Best 3d laser scanner for buildings

Building Construction 3D Laser Scanning

- Home

- Industries

- Pure Surveying

- Grow your business

- 3D laser scanning

- Building construction

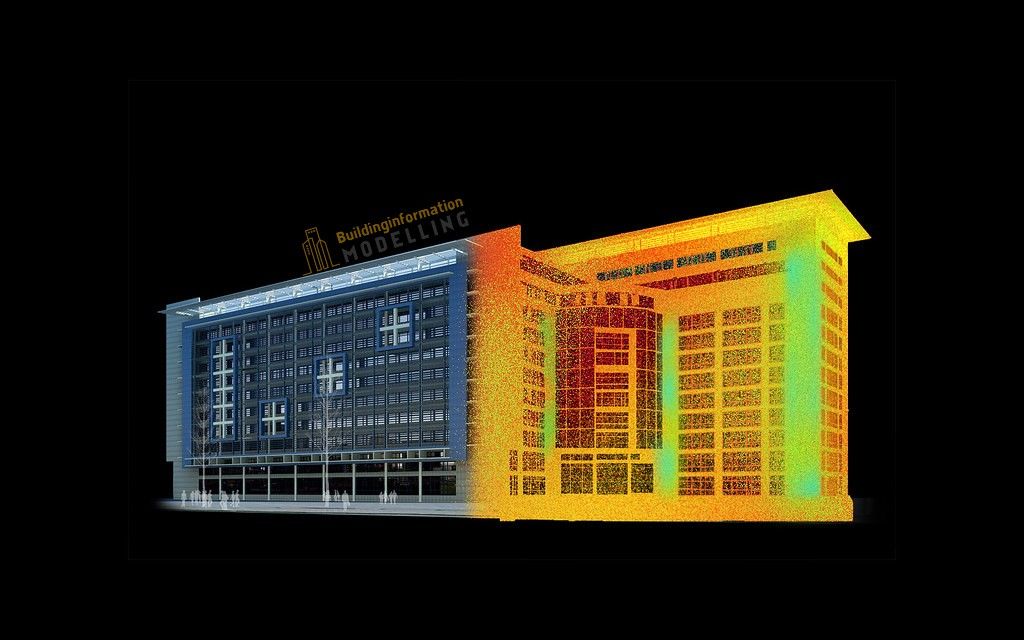

Leverage BIM to improve the planning, construction and renovation of buildings

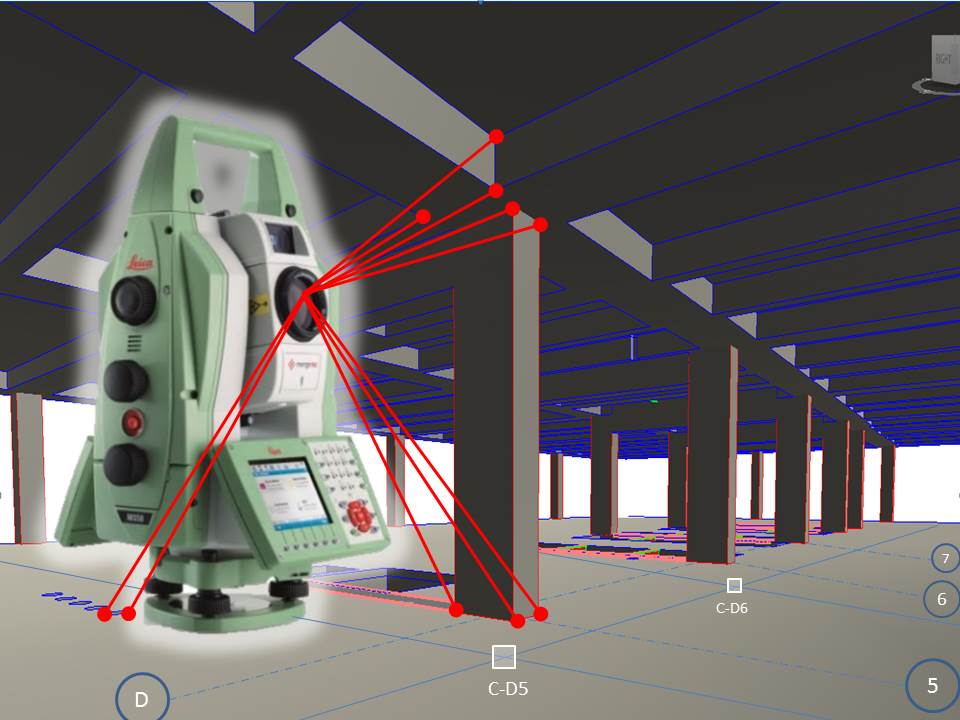

Using intelligent 3D models that are accurate and accessible, BIM has improved the way professionals in the architecture, engineering and construction (AEC) industries collaborate, reducing re-work and helping to eliminate wasteful processes.

