3D printing meat video

Scientists Create First 3-D Printed Wagyu Beef | Smart News

Scientists recreated the famous beef, which is prized for its fat marbling, or sashi. H. Alexander Talbot via Wikimedia Commons under [CC BY 2.0]Scientists in Japan successfully 3-D printed a cut of Wagyu beef that looks just like the real thing. The team at Osaka University in Japan used three dimenstional bioprinting to replicate the cut's specific arrangement of muscle, fat and blood vessels. They hope lab-grown meats could provide a more sustainable—and delicious—alternative to traditionally-raised beef.

“By improving this technology, it will be possible to not only reproduce complex meat structures, such as the beautiful sashi [or marbling] of Wagyu beef, but to also make subtle adjustments to the fat and muscle components,” study co-author Michiya Matsusaki said in a statement.

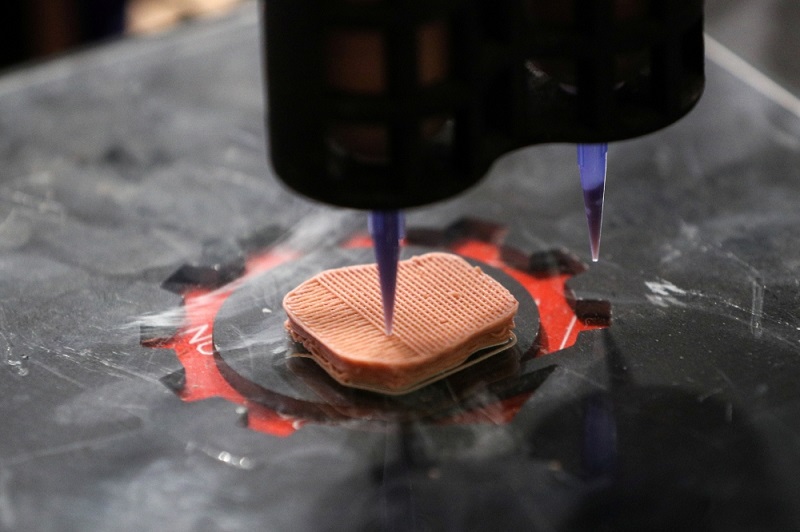

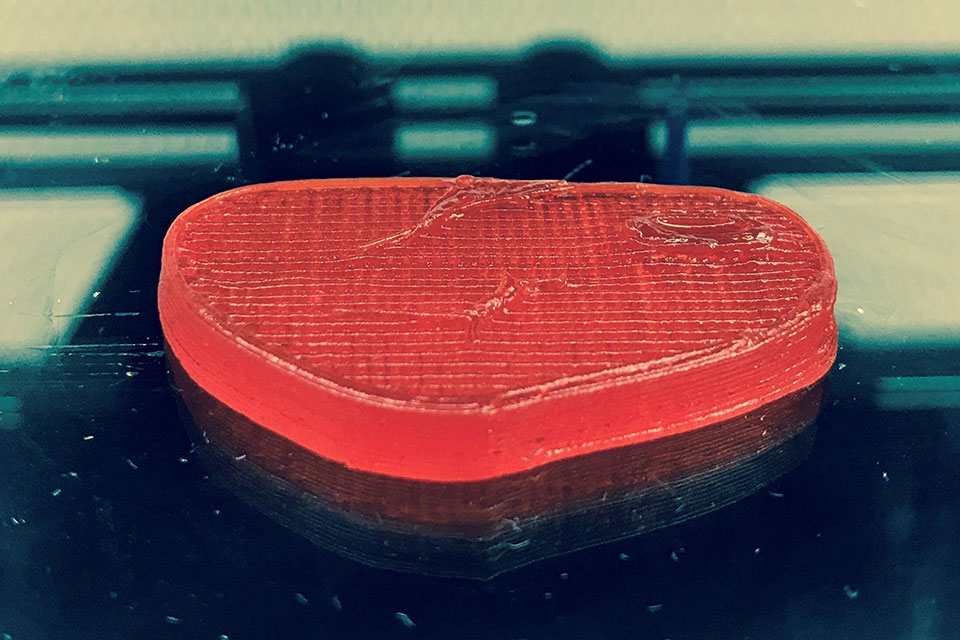

The study, published last month in Nature Communications, is the first to attempt bioprinting Wagyu beef—an expensive cut prized for its tenderness, flavor and delicate fat marbling. Like traditional 3-D printing, bioprinting uses a computer-generated model that deposits layers of material to create a final three-dimensional project. But unlike standard methods which use materials like plastic or metal, 3-D bioprinting stacks living cells to build complex structures like blood vessels and muscle tissue.

