What to know about 3d printers

10 Important Things To Know Before Buying A 3D Printer

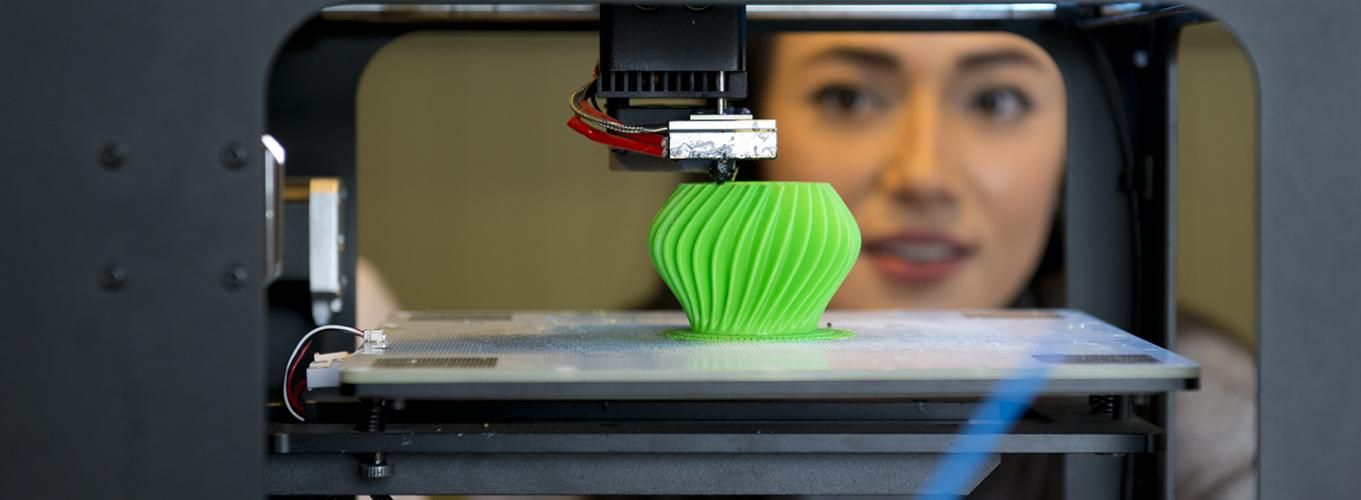

With the recent invention of a mosquito-repellant 3-D printed ring, the future possibility of 3D printing is reaching new heights. In just over the last two decades, 3D printing as a technology and industry has grown by leaps and bounds. From being a specialty, niche technology, 3D printing can now be seen in even consumers' homes.

Companies have plans to build entire schools and houses using 3D printers. But for those just getting into the field and looking to buy a 3D printer for the first time, there are some basic factors to keep in mind.

Expensive Does Not Mean Better

While sometimes a more expensive printer can equate to better quality, this is not always true. Over the last couple of years, the competition in the 3-D printing industry has skyrocketed, which has also led to cheaper and better products.

RELATED: Best Cheap Printers (Updated 2022)

The price of a 3D printer can depend on a lot of factors, like whether it is an FDM or SLS printer, the features each model provides and the brand associated, etc. , but for beginners, even cheaper 3D printers can provide adequate quality and features. Printers such as the Ender 3 can do pretty much everything a beginner would require.

PLA Is The Most Beginner Friendly Material

There are different materials available for 3D printers, and each one of them has different pros and cons. PLA or Poly Lactic Acid materials are the most versatile, cheapest, and safest to use. They are also some of the best materials to use for entry-level 3D printers.

PLA can be used to produce long-lasting objects, and it doesn't release as many harmful fumes during the process. PLA is also cheaper compared to other options, and it is biodegradable, as well. PLA also has a lower melting point which makes it easier for entry-level printers to utilize.

It Is Better To Get An Auto Leveling Printer

If the printing bed of a 3D printer is not level, it can lead to unstable foundations, clogging, or scratch marks on the object. While manual leveling printers have their advantages with certain functions, a beginner will rarely ever use them. Users can also get an auto-leveling attachment with their manual printers.

While manual leveling printers have their advantages with certain functions, a beginner will rarely ever use them. Users can also get an auto-leveling attachment with their manual printers.

An auto-leveling printer has sensors attached near the tip of the nozzle, which measures distance and balance and adjusts accordingly to make sure the bed is level before starting the process. There are some great 3D printers for even less than $500.

Make Sure The Filament Is Of Good Quality

The filament determines the quality of the object being printed. Bad-quality filament will lead to a brittle, deformed, or rough final object. Consumers can find a good quality PLA filament for about $30 per kg, and this can last most users for more than a month.

The price of the filament varies depending on the brand, quality, color, if it is glow-in-the-dark, extra strength, or has a better texture. Keep in mind that cheaper filaments don't always mean bad quality, it is better to always read the reviews. Other materials, like ABS or resin, might cost more.

Other materials, like ABS or resin, might cost more.

