Stratasys j750 3d printer price

New Stratasys J750 Brings One-Stop Realism to 3D Printing

Stratasys has once again transformed the impact of 3D printing on product development and delivery with the new Stratasys J750 3D printer. This new solution enables customers -- for the first time -- to mix-and-match full-color gradients alongside a wide range of materials to achieve one-stop realism without post-processing. This, together with the system’s superior versatility, makes the J750 the ultimate 3D printing solution for product designers, engineers and manufacturers, as well as service bureaus.

The new Stratasys J750 3D Printer transforms product design with full color 3D printing and texture mapping to create realistic prototypes in a single print operation, such as these cosmetic tubesThe new Stratasys J750 3D Printer transforms product design with full color 3D printing and texture mapping to create realistic prototypes in a single print operation, such as these cosmetic tubes

As the latest addition to the Objet Connex multi-color, multi-material 3D printer series, the J750 3D Printer enables efficient, informed decision-making to help accelerate the way products are designed, evaluated and brought to market. A true industry milestone, the J750 is expected to improve Total Cost of Ownership (TCO) by eliminating many of the traditional complex processes, time and resources required to create product-matching prototypes. Designers and engineers can physically experience true product prototypes within hours of developing an initial concept for immediate design and function validation with internal stakeholders and end users.

"We’ve used 3D printers for years, but nothing has come close to revolutionizing our design and ideation process the way the Stratasys J750 has,” said Brycen Smith, engineering technician supervisor for OtterBox. “Stratasys allows us to innovate in ways we never thought possible and gives us the ability to create true product-matching prototypes and to cut down the time necessary to bring products to market. The Stratasys J750 is a game-changer for both OtterBox and the 3D printing industry.”

Get your eBook on the J750 – “Design with Brilliance - Game-changing versatility and realism with the world’s only full-color, multi-material 3D printer. ”

”

The J750 lets users choose from more than 360,000 different color shades, plus multiple material properties - ranging from rigid to flexible and opaque to transparent. Prototypes can combine a vast array of colors, materials and material properties in the same part, speeding production of realistic models, prototypes and parts for virtually any application need - as well as delivering incomparable 3D printing versatility to produce tooling, molds, jigs and fixtures, and more.

“Today’s supply chain is considering transformational opportunities that can be realized through 3D printing capabilities. It is enabling new business opportunities to more quickly design and test products that are under development, as well as to actually manufacture commercial and industrial goods. [3D printing technologies] are also enabling the ‘new possible’ by producing new designs that could not be made with traditional manufacturing technologies, while negating assembly, improving performance and elevating part quality,” according to Michael Shanler, Research Director, and Pete Basiliere, Research VP for Imaging and Print Services, Gartner. *

*

Increased Productivity and Throughput with New PolyJet Studio and Six Material Capacity

