Ultimaker 3d printers

Powerful, easy-to-use 3D printing software

Trusted by millions of users, Ultimaker Cura is the world’s most popular 3D printing software. Prepare prints with a few clicks, integrate with CAD software for an easier workflow, or dive into custom settings for in-depth control.

Slicing features

At the heart of Ultimaker Cura is its powerful, open-source slicing engine, built through years of expert in-house development and user contributions.

Intent profiles print specific applications at the click of a button

Recommended profiles tested for thousands of hours ensure reliable results

‘Custom mode’ gives over 400 settings for granular control

Regular updates constantly improve features and printing experience

Integrated workflow

If you own a 3D printer, software matters. Get the most from your printer with software designed to suit your workflow.

Seamless integration with all Ultimaker products

CAD plugin integration with SolidWorks, Siemens NX, Autodesk Inventor, and more

Compatible file types: STL, OBJ, X3D, 3MF, BMP, GIF, JPG, PNG

Easy to use

Manufacturing doesn’t need to be complicated. We design our software so anyone can use it – both experienced or rookie 3D printer users.

Prepare your 3D model for print in minutes with recommended settings

Simply choose speed and quality settings, and you can start printing

Ultimaker Cura is free and open source software

Ultimaker Marketplace

Being open and collaborating is in our DNA. Now we bring this to the professional 3D printing market with the Ultimaker Marketplace.

Download material profiles from leading brands for your application

Avoid manual setup when using third-party materials

Download useful plugins to customize the print preparation experience, star-rated by our community

An Ultimaker Cura experience that keeps your infrastructure rock-solid

Ultimaker Cura Enterprise delivers stability and security with features that are tailor-made for businesses.

Utimaker Cura Enterprise can be deployed, configured, and managed with cross-platform systems distribution

Ultimaker Cura Enterprise receives two updates a year.

These are thoroughly tested by our community and ensure the most stable desktop application. We support updates for 12 months after release (including security patches and bug fixes)

These are thoroughly tested by our community and ensure the most stable desktop application. We support updates for 12 months after release (including security patches and bug fixes)Each release of Ultimaker Cura Enterprise is independently scanned, tested, and analyzed for vulnerabilities. We publish a summary of that report and we commit to continuously improving security

Backup & sync your materials & plugins

Save projects to the Digital Library

Access 3D printing e-learning courses

Join a community of 40,000+ active users

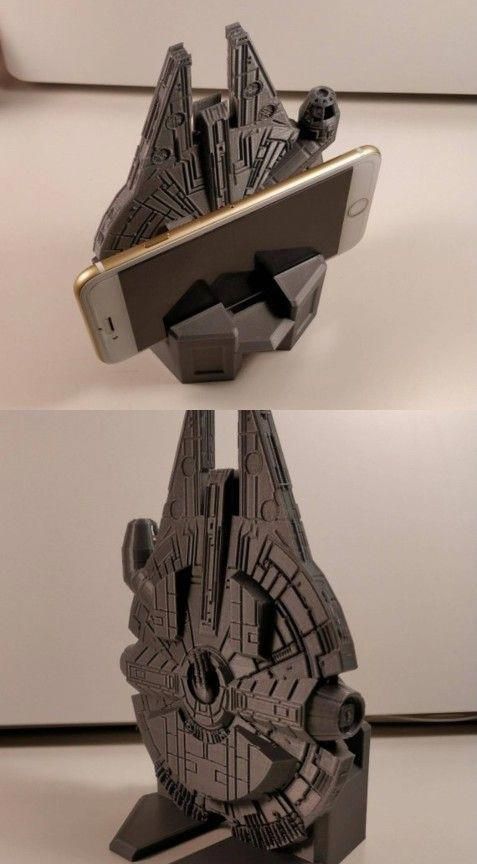

3D printers that simply work

Our award-winning 3D printers are robust, reliable, and easy to use. They deliver quality parts time and again. Designed and tested to run 24/7, they allow you to achieve the results you need more quickly and easily.

Learn about our 3D printers

Software ready for Industry 4.0

Trusted by millions of users across 14 languages, Ultimaker Cura slices your model and integrates with any workflow through Marketplace plugins. Then scale production and digital distribution with Ultimaker Digital Factory.

Then scale production and digital distribution with Ultimaker Digital Factory.

Material choice like never before

Ultimaker offers the widest material choice on the market. Through our Material Alliance, choose the perfect filament for your application – from advanced polymers to carbon fiber composites.

Learn about our materials

Support dedicated to your success

Wherever you are in the world, Ultimaker support is close by. Our global network of service partners offer professional installation, training, and maintenance in your language and time zone.

