3D printing provider

Custom Online 3D Printing Service

CapabilitiesCustom Online 3D Printing Service

Get instant online quotes on parts in over 70 metal and plastic materials. Free shipping on all US orders. ISO 9001:2015, ISO 13485 and AS9100D certified.

Our 3D Printing ServicesMaterialsApplications and BenefitsSizes and TolerancesAbout 3D Printing3D Printing GuideXometry's Online 3D Printing Services: High-Quality Rapid Prototyping and Production Parts

Xometry offers an industry-leading 3D printing service online. Whether you need prototypes or production parts, we can make them for you on demand in as fast as a day. We are your one-stop-shop for accurate, precise, custom 3D printed parts at an affordable price. Upload your 3D CAD file to get an online quote and lead time within seconds. We print everything from single prototypes to thousands of production-grade parts.

We use the latest additive manufacturing technology to build affordable functional parts in over 60 metals and plastics. Xometry offers eight high-quality 3D printing processes including selective laser sintering, fused deposition modeling, stereolithography, direct metal laser sintering, polyjet, Carbon DLS, binder jet metal, and HP Multi Jet Fusion. We use commercial and industrial-grade printers such as Stratasys Fortus 900mc and Fortus 450 FDM, EOS Polymer Laser Sintering (SLS) and DMLS, Concept Laser, SLM Solutions, 3D Systems, ExOne, and more. For a great introduction to additive manufacturing, please visit our Complete Guide to 3D Printing.

Use the 3D viewer above to preview Xometry’s part rendering features.

Thermoplastic 3D Printing

Selective Laser Sintering (SLS) 3D Printing Service

Upload your CAD file to get instant quotes on SLS parts. Parts ship in days. Free shipping on all US orders.

Selective Laser Sintering (SLS) 3D Printing Service

HP Multi Jet Fusion (MJF) 3D Printing Service

Quality prototypes and production parts. Free shipping on all US orders. ISO 9001:2015, ISO 13485, and AS9100D certified.

Free shipping on all US orders. ISO 9001:2015, ISO 13485, and AS9100D certified.

HP Multi Jet Fusion (MJF) 3D Printing Service

Fused Deposition Modeling (FDM) 3D Printing Service

High Quality Large Format FDM 3D Printing Free Shipping on All US Orders

Fused Deposition Modeling (FDM) 3D Printing Service

Thermoset 3D Printing

Stereolithography (SLA) 3D Printing Service

High-Resolution Prototypes in Days Free Shipping on All US Orders

Stereolithography (SLA) 3D Printing Service

Carbon Digital Light Synthesis™ (DLS™) 3D Printing Service

High-Performing Prototypes and Serialized Production Parts Free Shipping on All US Orders

Carbon Digital Light Synthesis™ (DLS™) 3D Printing Service

PolyJet 3D Printing Service

Prototypes, color concept models, and simulated overmold parts in days Free shipping on all US orders

PolyJet 3D Printing Service

Metal 3D Printing

Direct Metal Laser Sintering (DMLS) 3D Printing Service

Upload your CAD files to get an instant quote on metal prototypes and production parts. Free shipping on all US orders.

Free shipping on all US orders.

Direct Metal Laser Sintering (DMLS) 3D Printing Service

Metal Binder Jetting 3D Printing Service

Upload your CAD files to get an instant quote on parts. Free shipping on all US orders.

Metal Binder Jetting 3D Printing Service

Get flexible payment options for the parts your business needs.

The Best 3D Printing Material Selection

Durable Nylon

Nylon is one of the most versatile options for 3D printing with great feature detail and performance.

ABS and ASA

ABS and ASA 3D prints have a variety of colors and are a staple to 3D printed plastics.

ULTEM 9085 and ULTEM 1010

Tough, heat resistant, and durable ULTEM is engineered to withstand the most rigorous environments.

Elastomers and Rubber-like Materials

3D printed TPE and silicone-based elastomers give rubber parts without the need for tooling.