This new beef isn’t the first bioprinted cut of cow—an Israeli company unveiled their 3-D printed ribeye steak earlier this year—but Wagyu posed a specific challenge, according to Insider’s Cheryl Teh. The team needed to recreate the Wagyu's signature intramuscular fat content, known more commonly as fat marbling or sashi.

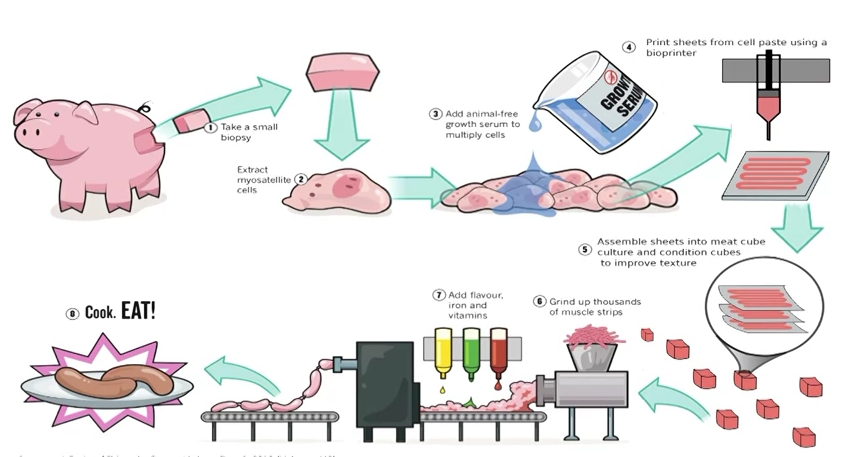

To create the manufactured meat, scientists used two types of stem cells from specific breeds of Waygu cows, reports Victor Tangermann for Futurism. By manipulating the stem cells, they could coax them into every type of cell needed to culture the meat. The individual fibers of muscle, fat and blood vessels were bio-printed in layers that replicated a perfect Waygu cut.

“Using the histological structure of Wagyu beef as a blueprint, we have developed a 3-D-printing method that can produce tailor-made complex structures, like muscle fibers, fat and blood vessels,” study co-author Dong-Hee Kang said in a statement.

No one has tasted the beef, so the meat’s flavor performance remains to be seen, reports Lauren Rouse for Gizmodo Australia. More studies are needed before anyone is green-lighting cooking or eating it. Because earlier experiments with cultured meats have grown largely unstructured cuts, the team hopes this high-controlled printing method can improve lab-grown meat texture, too. Theoretically, a customizable meat printing method means scientists could create tastier, more tender cuts of beef than exist today.

The scientists hope their 3-D printed meat will be an appealing option for those looking to reduce their reliance on livestock, which currently accounts for around 15 percent of U.S. greenhouse gas emissions. Though lab-made Wagyu beef could be a more sustainable alternative to traditionally raised meat, the high cost of production and limited regulatory oversight means it won’t be available on supermarket shelves any time soon.

Recommended Videos

This 3D Printing Technology Will Power the Global Cultivated Meat Market

You're reading Entrepreneur Asia Pacific, an international franchise of Entrepreneur Media.

