Wood 3d printing

New 3D Printed Wood is ALL Wood

Wood! It’s nature’s composite material!

Carbon fiber composites consist of long carbon fibers aligned along the direction of stress, bound up in a polymer (epoxy) matrix.

Wood consists of long cellulose fibers aligned along the direction of stress but bound in a natural polymer (lignin) matrix.

It’s a perfect analogy.

Although, most current wood filaments tend not to be so all-natural, as they comprise a small amount of wood fiber and a lot of artificial polymers, such as PLA.

Desktop Metal has released a new material via their Forust subsidiary which does away with the industrial thermoplastic altogether and instead uses what nature intended – lignin!

The company has found that lignin itself is perfectly fine for 3D printing with their binder jet printer system, and so have added sawdust to lignin to produce a feedstock that is made from 100% wood.

(Image credit: Forust)The recombined material is called Forustwood and it is created by jetting the lignin binder onto the powder bed, where it cures forming layers and eventually builds a 3D part.

The Forust material has a low carbon footprint as it is made from industry byproducts (sawdust and lignin) meaning that it is a sustainable way of producing complex wooden designs.

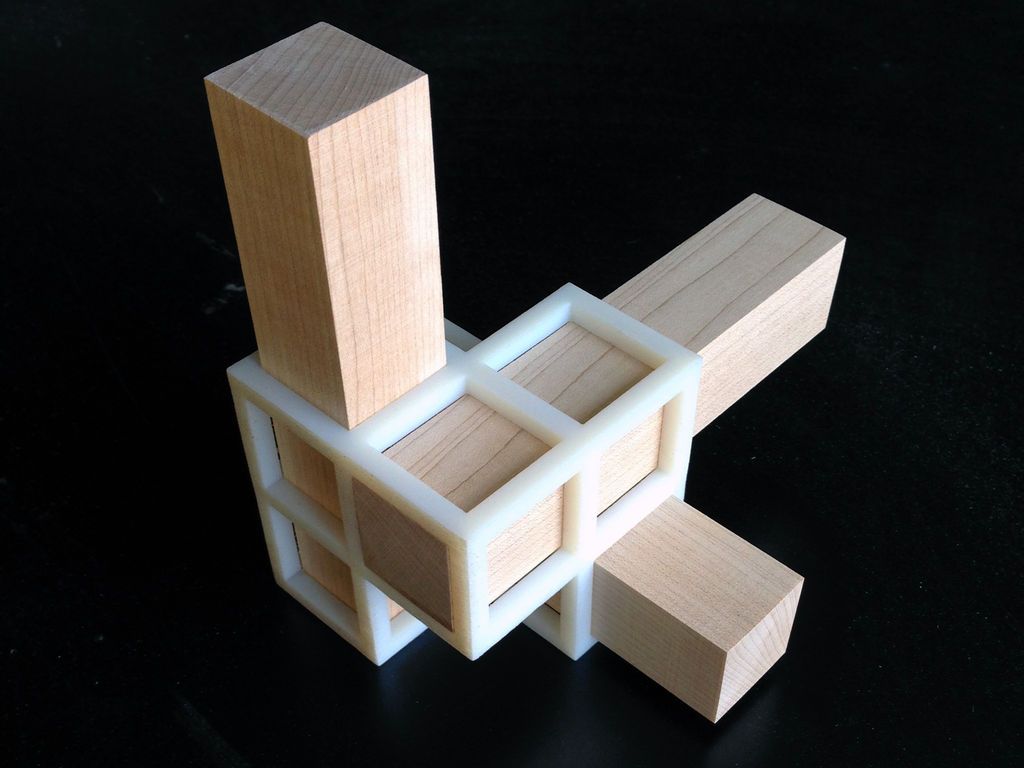

Like wood, it is easily sandable and machinable, and unlike wood it is mechanically isotropic. Take that, nature!

Of course, if you miss the days of using anisotropic wood materials you can always pretend that the wood is anisotropic by adding a digital grain pattern, which as you can see in the image above, is pretty convincing, visually speaking.

