3D resin printer reviews

Creality Halot-One Plus 3D Printer Review: 4K Resolution, Sub-$400 Price

When you purchase through links on our site, we may earn an affiliate commission. Here’s how it works.

Creality Halot-One Plus is just the right size for a desktop resin 3D printer.

(Image: © Tom's Hardware)

Tom's Hardware Verdict

Offering high resolution and an above-average build volume, the Creality Halot-One Plus is an impressive machine with a set of hardware features not typically seen at this price.

TODAY'S BEST DEALS

Pros

- +

4K+ resolution provides sharp detail and consistent surfaces

- +

Large 5-inch LCD interface is bright, fast, and responsive

- +

Halot Box slicer software is simple and easy to use

- +

Built-in Wi-Fi connectivity and remote print monitoring

- +

Integrated air filtration unit

Cons

- -

Z endstop placement at the top of the Z axis is a strange choice

- -

Creality Cloud platform appears to host many unauthorized models

- -

Four bolt build platform leveling can be messy

Why you can trust Tom's Hardware Our expert reviewers spend hours testing and comparing products and services so you can choose the best for you. Find out more about how we test.

Today's best Creality Halot-One Plus deals

19 Amazon customer reviews

☆☆☆☆☆

$319

View

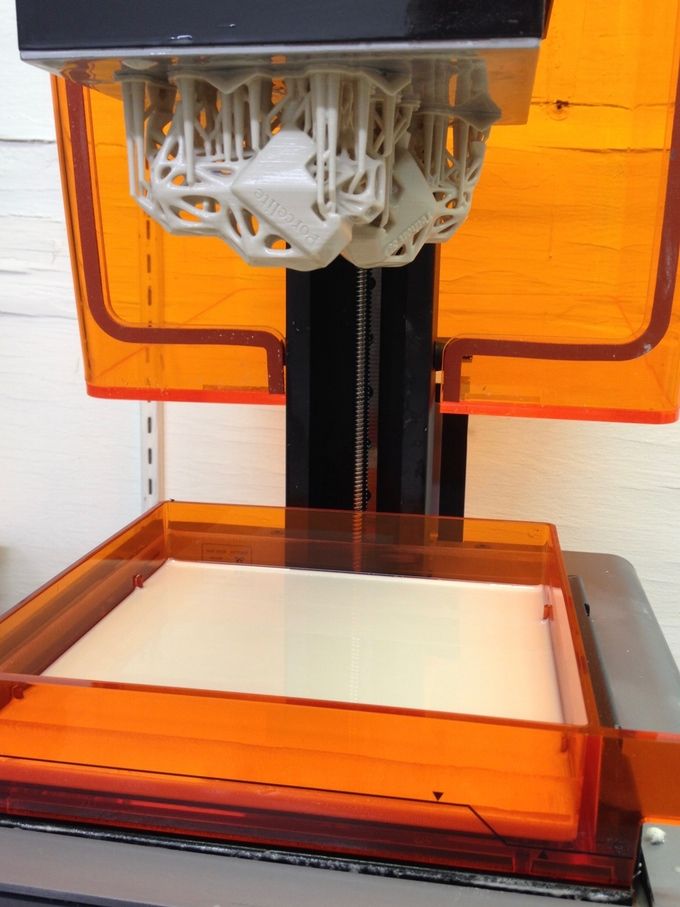

The Creality Halot-One Plus is the flagship printer in the Halot line of MSLA printers, offering 4K resolution, a 7.9-inch mono LCD with a 3 second exposure time, and other high-end features in a package that retails for just under $400. The Halot-One Plus appears to have been designed for the prosumer market, with features like Wi-Fi connectivity, air filtration, and other features that don’t typically appear in printers in this price range.

During testing, this printer proved to be a logical next-step in resin 3D printing, showing how these features can be successfully implemented at a lower price point while still maintaining functionality. We had issues with the Creality Cloud platform and the lack of attribution on published models, but the printer hardware itself places this among the best resin 3D printers.

We had issues with the Creality Cloud platform and the lack of attribution on published models, but the printer hardware itself places this among the best resin 3D printers.

Creality Halot-One Plus Specifications

Swipe to scroll horizontally

| Machine Footprint | 9.29" x 9.57" x 16.46" (23.6cm x 24.3cm x 41.8cm) |

| Build Volume | 6.77" x 4.02" x 6.30" (172mm x 102mm x 160mm) |

| Resin | MSLA Photopolymer Resin |

| UV Light | 4,500 uw/m2 Integral Light Source |

| Masking LCD Resolution | 4320 x 2560 |

| Masking LCD Size | 7.9-inch |

| XY Axis Resolution | .04mm |

| Interface | 5-inch LCD Touchscreen |

Included in the Box of Creality Halot-One Plus

(Image credit: Tom's Hardware)The Creality Halot-One Plus ships with everything you need to get started printing, including a set of Allen keys, plastic and metal scrapers to remove parts from the printer, a printed user guide, and a power cable, and some paper funnels for pouring resin back into the bottle from the vat. The printer itself is well-packed and protected, with a protective plastic covering over the UV-resistant lid.

The printer itself is well-packed and protected, with a protective plastic covering over the UV-resistant lid.

- Creality Halot-One Plus (Black) at Amazon for $319

Unlike with many other resin printers, including the Elegoo Mars 3, the Halot-One Plus does not include any consumables such as gloves, masks, or other cleaning supplies. This isn’t a large omission, but it means first time users will want to make sure they have all the proper supplies before they start printing.

One of the first features I noticed on the Creality Halot-One Plus was the large LCD screen. The 5-inch screen is bright, responsive, and feels like the type of capacitive screen you’d expect to see on a tablet or mobile phone. This screen is easy to read and use, and immediately sets the Halot-One Plus apart from similarly priced machines that use smaller screens. The Halot-One Plus also includes an onboard ARM Cortex-M4 quad-core 64 bit processor, which gives it more processing power than other similarly priced machines.

