PLA?

ABS or PLA? Everyone who decides to buy a 3d pen or a 3d printer must have a choice: “How to draw with a 3D pen? What plastic to choose? ABS or PLA? And although modern 3D pens work with any of them, each plastic for 3d pens has its own characteristics.

Let's try to figure out the pros and cons of each of them.

1. Let's try to consider the physical properties of 3d plastics, which can affect different moments of creativity. nine0002

2. Judging by the results in the table, we can definitely say that PLA plastic is more suitable for drawing with 3D pens, but let's look at the origin of plastics and the features of their operation.

PLA Plastic | ABS | |

| What is it made? | Vegetable base (corn, corn starch, soy) | Petroleum based |

| Prevalence | Less common, but plant-based plastics have been actively developed in recent years, and are increasingly used by manufacturers. | Most of the plastics you come across on a daily basis are ABS. |

| Smell | No smell at all, or there is a slight sweet smell slightly similar to the smell of corn. | Smell of burning plastic (we recommend working in a well ventilated area) |

| Hardness, strength | Hard, but more brittle. May break when subjected to bending force. | Rigid, impact resistant. It is also resistant to slight bending. |

| The melting temperature | 180 - 240c | 225 - 250c |

| Stability to the external environment | is exposed to moisture and sunlight and overheating during operation. In this case, overheating occurs at lower temperatures. nine0024 | Subject to moisture, sunlight, as well as to overheating during operation. At the same time, it is more resistant to chemicals. |

| Tack | High tack allows you to paint on most surfaces including glass, ceramic and metal. | Low tack but good enough for drawing on paper. |

| Appearance | Many appearance options including translucent and glow in the dark. nine0024 | Most often has a shiny glossy surface. |

| Environmental pollution | PLA is a plastic that is of vegetable origin and is biodegradable in a hostile environment. | Can be recycled like normal plastic. |

Conclusions: None of the 3d plastics has an objective advantage. Wonderful things can be created from any of them. But with a slight margin, in our opinion, PLA still wins. If you're a beginner and don't have the skill to create complex, sky-high creations, then PLA is your best bet. Although it has some limitations, it has much more possibilities. Many of its options allow you to create almost anything. Depending on the idea, you can draw with translucent and transparent 3d plastic, or take glow-in-the-dark plastic for 3d pens. And one of the important arguments is, of course, the smell. Most often, we buy a 3d pen for children, and children's health is the most important thing for us. nine0003

And one of the important arguments is, of course, the smell. Most often, we buy a 3d pen for children, and children's health is the most important thing for us. nine0003

We recommend PLA plastic. You can buy sets of plastic for 3d pens in our catalog.

.

