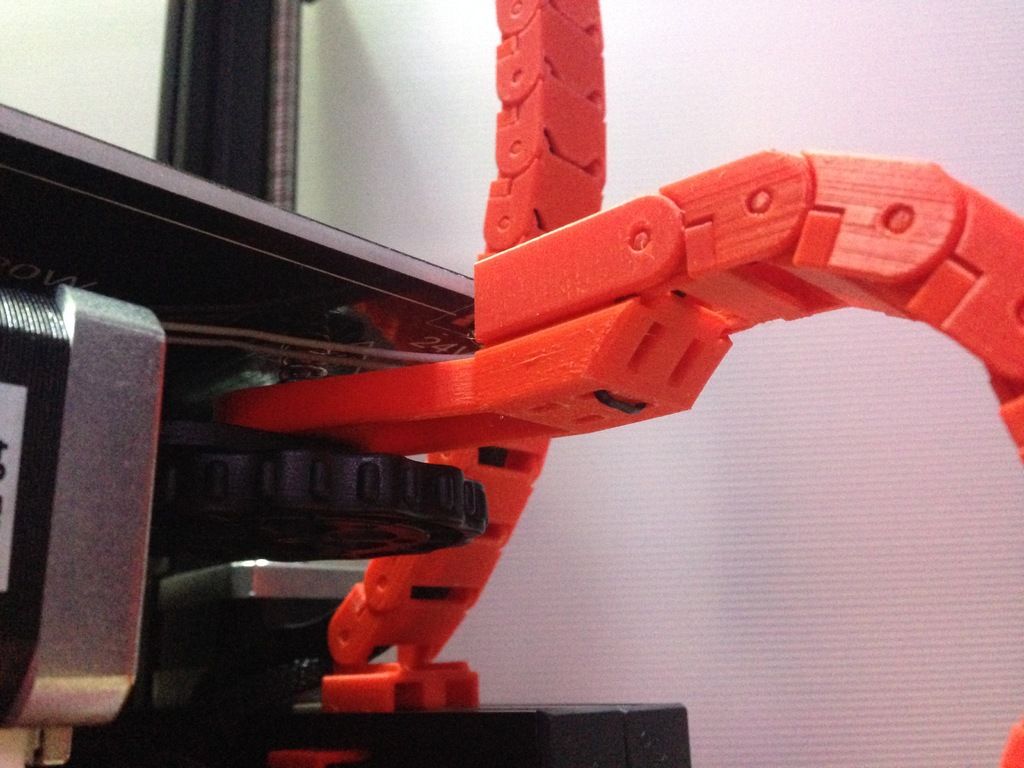

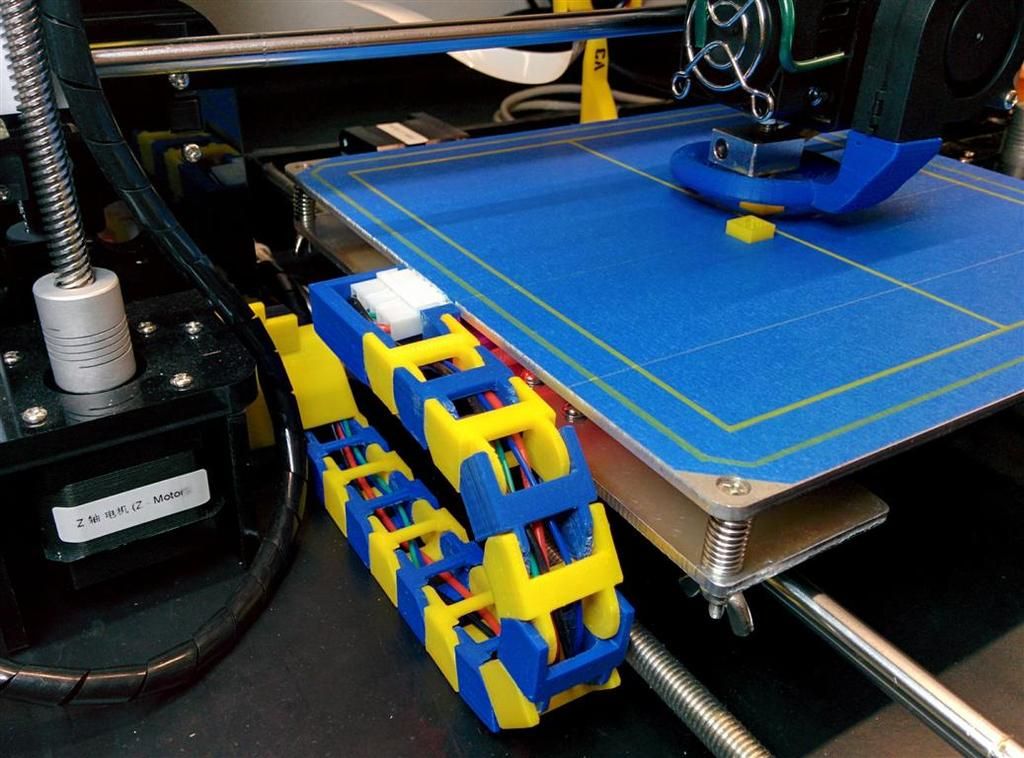

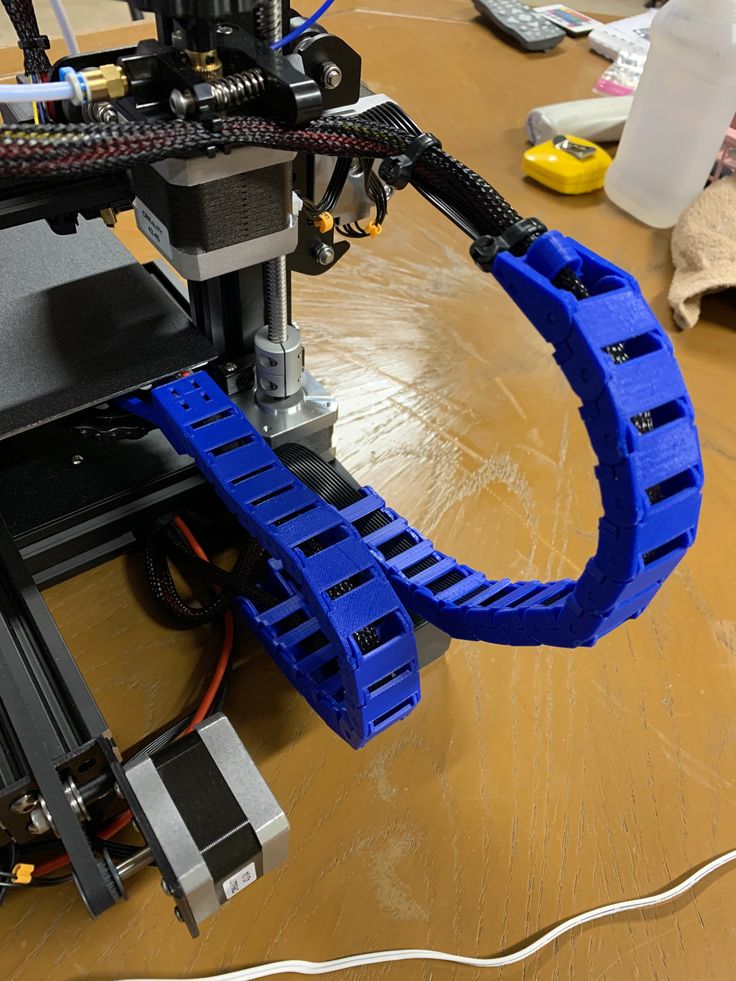

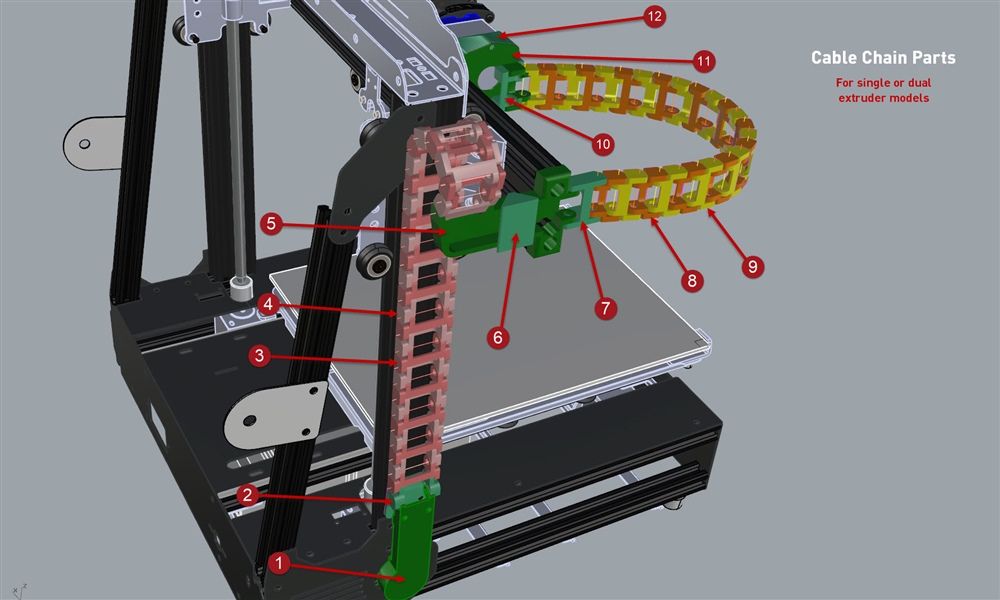

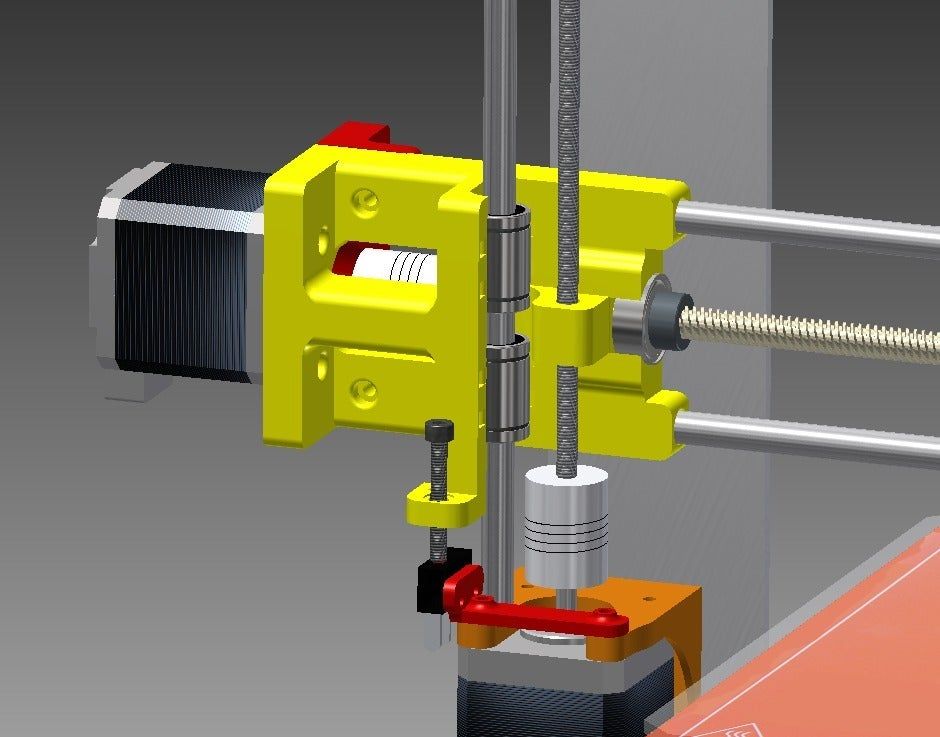

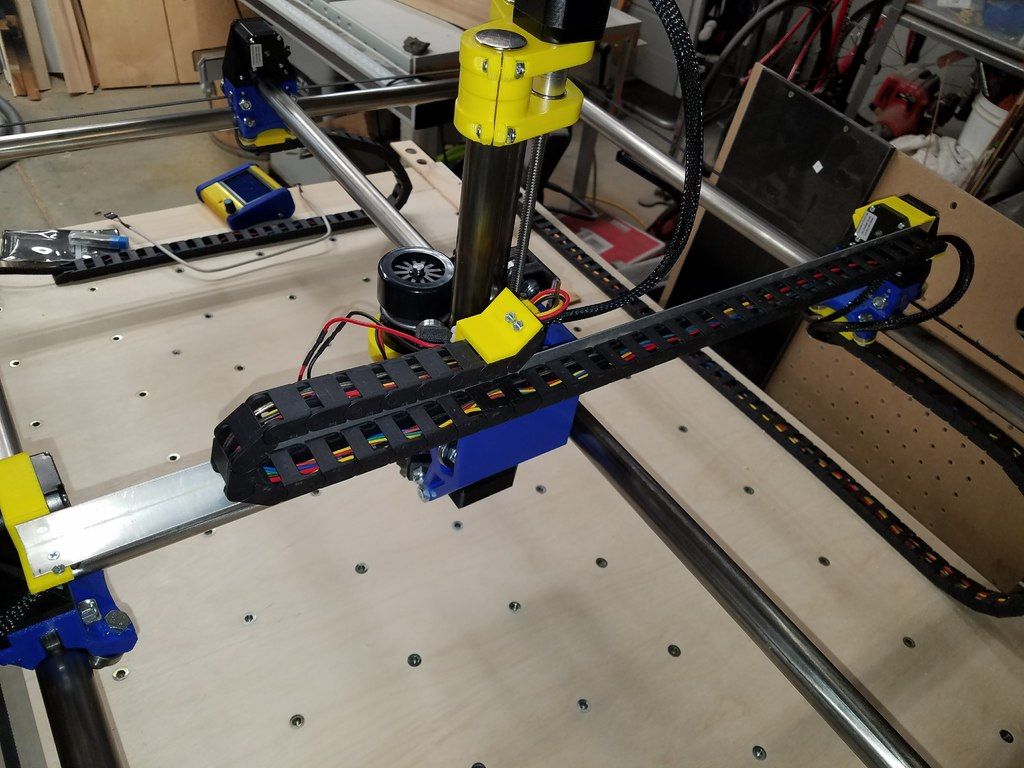

3D printer chain drive

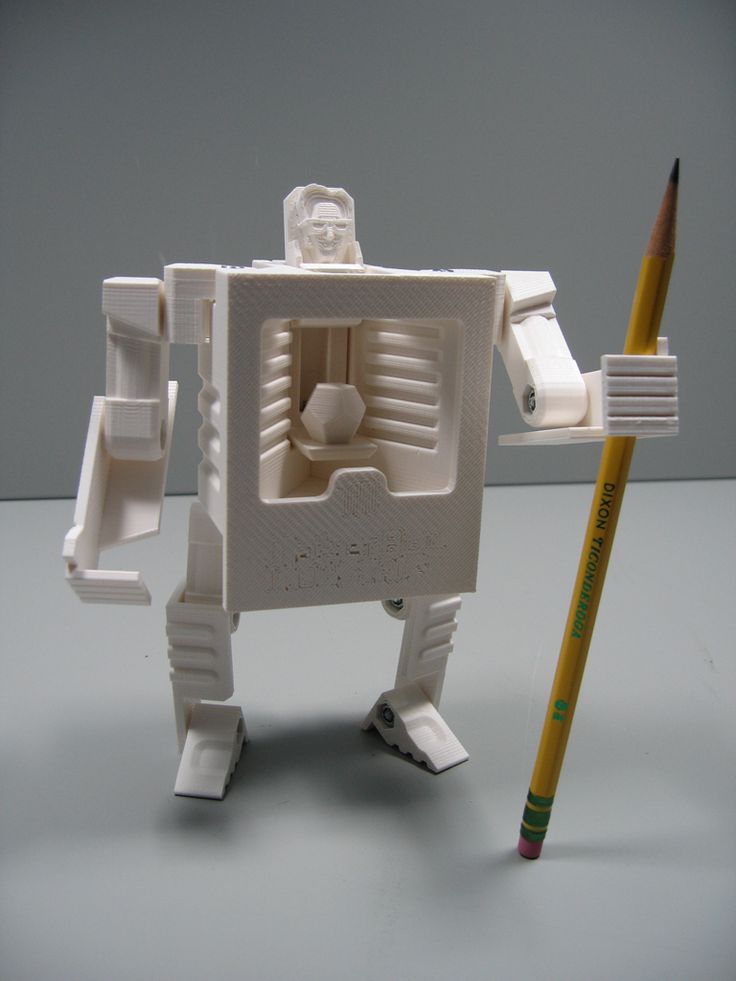

Amazon Robotics H-drive Robots Key Chain 3D Print STL

Click to zoom

7 sales |

5 out of 5 stars €1. 13

Loading

VAT Included

Listed on Dec 28, 2022

2 favorites

Report this item to Etsy

Choose a reason…There’s a problem with my orderIt uses my intellectual property without permissionI don’t think it meets Etsy’s policiesChoose a reason…

The first thing you should do is contact the seller directly.