Image 1 of 2

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)The Halot-One Plus has a dark blue UV-resistant lid, something that stands out from the typical red, orange, or yellow used on similar printers. This lid is close to opaque, and I can’t easily see through it during printing. The QR code printed on the top of the lid leads to the Creality Cloud site where users can purchase models, 3D printers, consumables, as well as a social platform for sharing prints.

(Image credit: Tom's Hardware)The Halot-One Plus features an integrated 100W power supply, so there’s no need for an external power brick. The build size, printer size, and other information is printed on a sticker on the back of the printer, as well as a QR code that appears to contain information specific to the printer. The base of the Halot-One Plus is heavy and dense, and feels very sturdy despite the plastic shell.

(Image credit: Tom's Hardware)The integrated air filtration system on the Halot-One Plus is a welcome addition and worked very well throughout our testing. The resin used in the MSLA printing process can have an odor during printing, and the integrated air filtration system significantly reduces the amount of odor from the Halot-One Plus. The air intake is located directly behind the resin vat, and runs automatically throughout the duration of printing.

The resin used in the MSLA printing process can have an odor during printing, and the integrated air filtration system significantly reduces the amount of odor from the Halot-One Plus. The air intake is located directly behind the resin vat, and runs automatically throughout the duration of printing.

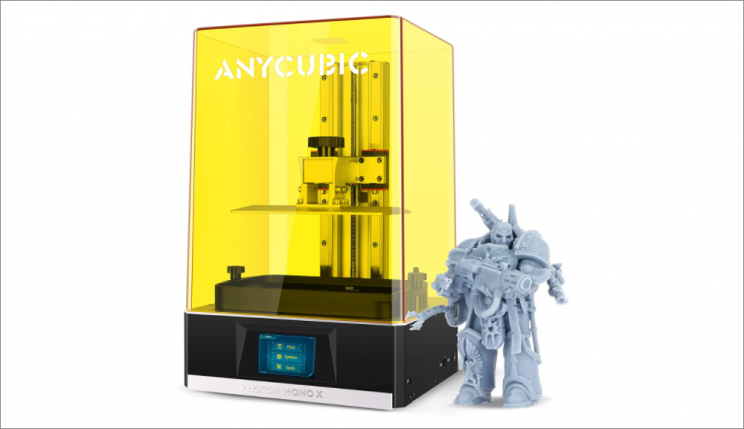

The Z axis on the Halot-One Plus uses a threaded rod with a captive nut for travel, and the dual linear rails allow for smooth and consistent movement. Most small format MSLA resin 3D printers use a single linear rail for travel, with dual rail systems being more common on larger machines like the Elegoo Saturn or the Anycubic Mono X. The build platform is suspended from a lightweight metal arm and doesn’t deflect, even when printing large and heavy parts.

(Image credit: Tom's Hardware)The Halot-One Plus has the Z endstop located at the top of the Z axis, an unusual design choice for an MSLA resin 3D printer. Typically, the leveling process involves dropping the platform to Z0 (the bottom of the Z axis) and ensuring the platform is planar with the LCD screen. The Halot-One Plus requires the entire platform be brought to the top of the printer to define Z0, and then lowered to the LCD screen and leveled. It’s hard to say if this is a less accurate process, but it’s definitely a more time-consuming one.

The Halot-One Plus requires the entire platform be brought to the top of the printer to define Z0, and then lowered to the LCD screen and leveled. It’s hard to say if this is a less accurate process, but it’s definitely a more time-consuming one.

The resin vat on the Halot-One Plus is smooth and easy to clean, with printed labels that indicate 250mL, 450mL, and 650mL fill levels. The vat also has a spout molded into the front right and back left corners, which makes pouring resin out of the vat and back into the bottle a simple and mess-free process. One of the screws that secures the vat to the frame had some flashing on the molded thumbscrew, and this meant the screw couldn’t actually fit into the mating hole without being trimmed. Not a major issue, but definitely a QC issue that should have been caught before the printer was packed and left the factory.