We will assume that this example has undergone some post-processing to achieve that finish. Still, it looks great…

Here’s another picture of a chair, printed with a lighter wood, with the digital grain still visible.

(Image credit: Forust)The woods can be printed in grainless or grained patterns, and so far come in a variety of wood types including teak, oak, walnut, and something called “natural”.

The wood parts can be printed at a variety of sizes (up to 180 x 90 x 30 cm according to the Desktop Metal site) and the process can be scaled up in terms of production output with the larger systems. Their RAM336 can churn out wood at a rate of up to 106 litres per hour.

Their RAM336 can churn out wood at a rate of up to 106 litres per hour.

This makes the Forustwood useful for a broad range of tasks from small ornaments to larger architectural parts.

“Applications for Forust’s wood parts are really limitless,” said Ric Fulop, CEO at Desktop Metal.

“There are many applications where polymers and plastics are used today where you can now cost-effectively replace with sustainably manufactured wood parts — luxurious high-end components in interiors, consumer electronics, instruments, aviation, boats, home goods and eventually in flooring and exterior roofing applications.”

Aside from Desktop Metal / Forust, there has already been a fair amount of academic research into the use of lignin as an additive for AM feedstocks, so we can likely expect more sustainable printed woods in future, covering a broad range of printing processes including potentially SLA and FDM also.

For now, the Forust material seems to be the first fully lignin/wood material to break onto the main stage.

Wood 3D Printing Is Being Used for More Eco-Friendly Lights

3D printing news News Wood 3D Printing Is Being Used for More Eco-Friendly Lights

Published on December 12, 2022 by Madeleine P.

Though best known for polymers and metals, more than ever 3D printing is widening its horizons when it comes to material development. This is especially the case when it comes to more sustainable materials. And what could be more eco-friendly than wood itself? At least that is the thought process of Forust and Desktop Metal. With the release of the Shop System™ – Forust Edition, the companies are seeking to make high-volume, affordable wood 3D printing using binder jetting. The technology has already been adopted for a number of projects including the creation of 3D printed decorative pendant lights, called Cocoon, through a collaboration with the designers HagenHinderdael.

As mentioned, Cocoon is the brainchild of Forust and HagenHinderdael, an award-winning creative practice who wish to combine suitable design and innovative technology in their immersive installations. Helmed by Sofia Hagen and Lisa Hindardael, the company pursues an approach that explores the relationship between immersive art and biophilic design, a concept that in and of itself aims to increase the connection between people and nature within buildings. And this has been achieved through the creation of Cocoon, a 3D printed, sustainable, decorative pendant that transforms wood waste into an organic, technologically advanced light.

Helmed by Sofia Hagen and Lisa Hindardael, the company pursues an approach that explores the relationship between immersive art and biophilic design, a concept that in and of itself aims to increase the connection between people and nature within buildings. And this has been achieved through the creation of Cocoon, a 3D printed, sustainable, decorative pendant that transforms wood waste into an organic, technologically advanced light.

The finished (left) and unfinished (right) Cocoon (photo credits: Anders Gramer)

Using Wood 3D Printing to Create Cocoon

Cocoon is the culmination of a variety of different concepts. However, the ultimate goal was to create a light that not only was sustainable, but which also resembled an organic structure, speaking to the natural materials used. And this was certainly achieved. Thanks to the use of Forust and Desktop Metal’s innovative wood 3D printing technology, Cocoon was developed using an innovative process that is able to reduce timber waste. The final part is thus not only eco-friendly, but fully degradable.

The final part is thus not only eco-friendly, but fully degradable.

The part was designed to look like an organic structure, notably taking a form reminiscent of cocoons in nature. It was designed using a binder jetting process wherein layers of powdered wood are bound together with lignin, a complex plant-derived polymer that is a key structural material in the support tissues of most plants. This process is thus not just a high-speed, wood 3D printing process which can create even end-use parts, but also non-destructive to the planet’s ecology. In this particular case, the resulting part is a 250mm x 460 mm Cocoon, available in two typologies, which can be hand-stained and finished after printing, including finishing with a wide variety of wood species such as natural, oak, teak and walnut.