Learn about our support

Ultimaker 2+ Review 2022 - Why This 3D Printer Is So Good

4.5

See Price

Today, we take a look at the Ultimaker 2+. Stylish and expensive, does it warrant its price tag and does it merit the accolades garnered from the press?

| Printing Area | 223x223x205mm |

| Printing Speed | 8, 16, 23, and 24 mm³/s |

| Supported Filament | PLA, ABS, CPE, CPE+, PC, Nylon, TPU 95A, and PP |

| Filament Diameter | 2. 85mm 85mm |

| Extruders | 1 |

| Extruders Diameter | 0.25mm, 0.4mm, 0.6 mm, 0.8 mm |

Table of ContentsShow

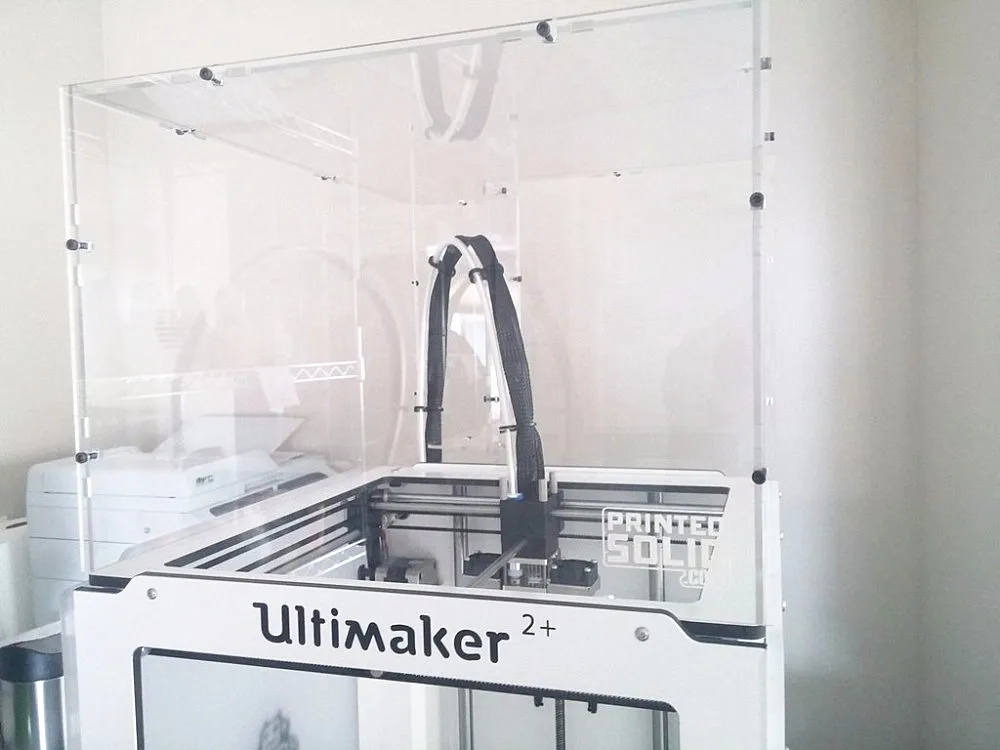

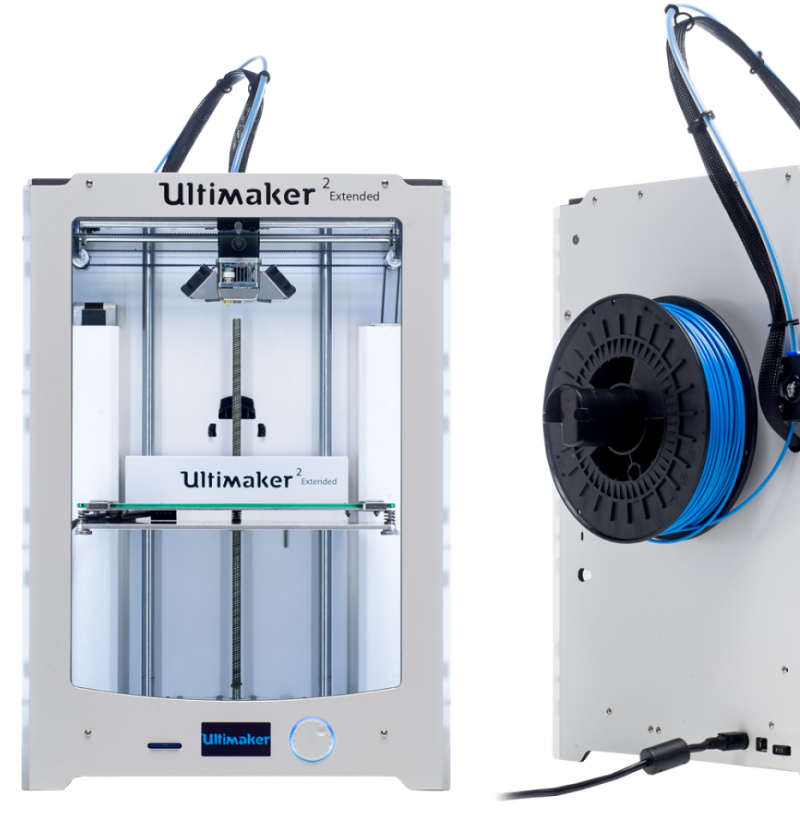

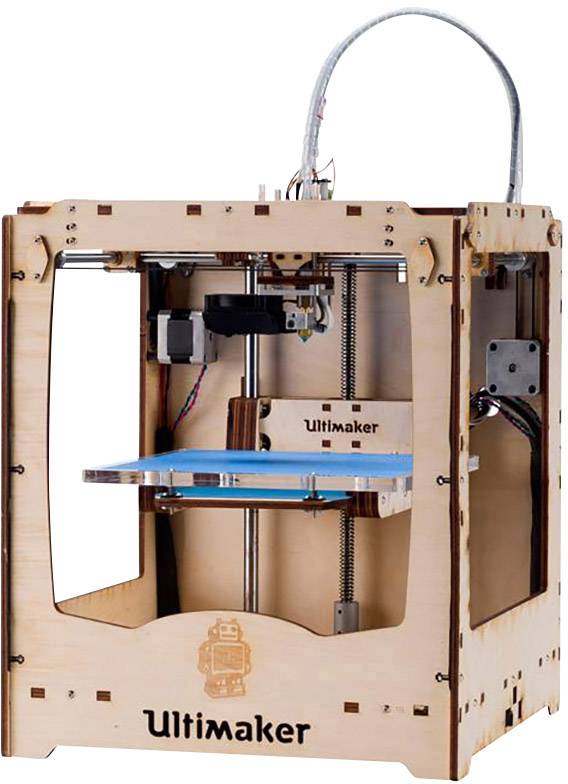

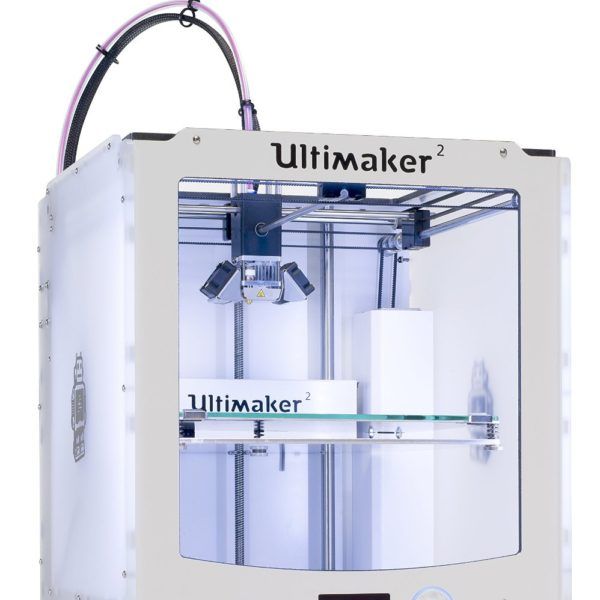

Design

The Ultimaker 2+ is a tweaked version of the seminal Ultimaker 2. The upgrades aren’t so much in the design of the machine – on the surface level, it looks identical to its predecessor – but instead in under the hood quality of life improvements.

The 3D printer is still very much geared towards a user-friendly experience where efficiency and all-around performance are paramount.

The Ultimaker 2+ features a cube semi-enclosed casing that offers a print area of 223x223x205mm, a generous amount of build volume by anyone’s estimation and ample space for the majority of projects. The cube design is made of acrylic supported by a metal frame, all hidden under sleek white plates embellished by a set of classy string LED lights.

The semi-open structure with an open front and top is more enclosed than other all-in-one solutions such as the 3D Systems Cube, adding an extra layer of security suited to younger users making use of the printer in an educational context.