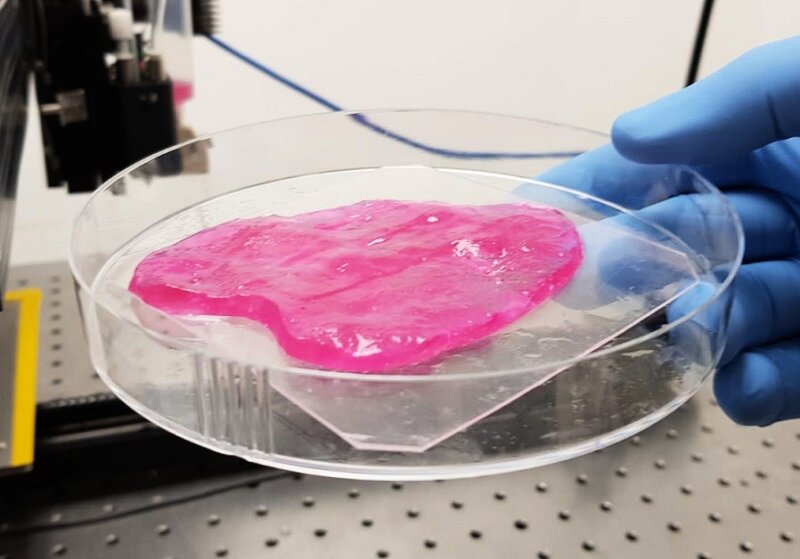

To the casual onlooker, nothing separates the lab-grown meat that Steakholder Foods (NASDAQ: STKH) allows you to print from the conventional edible meat, until you dig a little deeper. While there are several companies in the meat industry betting on meat alternatives, Steakholder Foods offers the technology that will power the entire global cultivated meat market.

As Arik Kaufman, CEO of Israel-based Steakholder Foods puts it, "we are recreating Star Trek and that is amazing." The comparison is from the magical replicator in the popular science fiction TV series that could create meals on demand. However, Kaufman is not one to deal in mere fantasy. "What we are doing here is a scientific feat," he notes. The startup is scaling up a process to help companies print meat products. Also known as cultured meat, this is made from animal cells rather than slaughtered animals. Steakholder Foods is also currently in a collaboration to print fish products, starting with eel and grouper.

Also known as cultured meat, this is made from animal cells rather than slaughtered animals. Steakholder Foods is also currently in a collaboration to print fish products, starting with eel and grouper.

According to Steakholder Foods' website, the 3D printed meat that the company's proprietary technology helps to print is "made up of muscle and fat tissue grown from animal cells and being developed to be indistinguishable from farm-raised meat in taste, texture and smell". Steakholder Foods intends to lead the industry in terms of technological support while servicing the cultured meat sector — a sector McKinsey estimates will be worth $25 billion global business by 2030.