Understand The Basic Workings Of A 3D Printer

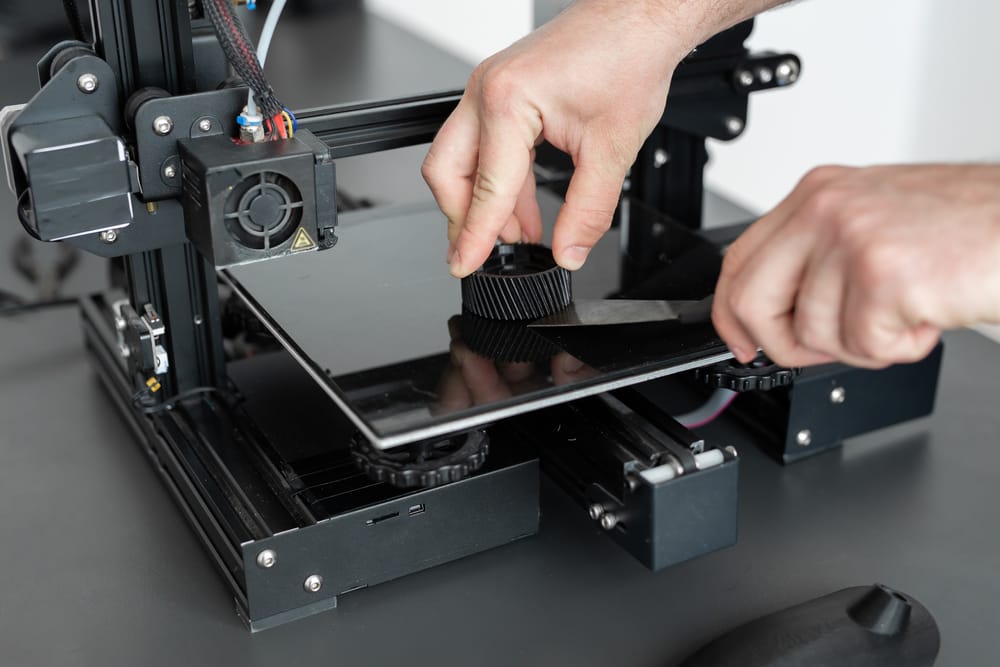

It is very important to understand the basic functioning of a 3D printer, as there can be a need for future upgrades, replacing parts, keeping rods lubricated, and replacing worn-out nozzles.

If a 3D printer is well maintained, cleaned, and updated from time to time, it can last for years while performing efficiently. Usually, 3D printers and their nozzles can last from three to six months with heavy use and up to three years with casual use. Understanding how a 3D printer works is very important when it comes to being comfortable with the machine.

Pay Attention To Print Bed Quality

The quality of a print bed will play a huge role in the final print quality. A bad print bed can lead to issues such as layer adhesion, not retaining temperature efficiently, prints sticking to the bed, or an uneven printing bed.

Print beds are made of plastic, aluminum, or glass, the latter being one of the most popular, usually because of the ease of removal of the final object. Some of the best and easiest printers to use consider the quality of the printer bed.

Some of the best and easiest printers to use consider the quality of the printer bed.

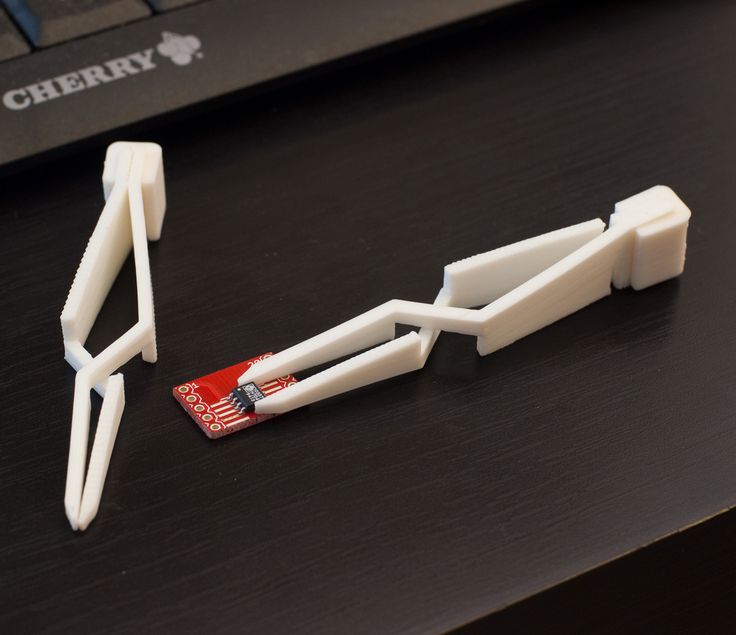

Keep A Set Of Tools At Your Disposal

Getting a 3D printer and some filament is not the end of the printing process, users will also require a set of tools to ease the final printing process. This usually includes a spatula, filament storage container, adhesive substances, and tweezers for cleaning final prints and nozzles.

RELATED: The Best Weapons, Tools, & Gadgets In The Mandalorian

A spatula is handy while removing the final print from the bed and without proper filament storage, the life of the filament can be greatly reduced.

Keep Safety In Mind

Operating a 3D printer can be very fun, but at the same time, it can also be dangerous to your property and your health. Make sure your 3D printer is in a well-ventilated room and that there are no fire hazards close by.

RELATED: The Best All-In-One Printers

Keep the printer out of reach of children and pets, as they can get very hot and also release harmful fumes. Getting an enclosure for the printer is also a great idea to keep it dust free and waterproof.