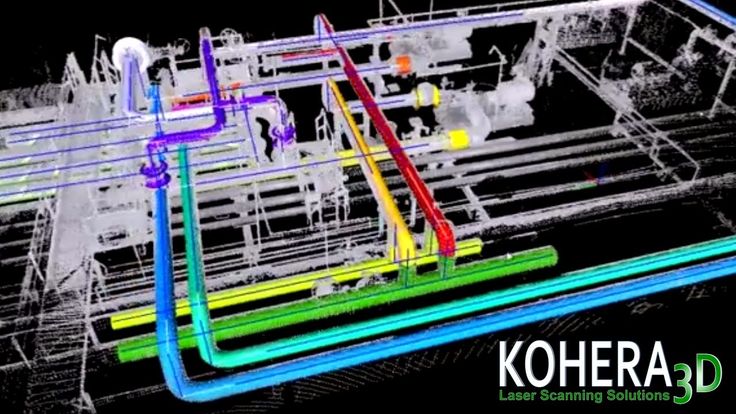

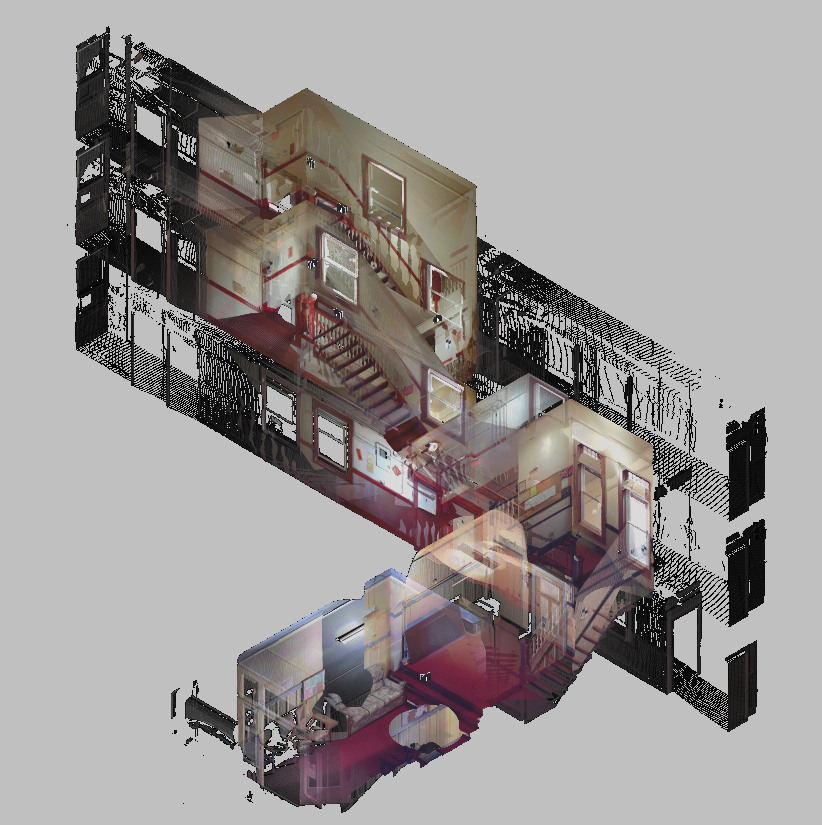

3D laser scanning solutions allows surveyors to provide as-built surveys, which prevent expensive rework by identifying any mistakes early in the design to construction phase. In addition, surveyors can play a pivotal role by using scanning technologies to improve the plan, design, construction, management and renovation processes for buildings.

Best 3D laser scanning solutions for building construction

Reality Capture software

A complete workflow

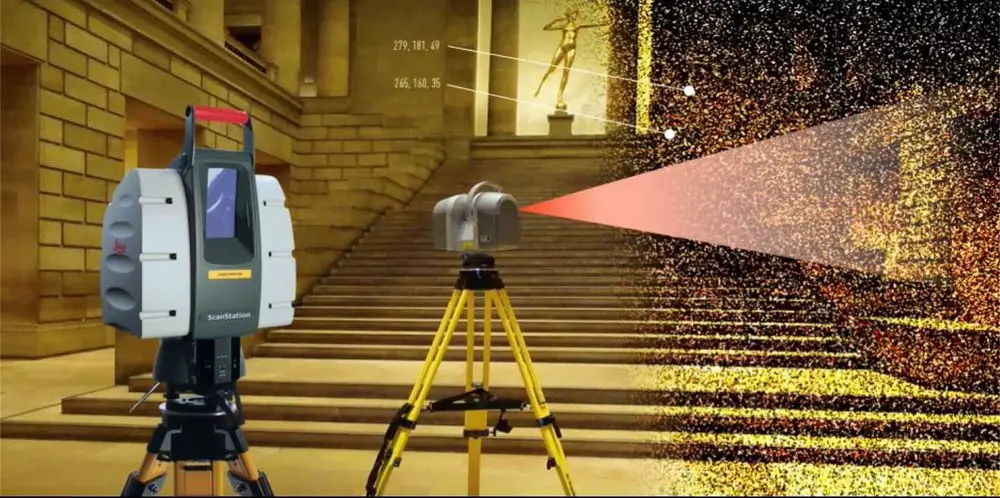

Leica Geosystems provides surveyors with the tools they need to capture, process, manage, collaborate, consume and deliver point cloud data.

Process your captured 3D scan data in the industry-leading 3D point cloud processing software Leica Cyclone.

Easily integrate point cloud data into the CAD platform of your choice with Leica CloudWorx to get the most out of BIM.

Collaborate and share easy access to point cloud data for anyone in your project ecosystem with Leica TruView.

Explore a building construction point cloud in TruView.

LEARN MORE

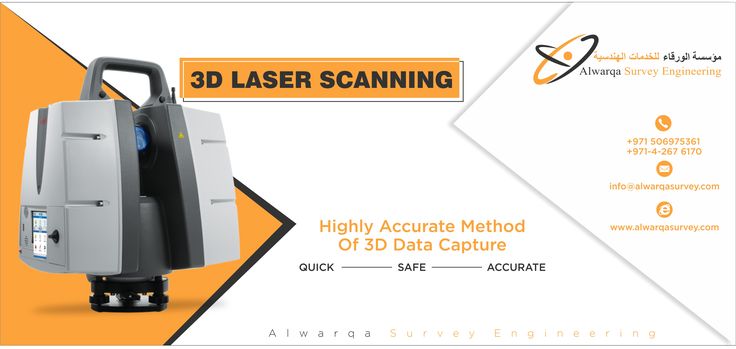

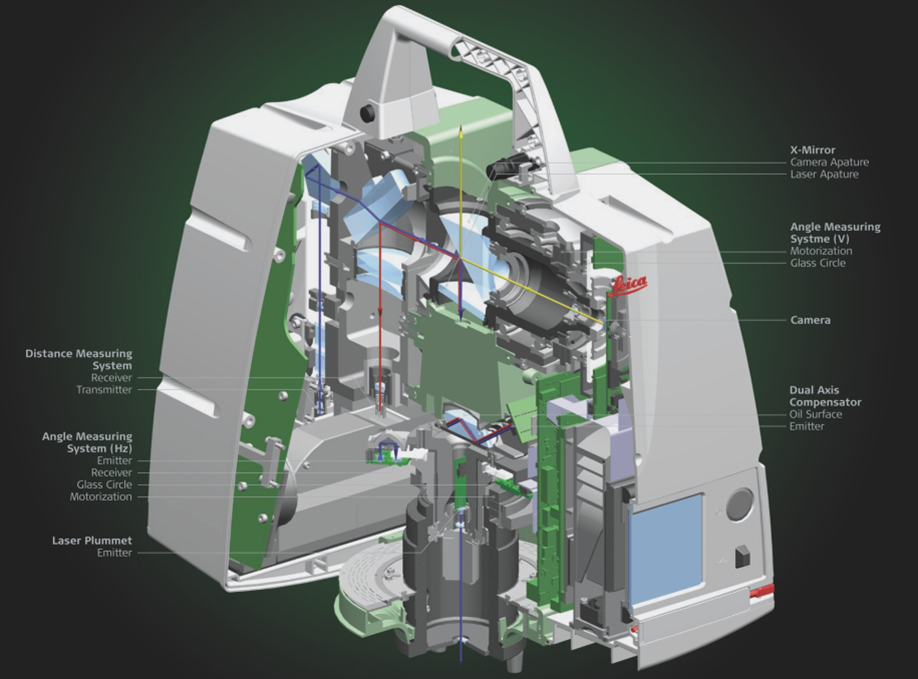

ScanStation P40

Get the highest accuracy

From creating as-built representations of buildings to measure, maintain or renovate, deliver highest quality 3D data for building construction and creating digital twins.