Image 1 of 3

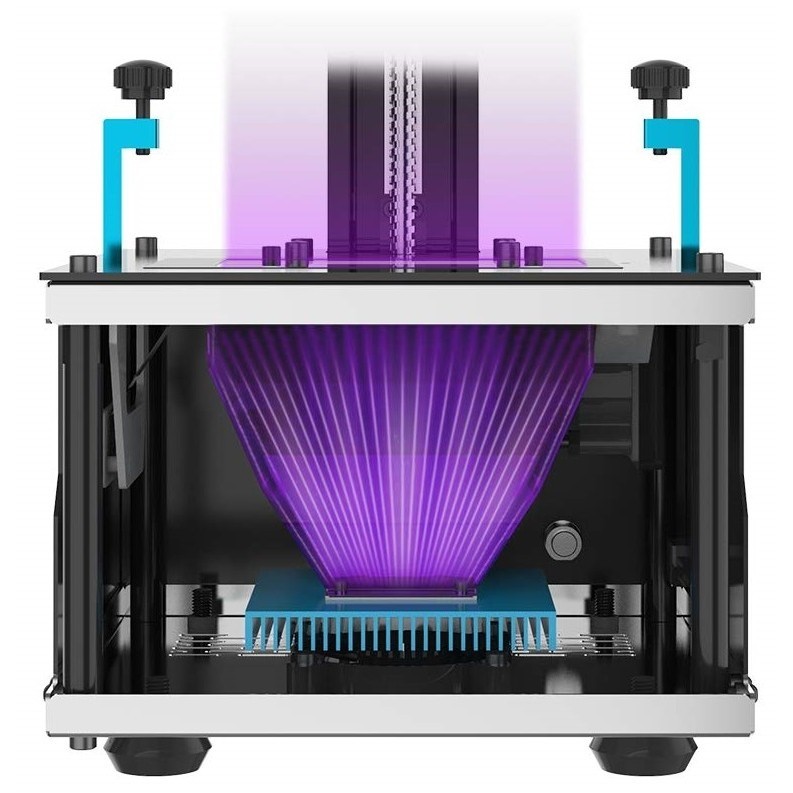

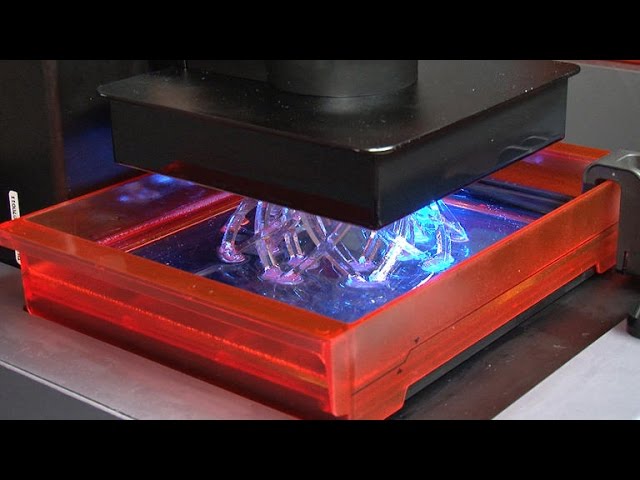

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)The light source of the Halot-One Plus is what Creality calls the “Integral Light Source”, which is a high-powered 4,500 uw/cm2 LED array that is projected through the masking LCD via an angled mirror in the base of the printer. This light source generates a substantial amount of heat during printing, which causes the onboard fan to run continuously during printing.

This light source generates a substantial amount of heat during printing, which causes the onboard fan to run continuously during printing.

The 7.9-inch masking LCD has a resolution of 4320 x 2560, a resolution that is slightly above the typical 4K resolution (4098 x 2560) used on similar resin 3D printers like the Elegoo Mars 3. This 4K resolution translates to an XY pixel size of .04mm (40 microns), which is high enough to capture fine details and texture when printing.

Image: Creality

(Image credit: Creality)Build Platform on Creality Halot-One Plus

The Creality Halot-One Plus uses a four bolt leveling system to ensure a planar relationship between the build platform and the masking LCD. Because the Z endstop is located at the very top of the printer, this process involves loosening the build platform connecting bolts, sending the built platform to the top of the printer to trigger the endstop, then reversing direction and sending the platform to the bottom of the Z axis. Once the platform is sitting flush on the masking LCD, the four bolts are tightened and the platform is leveled.

Once the platform is sitting flush on the masking LCD, the four bolts are tightened and the platform is leveled.

The Halot-One Plus has four upward-facing bolts that secure the build platform to the gantry arm, and these bolts tend to fill with resin during printing. This is a poor design choice, as resin tends to pool inside the bolt cap heads, in the knurling, and around the bolts, which is very difficult to clean and remove. Elegoo has solved this on their Mars 2 Pro and Mars 3 printers by using a simple captive ball joint that can be leveled with only two screws. Those platforms are easy to level and clean without additional effort.

(Image credit: Tom's Hardware)Printing Safety with Halot-One Plus

(Image credit: Tom's Hardware)The Creality Halot-One Plus uses 405nm UV resin, a material that you need to handle safely when in an uncured state to avoid injury. The resin can be harmful when making contact with skin, so make sure to wear gloves when pouring, cleaning up, or handling uncured resin. I also make sure I’m wearing gloves when removing the build platform after a print, as the resin tends to pool on top of the platform and can drip off while the platform is being removed.

I also make sure I’m wearing gloves when removing the build platform after a print, as the resin tends to pool on top of the platform and can drip off while the platform is being removed.

Make sure you use the Halot-One Plus in a well-ventilated room to minimize the danger from inhaling fumes. Any spills or uncured resin stuck to a surface should be cleaned using 99% isopropyl alcohol and the container for the resin should be kept closed and secured when not actively pouring material.

Printing the Included Test Print on the Creality Halot-One Plus

The test print included with the Creality Halot-One Plus is one of the best demonstration prints I have ever seen. The 8 hour print is titled “Kholek Suneater”, and it fills nearly the entire build area of the Halot-One Plus from corner to corner. This model comes pre-sliced using the same settings as in Halot Box (.05mm layer height, 3 second layer exposure time, 40 second base layer exposure time, etc.), and is ready to print directly from the USB thumb drive.

Creality has apparently identified one of the common applications of resin 3D printing (tabletop gaming and miniatures) and has embraced this by including a detailed miniature model with the Halot-One Plus. My previous experience with Creality’s test prints was poor; the Creality LD-002R (a budget MSLA resin 3D printer) included a test model that took over 19 hours to print and was not particularly impressive.

Image 1 of 3

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)This model has a very dense support structure, which is required to support all the various fine features including a long hammer and tail. The support structure was removed easily and left minimal marks on the printed model. Unfortunately, I broke the hammer during washing, but was able to glue it back on without much effort. The spikes on the armor, the thin tail, and the other details present on this model are sharp and in focus, and I believe that anyone who purchased this printer to make miniatures would be immediately delighted to see such a high-quality model come out of the printer without any additional preparation.

Preparing Files for Printing with Creality Halot Box

(Image credit: Creality)While resin 3D printers tend to be much more mechanically simple than filament FDM 3D printers, the software typically requires more setup work and the part preparation is a very important part of the process. Creality includes a copy of Halot Box with the Creality Halot-One Plus, which is the slicer design for the Halot series of printers.

Halot Box offers two separate menus for slicing parts: Basic Options and Advanced Options. As expected, Basic Options contains parameters like layer thickness, exposure time, build platform raise height, and more which users will likely adjust the most often. These options are pre-populated with parameters that are more focused on success as opposed to speed, with a 3-second layer exposure and a 40 second initial layers exposure. Advanced Options contains more complicated parameters, such as shrinkage compensation for X, Y, and Z axes, anti-aliasing, and other parameters.

Halot Box is a fully featured slicer and is capable of importing models, hollowing them for resin printing, adding support structures, and even more advanced features like adding text, slicing a model into pieces, and measuring between two points. These features make Halot Box just as feature-rich as ChituBox and Lychee slicer, both of which are also compatible with the Halot-One Plus.