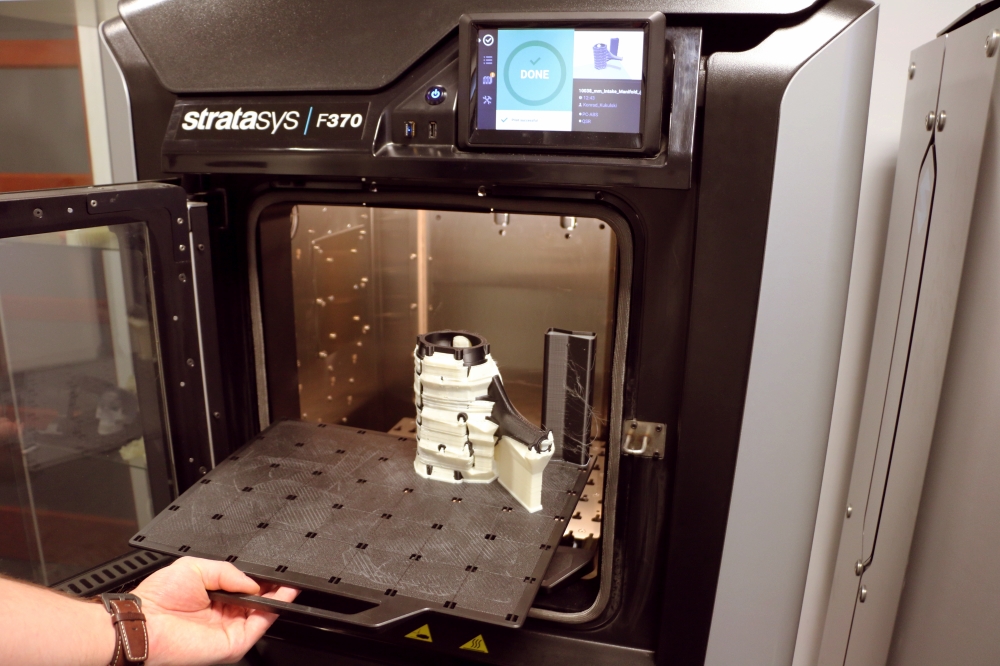

The new Stratasys J750 3D Printer features a large, six-material capacity and new state-of-the-art print heads for one-stop 3D printed realism with maximum uptime and efficiency

The new Stratasys J750 3D Printer features a large, six-material capacity and new state-of-the-art print heads for one-stop 3D printed realism with maximum uptime and efficiency

The J750’s one-stop realism is supported with a streamlined workflow, beginning with the all new PolyJet Studio™. The software’s new intuitive user interface allows users to simply choose materials, optimize the build and manage print queues. Assignment of colors, transparencies and rigidity is eased via familiar design controls. Color textures are able to be loaded fully intact via VRML files imported from CAD tools.

The Stratasys offering also minimizes downtime associated with material changeovers. Featuring a large, six-material capacity, it keeps the most used resins loaded and ready for printing. Newly designed, state-of-the-art print heads means simulated production plastics, like Digital ABS™, can be 3D printed in half the time of other Stratasys PolyJet systems. As 3D printed models are delivered complete across a broad spectrum of multiple combined colors, color textures and materials - no time is wasted on painting and assembly.

Featuring a large, six-material capacity, it keeps the most used resins loaded and ready for printing. Newly designed, state-of-the-art print heads means simulated production plastics, like Digital ABS™, can be 3D printed in half the time of other Stratasys PolyJet systems. As 3D printed models are delivered complete across a broad spectrum of multiple combined colors, color textures and materials - no time is wasted on painting and assembly.

“With the introduction of the J750, we are harnessing more than 25 years of experience to set a new historical milestone in 3D printing – reaffirming our commitment to keep our customers always on the cutting edge of innovation,” said Josh Claman, Chief Business Officer, Stratasys. “With its one-stop realism, the J750 is quite simply a game changer. By combining full color with multiple materials and a streamlined workflow, it recalibrates the impact of 3D printing in the product development cycle. Informed design decisions can be made immediately after ideation. The time saved by eliminating the painting and assembly process can lead to faster product delivery times. And the fact that the J750 is a multi-purpose system that can also produce production tools, manufacturing molds, teaching aids, and other models raises the bar in 3D printing versatility.”

The time saved by eliminating the painting and assembly process can lead to faster product delivery times. And the fact that the J750 is a multi-purpose system that can also produce production tools, manufacturing molds, teaching aids, and other models raises the bar in 3D printing versatility.”

Among the many organizations and businesses that can benefit from the J750 are consumer product companies, service bureaus, design firms, universities and research institutions, medical device companies, hospitals, medical schools, and special effects and animation companies.

Find out how the J750’s one stop realism and multi-purpose versatility can impact your business.

* Gartner Hype Cycle for 3D Printing, 2015, July 27, 2015.

HP Jet Fusion 580 vs. Mimaki 3DUJ-553 vs. Stratasys J750

Major changes are afoot in the color 3D printing market with multiple new technologies expected to become widely available this year. A quick rundown on everything that is happening: HP is expected to launch their new color 3D printer; the Mimaki 3DUJ-553 full-color 3D printer is expected to become more widely available; and additional software updates are expected to come to the Stratasys J750 color 3D printer that will help enhance color quality. In this post we’ll go over how each of these color 3D printers work, show sample 3D prints and discuss where each fits into the broader market compared to one another. Here is quick summary:

In this post we’ll go over how each of these color 3D printers work, show sample 3D prints and discuss where each fits into the broader market compared to one another. Here is quick summary:

- Stratasys J750- It’s been on the market for a few years now and through a recent software update color accuracy has greatly improved to now be on par with the Mimaki 3DUJ-553. That said, it is the most expensive of these three 3D printers machine and material-wise.