Getting an enclosure for the printer is also a great idea to keep it dust free and waterproof.

The Slower, The Better

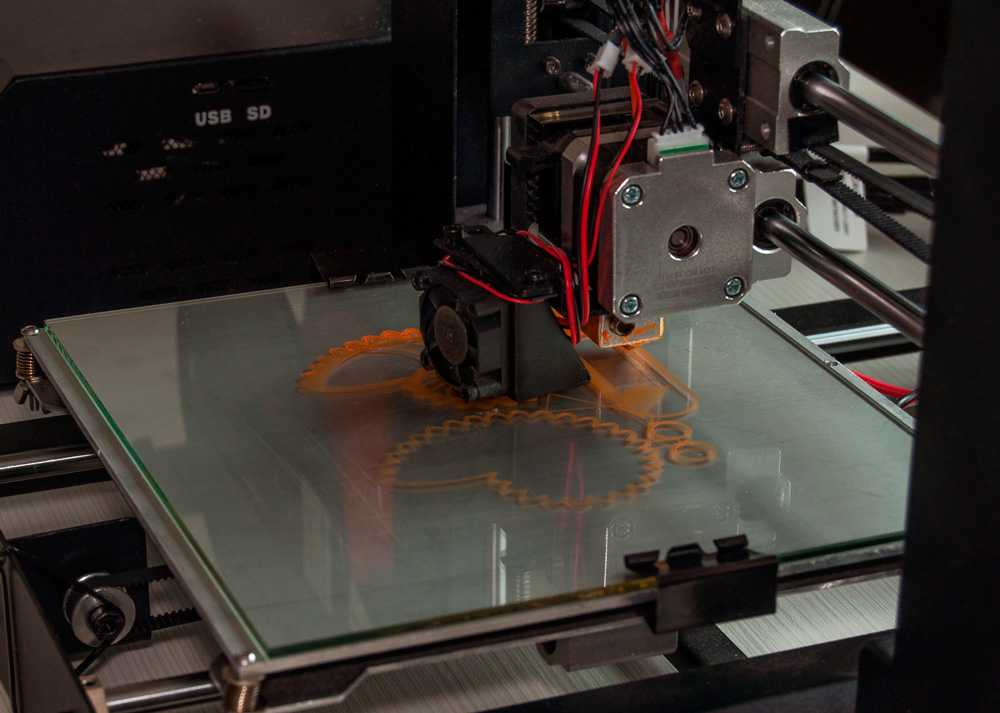

Getting the perfect 3D print can be a slow process. The overall quality of the final object heavily depends on the speed with which the printer is printing. This is one of the choices that people have to make: to either get a faster print but compromise on the quality or get the highest quality but wait for a long time.

The size of the nozzle will also impact the speed and quality of the prints. For example, if a 0.4mm nozzle takes 11 hours at 150mm/s, a 0.8mm nozzle can do it under 8 hours at 65mm/s. But at the same time, a bigger nozzle might not give the most detailed final product.