Leading the pack with 3D technology and key collaborations

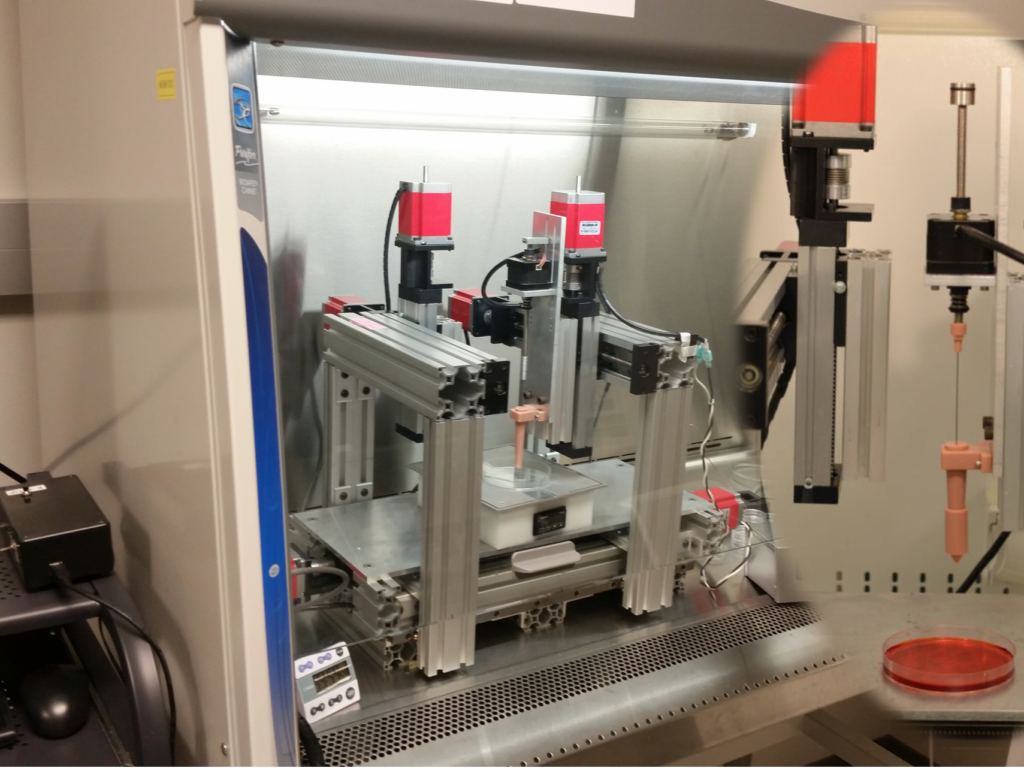

Commenting on the company's 3D technology, Kaufman claims its "the first high-output bioprinter that can print at a very high pace, with extreme precision and while keeping the cell viable throughout the process."

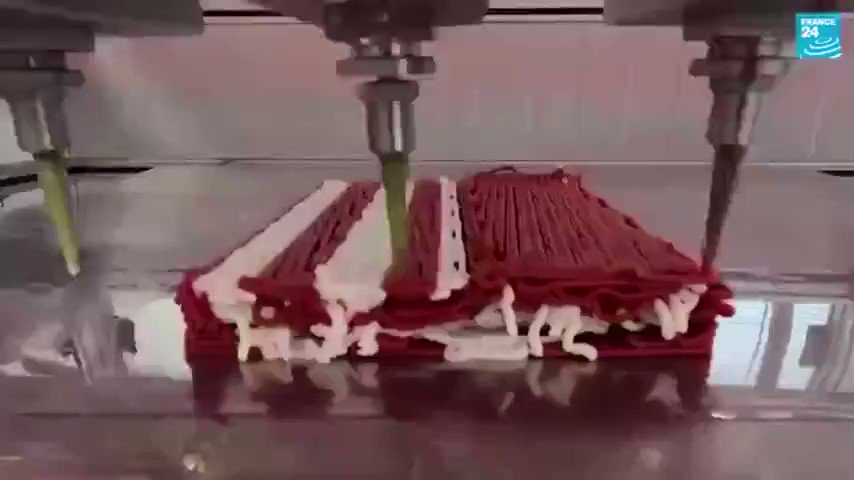

"We start off by creating bio-ink from the cell lines we have carefully selected for this task. We then load the bio-ink into the 3D printer, send a command to start printing, and voilà — an entire cut of meat is printed," he says.

We then load the bio-ink into the 3D printer, send a command to start printing, and voilà — an entire cut of meat is printed," he says.

Steakholder Foods recently received a grant of $1 million from the Singapore Israel Industrial R&D Foundation (SIIRD) as part of its collaboration with Singapore-based Umami Meats. Speaking on the impact of the collaboration, Yair Ayalon, Vice President of Business Development at Steakholder Foods, notes that industry collaborations are a critical aspect of the company's long-term business strategy.

"Our partnership with Umami Meats is especially meaningful following our recent patent application for fish texture and because it is being supported by a joint Israeli/Singaporean government initiative of which we are very proud to be a part," he adds.

The first prototype of the product is expected to be ready in the first half of 2023. It will be printed with Steakholder Foods' proprietary 3D bio-printing technology and bio-inks that will be customized for the cells.

The collaboration will enable Steakholder Foods to deploy its cutting-edge 3D bioprinting technology, developed by a team of the company's in-house mechanical engineers and cellular biologists. The way the meat is created is that at first, two special kinds of bio-ink are produced using lab-cultured animal cells — one for muscle and one for fat. After that, the product is printed layer by layer, in which the two bio-inks are applied in a variety of different sequences. By having precise control over the application of both inks, the juiciness and marbling of the cut can be optimized.