Metal 3D Prints

3D printed metal parts can achieve complex geometries without a sacrifice in performance.

Multi-Material Parts

PolyJet 3D can combine multiple properties in a single print for overmolds and other cosmetic features.

Materials for all Applications

Xometry has the widest variety of industrial 3D custom printing materials available for instant quoting.

New!

Flame Retardant Plastic 3D Printing

Xometry's 3D Print Service offers a variety of polymers that are flame retardant and qualify for UL-94 V-0 and FAR 25.853 60 second burn test. This includes FDM ULTEM 9085, FDM ULTEM 1010, and SLS Nylon 12, Flame Retardant. These polymers are perfect for aviation and aerospace applications. Learn more about 3D Printed Flame Retardant Plastics.

Ready to start making custom 3D printed parts?

Free shipping on all 3D printing orders!

Applications of 3D Printing

Concept Models

The speed and versatility of 3D Printing lets product developers create physical snapshots of their designs through the iterative process.

Rapid Prototyping

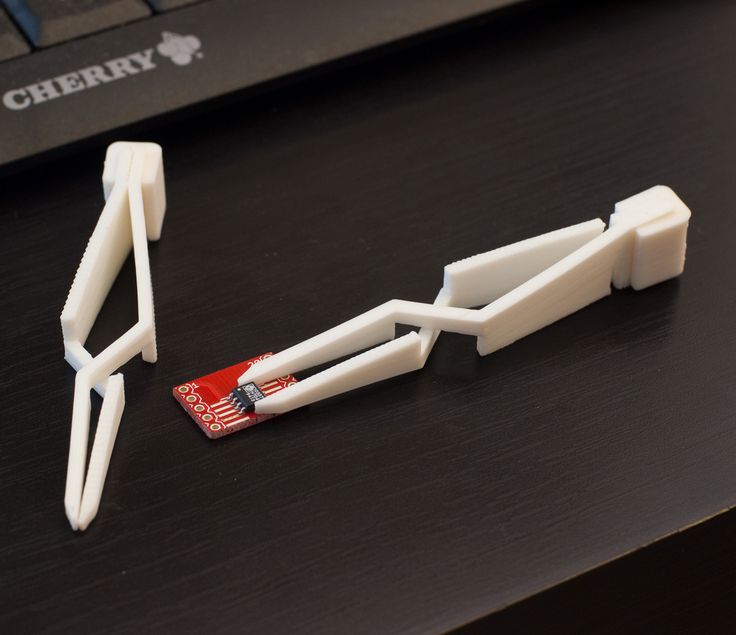

3D Printing can be used to create fully-functional prototypes, complete with moving parts, as well as all-in-one assemblies.

Direct Digital Manufacturing

The high accuracy and consistency of 3D printing makes it an ideal way to build production quantities of discrete or customized parts.

Advantages of 3D Printing

Rapid Turnaround

Parts can typically be shipped in as little as 1 day, allowing for faster design iterations and speed to market.

Durability

3D printing can offer great impact strength, medium flexibility, and high resistance to environmental factors.

Complex Geometry

Geometries can be built more easily due to the 3D printing process, adding complexity without additional cost.

Precision

3D printing can achieve precise parts and feature details.

Part Production

3D printing with Xometry helps you produce end-use parts on-demand, increasing throughput.

Scalability

With 3D printing, you can make a single part or component as easily as dozens of production pieces.

3D Printing General Tolerances

General Guidelines when Designing for 3D Printing

| Description | Tolerance Notes |

|---|---|

Description Part Size | Tolerance Notes Xometry can accommodate 3D printing up to 24" x 36" x 36" without the need to split and bond parts. |

Description Minimum Feature Size | Tolerance Notes 0.030" - 0.060" is typical. |

Description Minimum Wall Thickness | Tolerance Notes 0.020" - 0.060" is typical. |

Description Clearance Between Features | Tolerance Notes At least 0.030" |

General tolerances apply before secondary finishing or post-processing unless otherwise specified. Please check out Xometry's Manufacturing Standards for more information on tolerances per process.