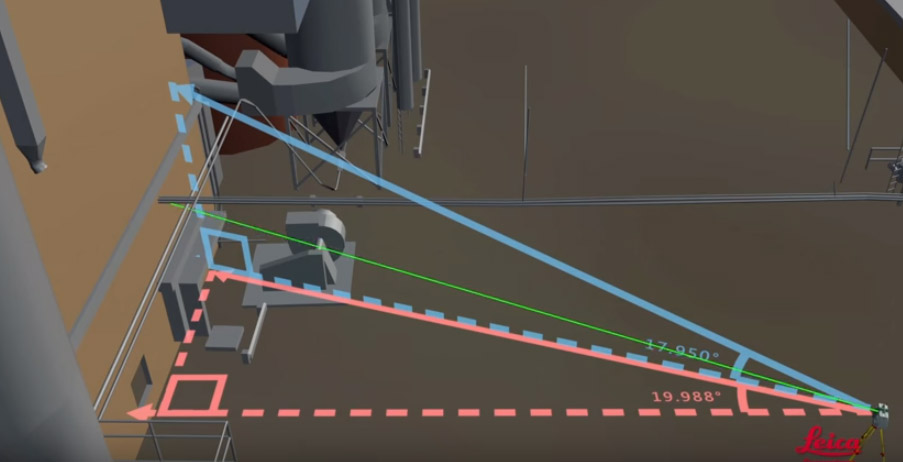

Supporting surveying workflows like traversing and resection with the ability to apply scale-factors, the P40 supports surveyors to get the highest accuracy.

Key specifications:

- 3D accuracy: 3.2mm at 50m and 5.9mm at 100m

- Scan speed: 1 mio pts/sec

- Temp range: -20°C to +50°C

- Range: Long (70-270m)

- Field registration: Surveying procedures

LEARN MORE

RTC360

Fast and agile

Move quickly in and around buildings to document prior to renovation or to record an as-built digital twin.

Supported by a Visual Inertial System (VIS) the RTC360 scanner tracks its movement without the need to use targets to stitch adjacent scans together.

Key specifications:

- 3D accuracy: 6.4mm at 50m and 12.5mm at 100m

- Scan speed: 2 mio pts/sec

- Temp range: -5°C to +40°C

- Range: Medium (40-130m)

- Field registration: VIS based

LEARN MORE

BLK360

Pure simplicity

Ideal for small areas, with the simple push of a button, a room is captured in 3D in seconds.

With Cyclone FIELD 360 app, BLK360 scans are easily aligned and checked for completeness before being transferred to the office for further processing.

Key specifications:

- 3D accuracy: 6mm at 10m and 8mm at 20m

- Scan speed: 360’000 pts/sec

- Temp range: +5°C to +40°C

- Range: Short (20-60m)

- Field registration: SW based

LEARN MORE

How Hollis captures, processes, manages and delivers reality capture data

Read how Tim Beach has incorporated laser scanning into existing survey workflows at Hollis. Using a complete 3D laser scanning workflow, Hollis produces deliverables of floor plans, sections, and elevations.

Using a complete 3D laser scanning workflow, Hollis produces deliverables of floor plans, sections, and elevations.

Read how Tim Beach has incorporated laser scanning into existing survey workflows at Hollis. Using a complete 3D laser scanning workflow, Hollis produces deliverables of floor plans, sections, and elevations.

READ MORE

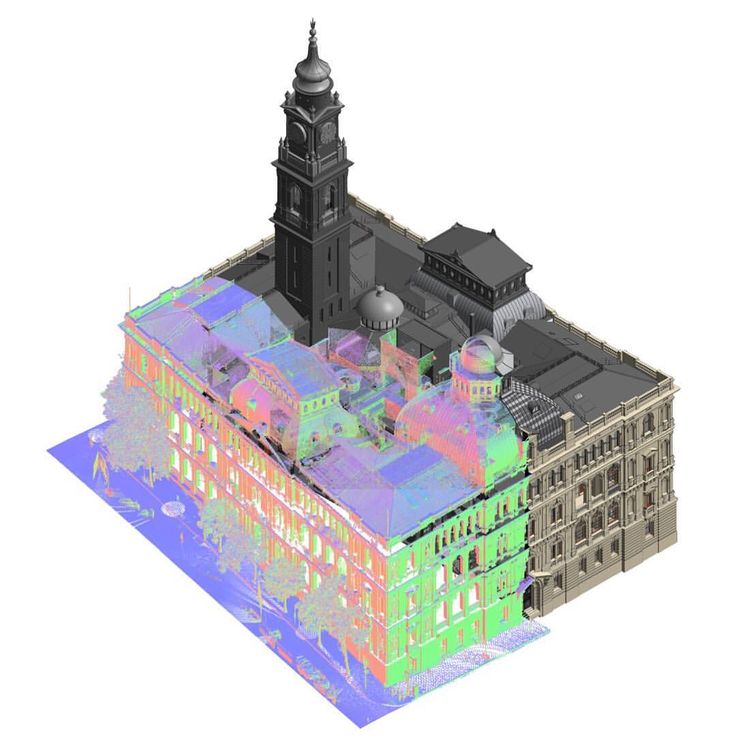

Speeding up BIM-reconstruction of historical building with laser scanning

Read how Trimetari Consulting obtained as-built documentation with point cloud data, creating 3D models that allowed the reconstruction of a historical building with laser scanning and BIM modelling in Russia.

