3D printing is not the future

3D Printing Is Not The Future

Skip to main content

Steven WeinbergSteven Weinberg

Process and Manufacturing Engineer at Crystal Fountains

Published Dec 22, 2015

+ Follow

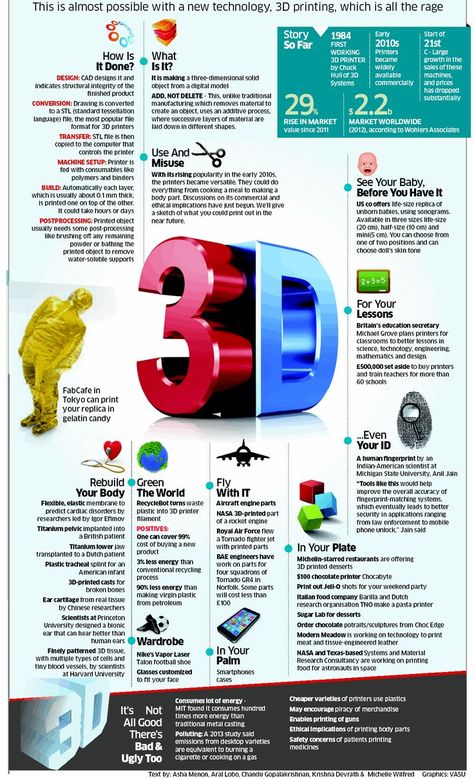

Additive manufacturing encompasses some pretty fantastic technology (I’m going to use ‘3D printing’ as a generic term from now on, based on general familiarity with the term). And, undoubtedly, there is a place for it, amongst all the other myriad manufacturing techniques available, far into the future. 3D printing has distinct advantages over other manufacturing methods.

Chief among these are:

- The ability to produce highly customized, complex geometry, relatively easily.

Light-weighting is a common result of this advantage, as is the ability to replace multiple parts in an assembly with a single 3D print. Otherwise impossible, or near impossible, geometry can be created with 3D printing.

- No tooling, and easy setup. This makes it a good choice for many prototyping jobs.

What it is not is the absolute future of making all things. Articles abound how 3D printing is going to absolutely disrupt this industry or that, and how it’s going to shape the very future of mankind going forward (no hyperbole here). I’ve even seen several that claim that LEGO is a prime target for replacement by 3D printing. In case you were wondering, LEGO, with incredibly high tolerances, mass uniformity, and a mind-staggeringly fast production rate, is probably among the best examples of a product that is not going to be replaced by 3D printing.

3D printing has severe limitations. Some, like surface quality and material costs, will probably continue to improve as time progresses. However, at least one problem seems to be inherent in the process. 3D prints are built pixel by pixel, and layer by layer. This means that resolution and speed are, at least somewhat, inversely proportional. If you increase pixel and/or layer size, you can increase speed, but lose resolution, and vice versa. Currently, as far as I’m aware, 3D printers tend to have only one layer size and one resolution available per print. That leads to the incredibly long build times typical of 3D prints. I recently saw an article, here on LinkedIn, about a 3D printing application, where they managed to improve fluid flow through a manifold, while reducing weight 50%. I was impressed. Now here was a solid application for 3D printing! Then the author mentioned in the comments that the build time was 2 days per print. Now, that may be acceptable in some special cases, but they’d be very exotic. Slap the original on a 5-axis CNC mill, and run it for a couple of hours, and you’d likely achieve similar weight savings.

However, at least one problem seems to be inherent in the process. 3D prints are built pixel by pixel, and layer by layer. This means that resolution and speed are, at least somewhat, inversely proportional. If you increase pixel and/or layer size, you can increase speed, but lose resolution, and vice versa. Currently, as far as I’m aware, 3D printers tend to have only one layer size and one resolution available per print. That leads to the incredibly long build times typical of 3D prints. I recently saw an article, here on LinkedIn, about a 3D printing application, where they managed to improve fluid flow through a manifold, while reducing weight 50%. I was impressed. Now here was a solid application for 3D printing! Then the author mentioned in the comments that the build time was 2 days per print. Now, that may be acceptable in some special cases, but they’d be very exotic. Slap the original on a 5-axis CNC mill, and run it for a couple of hours, and you’d likely achieve similar weight savings. With a bit of work, you could probably closely match the fluid flow characteristics of the 3D printed version, and still not take 2 days of machine time. One day, perhaps multiple resolutions and/or layer sizes will be available during a single print, but that would be a major paradigm change with significant technical challenges, including efficient and intuitive path-planning that takes variable cooling rates (if applicable) into account. It would bring 3D printing more into line with CNC milling, both in terms of time-to-run and complexity to program.

With a bit of work, you could probably closely match the fluid flow characteristics of the 3D printed version, and still not take 2 days of machine time. One day, perhaps multiple resolutions and/or layer sizes will be available during a single print, but that would be a major paradigm change with significant technical challenges, including efficient and intuitive path-planning that takes variable cooling rates (if applicable) into account. It would bring 3D printing more into line with CNC milling, both in terms of time-to-run and complexity to program.

This brings me to another supposed advantage of 3D printing. Perhaps one of the most widely known, and oft referenced. I’m referring to the ease of going from a computer model to a print. Is it really an advantage, when comparing to something like CNC machining? I would say, rather, that it’s a result of 3D printing’s weakness. CAM (Computer Aided Manufacturing) programs, used to create CNC toolpaths, typically have automation built in. Even the worst can essentially do what 3D printing does, as far as ease of going from a model to a part. Take the smallest tool (compare to a 3D printer’s nozzle size – or equivalent), and shallow cuts (compare to layer size), and go through every cut in the part. It will take forever, but it will get the job done, and all it takes is the touch of a button to create the toolpaths. Just like 3D printing. While it’s true that modern 3D printing software does replace solids with easier-to-print structures, the comparison is not that far off-base. The difference is that the CAM lets the skilled user create intelligent tool-paths, and cut down production time orders of magnitude. Take away this supposed advantage of 3D printing, and most of the wild claims about its place in the future of making stuff go away.