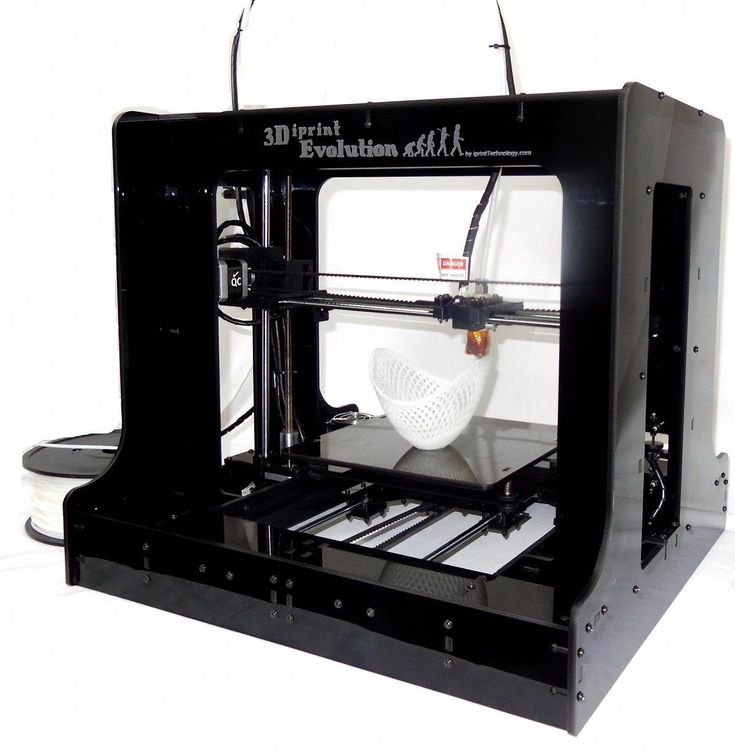

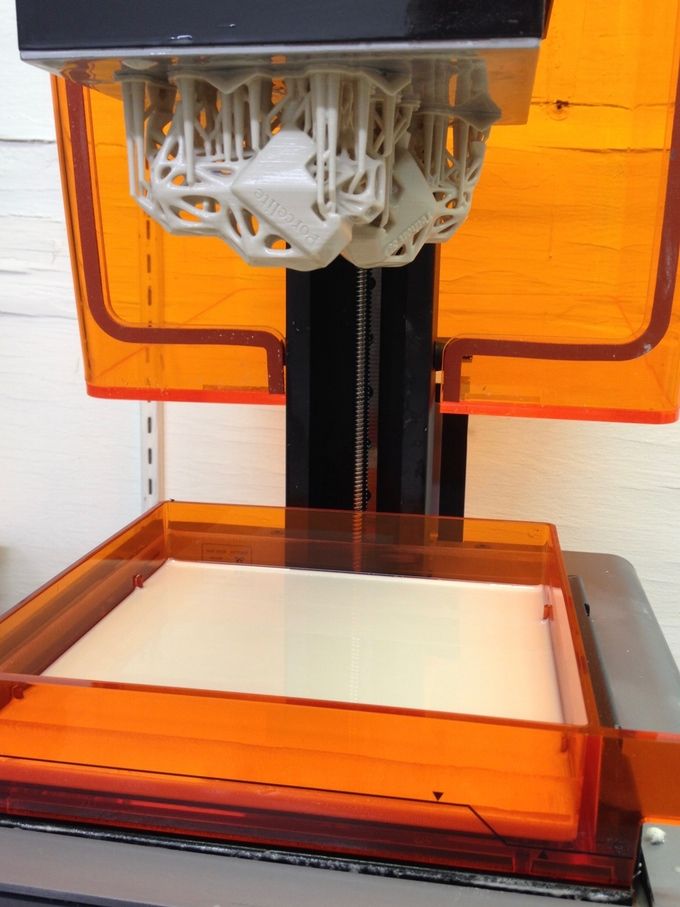

Stick With FDM Printers

The two most common types of 3D printers are SLA and FDM. While the former prints an object layer by layer using a liquid resin material and UV light and can also deliver a higher resolution and smoother finish, they can also be very expensive and the filament also costs a lot more.

FDA printers, on the other hand, are much better for beginners. They are cheaper and there is a wide variety of filament to choose from. They are also much easier to maintain. One thing to note is that SLA printers are getting cheaper, so that could be a future option for a beginner hobbyist.

NEXT: The 10 Best Smartphone Printers

6 Things You Should Know Before Buying a 3D Printer

When you learn about the many functions a 3D printer can perform, you can get pretty excited about getting one. 3D printers are fancy because of the many models you can get to print with them; figurines, smartphone cases, and an endless list of things.

There are different specifications of 3D printers, and they vary according to size, function, and technology. So, before you buy a 3D printer, read this article to learn things you should know about 3D printers.

1. Types of 3D Printers

Before buying a 3D printer, you should know the types of 3D printers that are available.