Read how Trimetari Consulting obtained as-built documentation with point cloud data, creating 3D models that allowed the reconstruction of a historical building with laser scanning and BIM modelling in Russia.

READ MORE

Using laser scanning technology for retail redevelopment

Equipped with the RTC360 and P40, RM Surveys was contacted by an architect firm about creating a survey-grade architectural and structural Revit BIM model for the redevelopment a shopping centre in Perth, Australia.

Equipped with the RTC360 and P40, RM Surveys was contacted by an architect firm about creating a survey-grade architectural and structural Revit BIM model for the redevelopment a shopping centre in Perth, Australia.

READ MORE

Rent a laser scanner from Leica Geosystems and see for yourself why laser scanning is the right fit for your business.

CONTACT US

Your surveying partner

Only Leica Geosystems has 200 years of experience helping surveyors. Find out how we can support you with premium quality measuring and positioning solutions and services.

Find out how we can support you with premium quality measuring and positioning solutions and services.

Only Leica Geosystems has 200 years of experience helping surveyors. Find out how we can support you with premium quality measuring and positioning solutions and services.

Read More

Grow your business

Discover how embracing digitalisation with technologies and processes can support your business to create new opportunities, stay competitive and improve productivity.

Discover how embracing digitalisation with technologies and processes can support your business to create new opportunities, stay competitive and improve productivity.

Get Inspired

Surveying solutions

Regardless of how complex your task is, a solution is available within our diverse measuring, positioning, visualising and collaborating portfolio to help you succeed and be more efficient.

Regardless of how complex your task is, a solution is available within our diverse measuring, positioning, visualising and collaborating portfolio to help you succeed and be more efficient.

DISCOVER OUR SOLUTIONS

Improve your skills

Learn the skills to be more efficient and react to business opportunities. Unlock your potential to offer better, faster and more specialised services to your clients.

Unlock your potential to offer better, faster and more specialised services to your clients.

Learn the skills to be more efficient and react to business opportunities. Unlock your potential to offer better, faster and more specialised services to your clients.

Start Now

Best 3D Scanner - The Top 10 3D Scanners for 2022 [Reviews]

Much like a regular scanner, laser scanning 3D uses various methods to analyze a physical object and then relay that data to a computer to create digital 3D models. The 3D digitizer process might be automatic or users might need to complete the model to their requirements by using software. The aim is usually to get an accurate model to the right standard and format, ready for 3D printing, for virtual reality applications or other purposes.

Such scanners are used in many professional industries, but with advances in home 3D printing, there are now also a good variety of home options. They are sometimes called portable 3D scanners or handheld scanners if they’re designed as such. These allow you to easily scan small to medium-sized objects for 3D printing.

They are sometimes called portable 3D scanners or handheld scanners if they’re designed as such. These allow you to easily scan small to medium-sized objects for 3D printing.

Some come completely assembled while others, like 3D printers themselves, you’ll have to put them together by yourself. The benefit for those that are good with that type of thing is it reduces the price and allows for easier upgrades and modifications.

Scanning is typically done using laser triangulation or various forms of structured light to surround the object and measure its 3D dimensions or ‘geometry’. High-quality 3D scanner camera lenses also capture the color and surface texture of the object. Using accompanying or third-party software, the model can then be scaled up or down, or completely modified.

It’s never been easier to scan 3D objects!

How Do 3D Scanners Work?So, how do you scan 3D objects into a computer? Whether it’s on an industrial scale, at a small business, or on a desk at home, 3D scanners all share similar characteristics in the way they work.

The majority use laser and/or white light technology and cameras. The physical object is placed in a bed, tray, or suitable location. Electromagnetic light bounces off the object, measuring its circumference, full dimensions, and all its finer details.

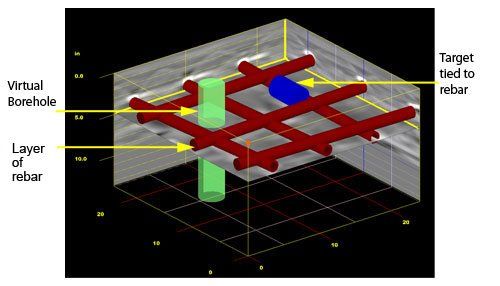

Depending on the scanner it may use multiple light sources, cameras, and other tech to aid this process. The collected data is called a point cloud, which refers to the number of points captured by the laser.

The more points collected the more accurate the scan. A high-resolution scanner can capture hundreds of thousands of points in seconds and reach millions overall. The whole process only takes a few minutes.

While the light tends to be a measure of the object’s geometry, HD cameras tend to capture the surface detail and color.

The data recorded can then be fed into a computer-aided design program or similar software for inspection and manipulation. E.g. if you’re planning to use it for 3D printing, the model might need scaling up or down, hollowing, have added support structures, be re-colored or have brightness/contrast changes, etc.

E.g. if you’re planning to use it for 3D printing, the model might need scaling up or down, hollowing, have added support structures, be re-colored or have brightness/contrast changes, etc.

There are, of course, different types of 3D scanner and scanning technology. So, let’s take a closer look at each one:

Types of 3D ScannersThere are several 3D scanner types. Before making your decision check out the section below:

Handheld vs StationaryHandheld and stationary 3D scanners often use the same technology and can overlap in their functions. The difference lies mainly in the design.

A handheld scanner has a grip and lets the user move around the object themselves to capture it at every angle.

A stationary scanner has to be positioned in front of the object, which is typically placed on a rotating plate and captures it as it spins 360 degrees. The user may have to reposition the object several times to capture every angle.

The user may have to reposition the object several times to capture every angle.

Newer designs are becoming smaller and more easily portable.