Even the worst can essentially do what 3D printing does, as far as ease of going from a model to a part. Take the smallest tool (compare to a 3D printer’s nozzle size – or equivalent), and shallow cuts (compare to layer size), and go through every cut in the part. It will take forever, but it will get the job done, and all it takes is the touch of a button to create the toolpaths. Just like 3D printing. While it’s true that modern 3D printing software does replace solids with easier-to-print structures, the comparison is not that far off-base. The difference is that the CAM lets the skilled user create intelligent tool-paths, and cut down production time orders of magnitude. Take away this supposed advantage of 3D printing, and most of the wild claims about its place in the future of making stuff go away.

Then you compare to typical mass-manufacturing techniques, and the claims about 3D printing seem downright absurd. Take sheet metal, as an example. A few quick cuts and bends, and you can turn a sheet of metal into a dazzling array of parts. Thousands of soda cans are produced a minute, with tolerances so tight that they can be automatically assembled and crimped air-tight with no sealant. And you want to tell me that 3D printing will ever be a threat? Staying on the soda theme, hundreds of bottles can be blow-molded per minute. How long would that take using 3D printing?

Thousands of soda cans are produced a minute, with tolerances so tight that they can be automatically assembled and crimped air-tight with no sealant. And you want to tell me that 3D printing will ever be a threat? Staying on the soda theme, hundreds of bottles can be blow-molded per minute. How long would that take using 3D printing?

Sure, you can 3D print customized products to suit your imagination. And there will be a market for that. But are you really going to spend 10-100 times the price for every little thing you buy, and then wait for each one of them to print on your machine at home? Ludicrous.

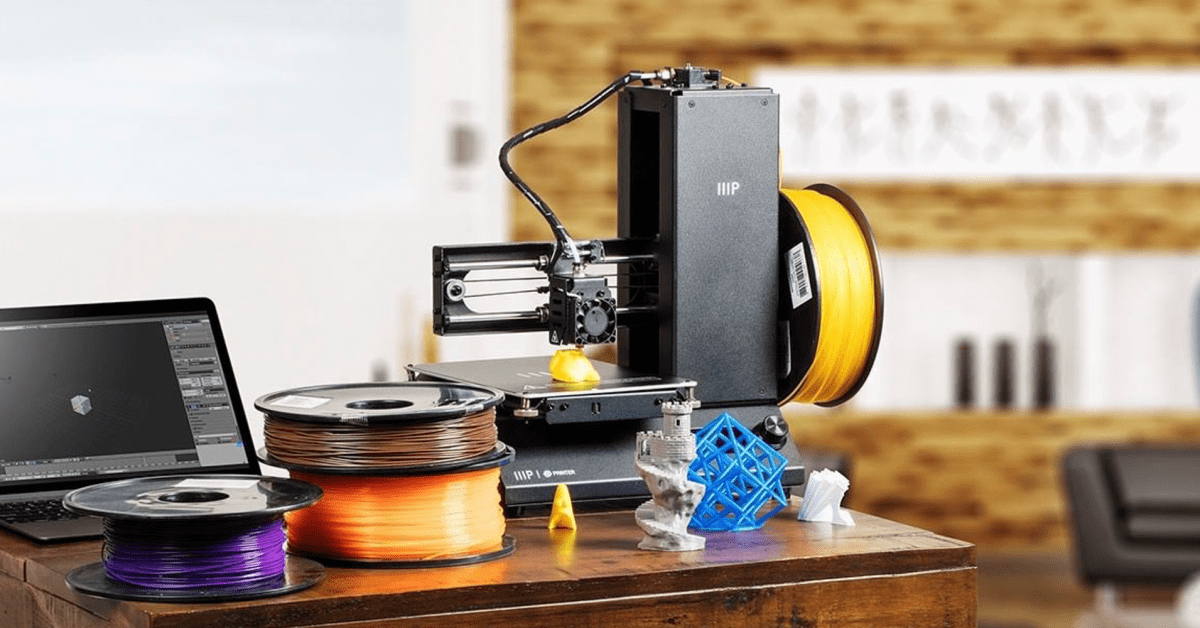

3D printing has a bright future. Both for the hobbyist and the professional. It already has a fond place in the heart of the maker movement, and that is only likely to grow. The technology, and the applications people use it for, will grow in leaps and bounds. 3D printing will help us achieve amazing things. But, at the end of the day, it is just one manufacturing technique among many, with its own pros and cons, and the best choice in only some cases. That is unlikely to change.

That is unlikely to change.

-

Bias is good - Necessary even

Sep 9, 2021

-

Handy Chart - Hole Tolerances for Metric dowels

Jun 18, 2019

-

Engineers, you may be wasting your time

Jan 4, 2018

-

Is Tesla a Ponzi Scheme? - Well, kind of

Nov 23, 2017

-

The biggest news about Wonder Woman's success isn't about women

Jun 19, 2017

-

Share your pie-in-the-sky ideas

May 2, 2017

-

Unpaid Internships: The future of education?

Mar 14, 2017

-

Simple design guide: Alignment dowels

Jan 16, 2017

-

Taking Rejecting the Gender Binary to its Logical Conclusion

Jan 31, 2016

-

Spotting a sham product - engineering analysis 101

Dec 14, 2015

3D Printing: Why the Hype Bit the Dust and the Future | by Narendra Singh | The Startup

THE NEXT GENERATION MANUFACTURING

3D Printing is supposed to be the revolution in next-generation manufacturing but does it live up to the hype.