The light’s shape has been designed to pay homage to the natural materials used (photo credits: Anders Gramer)

The shell is also a protective cover for the internal, integrated OLED light source. The OLED panel is made from a slimline technology that is “easy to the earth” and produced from 85% glass with a balance of organic materials and non-toxic metals. Not only that, but in the creation of the Cocoon, HagenHinderdael were able to use materials that would have otherwise been sent to the landfill. The aim of the light is to make people think beyond the tradition of product design to see how new technologies and processes can help create more sustainable initiatives for the lighting of the future.

The OLED panel is made from a slimline technology that is “easy to the earth” and produced from 85% glass with a balance of organic materials and non-toxic metals. Not only that, but in the creation of the Cocoon, HagenHinderdael were able to use materials that would have otherwise been sent to the landfill. The aim of the light is to make people think beyond the tradition of product design to see how new technologies and processes can help create more sustainable initiatives for the lighting of the future.

A Closer Look at the Shop System ™ Forust Edition

Of course, the key to the success of this beautiful decorative light is the technology used. The Shop System™ Forust Edition is, as the name suggests, a version of the best-selling Shop System™ that has been adapted to print with unfinished sawdust byproduct from the wood milling industry. As previously mentioned, it uses binder jetting, a technology that is increasingly popular for its speed and production capabilities, allowing for the creation of complex wood designs without the need for supports. Moreover, the machine itself is capable of creating parts within a build box measuring 350 x 222 x 200 mm (13.8 x 8.7 x 7.9 in) at a print speed of up to 1,6000 cc/hr or about 21 mm in z-height per hour.

Moreover, the machine itself is capable of creating parts within a build box measuring 350 x 222 x 200 mm (13.8 x 8.7 x 7.9 in) at a print speed of up to 1,6000 cc/hr or about 21 mm in z-height per hour.

The Shop System™ Forust Edition (photo credits: Desktop Metal)

Commenting on the technology, William McDonough, an architect and author of Cradle to Cradle, noted “The on-demand 3D printing of wood using waste natural materials is a gamechanger. By allowing millions of trees to remain in place in their forests, Forust is launching a highly evolved technology for the circular technosphere. We have only begun to explore its beneficial potentials, but it is clear they are immense.” And with Cocoon, we can certainly see the pertinence of this technology for a variety of applications including of course the creation of beautiful, functional wooden parts.

You can learn more about the Shop System™ Forust Edition along with other innovative binder jetting solutions from Desktop Metal in our exclusive video with the company from Formnext 2022 below. Additionally, you can find out more about Cocoon HERE.

Additionally, you can find out more about Cocoon HERE.

What do you think of the use of wood 3D printing to create Cocoon? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Anders Gramer

3d wood printing on a 3d printer

Varieties of 3D wood printers: ideas for making money

Wood remains one of the most popular craft materials in various fields of human activity. Modern processing devices expand the possibilities of creating wooden masterpieces. One of their best representatives is the wood printer, which deserves special attention.

3D wood printer: what is it?

The wood printer is an electronic device capable of transferring any image directly onto a wood surface from a computer without intermediate steps. Modern models can form a relief pattern, but are not intended for the manufacture of three-dimensional products. In fact, this device is designed to replace expensive hand-painting or woodcarving, while providing high image quality.

When printing with a printer, the composition (ink) penetrates into the surface fibers of the wood, which securely fixes the pattern on the material and increases its durability. A colorful image can be preserved for a long time without fading and without losing color. nine0003

3D wood printer capabilities

Wood printers are designed for printing images on solid wood, plywood, chipboard, fiberboard, MDF, furniture boards and other wood materials. By applying various design solutions, you can unrecognizably transform the interior of a residential or office space, shopping and exhibition halls, beauty salons and restaurants. Prints on furniture fronts turn standard items into exclusive pieces. With their help, highly artistic panels and billboards are created. nine0003

Prints on furniture fronts turn standard items into exclusive pieces. With their help, highly artistic panels and billboards are created. nine0003

A special effect is provided by 3D printers, which are capable of applying any images and multi-color coatings to three-dimensional figures of any complexity. You can provide a special decor not only, for example, on the countertop, but also on the legs of tables, the backs of chairs. This ability expands the possibility of manufacturing exhibition and advertising products. Using printers, you can create a relief pattern by applying the composition in layers.