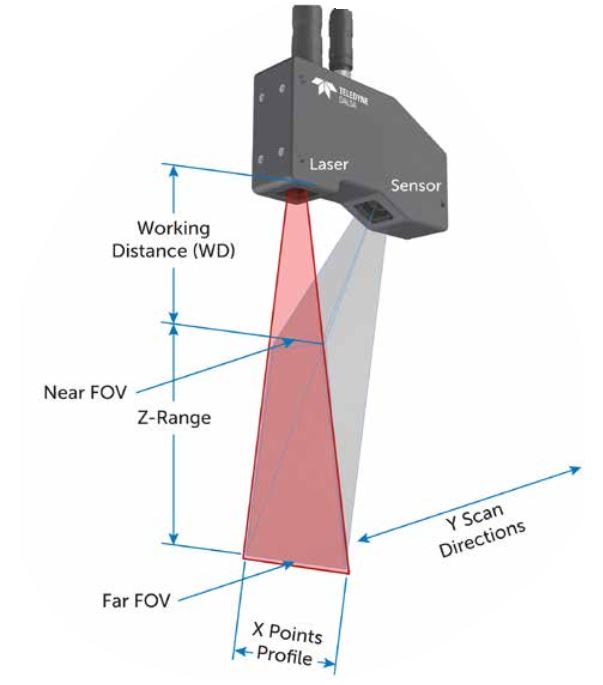

Laser TriangulationThe most common technology used in 3D scanning is laser trigonometric triangulation. It records millions of different points on the surface of the object to build an accurate overall polygon mesh. These are common in handheld options and industrial-grade scanner machines. They can also work long-range and for laser-tracking objects.

Structured-Light 3D ScannersSimilar and often used interchangeably with laser triangulation, structured light or ‘white light’ projects itself in a grid-like pattern over an object. It can then measure the structure of that grid as it applies to the object by using sensors/3D scanner cameras and triangulation.

Long RangeLonger range scanners use phase shift or pulse technology that can capture millions of points while rotating 360 degrees with the aid of mirrors. This is more commonly used to scan large objects like cars or buildings.

This is more commonly used to scan large objects like cars or buildings.

They might also use ‘time of flight’ technology that measures the distance of an object in relation to the speed of light and the time it takes for it to return to a sensor.

This is less relevant for everyday 3D scanning and printing.

3D Scanning ApplicationsThere are many different applications for 3D laser scanning - from those for 3D printing at home, to prototyping, industrial scale medical supply production and even architecture.

Hobbyist 3D printingCheaper 3D scanners are typically used by home users for scanning simple objects and 3D printing them for fun.

MedicalThe medical field and dentistry commonly use 3D scanning to create implants and aids to serve their patients’ needs. For example, scanning people’s feet with a high-quality 3D scanner allows for the creation of orthotics (shoe inserts). It is also used in the creation of prosthetics.

It is also used in the creation of prosthetics.

Industrial 3D scanners are used both in the creation and quality control of cars, planes, and even aerospace. It ensures existing parts are as accurate as their original models and that new viable parts are made.

Reverse Engineering and RepairsFrom the home computer desk to the manufacturing floor, 3D scanning allows users to reverse engineer or copy existing objects. Saved models also allow for the reconstruction of damaged objects.

Virtual RealityFrom creating realistic 3D worlds to the people that occupy them, 3D scanning devices are integral to the growing virtual reality industry. This ranges from AAA video games, virtual cinematography, and computer-generated imagery (CGI), to virtual tours and office meetings. It is also a side industry to motion capture.

ForensicsCSI has come a long way. Forensic experts nowadays don’t just have to rely on memory, photos, and evidence of a crime scene. They can capture the entire location in a full 3D model for closer inspection and for running through different scenarios.

Forensic experts nowadays don’t just have to rely on memory, photos, and evidence of a crime scene. They can capture the entire location in a full 3D model for closer inspection and for running through different scenarios.

From museums to libraries, 3D scanning is being used to log and preserve everything from artifacts to digitizing books. This also gives experts and the public remote access.

Architecture3D scanning can also help architects map the areas they will be designing their buildings in, take inspiration from existing architecture, and aid in building miniatures/prototypes.

What Should I Know Before Buying a 3D Scanner?Before you buy a 3D scanner, there are several things to consider:

- your budget

- what you’ll actually be using it for

- it’s speed and accuracy

- the device’s other features.

3D laser scanner price ranges vary greatly. On the cheaper end, you may be able to pick one up for home for just shy of $300, like the XYZprinting 3D Scanner 1.0 A. However, if you want the highest overall quality and the ability to scan small and large objects. Or, if you’re a professional and need a 3D part scanner in a field like medical implants or automotive parts, you’re looking at anywhere between $3,000 and $35,000.

Typically, it’s best to look for 3D scanners for sale online where you can find the best selection and prices.

3D PrintingWhile a dual 3D printer scanner combo is rare, if you want to scan models for 3D printing, you will need to make sure it has good accuracy and resolution. The software also must be able to export to a usable format. You will need to check your 3D printer and its own software to see what file types it accepts and then choose your scanner accordingly.

Fortunately, almost all of our 3D scanner reviews include devices that can export in common file types like OBJ and STL.

It’s typically only the more expensive scanners that are good for other applications, like VR, full-body scanning, architecture, and engineering.

Handheld vs StationaryWe already explained the difference, but basically, a handheld scanner is mobile, while the stationary one will require you to move and adjust the object. Neither is necessarily better than the other, it’s all down to your needs.

SpeedHow fast is the scanner? Do you have a lot of spare time or require the job to be done as fast as possible? All 3D scanners will take a few minutes to complete, while many scanning complex objects in high resolution can talk half an hour or longer.

Accuracy and ResolutionAccuracy refers to how close to the object being scanned your digitized model will be, measured in millimeters. Therefore, the smaller the better. The term resolution may be used interchangeably with accuracy or refer to the resolution of any cameras being used as part of the scanning process.

Therefore, the smaller the better. The term resolution may be used interchangeably with accuracy or refer to the resolution of any cameras being used as part of the scanning process.

Generally, the lower the millimeter, the better. Other factors also play a role in overall quality, such as lighting conditions, color, and depth.

Object Size and SpaceSome types of 3D scanners excel at scanning small objects while others are better at medium to large. Others are all-rounders. Before buying a scanner, you should decide the general size of the items you will be scanning.

You will also need to make room for the scanner. Although all the products on our list are small and relatively portable, stationary scanners at least need a table to work from. Likewise, there will be a minimum and maximum distance the scanner must be in relation to the object being scanned.

You’ll need more room when scanning larger objects in full.

All 3D scanners need to be connected to a computer or device to help monitor the process and for saving the digital model. This is usually done via a USB or HDMI cable. You will need to check that your computer or laptop meets the minimum requirements for the scanning and modeling software. Also, make sure that you have a tablet to make real-time monitoring easier.

SoftwareYour device will either come with its own software or a popular third-party program to aid the process and to help touch-up the model once it’s scanned. Different 3D printing software is better suited to different skill levels. Some programs have a lot of features for experienced users and others do most of the basic tasks automatically. Check our 3D scanner reviews to see the software each device comes with and how advanced and easy to use it is.