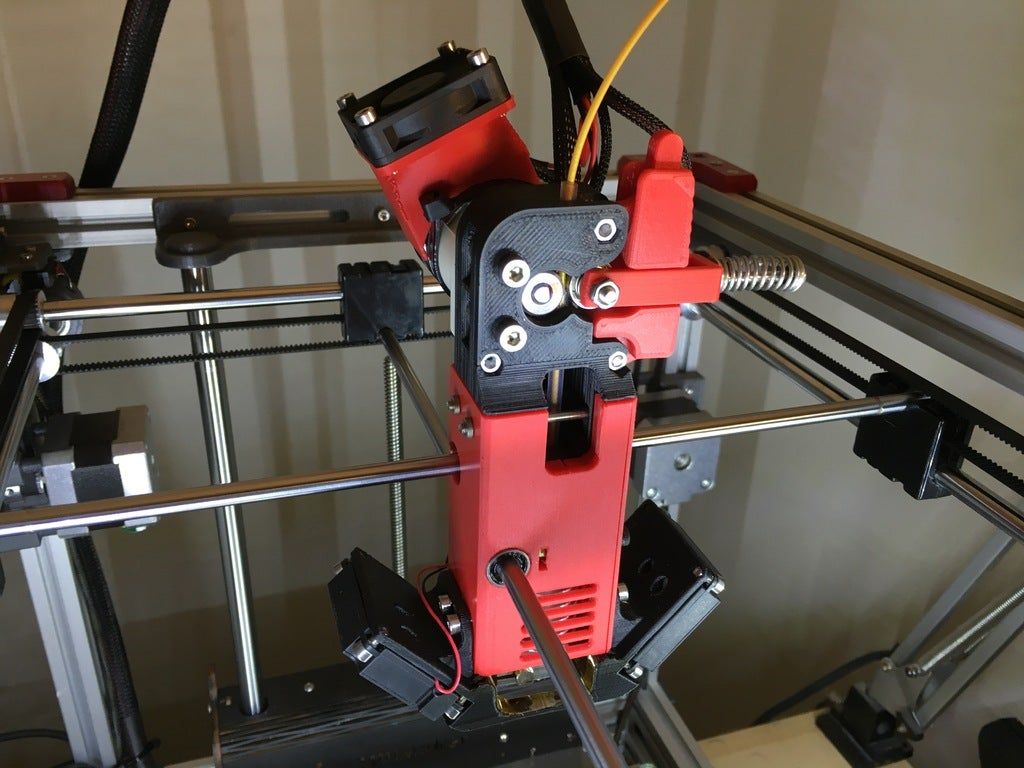

The device relies on a single extruder to control the X and Y axes, while the glass heated print bed ensures movement on the Z axis, both of which move on a motorized carriage setup. The extruder has been rejigged for the 2+ with a brand new cooling system with side-positioned fan caps that channel air just under the nozzle and in a uniform pattern from both sides for vastly improved temperature control.

The Ultimaker 2+ offers an impressive range of resolutions from 20 microns all the way to a sizeable 600 microns, which it sets it apart as one of the most accurate fused deposition modeling printers on the market.

One of the biggest gripes with the original Ultimaker 2 was issues with how the feeder snaked filament from the spool to the extruder, which often mangled the material to the point that the feeder struggled to find sufficient purchase and funnel the filament thread all the way to the extruder.

On the Ultimaker 2+, a geared feeder sentences the mangling problem to the past through better pressure control for the feeder teeth as it eases the filament towards the extruders. Incidentally, the upgrade also includes a more straightforward filament swapping procedure, which now only necessitates gently feeding the end of a fresh batch of the material through the entry point of the spool.

Incidentally, the upgrade also includes a more straightforward filament swapping procedure, which now only necessitates gently feeding the end of a fresh batch of the material through the entry point of the spool.

The Ultimaker 2+ supports PLA, ABS, CPE, CPE+, PC, Nylon, TPU 95A, and PP materials. Unlike numerous competitors that claim to offer such material versatility, the Ultimaker 2+ genuinely supports all these materials for serious versatility. The printer supports 2.85mm filament and an open system meaning third-party materials work beautifully. The unit also includes onscreen instructions explaining how to load in a separate kind of filament from removing it from the extruder (done more or less automatically by the machine) all the way to installing the new material spool.

Among the best features of the Ultimaker 2+ is the Olsson Block Kit. A set of four different extruder nozzle diameters ranging from 0.25, 0.4, 0.6, and 0.8mm, the kit allows you to interchange nozzles easily thanks to a provided hex tool and screwdriver. The process is simple and involves heating the extruder to remove any filament, then using the hex to remove and replace the nozzle. The variety means you can change between high detail prints and more substantial, less precise creations seamlessly.

The process is simple and involves heating the extruder to remove any filament, then using the hex to remove and replace the nozzle. The variety means you can change between high detail prints and more substantial, less precise creations seamlessly.

The menu system is a small display screen located at the bottom of the front panel navigated via a click wheel. The controls are intuitive and straightforward, providing useful instructions as well.

Adjacent to this is the SD card slot, the only connectivity option for the Ultimaker 2+, one of the very few issues we have for this model. There’s no direct PC to printer option through Wi-Fi for example, which may irk some users. We found it less of an inconvenience than we expected, and there’s a certain reassurance in not having to worry about a USB cable.

Ultimaker does ship its free proprietary print slicing and preparation software called Ultimaker Cura with the device, which supports macOS, Windows, and Linux as well as a host of file types (STL, OBJ, X3D, 3MF, BMP, GIF, JPG, PNG). The software isn’t as advanced or options-oriented as other open source equivalents, but we found it versatile enough for most prints. Cura did an excellent job of converting 3D models into the required .gcode file.

The software isn’t as advanced or options-oriented as other open source equivalents, but we found it versatile enough for most prints. Cura did an excellent job of converting 3D models into the required .gcode file.