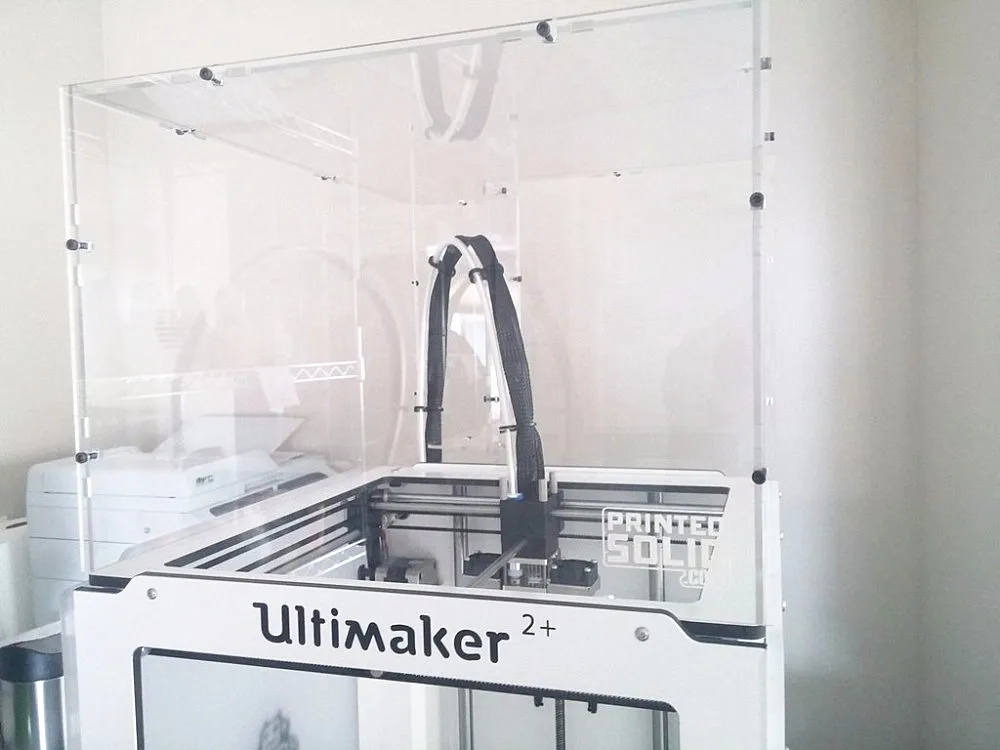

How to change, insert and extract

Modern 3D printing allows you to create objects and models of amazing complexity. However, the process requires experience and knowledge. Improper maintenance of the equipment, including changing the filament if necessary, may damage the device or result in loss of quality when printing products. In order to avoid such a problem, it is necessary to carefully study the nuances of the procedure before proceeding to change the filament. As a rule, for home 3D printing, plastic is used, which manufacturers have shaped into a filament, supplied in spools. It is about the replacement of this type of material that will be discussed in our article. nine0003

It is about the replacement of this type of material that will be discussed in our article. nine0003

How to prepare a 3D printer for plastic replacement?

Since refilling is one of the most difficult tasks in 3D printing, it deserves more attention.

A key task for a user who needs to change the bobbin filament in their 3D printer is device preparation. Printer preparation must be carried out in a strictly defined order:

- First of all, make sure that the device is connected to the computer with a USB cable. It is necessary to check how tightly the cord is inserted into the input jacks, and then check the operation of the device and its “visibility” to the system. nine0268

- Use the control panel of the 3D printer to start warming up the device to operating temperature. It is almost impossible to remove the old filament from an unheated printer without damaging the mechanism.

- After the printer is warm enough, inspect the extruder outlet for visible damage and excessive drips, and prepare the materials and tools needed to change the spool.

How to remove the plastic? nine0261

When changing the filament, most of the breakdowns occur when the remnants of the old plastic filament are removed from the working head of the extruder.

IMPORTANT! Remove filament residue only after the printer has warmed up sufficiently. Otherwise, the operating mechanism may be damaged and print quality may be noticeably reduced.

In order to remove the filament from the extruder, you will need:

- Turn on the heat of the 3D printer. nine0268

- Wait until the desired temperature has been reached. The temperature regime parameters must be set based on the characteristics of the replaced and refilled materials. For example, ABS and PLA plastics have different melting points, so replacement must be done as quickly as possible. When exposed to elevated temperatures, PLA deforms quickly and can clog the nozzle.

- Next, if the installed software supports the reverse function, you must enable this option and wait for the thread to exit from the corresponding hole.

nine0268

nine0268 - If the software does not have a reverse function, you must manually clean the channel, cutting the old thread as close as possible to the exit hole and inserting a new one.

- During the run, the plastic from the old spool will gradually come out of the extruder nozzle and the new filament will take its place.

IMPORTANT! When old material is replaced by new material during a run, it is recommended to adjust the head heating temperature based on the characteristics of the new plastic. nine0003

Replacing plastic

In order to replace the old plastic filament in the extruder with new material, you must:

- Remove the remnants of the old filament.

- Set the extruder head to maintenance mode.

- Remove the channel tube by pulling it up.

- Remove the filament rod from the extruder head by pressing down on the presser and gently pulling the plastic filament up.

- Thread the end of the plastic filament from the new spool by releasing the clamping mechanism and gently pressing on the end of the rod. nine0268

- When new filament is threaded into the feeder, the channel tube must be returned to the extruder.

- The final stage is the drawing of the filament. It is recommended to eject 30 to 50 units of material by warming up the printer to the required temperature and immediately removing the ejected material. You can perform this action from the control panel by selecting a command.

- The signal that the replacement of the plastic filament in the 3D printer was successful will be the uniformity of the material emitted and the absence of streaks in the process. nine0268

Resuming work

In order to resume work after changing the filament spool, the 3D printer must be returned to its original position. To do this, you will need to reuse the RepetierHost control panel section and the Home command.