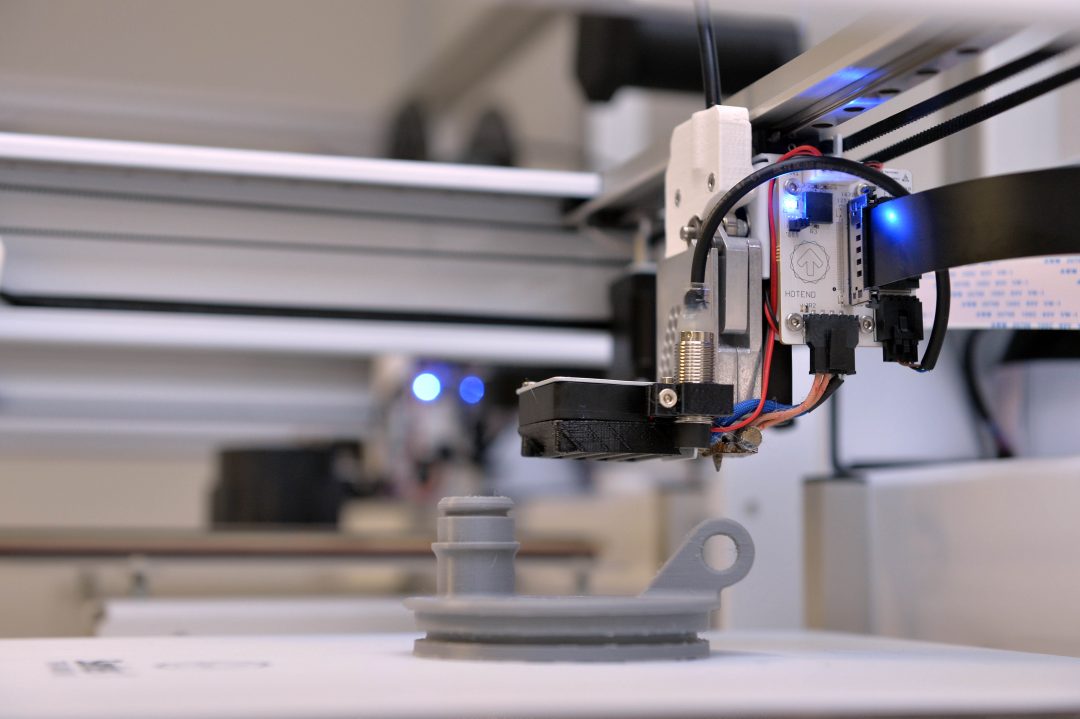

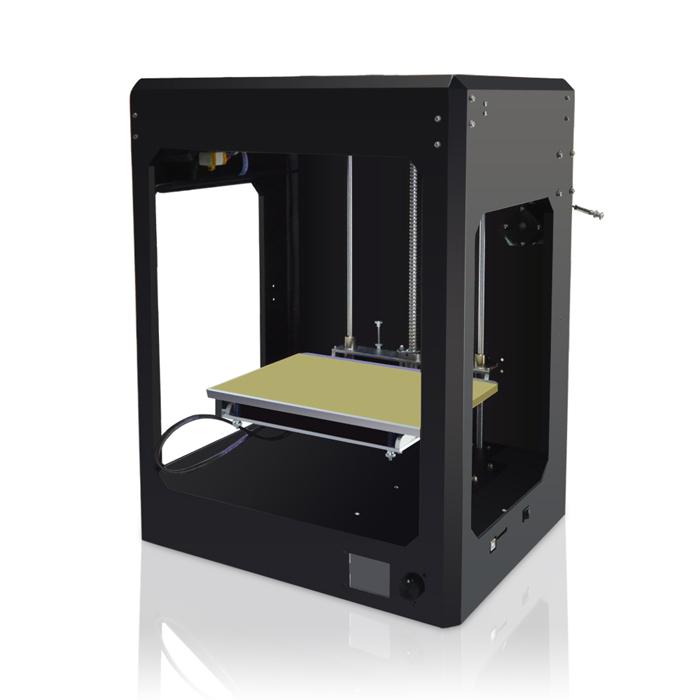

Fused Deposition Modelling (FDM) Printers

FDM technology was first developed by S. Scott Crump in the late 1980s and later commercialized in 1990. Fused Filament Fabrication (FFF) is an equivalent term for FDM created to give a phrase that is legally unimpeded in its use.

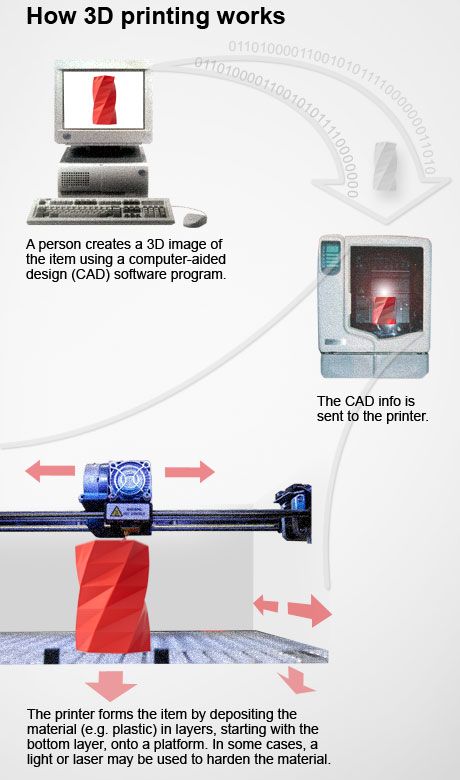

In order to create an object with an FDM printer, the files have to be in a computer-aided design (CAD) format which must be converted to a set-up that a 3D printer can understand, in most cases the STL design. These printers use both modeling materials and support materials. The modeling material constitutes the concluded object while the support material holds up the object during printing.

These materials take the form of a thermoplastic filament which is uncoiled and directed through an extrusion nozzle. The nozzle then melts the filaments and places them on a build platform or base. The build platform and nozzle are regulated by a computer which helps generate the X, Y, and Z coordinates to be adapted during printing. The nozzle moves vertically and horizontally over the base forming a thin layer of plastic which after cooling hardens and binds the layer beneath it. The base is then lowered to enable the formation of the next plastic layer, this process continues until the whole design is complete.

The nozzle moves vertically and horizontally over the base forming a thin layer of plastic which after cooling hardens and binds the layer beneath it. The base is then lowered to enable the formation of the next plastic layer, this process continues until the whole design is complete.

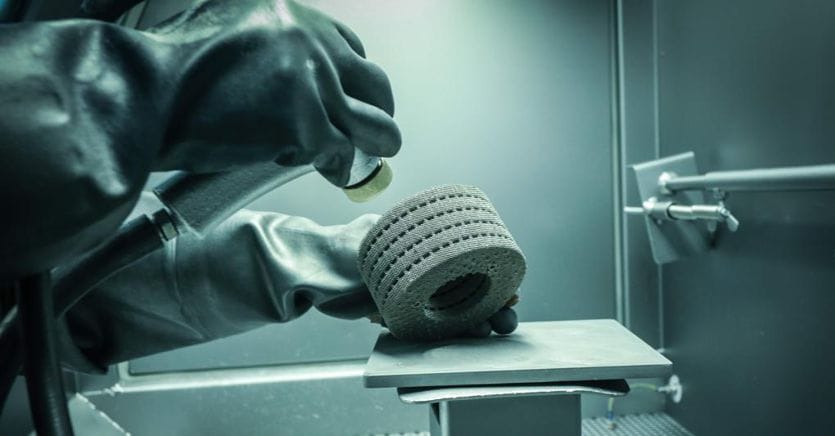

The final part of the printing using the FDM technology is removing the object from the printer once it is complete. This is done by soaking the object in a detergent and water solution or by breaking off the support base by hand. To improve the appearance, the object can be painted, sanded, or lacquered as desired.