What is 3D Printing?

What is 3D Printing?

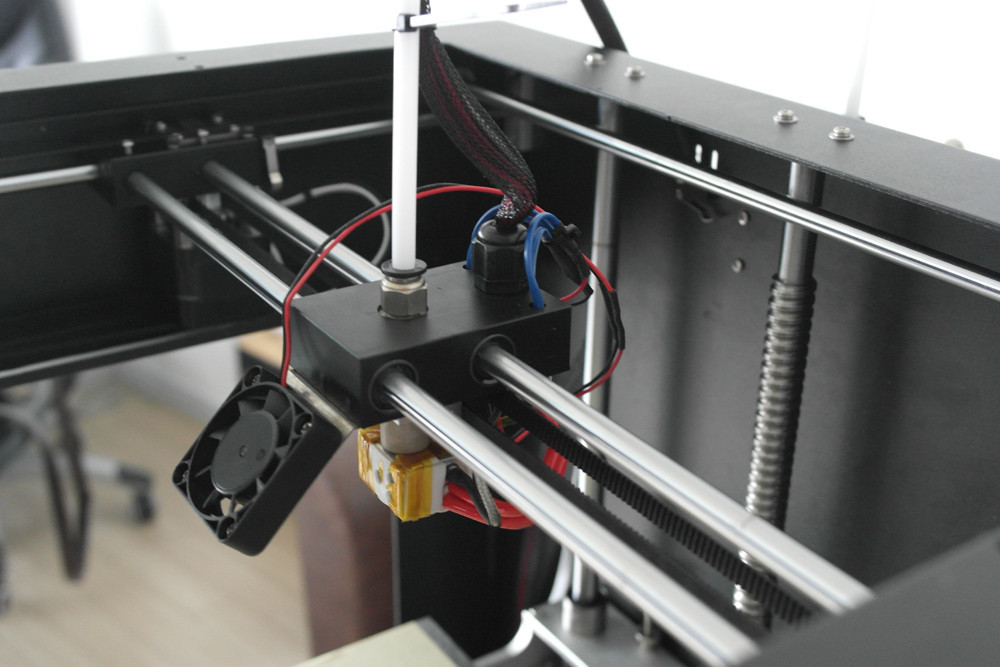

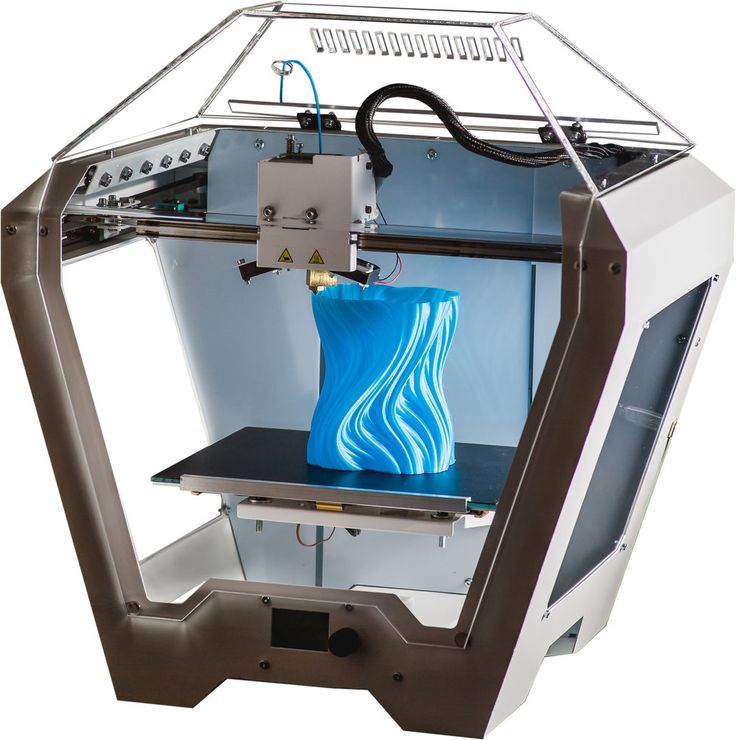

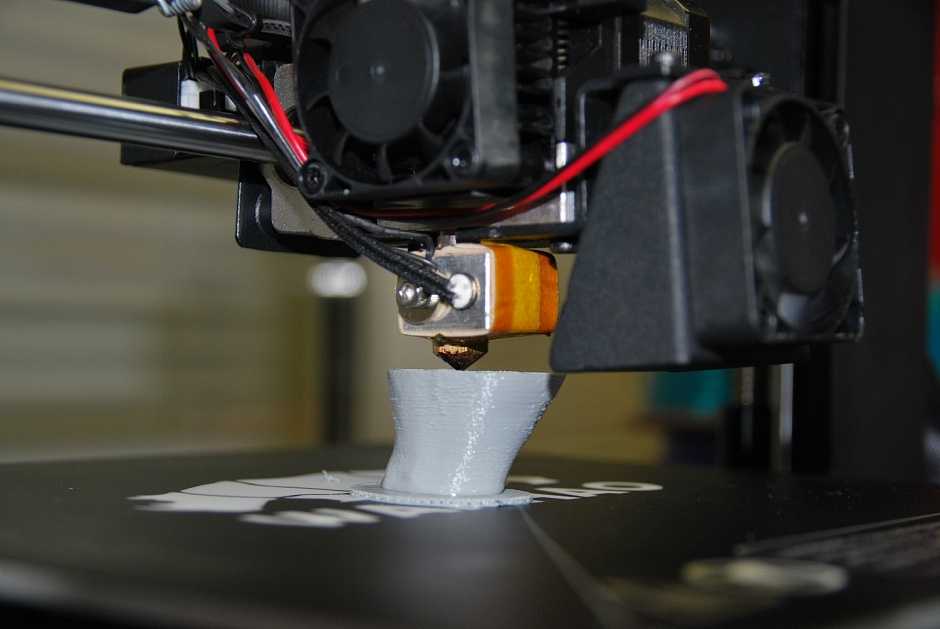

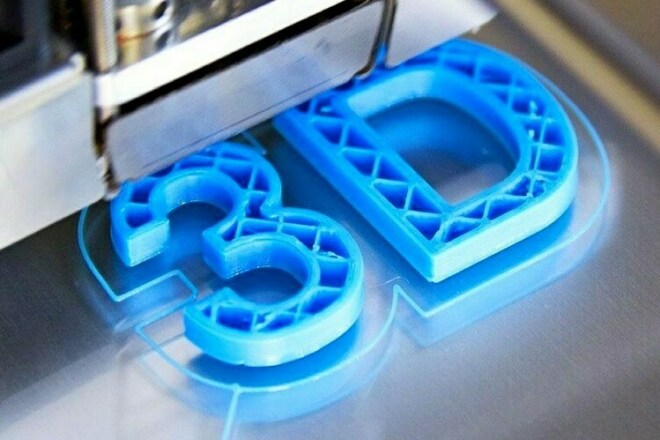

3D printing is an additive manufacturing process where materials are joined together to make objects from 3D model data (CAD). Typically, 3D printing is a layer-by-layer process where part geometries are “grown,” fusing with the previous layer. 3D printing processes can build objects in plastics, photopolymers, reaction polymers, composites, metal, glass, and other materials.

Typically, 3D printing is a layer-by-layer process where part geometries are “grown,” fusing with the previous layer. 3D printing processes can build objects in plastics, photopolymers, reaction polymers, composites, metal, glass, and other materials.

Instant Quote Demo

See how fast and simple it is to get a quote for 3D printing using the Xometry Instant Quoting Engine®.

Why Choose Xometry for 3D Printing?

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Quality Assurance

We are ISO 9001:2015, ISO 13485 and AS9100D certified.