If you’ve already done that, your item hasn’t arrived, or it’s not as described, you can report that to Etsy by opening a case.

Report a problem with an order

We take intellectual property concerns very seriously, but many of these problems can be resolved directly by the parties involved. We suggest contacting the seller directly to respectfully share your concerns.

If you’d like to file an allegation of infringement, you’ll need to follow the process described in our Copyright and Intellectual Property Policy.

Review how we define handmade, vintage and supplies

See a list of prohibited items and materials

Read our mature content policy

The item for sale is…not handmade

not vintage (20+ years)

not craft supplies

prohibited or that use prohibited materials

not properly labeled as mature content

Please choose a reason

Tell us more about how this item violates our policies.Tell us more about how this item violates our policies.

All categories

Craft Supplies & Tools

▷ roller chain and sprockets 3d models 【 STLFinder 】

Roller Chain and Sprockets

prusaprinters

When printed in PLA (recommended), the theoretical yield strength is about 22kgf for the chain, although a more realistic working load would be about 5kgf. I've included both STL and STEP files for the links and for a variety of sprockets (8 thru 30...

I've included both STL and STEP files for the links and for a variety of sprockets (8 thru 30...

Roller Chain Drive And Sprockets 16B type - ISO 606/DIN 8187

grabcad

Roller Chain Drive And Sprockets20/12 ISO 606/DIN 8187 16BRq. ...- roller links and sprockets: SW files.

