High tech 3d printing

High Tech 3D Design and Additive Manufacturing Industry Solutions

- Support

- Search

3D Solutions for the Technology Industry

High Tech Solutions

Innovate with design tools and additive manufacturing

Technology & Process Solutions

SOLIDWORKS High Tech solutions provide critical capability to connect electronics and mechanical design teams with requirements and project management disciplines, and external partners.

Our solutions allow High Tech designers to:

Learn More

Additive Manufacturing Solutions

In the competitive world of high tech design, having an in-house 3D printing capabilities enhances collaboration, reduces time to market, and helps protect your innovative ideas until launch.

Our additive solutions help high tech product designers to:

Learn More

Technology for High Tech Design

Drive innovation and connectivity with SOLIDWORKS software

Smart electrical consumer and IoT products involve the marriage of many different systems, resulting in design and manufacturing challenges. Mechatronic designers need a capable solution to solve their challenges in order to meet the desires of today’s consumers and the needs of cutting-edge businesses.

SOLIDWORKS offers a suite of software solutions that brings a greater level of connection and clarity to the process. Now teams can share data and ideas, quicker and easier than ever before:

Desktop / Software

SOLIDWORKS 3D CAD Software

SOLIDWORKS 3D CAD software delivers powerful design functionality with an intuitive user interface to speed your design process and instantly productive.

Desktop / Software

SOLIDWORKS Simulation

With SOLIDWORKS Simulation solutions, product engineers can virtually test new ideas, quickly and efficiently evaluate performance, and improve quality

Desktop / Software

SOLIDWORKS Visualize

SOLIDWORKS Visualize products help organizations leverage 3D CAD data to create photo-realistic marketing content that is print and web ready in minutes

Desktop / Software

SOLIDWORKS Electrical

SOLIDWORKS Electrical software simplify electrical product design with specific tools designed for engineering and intuitive interfaces for faster design

Customer Example

Nautel uses a combination of SOLIDWORKS products at every stage of production

Using a variety of products in the SOLIDWORKS family is meeting Nautel’s unique needs in equipment design, testing, production, deployment, servicing, marketing, and sales.

Global transmitter manufacturer Nautel run their business with SOLIDWORKS.

High Tech Process Management

Communicate and collaborate with your team and suppliers

Reduce the time and expense required to manage, archive, and track design documentation and cost-effectively automate documentation to securely archive and organize multiple versions of projects.

Desktop / Software

SOLIDWORKS PDM

SOLIDWORKS Product Data Management (PDM) products manage and synchronize your design data across your entire enterprise with a single solution

Desktop / Software

SOLIDWORKS MBD

SOLIDWORKS MBD (Model Based Definition) software is a drawingless manufacturing solution for communicating product and manufacturing information (PMI)

Desktop / Software

SOLIDWORKS Manage

Extends SOLIDWORKS PDM with advanced capabilities that allow teams to manage project timelines and resources, complex business processes, and advanced item management.

Additive Manufacturing High Tech Solutions

Advanced materials and techniques for prototyping

Overview

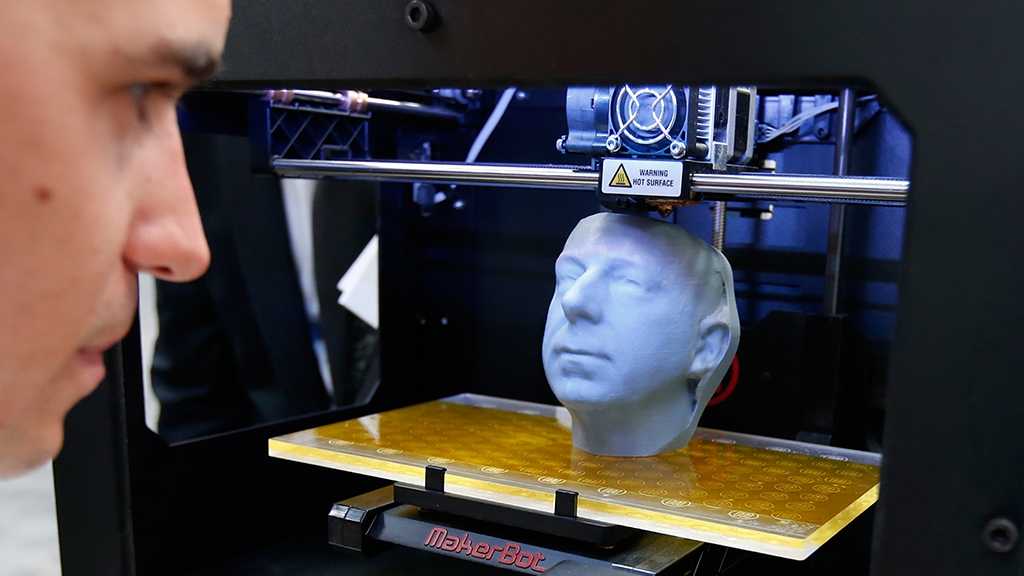

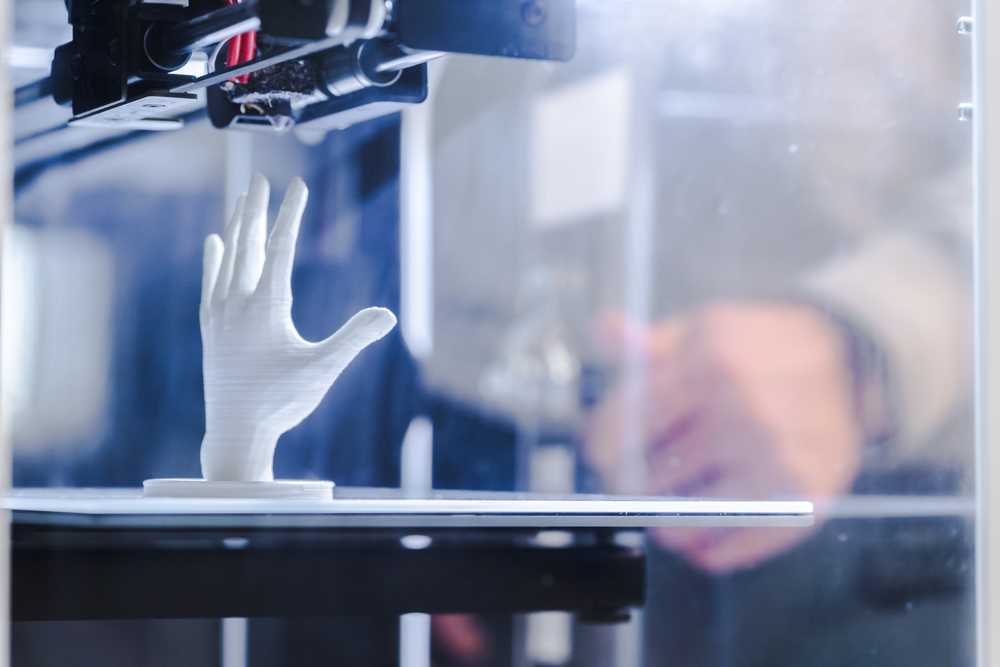

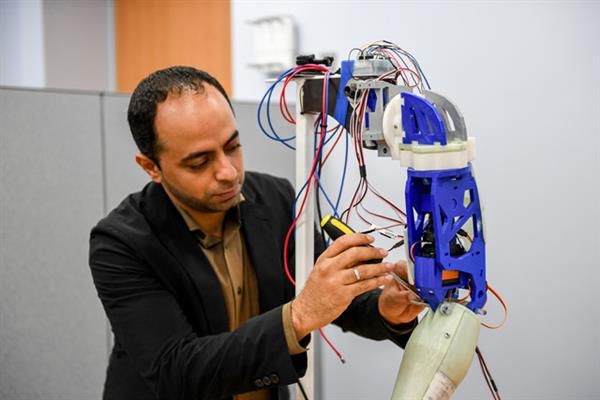

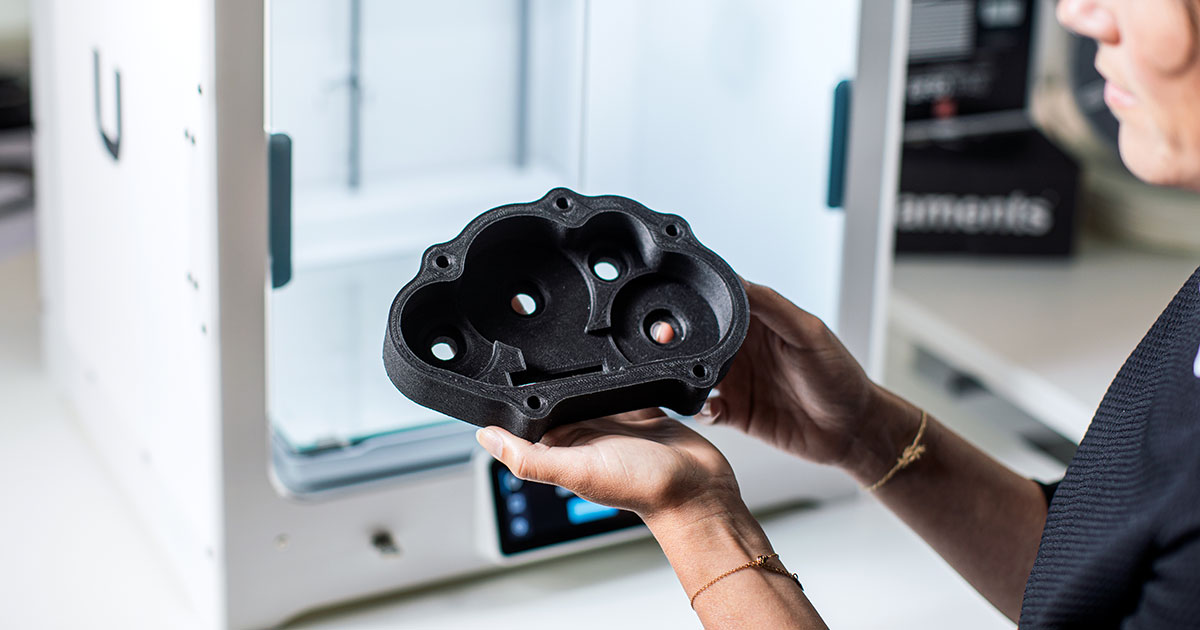

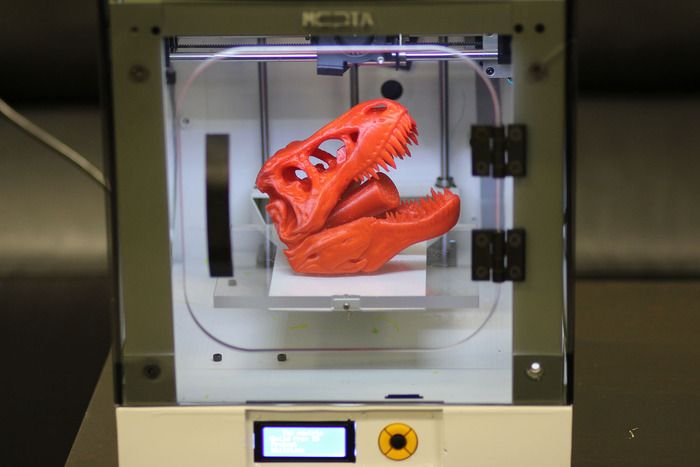

Designers, engineers, sales and marketing staff all utilize high tech 3D printed prototypes to better communicate the products aesthetics and performance.

Before a Cell Phone is held up to an ear, or a Black & Decker tool helps you improve your home, these products are ideas in the minds of designers and engineers. Prototyping gives them form and makes perfection possible.