- Mimaki 3DUJ-553- The Mimaki color 3D printer just recently became available in the U.S. Of these 3 printers, it has the best color quality, but loses to the HP Jet Fusion 580 when it comes to machine and material cost. You can read our full review here.

- HP Jet Fusion 580- The HP color 3D printer is expected to be released later this year. Details are still scant, but the printer could be quite impressive if it lives up to the hype that HP is putting around it.

Current State of Color 3D Printing

Before we dive in, let's discuss the current state of the color 3D printing market. While there are multiple full color 3D printers currently on the market, the Projet 660 has largely remained the industry standard. While there are a few nuances, the 2 main reasons it has remained on top are it’s resolution and material cost when compared with competing full-color 3D printers. You can read more here on why the Projet 660 is specifically the most popular 3D printer for 3D printed figurines, one of the main applications for color 3D printing. Despite all of this, the Projet 660 still leaves a lot to be desired with regards to reliability, quality, consistency and material cost- all things that we hope to see this latest generation of color 3D printers improve upon.

While there are multiple full color 3D printers currently on the market, the Projet 660 has largely remained the industry standard. While there are a few nuances, the 2 main reasons it has remained on top are it’s resolution and material cost when compared with competing full-color 3D printers. You can read more here on why the Projet 660 is specifically the most popular 3D printer for 3D printed figurines, one of the main applications for color 3D printing. Despite all of this, the Projet 660 still leaves a lot to be desired with regards to reliability, quality, consistency and material cost- all things that we hope to see this latest generation of color 3D printers improve upon.

How it works

The Stratasys J750 color 3D printer uses a polyjet 3D printing process, similar to the Mimaki color 3D printer. The polyjet printing process consists of resin that is jetted out of ink heads and then later cured by UV light to harden it. One downside of the polyjetting approach with resin is the need for support material which typically increases the cost of printing and can sometimes prove difficult to remove

The polyjet printing process consists of resin that is jetted out of ink heads and then later cured by UV light to harden it. One downside of the polyjetting approach with resin is the need for support material which typically increases the cost of printing and can sometimes prove difficult to remove

Machine and Material Cost

The Stratasys is rumored to cost between $300k and $400k and has a material cost that is 60% more expensive than the Mimaki 3DUJ-553.

Specs

| Build size | 490 x 390 x 200 mm |

| Print Mode / Thickness | High Speed / 27-micron High Quality / 14-micron (X-axis: 600 dpi; Y-axis: 600 dpi; Z-axis: 1800 dpi) |

Where it fits in

While the J750 has gotten a lot better with color accuracy since it was first launched, it is still a more expensive machine and more expensive to operate than the Mimaki full-color 3D printer. From a 3D printed figurine perspective, unless you want to use one of the J750’s other qualities, such as being able to 3D print in transparent material, it probably makes sense to always print with Mimaki. See below for a sample print from the J750:

From a 3D printed figurine perspective, unless you want to use one of the J750’s other qualities, such as being able to 3D print in transparent material, it probably makes sense to always print with Mimaki. See below for a sample print from the J750:

Check out our recent blog post for a full write up on the Mimaki 3DUJ-553 full-color 3D printer.

How it works

Similar to the Stratasys J750 full-color 3D printer, the Mimaki uses a polyjetting printing process to 3D print. The basic process is:

- Resin is fired out of inkjet print heads and cured by a UV LED light

- Once it completes a layer, a roller flattens out the layer and the UV LED light is fired again

- After a layer is complete, the build platform moves down and the process repeats

*Dissolvable support materials are used in cases where a part has an overhang

Price

The Mimaki costs ~$250k and has material costs ~4x over the 3D Systems Projet 660 color 3D printer.

Specs

| Build Size | 508 x 508 x 305 mm |

| Print Mode / Resolution / Thickness | Fast / 600 dpi / 42 micron Standard / 800 dpi / 32 micron High Quality 1270 dpi / 22 micron |

Where it fits in

Excerpt from our prior post on Mimaki:

Although, the Mimaki can produce very high quality parts, the major caveat is that the material is much more expensive compared to the material used for the Projet 660. This makes it cost prohibitive to 3D print at the larger sizes on the Mimaki full-color 3D printer. Until material prices come down, the Mimaki 3DUJ-553 full-color 3D printer will likely be limited to 3D printing only small, high resolution parts when it comes to the 3D printed figurine market.