Sprockets and Roller chain

grabcad

Chain Drive components

Roller Chains and Sprockets

grabcad

Roller Chains and Sprockets~ Learn CAD~Thanks To GrabCAD~ GIF

#40 Roller Chain Sprockets

grabcad

Series of Roller Chain Sprockets for #40 Roller Chain. Created in Fusion 360. ...User Parameters in the designs should allow you to modify things to work with any type of roller chain.

Created in Fusion 360. ...User Parameters in the designs should allow you to modify things to work with any type of roller chain.

420 roller chain. Modular, with chain lock and sprockets

myminifactory

420 roller chain, chain lock included 42 links 53,3 cm84 links 106,7 cm168 links 213,4 cm Sprockets:9T,11T,12T,36T,48T Chain printed in one piece.Support included with chain. ...Check orientation so the support is facing downwards.

Roller chain. Modular, with chain lock and sprockets

cults3d

Chain lock and sprockets included. Only the imagination sets the limit of what you could do with this thing! Perfect for mechanical projects with moving parts, or just a fidget toy in your desk. ... 42 links 53,3 cm 84 links 106,7 cm 168 links 213,4 cm ...

Only the imagination sets the limit of what you could do with this thing! Perfect for mechanical projects with moving parts, or just a fidget toy in your desk. ... 42 links 53,3 cm 84 links 106,7 cm 168 links 213,4 cm ...

Roller Chain Sprockets OpenSCAD Module

cults3d

This "knows" about many types of ANSI chain, Motorcycle Chain, and maybe Bicycle chain, but I've only tested with ANSI #25 roller chain because that's what L3-G0 uses. Sizes are: #25 , #35 , #40 , #41 , #50 , #60 & #80 roller chain, and 420, 425,...

Roller Chain Sprockets OpenSCAD Module

thingiverse

There're 3 functions that return some info about chain sizes:get_pitch(size) returns the pitch of the chain in inchesget_roller_diameter(size) returns the roller diameterget_thickness(size) returns the thickness of the sprocket (excluding any hub). ..

..

ANSI 40 ROLLER CHAIN SPROCKETS

grabcad

© PatreonSuport:http://bit.ly/patreon_rodrigotresdhttp://bit.ly/usd_donate-----------------------------------------ANSI 40 ROLLER CHAIN SPROCKETS Gear Sets for ansi Drive Chain 40.The purchase consists of tooth numbering gears from 9-114,...

#40 Sprockets and Roller Chain

grabcad

10 tooth drive, 60 tooth driven

chain and sprockets

grabcad

chain and sprockets

ANSI 80 ROLLER CHAIN SPROCKETS - 46 SPROKETS

cults3d

ANSI 80 ROLLER CHAIN SPROCKETS - 46 SPROKETS Gear Sets for ansi Drive Chain 80. ... Files in STEP,STL,OBJ AND IGS.

... Files in STEP,STL,OBJ AND IGS.

ANSI 60 ROLLER CHAIN SPROCKETS - 53 SPROKETS

cults3d

ANSI 60 ROLLER CHAIN SPROCKETS 53 SPROKETS Gear Sets for ansi Drive Chain 40. Files in STEP,STL,OBJ AND IGS. ... ANSI.SPROCKET.SINGLE.PITCH.60.TEETH.9.stp ANSI.SPROCKET.SINGLE.PITCH.60.TEETH.10.stp ANSI.SPROCKET.SINGLE.PITCH.60.TEETH.11.stp...

ANSI 40 ROLLER CHAIN SPROCKETS - 56 SPROKETS

cults3d

ANSI 40 ROLLER CHAIN SPROCKETS Files in STEP, STL,OBJ and IGS. Gear Sets for ansi Drive Chain 40. ... The purchase consists of tooth numbering gears from 9-114, interleaving, See listing below: ANSI. SPROCKET.SINGLE.PITCH.40.TEETH.9.stl...

SPROCKET.SINGLE.PITCH.40.TEETH.9.stl...

3D printable chain and sprockets

grabcad

420 roller chain, chain lock included42 links 53,3 cm84 106,7 cm168 links 213,4 cmSprockets:9T,11T,12T,36T,48TRemix from https://www.thingiverse.com/thing:2793147

Roller Chains and Sprockets

grabcad

Share for everyone...

ANSI 40 ROLLER CHAIN SPROCKETS 3D print model

cgtrader

ANSI 40 ROLLER CHAIN SPROCKETS Gear Sets for ansi Drive Chain 40. The purchase consists of tooth numbering gears from 9-114, interleaving, See listing below: STP ANSI.SPROCKET.SINGLE.PITCH.40.TEETH.9.stp ANSI.SPROCKET.SINGLE.PITCH.40.TEETH.10.stp...

The purchase consists of tooth numbering gears from 9-114, interleaving, See listing below: STP ANSI.SPROCKET.SINGLE.PITCH.40.TEETH.9.stp ANSI.SPROCKET.SINGLE.PITCH.40.TEETH.10.stp...

CHAIN AND 3 x SPROCKETS SolidWorks

grabcad

Chain with 3 sprockets, quick exercise

Chain & Sprockets

grabcad

ANSI RS80 Chain Sprockets

Chain & Sprockets

grabcad

... 13. Even set at 10,000 passes for rendering, the max setting, it still came out looking a little soft and grainy. Not 100% happy with the results but it will have to do until the next software update...... You are all my Friends..... ... =)

Not 100% happy with the results but it will have to do until the next software update...... You are all my Friends..... ... =)

Chain and Sprockets Model

grabcad

Follow me on:► Youtube Channel: https://www.youtube.com/SolidworksTutorialHP?sub_confirmation=1► Fanpage: https://www.facebook.com/groups/SolidworksTutorials/► GrabCad: Mr Hieu Phuong

Roller Chain and Sprocket Ansi 80

grabcad

Roller Chain and Sprocket Ansi 80

#35 Roller Chain Inside and Outside Links

grabcad

#35 Roller Chain Inside and Outside Links

SPROCKET AND ROLLER CHAIN BISIMPLEX - ANSI 80

grabcad

SPROCKET AND ROLLER CHAIN BISIMPLEXENGRENAGEM BISIMPLESI´M BACK!

Roller Chain

grabcad

Roller Chain

Roller Chain

grabcad

Roller Chain

Roller Chain

grabcad

Roller Chain

Chain roller

grabcad

Chain roller

Roller Chain

grabcad

Roller Chain

90,000 workers made on a 3D printer of polymers with improved friction propertiesExtremely long-term worker service life with improved sliding properties

Test parameters:

- Moment 4.