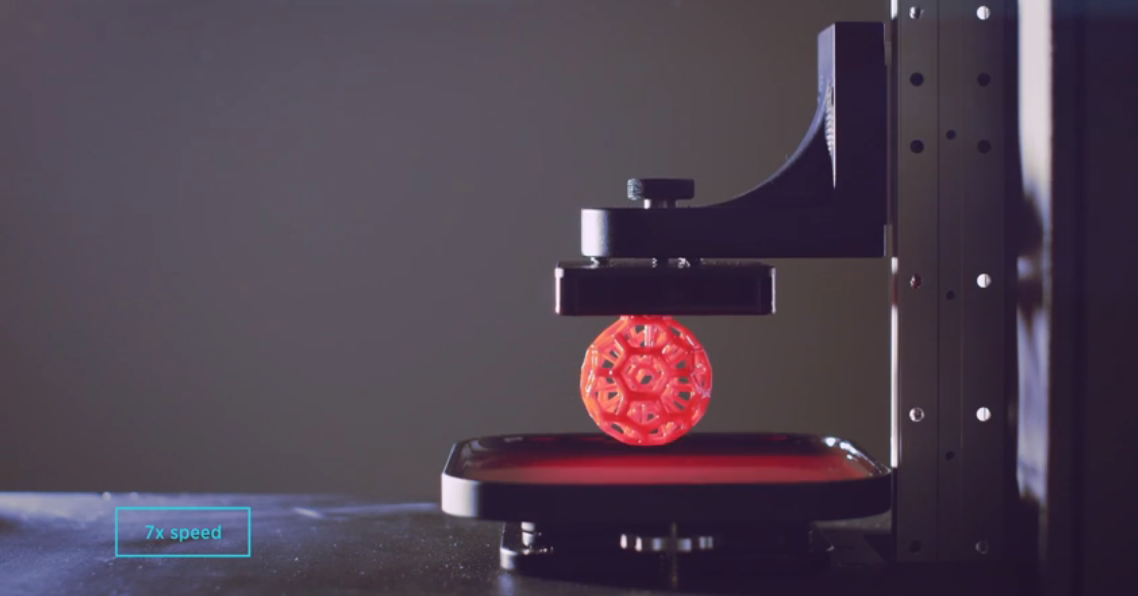

The quickest way to get accurate prototypes is with 3D printing. Watch the video below to learn how it makes product design faster and better, and designers more confident.

3D Printing Technologies

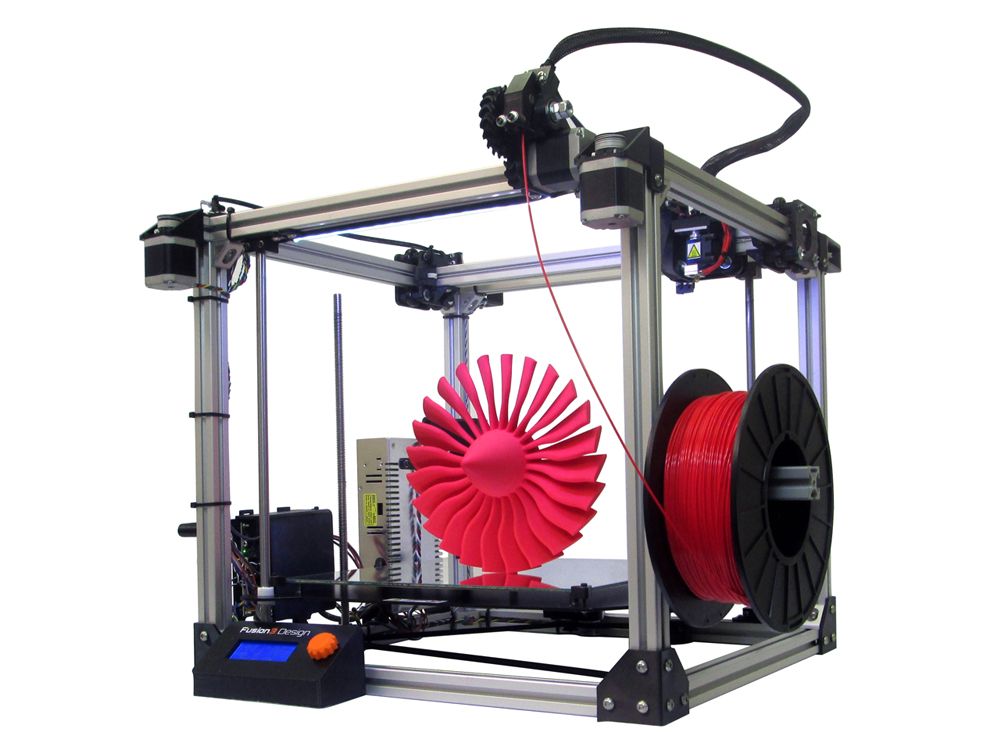

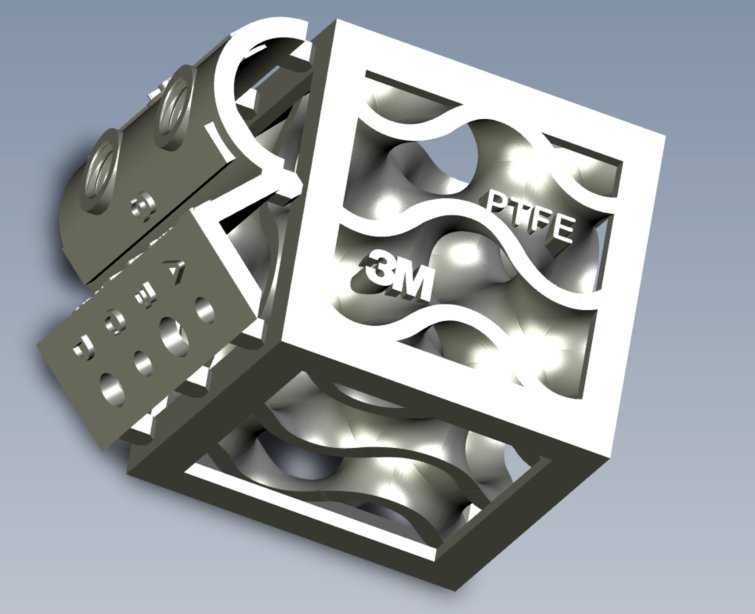

3D printing allows high tech manufacturers to test for fit, form and function and in some cases test their designs in real world conditions.

Realistic appearance models are achieved with Stratasys PolyJet 3D printers which work with an extensive array of materials which include clear, flexible, rigid, rubber-like and with a full spectrum of vibrant colours. Make your design reviews and focus-group sessions more productive with lifelike prototypes.

Make your design reviews and focus-group sessions more productive with lifelike prototypes.

When you need to build your prototypes in the same materials as your finished product, Stratasys offer patented FDM technology. FDM printers work with material such as ABSi, PC, PC-ABS and Nylon 12 to name a few. Save time and money by prototyping early in the design process

Additive Manufacturing Machines & Materials

Stratasys 3D Printing gets high tech products created faster

Stratasys PolyJet 3D Printers and materials improve communication and collaboration because they produce amazingly accurate representations of your high tech product housings which you can share with your team and your clients for a faster, more confident buy-in.

FDM Material

ABS-ESD7

ABS-ESD7 thermoplastic Stratasys 3D printing material has static dissipative properties for applications where a static charge can damage products, impair their performance or cause an explosion.

PolyJet Material

Digital ABS Plus

Digital ABS Plus™ is designed to simulate standard ABS plastics for better impact strength with high-temperature resistance, toughness and superior finish.

PolyJet Material

DraftGrey

Stratasys DraftGrey is a rigid PolyJet 3D printing material used exclusively with the Super High Speed print mode for concept modeling.

3D Printer

Fortus 450mc

A workhorse 3D printer for engineers that require demanding flexibility to print larger-sized or many parts in an array of engineering-grade materials with high speed and unfailing throughput.

PolyJet Material

High Temperature (RGD525)

Stratasys High Temperature PolyJet 3D printing material is ideal for thermal testing prototypes that require hot-air or hot-water flow.

3D Printer

Objet260 Connex3

The Objet260 Connex is a colour, multi-material 3D printer compact enough for office use, which now makes colour 3D Printing more accessible to designers.

PolyJet Material

Rigid Opaque (Vero)

Rigid Opaque (Vero) multi-purpose, multi-colour photopolymers offer strength, stiffness and versatility in blue, white, black, gray, cyan, magenta & yellow.

PolyJet Material

Rigid Translucent (RGD720)

Rigid Translucent (RGD720) is a multipurpose PolyJet photopolymer for translucent plastic simulation, featuring high dimensional stability with surface smoothness.

PolyJet Material

Rigid Transparent (VeroClear)

Stratasys VeroClear is a rigid transparent material that simulates PMMA (polymethyl methacrylate), commonly known as acrylic, used as an alternative to glass .

PolyJet Material

Simulated Polypropylene (Rigur & Durus)

Rigur & Durus are advanced simulated polypropylene materials for 3D printing precision prototypes. Both offer durability and beautiful surface finish.

3D Printer

Stratasys F123

The Stratasys F123 series combines powerful FDM technology with design to print GrabCAD software for the most versatile and intelligent solution available

PolyJet Material

VeroUltra

Stratasys VeroUltra a rigid colour 3D printing opaque material significantly improves the colour opacity and uniformity of 3d printed parts.

PolyJet Material

VeroUltraClear

Stratasys VeroClear is a rigid transparent material that simulates PMMA (polymethyl methacrylate), commonly known as acrylic, used as an alternative to glass .

Additive Manufacturing Applications

How do High Tech engineers use 3D printers?

Application

Production End-use Parts

Stratasys 3D Printers are ideal for low production runs as they build the most durable, stable, repeatable on-demand end-use parts in the industry

Application

Rapid Prototyping

Rapid prototyping with a Stratasys 3D Printer helps companies turn great ideas into successful products faster than ever before by 3D printing your prototypes.

Tool

Injection Molds

3D Printing has made it feasible to create custom injection, blow, and silicone molds for low volume production and validation of the metal mold design.

Why Stratasys 3D Printing for High Tech?

Recommended High Tech Machine

Objet260 Connex3

Compact Colour Multi-Material 3D Printer

The Objet260 Connex3 is a colour, multi-material 3D printer compact enough for office use, which now makes colour 3D Printing more accessible to a wide variety of users.

Make sure your Parts Fit Together

Fit, form & function tests is essential for the electronics design process, you need a system that can produce highly accurate, high-resolution parts.

Create Life Like Prototypes

For prototypes built from production-grade thermoplastics, Stratasys offers patented Fused Deposition Modeling (FDM) Technology. FDM 3D printers work with ABS, PC and other thermoplastics, so you can build prototypes from the same material as the finished product. Get your concept off the starter’s block in record time.

Experiment with Different Materials

For astonishingly realistic appearance in a 3D printed model, Stratasys PolyJet 3D printers work with an impressive array of materials including clear, flexible and rigid. Design reviews and focus-group sessions can be more productive with lifelike prototypes.

Design reviews and focus-group sessions can be more productive with lifelike prototypes.

Create prototypes using the same processes and materials as your finished product. At a fraction of the cost of machining, you can 3D print smooth, accurate Digital ABS injection molds, tough polycarbonate forming patterns or detailed casting patterns.

Featured Case Study

Fishman use 3D Printing to test their designs

Fishman are able to rapidly create fully-functional guitar amplification device prototypes.

These parts are so realistic that their customers can’t actually tell them apart from the real production parts!

High Tech Industry Resources

Access High Tech news, case studies, and white papers

News Story

iSkin use SOLIDWORKS to create mobile & music device protection cases

Case Study / Javelin Case Study

Canadian Sunrise Power use DriveWorks to reduce design time from two days to two hours

News Story

Thalmic Labs design Wearable Technology with SOLIDWORKS

Case Study

Speeding Time-to-Market for Electronics Packaging Systems with SOLIDWORKS Conceptual Designer

White Paper

Empowering Conceptual Design via the single modeling environment

White Paper

Transparent Cloud Data Management facilitates innovation in Conceptual Design

White Paper

What is Aras PLM and how does it solve Product Lifecycle Management challenges?

White Paper

End the Disconnect between your Mechanical and Electrical Design

Download / Trial

3D Content Central – A FREE online directory of downloadable 3D parts

On-demand Webinar

Increase Your Sales by leveraging SOLIDWORKS Data and DriveWorks

White Paper

Modernizing Technical Communication by leveraging 3D CAD Data

White Paper

SOLIDWORKS Design to Manufacturing Process

White Paper

Transforming Product Design for Smarter Products and the Internet of Things

News Story

Stratasys J735 3D Printer sets new standards for realism, colour and speed in rapid prototyping

On-demand Webinar

Integrating design validation into the product design cycle to solve multi-physics problems

White Paper

Six Business Advantages to Owning an In-House 3D Printer

Interested in a High Tech solution?