Become an additive expert with our Complete Guide to 3D Printing

3D Printing Services Available at Xometry

Bronze 3D Printing Service

Get instant online quotes on parts in over 70 metal and plastic materials. Free shipping on all US orders. ISO 9001:2015, ISO 13485 and AS9100D certified.

Free shipping on all US orders. ISO 9001:2015, ISO 13485 and AS9100D certified.

Bronze 3D Printing Service

Color 3D Printing Service by Xometry

Get instant online quotes on parts in over 70 metal and plastic materials. Free shipping on all US orders. ISO 9001:2015, ISO 13485 and AS9100D certified.

Color 3D Printing Service by Xometry

Large Scale 3D Printing Service on Xometry

Get instant online quotes on large scale 3D printed parts in over 70 metal and plastic materials. Free shipping on all US orders. ISO 9001:2015, ISO 13485 and AS9100D certified.

Large Scale 3D Printing Service on Xometry

Rubber 3D Printing Service on Xometry

Get instant online quotes on parts in over 70 metal and plastic materials. Free shipping on all US orders. ISO 9001:2015, ISO 13485 and AS9100D certified.

Rubber 3D Printing Service on Xometry

3D Printing Services Near You

AlabamaArizonaArkansasCaliforniaColoradoConnecticutDelawareFloridaGeorgiaIdahoIllinoisIndianaIowaKansasKentuckyLouisianaMaineMarylandMassachusettsMichiganMinnesotaMississippiMissouriMontanaNebraskaNevadaNew HampshireNew JerseyNew MexicoNew YorkNorth CarolinaNorth DakotaOhioOklahomaOregonPennsylvaniaRhode IslandSouth CarolinaSouth DakotaTennesseeTexasUtahVermontVirginiaWashingtonWest VirginiaWisconsinWyoming

Shapeways: 3D Printing Service Online

3D Printing Service

Create and customize. Streamline and save. Break down design barriers and scale your business with Shapeways 3D printing services.

Streamline and save. Break down design barriers and scale your business with Shapeways 3D printing services.

Why 3D Printing?

Reduce Assembly Time

Don’t waste time putting products together! Rely on 3D printing to make complex geometries that can be printed as one piece—or consolidated in one build.

Fast Turnaround

Working on a project for a customer that has to be just right? Get models back fast, and 3D print new iterations, if needed, for final feedback and production.

Reliable Quality

Proprietary processes, expert 3D printing operators, and inspections are our secrets to delivering exceptional, quality products every time.

Parts 3D Printed

3D Printing Technologies

Materials and Finishings

Countries Shipped

Customers Served

Cutting Edge Technologies

Manufacture high-quality products in over 90 of the best materials and finishes, from plastics to metals.

HP Multi-Jet Fusion

- Nylon 12 with a smooth and finished surface

- Exhibits incredible strength, durability and stiffness

- Supports complex geometries and thin features HP Technologies

Our Services

Production Parts

Upload customized models for 3D printing service—ensuring durability and strength in materials that result in end-use products meant to last. Our Services

Rapid Prototyping

Take the guesswork out of product development with 3D printing services for high-performance models used in meetings, testing, and perfection of final parts. Prototyping Service

E-commerce Integrations

Launch your business through our marketplace by connecting to the Shapeways platform through our API, Shopify, or Etsy E-commerce Integrations. E-commerce Integrations

Professional Design Services

Bring your idea to life with 3D file design and optimization. Through our partnership with ZVerse, every customer has access to expert 3D Design solutions for any project need. Design Service

Design Service

Rapid Prototyping

Our high quality printing enables you to assess factors such as ergonomics, usability, manufacturability, and material testing. Prototyping Service

E-commerce Integrations

Launch your business through our marketplace by connecting to the Shapeways platform through our API, Shopify, or Etsy E-commerce Integrations. E-commerce Integrations

Materials

Nylon 12 [Versatile Plastic]