On the back of the printer is a USB port used only for firmware updates, not to be confused as a link between PC and printer for printing purposes.

Printing

Using the Ultimaker 2+ is among the most satisfying, easy, and results driven printing experiences on the market today. The quality of the prints, regardless of size or complexity, is high with few errors or inconsistencies. As with any printer, prolonged use leads to the occasional problem, but nothing that jeopardized a whole project or resulted in a web of filament destined for the trash can.

The different nozzle diameters work equally well. The same goes for the mixed layer resolutions from finely detailed prints to more slapdash tests. The speed of the printing is also worth noting, and the 30 to 300 mm per second print head travel speed is nothing short of remarkable if we consider the level of quality. It may not rival the speed of other high tier printers but is more than respectable.

It may not rival the speed of other high tier printers but is more than respectable.

We were baffled by the simplicity of the process from switching on the machine, inserting the SD card, choosing a print, and letting the Ultimaker 2+ do its thing.

Compared to the Ultimaker 2 and even other similarly priced models, the Ultimaker 2+ is an unbelievably quiet 3D printer. It makes a reasonable racket, but it’s bearable, and we found that being in the same room for prolonged stints during a print was more than okay.

Overall, the botched jobs we encountered are too few to rate the printer quality as anything short of exceptional.

Assembly

The Ultimaker 2+ arrives pre-assembled and is well packaged. The box includes a quick start guide, marketing documentation, one spool of PLA filament, a spool holding attachment, the printer, 4GB SD card, PSU, power cord, grease, Olsson Block Kit, calibration card, glue, sample print, lube, USB cable, and tools.

The quick start guide is clear and concise, making it possible to have the machine set up within 20 minutes or less.

The setup involves removing the protective packaging and snapping the protective ties holding down the axes before installing and securing the glass build plate via metal clamps and attaching the filament cartridge to the back of the device.

Although the Ultimaker 2+ doesn’t include bed auto-calibration, it does feature an assisted bed leveling system for manual calibration. The user levels the bed manually by moving the extruder to three points at 1mm distance (measured thanks to the calibration card) from the plate by adjusting the corner dial screws but gets a healthy dose of assistance from the Ultimaker 2+.

The process centers on ease of use and the on-screen instructions are clear and concise. You’d be hard pressed to find a manual calibration system that is as easy to use as the one seen on this machine.

Under normal circumstances, a seasoned maker is best equipped to perform a manual calibration, but in the case of the Ultimaker 2+, a novice is more than capable of doing so successfully without assistance.

From here, feed the filament into the feeder when prompted and then start the first test print. Feeding the filament requires finesse and not feeding it too far into the feeder. Push too far, and the feeder is likely to jam, but feeding it gently until it’s gripped then letting the machine do the rest completely negates any jamming issues.

Support

Ultimaker offers a comprehensive 12-month warranty that covers defects in material, design, and workmanship. From what we understand, Ultimaker stands by the quality of their product and are quick to offer repairs and replacements in the case of issues. Specific vendors may provide additional refund/exchange options.

Ultimaker also offers lifetime expert support through a rich archive of troubleshooting guides, articles, tips and tricks, print ideas, forums, and manuals, as well as a dedicated email, live chat, and telephone support team. The company’s support services are renowned for the quality of their work.

Verdict

Dutch manufacturer Ultimaker markets the Ultimaker 2+ as a workhouse device, and we’d be hard-pressed to disagree. It’s reliable, versatile, and produces quality prints day in, day out. It does come at an expensive price ($2500 range) and isn’t for the entry-level buyer, but then again quality always comes at a price.

It’s reliable, versatile, and produces quality prints day in, day out. It does come at an expensive price ($2500 range) and isn’t for the entry-level buyer, but then again quality always comes at a price.

The only real negatives are the standalone SD card connectivity, the sometimes delicate filament feeding procedure, and the manual calibration, albeit an assisted one. We must note that for most other models these would be a minor inconvenience, that’s how good the Ultimaker 2+ is.