Call us free at 1-877-219-6757 and get your questions answered

Home › Industry Solutions › High Tech

Who we are and what we do

We are Canadian experts in 3D and have enabled thousands of companies to aim high with SOLIDWORKS solutions for 3D Design, Data Management & Workflow, Manufacturing & 3D Printing.

No matter the size of your business, we have the skills and experience to propel your organization to new heights.

Subscribe to our Newsletter

Get the latest 3D Technology News and Events by subscribing to our Tech Newsletter

NOTE: By subscribing you are granting permission to receive news and promotion emails from us, you can unsubscribe at any time. View our privacy policy

© 1997 - 2023. All Rights Reserved by Javelin Technologies Inc.

Privacy Policy | Accessibility Policy | Terms of Use

Call 877-219-6757 / 905-815-1906

Office Locations: Ontario·Manitoba·Alberta·British Columbia

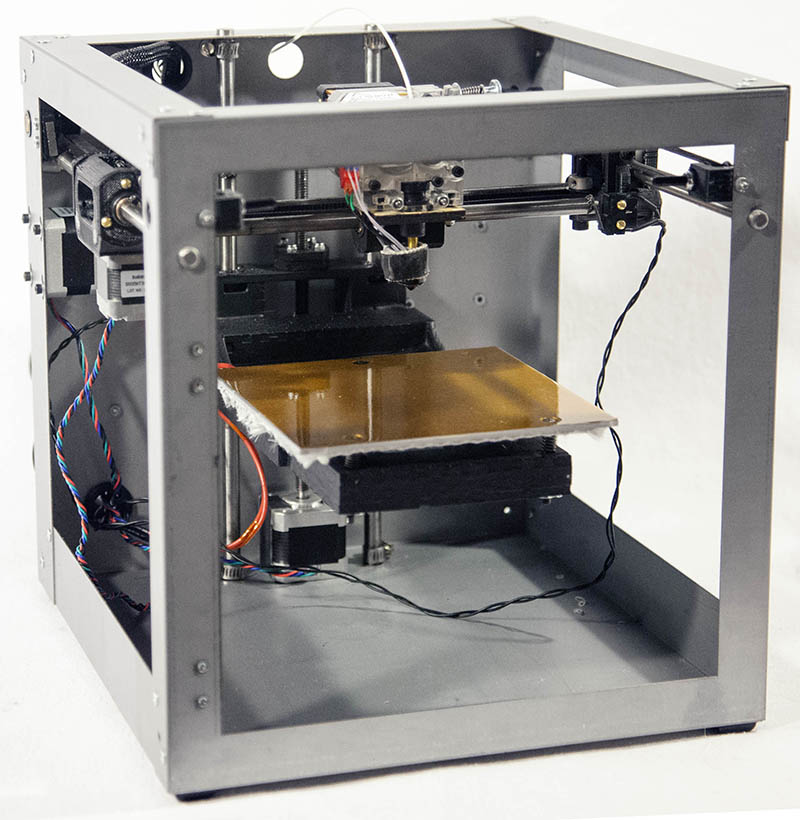

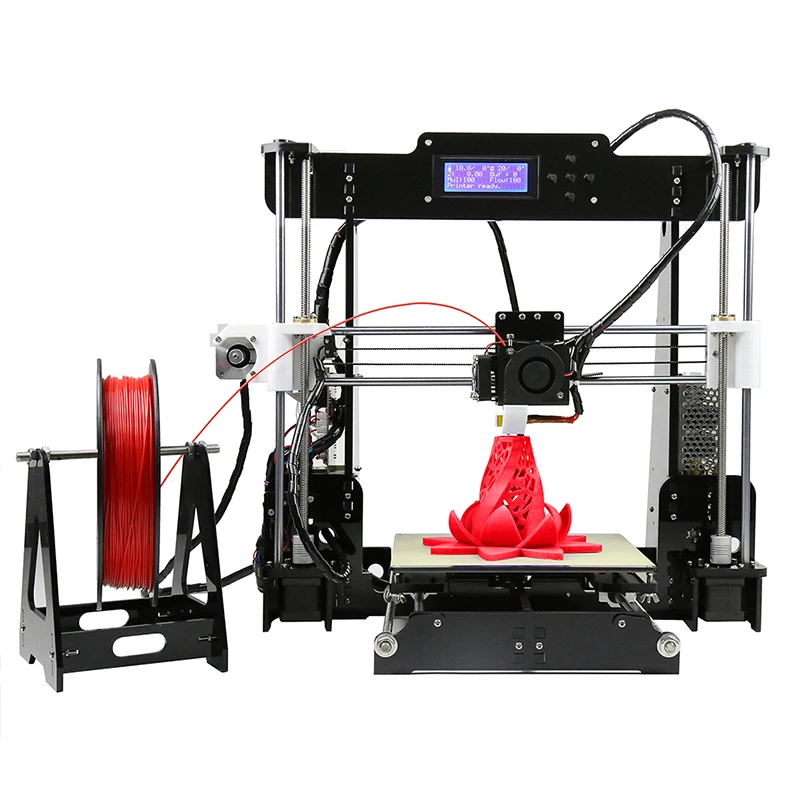

Best 3D Printers Of 2023

When you purchase through links on our site, we may earn an affiliate commission. Here’s how it works.