Nylon 12 [Versatile Plastic] is a durable nylon plastic that can be used for a wide range of applications, both for prototyping and for end products. Printed using Selective Laser Sintering (SLS) 3D printing services, when thin, it's flexible enough for hinges and springs and when thick, strong enough for structural components. Material Details

Accura 60

Accura 60 is a translucent and rigid acrylate-based plastic. Shapeways 3D prints this material using a large-format Stereolithography (SLA) printer capable of producing small to large parts with high resolution and detail as well as smooth surfaces with limited layer lines. Material Details

Material Details

Stainless Steel 316L

Stainless Steel 316L is manufactured using ExOne’s ‘Triple Advanced Compaction Technology’ with Binder Jetting. Unlike our Steel that is infused with bronze, this material is a single alloy, composed of pure Stainless Steel. Material Details

Nylon 12

Nylon 12 (Versatile Plastic) is a durable nylon plastic that can be used for a wide range of applications, both for prototyping and for end products. Printed using Selective Laser Sintering (SLS), when thin, it's flexible enough for hinges and springs and when thick, strong enough for structural components. Material Details

Accura 60

Accura 60 is a translucent and rigid acrylate-based plastic. It is 3D printed using a large format stereolithography (SLA) printer capable of producing small to large parts with high resolution and detail as well as smooth surfaces with limited layer lines. Material Details

Stainless Steel 316L

Stainless Steel 316L is manufactured using ExOne’s "Triple Advanced Compaction Technology" with a binder jetting system. Unlike our Steel that is steel infused with bronze, this material is a single alloy, 100% Stainless steel 316L. Material Details

Unlike our Steel that is steel infused with bronze, this material is a single alloy, 100% Stainless steel 316L. Material Details

Testimonials

I like the ease of use in the Shapeways platform, being able to 3D print on-demand orders for the first time, and most of all–being able to scale my business. In the beginning years ago I basically had the change in my pocket and a credit line at my bank so I couldn’t order a ton of things, and you never know what’s going to sell.”

Steven Jaworski

Owner | Voytek Medical

During the process, we used Shapeways capabilities to 3D print many prototypes. That meant we had the option to iterate very quickly, print objects, and test them to see if they were working correctly in terms of complexity, or too much complexity.”

Yonatan Assouline

Manager & Co-Founder | Flamingo Works

Shapeways was really great when we worked together before, which led us to reach out again. It’s been so helpful to talk with them about what we could do in every aspect of 3D printing and finishing, and it saved us a lot of time in experimentation. ”

”

Nathan Lachenmyer

Director of Technology | Sitara Systems

I like the ease of use in the Shapeways platform, being able to 3D print on-demand orders for the first time, and most of all–being able to scale my business. In the beginning years ago I basically had the change in my pocket and a credit line at my bank so I couldn’t order a ton of things, and you never know what’s going to sell.”

Steven Jaworski

Owner | Voytek Medical

During the process, we used Shapeways capabilities to 3D print many prototypes. That meant we had the option to iterate very quickly, print objects, and test them to see if they were working correctly in terms of complexity, or too much complexity.”

Yonatan Assouline

Manager & Co-Founder | Flamingo Works

Shapeways was really great when we worked together before, which led us to reach out again. It’s been so helpful to talk with them about what we could do in every aspect of 3D printing and finishing, and it saved us a lot of time in experimentation. ”

”

Nathan Lachenmyer

Director of Technology | Sitara Systems

Previous Next

Recent Articles

Trusted by Businesses Around the World

Russian 3D printing service provider ranked among the best companies in the world

INNOVAKS, an accredited provider of the Skolkovo Technopark CCU in the field of small-scale, pilot and additive manufacturing, was included in the list of the world's leading 3D printing service providers published by at www.wohlersassociates.com. This is the first company from Russia and the CIS in the list of the best specialists in the field of additive technologies

Wohlers Associates (USA) is a leading independent consulting company in the field of additive technologies, for more than 30 years of its existence has earned credibility in the global community and is a recognized industry expert. For more than 20 years, the company has published an annual Wohlers report on additive manufacturing and 3D printing. It is the undisputed industry report on the subject, often referred to as the "Bible of 3D printing".