Stereolithography (SLA)

The SLA printing process creates a model by illuminating a UV light beam on resin or any other photosensitive liquid to harden the area and create the desired model. This method makes the object of higher quality than that of FDM printed objects.

SLA printing uses similar technology to other minor 3D printing processes like Digital Light Processing (DLP) and LCD.

Selective Laser Sintering (SLS)

The SLS printing model also uses a process similar to that of SLA. However, the only difference is that SLS uses lasers instead of Ultraviolet light beams and powders instead of photosensitive liquid. The laser melts and fuses the powder to create a solid model.

SLS printing process is the 3D printing process that can print metal objects and models.

2. Your Budget

When you know about the price of 3D printers and the cost of running them, you might reconsider getting one. However, do not panic; you can get a 3D printer for as low as 180 EUR- a simple model like Creality’s Ender 3.

The FDM printer price ranges from 500 to 1500 EUR, while an SLS price ranges from 6000 to 18,500 EUR. Here you can get the best price from best buy 3D printers.

Note that the cost of the 3D printer does not cover all the materials you will need to print the models and objects. The cost of the material varies directly with the cost of the 3D printer. The prices of filaments change regarding the materials that were used in their production.

The prices of filaments change regarding the materials that were used in their production.

So, do not just consider the initial cost of getting the 3D printer; consider the subsequent amount you will need to 3D print objects. Spare parts are very affordable, and the price of 1 kg of the most popular filaments is around 20 EUR. With 1kg of filament, you can print a huge amount of 3D products. The consumption of filament depends on several different factors, so it is difficult to determine the exact number of models you can make with 1000g of material. Consumption is affected by model fullness, layer thickness, product size,…

3. Features

When you decide what type of printer you would like to get, you should check out the features you want your printer to have. Some FDM printers can cool the nozzle when you are done printing, and some other printers can move the nozzle away after printing to prevent overheating or the production of excess filament.

Apart from these safety features, be sure to check for other features like:

- type of plate,

- touchscreen interface,

- build volume,

- print bed size,

- sensor filament,

- bed leveling,

- how many extruders have,

- Does it have a direct drive extruder or a Bowden tube system,

- Wi-fi connection,

- Diameter of filament (1,75mm or 2,85mm), …

4.

End Result 3D model/ Which 3D material is best to use?

End Result 3D model/ Which 3D material is best to use? What you intend to print will determine the type of material and the 3D printer you will use. Each type of 3D printer has different kinds of material it supports. 3D filaments are very different from each other in their properties. If you want beautiful, aesthetically pleasing filaments, then SILK or PLA will be the right choice for you. However, if you need a strong and light filament, you will print the PAHT filament with carbon fiber. It is important to know the properties of the materials with which you will 3D print;

PLA FILAMENT (Polylactic Acid)

PLA filament is one of the most popular materials in the 3D world. It is used to create household items, figures, vases, phone accessory cases, holders, and home plastic materials. You can get it in full and transparent colors, with the addition of wood (PLA WOOD), glitter (PLA glitter), a special pearl gloss (PLA Pearl), …

Pros

- It is eco friendly and biodegradable

- It cools quickly, which prevents model warping

- Suitable for non-heated print beds and adhesives

Cons

- It has a low melting point which sometimes causes models to deform when you subject them to high heat.

- It is not suitable for making joints or interlocking parts.

ABS FILAMENT (Acrylonitrile Butadiene Styrene)

ABS filament is also a type of plastic made from petroleum-based substances. It is known for being flexible and strong. It is suitable for outdoor products because it can withstand harsh conditions.

Pros

It is very adaptable, making it easy to use to create joints and interlocking parts.

It does not deform when subjected to high heat because it has a high melting point.

Cons

Its high melting point makes it cool slowly and can cause model warping.

It emits fumes that can be dangerous to one's health.

PETG filament (Polyethylene Terephthalate Glycol)

PETG is a thermoplastic polyester modified with glycol. It has a combination of PLA’s ease of use and ABS durability. It is used to make mechanical components, food containers, and water bottles. If you need a hard, strong piece and you are deciding between PLA and PETG filament, choose PETG and you will not be disappointed. In addition to its durability, it is also important to mention that is made of eco-friendly materials, as it is one of the few filaments that can come into contact with food. However, always ask the manufacturer for a food safety certificate.

If you need a hard, strong piece and you are deciding between PLA and PETG filament, choose PETG and you will not be disappointed. In addition to its durability, it is also important to mention that is made of eco-friendly materials, as it is one of the few filaments that can come into contact with food. However, always ask the manufacturer for a food safety certificate.

Pros

- It is FDA-approved that it is suitable for edible consumption containers.

- It does not cause model warping

- It is heat and water-resistant

- It has good electrical properties

Cons

- It is not biodegradable

- It is more expensive

5. Goals

This is also one of the most important factors to consider before buying your 3D printer. Your goal will determine the type of 3D printer to get, the features it should have, and what filaments should you use.

It is important to think about the conditions in which you will use the printer. Outdoor use might require the printer to be waterproof and UV-resistant. And if you want it for indoor use, it must fit into your home. It is important to consider that if you are going to print ABS filament you will smell it during printing since it has a specific odor and is not the safest choice for your bedroom or your kids’ room.