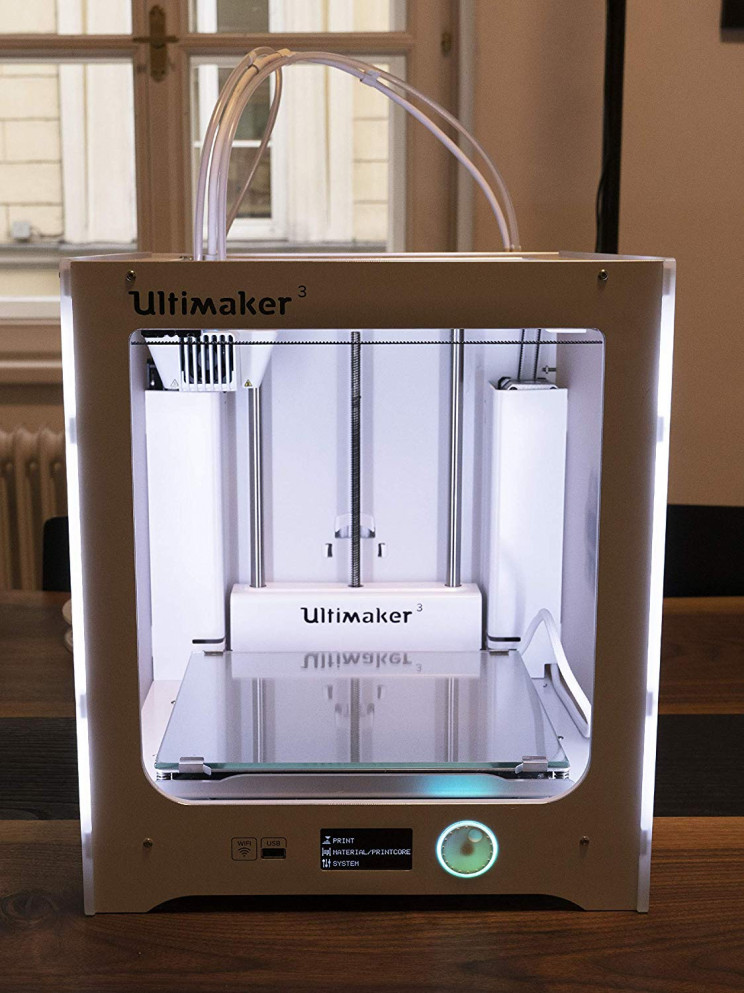

Ultimaker 3 | 3d printers Ultimaker

Professional and reliable 3D printing becomes available! The ability to flexibly select pre-installed hardware and software settings will certainly allow you to achieve better results.

Order

From € 1,195.00 excl. VAT

THREE IS

THE MAGIC NUMBER

There is a kind of 3D alchemy that comes from combining our software, materials and printer. Together, they create one of the most satisfying and seamless 3D prints ever. It really is a kind of magic...

Together, they create one of the most satisfying and seamless 3D prints ever. It really is a kind of magic...

Smart extruder system

"AA" print cartridge for PLA, ABS, Nylon, CPE, etc., and "BB" for PVA. nine0003

Superior quality materials

Ultimaker's latest CPA and PVA filaments provide superior print quality.

Monitor the progress of the print.

Thanks to the built-in camera, now you can control the progress of 3D printing - remotely.

The fastest,

most accurate

The printhead is so light it can print at extreme speeds while maintaining superb print resolution of 20 microns. And the heated platform will allow you to use different types of materials for printing.

And the heated platform will allow you to use different types of materials for printing.

>

Everybody Smaller nine0002 >Basic Characteristics

- Layer thickness

- up to 20 micron

- Speed

- 30 mm/s - 300 mm/s

- Nozzle temperature

- 180° - 280° C

- Nozzle/filament diameter

- 0.