Photo by Rebecca Hansen on Unsplash

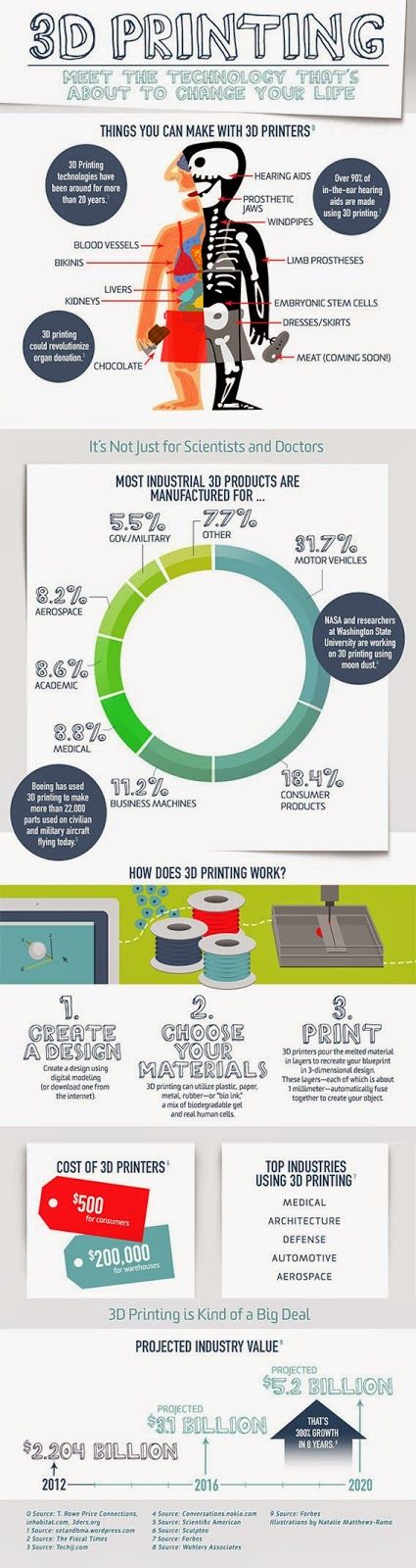

Photo by Rebecca Hansen on UnsplashDid you always dream of printing your own amazing 3D models with a 3D printer at your home? But now, you wonder what happened to 3D printing being the next big thing. It seems that it is not easy to just put a printer in everybody’s home. Instead, there needs to be a whole paradigm shift. Perhaps you are even wondering what the heck is 3D printing. Let’s start from the beginning. Shall we?

You may have joked that I will buy a 3D printer, print a 3D printer and then keep printing them to sell to everyone. Great plan right or is it?

3D Printing is an emerging technology. It is getting transformed into a novel way in which we can build. For eg., We used to only write, draw and paint. Now art, text, and paintings can be also printed on A4. Now, this gave birth to the next-level idea of printing objects themselves instead of traditional manufacturing and assembly.

On paper, it sounds cool and that 3D printing can breakdown the existing paradigms and bring a new revolution. Is it really true or just a hype?

Is it really true or just a hype?

The value chain of 3D printing might seem pretty straightforward. One buys the 3D printer and starts printing stuff. Super easy. Wrong. Yes, the 3D printers have been hyped and marketed as something that can be used at a push of a button. Just 3 to 5 years ago, it was being predicted that every household will have a 3D printer like microwave ovens or computers. The experts forgot that even computers took 50 years to become mainstream.

But this is the 21st century. Surely, a 3D printer might not take that much time. So, what’s the correct value chain at the moment.

One can deduce the chain by exploring the areas where 3D printers are being used and can be used.

- Industry: Manufacturers have to cater to different types of businesses. A 3D printer might be as small as a table appliance or as big as a machine that can print whole houses.

There will be regular maintenance services involved and also updates in the technology as this will be ever-changing technology. There will be software to make the designs and designers to make that software.

There will be regular maintenance services involved and also updates in the technology as this will be ever-changing technology. There will be software to make the designs and designers to make that software. - Homes: It might take some time to have people accept a 3D printer as a regular printer. Most people would use it for hobbies. Though there are immense applications in domestic use.

3D printing has left a lot of people in doubt when compared to the hype that was made around it. A lot of hype is dying out since people are realizing that it is not as easy as putting one’s clothes on. Why? Because, unlike the 2D printers where printing occurs with a press of a button, in 3D printing, one needs to design a model on the computer. They also need to know the basic knowledge of how 3D printers work. 3D design programs can have steep learning curves. After a point of time, it may make sense to just use templates from a website unless you are really dedicated and prefer personalization.

Most people get frustrated with 3D printing when it does not behave well and the objects come out deformed. It is due to high expectations of perfectly shaped artifacts on the click of a button. 3D printers are also expensive at the moment. One will mostly find them in Universities or industries.

We can see that 3D printing is being widely adopted by large companies. For eg. General Motors is saving on loads of revenue because they can make multiple nozzled engines as a single item and much lighter thereby saving fuels. Earlier, it was a great challenge to manufacture separate parts and assemble them. Their sales went up for aeroplane engines. Most of these large companies use 3D printing for prototyping. It might not seem much but failing ideas early on is way better than failing ideas later. A small model printed in-house can be a source of instant feedback and save a lot of hours.

Whole houses can be built in an extraordinary lesser amount of time than the traditional way of building. Though we don’t expect another Burj Khalifa with 3D printing yet.

Though we don’t expect another Burj Khalifa with 3D printing yet.

Another company, MADE IN SPACE has developed gravity independent 3D printers. Astronauts had to earlier carry all the necessary spare parts for emergencies. Now, they can carry 1 machine and print anything whenever required. It reduces payload and cost. We can imagine how revolutionary this can be for ambitious missions such as Mars Mission. One would bring the machine rather than all the material.

