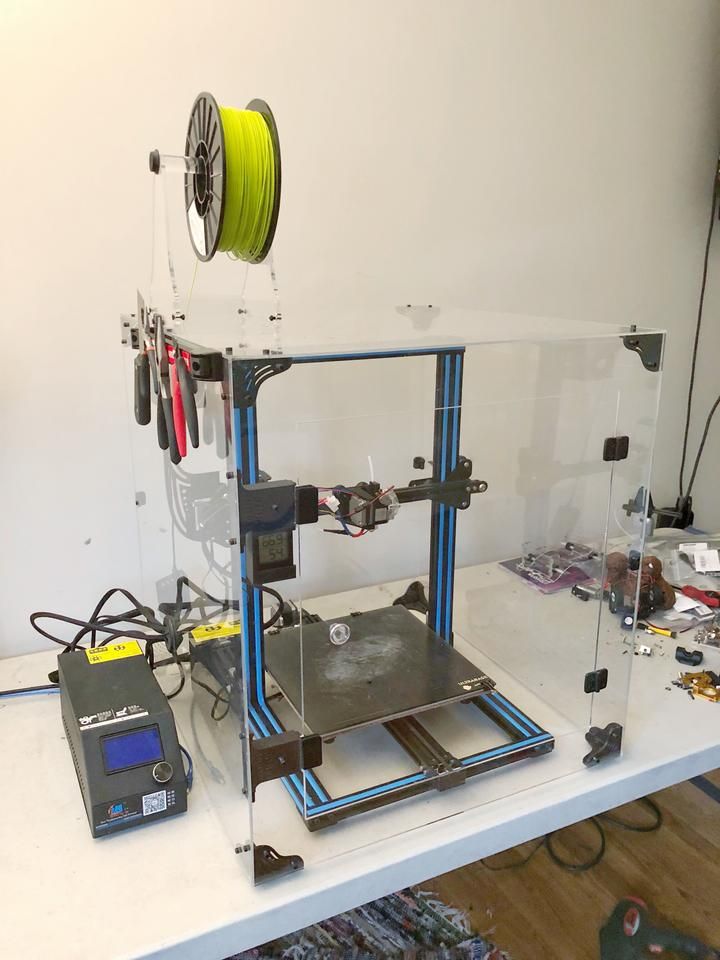

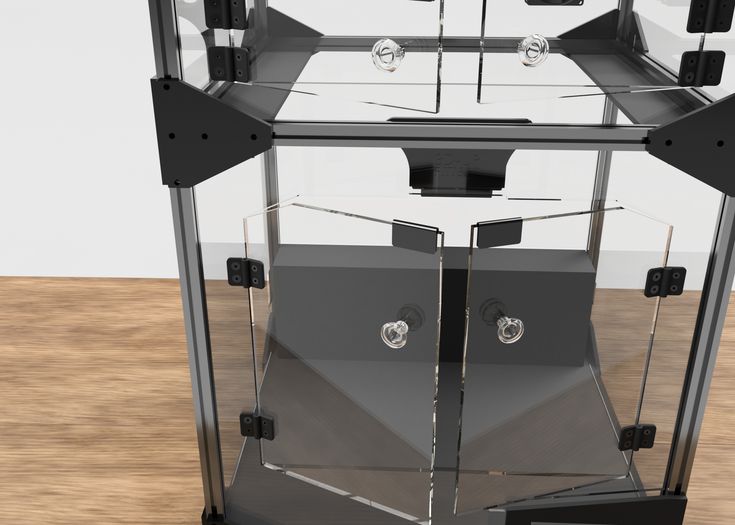

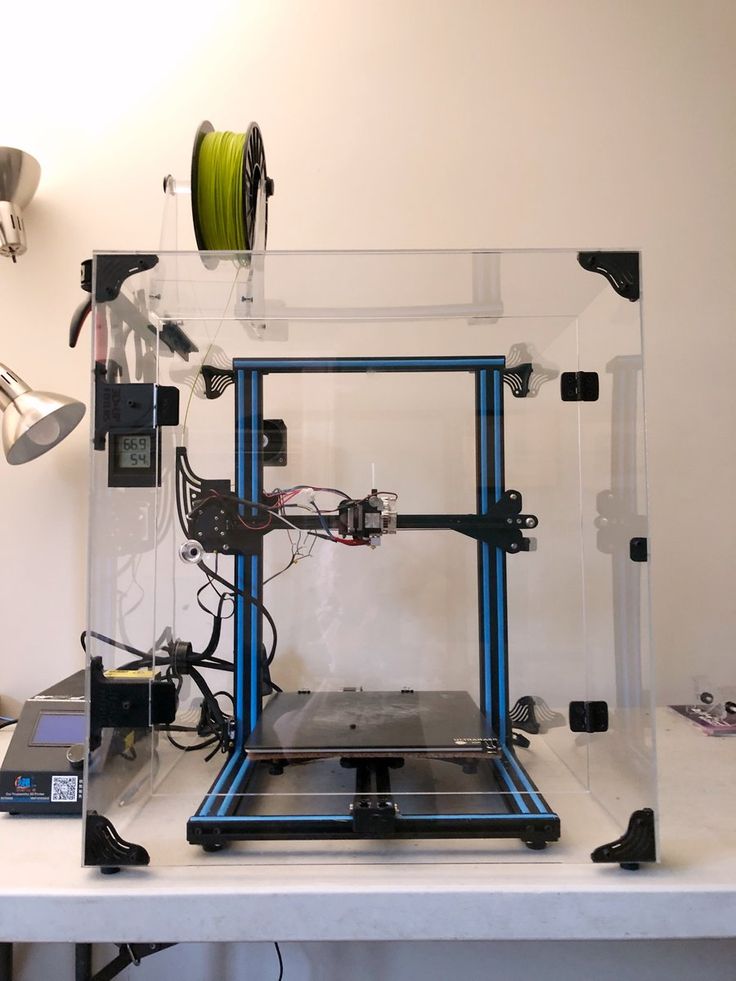

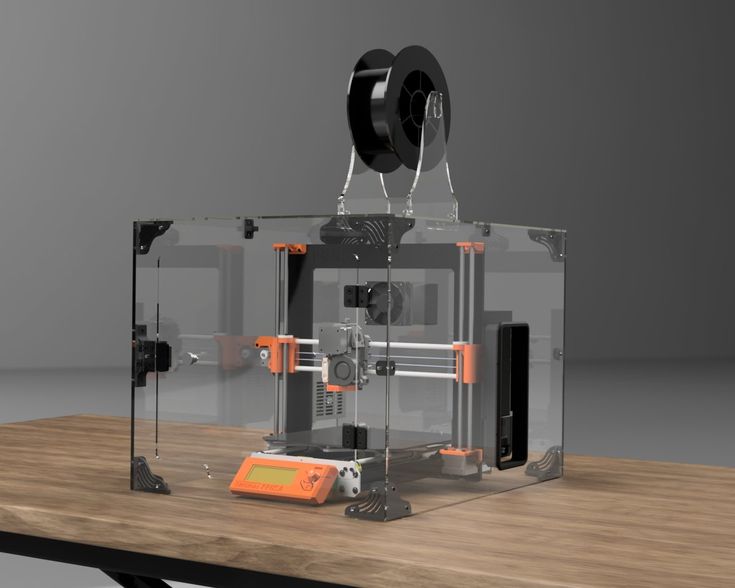

3D printer acrylic enclosure

Creality Ender 3/PRO 3D printer Enclosure

More photos (16)

PreviousNext

Do you have a question?

--

Quick Contact

Add to favourite products Add to compare list

Do you have a question?