Wrap UpWhether you’re looking for a tool for your home or something more on an industrial scale for your business, our 3D scanner reviews have something for everyone. From handheld devices to structured lightboxes with turntables, you’ll be creating 3D models or reverse engineering parts in no time. Perhaps you’ll even do a 3D selfie or two!

From handheld devices to structured lightboxes with turntables, you’ll be creating 3D models or reverse engineering parts in no time. Perhaps you’ll even do a 3D selfie or two!

If you’re still unsure about 3D printing after reading our reviews and guides, check out our answers to your most commonly asked questions below.

scopes and overview of models / Sudo Null IT News

3D laser scanning - creating a digital model of a physical body using a laser beam. The technology is non-contact, works at close and long distances, eliminates damage to objects during scanning. The principle of operation of 3D laser scanners: a directed laser beam is reflected from the surface of an object, forming a cloud of points. Each point has its own coordinates in space. The software identifies them and creates a finished 3D digital model based on this data. nine0003

From the overview you will find out where laser scanning is used and what equipment is used to solve related problems.

Purpose of laser scanners

Source: newequipment.com

Compared to traditional measurement methods, laser scanners have an important advantage - they can digitize objects with complex surfaces and work in hard-to-reach places for humans. The main areas of application of devices are input and output quality control in production, inspection of working devices in order to prevent and eliminate defects, reverse engineering and other areas. nine0003

Construction, renovation and renovation of objects

Source: ellisdon.com

During the preparation of the building design, it is necessary to evaluate the features of the site and the cost of the forthcoming works. With the help of 3D laser scanners, a landscape model is created, on the basis of which further work is carried out. During the construction process, intermediate control of the geometry of future buildings is required: walls, corners, openings, etc. Laser scanning copes with this task more accurately and faster than conventional measuring technologies. nine0003

Laser scanning copes with this task more accurately and faster than conventional measuring technologies. nine0003

The basis for an exterior or interior renovation is often an accurate digital model, on the basis of which changes and additions to the current interior or exterior are planned. Laser scanners are also indispensable in this area.

Road networks and transport

Source: autodesk.com

Laser scanning is becoming an integral part of the planning and creation of urban and suburban road networks, tunnels, pedestrian sections, railways, ports. The technology is used to assess the current state of coatings, plan and estimate the cost of repairs, to obtain models of perennial structures, such as bridges. The equipment is involved in the design, manufacture, repair and tuning of cars, air transport and ships. nine0003

Public utilities

Source: 3dscanner.es

With the help of 3D laser scanners, it became possible to quickly digitize and document engineering communications. Scanning significantly saves time during maintenance and reconstruction. The devices work remotely, minimizing the risks of people when working in adverse conditions and in hard-to-reach areas.

Scanning significantly saves time during maintenance and reconstruction. The devices work remotely, minimizing the risks of people when working in adverse conditions and in hard-to-reach areas.

Oilfield installations

Source: ramboll.com

Oil production complexes located in the water require constant monitoring of work processes. Objects are regularly exposed to adverse and changeable environmental influences: winds of different strengths and directions, currents, temperature changes, etc. 3D laser scanning is becoming an integral part of the inspection of oil production installations. The equipment allows you to quickly identify and fix deformations and other damage, control wear, calculate the timing of scheduled maintenance, and prevent accidents. nine0003

Forensic examination

Source: faro.com

Photographs and manual measurements in investigative processes and forensic examinations are being replaced by 3D laser scanning. The devices create three-dimensional models of scenes of incidents with accurate fixation of the location of objects and the distances between them. The data is used in the process of pre-trial and litigation.

The devices create three-dimensional models of scenes of incidents with accurate fixation of the location of objects and the distances between them. The data is used in the process of pre-trial and litigation.

Other applications

Source: news.microsoft.com

3D laser scanners facilitate and optimize workflows in the following areas:

- In cartography and geodesy - when creating terrain plans, maps, geographic information systems (GIS).

- In archeology - in the restoration and preservation of ancient artifacts.

- In paleontology, to create missing parts of excavated skeletons.

- In medicine, including plastic surgery and dentistry. nine0080

- automotive industry,

- mechanical engineering,

- aerospace industry,

- oil and gas industry,

- shipbuilding,

- building and architecture,

- arts and culture,

- medicine,

- jewelry,

- science and education.

- measurement speed,

- high accuracy of digitizing objects of complex geometry,

- can work autonomously,

- are easy to operate.

- Quality control: the ability to check any geometric parameters, including input and output control, metrological control of parts and production equipment.

- Reverse engineering of products for prompt receipt of project documentation and product upgrades.

- Design and simulation for the purpose of prototyping and evaluation of the appearance of products, modernization of production facilities and equipment. nine0073

- Digital archiving of any required assortment (eg discontinued parts). Models stored in digital libraries are available remotely from anywhere in the world.

- Portable devices for metrological 3D measurements from ZG Technology (China). The line includes a wide range of instruments, from an affordable handheld 3D scanner to a powerful optical tracking measurement system, as well as photogrammetry and portable CMM. ZG's unique strengths include the world's first handheld MarvelScan solution with three cameras for markless laser scanning and tracker, and proprietary instant hole capture technology. ZG Technology 3D scanners provide measurement speed up to 1 million 350 thousand points per second and accuracy up to 0.

01 mm. nine0073

01 mm. nine0073 - Stationary Russian-made RangeVision PRO 3D optical scanner is an industrial solution for metrology, available to companies of any level. The device is designed to digitize objects from 1 mm to 5 m and offers the highest level of accuracy (up to 0.018 mm) and 3D resolution (up to 0.04 mm). This is the first domestic 3D scanner approved by the Federal Agency for Technical Regulation and Metrology as a type of measuring instrument.

- Creaform handheld 3D scanners for digitizing products ranging in size from a few centimeters to 6 meters. The Go!SCAN series devices (including the latest Go!SCAN SPARK) are based on structured illumination technology; HandySCAN 3D and MetraSCAN 3D are laser devices that are certified industrial grade metrology tools. The new generation MetraSCAN BLACK|Elite model is the fastest handheld 3D laser scanner on the market (1.

8 million measurements per second). The volumetric accuracy that Creaform technology can provide is up to 80 microns per 16 cc. m.

