Xyz printing 3d scanner

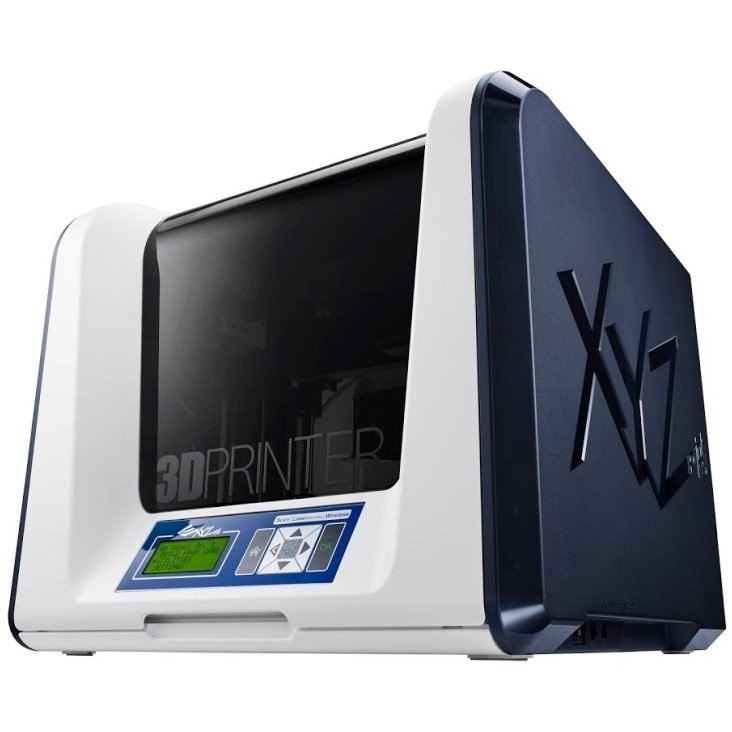

XYZprinting da Vinci Color AiO with 3D Scanner (PartPro200 xTCS) | 3D Prima

Product videos

XYZ Printing

0 Reviews

read more

Incl. VAT excl. Shipping

Wish list

Questions about the product

| Technical specifications | |

| Usable Filament Diameter | 1.75 mm |

| Extruder Type | Bowden |

| Build Area | 200 mm x 200 mm x 150 mm |

| Build Plate Leveling System | automatic |

| Build Chamber During Process | Closed |

| Extruder Number Of | 1 |

| Installation Space / Requirements | |

| Total Mass Overall Dimensions | 600 mm x 581 mm x 640 mm |

| Total Weight | 34 kg |

| Ambient Operating Temperature | 15°C - 30°C |

| Max Power Consumption | 240 W |

| Voltage | AC: 100 V - 240 V |

| Equipment | |

| Touch Screen | Yes |

| Connection | |

| USB Port | Yes |

| WLAN | Yes |

| Accuracy | |

| Layer Height | 0. |

| Shipping | |

| Shipping Box | 710 mm x 700 mm x 820 mm |

| Shipping Weight | 45 kg |

Other suitable products

Questions about the product?

Expect a delivery time a few days longer than usual. We will handle your order as soon as possible, but we can't guarantee delivery date during the Christmas holidays.

Shipping charges are based on the product's total weight and shipping method chosen.

Exact shipping charge is presented at checkout when you select shipping methods and your country. No other hidden costs.

Free shipping for all EU orders above EUR 100!

Fast delivery

Our goal is that all orders placed before 12:00 are shipped out from us the same day if the products are in stock.

All items shown with “in stock” status are in stock in our own warehouse for immediate delivery.

Delivery within EU will be shipped by FedEx, UPS, International tracked mail. You choose method in the checkout.

Delivery time will be around 2 - 6 days to most European countries.

Worldwide delivery around 4 - 7 days.

You will receive and mail from us with the tracking nr of the parcel as soon as we have shipped your order.

Free shipping for all EU orders above EUR 100!