Outdoor use might require the printer to be waterproof and UV-resistant. And if you want it for indoor use, it must fit into your home. It is important to consider that if you are going to print ABS filament you will smell it during printing since it has a specific odor and is not the safest choice for your bedroom or your kids’ room.

When deciding where a 3D printer will be placed, you need to think about what print size suits you; how big do you want your 3D printed items to be? If you are looking to print small items such as figurines, phone accessories, car accessories, useful items for your home, etc. you can look at the Ender 3 or Ender 5 series printers. However, if you need larger models, the CR-10 series will be right for you, as it offers a larger print area and consequently larger prints. The CR-10 MAX printer is considered one of the largest on the market, offering prints up to 450 x 450 x 470 mm.

6.

Safety

Safety You should look out for safety features before getting your 3D printers, primarily if you use them in your home or areas accessible to children. 3D printers work with heat, and you will need to take extra care to avoid bad burns.

Some 3D printers have enclosures around the print areas, while some take the nozzle away once you pause or stop printing.

Safety also extends to how environmentally friendly the 3D printer is. Some 3D printers use materials (like ABS plastics) that produce fumes. This type of 3D printer might not be suitable for indoor use or in a place that is not well-ventilated.

In addition, know what material is suitable for specific products. If you want to produce kitchenware or consumables containers, you must ensure the material is food-safe. Note that an FDM-type 3D printer can collect bacteria with its porous surfaces, making it unsafe for food containers.

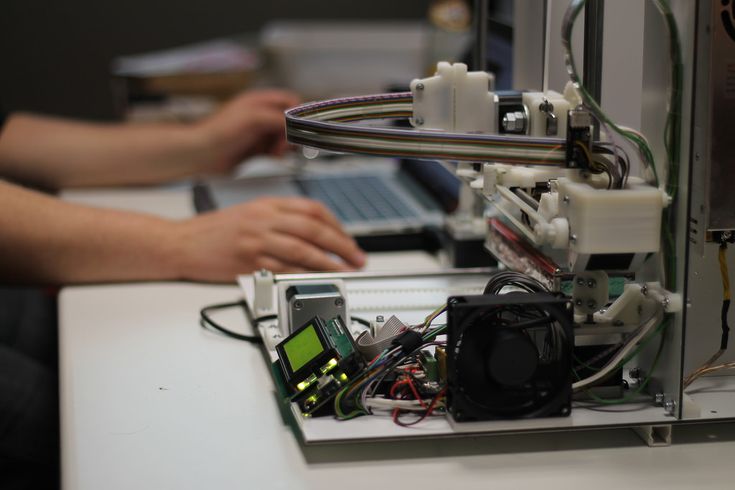

Building vs. Buying a 3D Printer

3D printing technology leaves a chance for you to be a 3D printer maker or creator. You do not necessarily have to buy a 3D printer because you can build one for yourself. And even though making a 3D printer might be more time-consuming and hectic, it is cheaper than buying a new one.

You do not necessarily have to buy a 3D printer because you can build one for yourself. And even though making a 3D printer might be more time-consuming and hectic, it is cheaper than buying a new one.

If you decide to go with building your 3D printer, you can get the 3D printer kits where you will find an instruction manual, or you can check online to find available tutorial videos. When building your 3D printer, it is better to use a combination of videos and instruction manuals so that you do not make mistakes.

And if you do not have the time or energy to do this, get a pre-assembled 3D printer. The 3D printers you can buy these days usually come with a few parts that need to be assembled. It is definitely easier and less time-consuming, so if you can’t wait to start with 3D printing, is best to buy a 3D printer.

Extra Tips for Getting a 3D printer

Get an Auto-levelling 3D printer.

If you are into the 3D printing service, it is better to go for an auto-leveling 3D printer rather than a manual-leveling one. Manual leveling requires pre-leveling knowledge and a few DIYs. And in cases where the print bed is not leveled, it can cause scratch marks on the prints, poor adhesion, and nozzle clogging.

Manual leveling requires pre-leveling knowledge and a few DIYs. And in cases where the print bed is not leveled, it can cause scratch marks on the prints, poor adhesion, and nozzle clogging.

Get a decent filament.

The level of quality of your final product is of the essence. If you want to get the best final product, do not go cheap on the filament, as it determines how well the final product will be.

Conclusion

Getting a 3D printer requires your money and attention; you need to pay attention to the details to get the appropriate one for the intended purpose. Consider what you want to print, look out for the features you want in it, and determine if the quality of the final 3d model presents what you want.

Follow these tips diligently, and you will choose the 3D printer you want and need.

What every 3D designer needs to know about modeling for 3D printing?

What every 3D designer needs to know about modeling for 3D printing?What every 3D designer needs to know about modeling for 3D printing?

In order for the 3D printer to eat your 3D model and not rebel, you need to cook it properly. We have written a simple recipe that includes the main aspects of competently preparing a 3D model for 3D printing.

We have written a simple recipe that includes the main aspects of competently preparing a 3D model for 3D printing.