In addition to that, the technology allows the 3D printing of the product in any shape, width, and marbling ratio. The result is a delicate piece of tasty meat that can be prepared for a delicious meal.

Global dominance with technology at scale

According to a 2017 article published in The Guardian, raising livestock for human consumption generates nearly 15% of total global greenhouse gas emissions, which is greater than all transportation emissions combined. It also uses nearly 70% of agricultural land, making it the major contributor to deforestation, biodiversity loss, and water pollution.

It also uses nearly 70% of agricultural land, making it the major contributor to deforestation, biodiversity loss, and water pollution.

While that article is nearly six years old, much hasn't changed today. Agriculture — including livestock — still contributes to 11% of greenhouse gas emission, per a report by the United States Environmental Protection Agency.

But with the advent of meat printing, it's now possible to solve this greenhouse menace. In fact, a new study suggests that making adjustments can halt the pileup of greenhouse gas emissions for 30 years. So, it's not surprising that governments around the world are becoming more interested in cultivated meat, while also enacting and enforcing necessary regulations to check and rectify any potential anomalies.

As Steakholder Foods begins to make inroads into the United States, the company is super-focused on ensuring its technology is of the highest standards and aligns with regulations. "It is amazing to see the advancements regulatory-wise in the US market. We are working towards regulatory submissions in Singapore and the US," says Kaufman.

We are working towards regulatory submissions in Singapore and the US," says Kaufman.

More on the technology

The Steakholder Foods printer gained industry-wide interest in the second half of 2022 when the company embarked on a world tour with a prototype, printing steaks on demand at conferences and events in three continents. According to Kaufman, "we are leveraging this interest to accelerate business collaborations and strategic partnerships for the purpose of commercializing our 3D bio-printing capabilities."

Recently, Steakholder Foods announced the acquisition of a trademark in Japan, which has been in talks about a regulatory framework for the production and consumption of lab-grown meat in the country. In a letter to investors at the end of 2022, Kaufman stated the ambition for the new year: "The team at Steakholder Foods is pushing forward to submit products for approval in Singapore, and the USA in 2023."

Ideally, the product will have to pass the stringent test that the US Food and Drug Administration (FDA) will administer on it. However, the Steakholder team is undaunted and certain of its technology's quality and capacity to empower players in the cultivated meat industry to print meat at the highest hygienic level.

However, the Steakholder team is undaunted and certain of its technology's quality and capacity to empower players in the cultivated meat industry to print meat at the highest hygienic level.

"Cultivated meat is also referred to as 'clean meat' for a good reason. It is produced in a clean environment, without hormones and pathogens and provides a much safer solution for 'lab to table' unlike the 'farm to table' options we know today," says Kaufman.

"For cultivated meat, our technology ensures the process can be completely monitored and transparent from the producer to the end-consumer," he adds.

Meat for printing: how startups prepare steaks in a 3D printer :: RBC Pro

Pro Project partner*

TV channel

Pro

Investments

Events

RBC+

New economy

Trends

Real estate

Sport

Style

National projects

City

Crypto

Debating Club

Research

Credit ratings

Franchises

Newspaper

Special projects St. Petersburg

Petersburg

Conferences St. Petersburg

Special projects

Checking counterparties

RBC Library

Podcasts

ESG index

Policy

Economy

Business

Technology and media

Finance

RBC CompanyRBC Life

Material section Main

Management · Global Business Trends

Articles Bloomberg

The global market for meat substitutes has already reached $14 billion. But so far, such products are more expensive than real pork or beef, and their texture is far from the original. Startups from Israel and Spain promise to solve both problems with a 3D printer . There are books about meat on the shelves, and refrigerators are literally bursting with packages of minced meat and tenderloin, or something very similar to minced meat and tenderloin.

But so far, such products are more expensive than real pork or beef, and their texture is far from the original. Startups from Israel and Spain promise to solve both problems with a 3D printer . There are books about meat on the shelves, and refrigerators are literally bursting with packages of minced meat and tenderloin, or something very similar to minced meat and tenderloin.