Below you can see delivery time for European countries.

| Country | Delivery Time in Days | Free Freight over EUR 100 order |

| Albania | 4 | No |

| Andorra | 3 - 5 | No |

| Armenia | 4 - 6 | No |

| Austria | 2 - 3 | Yes |

| Azerbaijan | 4 - 6 | No |

| Belarus | 4 - 6 | No |

| Belgium | 2 - 3 | Yes |

| Bosnia & Herzegovina | 3 - 4 | No |

| Bulgaria | 3 - 5 | Yes |

| Croatia | 4 - 5 | Yes |

| Cyprus | 4 - 5 | Yes |

| Czech Republic | 3 | Yes |

| Denmark | 2 | Yes |

| Estonia | 3 | Yes |

| Finland | 2 | Yes |

| France | 2 - 4 | Yes |

| Georgia | 4 - 6 | No |

| Germany | 2 | Yes |

| Greece | 3 - 4 | Yes |

| Hungary | 3 - 4 | Yes |

| Ireland | 3 - 4 | Yes |

| Italy | 2 - 4 | Yes |

| Kosovo | 3 - 4 | Yes |

| Latvia | 3 - 4 | Yes |

| Liechtenstein | 2 - 4 | Yes |

| Lithuania | 3 - 4 | Yes |

| Luxembourg | 2 - 3 | Yes |

| Macedonia | 3 - 4 | Yes |

| Malta | 4 - 5 | Yes |

| Moldova | 4 - 6 | No |

| Monaco | 3 - 4 | Yes |

| Montenegro | 4 - 5 | Yes |

| Netherlands | 2 | Yes |

| Norway | 2 | Yes |

| Poland | 3 - 4 | Yes |

| Portugal | 5 - 6 | Yes |

| Romania | 3 | Yes |

| Russia | 4 - 6 | Yes |

| San Marino | 4 | Yes |

| Serbia | 3 - 5 | Yes |

| Slovakia | 3 | Yes |

| Slovenia | 3 | Yes |

| Spain | 3 - 5 | Yes |

| Sweden | 1 | Yes |

| Switzerland | 4 | Yes |

| Turkey | 4 - 6 | No |

| Ukraine | 4 - 6 | No |

| United Kingdom | 3-6 | No |

Shipping charges are based on the product's total weight and shipping method chosen.

Exact shipping charge is presented at checkout when you select shipping methods and your country. No other hidden costs.

Free shipping for all EU orders above EUR 100!

Fast delivery

All orders placed before 12:00 are shipped out from us the same day if the products are in stock.

All items shown with “in stock” status are in stock in our own warehouse for immediate delivery.

Delivery within EU will be shipped by FedEx International Economy.

Delivery time will be around 2 - 6 days to most European countries.

Worldwide delivery around 4 - 7 days.

You will receive and mail from us with the tracking nr of the parcel as soon as we have shipped your order.

Free shipping for all EU orders above EUR 100!

Below you can see delivery time for European countries.