8 million measurements per second). The volumetric accuracy that Creaform technology can provide is up to 80 microns per 16 cc. m. - Creaform also produces 3D scanners and software under the peel 3d brand, combining affordability, ease of use and high quality. The line is designed to solve the problems of reverse engineering and digitalization of objects in such areas as art, preservation of cultural values, consumer goods, science and education, human body scanning. Peel 3d devices are capable of measuring objects from 0.3 to 3 m with an accuracy of 0.1 mm.

- Solutionix fixed optical 3D scanners for small objects (10-500 mm) with many small parts. Allow to receive an error less than 8 microns.

- FARO Focus 3D geodetic laser scanners perform fast and accurate scanning of large objects, complex structures, premises and landscapes. They operate in the range from 0.6 to 350 m, they are distinguished by increased accuracy, ease of operation and the ability to operate in the most difficult environmental conditions.

nine0073

nine0073 - EPiC budget 3D terrestrial laser scanners are based on the principles of simplicity, convenience and affordability. Their main advantages are super light weight, high shooting speed (from 30 to 90 seconds), 360-degree panoramic camera and the ability to control from a mobile device.

Overview of models and manufacturers

FARO Focus

Source: ifworlddesignguide.com

FARO is one of the popular manufacturers of laser scanning devices. The new Focus3D S-series instruments stand out from other scanners in lightness and compact size, as well as the ability to work in bright sunlight and keep in touch with the location using GPS.

The new Focus3D S-series instruments stand out from other scanners in lightness and compact size, as well as the ability to work in bright sunlight and keep in touch with the location using GPS.

The FOCUS 3D S 150 scanner works at a distance of up to one hundred and fifty meters, with an accuracy of up to ±2000 microns at a maximum distance. The device is used in design, architecture and construction, for digitizing equipment and other objects. nine0003

You can learn more about this model on the website.

Source: youtube.com

Focus3D S 350 scans with the same accuracy as the previous device, but the distance to the measurement object is increased to 0.35 km. The device is designed for outdoor use.

Source: kkgeosystem.blogspot.com

SHINING 3D

Source: shining3d.com

FreeScan is a line of well-known Chinese manufacturer of digital equipment SHINING 3D. These are universal laser handheld 3D scanners FreeScan X5 (X5+), FreeScan X7 (X7+) weighing up to 1 kg, with an excellent set of professional features. nine0003

These are universal laser handheld 3D scanners FreeScan X5 (X5+), FreeScan X7 (X7+) weighing up to 1 kg, with an excellent set of professional features. nine0003

Basic parameters:

Specifications

Creaform

Source: foundry-planet.com

Creaform's SCAN 3D range is characterized by high scanning quality combined with ease of use. Portable laser scanners HandySCAN 3D, MetraSCAN 3D have a clear interface, do not require special skills and complex user training.

Instrument features:

ScanTech

Handheld range

Source: cmmxyz.com

The HandHeld Prince series uses blue and red laser beams to scan large and small objects with high accuracy. Scanners can operate in bright sunlight and low light conditions. Due to its compact size, high speed and detail, the equipment is widely used in reverse engineering, quality inspection, digitization of museum, archaeological and other objects. nine0003

nine0003

Key features:

Composite series

Source: twitter.com

In addition to the dual scan mode, the KSCAN20 is equipped with a photogrammetry system, thanks to which the working area of the device is 2.5 m * 3 m with an accuracy of 35 µm / m.

Blue and red lasers provide high-speed scanning of up to 650,000 measurements per second with a resolution of 0.01 mm.

Key Features:

3D Laser Scanner Applications

Reduce construction costs and time with FARO Focus

Source: autodesk.com

US construction company Gilbane invested $60,000 in a FARO Focus-S 350 laser scanner, software, and employee training. At first glance, the amount seems too large for a small-scale firm. But, after the calculations, the company's management came to the conclusion that the investment will pay off in the shortest possible time. nine0003

According to Gilbane's director of 3D design, John Tocci Jr. , after introducing the expensive new technology, the company began to use the equipment even in areas where it was not originally planned. The specialists managed to save $30,000 for one hour of Focus-S 350 and Autodesk Revit software.

, after introducing the expensive new technology, the company began to use the equipment even in areas where it was not originally planned. The specialists managed to save $30,000 for one hour of Focus-S 350 and Autodesk Revit software.

Source: autodesk.com

Building a digital model of air ducts and other systems made it possible to avoid errors during the installation of physical objects, which could take several weeks. The use of FARO Focus in the assembly of plumbing, electrical and mechanical installations helped to optimize costs at all stages of work

Case “Modernization of the building of the University of Miami”

Source: elevar.com

At the time of the start of work, the architects had drawings made 85 years ago, and a little more than 4.5 thousand square meters of the old building. Using a 3D laser scanner, Gilbane digitized the training areas in one day. Modernization of load-bearing structures, as well as the main utility systems: plumbing, electrical and ventilation, was based on data obtained from scanning. nine0003

Modernization of load-bearing structures, as well as the main utility systems: plumbing, electrical and ventilation, was based on data obtained from scanning. nine0003

Quality Inspection with ScanTech

Source: 3d-scantech.com

The advantage of metal stamping over forging and casting is the lower weight and thickness of the resulting parts. The use of molds gives high accuracy and maximum compliance of the obtained parts with the specified characteristics, but does not completely exclude deviations and deformations. Which, in turn, can lead to difficulties in assembling finished products and reducing product quality. Therefore, constant quality inspection is a necessary part of production. nine0003

Having understood the problems of the manufacturer, ScanTech experts proposed to check the quality of stamped parts using the PRINCE laser scanner. The ability to switch blue and red laser modes allowed the device to combine the functionality of traditional portable and metrological 3D scanners. The mode of operation with an active beam of a red laser provides fast digitization of objects. In the case of increased requirements for accuracy and detail, turn on the blue laser beam mode. nine0003

The mode of operation with an active beam of a red laser provides fast digitization of objects. In the case of increased requirements for accuracy and detail, turn on the blue laser beam mode. nine0003

The photo shows the stages of work:

1. Installing markers - takes about two minutes.

Source: 3d-scantech.com

2. Digitizing a part takes about three minutes.

Source: 3d-scantech.com

Source: 3d-scantech.com

3. Deviation detection - lasts 3 minutes.

Source: 3d-scantech.com

The digital model shows the parameters and deviations, allows you to correct errors at the design stage. The case clearly shows that the process required a minimum of time and effort. nine0003

Using FARO 3D scanners on Justin Timberlake's world tour

Source: disguise. one

one

Timberlake's "Man of the Woods" program features scenery brought to life on stage. First, the ScanLAB team digitized a number of corners of the forest in the US state of Oregon. Laser projectors then directed images over the auditorium and stage, painting amazing pictures of the Portland landscape on translucent canvases suspended in the air. nine0003

Source: faro.com

Two Faro Focus X 330 laser scanners, Faro Scene 6.2 software were used to prepare visual effects. In total it took 40 digital copies and 1 working day in the concert hall.