Technicians and researchers here are downright obsessed with their work. And no, the main goal of a startup is not at all to sell customers the perfect beef tenderloin. The company wants to create high-quality plant analogues. Redefine Meat is currently working on a 3D printer that, according to the creators, will be able to print steaks so juicy and full of flavor that even the most demanding meat eaters will not be able to distinguish them from real ones. “All meat alternatives are now made from a homogeneous mass,” says CEO Eshar Ben-Shitrit. “But if you start printing them on a 3D printer, you can control the structure, mass and improve the taste. ”

”

Startups like Redefine Meat and their investors say 3D printed steaks will taste just like the real thing. The essence of the technology is this: you just need to create the perfect “recipe”, and then print it as many times as you need. The computer program first creates a detailed model of the steak with fibers, layers of fat and blood, depending on which steak is being simulated. The circuit is then sent to a printer loaded with vegetable ingredients to print "meat". In order to get a steak, you just need to press a button.

What risks and opportunities are fraught with 3D-printing of meat

It would seem, why invent, everything has already been invented. Take at least the delicacies according to the recipe "Just add water." They are even cooler than 3D printing, because they are extremely unpretentious. It does not require special equipment, detailed layouts, consumables, cleaning, maintenance. Splashed with boiling water, and the digestive foam unfolds in a matter of minutes, like a pontoon bridge from hunger to satiety.

It does not require special equipment, detailed layouts, consumables, cleaning, maintenance. Splashed with boiling water, and the digestive foam unfolds in a matter of minutes, like a pontoon bridge from hunger to satiety.

However, innovators do not stand still. They have developed a 3D Pandora's box and are slowly releasing printed food out of it.

Israeli startup Redefine Meat uses a 3D printer to create vegan steaks that mimic the texture, taste and appearance of beef. And Japanese scientists from Osaka University , using 3D printing technology, managed to get artificial marbled beef.

How is this different from everything that used to fill plates and stomachs?

What is alarming about the new technology

As recently as 10 years ago (12 to be precise) , no particular trouble was observed. Pioneers at MIT developed a "cooking printer" that printed edibles but didn't create them. Just serving, basically. Absolutely harmless technology.

Just serving, basically. Absolutely harmless technology.

Then it logically developed into more and more precise and complex mechanisms for creating masterpieces from chocolate, pasta - whatever. It was already possible to exquisitely decorate your edible fantasies, not yet swaying at the foundations of the universe. The golden age of portraits on cappuccino foam, witty figurines on wedding and divorce cakes (if you didn't know, it's an entire industry) . Everything went on cheerfully and carefree, as it should be on the eve of a big nix.

And then it began - the seal of meat. The man again pressed the button under the inscription "DO NOT PRESS!" I poked it several times at first, then secured it with a toothpick so that it would not back out, and delved into innovation.

Unlike the first timid "cooking printers", now everything is serious. First meat, and in January 2022, fish appeared. So, Israeli startup Plantish has created a 3D printed vegetable-based salmon fillet made from legume proteins and algae extract that mimics the original in texture and taste.

They print high quality meat, you can't fault it. But the cost is still higher than that of a real slaughtered, from flayers and concentration camps for fish, which are delicately called nurseries. Only these ranks converge rapidly. Like railroad tracks in a sunny landscape. And we rush along them towards the beautiful distance, which is getting closer with every beat of our real unprinted hearts.

But completeness! What is bad and disturbing here? On the contrary, a technology has finally appeared that will protect peaceful animals, fish, other fauna and even, by the way, flora. It will be possible to feed everyone without eating anyone - isn't that wonderful! The wolves are full, the sheep are safe.

Mankind is on the threshold of a new era - total abundance at no one's expense, as if by magic. A bit like "free" credit card rates. Banks teach us that a mousetrap can be with a deferred payment, but it will slam shut. Every grace period ends sooner or later.

What will 3D printing of meat and fish lead to? Including "greens", vegans and gourmets who joined them.

A truly heavenly time will come when almost any food will be available to everyone. Quality, the best. Nutrient-rich, aesthetically pleasing, fresh from the printer. And what is important, with pristine karma, including the conscience of cooks.