| Country | Delivery Time in Days | Free Freight over EUR 100 order |

| Albania | 4 | No |

| Andorra | 3 - 5 | No |

| Armenia | 4 - 6 | No |

| Austria | 2 - 3 | Yes |

| Azerbaijan | 4 - 6 | No |

| Belarus | 4 - 6 | No |

| Belgium | 2 - 3 | Yes |

| Bosnia & Herzegovina | 3 - 4 | Yes |

| Bulgaria | 3 - 5 | Yes |

| Croatia | 4 - 5 | Yes |

| Cyprus | 4 - 5 | Yes |

| Czech Republic | 3 | Yes |

| Denmark | 2 | Yes |

| Estonia | 3 | Yes |

| Finland | 2 | Yes |

| France | 2 - 4 | Yes |

| Georgia | 4 - 6 | No |

| Germany | 2 | Yes |

| Greece | 3 - 4 | Yes |

| Hungary | 3 - 4 | Yes |

| Ireland | 3 - 4 | Yes |

| Italy | 2 - 4 | Yes |

| Kosovo | 3 - 4 | Yes |

| Latvia | 3 - 4 | Yes |

| Liechtenstein | 2 - 4 | Yes |

| Lithuania | 3 - 4 | Yes |

| Luxembourg | 2 - 3 | Yes |

| Macedonia | 3 - 4 | Yes |

| Malta | 4 - 5 | Yes |

| Moldova | 4 - 6 | No |

| Monaco | 3 - 4 | Yes |

| Montenegro | 4 - 5 | Yes |

| Netherlands | 2 | Yes |

| Norway | 2 | Yes |

| Poland | 3 - 4 | Yes |

| Portugal | 5 - 6 | Yes |

| Romania | 3 | Yes |

| Russia | 4 - 6 | Yes |

| San Marino | 4 | Yes |

| Serbia | 3 - 5 | Yes |

| Slovakia | 3 | Yes |

| Slovenia | 3 | Yes |

| Spain | 3 - 5 | Yes |

| Sweden | 1 | Yes |

| Switzerland | 4 | Yes |

| Turkey | 4 - 6 | No |

| Ukraine | 4 - 6 | No |

| United Kingdom | 3-6 | No |

This item cant be delivered in the selected country. Please change the country.

Please change the country.

Aland Islands Albania Algeria Andorra Argentina Australia Austria Bahrain Bangladesh Belgium Bermuda Bhutan Bolivia Bosnia and Herzegovina Bulgaria Canada Canary Islands Cayman Islands Chile Croatia Cyprus Czech Republic Denmark Estonia Faroe Islands Finland France Georgia Germany Gibraltar Greece Greece, Islands Greenland Guernsey Heligoland, Germany Hungary Iceland Indonesia Iran Iraq Ireland Isle Of Man Israel Italy Ivory coast (Côte d'Ivoire) Japan Jersey Jordan Kosovo Kuwait Latvia Lebanon Libya Liechtenstein Lithuania Luxembourg Macedonia Malta Martinique Mexico Moldova Monaco Montenegro Netherlands New Zealand Northern Ireland Norway Peru Poland Portugal Puerto Rico Romania San Marino Saudi Arabia Serbia Singapore Slovakia Slovenia South Africa Spain Spain, Balearic Islands Sweden Switzerland Thailand Tunisia Turkey USA United Arab Emirates United Kingdom Uruguay

XYZ hand held 3d scanner troubleshooting - Scanning - Talk Manufacturing

Tim_Jason_Sparr

#1

so i just got my scanner a new imac and run and installed parallels and have windows 10 running smoothly on my mac … installed the intel real sense sdk as part of the xyz packaged software and i keep getting a error 5041 device not found , please try again message , i have updated the software and controlled all drive updates for the usb 3 ports , its still not working , can any one help …

1 Like

Xeno

#2

Did you assign the right USB port to Parallels ?,

when you plug in your device, Parallels should ask where you want the USB device connected to, Win or OSX.

Tim_Jason_Sparr

#3

yes i did … im just wondering if perhaps the scanner has an internal fault as the button on the scanner lights up … i shall look into trying the scanner on a up to date pc ( local pc outlet ) … if it gives the same error perhaps its a hardware problem … will let hou know … Thanks for you help …

micahwelner

#4

@Tim_Jason_Sparr did you ever figure this out! i was about to purchase the XYZ before i realized it wasn’t mac friendly. then i remember parallels which i already had a copy of. did you ever get it to work through parallels? hope so! let me know thanks happy holidays

Tim_Jason_Sparr

#5

I haven’t managed yet to run it through parallels . I went to a PC shop and they had it up and running on a new pc with the latest intel chip . I have a new iMac ( literally a month old) and the technician at the pc shop thought there may be an issue with the type of intel chipset that mac uses . its all down to the intel real sense camera that the device uses and perhaps also usb power issues . It may be a graphics card issue too . For now if you haven’t a pc I’m not sure if its going to work . Which is a shame , would be nice if xyz-printing had a wiki or its own help page on this considering the 3d printer (junior) runs ok on my iMac , suppose its about licensing with intel or microsoft or something … anyone else manage to solve this …please help out as i have a scanner doing nothing … would have been nice to get it up and running for the holidays …

I went to a PC shop and they had it up and running on a new pc with the latest intel chip . I have a new iMac ( literally a month old) and the technician at the pc shop thought there may be an issue with the type of intel chipset that mac uses . its all down to the intel real sense camera that the device uses and perhaps also usb power issues . It may be a graphics card issue too . For now if you haven’t a pc I’m not sure if its going to work . Which is a shame , would be nice if xyz-printing had a wiki or its own help page on this considering the 3d printer (junior) runs ok on my iMac , suppose its about licensing with intel or microsoft or something … anyone else manage to solve this …please help out as i have a scanner doing nothing … would have been nice to get it up and running for the holidays …

pomusa

#6

I bought this item recently and it was missing the SD card. I was wondering if you still have the driver for Windows 10?