--

Quick Contact

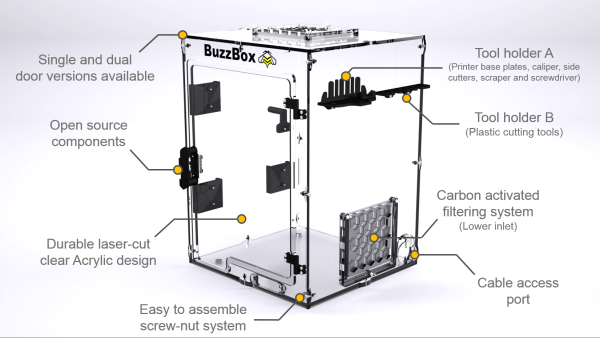

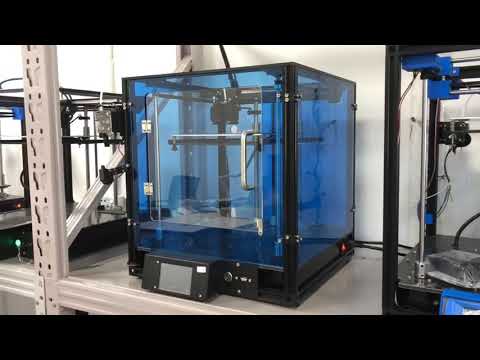

TS Acrylic - Creality Ender 3 / Ender 3 PRO Enclosure

This enclosure was primarily designed for use with Creality Ender 3 / Ender 3 PRO, but other similar size 3D printers also fit great. Please, check your printer dimensions and internal dimensions of our enclosure below before making your purchase.

Why should you want to have an Enclosure for your 3D printer?

- significant reduction in fumes and unpleasant smells

- controlled ambient temperature improves reliability and consistency of your 3D printing

- additional noise reduction

- dust protection for your printer and improved 3D printing safety

Why buy from Us?

- You are making your purchase direct from manufacturer.

We are based in the Czech Republic.

- We obtain all our materials at large quantities and volume discount. This way we can offer our TS acrylic enclosures at prices comparable to cost of raw material for DIY enclosure projects.

- C02 laser cutting technology leaves the edges of acrylic parts clear and polished.

- 4 mm thick clear acrylic sheets are used to ensure excellent strength and stability.

- We only use high-quality materials and components from renowned European manufacturers and suppliers.

- All included PETG parts can be also downloaded for free as STEP and STL files, so you could print these in a different color or modify.

Main features:

- The front door with two magnets allows for both left hand or right hand installation.

- You can enjoy completely unobstructed view of your 3D printing thanks to high quality clear acrylic sheets used.

- Honeycomb ventilation inlet holes for PSU and PSU cable inlet are placed on the right side of enclosure.

- On the left side you will find USB cable inlet, filament slot and a cut out for optonal installation of any regular 60 mm PC or USB fan.

- The package also includes a practical bearing based filament holder, which can hold spools of any width and can be placed anywhere on top of enclosure.

- Honeycomb ventilation inlet holes and cut out for 60 mm optional fan can be closed by attaching provided 2 mm clear acrylic covers.

- The enclosure is provided as a flat-pack kit with all clear acrylic parts, nuts, bolts, high quality injection-molded door hinges, ball bearings for the filament holder, black PETG printed parts and tools. You may download detailed assembly instructions in pdf format here.

Weight and dimensions:

External dimensions without filament spool holder: (W x H x D): 48,5 × 48,8 × 58,5 cm

Internal dimensions: (W x H x D): 47,7 × 48,4 × 55,4 cm

Net weight: 6,2 kg

Gross weight: 7,9 kg

Included:

- 4 mm thick clear extruded acrylic (XT) parts

- 2 mm clear extruded acrylic (XT) covers for honeycomb ventilation inlet holes and 60 mm ventilator cut out

- black PETG plastic parts

- ball bearing based acrylic filament spool holder for 1 kg filament spools

- all fasteners (bolts, nuts, injection molded hinges etc.

)

) - complete set of assembly tools (except for 7mm / 8mm wrench)

- illustrated, step by step assembly instructions (download in pdf format here)

Not included:

- optional 60 mm fan (you can use any standard 60 mm 12V PC or 5V USB fan)

- 3D printer

- 3D printing filament

TS Acrylic for Creality Ender 3 / PRO - Assembly Instructions (pdf, 3.2 MB)

TS Acrylic printable PETG parts - STEP and STL files (zip, 159.2 kB)