4mm/2.85mm

4mm/2.85mm - File transfer nine0053 via WiFi, USB and Ethernet

- Print Technology

- FDM

all Features

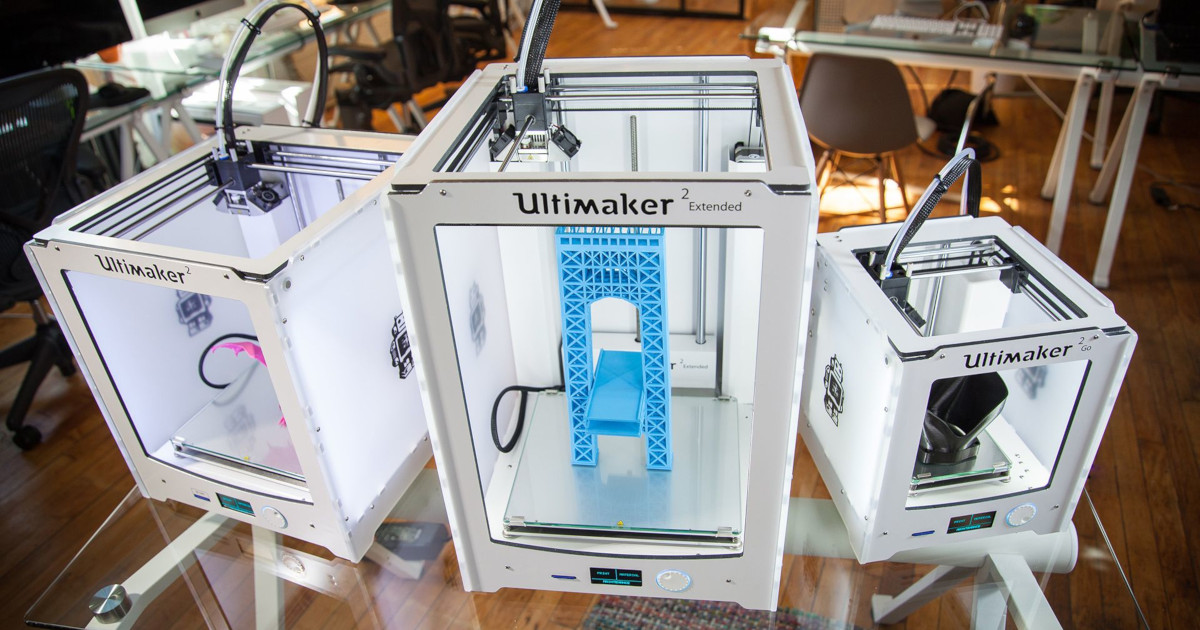

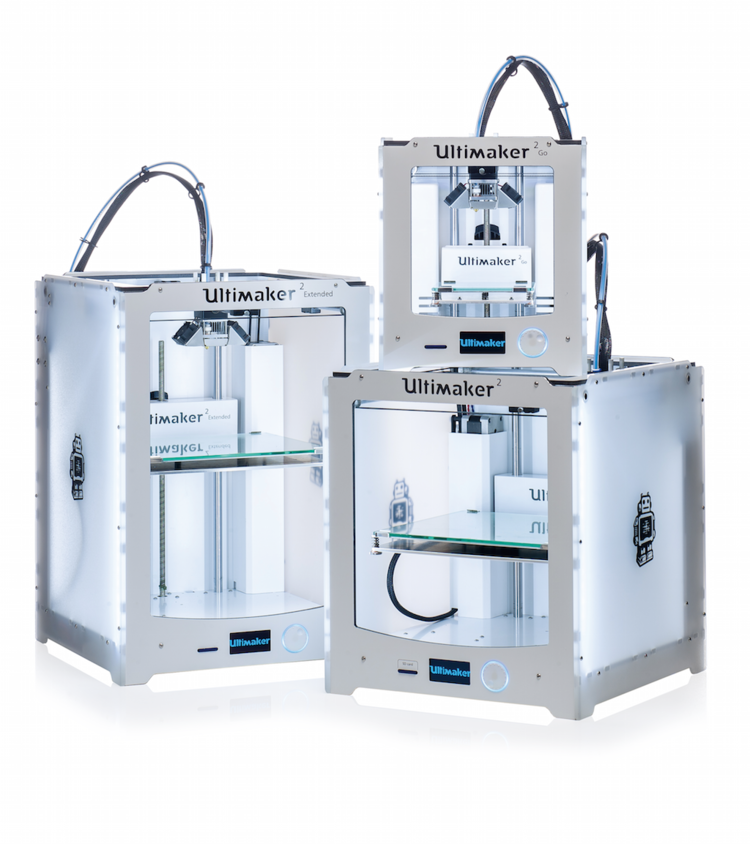

Ultimaker 3

Maximum print size 215 x 215 x 200 mm

Printer dimensions 357 x 342 x 388 mm

Printing surface Glass

Print material ABS, PLA, Nylon, PVA, etc.

What's included? Ultimaker 3 3D printer, 2 x 350g plastic spools, setup instructions, calibration card, NFC spool holder, etc.

Created through an open source collaboration, this is one of the best 3D printers out there. nine0003

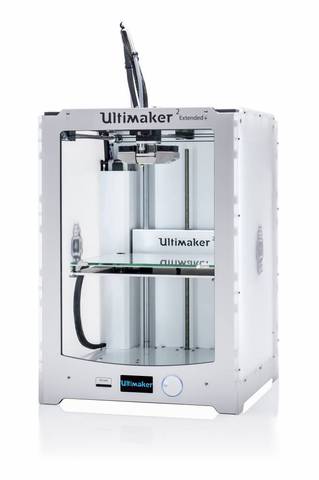

Ultimaker 3 Extended

Maximum print size 215 x 215 x 315 mm

Printer dimensions 357x342x? mm

Printing surface Glass

Print material ABS, PLA, Nylon, PVA, etc.

What's included? Ultimaker 3 Extended 3D printer, 2 x 350g plastic spools, setup instructions, calibration card, NFC spool holder, etc. nine0007 Created through an open source collaboration, this is one of the best 3D printers out there.

Ultimaker 3

Flexible hardware and software presets and 2 extruders will definitely get you the best results. 333 000 rub.

Ultimaker 3 Extended

Larger version of the Ultimaker 3 Extended 3D printer allows you to print objects up to 315mm in height. nine0047 410 000 rub.