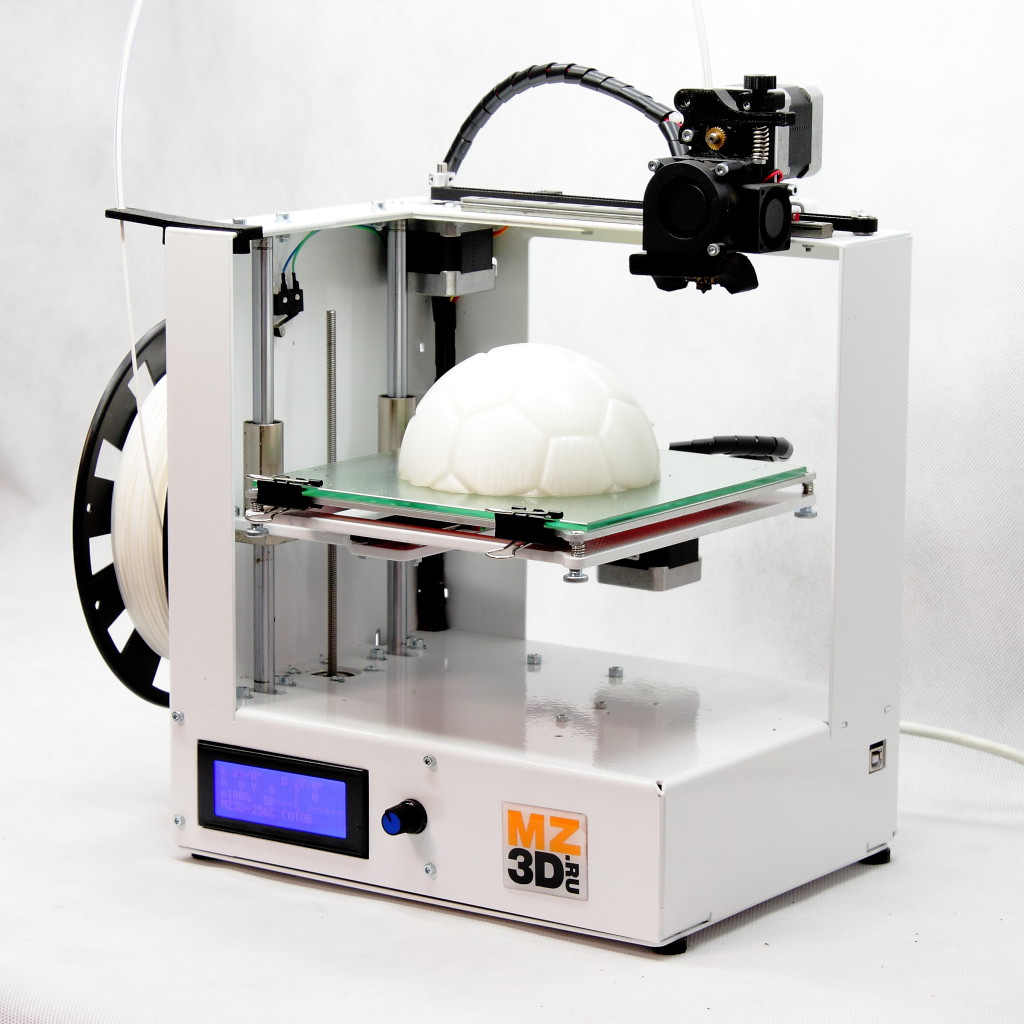

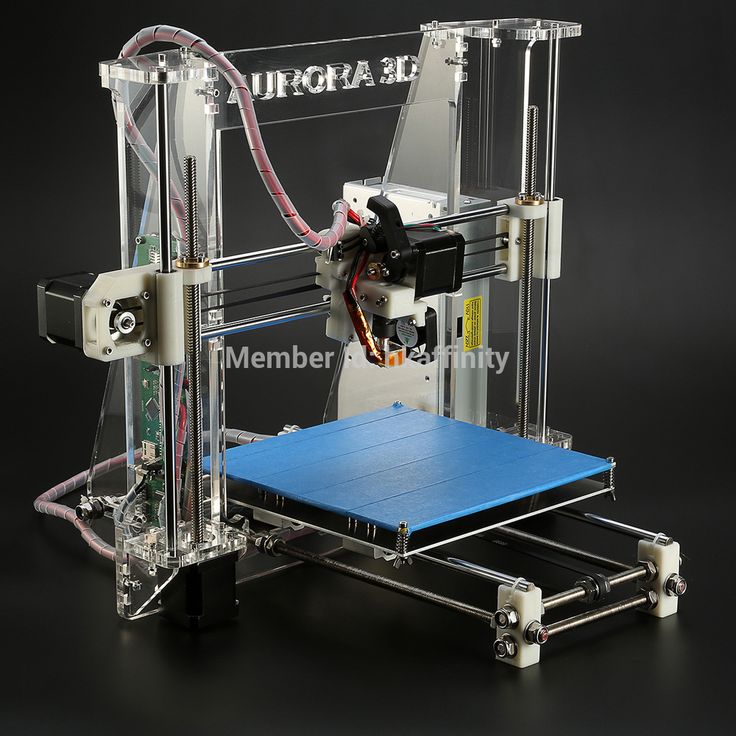

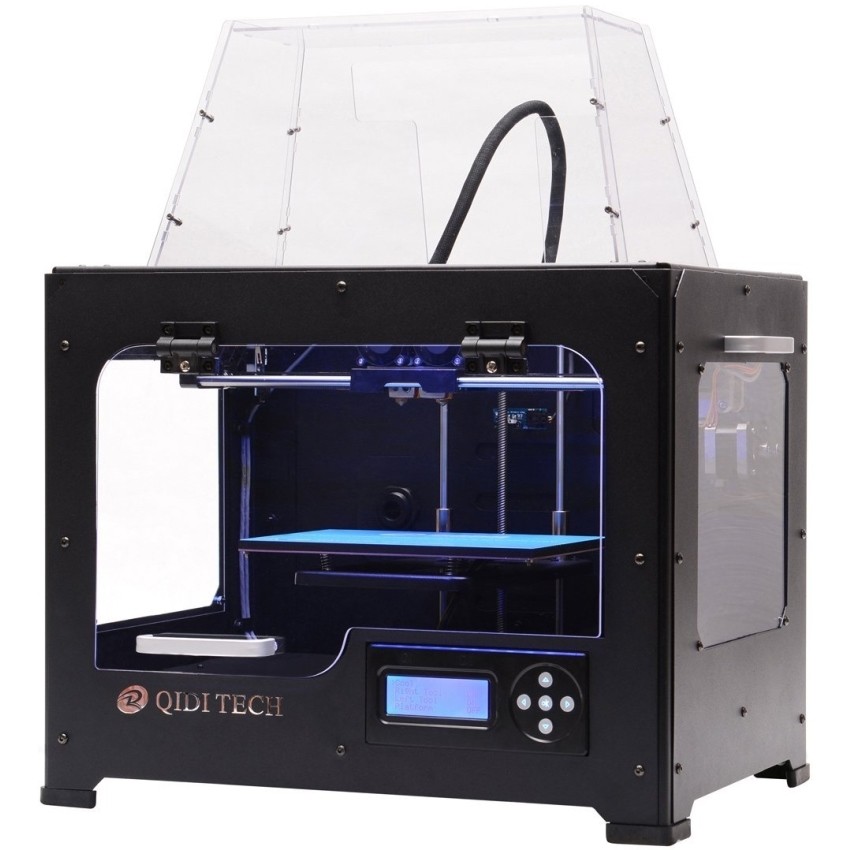

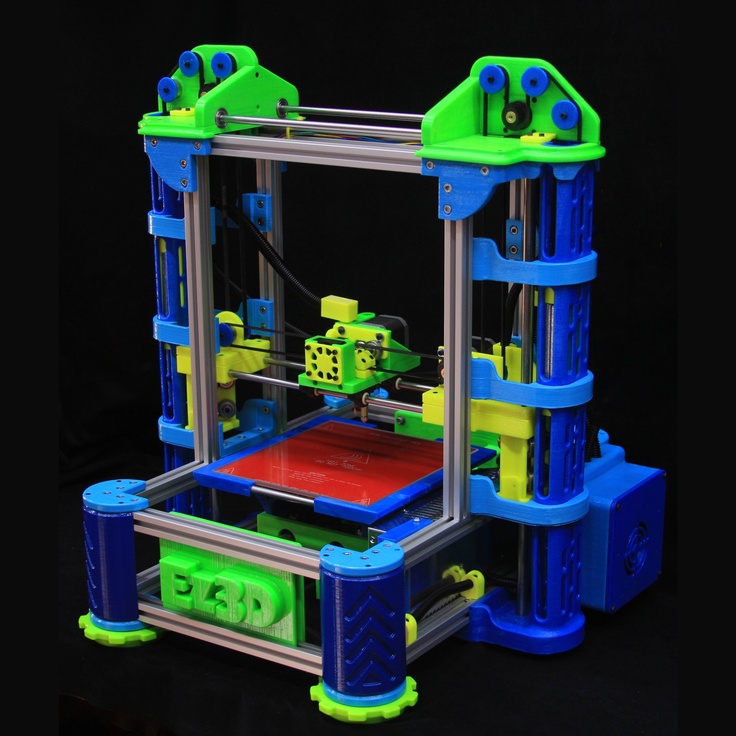

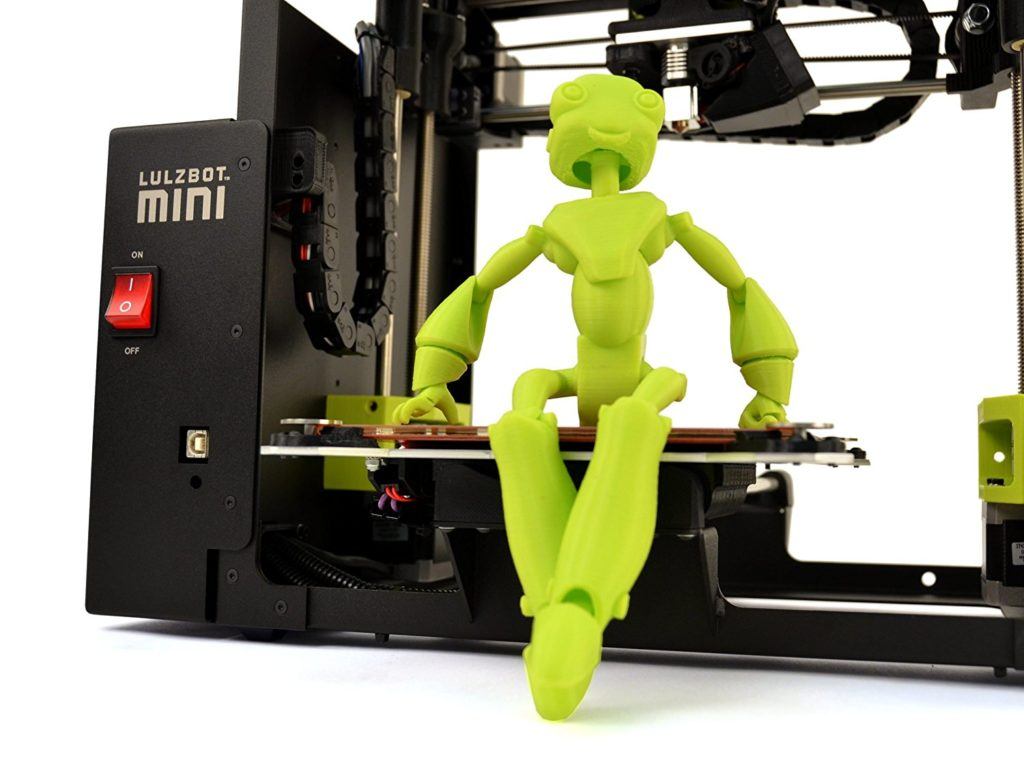

(Image credit: Future)The best 3D printers have become more affordable, and the 3D printer market is growing at an explosive rate, with new brands and styles of printing making an appearance each year. Where many 3D printers used to be huge, expensive machines, developments in technology and production now mean that many of the best options you can buy are increasingly affordable and can sit on a desk in your home without needing dedicated workshop space.

Where many 3D printers used to be huge, expensive machines, developments in technology and production now mean that many of the best options you can buy are increasingly affordable and can sit on a desk in your home without needing dedicated workshop space.

As more products hit the market, the choice of 3D printers that cater to all sorts of user needs and budgets expands. While having more options brings more features and lower prices, picking the best 3D printer for your specific needs can be difficult. However, this guide can help, as we pick some brilliant 3D printers for all uses and budgets, with clear buying advice to help you determine which one you should buy.

Printing hardware has taken off in recent years, so while a handful of filament printers (otherwise known as FDM printers) were all that was once available, there's now a wide variety of different styles to suit your needs across a range of budgets.

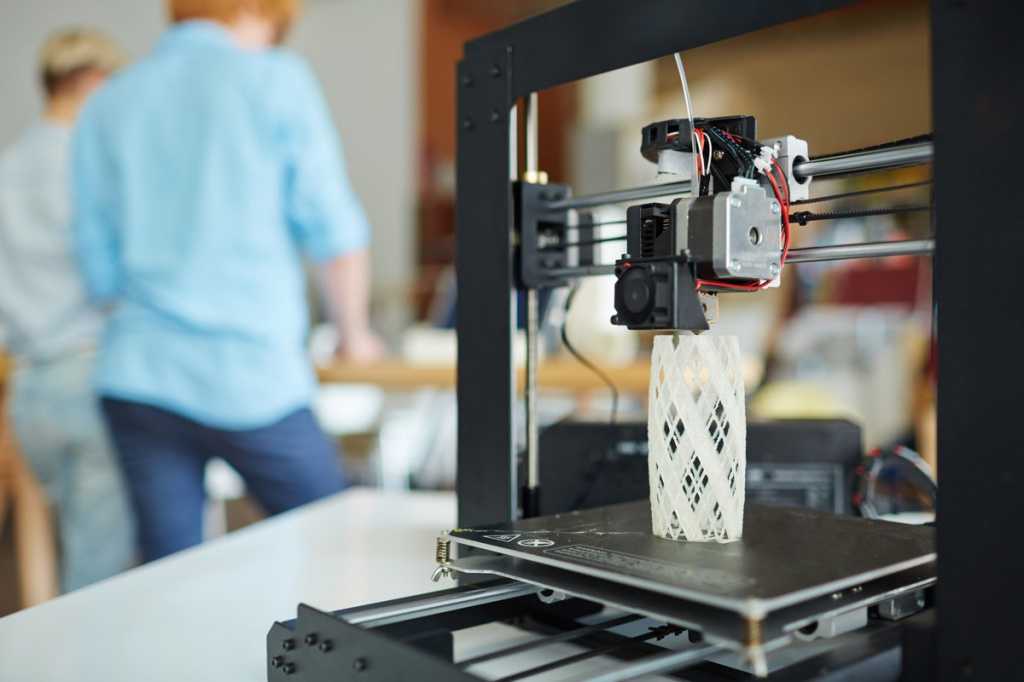

Where office-style printers print ink onto paper, you can use 3D printers to build real-world objects made from plastic, metal, and wood digital models for straight-to-market products, spare parts, or prototyping. FDM printers now come in all shapes and sizes and are well-suited to prototyping and crafting larger objects. At the same time, resin-based (SLA, MSLA, and DLP) printers allow for much greater detail, typically at a smaller scale, making them a fantastic buy for anyone looking to design jewelry or create tabletop miniatures.

FDM printers now come in all shapes and sizes and are well-suited to prototyping and crafting larger objects. At the same time, resin-based (SLA, MSLA, and DLP) printers allow for much greater detail, typically at a smaller scale, making them a fantastic buy for anyone looking to design jewelry or create tabletop miniatures.

Whether you are a hobbyist looking to get started in the world of 3D printing or if your business relies on it, 3D printing is a method of creating physical products, unlike any other way we have seen. Printing in 3D is an easy way to create products through additive measures, meaning there is little to no waste. Additionally, the limits are near endless because you can theoretically 3D Print just about anything.

Whether you’re just starting to 3D print or are an expert, here are the best 3D printers we think you should consider. We've compared these printers across size, functionality, and use case, so there should be something for you, whatever it is you’re looking for. We also looked at their print resolution, build platform, filament type, and pricing.

We also looked at their print resolution, build platform, filament type, and pricing.

Remember that the more expensive choices are better suited for professionals, while the best cheap 3D printers are ideal for those just starting.

The best 3D printers of 2023 in full:

Why you can trust TechRadar Our expert reviewers spend hours testing and comparing products and services so you can choose the best for you. Find out more about how we test.

Original Prusa MINI (Image credit: Prusa)1. Original Prusa MINI+

Small, affordable, and remarkable 3D printer

Specifications

Print technology: Fused Deposition Modeling

Build Area: 18 x 18 x 18cm / 7 x 7 x7in

Minimum layer resolution: 50 microns

Maximum layer resolution: 200 microns

Dimensions: 33 x 33 x 38cm / 13 x 13 x 15in

Weight: 4.5kg / 9.92lbs

Today's Best Deals

Reasons to buy

+

Great value for an FDM printer

+

Easy to use

+

Supports a variety of filament types

Reasons to avoid

-

Reel sits separately

-

Imperfect print quality

-

Calibration can be tricky

This affordable open-frame 3D printer is small enough to sit on your desk and easy enough to assemble yourself without expertise. It comes in kit form and uses FDM (Fused Deposition Modeling) to turn popular modeling materials such as PLA, PETG, ASA, ABS, and Flex into printed products.

It comes in kit form and uses FDM (Fused Deposition Modeling) to turn popular modeling materials such as PLA, PETG, ASA, ABS, and Flex into printed products.

There’s a Network LAN and USB port for simple connectivity and a user-friendly interface. The 2.8-inch 65k color screen makes navigating the options and settings easy, and on first starting the machine, it takes you step-by-step through the setup process. This entry-level printer should be the first choice for crafters, modelers, and engineering enthusiasts.

The Original Prusa MINI+ is a replacement for the Original Prusa MINI (no +), with the key advantage being that it now comes with a superPINDA sensor, allowing the first layer calibration to be faster and more reliable.

Read the full review: Original Prusa MINI.

CEL-UK RoboxPro (Image credit: CEL-UK)2. CEL-UK RoboxPro

Best 3D printer for commercial printing

Specifications

Print technology: Fused Deposition Modeling

Build Area: 210 x 300 x 400mm / 8. 27 x 11.81 x 15.75in

27 x 11.81 x 15.75in

Minimum layer resolution: 50 microns

Maximum layer resolution: 500 microns

Dimensions: 513 x 508 x 605mm / 20.2 x 20 x 23.82in

Weight: 26kg / 57.3lbs

Today's Best Deals

Reasons to buy

+

Swappable print heads

+

Dual Extruder and auto bed leveling

+

Wi-Fi ready, no wires needed

Reasons to avoid

-

Large scale printer, not ideal for home use

-

Can be difficult to load filament

CEL-UK is a leader in 3D Printer innovation, with the original Robox printers introducing many new features to the world of FDM 3D printers. The RoboxPro comes with a feature set that reads like a 3D print wish list; auto filament loading, auto bed leveling, Wi-Fi, network printing, and swappable tool heads.