Share Tweet Pin It

TUKKARI - 3D Printer Enclosures

Recommended (8)Recommended 8

Bestseller Quick Info

Manufacturing Time: 3 Weeks

US $ 231 excl. VAT

Add to Cart

Bestseller Quick Info

Manufacturing Time: 3 Weeks

US $ 272 excl. VAT

VAT

Add to Cart

Discount Shipping Bestseller Quick Info

Manufacturing Time: 3 Weeks

US $ 228 excl. VAT

Add to Cart

Discount Shipping Bestseller Quick Info

Manufacturing Time: 2 Weeks

US $ 152 excl. VAT

Add to Cart

Discount Shipping Bestseller Quick Info

Manufacturing Time: 2 Weeks

US $ 158 excl. VAT

Add to Cart

Bestseller Quick Info

Manufacturing Time: 3 Weeks

US $ 245 excl. VAT

Add to Cart

Quick Info

Manufacturing Time: 3 Weeks

US $ 245 excl. VAT

VAT

Add to Cart

Quick Info

Manufacturing Time: 3 Weeks

US $ 245 excl. VAT

Add to Cart

PreviousNext

New releases (4)New releases 4

Discount Shipping New Quick Info

Manufacturing Time: 2 Weeks

US $ 184 excl. VAT

Add to Cart

Discount Shipping New Quick Info

Manufacturing Time: 2 Weeks

US $ 179 excl. VAT

Add to Cart

Discount Shipping New Quick Info

Manufacturing Time: 2 Weeks

US $ 179 excl. VAT

VAT

Add to Cart

Discount Shipping New Quick Info

Manufacturing Time: 2 Weeks

US $ 173 excl. VAT

Add to Cart

PreviousNext

In our online shop you will only find manufactured goods of our own production. We are equipped with large format CNC centers, automatic bending machine and CO2 laser for advanced material processing.

Despite higher prices of quality acrylic sheets and other materials used, we are able to offer all our products at decents prices as we sell and ship direct without using resellers or distributors.

We put quality first and use only high-quality materials and components from renowned European manufacturers and suppliers.

Our products are not made to particular order. We strive to always keep most of items in stock and available for your instant purchase.

We strive to always keep most of items in stock and available for your instant purchase.

Welcome! In our online shop you will find selection of quality enclosure kits for your favorite 3D printers. We are manufacturer based in the Czech Republic and currently deliver direct to all EU countries, United Kingdom, Switzerland, USA, Canada, Australia and many other countries around the world.

Our products have been highly rated by our customers for its functionality, original design, decent price and even those little things suchlike detailed printed manuals or a bit of overkill on packaging ensuring your enclosure kit will reach your home or company safely. We only use high quality materials and components from renowned European manufacturers and suppliers.

Our 3D printer enclosures are made of thick clear acrylic, often combined with other materials such as melamine faced panels of different colors. They are bulky, rigid and designed to last.