9NM

9NM - Speed: 12obs

- Material Material Material Mater : hard anodized aluminum

- Duration: two months

Rating

► POM (turned): Complete failure after 621,000 cycles

► iglidur I6 (laser sintering): Low wear after 1 million cycles

3D printed gears based on high quality iglidur polymers

► Predictable service life

► All geometries available: special shapes and wear pieces

► Improved tooth base geometry for longer service life

► Self-lubricating properties: running without lubrication thanks to solid lubricants

Up to 5 times longer service life than conventional polymer gears

Tried and tested: gears made from iglidur material show a significant increase in service life compared to gears made from traditional polymers made by machining or injection molding .

Which material is best for which type of transmission?

- iglidur I3 is characterized by increased strength and is especially suitable for spur gears, as well as helical bevel gears, the material can be used for all other types of wear-resistant transmission mechanisms.

nine0010

nine0010 - iglidur I6 has improved sliding properties and is therefore ideal for worm gears or other gears where food grade requirements are required.

- iglidur I8-ESD suitable for making gears that need to be antistatic, e.g. for ATEX zones

Our customers equipment with 3D printed gears

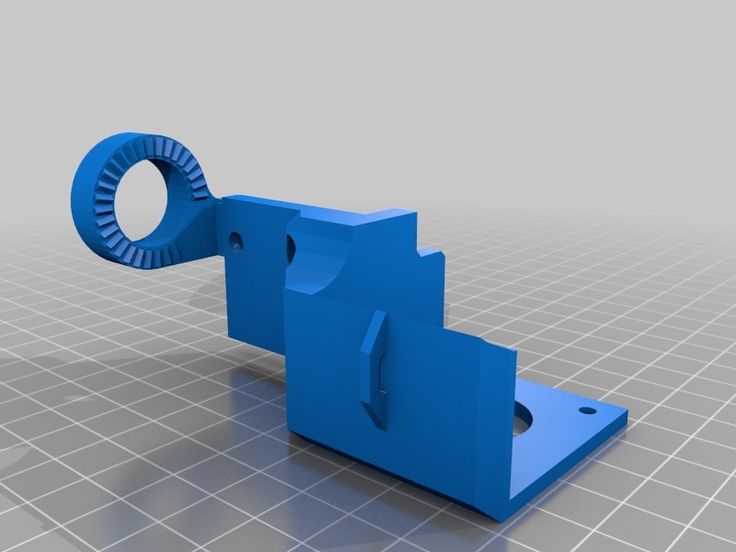

Polymer gear for engine tuning

The Formula Student Team from Weingarten near Ravensburg was also looking for specially designed polymer gears for racing cars. Gears were used as chain tensioners as part of the chain drive, so they had to be especially strong. Unfortunately, the production of gears of non-standard sizes takes a lot of time, the classic production process on a metal-cutting machine is a time-consuming undertaking. nine0027 igus® 3D printing service made it possible to deliver and test polymer gears in less than 72 hours. The material used was iglidur® I6, which has the special wear properties of - it retained its full functionality after 1 million cycles in the test lab, making it ideal for use in race car construction. In this case, the special components produced by additive manufacturing not only managed to be delivered to the customer in the shortest possible time, but they also turned out to be more durable and economical. nine0007

nine0027 igus® 3D printing service made it possible to deliver and test polymer gears in less than 72 hours. The material used was iglidur® I6, which has the special wear properties of - it retained its full functionality after 1 million cycles in the test lab, making it ideal for use in race car construction. In this case, the special components produced by additive manufacturing not only managed to be delivered to the customer in the shortest possible time, but they also turned out to be more durable and economical. nine0007

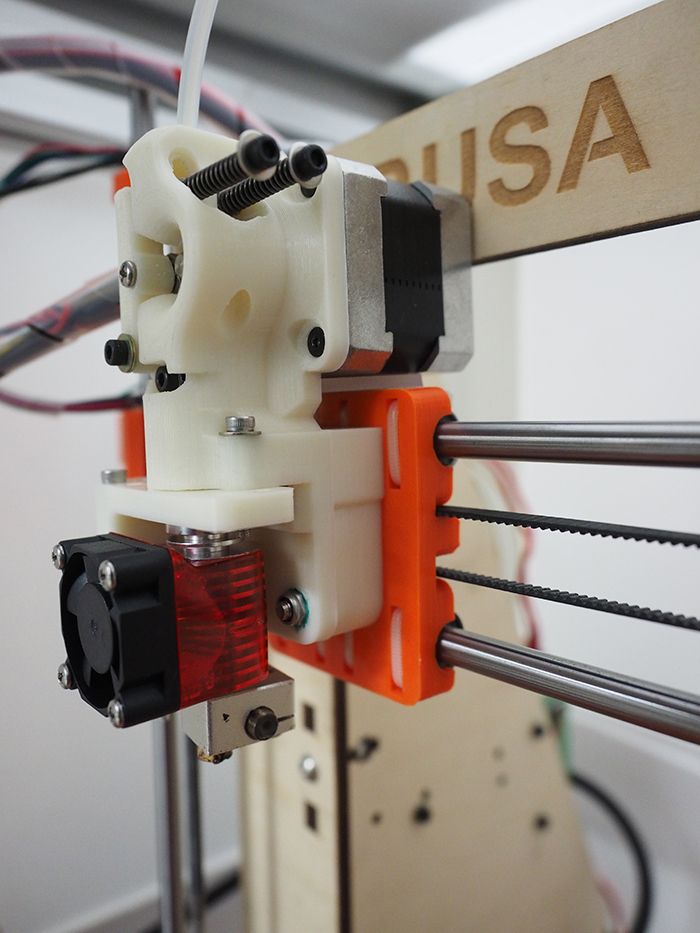

3D printed race car gears

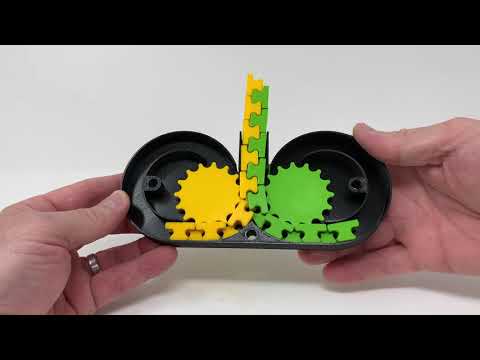

Layered Polymer Gears for Silent E-Bikes

Strong, wear-resistant, no lubrication required: polymer properties outperform metal

Light weight and quiet operation are especially important for e-bike construction.