3D printing doesn’t just seem to be another addition to our closet. Just like how computers changed the whole tech industry from its players, the type of jobs and methodology, 3D printing wants to do the same.

- 3D printer manufacturers: These companies are the new kids on the block. They will manufacture the machine that will be bought by either businesses or homes. There can be a range of 3D printers. It is not surprising to imagine that there will be even a sector of different kinds of manufacturers.

- Cartridge Manufacturers: But, why can’t the manufacturers just make their own cartridges? 3D printers can use both soft materials and hard materials. Also, metal is used in industries. But with the expanding scope, we might soon need specialized cartridges for bricks, silicon, cloth fabric, wood, glass to even food ingredients. One company can’t manufacture these.

- Service Providers: Just like any machine, 3D printers will require maintenance regularly. The manufacturers may provide it but just like any electronics or electrical equipment, a range of third party service providers will crop up to meet the increased demands from their users.

- 3D Printing Bootcamps: 3D printing is not a child’s play. Most universities are beginning to include at least a basic course in their curriculum to give students hands-on experience. But, everyone does not go to university. Will we see a rise of 3D printer alternative schools or boot camps like the coding boot camps? This is something only time can tell.

- Parts Manufacturers: Currently, we have many companies that provide smaller parts for a bigger system. They would undergo a total revamp and change their systems to 3D printing technology.

- 3D printing consultancies/agencies: How about outsourcing? We talk about 3D printing in-house and for a hobby. But it could be that even this work might be outsourced to 3D printing agencies.

- 3D printing freelancers and professionals: It might not be long that the businesses start hiring 3D print designers who can either work full time or even as freelancers similar to developers or UX Designers.

As with any technology in this ever-connected world, what happens to our 3D printed model.

- Privacy and IP: Since everything is getting connected to the network, there will be a need to protect people’s privacy on what they print. Industries would like to keep their trade secrets. We will need to formulate laws to protect people and businesses' interests just like with other digital property.

- Safety: Safety is a big concern when we consider industries like Aviation, Aerospace, hospitals, etc. The parts used in these industries are checked for safety parameters by various regulators. But in the case of 3D printing, many small parts are not needed but a big consolidated part or even the whole product can be printed. It can be a challenge both in terms of time and money to make new regulations and convince the regulators. Printing of certain items like guns would likely be banned.

It is not hard to see the booming future of 3D printing. The problem has been in the way 3D printing has been marketed. It is also possible that we are still looking narrowingly on this technology. In the past, people have used different technologies in the most unusual ways possible.

Hyping up the expectations and then not delivering is what that has happened to 3D printing revolution. We need to give time to this evolving technology and hope to see what the future holds.

Initially, Instant Messaging apps never thought that it could be used for group organizations and even conducting businesses. Of course, it is a printer but we already have players like MADE IN SPACE thinking of building colonies on Mars by just taking 3D printers there. We should aim high just like them.

Or we will keep printing like this.

Some more articles to quench your thirst for this amazing technology.

Best 3D Printers for the Makers in You

Giving shape to your designs is not that difficult anymore. All you need is a proper 3D printer. But to get one at an…

medium.com

Women Were the First 3D Printers…

Think about it — technology is simply a reflection of humankind. Made you think! ;)

medium.com

Penn Engineering’s Jordan Raney is Reimagining Materials for 3D Printers

Thanks to technologies like 3D printing, shapes and structures that would have been arduous or impossible to make a…

medium. com

com

what lies ahead for 3D printing

The prospects for 3D printing

Even now, the prospects for 3D printing are extremely promising. Scientists are actively developing existing 3D printing techniques, developing new technologies and types of materials, and finding new areas of application. Many call 3D printing the technology of the future, and for good reason. The technique is able to completely turn the usual way of life, changing the way most things are produced. In fact, a 3D printer is a real multifunctional factory, small and compact. Due to this, the future of 3D printing can definitely be called successful. nine0005

3D printers can significantly reduce production costs, thereby reducing the cost of products. Judging by the growing trend towards the popularization of 3D technologies, raw materials for 3D printing will become the main commodity unit in the future. In general, the prospects for 3D printing are defined for many areas. And now we will try to reveal them as much as possible.

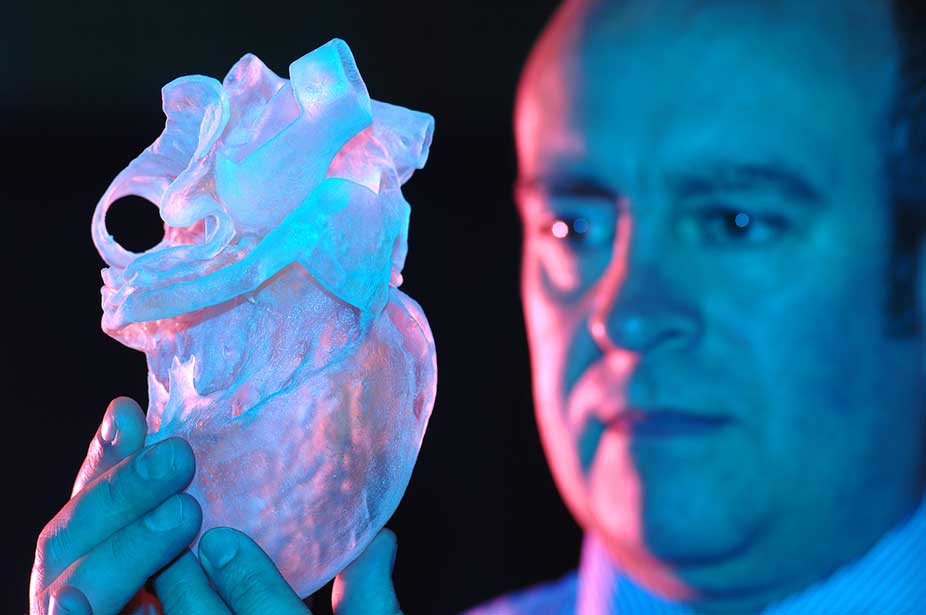

The Future of 3D Printing

If you try to imagine the future of 3D printing, your imagination paints a rather interesting picture. Given the great interest of scientists in the 3D bioprinting technique, which is one of the most promising 3D printing technologies, the production of artificial organs on a 3D printer is not far off. It is also safe to say that the future of 3D printing will bring us dramatic changes in areas such as:

- Construction. 3D printing of houses, or contour construction, attracts many with its futurism and simplicity. The first steps in this direction have already been taken. The pioneers in 3D printing of houses were the Chinese, followed by the government of Dubai who discovered contour building. The first 3D printed office building has already been built in this city of the future, and an entire block is planned to be printed in the near future. And just recently, the first printed house in Europe was created on a 3D printer; nine0014

- Electronics.

When listing the prospects for 3D printing, this point should be given special attention. Scientists believe 3D printing of electronics is the future of digital device manufacturing, and with good reason. Graphene properties and its application in additive manufacturing are currently being actively researched. A huge breakthrough in this area is the creation of a graphene battery with an unlimited service life on a 3D printer;

When listing the prospects for 3D printing, this point should be given special attention. Scientists believe 3D printing of electronics is the future of digital device manufacturing, and with good reason. Graphene properties and its application in additive manufacturing are currently being actively researched. A huge breakthrough in this area is the creation of a graphene battery with an unlimited service life on a 3D printer; - Automotive and aerospace industry. The future of 3D printing is largely based on its ability to reproduce almost any element of varying complexity. In this regard, 3D printing is already widely used in the development of aircraft, machines and satellites. The ISS even has its own 3D printer, not to mention a number of successful 3D printing of cars. nine0014

- Pharmaceutical industry. Yes, yes, you can imagine. The future of 3D printing is in the manufacture of tablets and other medicines. This is confirmed by epilepsy pills legalized in the USA, made according to a special technique.

The essence of this perspective of 3D printing is the gradual release of active substances, so that instead of many tablets, you can drink just one.

The essence of this perspective of 3D printing is the gradual release of active substances, so that instead of many tablets, you can drink just one. - Food industry. 3D food printers are gradually gaining space in cafes and restaurants. While this is probably one of the most raw 3D printing technologies out there, it has potential. Food 3D printers are especially interesting for the possibility of making food for astronauts, as well as the freedom to display culinary talent. This is confirmed by the amazing 3D-printed desserts of our compatriot. nine0014

Other questions and answers about 3D printers and 3D printing:

- Finance Which 3D printer manufacturers are best?

- Finance Which 3D printer is better to buy?

The future of 3D printers

Now let's try to imagine the future of 3D printers. There are several important points to be noted here. Below we list the most likely scenarios for the future of 3D printers.

- Improving the reliability and quality of instruments. Surely, many users are looking forward to this, because most of the existing models of 3D printers cannot boast of uninterrupted operation and the absence of printing errors; nine0014

- Large-scale distribution. It is certain that the future of 3D printers will please us with their popularization. Even now, one can observe a growing trend towards the use of 3D printing in almost all areas of industry. In parallel with the fact that more and more users learn about the possibilities of technology, the demand for desktop 3D printers is also growing;

- Availability. In continuation of the previous paragraph, it is worth noting that the growing demand for 3D printers will lead to lower prices for these devices. The use of 3D printing for domestic purposes is gaining momentum, which brings new equipment manufacturers to the market. Naturally, such a step will entail a reduction in the cost of devices; nine0014

- Enlargement of the construction area.

3D printing of large-sized objects has long occupied the minds of developers. Of course, this applies to industrial 3D printers, because the functionality of 3D printing at this scale will allow you to create full-fledged components, for example, cars and aircraft;

3D printing of large-sized objects has long occupied the minds of developers. Of course, this applies to industrial 3D printers, because the functionality of 3D printing at this scale will allow you to create full-fledged components, for example, cars and aircraft; - Expanding the range of available materials. The future of 3D printers depends a lot on 3D printing materials, because more means more possibilities. The development of special equipment and related materials is being carried out by many companies, and news about the release of new polymers is constantly appearing. nine0014

3D technologies of the future

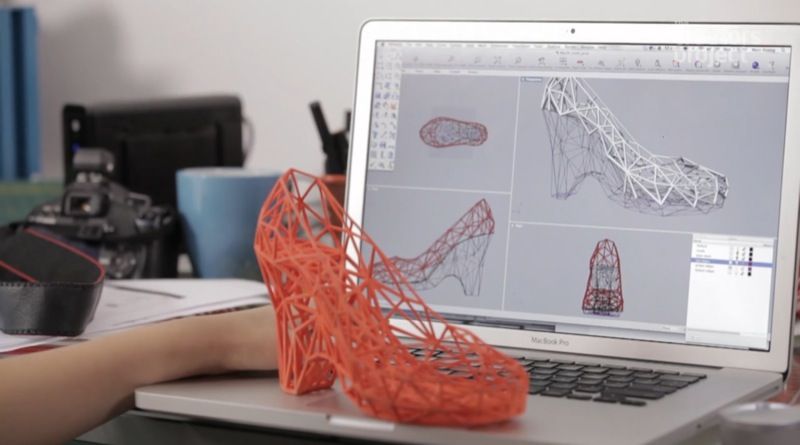

Summing up, it remains to consider only 3D technologies of the future. These include various futuristic scenarios that, to one degree or another, are already beginning to develop today. These include the technique of virtual reality, 3D scanning to create the perfect clothes and shoes, 3D printed makeup, and more. In a way, 3D technologies of the future also include bioprinting. By the way, scientists are talking about building the first 3D printed settlement on the Moon and Mars, so the prospects for 3D printing are also relevant outside the Earth. nine0005

By the way, scientists are talking about building the first 3D printed settlement on the Moon and Mars, so the prospects for 3D printing are also relevant outside the Earth. nine0005

This was a list of the main scenarios for the future of 3D printing. Let's see how they are destined to come true. If you have additional questions that we have not covered, write to us by e-mail and we, if necessary, will add your questions! Best regards, 3DDevice team.