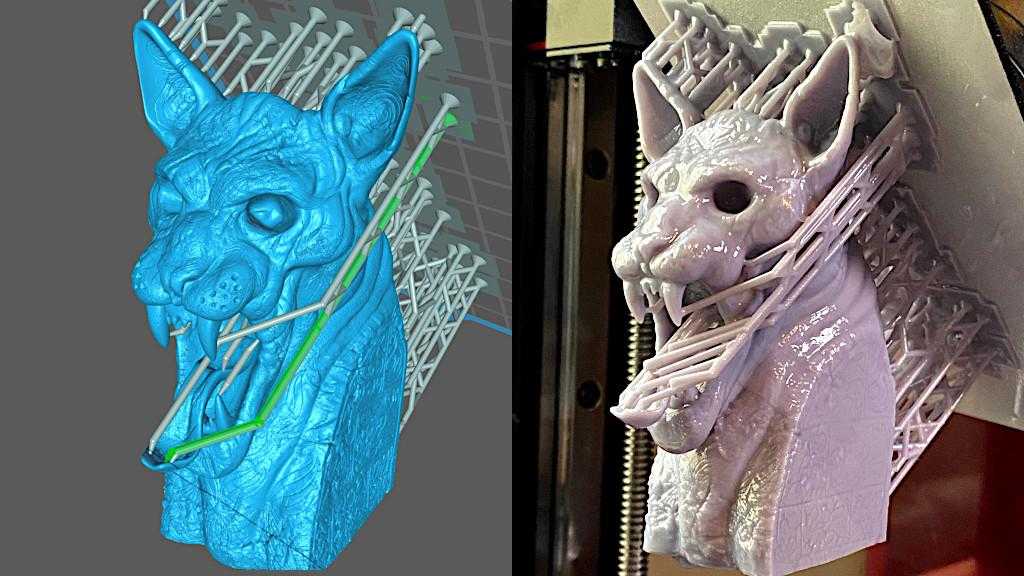

(Image credit: Tom's Hardware)I prepared this model of a dragon using the default Halot Box settings, including a 5mm shell after hollowing, medium support settings, and default slicer settings. Sliced with a .05mm layer height and a 3 second exposure time, this print took just over 12 hours to print out using Anycubic Water Washable Aqua Grey resin. The process of importing a model, hollowing, adding drain holes, adding support, and slicing took about 5 minutes and was intuitive and easy.

Image 1 of 3

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)Comparison of the Creality Halot-One Plus vs.

Elegoo Mars 3(Image credit: Tom's Hardware)

Elegoo Mars 3(Image credit: Tom's Hardware)The 4K resolution mono LCD on the Creality Halot-One Plus makes it a natural competitor to smaller resin printers like the Elegoo Mars 3, but the larger build volume and Wi-Fi capabilities help it to edge out most competition. Instead of focusing on Z height, the Halot-One Plus has a large surface area on the build platform, providing additional space for printing multiple parts.

Swipe to scroll horizontally

| Header Cell - Column 0 | Creality Halot-One Plus | Elegoo Mars 3 |

|---|---|---|

| Masking LCD Resolution | 4320 x 2560 | 4098 x 2560 |

| Masking LCD Size | 7.9 inches | 6.7 inches |

| XY Resolution | .04mm | .035mm |

| Build Dimensions | 6. 77 x 4.01 x 6.29 inches 77 x 4.01 x 6.29 inches | 5.64 x 3.52 x 6.89 inches |

| (172mm x 102mm x 160mm) | (143mm × 89mm × 175mm) | |

| Build Volume | 170.76 cubic inches | 136.79 cubic inches |

| Printer Dimensions | 9.29 x 9.57 x 16.46 inches | 8.93 x 8.93 x 17.28 inches |

| (23.6cm x 24.3cm x 41.8cm) | (22.7cm x 22.7cm x 43.85cm) | |

| Printer Volume | 1463 cubic inches | 1378 cubic inches |

| Build / Footprint Ratio | 11.70% | 9.90% |

| (higher is better) | ||

| Price | $399 | $299 |

The Halot-One Plus has a somewhat squat appearance in contrast with the taller and narrower Mars 3, and the large LCD screen on the front gives it an appearance that is closer to an appliance than a 3D printer. The build volume is somewhere between the Elegoo Mars 3 and the Elegoo Saturn, and the price also sits between the two.

The build volume is somewhere between the Elegoo Mars 3 and the Elegoo Saturn, and the price also sits between the two.

The Halot-One Plus is slightly larger in size than the Mars 3, but the differences in build volume and X/Y area are clear when comparing the two. In addition, the built-in air filtration system, large LCD, and dual Z axis linear rails give the Halot-One Plus a more industrial appearance. The front-facing USB port makes swapping out USB drives easy on both printers, but the power button on the Halot-One Plus is located on the back of the machine as opposed to the front-mounted power button on the Mars 3.

The build platform of the Halot-One Plus has a lightly textured surface, which gives printed parts a more complex surface to bond to during printing. Placing the platform of the Halot-One Plus and the Mars 3 side-by-side highlights the difference in build area, with the Halot-One Plus being a full inch longer in the X axis and just under half an inch wider in the Y axis. The difference in build area is complemented by an increase in pixel resolution, which makes the Halot-One Plus XY pixel size .04mm, a 5 micron difference from the .035mm resolution of the Mars 3.

The difference in build area is complemented by an increase in pixel resolution, which makes the Halot-One Plus XY pixel size .04mm, a 5 micron difference from the .035mm resolution of the Mars 3.

Printing a Large Model on Creality Halot-One Plus

(Image credit: Creality)The build platform on the Creality Halot-One Plus is large enough to fit busts from Loot Studio, so I printed the bust of Korut The Mechappilian. The model prints in 5 pieces: the bust, left arm, right arm, base, and minigun. I was able to fit the bust and both arms onto a single build platform, and printed the minigun and base separately. Processing these files in Halot Box was easy, and just involved dragging the models into the window, clicking “slice”, and exporting. No additional steps were needed, and I used Anycubic Grey Craftsman Resin and the default exposure settings.