" The standard metal gear makes a lot of noise during operation. We removed it and gave it to igus® for 3D printing using iglidur I3 material. Everything was simple and fast. We used the 3D printing service, downloaded the appropriate "

Everything was simple and fast. We used the 3D printing service, downloaded the appropriate "

3D printed chain sprocket for electric bikes

3D Printed Resin Gears for Prototyping

iglidur® I6 gear train for electric vehicle charging system

Easelink, a Graz-based company, has developed "Matrix Charging", a charging system that automatically connects to the underside of an electric vehicle to charge it while parked. To develop an economical and high-quality system, the designers chose prototype gears made from iglidur® polymers using additive manufacturing technology. The igus® 3D printing service ensured fast delivery, testing and development of simple elements until the perfect result. iglidur® I6, a particularly wear-resistant and lubrication-free laser sintered powder material, is ideal for the construction of gears, shafts and other heavily loaded components that typically require regular lubrication and maintenance as well as frequent replacements. nine0007

nine0007

Rapid gear prototyping with laser sintering technology

Previous NextWear test for 3D printed products

iglidur polymers are more wear resistant than PLA, ABS and other materials and manufacturing processes

nine0004 Comparison of 3D printing resinsWhy 3D printing at igus?

More information about

- Our materials

- additive manufacturing

- Services and support

3D printing information

3D printing news

Industrial 3D printing innovations. New products and services for additive manufacturing based on wear-resistant polymers. nine0007

Overview of our innovations

FAQ: Q&A

iglidur 3D printed worm gears

What is iglidur I6 and why is it a great material for worm gear design?

iglidur I6 is a laser sintered material specially developed for the production of worm gears. In addition to the common advantages of all iglidur polymers, such as wear resistance and no need for lubrication, iglidur I6 has special sliding properties that increase the functionality of the worm gear. The idea of developing such a material came from the design engineers who created our robolink robotic arm. In tests, worm gears made from iglidur I6 have repeatedly proven to be more wear resistant than other 3D printed polymer worm gears. Polymer worm gears are suitable for industrial applications only if they are made from high quality polymer. Early tests with PLA and ABS materials failed because the high coefficient of friction caused components to wear relatively quickly. It is for this reason that designers began to develop new polymers with the required properties. Special versions are available for high temperature or food processing applications. Wear resistance tests of these materials confirm that they are characterized by a high degree of wear resistance. The characteristics of the iglidur I6 material can be found here.

In addition to the common advantages of all iglidur polymers, such as wear resistance and no need for lubrication, iglidur I6 has special sliding properties that increase the functionality of the worm gear. The idea of developing such a material came from the design engineers who created our robolink robotic arm. In tests, worm gears made from iglidur I6 have repeatedly proven to be more wear resistant than other 3D printed polymer worm gears. Polymer worm gears are suitable for industrial applications only if they are made from high quality polymer. Early tests with PLA and ABS materials failed because the high coefficient of friction caused components to wear relatively quickly. It is for this reason that designers began to develop new polymers with the required properties. Special versions are available for high temperature or food processing applications. Wear resistance tests of these materials confirm that they are characterized by a high degree of wear resistance. The characteristics of the iglidur I6 material can be found here. nine0007

nine0007

Advantages of worm gears made by 3D printer

The most important advantages are wear resistance properties, impact strength, internal resilience to reduce surface pressure, exceptional impact strength, automatic lubrication properties, corrosion resistance, quiet operation, no need for maintenance, as well as good properties for emergency operation. The most important criterion for the use of a polymer. Special materials have excellent wear resistance and hardness; high precision, detailed surface treatment; and extremely long service life, which also characterizes the work of worm gears made from them. nine0007

Advantages of polymer worm gears over metal counterparts

In principle, polymer gears are designed to run without additional lubrication, so worm gears made from iglidur on the printer run without lubrication. The user benefits greatly as downtime and maintenance costs are greatly reduced when high quality polymer worm gears are used. The 3D printer manufacturing method provides design engineers with a more flexible approach than turning and milling metal or polymers. Worm gear geometry can be perfected first and compromises deferred until later. The improved geometry means it takes more time to design polymer worm gears than milled gears. Surface pressure and wear properties are significantly reduced due to large contact areas. nine0007

The 3D printer manufacturing method provides design engineers with a more flexible approach than turning and milling metal or polymers. Worm gear geometry can be perfected first and compromises deferred until later. The improved geometry means it takes more time to design polymer worm gears than milled gears. Surface pressure and wear properties are significantly reduced due to large contact areas. nine0007

Which equipment is best suited for metal gears?

Usually a worm wheel is used at the outlet of the gearbox. Traditionally, it is made of a copper-tin alloy. This material has excellent properties in dry conditions when interacting with steel components. This is an important argument in favor of the use of metal worm gears in conditions where a large amount of heat is generated or high torque is transmitted. Worm gears made of metal are also often part of the cooling and lubrication circuits. In many cases, the worm is made from hardened steel and is used in conjunction with a worm gear made from a softer metal such as brass or bronze. However, self-lubricating polymers for the manufacture of worm wheels are increasingly being used. nine0007

However, self-lubricating polymers for the manufacture of worm wheels are increasingly being used. nine0007

Requirements for the design of the worm wheel or worm gear

The design of the worm gear and worm gear requires a very precise unification of the geometry of the tooth profile. This is necessary to transmit the specified torques, as well as to ensure wear resistance and abrasion resistance of the tooth profile. Simple and cost-effective technologies for the production of piece products and small batches of products are important if the found design solution is to be transferred to a computer and 3D printing systems, which makes them commercially attractive. nine0007

Worm gear material combination

Hard anodized aluminum gear worms are especially suitable for heavy duty applications. However, the corresponding gear worms, which are 3D printed by igus in iglidur I3, are strong enough for normal loads, as the material is highly resistant. Another significant advantage is also the absence of restrictions on the design of forms, since even complex and rare forms of the worm mechanism, such as globoid screws, can be made on a 3D printer, and quickly and inexpensively. nine0021

Another significant advantage is also the absence of restrictions on the design of forms, since even complex and rare forms of the worm mechanism, such as globoid screws, can be made on a 3D printer, and quickly and inexpensively. nine0021

What is a worm gear?