Our store offers a wide range of 3D printers, 3D scanners, 3D plastics and resins, as well as other accessories at the best prices on the Ukrainian market with delivery to all cities (Kharkiv, Nikolaev, Dnepropetrovsk, Lviv, Zaporozhye, Kherson, Donetsk, Odessa ). We also provide 3D printing, 3D scanning and 3D modeling services. For all questions, please contact us in any way convenient for you. Contacts are listed here. We look forward to collaborating! nine0005

Back to home

3D printing and the future of small-scale production

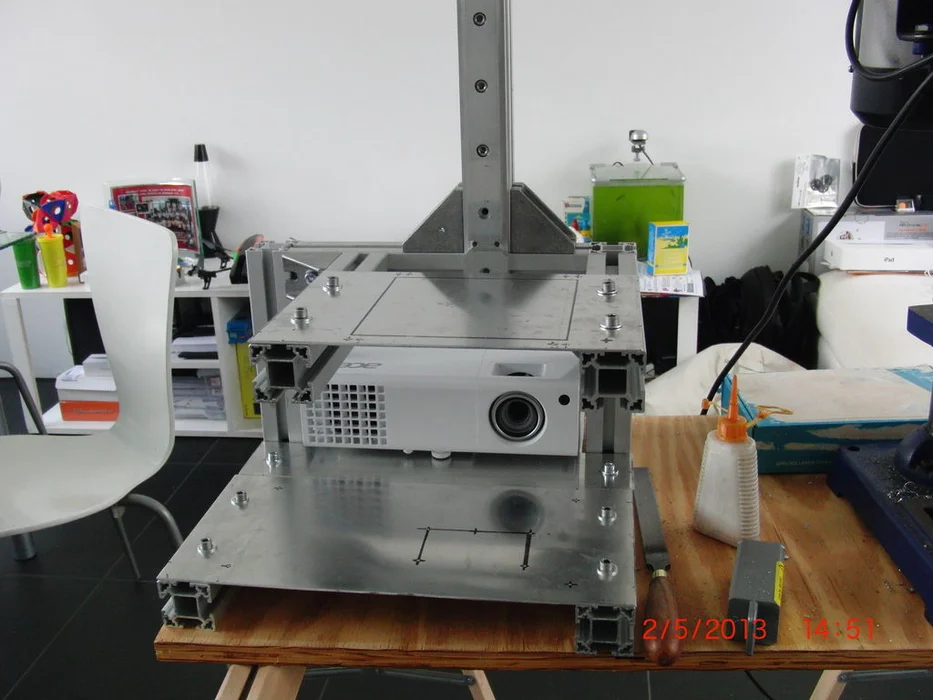

Modern desktop 3 D-printing began a little over 10 years ago when a community of enthusiasts arose pRap. 9006 The goal of the project was to "self-copy", replicate the components of the 3D printers themselves. The task was to small-scale production of 3 D-printers on the same 3 D-printers. The idea was picked up and developed by the Czech engineer and entrepreneur Josef Prusa. He created the biggest farm 3 D-printers for printing plastic parts produced by his factory 3 D-printers. The total number of printers in his factory reaches 1000 pieces; the achievement was even registered in the Guinness Book of Records.

9006 The goal of the project was to "self-copy", replicate the components of the 3D printers themselves. The task was to small-scale production of 3 D-printers on the same 3 D-printers. The idea was picked up and developed by the Czech engineer and entrepreneur Josef Prusa. He created the biggest farm 3 D-printers for printing plastic parts produced by his factory 3 D-printers. The total number of printers in his factory reaches 1000 pieces; the achievement was even registered in the Guinness Book of Records.

In this case, I would note the marketing talent of Josef Prusz , because his company produces about 100,000 printers a year: production can hardly be called small-scale. However, he continues to print plastic components for his printers on them. Thus, their reliability is emphasized, because printing is part of the testing process, on the one hand, and on the other hand, it demonstrates to customers the quality of models made on a 3D printer. The effectiveness of such an approach from the point of view of the production itself is negligible. A single injection molding machine would easily handle this task, saving a lot of space and electricity, and there would be no need for a large number of jobs. nine0005

The effectiveness of such an approach from the point of view of the production itself is negligible. A single injection molding machine would easily handle this task, saving a lot of space and electricity, and there would be no need for a large number of jobs. nine0005

Opportunities 3 D-printing for small-scale production

What are the possibilities of desktop 3D printing for small-scale production? I note right away that this article is about desktop 3D printers. I will not consider industrial systems in it, since they are in a different price category, both for the equipment itself and for printing materials.

First, let's talk about what can be produced on 3D printers. Usually we are talking about small plastic elements, plugs, clamps, housings, holders and other similar elements. The choice is to order a mold or 3D print the elements. It is easy to make a choice by calculating the cost of a mold, the cost of products obtained on an injection molding machine and the cost of printing the same product on a 3D printer of the required circulation. nine0005

nine0005

You need to understand: how many units of production per unit of time do you need to produce and, accordingly, how many and what kind of 3D printers will be needed for this task? Having made such an initial analysis and having previously understood that 3D printing is what suits you, you should carefully start choosing equipment.