(Image credit: Tom's Hardware)The first filled build platform printed flawlessly, and the level of detail was incredible. The lizard-like texture on the model looked realistic, and the smooth armor components had a consistent and even appearance. The 3-second exposure time seemed like a perfect fit for this resin as the support material snapped off easily and without leaving major pockmarks on the model.

The lizard-like texture on the model looked realistic, and the smooth armor components had a consistent and even appearance. The 3-second exposure time seemed like a perfect fit for this resin as the support material snapped off easily and without leaving major pockmarks on the model.

Image 1 of 3

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)After washing and curing the model, the general surface quality was still very impressive. The smooth surfaces have an even appearance and there are virtually no layer lines present, owing to the .05mm layer height and the .04mm X/Y resolution. The nubs left by the support structure detach easily, and can be removed by simply running a pair of tweezers over them.

(Image credit: Tom's Hardware)The final assembled bust looks more like a resin collectible than a 3D print, and the general quality was as good as any resin 3D printer under $2,500 that I have used. The joints fit together with simple peg and hole locating features, and they were a perfect friction fit. You can clearly make out the lizard skin texture on the model, and the fine detailing on the armor is easy to see without magnification.

You can clearly make out the lizard skin texture on the model, and the fine detailing on the armor is easy to see without magnification.

Printing Models from Creality Cloud

(Image credit: Creality)Creality has implemented Creality Cloud into its Halot Box software, which allows users to download models directly from the internet into their slicer. This feature has come under scrutiny due to the widespread abuse enabled by the ability to mass upload models, regardless of their copyright or designer intent. YouTuber Bryan Vines made an excellent video discussing this topic, which shows how the platform was intended to be used versus the current usage.

For example, on the front page of the Creality Cloud, I saw the chainmail model by Agustin “Flowalistik” Arroyo. This model is currently available with a Creative Commons Attribution license, which means attribution is required when sharing the model or derivatives. The model on Creality Cloud has been uploaded by “user3265593031”, and features the picture from Printables as well as filenames with “flowalistik” in them, further proving they were uploaded by someone other than the creator.

The chainmail model was easily downloaded, sliced, and sent to the printer without any additional steps required through Halot Box. While this does make searching for and downloading models a simple process, it’s troubling to see that the original creator has no effective recourse for limiting this type of piracy. In this case, I was aware of the original creator but it would be completely understandable that most users may not, and may even think the model was being provided by Creality directly.

(Image credit: Tom's Hardware)The Halot-One Plus is also able to download models from Creality Cloud directly from the printer interface without using Halot Box or any other slicer software. While this is a convenient feature, it is still subject to the same issues as downloading models from Creality Cloud via Halot Box. For instance, I downloaded this Minion file from the printer interface, but have no easy way to determine who the original designer was, what copyright license they used, and their intent for the printed model. In addition, the model printed completely solid and used significantly more resin than I was expecting for such a small print.

In addition, the model printed completely solid and used significantly more resin than I was expecting for such a small print.

Image 1 of 3

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)The Creality Halot-One Plus is a sleek, smart, and well-performing printer that worked well during our testing and left me impressed with the quality of prints made with minimal to no adjusting of the default settings when using the Halot Box slicer. The 172mm x 102mm x 160mm build volume is larger than other similarly priced printers, and the 4K resolution of the masking LCD provides sharp detail and fine features.

The Halot-One Plus sits in the awkward spot between small and large format resin 3D printers, and it’s hard to see if there is a place in the market for this machine. The large onboard LCD and built-in Wi-Fi connectivity are something you would expect on a more expensive printer like the Prusa SL1S, but are users currently looking for these features over build volume and print speed? That’s a hard question to answer, and only time will tell if the Halot-One Plus becomes a popular model.

If resolution isn’t your primary concern and you’re looking for the most build volume for your dollar, the Elegoo Saturn (on sale on Amazon for $369) and Elegoo Saturn 2 (available as a pre-order for $550) provide larger build volumes for a similar price tag. If you want to go in the other direction and find a printer with a higher resolution and aren’t worried about the price, the Phrozen Sonic Mini 8K provides an eye-watering .022mm XY resolution at an $899 price tag.

Creality Halot-One Plus: Price Comparison

19 Amazon customer reviews

☆☆☆☆☆

$319

View

powered by

Andrew Sink first used a 3D printer in 2012, and has been enthusiastically involved in the 3D printing industry ever since. Having printed everything from a scan of his own brain to a peanut butter and jelly sandwich, he continues to dive ever more deeply into the endless applications of additive technology. He is always working on new experiments, designs, and reviews and sharing his results on Tom's Hardware, YouTube, and more.

He is always working on new experiments, designs, and reviews and sharing his results on Tom's Hardware, YouTube, and more.

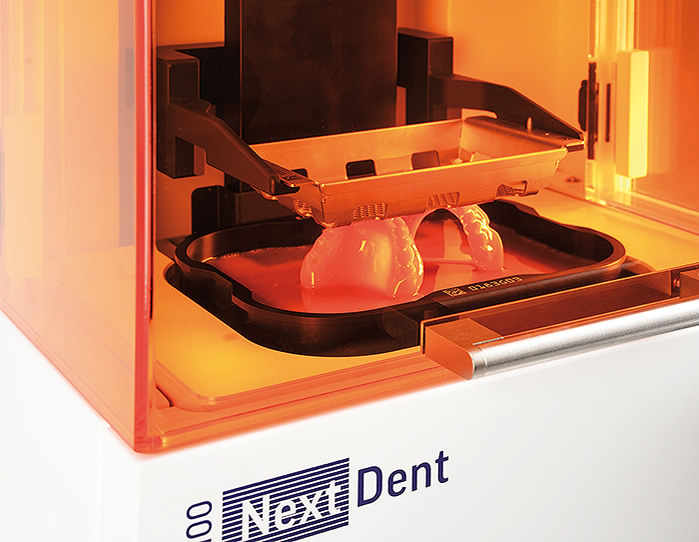

Elegoo Saturn 3D Printer Review: Large Volume, High Quality, Great Value

Tom's Hardware Verdict

The Elegoo Saturn impressed us with its high-quality output, impressive attention to detail with regards to machine design, and large build volume.