Below is a sample print from the Mimaki 3DUJ-553:

HP Jet Fusion 580How it works

As the name implies, the HP Jet Fusion 580 uses a multi jet fusion process to 3D print. Multi jet fusion works by first spreading a thin layer of power over a bed. Inkjet nozzles then pass over the power and release agents (to both fuse and prevent from fusing) on different parts of the powder bed. Next, a high energy IR source passes over the power to sinter the powder together. The process repeats many times until a full 3D object is created. Once complete the unsintered powder is recycled to use in another print build.

Multi jet fusion works by first spreading a thin layer of power over a bed. Inkjet nozzles then pass over the power and release agents (to both fuse and prevent from fusing) on different parts of the powder bed. Next, a high energy IR source passes over the power to sinter the powder together. The process repeats many times until a full 3D object is created. Once complete the unsintered powder is recycled to use in another print build.

Price

We still don’t have full details on what the color version of the HP Jet Fusion 580 will cost, but past press articles have mentioned ~$100k. As for materials, it is still anyone’s guess until HP releases their new color 3D printer.

Specs

The current monochrome HP Jet Fusion 580’s specs are:

| Build Size | 332 x 190 x 248 mm |

| Layer thickness / Resolution | 80 micron / 1200 dpi |

Where it fits in

Of the 3 3D printers we’ve reviewed today, the HP Jet Fusion 580 is the most difficult to evaluate since it is still unreleased. If materials are priced similar to the HP Jet Fusion 580 monochrome 3D printer, then HP’s new color 3D printer could very well replace the Projet 660. Stay tuned. We’ll update this blog post as more details get released in the coming months.

If materials are priced similar to the HP Jet Fusion 580 monochrome 3D printer, then HP’s new color 3D printer could very well replace the Projet 660. Stay tuned. We’ll update this blog post as more details get released in the coming months.

Only time will tell how these full color 3D printing technologies get adopted by industry. With this latest wave of color 3D printers, we'll likely see new applications for 3D printing made possible just as we did with 3D printed figurines in the last wave circa 2014. The main things to watch in this wave are increased resolution, stronger materials and cheaper material costs. As a company whose product is deeply connected to the capabilities of full-color 3D printers, we're very excited for what these new technologies will mean for our customers.

Want to see examples of what the current generation of color 3D printers can do?

3D printer Stratasys J850 digital anatomy at the manufacturer's price with delivery – TopStanok

- Description

- Characteristics Har-ki

Description

Stratasys J850 Digital Anatomy, a printer specifically designed for printing realistic organs and body parts. nine0009

nine0009

The printer has the ability to print with three specially selected materials that allow you to make the most realistic model of the organ, to prepare for the operation and to better understand the possible methods of exposure. At the same time, the structure of the product also completely repeats real materials, which allows for a preliminary trial operation.

The J850 Digital Anatomy also allows medical students to perform surgery and improve their skills for the next real job. nine0009

Full-color printing makes it possible to obtain a product that exactly repeats the anatomical features of the human body, including the smallest veins and vessels. As a result, the cost of training compared to other methods is reduced by more than 70%.

J850 Digital Anatomy is a combination of chemistry and technology that creates human bones and tissues at an unprecedented level of realism.

Video

General characteristics

| Specification | strat-j750 |

|---|---|

| General characteristics 3D printing | nine0041|

| Print technology | PolyJet |

| Media | Photopolymer |

| Features (filter) | nine0039 Multimaterial, Colored|

| Country of origin | US |

Architectural 3D Printing: Which Materials to Use

Composite Powder | Various types of plastic | Polymer resins

The use of 3D printing for the production of architectural models is a common practice. The advantages of this approach are obvious: minimum time, low cost, printing directly from a computer 3D model, high accuracy of small details.

The advantages of this approach are obvious: minimum time, low cost, printing directly from a computer 3D model, high accuracy of small details.

Why 3D printing is beneficial for architectural models

Let's look at the most popular materials used for 3D printing in architectural modelling.

Composite powder

Special fine gypsum-based material. Used in professional 3D printers of the ProJet x60 series using ColorJet Printing technology. The model construction method is based on layer-by-layer gluing and coloring of the material with a special binder.