The main focus of the machine is quality and reliability, designed for anyone wanting a printer that can realize product ideas and get them to market. The enclosed design makes it an ideal choice for commercial and educational use.

The enclosed design makes it an ideal choice for commercial and educational use.

There's a sizable touchscreen panel built into the front of the machine. It displays the current materials and can be used to navigate settings and print directly from USB or other external drives.

Read the full CEL-UK RoboxPro review.

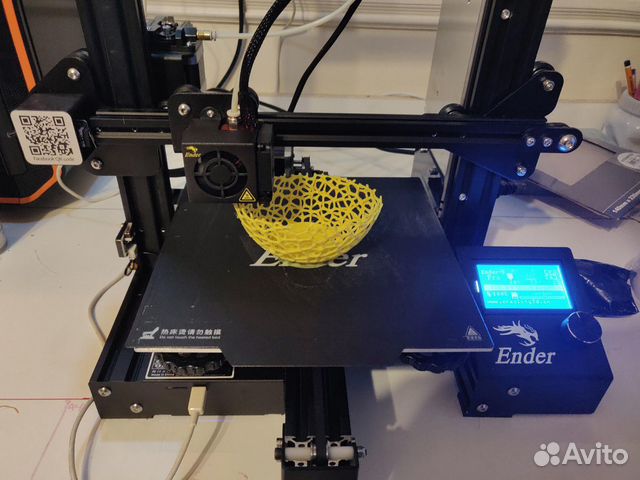

(Image credit: Creality)3. Creality Ender-5 S1

An ideal 3D printer for any 3D print enthusiast or small business on a budget

Specifications

Print Technology: Fused Deposition Modeling

Build Area: 220 x 220 x 280mm / 8.66 x 8.66 x 11in

Minimum Layer Resolution: 50 microns

Maximum Layer Resolution: 350 microns

Dimensions: 425 x 460 x 570mm / 16.73 x 18.11 x 22.44in

Weight: 12.1kg / 26.68lbs

Today's Best Deals

Reasons to buy

+

Incredible value

+

Robust design

+

High-quality tool head

Reasons to avoid

-

Not a true CORE XY printer

-

Large footprint

-

No enclosure for enhanced materials (Optional enclosure extra)

Having a predecessor with a quality reputation instantly puts pressure on the new model to perform. From the small amount of initial construction needed to build the printer to the outstanding bed leveling technology, the Ender-5 S1 proves to be a worthy upgrade and on a completely different level of quality to the original Ender-5.

From the small amount of initial construction needed to build the printer to the outstanding bed leveling technology, the Ender-5 S1 proves to be a worthy upgrade and on a completely different level of quality to the original Ender-5.

The cubed design might not be a true CORE XY printer, but the robust frame and tool head’s design and precision enables a print quality that pits this printer against models that are at least twice the price.

The design is refined, the tool head completely overhauled, and with upgrade options such as an enclosure and laser head, there is plenty of add-ons to expand your creativity. This is a printer designed for both enthusiasts and small business users alike.

Read our full Creality-5 S1 review.

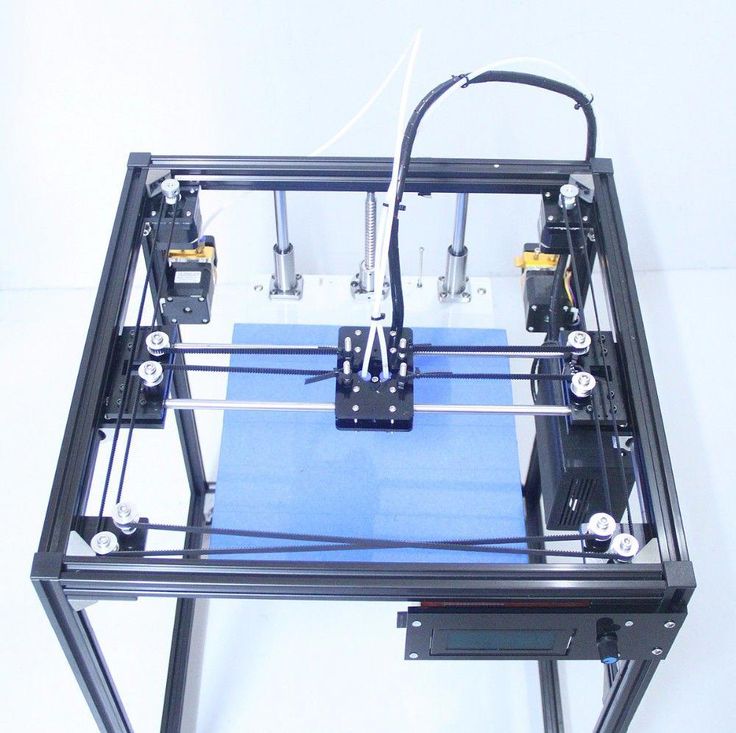

(Image credit: TRILAB)4. TRILAB DeltiQ 2

Distinctive delta design for professional 3D printing

Specifications

Print technology: Fused Deposition Modeling (FMD)

Build area: 25 x 25 x 30cm / 9. 84 x 9.84 x 11.81in

84 x 9.84 x 11.81in

Minimum layer resolution: 50 microns

Maximum layer resolution: Variable

Dimensions: 41 x 50 x 81cm / 16.14 x 19.69 x 31.89in

Weight: 10kg / 22.04lbs

Today's Best Deals

Reasons to buy

+

Elegant design

+

Easy expansion

Reasons to avoid

-

Not suitable for all materials

-

Fully open design

This elegant delta design should get your attention if you’re looking for a professional 3D printer for fairly large and complex projects. It uses FDM technology to build 3D models from rolls of filament. Still, instead of the more common cartesian printers, the TRILAB DeltiQ 2 has a fixed round build plate with the extruder suspended between three arms that move the print head along three axis. It gives this model a fairly small footprint, while its high tower design ensures it can print some quite large pieces.

Unlike most 3D printers, it has two extruder options, one for standard PLA and PETG and the other for flexibles. It just requires a little retooling to swap between them. The TRILAB DeltiQ 2 uses some of the best components available in its construction, and the interface is a smartphone running a dedicated app. This handsome, high-end workshop printer would sit well in any laboratory, studio, or classroom.

Read our full TRILAB DeltiQ 2 review.

Original PRUSA SL1 (Image credit: PRUSA)5. Original PRUSA SL1S SPEED

The best MSLA printer just got better

Specifications

Print technology: Stereolithography

Build area: 320 x 450 x 500mm / 12.6 x 17.72 x 19.69in

Minimum layer resolution: 25 microns

Maximum layer resolution: 100 microns

Dimensions: 400 x 237 x 225 mm / 15.75 x 9.33 x 8.86in

Weight: 4.5kg / 9.92lbs

Today's Best Deals

Reasons to buy

+

Rapid printing

+

Great build quality

Reasons to avoid

-

High maintenance

-

Limited build volume

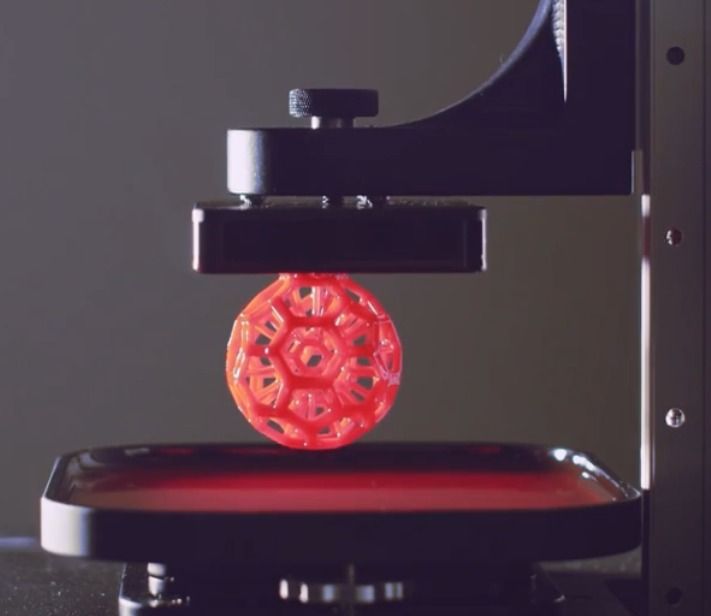

Prusa Research revolutionized the FDM 3D printer market, and this model looks set to do the same for SLA printers. While this printer uses stereolithography technology, it's a slight variant known as MSLA.

While this printer uses stereolithography technology, it's a slight variant known as MSLA.

This uses a monochrome LCD and UV LED to expose the resin, which is cheaper than precision lasers but just as accurate. The SL1S SPEED replaces the outgoing SL1, and as you might have guessed from that model name, it’s faster – around ten times faster and comes with a vastly improved print quality.

The SL1S's physical design hasn't changed a great deal over the SL1. It features the same touchscreen LCD on the front, which is again good and responsive.

The speedy new model looks set to lead the SLA market with support from the excellent PrusaSlicer software and a huge open-source community.

Read our full Original Prusa SL1S 3D printer review.

Anycubic Vyper (Image credit: Anycubic)6. AnyCubic Vyper

The best beginner friendly FDM 3D printer

Specifications

Print technology: Fused Deposition Modeling

Build area: 245 x 245 x 260mm / 9. 65 x 9.65 x 10.24in

65 x 9.65 x 10.24in

Dimensions: 508 × 457 × 516mm / 20 x 17.99 x 20.31in

Weight: 10kg / 22lbs

Today's Best Deals

Reasons to buy

+

Built-in accessories drawer

+

Reliable automatic bed-leveling

+

Great value for the features you get

Reasons to avoid

-

Excessive initial stringing

-

Questionable build quality in places

-

Cura profile needs fine-tuning

If you have ever wanted to get into the world of 3D printing, but it seemed too intimidating for you, the AnyCubic Vyper is a great intro level option. While perfect for beginners with its auto-leveling feature and minimal assembly, seasoned printing hobbyists will also appreciate what it can offer, albeit with a few adjustments.

As the 'automatic leveling' might imply, the AnyCubic Vyper removes the need to align your build plate manually should you want to move the machine to a different location. It's fast and accurate, saving time when setting up your first print, which makes setting up and getting started a breeze.

It's fast and accurate, saving time when setting up your first print, which makes setting up and getting started a breeze.

The touchscreen control panel is satisfyingly fast and easy to use, but we found that the estimated print completion time was consistently incorrect. Once the printer is properly optimized, you'll enjoy impressive print quality.

Read our full AnyCubic Vyper review.

Raise3D E2 (Image credit: Raise3D)7. Raise3D E2

The best workhorse 3D printer

Specifications

Print technology: Fused Deposition Modeling

Build area: 330 x 240 x 240mm / 12.99 x 9.45 x 9.45in

Minimum layer resolution: 20 microns

Maximum layer resolution: 250 microns

Dimensions: 607 x 596 x 465mm / 23.90 x 23.46 x 18.31in

Weight: 35kg / 77.16lbs

Today's Best Deals

Reasons to buy

+

High-resolution print capability

+

Innovative ouch screen interface

+

Dual Extruder system can work independently

Reasons to avoid

-

Huge and heavy, not ideal for home use

-

Careful placement of bed required

-

Needs manual assistance for filament loading

3D printing has come of age, and machines like the Raise3D E2 bring high-end FFF printing to home, education, and business users. This dual extrusion printer goes head-to-head with the RoboxPro and will fulfill most companies' design and development needs with slick business and network integration.

This dual extrusion printer goes head-to-head with the RoboxPro and will fulfill most companies' design and development needs with slick business and network integration.

The printer display is vast and detailed, and you can swiftly access all the printer settings through the fast and responsive touchscreen interface. You can print directly from a USB key, wired connection, network, or Wi-Fi, making it ideal if several people are utilizing the printer. You will also find many step-by-step videos for many of the printer's features.