I was wondering if you still have the driver for Windows 10?

thanks

Boon

Tim_Jason_Sparr

#7

i will take a look … its now still in its box … will try to get it running this weekend

PAK5000

#8

I get the same error on a windows 10 pc. and there was no SD card in the box. and i can’t find the driver on their site. also, on the first machine i installed this on, it never prompted for a driver. the scan quality was just very low and compared to the how to videos, it took me a lot longer to get a scan. then the scan button would not enable. the button on the scanner lit up but did nothing. that was in xyz handy. i tried 3d sense. as soon as i hit the scan button the app crashed. so tech support said try another pc. xyzhandy wants a mystery driver and 3dsense does not detect a scanner. i think the scanner went bad and am working with them to get a replacement.

the button on the scanner lit up but did nothing. that was in xyz handy. i tried 3d sense. as soon as i hit the scan button the app crashed. so tech support said try another pc. xyzhandy wants a mystery driver and 3dsense does not detect a scanner. i think the scanner went bad and am working with them to get a replacement.

updating all the windows drivers, the intel realsense and graphic card drivers, did get it working for a short time on the original pc. but there was no SD card. and the apps never prompted for a driver. i think it is just a bad scanner they need to replace.

The Iron Man suit and the revolution in stop-motion animation

XYZ Media

A technology that has already affected industry and medicine is now changing cinema.

One of the most difficult tasks in filmmaking is the creation of objects important to the plot, whether they be weapons, figures for animation, complex mechanisms and futuristic costumes.

All this requires the right material. Usually objects are created manually, which takes a lot of time and money and often brings inconvenience in operation.

3D printing could be a solution. This technology has already been used in cinema and there is every indication that it will significantly affect the industry in the future.