Features:

- Accuracy to 0.1 mm

- Full color printable

- Low cost

- Maximum finished object size 50 cm

- Post-processing needed to make mockups more durable

Powder 3D printing - the ability to produce full-color layouts at a low cost. The ProJet x60 series 3D printers use a standard CMYK color palette, which greatly facilitates the work of designers and planners. Composite powder is the most versatile material for producing spectacular display pieces.

Composite powder is the most versatile material for producing spectacular display pieces.

| ProJet 260 nine0040 | ProJet 460 | ProJet 660 |

Different types of plastics

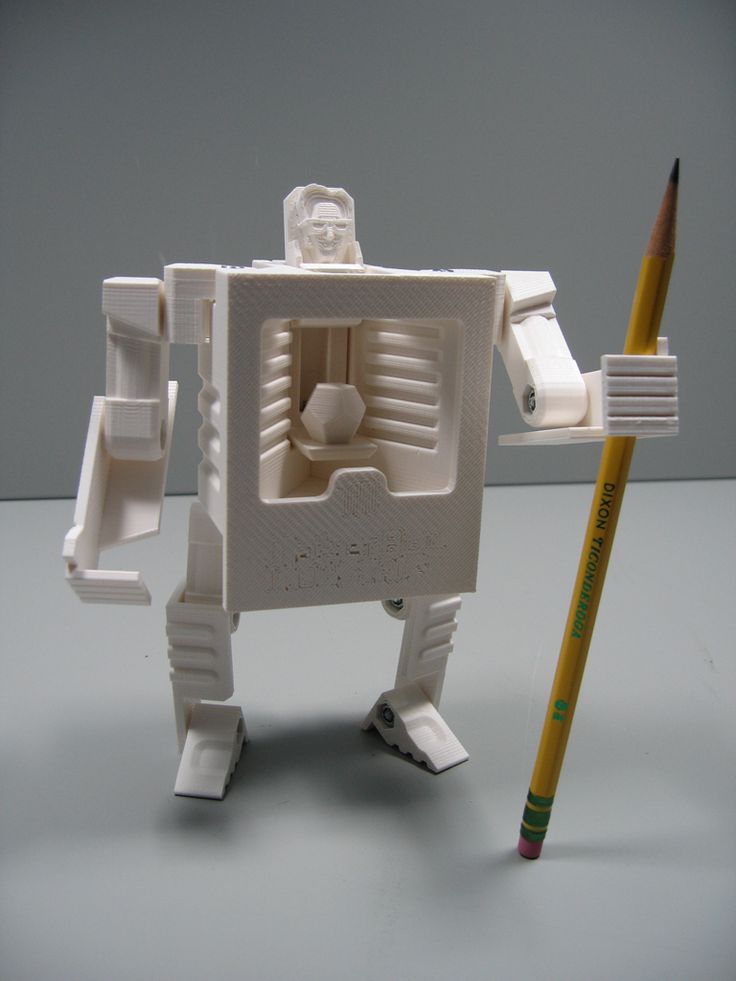

There are many different types of plastics on the market. They can be of almost any color and value, mimic the visual properties of stone, wood and other materials. The low cost of plastic is offset by not the highest detail.

Features:

- Accuracy up to 0.12 mm

- Layered surfaces (no post-processing)

- Ability to use unlicensed materials

- Fine detail

- Only selected colors available

Plastic suitable for printing rough layouts, individual parts of the composition. It is difficult to make complex large-scale projects with its help. However, if you need a very large panorama in a short time, it is only possible to produce it with an FDM printer with a large camera. For example, BigRep ONE.

For example, BigRep ONE.

| BigRep ONE nine0040 | MakerBot Replicator 5 | Picaso Designer Pro |

Resin

Photopolymer 3D printing produces more precise and detailed objects. This is important when your layout consists of very small details. This group includes rigid transparent and opaque materials in different colors.

Features:

- Accuracy up to 0.016 mm nine0003 Smooth surfaces, high detail

- Availability of transparent materials

- No post-processing required

- High cost

- Cannot withstand temperatures above 60 o C

The main advantage of polymer materials in architectural modeling is their accuracy. They usually create very complex structures. The presence of transparent materials opens up additional possibilities for designers (lighting, windows, transparent roofs).