Home and educational users will benefit from a simple interface and near-faultless reliability. The only drawback of this machine is its size and weight.

Read the full Raise3D E review.

(Image credit: Anycubic)8. Anycubic Photon M3

Detailed 3D modelling for beginners

Specifications

Print technology: Stereolithography (SLA)

Build area: 18 x 18 x 18cm / 7.09 x 7. 09 x 7.09in

09 x 7.09in

Minimum layer resolution: 50 microns

Maximum layer resolution: 200 microns

Dimensions: 18 x 16.4 x 10cm / 7.09 x 6.46 x 3.94in

Weight: 7kg / 15.43lbs

Today's Best Deals

Reasons to buy

+

Good value

+

Detailed models

Reasons to avoid

-

Print size is small

-

Poorly placed USB port

The Anycubic Photon M3 is the ideal entry-level resin printer to introduce you to 3D printing. It’s relatively easy to set up and operate, and the box includes everything you need to get started except for the UV resin. This compact model will fit easily on your desk in a well-ventilated room, though the build volume is somewhat limited at 180 x 163.9 x 102.4mm or 7 x 6.5 x 4 inches.

This modest machine can turn out surprisingly detailed models for printing small plastic parts or artistic pieces. The interface is a 7.6-inch panel, and the software will help you print your project and slice it. If you want to make larger models, you should consider one of Anycubic’s larger 3D printers, but this is a great place to start for $299 (about £275 / AU$480).

The interface is a 7.6-inch panel, and the software will help you print your project and slice it. If you want to make larger models, you should consider one of Anycubic’s larger 3D printers, but this is a great place to start for $299 (about £275 / AU$480).

Read our full Anycubic Photon M3 review.

Snapmaker 2.0 A350 (Image credit: Snapmaker)9. Snapmaker 2.0 A350

Best 3-in-1 3D printer

Specifications

Print technology: Fused Filament Fabrication, CNC, Laser

Build area: 350 x 350 x 350mm / 13.78 x 13.78 x 13.78in

Minimum layer resolution: 50 microns

Maximum layer resolution: 300 microns

Dimensions: 645 x 480 x 580mm / 25.39 x 18.90 x 22.83in

Weight: 29kg / 63.93lbs

Today's Best Deals

Reasons to buy

+

3D printer, CNC, and Laser cutter in one

+

Solid design and build quality

+

Easy to understand software

Reasons to avoid

-

Switching between uses takes time

-

Enclosure purchased separately

-

Very noisy when printing

A true 3-in-1 machine makes sense because 3D printers, CNC, and Laser cutters all use the same basic mechanics and technology. The original Snapmaker has a dedicated following, so it is no surprise that Snapmaker 2.0 builds on its predecessor's reputation and features.

The original Snapmaker has a dedicated following, so it is no surprise that Snapmaker 2.0 builds on its predecessor's reputation and features.

The SnapMaker boasts excellent build quality and comes with clear assembly instructions. The assembly takes around 20 minutes. There's a 5 inch (720x1280px) touchscreen on the machine that can be used to select options, preview models, calibrate and open stored files. The touch screen is a powerful addition to the usability of the machine — it runs on Android OS and features a Quad-Core A7 CPU @ 1.1GHz.

The A350 is the largest of three Snapmaker models and proves proficient in all disciplines. Swapping between the three heads and beds does take time to reconfigure and calibrate, but for the price and features, it's worth it.

Read the full Snapmaker 2.0 A350 review.

(Image credit: Bambu Lab)10. Bambu Lab P1P

A blazing fast printer made to hit the ground running

Specifications

Print technology: Fused Deposition Modeling

Build area: 256 x 256 x 256mm / 10. 2 CoreXY acceleration, vibration compensation and pressure advance technology. The printer also has an automatic bed leveling sensor and a Direct-drive Extruder for better filament control.

2 CoreXY acceleration, vibration compensation and pressure advance technology. The printer also has an automatic bed leveling sensor and a Direct-drive Extruder for better filament control.

With a fast setup time, you’ll be up and printing in no time. And for those looking for the ultimate in customization, Bambu Labs provides templates for printing your own custom side panels. Additionally, the P1P allows up to 16 colors through their Automatic Material System (AMS). Control the printer with an onboard screen or connect with Bambu slicing software and mobile app.

The Bambu P1P also offers users advanced parts that can be printed and assembled with electronics from the Bambu store. With an all-metal hotend, filament run-out sensor, power loss recovery, fans with speed feedback and semi-automatic belt tensioning, users are setup for success out of the box.

- We've also featured the best printers and the best laptops for graphic design.

Frequently Asked Questions

What is a 3D printer?

A 3D printer is a machine that creates three-dimensional objects using computer-created designs (like a digital 3D or CAD model).

These machines rely on an additive manufacturing process to build objects layer by layer.

How to choose the best 3D printers for you?

To select the best 3D printer, you'll need to consider what you're going to do with it. If you're going to be printing small objects, then a small-size printer is apt, but a large printer is naturally the best option for bigger creations.

For printing high-quality objects with fine details, you'll need a high resolution printer, but these prints will cost more and take more time to get ready.

Look out for the printer's interface and the overall ease of use, along with other aspects like the kind of software it uses, the type of filament, build platform, and pricing.

The best 3D printers: How we test

3D printers are tested using a collection of bespoke benchmarks that help show the strengths and weaknesses of each model that, after time, can be compared against other products. These will differ depending on printer type, but a filament printer will be tested for stringing, bridging, and speed, as well as additional commentary on detail, achieved, and noise levels.

This will be done fairly, with dues given to different materials and printer types, with resin printers being subject to smaller, more detailed models to replace the stringing test. Design, price, and performance will also be explored as sections within the reviews.

All our tests are conducted from the perspective of the printers target market where possible, so expect to see a lot of tabletop miniatures and figurines alongside the usual 'benches' (test models that are also dubbed as 'torture tests' to see where a printer needs to be better optimized for future prints).

Round up of today's best deals

Creality Ender-5 S1

$559

$499

View

See all prices

Anycubic Vyper

$499

$429. 99

99

View

See all prices

Raise3D E2

$3,499

View

See all prices

Anycubic Photon M3

$319.99

$249.99

View

See all prices

Deal ends Mon, Mar 27

SnapMaker 2.0

$1,399

View

See all prices

powered by

Sign up to the TechRadar Pro newsletter to get all the top news, opinion, features and guidance your business needs to succeed!

Contact me with news and offers from other Future brandsReceive email from us on behalf of our trusted partners or sponsorsCollin is the B2B Hardware Editor for TechRadar Pro. He has been in journalism for years with experience in both small and large markets including Gearadical, DailyBeast, FutureNet and more.

He has been in journalism for years with experience in both small and large markets including Gearadical, DailyBeast, FutureNet and more.

Using 3D Digitization to Expand the Possibilities of 3D Printing

In this article, we'll take a closer look at the benefits of digitizing with 3D hardware. Find out more about how 3D scanning can help professionals across industries from manufacturing to design.

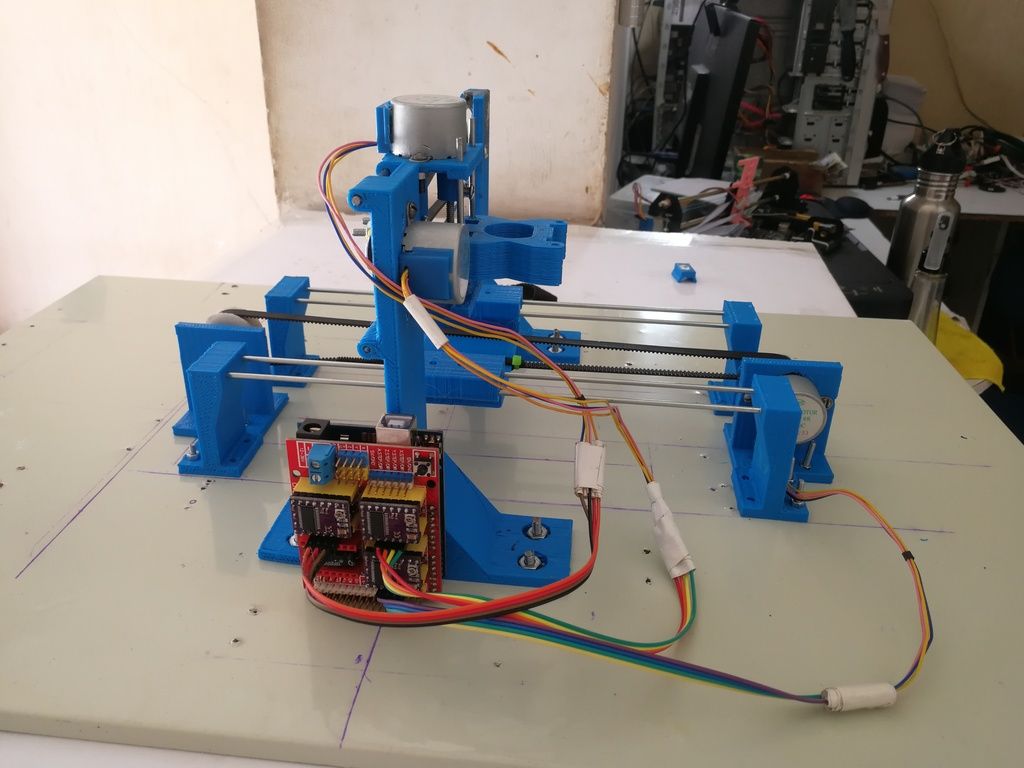

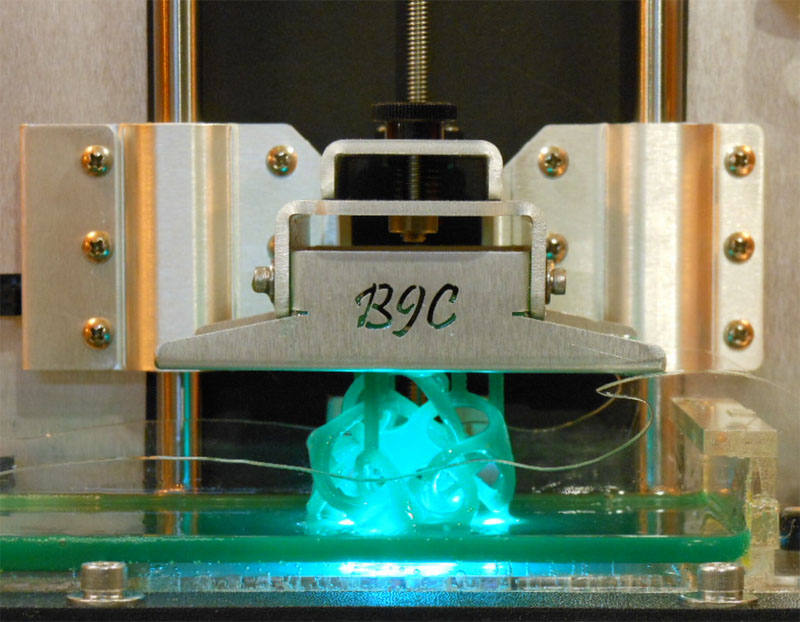

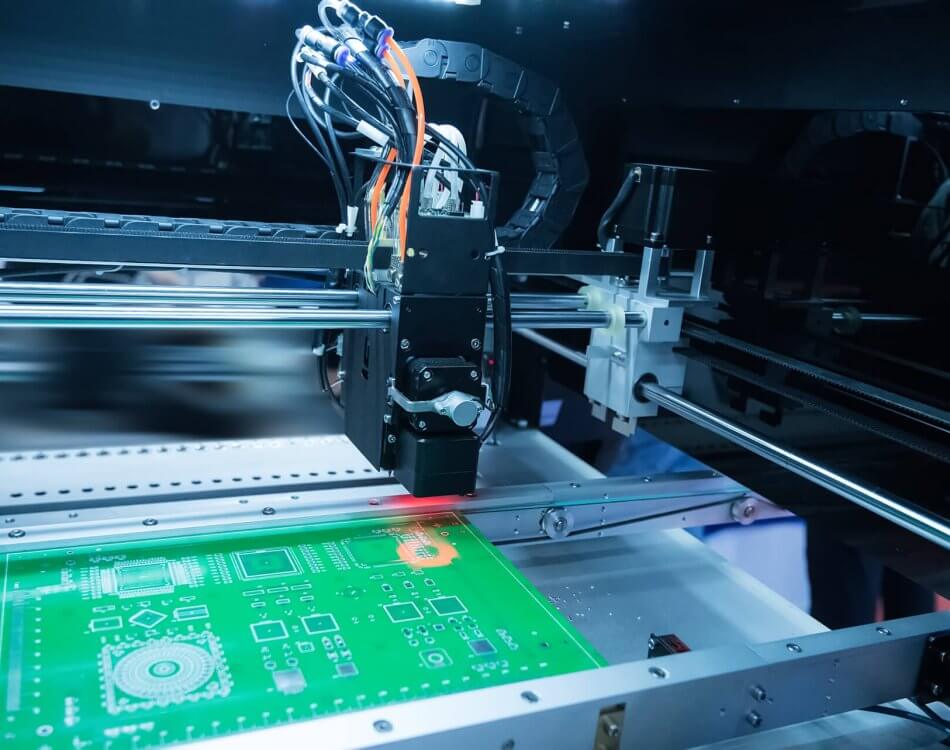

High-tech 3D printing is the process of creating objects from a digital or CAD model. The material is applied, bonded or cured in a precise pattern that is automatically created under computer control. Most devices work on the principle of layer-by-layer application of material.