The worm gear is the counterpart to the worm in the worm gear. Since the sliding properties are especially important for worm gears, they are usually made of bronze. 3D printing worm gears from high-quality polymers costs many times less and, importantly, is faster, and at the same time has comparable characteristics.

What is a worm gear?

Worm gears are used where reliable, precise and quiet gearbox operation is required. Quiet and durable operation is of particular importance. Worm gears can be used to realize axial movement between the drive and the power take-off. On a small area, a significant force is transformed. Therefore, the main applications for worm gears are conveyor systems, robotics, profile processing, separators, extruders, mining machines and rowing machines. Worm gears are used in presses and rolling mills, theater and stage equipment, actuators for construction machinery and lifting equipment. nine0007

Worm gears are used in presses and rolling mills, theater and stage equipment, actuators for construction machinery and lifting equipment. nine0007

How does a worm gear work?

A worm gear is a special type of gear in the shape of a worm. The tooth moves around the gear shaft in a similar way to the movement of a screw. The mating gear is the worm gear. The worm can be represented as a spur gear with a diagonal thread. The peculiarity is that it has only one tooth. Although there are worm screws with two or more teeth. This design allows you to get a relatively high gear ratio. A popular feature of the worm gear is self-locking. The worm screw can drive the worm gear. And if it is the other way around, then self-locking will prevent this. Moving large loads can also be a problem, as sudden stop of the gearbox is not recommended for such equipment. nine0007