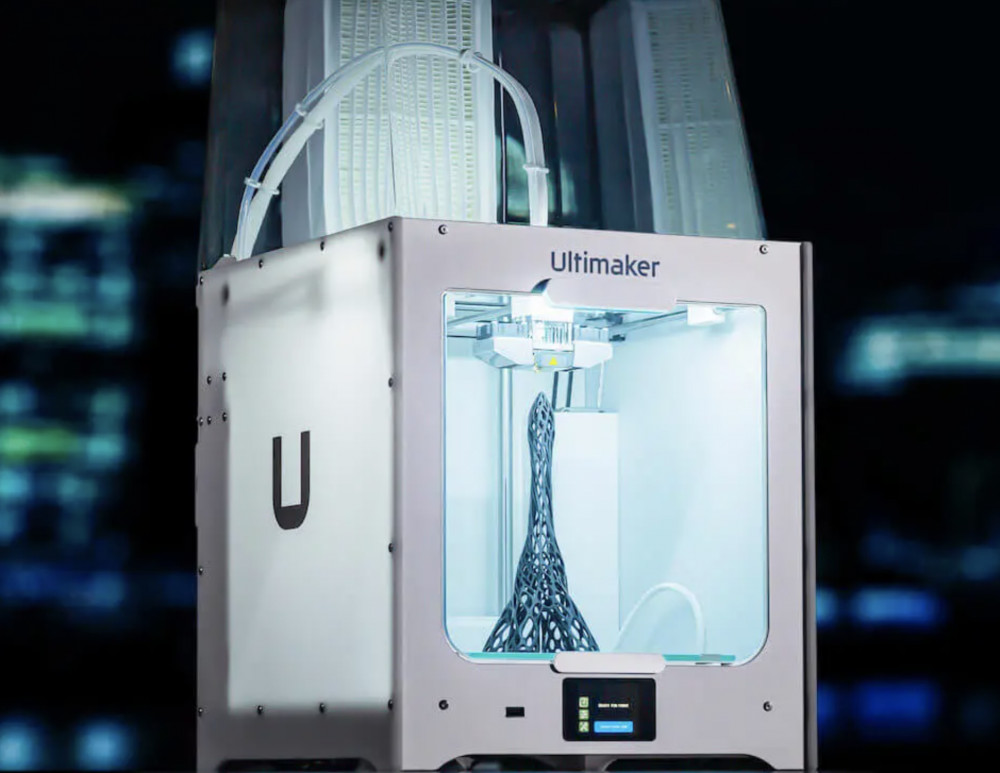

3D printer Ultimaker S5

Volkswagen Autoeuropa saved over €250,000 in 2017 with additive manufacturing. In the photo above, a detail for protecting the wheel. Previously made for €800, on the Ultimaker S5, the cost was €21. Development time decreased from 56 to 10 days.

Before: hand assembled, using plaster, model cost €15, assembly time 3-5 hours. nine0007 After: Ultimaker 3D printers, model cost €0.50, print time 2-4 hours, automated process.

Print Quality

TheUltimaker S5 is an FDM 3D printer capable of printing layers with a minimum thickness of 20 microns. This print quality results in smooth prints.

The Ultimaker S5 has three nozzles: 0.8, 0.4 and 0.25mm for fast printing and fine detail.

Shafts with linear bearings are used as guides, plastic is fed through a Bowden extruder. Thanks to this, the printer prints quickly. nine0003

Dual extrusion system allows printing with both two colors and two materials. Print materials such as nylon, CPE or PLA along with water-soluble PVA backing and realize complex geometries with ease.

Consumables

TheUltimaker S5 is optimized for ABS, PLA, Tough PLA, Nylon, CPE varieties, PVA, PC, TPU 95A, PP, Breakaway and more.

For PLA printing, a fan is installed on the extruder. Cools the model during printing, reduces the deformation of the printed model. nine0003

Unlike many FDM printers, the Ultimaker S5 prints ABS stably, because it has a heated bed, the case is closed.

The

Ultimaker S5 prints materials with a diameter of 2.85 mm. Coils "open type", non-chip cartridges. Experiment with plastics from other manufacturers, because you are not tied to Ultimaker consumables.

Print area:

nine0002 Printer print area 330 x 240 x 300 mm. Left or right nozzle alignment, or dual extrusion.

Management:

Control printing via the touch screen.

The thread flow sensor will detect if the material has run out and alert you.

You can start printing via Wi-Fi, LAN Ethernet, or a USB flash drive. Follow the print with the built-in camera.

The

Ultimaker Cura prepares your model for printing.

Design - Preparation - Print.

There are both basic settings for beginners and advanced ones for professionals.

The program accepts models in STL, OBJ, X3D and 3MF formats, supported by Windows, MacOS and Linux.

Contents:

- 750g Ultimaker Tough PLA Spool

- Ultimaker PVA Coil 750g

- Two replacement print modules 0.4 AA

- One replacement print module 0.4 BB

- Glass worktop

- Aluminum worktop

- Network cable

- USB stick, glue, hex screwdriver, oil and grease

- Calibration card and XY calibration sheets

Appearance:

The printer is made in a minimalist style, with glass doors.![]()