3D printing allows you to recreate any object you see, regardless of its size, shape or color. This is one of the newest technologies in the world, which is likely to become revolutionary in many industries, including manufacturing and medicine.

There are several ways to create a 3D model for printing. One of them is 3D scanning or digitization. With Scantech's high-precision 3D scanners, designers and engineers can create accurate 3D models of objects, both small and large.

One of them is 3D scanning or digitization. With Scantech's high-precision 3D scanners, designers and engineers can create accurate 3D models of objects, both small and large.

How can 3D digitization technology be used to empower the 3D printing industry?

Checking 3D printed parts

Additive manufacturing (3D printing) requires, like any other, strict quality control. Any product that reaches users must be of proper quality.

Scantech offers customized solutions for automated quality control. The basis of the solution is an industrial-grade 3D scanner, which has a maximum accuracy of 0.025 mm. The measurement accuracy of the device meets the control requirements for most parts printed on a 3D printer.

Scanned data processing allows the automatic generation of a color map that helps to compare the received data with the original CAD model. In this way, we can tell at a glance whether a part matches the original model or not. In addition, comparison templates can be pre-configured according to inspection requirements. Such parameters are used to check the deviation of the section, distance between centers, contours, flatness, center coordinates, etc. Each scanned part is compared against the selected parameters, and all data is visible in the report, which is automatically generated.

Such parameters are used to check the deviation of the section, distance between centers, contours, flatness, center coordinates, etc. Each scanned part is compared against the selected parameters, and all data is visible in the report, which is automatically generated.

This quick and comprehensive test method can be used in two ways. One of them is scanning printed parts, comparing them with standard drawings, analyzing the quality of the parts, evaluating the stability of 3D printing, and generating an inspection report. This verification method ensures that the products will meet all requirements.

Another is using a 3D scanner to detect and compare different parts in the same batch or different batches, analyze the stability of 3D printers, and help research and development of 3D printers with more stable printing.

Parts Reverse Engineering and Refurbishment

Some users are using 3D scanning technology to offer customers intelligent solutions for repairing broken parts.

Using a 3D scanner and reverse engineering software, you can get object data and then restore broken or lost items. The integration of these technologies makes it possible to solve the problem of import substitution, the lack of rare parts, reduce the cost of producing a new part, or simply reduce the waiting time.

Medical rehabilitation

In the field of medicine, treatment requires individual products designed specifically for the patient: anatomically designed braces, prostheses, orthopedic insoles and other products. 3D technologies allow you to quickly produce custom-made products, while retaining all the features that cannot be realized in products made in large-scale production.

Let's take a case study: spinal orthopedics.

Shanghai TPM3D made orthopedic corsets for patients using iReal 3D non-contact scanning technology and nylon 3D printing. Making a custom brace that is lighter and more breathable takes less time. In addition, the corset is waterproof and antibacterial, and is also ideal for long-term wear. A plastic corset is more comfortable to wear, while it has the same orthopedic effect as plaster products.

A plastic corset is more comfortable to wear, while it has the same orthopedic effect as plaster products.

A selection of articles from the "Knowledge Base" section from the LIDER-3D website: 1) Choosing a portable 3D scanner: 5 things you need to know • 2) Introduction to coordinate metrology. Part 1 • 3) How to produce quality products?

Art, painting and design

In art and design, 3D scanning technology helps to obtain, for example, a prototype for engraving. After obtaining the necessary data, you can immediately start creating products on a 3D printer or use the resulting model for traditional production.

For example, Shanghai UnionTech, together with Lu Renjie, helped to recreate the ancient Chinese mythological world: "Classic of Mountains and Seas" with the help of 3D digitization. Since clay sculpture is not easy to preserve for a long time, printed figurines were used for the exhibition. With the help of 3D scanning and 3D printing, the company's specialists created 809 exquisite exhibits. This avoided the difficulty of traditional clay modeling and was a great way to represent a fantasy world.

This avoided the difficulty of traditional clay modeling and was a great way to represent a fantasy world.

What's more, the data captured by the high-precision laser scanner can be used for other types of production (such as engraving, CNC, etc.) and scaled up for the production of products for advertising campaigns and promotions.

Car Customization

The automotive industry is rapidly entering the era of personalization. That is why the demand for tuning and customization of their own cars has increased sharply among users.

3D scanning can help to change the appearance of the car (for example, install a rear wing, bumper, new interior elements, change the exhaust pipe, etc.). Scanning allows you to get accurate data about the part, which will allow you to create a new part on this basis. With large-format 3D printing technology, it can take much less time from an idea to a project than with traditional part manufacturing.

3D reproduction of cultural relics

Kuenboya Institute of Intelligent Manufacturing and SCANTECH 3D conducted high-precision 3D scanning of cultural relics at the Yecheng Museum in Handan, Hebei Province, and archived the data to facilitate further research and restoration of cultural property.

Thanks to 3D printing technology, it is possible to copy cultural relics in 1:1 scale for exhibition, thus avoiding irreparable damage to authentic objects during transportation and display.

Paleontological reproduction

In 2021 in Lufeng, Yunnan, SCANTECH participated in the entire digital collection and restoration of dinosaur fossils. Using high-precision 3D scanning, data from recently discovered dinosaur fossils has been obtained. Then the software for post-processing and reconstruction of the 3D model was used. After all the stages of work, the specialists performed 3D printing to restore the remains of the dinosaur. So scientists were able to determine the morphological evolution of Lufengosaurus 200 million years ago.

3D scanning can truly restore all the details, including even tiny cracks in fossils. To recreate the remains of a dinosaur, the latest high-strength photosensitive resin was used as a printed material, which was later used for science exhibitions.

After 3D scanning and 3D printing were completed, scientists were not only able to get closer to understanding the appearance of dinosaurs, but also to get a lot of other information from accurate data. The 3D scan data will be the basis for conducting relevant research and tracking the main life stages of the dinosaur, its relationship with modern dinosaurs and habitat.

Using 3D technology, researchers have found a loophole in time and space, giving us a unique scientific journey. With the help of new technologies, we have the opportunity to explore information about life on Earth 200 million years ago.

Total

3D digitization technology allows you to expand the possibilities of 3D printing in different areas. The search and study of new areas of application of technology, as well as the cooperation of leading manufacturers with various companies involved in 3D printing, will solve the problems of 3D scanning and use the experience gained in new industries.

Thank you all, the material was translated by a team of LIDER-3D specialists, we will be glad to hear your questions in the comments.

If you are interested in Scantech 3D scanners, you can get detailed expert advice by contacting us at LIDER-3D, as well as purchase equipment from our website.

Follow us on social networks: Telegram, VKontakte, Ya.Zen, RuTube, YouTube, TikTok, My World, Odnoklassniki to be the first to receive the most interesting materials!

3D printers in construction: prospects for application

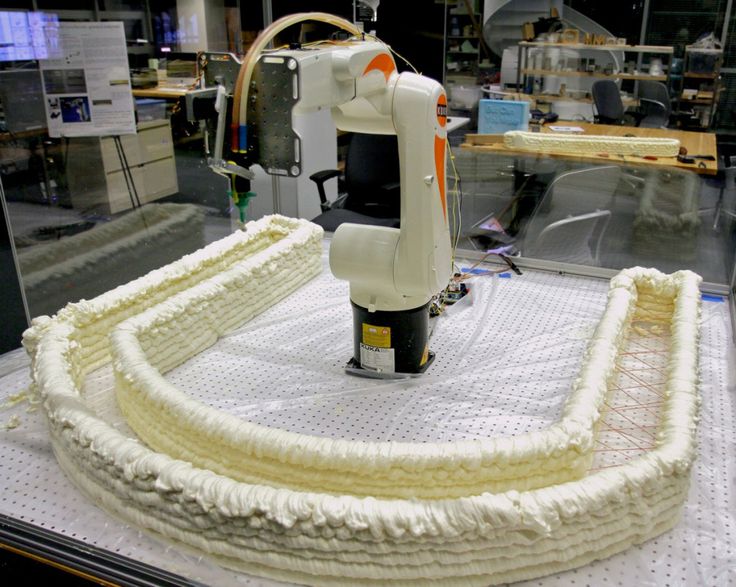

At first glance, 3D printing structures seem to be some kind of shell of a half-finished building. But upon closer examination, you will not find even a brick. Layers of material seem to build up one on top of the other - this is how a complex structure is created. It's a futuristic world of 3D printing where robotic arms automatically layer and compress layers of concrete or plastic or any other material into a foundation and build a structure.

This method of construction is quite niche today - only a few prototypes of 3D houses and offices have been printed in the world. However, this technology represents an exciting and potentially powerful solution to building change.

What is 3D printing in construction, what is the potential, and will we be working on 3D printed projects in the near future?

- What is 3d printing in construction?

- 3D printers in construction: how is it done?

- 5 examples of innovation

- How can 3d printed projects help construction companies?

- 3D printing distribution

- Civil engineering 3D printing

- Wiki House technology - an open source project for 3D printing: what is behind the concept

- Reverse side of the coin

- How 3D printing can be integrated into construction

- About PlanRadar

3D printing in construction - what kind of technology?

3D printing for construction uses both a 3D printer, which has a robotic "crane-arm" that builds structures directly on the construction site, and the creation of certain elements by printers at the factory, which are already assembled into a structure on site.

The concept of 3D printing is not new: it first appeared in the 80s. But it's only in the last decade that this technology has been improved enough (and the cost significantly reduced) to become a real mainstream.

3D printers are not much different from conventional inkjet office printers. The software tells the printer about the dimensions of the final product. And then the printer starts to output the material to the platform according to the plan. 3D printers often use liquid metals, plastics, cement, and variations of various materials that, when cooled and dried, form a structure.

In a 3D construction printer, the CAD or BIM programs tell the device what to print, and the machine begins layering the material according to the design plan.

3D printers in construction: how do they work?

3D printing concept - The printer extrudes a defined liquid mixture in layers, level by level, creating a design based on a 3D model. The prepared mix of concrete, filler, plasticizer and other components is loaded into the hopper of the device and fed to the print head. The mixture is applied to the surface of the site or to the previous printed layers. This is how most 3D printers work. Among them, there are three types of devices for 3D printing:

The mixture is applied to the surface of the site or to the previous printed layers. This is how most 3D printers work. Among them, there are three types of devices for 3D printing:

Robotic printer

Read also: New technologies in construction 2021

5 innovative examples of 3D printing

To date, only a few 3D printing projects have been implemented in the construction industry. Here are five of the most impressive and promising projects:

Dubai City Hall Office Building, UAE

1. Dubai City Hall Office Building, UAE

3D printed building. The office block built in the UAE is 9,5 meter high building with an area of 640 m2.