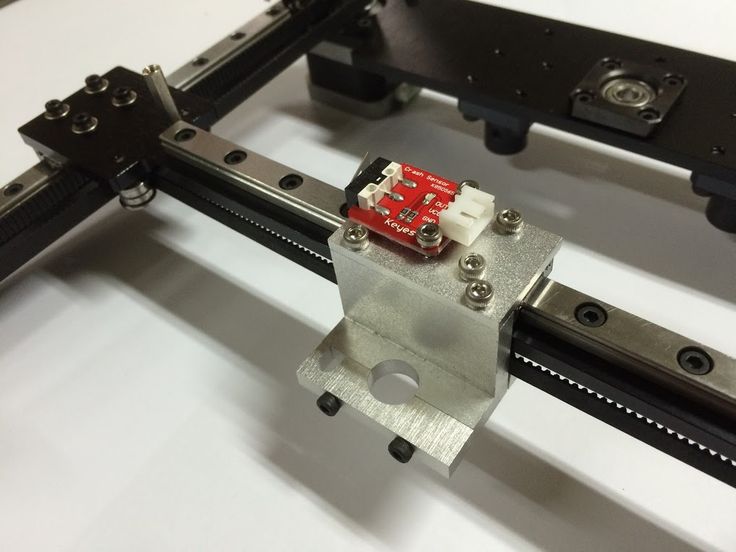

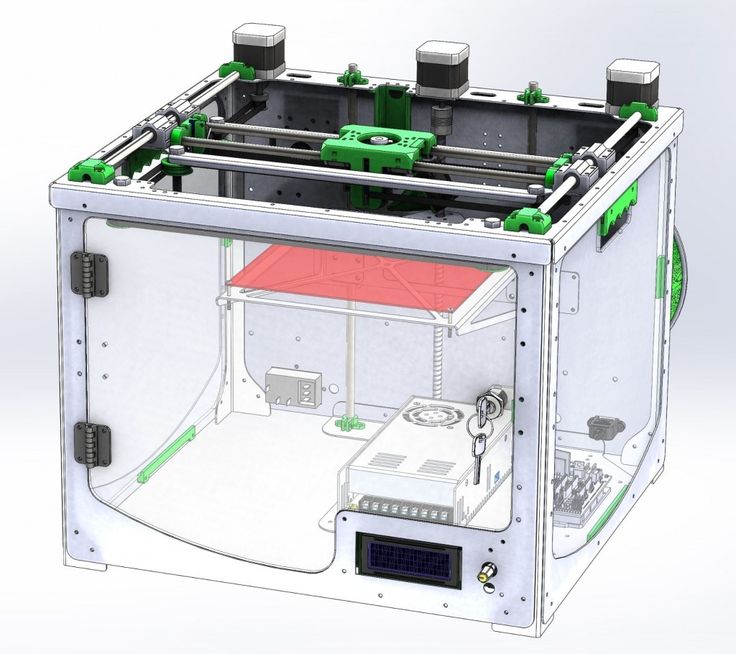

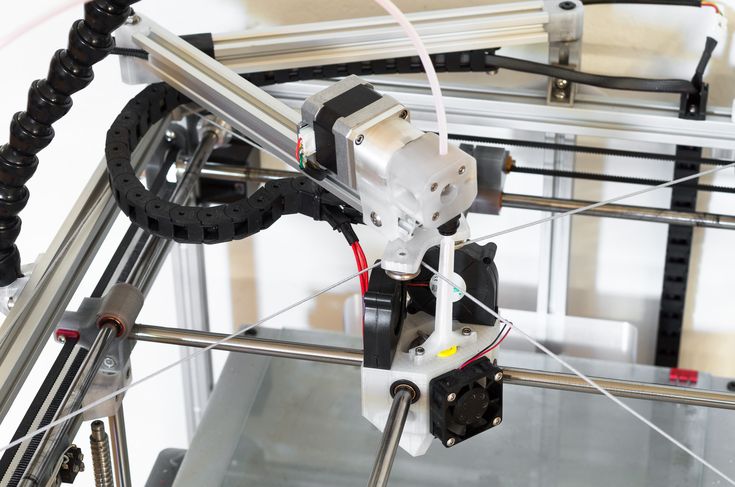

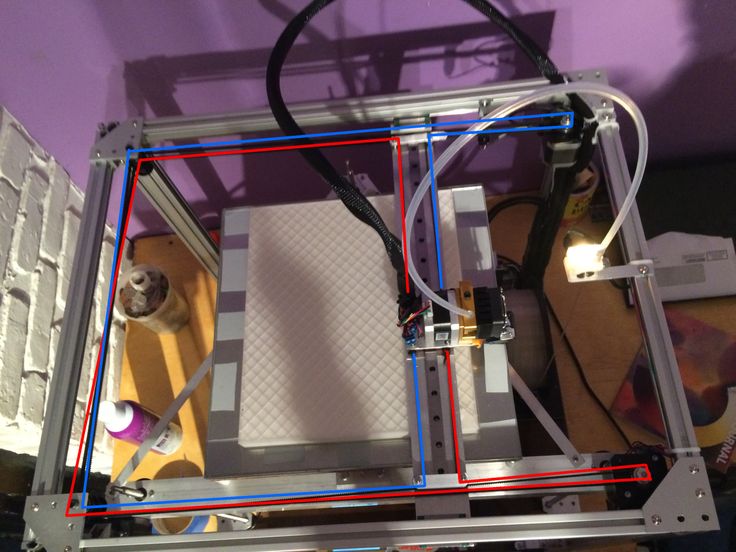

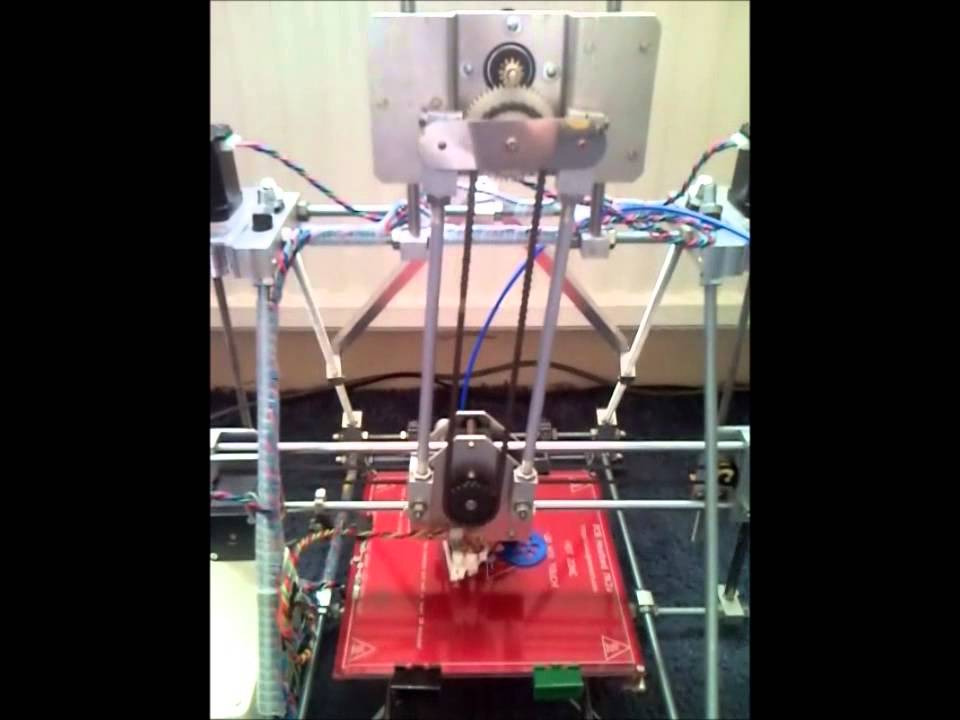

3D printer using rack and pinion drive / Sudo Null IT News

Before assembling my CNC router, I planned to assemble a 3D printer. However, after I got a CNC router, I realized that I didn’t really need a 3D printer. But the kit purchased for it (motors, linear bearings, etc.) and the already made extruder "irritated" the look. I decided to try to make a compact design on a gear rack drive that is non-standard for a 3D printer.

However, after I got a CNC router, I realized that I didn’t really need a 3D printer. But the kit purchased for it (motors, linear bearings, etc.) and the already made extruder "irritated" the look. I decided to try to make a compact design on a gear rack drive that is non-standard for a 3D printer.

The design turned out to be more similar to the classic CNC router layout, but that's what I intended. Although, since I didn’t “lick it”, some flaws were found during the assembly process (poor access to the rail adjustment screw, etc. on the little things).

The drive was chosen for the following reasons:

- I found few mentions of such a choice for a 3D printer, and it became interesting “why is it not used?”

- I have a CNC router that cuts gears and racks very accurately with a 1mm module. nine0010

The goal was to test the feasibility of a design using a rack-and-pinion drive.

The ability to make gears on my own has long interested me. After many experiments, I settled on the version of plug-ins for inkscape.

After many experiments, I settled on the version of plug-ins for inkscape.

Plugin for inkscape "gears_evolvente.py" (Copyright © 2011 Dave Web), slightly modified to form additional elements (center mark, hole, additional circle - pitch diameter, etc.)

Rack plugin rack_gear.py (Copyright © 2013 Brett Graham). He also improved on the little things.

Module 1mm, as the minimum module that the 1mm cutter cuts without major deviations from the required shape. Textolite or fiberglass is ideal as a material. Additional processing is not required.

Gears cut in this way are also used in other projects. Gears withstand a decent load.

It took a total of 5-6 hours to develop the design (inkscape) and prepare the g-code (HeekCNC). For cutting / milling parts from a 5mm fiberglass sheet - 2 pm (about 4 hours). It took about 1.2 sq. meters and one killed cutter. On the assembly - did not count. Collected slowly for 2 weeks and not every day. As a control controller, I used my own development for STM32F103 with the necessary coefficients for the mechanics of this design. I added control of the 4th axis (extruder), but did not bother with heating and its control. nine0007

As a control controller, I used my own development for STM32F103 with the necessary coefficients for the mechanics of this design. I added control of the 4th axis (extruder), but did not bother with heating and its control. nine0007

Rail play

Experiments on the assembled 3D printer showed that the backlash in the rack-and-pinion pair is 0.05-0.07 mm by micrometer with an hour scale when the rack is loaded in the range of 0.5-1Kg.

This play was, with the gap set in the pair, sufficient to move easily and without jamming. The gap is set by a rigid clamping of the rail with screws (an oval hole on the rail). Gear on the axis of the stepper motor. The motor is bolted to the base. How much of that 0.07mm bends the rather flimsy 8mm rails is hard to say. nine0007

Rail non-linearity

Unfortunately, I do not have an accurate tool that allows me to measure the linearity of movement. Using a caliper, the distance is only to determine that the error of linear movement by 50mm (according to the steps of the stepper motor) does not exceed 0.