Author: Mark Tyutyunnik

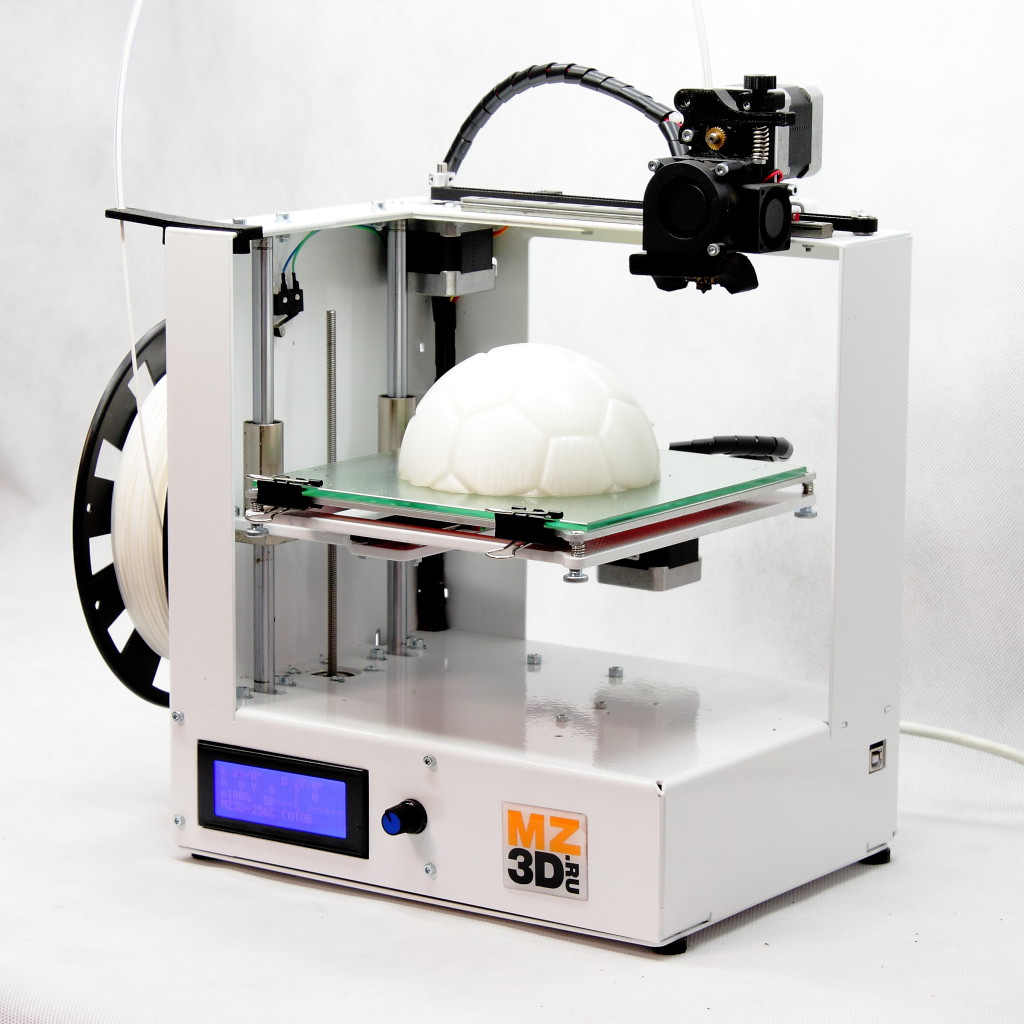

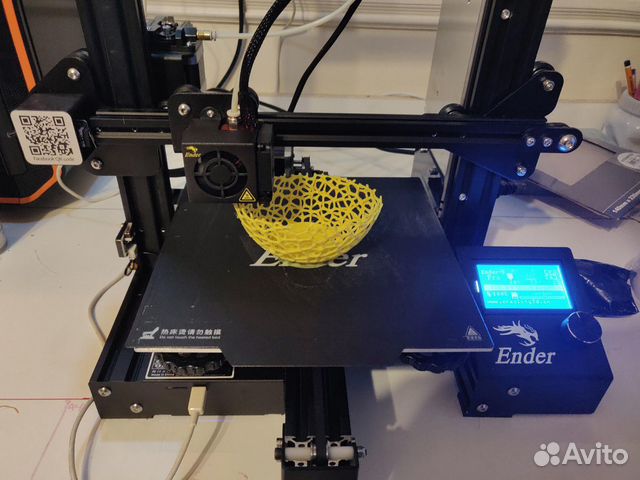

What is 3D printing?

3D printing (additive manufacturing, AM) is the construction of three-dimensional objects from models created in CAD (computer-aided drawing programs) or other 3D digital models.

It is not necessary to make drawings for future objects on your own, you can download already developed 3D models - for example, here. Then you need to cut the model into thin layers (using special programs for slicing), in accordance with which the material will be superimposed during printing. By uploading the file with the model to the printer (via an SD card, flash drive or Wi-Fi), even a beginner can print the object.

Additive manufacturing has greatly influenced the development of a wide range of industries. It is used in the creation of weapons, the construction of buildings, the development of medicines and in other areas.

Gradually, this technology was adopted in the cinema.

The benefits of 3D printing are many. Firstly, the production of objects is carried out quickly and efficiently. Secondly, very complex objects can be made using this technology, which eliminates additional assembly steps and provides more freedom for designers.

Another advantage of additive manufacturing is the variety of materials. Printer manufacturers offer a set of sources, but the user always has the opportunity to mix different substances and even simulate ceramics or metal.

How 3D printing works

One of the most important parts of 3D printing is the scanner . It collects the physical data of an environmental object or (volume, texture and color) to create a digital model.

It collects the physical data of an environmental object or (volume, texture and color) to create a digital model.

There are two main types of 3D scanners: contact and non-contact. The former explore the object through physical contact. The second is to collect radiation from the target object using a laser, structured light, photogrammetry, or optical coordinate measurement.

SLS-technology is used to manufacture parts of mechanisms and objects with complex geometry. It helps to achieve high strength and precision. A roller rolls the powder, consisting of 50 micron diameter nylon spheres, onto a platform, and the printer heats it up to sintering temperature. Then, with the help of a laser, these spheres are sintered layer by layer until the necessary detail is obtained.