Which 3D printers are suitable for printing on wood, MDF, chipboard, solid wood and veneer? nine0007

There are different types of wood printers:

- Laser. A tinting powder is applied to the surface, which is sintered using a laser beam.

- Jet. A special paint is squeezed out onto a wooden surface with microdrops, which instantly hardens with slight heating.

- Sublimation printer. This is a high performance professional machine. It is much more expensive than the previous varieties, but provides the highest quality, allowing the production of printed products. nine0028

The choice of equipment is made on the basis of the intended use, i.e. a realistic assessment of the photographic accuracy of the image. The most important criteria: the size of the working area, resolution, performance, dimensions and cost.

What can it be used for?

The wood printer offers great opportunities for developing your own business. We can recommend the following decorating and design business ideas:

- cabinet fronts; nine0028

- table tops, chair seats and other pieces of furniture;

- original, exclusive elements for interior design;

- entrance and intermediate doors for residential and office premises;

- bar counters;

- ceiling and wall elements, partitions for room zoning, false panels;

- signboards, banners, posters, information stands and signs, various advertisements and information announcements;

- exhibition structures; nine0028

- various 3D figures, figurines, souvenirs;

- panels and paintings.

Woodcarving can be imitated with the printer. It is allowed to transfer any photographic image to a wooden surface. It creates the opportunity to qualitatively repeat the products of folk art, while maintaining a highly artistic style.

Natural wood will never go out of style in interior design. Wood printers empower designers and help create original products at home. It is important to choose the right reliable model and have the desire to express yourself in creativity. nine0003

- March 14, 2021

- 5782

Get expert advice

| 3DNews Technologies and IT market. News printers, print servers, scanners, copiers... MIT scientists develop 3... The most interesting in the reviews 05/26/2022 [14:34], Ruslan Avdeev Scientists at the world-famous Massachusetts Institute of Technology (MIT) have found a potential way to make natural wood furniture and other objects of any shape using 3D printing. Zinnia elegans / Image Source: manfredrichter/pixabay.com Wood can be classified as a renewable resource, but for now, humanity is consuming it so fast that the forests do not have time to recover. According to the MIT website, every year the total area of \u200b\u200bforests in the world is decreasing by an area the size of Iceland - this has an extremely negative effect on both wildlife and climate. nine0003 A team of scientists at MIT has demonstrated a technology that can create a very wood-like material from plant cells in the lab. In doing so, they learned to some extent control both its density and strength. The idea of scientists is to create products of a given shape without the need for further processing, which inevitably consumes energy and generates waste from production activities. According to study lead author Ashley Beckwith, there is a great resource for scaling up the technology and growing 3D structures. To begin with, the scientists took the cells of the zinnia plant (Zinnia elegans), after which they were placed in a liquid medium for two days, and then transformed into a special, thicker biogel with nutrients and two types of phytohormones - by changing their content in the composition, you can control the physical and mechanical properties of the future material. After that, the team began to print figures of various shapes using biogel - in much the same way 3D printing is done. After three months of incubation in the dark, the material was dehydrated, and the final result was an object of tree-like matter. In one of the tests, scientists even managed to create a tree model from the material. nine0003 Image Source: news.mit.edu Experiments were performed with different levels of phytohormones - lower levels resulted in lower density, while higher levels allowed the creation of more rigid structures. Such experiments in the future will make it possible to create lighter and softer or, conversely, more rigid objects. |

In the future, this will help protect the environment from depletion.

In the future, this will help protect the environment from depletion.  nine0003

nine0003