Pros

- +

+ Native integration with ChituBox slicer

- +

+ Exceptionally large build-volume-to-price ratio

- +

+ Rigid dual-Z linear rail system

- +

+ Leveling process is simple

Why you can trust Tom's Hardware Our expert reviewers spend hours testing and comparing products and services so you can choose the best for you. Find out more about how we test.

Today's best Elegoo Saturn deals

$379. 99

99

$299.99

View

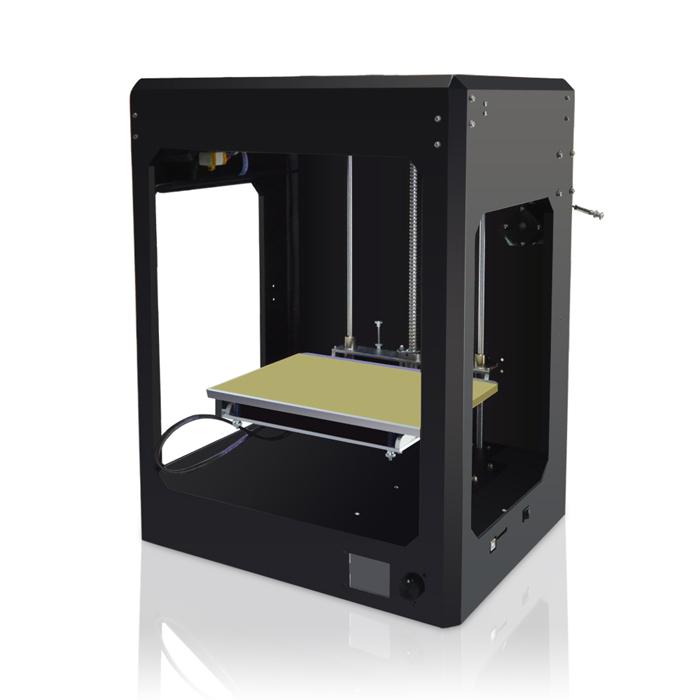

Reduced Price

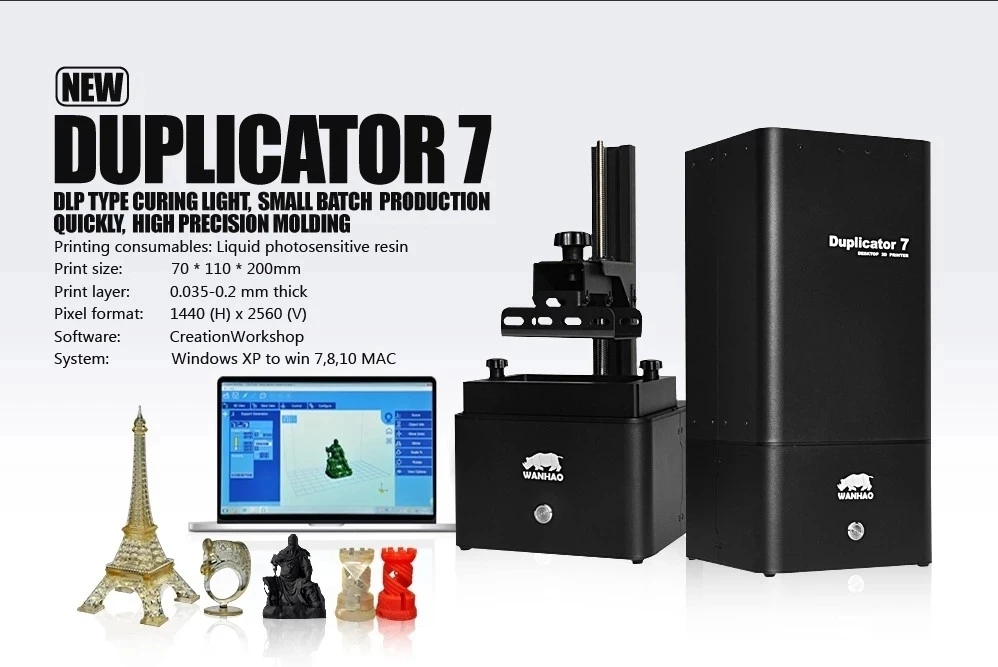

The larger counterpart to the Elegoo Mars series of printers, the Elegoo Saturn is a large-volume resin MSLA 3D printer that has found a way to offer increased build volume without sacrificing part quality. By increasing both the size and the resolution of the masking Mono LCD, the Elegoo Saturn is able to offer the same XY resolution of the Mars 2 Pro while increasing the total build volume.

One of the best 3D printers, the Saturn impressed me with how easy it was to set up and use but the scarce availability of the typically $500 printer may be a source of frustration when searching for one to buy.

Elegoo Saturn Specifications

Swipe to scroll horizontally

| Machine Footprint | 11.02" x 9.44" x 17.55" (28cm x 24cm x 44. 6cm) 6cm) |

| Build Volume | 7.55" x 4.72" x 7.87" (192mm x 120mm x 200mm) |

| Resin | DLP Photopolymer Resin |

| UV Light | 405nm UV LED Matrix |

| Masking LCD Resolution | 3840 x 2400 |

| Masking LCD Size | 8.9-inch |

| Interface | 3.5-inch LCD Touchscreen |

| XY Axis Resolution | .05mm |

Included in the Box of Elegoo Saturn

(Image credit: Tom's Hardware)The Elegoo Saturn ships in a well-packed box and includes all of the accessories you need to start printing as soon as the printer is out of the box. Included in the accessories box is a metal scraper (for removing parts from the build platform), a plastic scraper (for removing parts from the FEP sheet and stirring the resin), some paper funnels with a wire mesh (for filtering resin), wire cutters (for removing support material), latex gloves, and a healthy number of spare bolts, Allen keys, and other easy-to-lose parts. The included USB stick comes pre-loaded with a test print, the Chitubox slicer app, a digital copy of the user manual, and a few files from the 3D model repository site MyMiniFactory.