First of all, keep in mind that our site has a special form for automatic verification of 3D models. Thanks to this form, you can quickly and easily check the model for suitability for 3D printing. If the model has passed the test, then the customer receives a notification by mail and the model will appear in the "My Models" section of the User's Personal Account. If the file did not pass the check, you will receive a message by mail indicating the errors found in the 3D model. In order not to be rejected by the program in 3D printing, before downloading a file, go through our list and check if you have taken everything into account.

How to prepare a 3D model for 3D printing:

-

Export the 3D model in the desired format - most often STL and WRL files are accepted for printing on a 3D printer - to scan colors when printing with multi-color plaster, a .

jpg or .png file with a texture must be attached to the WRL file.

jpg or .png file with a texture must be attached to the WRL file. -

Check that the 3D model file does not exceed the allowed size. For online download of 3D models, we accept files no larger than 50 MB (files larger than 50 MB are accepted by mail).

-

Make sure your model meets the minimum and maximum dimensions required for 3D printing in the selected material. 3D printers for printing from one material or another have different size restrictions - you can find the allowable sizes on the pages of materials for 3D printing on our website.

-

As you build your model, please refer to our website for your individual material requirements for 3D printing: check wall thicknesses, bulge or engraved details, etc.

-

Make sure your 3D model is not "turned inside out". To do this, all normals must be oriented outward - this allows the 3D printer to determine the inner and outer surfaces of the model.

-

Make sure your 3D model doesn't have holes in the mesh. Remember the basic modeling requirement for 3D printing is that the model must be “waterproof”, i.e. have a closed polygon mesh.

-

Check that in the 3D model:

no overlapping polygons ,

each polygon has a given thickness (no polygons with zero thickness),

internal polygons are missing (no faces inside the model, e.g. inside walls),

each edge has no more than two adjacent faces (polygons),

there are no matching edges - edges created in the same place are merged into one common edge.

If you have checked the 3D model and marked done in every step, feel free to upload the file to our online form to check the model and calculate the cost of 3D printing from a particular material. If, after uploading, it turned out that you missed something and there are errors in the 3D model, for a simple and quick “treatment” of the model, we recommend using the Netfabb program, which fixes more than 95% of the most common modeling errors for 3D printing. Or you can always send the model to us by mail, and we will definitely help you figure it out and finalize the model.

Or you can always send the model to us by mail, and we will definitely help you figure it out and finalize the model.

Rules for 3D modeling for 3D printing

It is known that a prerequisite for 3D printing is the presence of a 3D model, according to which the printer will grow a three-dimensional object. But, even after simulating an object, you should not assume with absolute certainty that the job is done, and soon the printer will give you the finished product. The fact is that not all models are suitable for 3D printing. There are certain requirements for the dimensions, thicknesses and design of models - and these requirements vary depending on the material used and the printer. In addition to these individual characteristics, there are general requirements that distinguish print models from other 3D models. And now we will talk in more detail about how to prepare a model for 3D printing.

First of all, you need to remember that STL files (for one-color models) and WRL (for color plaster 3D printing) are suitable for 3D printing. Almost all 3D modeling programs allow you to export models to STL, so this should not be a problem. You should also take into account that for online download on our website, files no larger than 50 MB each are accepted, as well as an extended list of formats that are automatically exported to STL: STP, STEP, OFF, OBJ, PLY and directly STL. If the file size is more than 50 MB, then you need to send the model to our email address: [email protected]. By the way, one of the easiest ways to reduce the volume of the model and the file size is to create hollow 3D models, we already wrote about how this works in our blog.

Before you start creating a model for 3D printing, it is important to understand what material you want to print the product from. Each material has its own individual characteristics for 3D modeling - maximum and minimum model dimensions, wall thicknesses, distance between moving parts, etc. You can learn more about the requirements for a particular material in the appropriate section on our website.

You can learn more about the requirements for a particular material in the appropriate section on our website.

If you use the online model upload on our website, it will automatically check for standard 3D modeling errors. Models are checked instantly, and if errors that prevent 3D printing were not found, then immediately after uploading the model will appear in your personal account in the "My Models" section. If the model did not pass the test, then you will see a notification that the file cannot be loaded, then you will need to check and refine the model again.

What are the most common errors encountered when modeling for 3D printing?

- Inverted normals - incorrectly oriented normals. Normals should always be directed outward, they define the boundaries of the object and allow the 3D printer software to understand which is the inside and which is the outside of the model. If at least one of the normals is directed in the opposite direction and contradicts the other normal, then this causes a failure in 3D printing, since the printer cannot distinguish between the front and back sides of the object.

- Non-manifold geometry - Non-manifold 3D model is a prerequisite for 3D printing. The essence of this concept is that each edge of a 3D model must have exactly two faces.

The following errors are usually included in this concept:

o Mesh with holes - "unclosed" mesh problem. Remember the basic rule of 3D modeling: your model must be "watertight" or "airtight". If a hole is formed, it means that some edge is missing one face, therefore the model is not manifold, and therefore not suitable for 3D printing.

o Presence of internal polygons. There must be no faces inside the model, for example inside walls.

o Common ribs. An error occurs when more than two polygons are attached to the same edge. Each edge in your 3D model should connect only two adjacent faces.

o Matching edges. Occurs when two separate edges are created at the same location and are not connected, such edges must be merged into one common edge.

.jpg?x-oss-process=image/resize,p_100/format,webp)