Probably, this is a special feeling - to chew a cutlet, for the sake of which no one was killed. The vegans looked at each other knowingly, but the plants are exactly the same living creatures. There were experiments proving that they have memory and emotions. The fact that we are used to sprinkling them with vinegar and neatly laying them out on dishes in neat pieces speaks only of our attitude. In a different scenario with a salad, we could discuss the weather, and Mr. Pumpkin would have a construction blog.

However, talking would change nothing. You can play quite complex games with octopuses, fish and birds recognize people after a long separation. It doesn't really help them all. The Red Book is not by chance of this color.

It doesn't really help them all. The Red Book is not by chance of this color.

The whole biosphere on the Earth lives due to the fact that some forms of life eat others. Microcosm, macrocosm. They say there were also dinosaurs, and so they also ate be healthy, until the ancient Mask flew from Mars in a large flotilla on a friendly visit.

This world order is not exactly to my liking. The fact is that they have already tried to break the biological balance several times, and everything is somehow unsuccessful. Then the sparrows in the Middle Kingdom will be killed, and then at least eat caterpillars and locusts instead of harvest, because (suddenly) something went wrong. That in Australia, rabbits were bred, and then they had to build the Great Australian Wall from them, which still did not really protect.

But these are all flowers.

Let's imagine that the printing of food is really established. Not in the form of exotic boutique fads, but massively and everywhere.

Like electricity or the Internet. But this will inevitably happen. In 2013, artificial meat for a burger cost $325,000, after 5 years the amount dropped to $11. Now we are approaching the point where will be cheaper to print than to grow. As soon as this happens, after a short pause for awareness, the flayers will go under the knife.

Billions (not an exaggeration) of livestock units will turn out to be useless and unprofitable. Unfortunately, instead of starting to dance through the chamomile meadows, they will probably die very quickly and unpleasantly. They will try to sell their carcasses on the cheap before the new technology swept away the entire market. Like chamomile, as well as other fields. But this will not help anyone, and the farmers will follow after the pigs, cows, other primers.

Entire industries will be sucked into the rapidly growing black hole. Almost all agriculture, various types of vodstva, at the same time the forestry will go there too. And also a lot of things from the processing industry, transport. Retail and wholesale trade will be hit hard. Even catering will get it.

And also a lot of things from the processing industry, transport. Retail and wholesale trade will be hit hard. Even catering will get it.

Automation already threatens to create unemployment higher than ever. At the intersection of trends of AI, robots and 3D food printing, billions of people who were fired from work will be added to the billions of “fired” animals .

The consequences will be truly dramatic. Oddly enough, despite the abundance of leisure and creativity, it's not design or NFTs that the hungry, frantic crowds will get into. I don’t even want to think what kind of Apocalypse can begin.

But the Titanic would not be complete without the upper decks. Here they will come off not childishly. After all, you can print not only chicken or capelin. How about a menu from the same Red Book? Or Jurassic Park? Or even feasts by invitation without QR codes in large vaulted halls to the fascinating speeches of the lecturer Hannibal.

Here the nerds get a little freaked out and, nervously adjusting their glasses, they start mumbling that they meant something completely different, and in general they had good intentions. But they will be hard to hear over the roar of the crowd: “Chop! A couple more!"

But they will be hard to hear over the roar of the crowd: “Chop! A couple more!"

Is there light in the circular tunnel

The problem is not technology, of course. It's bad that Neanderthals modernize clubs faster than they evolve themselves. In an ideal spherical world, food and even meat printers could indeed save many lives, feed and equip everyone.

Here it should be noted that according to the UN, in 2022 (yes, right now) about 45 million people are hungry or may be starving, which is not much better. In this context, any way to feed people looks not just tempting, but strictly necessary.

What do we say to quality standards in such a situation? That's right, somehow then . Yes, "green" technologies are no strangers to the fact that they only have a beautiful showcase. Production may no longer be very environmentally friendly, and even more so support. In artificial products, stimulants of taste, smell, color and consistency are asked by themselves.