The included USB stick comes pre-loaded with a test print, the Chitubox slicer app, a digital copy of the user manual, and a few files from the 3D model repository site MyMiniFactory.

Elegoo shipped this Saturn with a ‘tomshardware.com’ sticker applied to the UV-resistant lid, which was a nice touch for a review unit. As far as I can tell, this is the only difference between this unit and a typical retail unit, so my experience with this printer should be similar to yours if you purchase it directly from Elegoo.

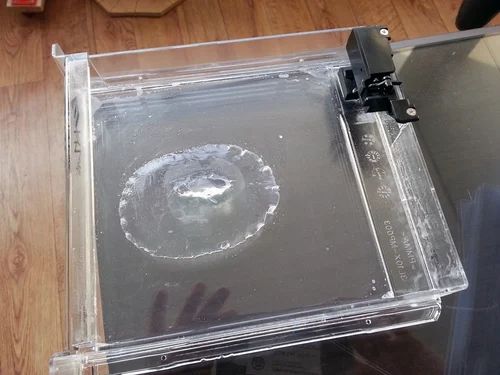

(Image credit: Tom's Hardware)The Saturn is a typical resin MSLA 3D printer which utilizes a vat of resin, a masking LCD, a UV light source, and a single axis of movement. It took me under five minutes to assemble this printer, and most of that time was removing foam and packaging from the box. The printer doesn’t require any mechanical or electrical assembly, and only needs to be calibrated before printing. The calibration process is almost effortless (more on that later), and the out-of-the-box experience felt quick and easy.

Image 1 of 2

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)The Saturn uses an 8.9-inch masking LCD with a resolution of 3840 x 2400, which gives it an effective XY resolution of .05mm. The masking LCD ships with a pair of protective stickers on it during shipping, and I had no problem removing them before printing. The black protective tape around the masking LCD needs to be left on the machine, and the manual makes sure to mention this first so a new user doesn’t accidentally remove it while removing the rest of the stickers.

Image 1 of 2

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)The resin vat on the Saturn uses four bolts that protrude from the bottom as locating posts which makes locking the vat into place a fast and repeatable process. One of the biggest problems I have when cleaning resin vats is that they typically sit with the delicate FEP film flush against the surface they are laid down on, so even a small bump in a table can possibly dent or deform them. The four posts on the corners of the Saturn’s vat keep the FEP film slightly elevated during cleaning, which is a small feature but a welcome change in design.

The four posts on the corners of the Saturn’s vat keep the FEP film slightly elevated during cleaning, which is a small feature but a welcome change in design.

The resin vat also has a max fill line printed right on it which takes away the stress from potentially over-filling and spilling resin. This feature, along with the spout that is molded into the vat, indicates that Elegoo has put some thought into the needs of users who are frequently changing vats or draining and replacing resin.

Image 1 of 2

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)Unlike most resin MSLA 3D printers which use a single linear rail for the Z axis, the Saturn uses a threaded leadscrew and a pair of linear rails for added stability. The Saturn features a larger build volume than most MSLA 3D printers, which means more weight is suspended from the cantilevered build platform. Between these two rails and the solid machined bracket for the build platform, the Saturn is able to print without bending the build platform bracket during lift moves, and I was impressed with the rigidity of the system.

The Saturn uses a USB stick for transferring files to the printer, as well as an Ethernet connection for adding the machine to a network. If you’re interested in using the Saturn as part of a high volume print farm, the ability to network the machine means you can transfer files without the need for an external drive. The two fans on the back of the unit provide airflow for the controller board and UV LED light source, but don’t provide air filtration like the fan in the Elegoo Mars 2 Pro. Despite the lack of air filtration, the Saturn didn’t seem to emit an odor any worse than the Mars 2 Pro during printing, but if you’re concerned about air quality you’ll want to take this into account.

Leveling the Build Platform on Elegoo Saturn

(Image credit: Tom's Hardware)When printing on an MSLA resin 3D printer, you want the build platform to be perfectly level with the FEP film so the resin cures evenly across each layer. This leveling process can be a challenge for beginners and it can be frustrating to have failed prints due to poor bed leveling. Elegoo has addressed this problem by using a unique leveling process that is fast, simple, and easy to complete. The Elegoo Saturn uses a build platform held rigid by two bolts and includes simple step-by-step instructions for the leveling process.

Elegoo has addressed this problem by using a unique leveling process that is fast, simple, and easy to complete. The Elegoo Saturn uses a build platform held rigid by two bolts and includes simple step-by-step instructions for the leveling process.

Image 1 of 2

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)After loosening the two bolts on the build platform and placing the included piece of leveling paper over the masking LCD, I dropped the Z axis to the home position and watched as the build platform self-leveled and sat perfectly flush. Once the axis had come to a rest, I simply tightened the two screws in the order indicated and lifted the build platform up. Compared to the leveling process on a printer like the Longer Orange 10 that uses four screws that need to be tightened in a star pattern and tend to shift during tightening, the Saturn feels almost effortless to set up.

Printing Safety with Elegoo Saturn

(Image credit: Tom's Hardware)The Elegoo Saturn uses 405nm UV resin, a material that you need to handle safely when in an uncured state to avoid injury. The resin can be harmful when making contact with skin, so make sure to wear gloves when pouring, cleaning up, or handling uncured resin. I also make sure I’m wearing gloves when removing the build platform after a print, as the resin tends to pool on top of the platform and can drip off while the platform is being removed.

The resin can be harmful when making contact with skin, so make sure to wear gloves when pouring, cleaning up, or handling uncured resin. I also make sure I’m wearing gloves when removing the build platform after a print, as the resin tends to pool on top of the platform and can drip off while the platform is being removed.

Make sure you use the Saturn in a well-ventilated room to minimize the danger from inhaling fumes. Any spills or uncured resin stuck to a surface should be cleaned using 99% Isopropyl Alcohol and the container for the resin should be kept closed and secured when not actively pouring material.