An Apis Cor 3D printer moved around an open-air construction site with a crane and erected different parts of the structure.

2. Office of the Future, UAE

Office of the Future, UAE

Another impressive 3D printed building in the UAE, the Office of the Future is a unique, fairly large structure that currently houses the temporary headquarters organization Dubai Future Foundation.

For this building, the elements were not created on site and were printed in 17 days, while the building itself was assembled in 48 hours.

3. WinSun 3D Printer Houses, China

WinSun 3D Printer Houses, China

WinSun 3D Printing Company of China has also applied factory 3D printers to the construction of residential buildings. The company has created several house projects, including a small multi-storey building. All construction details can be printed quickly and cheaply and then quickly assembled on the construction site.

The company calculated that it would cost as little as $161,000 to build and print their five-story building.

4. 3D printed number plate in Lewis Grand Hotel, Philippines

3D printed number plate in Lewis Grand Hotel, Philippines

When planning a trip to the Philippines, consider staying at the Lewis Grand Hotel in Angeles City , Pampanga, where visitors will be greeted with the world's first 3D printed hotel suite. The hotel room was designed by Lewis Jakich, hotel owner and materials engineer, in collaboration with 3D printing specialist Anthony Rudenko. They created a massive 3D printer that prints sand and concrete based on volcanic ash. The room was printed in 100 hours.

The hotel room was designed by Lewis Jakich, hotel owner and materials engineer, in collaboration with 3D printing specialist Anthony Rudenko. They created a massive 3D printer that prints sand and concrete based on volcanic ash. The room was printed in 100 hours.

5. Two-story mansion in Beckum, Germany

Two-story mansion in Beckum, Germany

The first 3D-printed residential building with an area of about 80 square meters - the brainchild of the German construction company PERI GmbH and the architectural design bureau MENSE-KORTE ingenieure + architecture. A BOD2 3D printer was used to print one square meter of double wall cladding in 5 minutes. The building is a structure with three-layer hollow walls filled with insulating mass. Installation of hollow pipes and connections during printing was carried out manually.

3D printing in construction seems really impressive, but what are the real benefits of such technology?

How can 3D printed designs help construction companies?

Proponents of 3D printing houses and commercial offices point to several advantages of this method of construction:

- Waste-free construction

In the UK, almost a third of the waste comes from the construction industry. According to the Transparency Market Research Group, the construction industry worldwide will produce 2.2 billion tons of construction waste by 2025. And although most of the waste is related to the demolition of buildings, the construction sites themselves produce a lot of waste.

According to the Transparency Market Research Group, the construction industry worldwide will produce 2.2 billion tons of construction waste by 2025. And although most of the waste is related to the demolition of buildings, the construction sites themselves produce a lot of waste.

Conversely, 3D printing can reduce waste to almost zero. A 3D printer uses a well-defined amount of material that is required to print a design - no more, no less. This can be a big savings.

- Reduced energy consumption

3D printing in construction encourages the use of locally available materials and natural ingredients. This practice can reduce energy costs in transportation, construction and manufacturing, as most local materials require less energy to process or install. If traditional materials with toxic chemical impurities are replaced with natural ones, then the toxicity of the entire construction can be reduced. In addition, local materials are often better suited to local climates and can reduce a building's heating or cooling load, which also reduces construction costs.

- Save time and money

As with AI in construction, a 3D printer can run 24 hours a day, 7 days a week. This means construction projects have the potential to be completed much faster and a number of low-skilled labor costs can be avoided. What's more, 3D printing eliminates the need for temporary structures, such as formwork and scaffolding, that are commonly used in traditional construction. Studies of 3D printed concrete structures have shown a significant reduction in formwork requirements, reducing costs by 35-60%.

- Can realize unusual design shapes

One of the most attractive characteristics of 3D printers is their ability to create complex and unusual design designs, including a single, unique one. Since the job of a 3D printer is to layer the material, they can be programmed into absolutely any unusual shape that would be much more difficult to create with traditional techniques.

- Minimize human error and improve safety

Published statistics of workplace injuries by the American agency BLS in 2020 indicates that construction is one of the most traumatic areas and a high incidence of diseases. Every day, about 5333 workers die on the construction site. And with the advent of 3D printing, the number of work injuries and fatalities will obviously decrease, as it makes construction more programmable and automated. Robotic construction requires standardized, accurate and complete digital building information, making this technology more accurate and efficient, with minimal rework due to human error or any information inconsistencies. The usual problems with materials and components that need to be stored somewhere, protected from damage are leveled out, problems with installation and work in progress due to damage also disappear - 3D elements are created as they are built, they do not need to be moved and stored.

- Exploring new markets

The use of a 3D printer also allows construction companies to enter new market sectors that were previously inaccessible to them. And for start-up companies, having a 3D printer will be a competitive advantage. What's more, 3D printing is a brilliant way to elevate or improve the reputation of a construction company's brand among those who believe that concrete production has an impact on the planet's environment.

Distribution of structural 3D printing

3D printing for structural reinforcement, small scale components and structural steel could revolutionize design, construction and space exploration. In addition, the European Space Agency (ESA) believes that using 3D printed metals to create high-quality complex shapes can significantly reduce their cost, and they will become very common.

ESA has developed a project with the European Commission to improve the printing of metal components that can be used in space. In total, 28 European partners have united for the joint project AMAZE (Additive Manufacturing Aiming Towards Zero - layer-by-layer 3D printing for zero waste from production and efficient production of high-tech metal products).

In total, 28 European partners have united for the joint project AMAZE (Additive Manufacturing Aiming Towards Zero - layer-by-layer 3D printing for zero waste from production and efficient production of high-tech metal products).

Almost everything can be designed on a computer, so AMAZE plans to install a 3D printer on board the spacecraft, and as soon as an astronaut needs any part, a tool, he can simply print it.

Structural 3D printing

Civil engineering 3D printing

Civil engineering 3D printing has been gaining popularity over the past decade, as has the aerospace and biomedical industries. This revolutionary manufacturing technique is based on its unique ability to create any geometric shape without any formal restrictions, minimizing waste but increasing productivity and results. The construction industry's push towards automation has recently reached important milestones, including the creation of the first structures using robotic "arms" and 3D printing technology.

The use of 3D printing in the creation of structural elements from polymer materials, concrete and metals is becoming more common.

These civil engineering technicians can create freeform and innovative architectural designs using CAD-integrated software.

However, despite considerable research in the aerospace and bioengineering industries to evaluate and analyze this mechanism, there is still a lack of understanding of its use, the impact of 3D printed materials in civil structures, both in terms of material properties and structural response.

Imperial College London

Read also: Best Building Apps in 2021

WIKI HOUSE - 3D printing in construction: what is the concept behind

Wiki House is an innovative project created by a small group of architects in London in 2011 . It offers an open source digital house design system that allows users to create, upload and share designs and print their own houses.

The kit does not require any special knowledge and training and can be created in 1 day. Elements are digitally cut from ordinary sheet material, like plywood, using a CNC machine. And it's much faster, less costly, and doesn't require the involvement of experts, as in conventional traditional construction.

Elements are digitally cut from ordinary sheet material, like plywood, using a CNC machine. And it's much faster, less costly, and doesn't require the involvement of experts, as in conventional traditional construction.

A standard two bedroom house can be built for less than £50,000 and additional components such as cladding, insulation, windows and more can be added to the main frame of the structure. The first house that was built on the basis of the open source Wiki House technology was a two-story building. The 3D printed house was presented at the London Design Festival in 2014.

The Wiki House movement was spearheaded by Alastair Parvin, whose TED presentation "Architecture for People, Built by People" talked about the promise of 3D printing in construction. The creator of this project believes that Wiki House can help solve the housing problem, especially in emergency situations such as earthquakes (there is already evidence that 3D-printed houses can withstand shocks up to magnitude 8).

In the future, this could become a real alternative to low-cost houses, while allowing the customer to control the design of the project.

3D building built using Wiki House

Will 3D printing be the sustainable future of building?

3D printing has the potential to revolutionize the supply chain and structure, thanks to a new design and manufacturing method. According to the study, 3D printing can help the construction industry become more economical, more efficient and greener.

Saxon University of Applied Sciences scientists Ivo Kotman and Neils Faber claim that 3D printing technology will be a "game changer". They explored the possibilities of 3D printing concrete, and their conclusions are:

- 3D printing shortens the supply chain and the overall design process. 3D printing right on the job site eliminates time-consuming steps in the design process. The architects, engineers, contractors, clients, and executives who normally have to be actively involved in a project are no longer needed in 3D printing.

Since all tasks can be combined in one figure of the architect, who uses the modeling method and reproduces the exact holistic designs.

Since all tasks can be combined in one figure of the architect, who uses the modeling method and reproduces the exact holistic designs. - Pipe fitting and electrical wiring become easier and more efficient. Heating systems, insulation, plumbing and electricity all require the laborious on-site installation of conventional construction. However, in 3D printing, some of these features can be incorporated into the 3D printing process. Cavity wall printing is less resource intensive, improves insulation, and allows the use of 3D-printed hot or cold water channels. Moreover, the need for on-site installation is eliminated, which directly affects the reduction of waste.

- The best logistics. 3D printing eliminates 3 logistics and shipping issues. Firstly, a lot of materials and elements often deteriorate upon delivery, and if everything is printed on site, then damage is minimized

Secondly, in order to withstand transportation, the parts must be with increased technical characteristics, which by default increases the cost of them, and therefore the entire project. 3D printing right on the construction site will help to avoid such additional costs.

3D printing right on the construction site will help to avoid such additional costs.

- Creation of individual house designs available to the general market. Usually, building a house with the involvement of an architect is an expensive pleasure for most consumers. But with concrete 3D printing, you don't have to worry about the chosen shape, it won't cost more. In fact, this means that in the future, more people will be able to buy houses of their own design, according to their individual needs

Reverse side of the coin

While 3D printing is definitely attractive, it's still important to look at it impartially, removing some of the promotional stimulus. Skeptics note several disadvantages of this technology.

Skeptics note several disadvantages of this technology.

- Research and development costs

Most construction companies operate with relatively low profitability. To start using 3D printing everywhere, significant investments will be required.

- Will consumers see this as a marketing ploy?

3D printed houses, offices, shops and other infrastructure are often impressive. But do most people really want to live or work in one? For most people, brick houses are much more familiar and attractive. Other technologies such as prefabricated houses also seemed like an attractive technology of the future for some time, but have not been widely adopted, despite the fact that in many cases they were cheaper than traditional ones.

- Difficulty integrating with other components

3D printers can create unique and interesting designs. However, if you need a building that will use different materials or different elements that will not be suitable for 3D printing, then it will be a challenge to include a 3D printer for the building process.

- Skilled labor shortage

With the current problem of a shortage of skilled labor in the construction sector in general, 3D printing will require an even larger set of specialized knowledge and skills, which will have to be selected from an already small niche of candidates. So finding specialists to work in 3D printing for construction may be another difficult task in the future.

- Construction quality control

Weather conditions can slow down the traditional building process, but things are even worse for 3D printing. The environmental factor for commercial construction may reduce the demand for 3D printing. What's more, quality control can be a much more serious task, requiring constant monitoring of the process by real people at the construction site.

- No standards and regulations

Despite the regular mention of 3D printing in the media, it still has not had a significant impact on the construction sector. There is an obvious liability issue when using these printers, even more so than human liability when doing some construction work. And quite a few other ambiguities regarding this technology. So until norms and standards are established, as well as rules in this area, 3D printing is unlikely to become mainstream in the construction industry.

There is an obvious liability issue when using these printers, even more so than human liability when doing some construction work. And quite a few other ambiguities regarding this technology. So until norms and standards are established, as well as rules in this area, 3D printing is unlikely to become mainstream in the construction industry.

Read also: New technologies in construction 2021

How can 3D printing be integrated with construction?

At the moment there is strong evidence that 3D printing is worthy of attention and can be applied in the construction segment, and most likely that this technology will be used more in the coming years. True, it is not known how widely these devices will be used on the construction site, or whether they will remain only a tool for the manufacture of block elements for prefabricated structures. But for certain projects, it is reasonable to assume that 3D printers and this technology in construction will be a must-have tool in the arsenal of builders.