BigRep ONE brand printers are mainly used in cinema. A build chamber with a volume of >1m3 simplifies the additive manufacturing of large-scale objects.

The fast speed and convenience of this kind of production is made possible by the camera, which creates large, life-size parts and allows direct observation of the process. When NeoMetrix Technologies released a video of the development of a functioning car on the BigRep ONE printer, the reason for the technology's popularity in film production was perhaps obvious.

The use of 3D printing in animation

Laika Entertainment has pioneered the full scale application of technology in film. The company has resorted to additive manufacturing to provide naturalistic facial animation for stop-motion dolls. The idea was to take puppet "acting" to the next level.

When working on The Nightmare Before Christmas, director Henry Selick used sculpting by hand and the usual replacement of faces - first they shot the head with one facial expression, and in the next frame they replaced it with another. But the range of emotions with this approach turned out to be very meager. When producing Coraline in the Land of Nightmares, Selick wanted the main character to be able to show as many subtle expressions as possible. That is why the director decided to conduct an experiment using 3D printing.

When producing Coraline in the Land of Nightmares, Selick wanted the main character to be able to show as many subtle expressions as possible. That is why the director decided to conduct an experiment using 3D printing.

Leading additive manufacturing industry advocate Brian F. McLean Visual effects specialist for Coraline, Paranorman, Family of Monsters and Kubo: The Legend of the Samurai. He has probably the most experience with 3D printing in the film industry today.

In Coraline, McLean used traditional stop-motion animation, combining it with new methods. Additive manufacturing has been used to create facial expressions of characters with thousands of details. The specialist used three Objet printers, with the help of which the animators developed about 20 thousand facial areas that could convey more than 200,000 facial expressions.

The image above clearly shows the line of alignment of the upper and lower parts of the face, which was removed in post-production. Using traditional methods, this amount of work would have taken about 30 years, but thanks to 3D printing, it turned out much faster.

Using traditional methods, this amount of work would have taken about 30 years, but thanks to 3D printing, it turned out much faster.

It is even more difficult to imagine how many years Paranorman would have taken to produce. The animators used about 40 thousand different facial elements to expand the emotional range. Each of the 40,000 elements was put into a special face library. Thanks to their combination, Norman alone had about 1.5 million facial expressions. Each short half-minute episode required about 250 different expressions for one character.

About 56,000 faces were printed for Monster Family, which were divided into two main areas: eyebrows and mouth.

Each of the options had special names, such as "raised eyebrows" or "pursed lips." Combining them, McLean got the unique expression he needed.

According to McLean, the aim of the rapid prototyping department was "to push stop motion into uncharted territory. " This idea reached its peak in The Monster Family, where they tried to touch every muscle of the face, and the heads were printed specifically for one frame and were no longer used in the production of the cartoon.

" This idea reached its peak in The Monster Family, where they tried to touch every muscle of the face, and the heads were printed specifically for one frame and were no longer used in the production of the cartoon.

McLean credits lead texture artist Tori Bryant for finding a way to recreate the nuances of coloring layouts by hand using additive manufacturing. She figured out how to compensate for the lack of color calibration on the printer and found that applying traditional drawing and coloring techniques to digital models resulted in a more believable result.

McLean has also used 3D printing on Laika's latest two projects: Kubo: The Legend of the Samurai and Lost Link. The scale increased again - only the main character could have 48 million facial expressions. In addition, when creating both cartoons, PolyJet 9 technology was used.0044 , with the help of which painted the printed objects in the required colors.

3D printing in big-budget movies

Disney pioneered the use of 3D printing in feature films - Jason Lopez (Legacy Effects specialist who worked with Marvel Studios from Iron Man 2 to Guardians of the Galaxy 2 ”) using this technology greatly accelerated the creation of the Iron Man suit. First, experts scanned the body of Robert Downey Jr. - this was necessary to make wearing the suit more comfortable - and then printed armor fragments on Objet Geometries from various materials. Rubber was used for action scenes and fast movements, and metal for close-ups.

For Thor: Ragnarok, Hela's helmet was designed by José Fernandez, costume designer at Ironhead Studios, using this technology. It used SLS (laser sintered nylon powder) with the addition of reinforced carbon fiber so that the headgear was not heavy.