Source: www.esa.int

Considering the limited preparation time, the large surface areas for displaying the image and the corresponding need for high image resolution, creating visual effects in a short time without using the chosen technology was impossible. nine0003

Selection guide for 3D laser scanners

In the review, we introduced you to the equipment of market leaders with an excellent reputation. All the devices described have high performance, so we recommend that you pay attention to these devices for use in various fields:

All the devices described have high performance, so we recommend that you pay attention to these devices for use in various fields:

FARO Focus: Focus3D S350, Focus 3D S150.

Creaform: MetraSCAN 350 (350 Elite), MetraSCAN 750 (750 Elite), HandySCAN Black (Black Elite).

SHINING 3D: FreeScan X5 (X5+), FreeScan X7 (X7+). nine0008 ScanTech: KSCAN20, PRINCE 775, PRINCE 335.

Results

Source: 3d-scantech.com

The cases discussed clearly prove that the use of 3D laser scanning optimizes workflows in many areas. The range of tasks solved with the help of 3D laser scanners is constantly expanding.

Buy a professional 3D laser scanner in Top 3D Shop — experienced specialists will help you choose the most suitable equipment, software for your business, and offer a project to modernize production. nine0003 90,000 select 3D scanner: types, advantages solved, tasks

3D scanners

Fundamentals 3D

reverse engineering

Geometry Control

The best on the topics

Automatization of quality control

Author: Semen Semyon Popadyuk

Author: Semyon Popadyuk

Benefits of 3D Scanners | What tasks does 3D scanning solve | Criteria for choosing a 3D scanner | Professional 3D scanning for fast and efficient production solutions nine0003

Modern 3D scanners have a wide range of features and a variety of functionality. They are used everywhere - in manufacturing, construction, education, the entertainment industry and are used even in everyday life. In order to choose the scanner that suits your needs, there are a number of aspects to consider, which we will discuss in this article.

They are used everywhere - in manufacturing, construction, education, the entertainment industry and are used even in everyday life. In order to choose the scanner that suits your needs, there are a number of aspects to consider, which we will discuss in this article.

Order a free test 3D scan using equipment from the world's leading manufacturers:

Leave a request

Benefits of

3D ScannersWhat is a 3D scanner? This is a device designed to quickly analyze a physical object and create its accurate 3D computer model. The principle of its operation is based on calculating the distance to the object using two cameras. In addition to the cameras, a backlight is used - LED or laser.

3D scanners are classified both according to their form of execution (stationary and portable) and according to the areas of use, mainly divided into professional and household. nine0003

Watch the video review series of the ZG AtlaScan handheld 3D laser scanner

3D scanners make it possible to significantly reduce the time and costs at the development stage, improve the quality of products and, ultimately, speed up the release of the product to the market. They can be used at any stage of product lifecycle management and will help to optimize the production process of enterprises in various industries, including: nine0003

3D scanning devices remove many of the limitations of traditional measuring equipment. Such tools familiar to the metrologist as templates, micrometers, calipers are inexpensive, but they are characterized by subjective readings and are not suitable for complex measurements. Coordinate measuring machines are more accurate than 3D scanners, but they are more expensive, larger, and require specialized operator training. nine0003

Such tools familiar to the metrologist as templates, micrometers, calipers are inexpensive, but they are characterized by subjective readings and are not suitable for complex measurements. Coordinate measuring machines are more accurate than 3D scanners, but they are more expensive, larger, and require specialized operator training. nine0003

Optical inspection systems, which include 3D scanners, are the best solution in terms of price and quality, as they provide:

Thanks to a 3D scanner, the work of a designer, technologist, and constructor is greatly facilitated: the performance of time-consuming complex measurements and the creation of a design from scratch are a thing of the past. nine0003

nine0003

What tasks does 3D scanning solve

3D scanner selection criteria

The main criterion is scanning accuracy . High-precision devices (10-30 microns) will help to get a phenomenal result: they are able to transfer the most complex surface geometry into 3D with minimal errors. Such 3D scanners are used in reverse engineering, quality control, medicine, and are used to digitize molds, device parts, etc. 3D scanners with an accuracy of 30–100 engineering. nine0003

3D scanners with an accuracy of 30–100 engineering. nine0003

ZG AtlaScan is the world's first 3D scanner with hole capture

When choosing a 3D scanner, you should also consider resolution (detail) , i.e. the degree of discreteness that is available when digitizing an object. The highest level of detail allows you to display the smallest elements in the 3D model.

Р the size of the scanned objects and, respectively, the mobility of the 3D scanner directly depend on the type of device that you select. When digitizing parts and objects of small and medium parameters, hand-held scanners are usually used. Stationary scanners are suitable for capturing complex small and medium-sized products with small details. Scanning of large objects (buildings, structures, communications) is performed using ground-based laser devices (range finders).

When studying the functionality of 3D scanners, pay attention to such points as the conditions of use, scanning speed, the surface of the scanned object, and color. nine0003

nine0003

Please note that the next step after scanning is to obtain and further work with the CAD model, and for this you will need specialized software.

Processing 3D Scan Data for Reverse Engineering in Geomagic Design X Software

Professional 3D scanning for fast and efficient production solutions

iQB offers cutting-edge solutions that successfully operate in leading enterprises around the world: nine0003

RangeVision PRO Fixed Scanner Creates Yamaha R3 Sport Fairings with Improved Aerodynamics, High Strength and Lighter Weight nine0003

Many of the above scanners are included in the register of measuring instruments of the Russian Federation and have the appropriate certificates.

nine0002 A variety of 3D scanning devices on the market will allow you to choose exactly the model that is needed for solving specific problems. The price range is also wide: from simple devices costing up to $500 to high-precision professional 3D scanners costing tens and even hundreds of thousands of dollars.