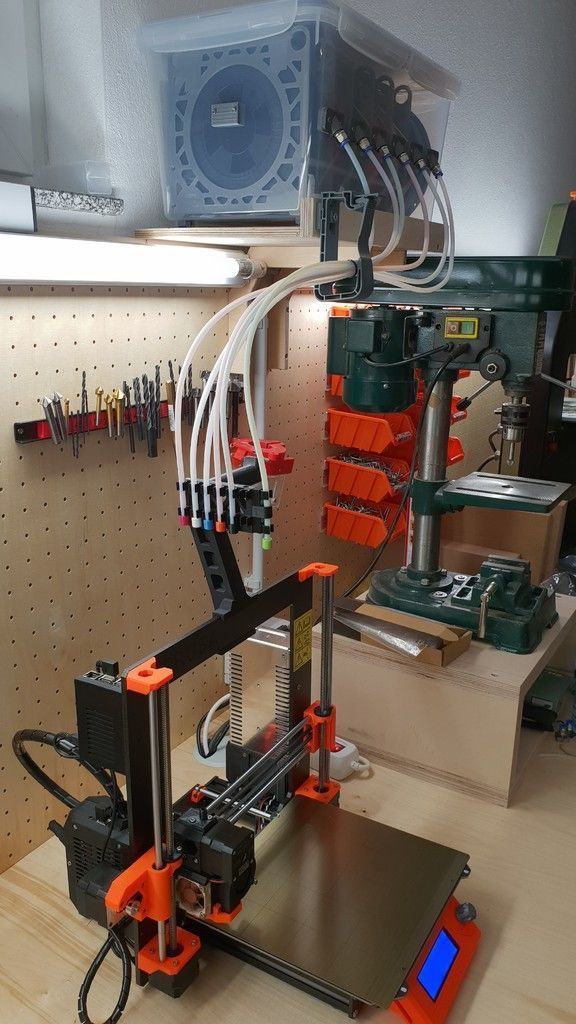

We print the simplest case for a homemade device / Sudo Null IT News

Printing a suitable case for your device is probably the most popular thought when introducing any inventor to 3D printing technology. But in practice, everything turns out to be not as simple as in an advertisement for a 3D printer, and under the cut, I will tell you in more detail what conclusions I came to in trying to compose a convenient case design.

But in practice, everything turns out to be not as simple as in an advertisement for a 3D printer, and under the cut, I will tell you in more detail what conclusions I came to in trying to compose a convenient case design.

Everything is fine with 3D printing - it's just a magic wand for the craftsman, except that most will only be able to afford models of printers in the lower price range. And after taking possession of a 3D printer, most, like me, will face the imperfection of budget 3D printing technology, namely FDM technology (layer-by-layer deposition - uses most of the available printers), regardless of whether you assembled the printer yourself or bought it in a store. The main problems are the shrinkage of the material after cooling, which causes deformations and inaccurate linear dimensions of the printed parts. If you came up with some cool design in the likeness of mass-produced cases, then the case of your device will be generously saturated with neat bevels, holes or snaps exactly in size for ease of assembly . .. even being a professional in modeling and taking into account the problems listed above when printing, you will get tired of mixing all these sizes and think in what position it is better to print each detail so that nothing bends during shrinkage, as is often the case. Shrinkage is evil, especially frustrating and time-consuming when your design has many dimensions that need to be accurately maintained for assembly and a beautiful look. But not everything is so bad and this is not a reason to retreat). nine0003

.. even being a professional in modeling and taking into account the problems listed above when printing, you will get tired of mixing all these sizes and think in what position it is better to print each detail so that nothing bends during shrinkage, as is often the case. Shrinkage is evil, especially frustrating and time-consuming when your design has many dimensions that need to be accurately maintained for assembly and a beautiful look. But not everything is so bad and this is not a reason to retreat). nine0003

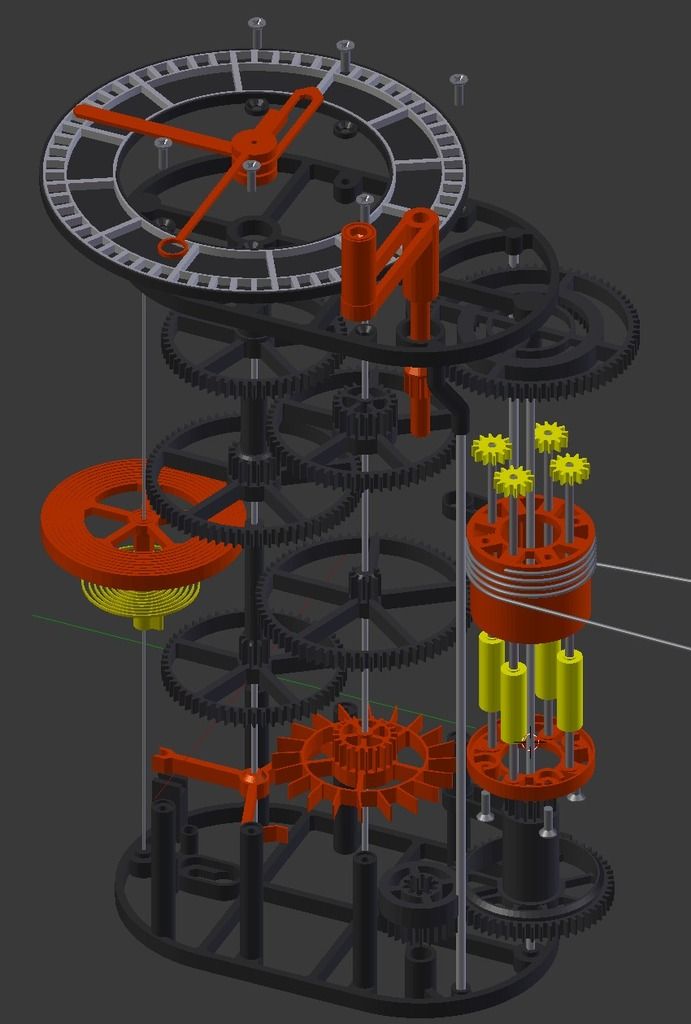

Based on my printing experience, I came up with a simple design for a prototype device box that will be easy to print on any fdm printer and suitable for many projects.