3D printed synthetic materials such as nylon have also been used in the development of other Disney projects: Queen Ramonda's headdress from Black Panther; Kylo Ren costume, shining chrome stormtrooper armor, some parts of Rey's staff, C3PO droid as a costume for actor Anthony Daniels from The Force Awakens, Interpol car from The Muppets 2. Disney is again the first to apply new technologies, as it was with virtual production or the first “animation” of an actor using a mockup.

Disney is again the first to apply new technologies, as it was with virtual production or the first “animation” of an actor using a mockup.

Additive manufacturing is also used by Sony Pictures Entertainment, Universal Pictures and Warner Bros.

Rapid prototyping for 007: Skyfall created an Aston Martin DB5 and a one-third life-size helicopter specifically for the explosion scene, which proved to be significantly cheaper than any other method.

Stratasys printers were used to design the armor for the 2014 RoboCop remake.

A The red stripe on the visor was printed using a transparent photopolymer material.

The Apollo 11 spacecraft for Man on the Moon was also recreated using large scale printers - it was created using BigRep ONE V3.

Weta Workshop, a special effects and props company, used this technology to design helmets, sword hilts, spears and axes for the Hobbit trilogy. Animatronics engineer Rob Sheeney has stated that using 3D printing is beneficial as it is more economical and less time consuming. Then, in 2012, Weta Workshop also tested large-scale printers.

Then, in 2012, Weta Workshop also tested large-scale printers.

How 3D printing will change cinema

Cinematographer Victor Marin (Young Americans) believes this technology will play an increasingly important role in the future. He recommends combining methods, instead of replacing traditional ones with innovative ones.

Julia Koerner (helped with 3D printing for the Black Panther designers) also calls for a combination of these methods. She sees the benefits of additive manufacturing in creating really complex and detailed structures that can't be created with traditional methods. In his work, Koerner tries to combine traditional methods with progressive ones.

Gilles-Alexandre Deschaux, creator of stop-motion short Chase me :

“3D printing is already widely used in the film industry, from stop-motion films to big American blockbusters and commercials. 3D printing is often used to create decorative items and props, but not only there. At the development stages, it is used to promote new individual projects and conceptual solutions.

3D printing is often used to create decorative items and props, but not only there. At the development stages, it is used to promote new individual projects and conceptual solutions.

According to Pinewood Studios 3D supervisor Jet Cooper, the possibilities of this technology are already “incredible”, because if you want, you can even scan someone's face with all the wrinkles and pores.

Jet Cooper, Pinewood Studios 3D Supervisor:

“Voxeljet has the biggest printers. Their maximum format: 4000 mm x 2000 mm x 1000 mm. This is the largest printer in the world as far as I know. We have a 1060mm x 500mm x 600mm resolution printer at Pinewood. Anything over this size, we print in parts and then put them together.

3D printing is used to create props, and the metal coating of the material makes it strong and durable. But the Germans are working on a new material - epoxy resins, which are as strong as stone. They are extremely hard. "

"

3D printing is developing rapidly and is becoming cheaper every time, especially when compared to traditional methods or the use of computer graphics. Perhaps the day is not far off when handmade props and scenery will almost cease to be used in films - they will be replaced by cheaper and faster “printed” counterparts.

Like this article?

WANT TO GET BEST ARTICLES

FROM XYZ ONCE A WEEK?

Subscribe to the XYZ newsletter

By clicking on the button, you agree to the terms of data processing

How physics was used to create animations in Star Wars Jedi: Fallen Order.

About creating physical animations for Star Wars Jedi: Fallen Order and the problems that game designers faced. There are 3 ways to adjust the animations in the game for physics.

How Unreal Engine is used in movies

The game engine Unreal Engine 4 is being used in movies. For example, in The Mandalorian they created virtual objects right on the set. We tell you how...

We tell you how...

Techno Print 3D Company

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them. Many will say that it is wrong to compare them or Read more→

XYZprinting, best known for its daVinci line of desktop 3D printers, is bringing five new devices to the professional and industrial environment. One will use laser sintering technology, the second full color inkjet printing and three DLP machines.