If you already know what you are going to print, the choice becomes easier. If you plan to produce models with different tasks in the future, you should carefully analyze the possible options before buying. The main factor influencing the choice of equipment is the presence or absence of certain functionality in future models. The printer should print with materials that will ensure the functionality of your products. For example, a future part must withstand a certain heating or cooling temperature, be strong, rigid, wear and impact resistant, or, conversely, soft, rubber-like, elastic, flexible. The more versatile a 3D printer is, the more expensive it is. Indeed, for printing various types of plastic, printers are equipped with closed chambers, interchangeable extruders, perforated platforms, feed mechanisms with adjustable filament pressure, etc. nine0005

Indeed, for printing various types of plastic, printers are equipped with closed chambers, interchangeable extruders, perforated platforms, feed mechanisms with adjustable filament pressure, etc. nine0005

Solution options based on FDM/ FFF technologies

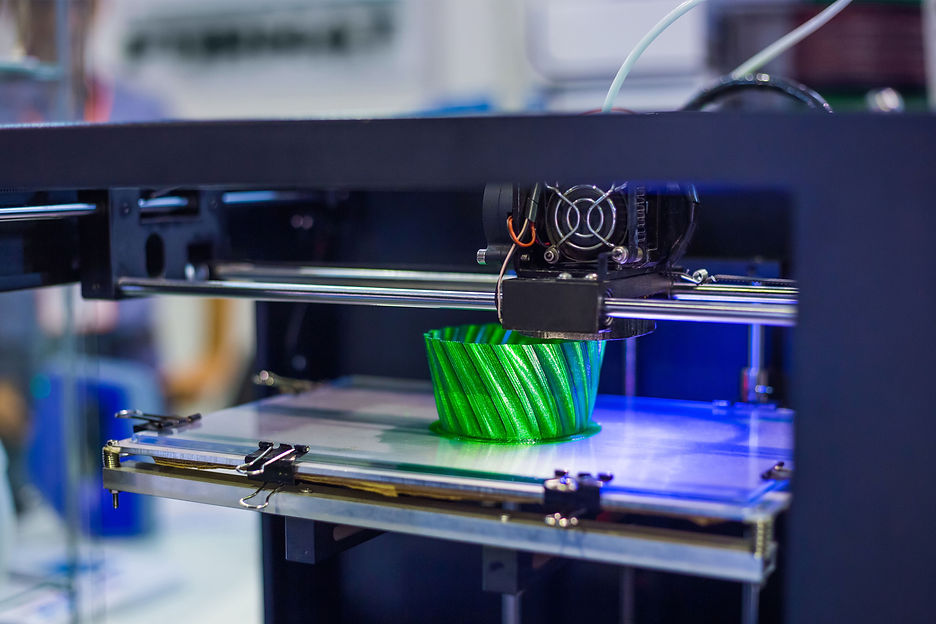

This is the FDM/FFF printing technology most commonly used today for small-scale production. Let's look at a few technological solutions that manufacturers offer. The most affordable and suitable for printing simple models from plastics such as PLA or PETG is a solution based on budget printers such as CrealityEnder-3. These are very simple models that are installed on racks. nine0005

3D printing farm in Creality3D

Among the advantages of this solution: the ability to quickly deploy it in almost any suitable place, quickly increase the number of printers to increase the productivity of the farm. Of the minuses: the impossibility of printing with engineering plastics, the need to manually remove models, as well as the impossibility of remote monitoring and control over printing.

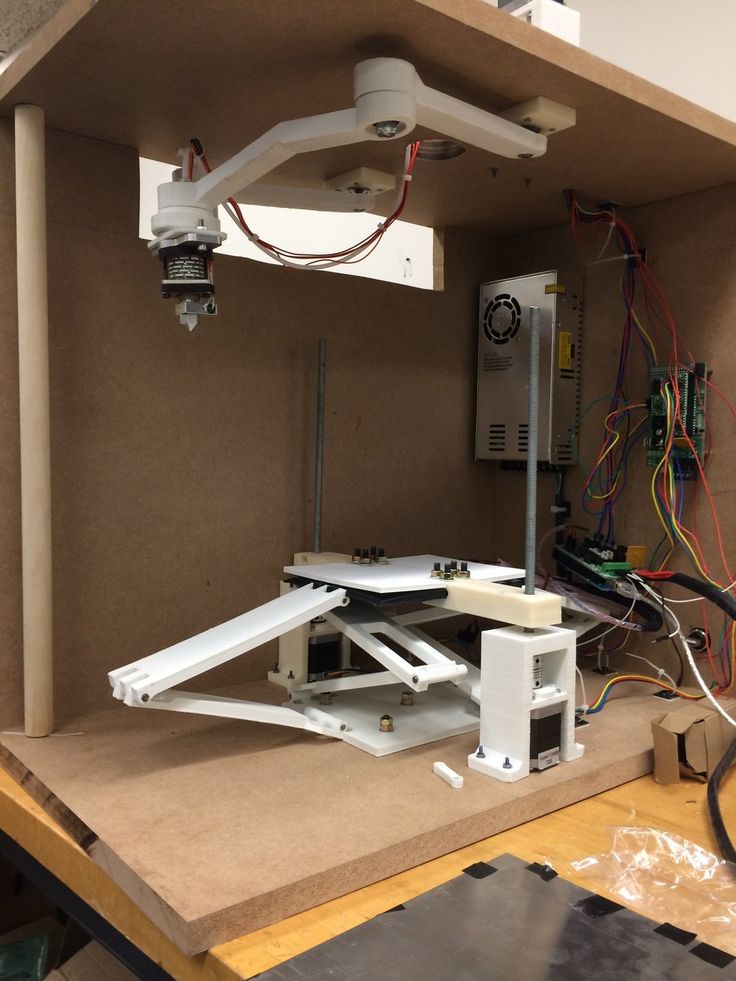

The next level of small-scale production organization is a printer farm capable of handling the most diverse tasks. For example, a farm built on the basis of Raise3DPro2 3D printers. Each such printer is equipped with two extruders, a closed camera and a built-in webcam for remote monitoring. On such printers, you can easily change the "manufactured" models. Today it can be simple plugs made of PLA plastic, and tomorrow it will be complex models made of carbon fiber or nylon gears. The disadvantages include only the high cost of equipment and the remaining need to shoot finished models manually. nine0005