The design consists of two parts: the chassis - on which we will mount the parts, and the casing itself - which will hide all the shame that we soldered) One is easily inserted into the other and, for reliability, is fixed with a single screw at the back of the case.

The chassis is printed in a horizontal position to easily accommodate horizontal component mounting locations. Then I just glue them in the corners with droplets of hot glue, it's faster and easier to disassemble them later if necessary. nine0003

Then I just glue them in the corners with droplets of hot glue, it's faster and easier to disassemble them later if necessary. nine0003

Chassis I recommend to generously pierce the bottom and sides to save material, less deformation during shrinkage and easier peeling off the table. I just extrude circles, do you remember what bubbling is?)

And I print the casing vertically. In this position, you can make thin even walls and the texture on almost the entire visible part of the body is obtained in one direction, it looks neat. If necessary, you can finish the mounting ears or legs.

Even if you can't exactly maintain the size the first time and you have to grind off the edges of the chassis a little with a file, there will be absolutely no traces of processing from the outside of the device.

The tapered feet on the bottom of the body are printed without supports, eliminating post-processing and saving material/time.

If you print on adhesive tape or glue, the surface that sticks to the table is usually uneven and needs to be processed. With this approach, it will be on the back side of the case (on the side of the interface connectors), which no one usually sees. nine0003

With this approach, it will be on the back side of the case (on the side of the interface connectors), which no one usually sees. nine0003

I printed this case from PLA plastic with a 0.3mm nozzle on a Russian-made MZ3D-256 printer with the following structure settings: wall thickness 0.6mm, infill 23%, without substrate printing.

The size of the case in my example allows you to place inside an arduino uno, a pair of relays, a stepper motor driver, a voltage converter, various communication connectors and control / indication elements.

Of course, you will draw the chassis of the required size for your modules, as long as the printer's printable area is enough to print the casing in one piece. In my opinion, this design will be the most simple and convenient. nine0003

The benefit from the case is obvious) The design does not fall apart, wires do not stick out of the device, it does not look like a bomb, no one knows that it works on an arduino and it is not a shame to show it at an exhibition or give it to programmers to write firmware.

I hope this information was useful to someone, thank you for your attention.

The pictures show not an audio amplifier, but an irrigation controller, just audio connectors are very convenient for connecting low-current loads. nine0003

UPD. Thanks to UFO for taking the community on board and to all the participants for the warm welcome :)

And of course, files, I save time for inventors)