It is the undisputed industry report on the subject, often referred to as the "Bible of 3D printing".

Wohlers Associates places on the site those companies that successfully implement projects, carrying out engineering processes within them, in various industries. The availability of high-quality high-performance equipment is a prerequisite. The mention on the resource is an indicator of professionalism and a high level of services provided.

Photo: INNOVAX

In the list of the best specialists in the field of additive technologies, INNOVAX is on a par with recognized world mastodons, including Stratasys, Materialize, Citim, Addaero, CFK, Spring, EMS, CRP Technology.

INNOVAKS realizes its rich potential and proves that domestic players in the digital production market have very optimistic and ambitious plans for the future. By introducing advanced materials and advanced technologies in the manufacture of parts and elements that were previously put into serial production, the company opens up new opportunities in industrial production, allows solving existing problems, eliminating shortcomings and optimizing many processes.

Thus, one of the INNOVACS projects was the improvement of the design and production technology of elements for the cockpit air conditioning system in the SSJ-100 aircraft

At the moment, parts are made of aluminum, which causes a high labor intensity of the process (welding, assembly, painting are required) and production costs (due to the development and creation of tooling). In addition, the presence of welds in finished elements significantly reduces such an important indicator for the aircraft industry as reliability.

Representatives of INNOVAKS looked at the project from a fundamentally new perspective. The result of a fresh approach was a proposal to replace the material from aluminum alloy to Ultem thermoplastic, to produce parts on a 3D printer, and to review the design of the manufacture of pipes and brackets for their fastening in order to reduce the number of joints that increase noise levels.

Calculations have shown that the developed parts have no strength reduction. In addition, in the finished samples, a decrease in weight was noted, an improvement in aerodynamic characteristics due to the absence of corners and the turbulences associated with them. The time spent on manufacturing parts has decreased.

In addition, in the finished samples, a decrease in weight was noted, an improvement in aerodynamic characteristics due to the absence of corners and the turbulences associated with them. The time spent on manufacturing parts has decreased.

Details - in the message of the INNOVAKS company

MIPT scientists printed antennas for 5G towers on a 3D printer

Trends

TV channel

Pro

Investments

Events

RBC+

New economy

Trends

Real estate

Sport

Style

National projects

City

Crypto

Debating Club

Research

Credit ratings

Franchises

Newspaper

Special projects St. Petersburg

Petersburg

Conferences St. Petersburg

Special projects

Checking counterparties

RBC Library

Podcasts

ESG index

Policy

Economy

Business

Technology and media

Finance

RBC CompanyRBC Life

RBC Trends

Photo: Unsplash

Russian scientists have figured out how to make cheap communication antennas: 3D print them out of plastic and then cover them with a metal shell

What happens

- Scientists from the Moscow Institute of Physics and Technology proposed to print high-precision antennas on a 3D printer from plastic, and then cover them with metal so that the antennas conduct current.

- The metal sheath consists of metals with a high electrical conductivity, such as copper.

- At frequencies greater than 5 GHz, plastic prevents the antenna from working well. So the researchers removed the plastic base, leaving the metal shell. During the experiments, it turned out that such antennas work even better than standard ones.

- Such antennas, according to the creators, will help provide high-quality 5G and even 6G communications.

- According to Dmitry Filonov, head of the laboratory of radiophotonics at the Center for Photonics and Two-Dimensional Materials of the Moscow Institute of Physics and Technology, the proposed method, although it cannot compete in productivity with metal printing, can produce reliable antennas at a low cost.

What it means

The 3D printing industry is constantly evolving. Almost everything is printed on a 3D printer: houses, organs, food. According to the consulting company Grand View Research, the global 3D printing market in 2021 was estimated at $13.

.jpg?x-oss-process=image/resize,p_100/format,webp)