3D printing farm at 2050.AT

Another solution is a printer-based farm with two independent IDEX type extruders. In the photo below you can see a similar farm based on Raise3DE2 printers. The solution has the added benefit of increasing productivity: each printer can print two identical models at the same time instead of one. The disadvantages remain the same: the need to shoot models manually and the rather high cost of the printers themselves. The benefits are the same - plus increased productivity. nine0005

The benefits are the same - plus increased productivity. nine0005

3D Printing Farm at 3D.RU

If small-scale production is one of the possible applications for the previous solutions, then the printer, which will be discussed next, was created specifically for this task. The TierTimeX5 model is a mini conveyor with 12 interchangeable pads for long continuous printing. After the printing of the model or models is completed, the platform moves off the platform, a new one takes its place, after which printing can continue. In this case, both the same and different models can be printed. The printer also supports a print queue: different employees can send jobs to it, they will be executed as they arrive. Models from the sites will still have to be removed manually, so it’s too early to talk about full automation. nine0005

Of the minuses, it is worth noting the high cost of equipment and its low productivity. For comparable money, you can buy up to 10 printers of the same level, but their performance will be 10 times greater. True, they will take up much more space; keeping track of 10 printers is also much more difficult than keeping track of one. At the same time, it should be taken into account that if one of the 10 printers breaks down, you still have 9 more. If the only printer breaks down, you are left without equipment for an indefinite period of time - depending on the repair time. nine0005

True, they will take up much more space; keeping track of 10 printers is also much more difficult than keeping track of one. At the same time, it should be taken into account that if one of the 10 printers breaks down, you still have 9 more. If the only printer breaks down, you are left without equipment for an indefinite period of time - depending on the repair time. nine0005

Another printer option designed specifically for low volume production is the Creality3DCR-30 PrintMill ribbon type. The printer is created on the principle of a conveyor belt: models can be printed endlessly and fall into the box themselves, you just have to remember to change the plastic. Human participation is minimal, but due to the complex design, where printing is carried out at an angle of 45 °, there are many restrictions on the geometry of models, the location of supports and other nuances. But this is the most automated process of all possible today, especially given the modest budget for the purchase. nine0005

nine0005

In an effort to fully automate small-scale production, manufacturers and builders of 3D printing factories or small-scale production add various equipment. In particular, to automate the removal of models, “cobots” (collaborative robots) are used, which are programmed to remove the platform along with the printed model and install a new printing platform, after which printing resumes. This is an insanely expensive solution that does not really improve productivity and can only be justified in countries with incredibly high wages. nine0005

| 3D Printing Farm VooDooManufacturing | 3D Printing Farm VooDooManufacturing |

Another possible solution for the complete automation of the small-scale production process using 3D printing was presented by the Latvian company MassPortal. She created a portal system for this task. The printers are installed in a rack, where the manipulator arm removes the platforms with finished models and transfers them to a special storage rack. The solution almost completely automates the entire process, but the cost is so high, and the system itself is so cumbersome that it is not worth talking about its effectiveness for a wide range of tasks. nine0005

The solution almost completely automates the entire process, but the cost is so high, and the system itself is so cumbersome that it is not worth talking about its effectiveness for a wide range of tasks. nine0005

Photopolymer Solutions

All of the solutions discussed earlier in this article were based on FDM/FFF technology, which involves printing with molten plastic filament.

Recently, photopolymer 3D printers are gaining popularity, which print on the principle of forming a model from a liquid photopolymer. From the point of view of small-scale production, this technology has a number of advantages. First of all, performance. The technology allows you to illuminate the entire layer at once - in this way, the printer spends the same time printing one or any other number of models that fit into the construction area. Whereas earlier desktop photopolymer printers had modest pad sizes and, accordingly, their production potential was not very high, already this year a number of models with a large print area and high detail were introduced, for example, the PhrozenSonicMega 8K printer model. nine0005

nine0005

Printing models in the photo lasted 3.5 hours. It is quite easy to calculate the performance of the printer. In this case, even one printer is a mini-factory and is capable of solving serious production problems. Also important is

but note that, unlike FDM / FFF printers, all photopolymer 3D printers are initially universal - you can print on them with any resins available on the market or even those that will appear in the future. nine0005

It should come as no surprise that the creators of 3D printing farms were inspired by the huge opportunities that were opening up and many small-scale productions were created based on such equipment. For example, the British company Photocentric has opened the largest such center in Europe based on its LCMmagna model. It came in handy during the pandemic, when it was necessary to urgently establish the production of elements necessary for the treatment of patients, for example, replacement valves for ventilators. nine0005

nine0005

Unfortunately, it can't do without significant disadvantages, but let's talk about everything in order. First of all, this is the process of post-processing of printed models, which consists of washing the models in alcohol and subsequent illumination in a UV camera. Without these procedures, the model will not acquire the final quality. Processes cannot be automated, they require a lot of labor — this must be taken into account when choosing equipment. In addition, it should be taken into account that the cost of photopolymer resin is on average 3 times more than plastic for 3D printing, respectively, the cost of the resulting products will be higher. Another factor that must be taken into account is the need for special preparation of the installation site for printers, the availability of high-quality ventilation and the possibility of waste disposal. nine0005

Summary

In summary, even a single 3D printer is a suitable solution for small-scale production.