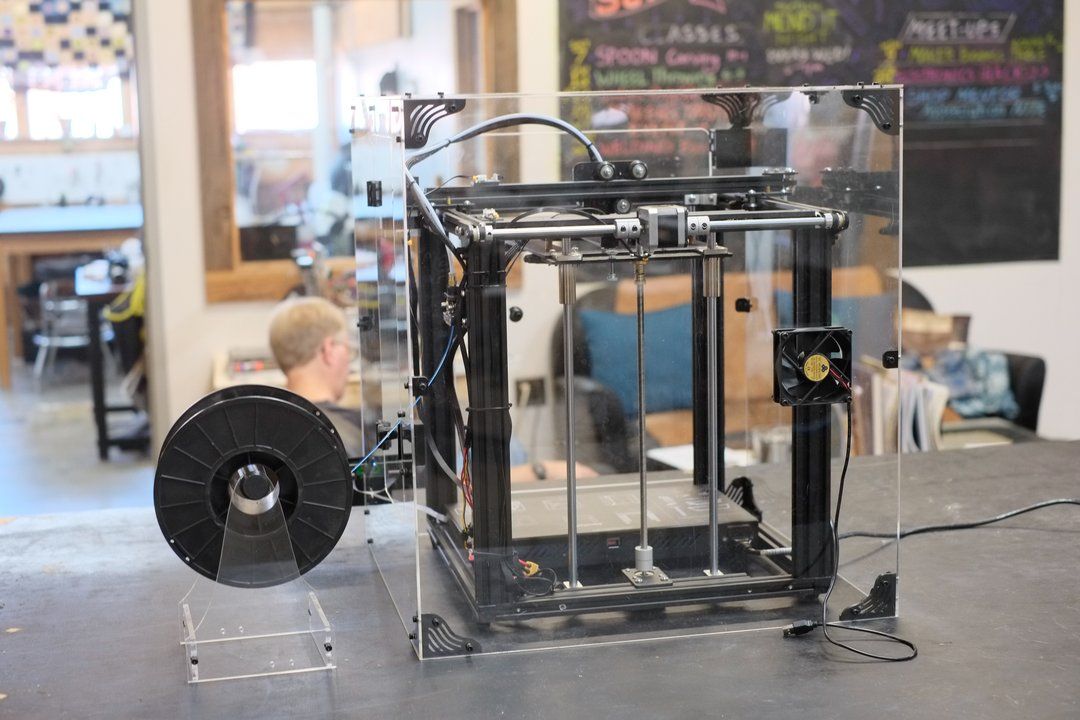

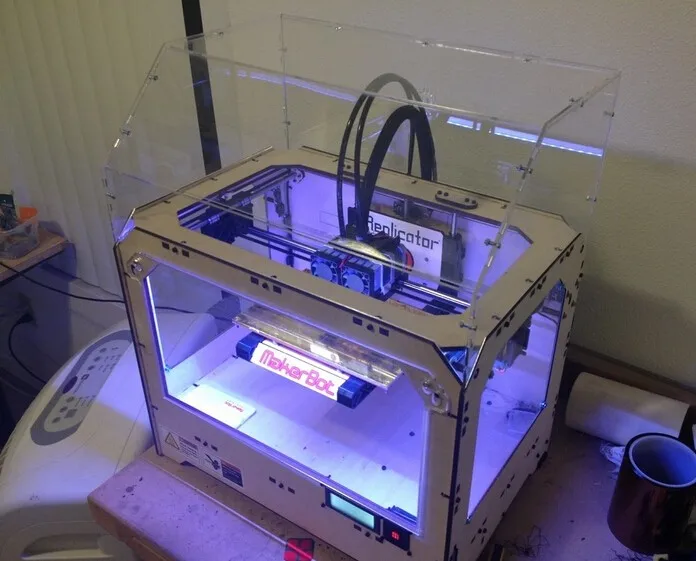

3D printer Wanhao Duplicator 4x in a wooden case

Home »3D Equipment» 3D Printers »Wanhao

Purpose

Prototypes Print

225x145x15

9000 9000 9000 9000 9000 9000 9000

ABS, PLA, Nylon

Color

Two -tone models

Dimensions

320x466x382 mm

accuracy

0.1 mm

4

DUPLICATOR 4X BLACK SH

MBot 3D Cube II two extruders

In stock

Free delivery in Moscow

Official warranty 1 year

WANHAO

List price

- Description

- Specifications

- Documents

- Additional options

- Paper

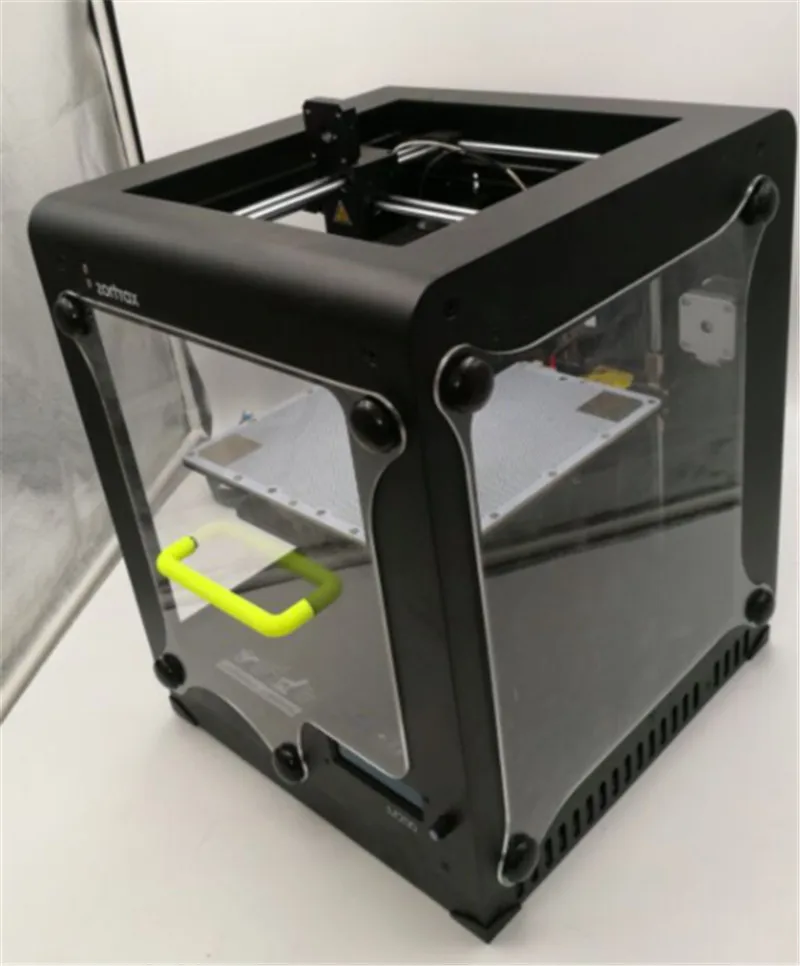

Wanhao Duplicator 4X 3D printer is an improved version of the Duplicator 4 3D printer. The designers made minor changes - acrylic inserts covering the sides of the printer were added, as well as an acrylic cover that is placed on the upper beams of the printer, thus making the structure completely closed. It seems not a big plus, if you do not remember the need for high-quality ABS printing. The closed case does not allow foreign air currents to penetrate inside, which can lead to warping and peeling of plastic from the countertop. This task is facilitated by the constancy of temperature inside such a case. nine0003

The designers made minor changes - acrylic inserts covering the sides of the printer were added, as well as an acrylic cover that is placed on the upper beams of the printer, thus making the structure completely closed. It seems not a big plus, if you do not remember the need for high-quality ABS printing. The closed case does not allow foreign air currents to penetrate inside, which can lead to warping and peeling of plastic from the countertop. This task is facilitated by the constancy of temperature inside such a case. nine0003

It is thanks to the closeness that this 3D printer is highly recommended to anyone who plans to print with ABS plastic. Recall that ABS is used to print strong and durable models: various cases of household and industrial equipment, machine parts, stationery, sports equipment, etc. If your future tasks fall into one of these categories, then the Duplicator 4X certainly deserves attention.

| Print technology | FDM\FFF |

| Media | ABS, PLA |

| Construction area size | 225 x 145 x 150 mm |

| nine0002 Layer thickness | 0.1 mm -0.4 mm adjustable |

| XY Positioning Accuracy | 0.02mm |

| Z-axis positioning accuracy | 0.005mm |

| Number of extruders (print heads) | 1 |

| Thread diameter (mm) | 1.75 mm |

| Operating temperature of printer components | max. nozzle 260C |

| Performance | nine0153 |

| Motherboard | 5 axes, 1/16 microstep motor |

| Operating systems | Windows XP, Windows 7, Mac OSX, Vista, Linux |

| Connection interface nine0156 | USB, SD |

| Software | REPLICATOR G included |

| Supported file formats | . |

| Power supply | nine0002 110 - 220 |

| Dimensions (without packaging) | 320 × 466 × 382 mm |

| Weight (without packaging) | 12 kg |

| Display | LCD display allows you to interact with your 3D printer directly without a computer |

| Warranty | 12 months |

| Manufacturer | WANHAO |

| Country of origin | China |

Equipment

| Printer | 1 pc. |

| Power Cord | 1 pc. |

| USB cable | 1 pc. |

stl, code

stl, code