(Image credit: Tom's Hardware)The build platform on the Saturn is designed with a trapezoidal shape that allows uncured resin to drip off and prevents it from pooling on the top of platform during printing. Despite this shape, I noticed that resin had a tendency to collect at the very edge of the platform, and I couldn’t help but wonder if a more aggressive angle or a chamfered edge would help to allow more resin to drip back into the vat during printing. This is a relatively minor point, as the majority of resin will drip downwards during printing and cleaning the edge of the build platform doesn’t require much effort.

This is a relatively minor point, as the majority of resin will drip downwards during printing and cleaning the edge of the build platform doesn’t require much effort.

Printing the Included Test Prints on the Elegoo Saturn

Most 3D printers include a prepared test print as an opportunity for the manufacturer to demonstrate the strengths of their machine. Despite this relatively simple premise, I’ve found that test prints can be a source of frustration for first time users as they have a tendency to have issues that most first-time users won’t be expecting.

Image 1 of 2

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)Unfortunately, the Elegoo Saturn falls short in this category and my experience with the included test print was really the only major disappointment I had while writing this review. The Saturn includes a test print on the included USB drive called “_Rook_SATURN.ctb” that consists of two chess pieces with fine details on the interior and exterior of the model. This test print completes in a very reasonable 3 hours and 49 minutes, and I was impressed with the fine detail on the models once the print had completed. Unfortunately, this is where things took a bit of a turn.

This test print completes in a very reasonable 3 hours and 49 minutes, and I was impressed with the fine detail on the models once the print had completed. Unfortunately, this is where things took a bit of a turn.

The build platform on the Saturn has a sandblasted textured finish which helps cured resin adhere during printing and prevents parts from delaminating. When removing a part, a thin raft can be bent (as seen in the picture above), which allows the part to easily detach from the build platform without too much trouble. This is a delicate balance; too thin and the part won’t adhere to the plate, too thick and the part can’t be easily removed. I had no trouble with any of the parts I sliced in Chitubox, but as you’ll see below, the included test print was significantly more difficult to remove.

(Image credit: Tom's Hardware)Once printed, the detail on the rooks was impressive, but the solid base of the model printed directly on to the build plate didn’t present an intuitive method of removal. After using the included metal scraper and attempting to gently pry the parts off, I wondered if this was a common problem or if the Elegoo Water Washable Ceramic Grey resin I was using simply wasn’t compatible with the settings provided. A quick Google search for “Elegoo Saturn Test Part Stuck To Plate” shows that this is not an uncommon problem, with some users resorting to using a rubber mallet to remove the parts from the build plate.

After using the included metal scraper and attempting to gently pry the parts off, I wondered if this was a common problem or if the Elegoo Water Washable Ceramic Grey resin I was using simply wasn’t compatible with the settings provided. A quick Google search for “Elegoo Saturn Test Part Stuck To Plate” shows that this is not an uncommon problem, with some users resorting to using a rubber mallet to remove the parts from the build plate.

I was eventually able to remove the prints from the bed, but it required significantly more effort than I was comfortable with and resulted in both parts being chipped along the bottom layer. This could have been avoided with a demo model that was suspended from a support structure or simply used a sacrificial raft during printing to prevent such a wide and thick model being printed directly on the build plate. It’s worth noting this was the only time I experienced this issue during this review. The rest of the parts I prepared using Chitubox for printing were easily removed and didn’t require excessive force to remove from the plate.

Preparing Files for Printing with Chitubox

(Image credit: Chitubox)The Elegoo Saturn uses Chitubox for slicing, preparing, and exporting files for 3D printing. Chitubox is a feature-rich program which reduces the need for secondary programs to generate supports, hollow models, or make other changes that would typically require a longer workflow. The general process for preparing a 3D model for resin 3D printing goes like this:

- Import 3D model

- Angle model for printing (avoiding wide per-layer cross-sections)

- Hollow model

- 4Add drain holes

- Generate support material

- Slicer

- Delete islands

- Export printable file

Chitubox makes this easy, as each step can be accomplished within the software without the need to export the file to various third-party softwares. Chitubox also includes a built-in profile for the Elegoo Saturn which gives good quality results without any tweaking or modifications. I’ve been a fan of Chitubox since I started using it, and the ease-of-use and native support for the Saturn makes it a logical choice.

The profile for the Saturn that is included with Chitubox is what I would consider a good starting point for base settings. The Z resolution of .05mm is high enough to give a good quality print, but not so high as to cause an excessively long print time. The per-layer cure time of 2.5 seconds makes the Saturn a speedy printer when compared to machines with 9 second per-layer cure times like the Creality LD-002R.

(Image credit: Tom's Hardware)For a first test, I used the Ancient Statue model from Loot Studios and prepared it using the default settings in Chitubox without making any modifications. For resin, I used the Elegoo Water Washable Ceramic Grey , which has worked very well for me in the past on the Elegoo Mars 2 Pro. This model used about 28 grams of resin and printed out in just under 4 hours, which seems in line with what I would expect from a Mono LCD 3D printer.

Image 1 of 2

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)The Water Washable Ceramic Grey resin looked great after printing, and the support structure removal process is simplified by not requiring any isopropyl alcohol or other chemicals to remove the excess resin. A quick soak in a small tub of hot water dissolved the excess resin from the surface of the printer and also softened the support structure. After removing the support structure, I cured the model for a total of two minutes in 30 second increments to prevent it from warping.

A quick soak in a small tub of hot water dissolved the excess resin from the surface of the printer and also softened the support structure. After removing the support structure, I cured the model for a total of two minutes in 30 second increments to prevent it from warping.

It’s worth taking a moment to reflect on the printing process so far before we really look at this model. The steps to create this model are all simple and straight-forward, and a beginner could easily follow along to calibrate the bed, fill the resin vat, and process the file for printing. The resulting print looks sharp and detailed, and even small details like the cracks in the stone of the statue resolve and don’t require any touch-up work. Putting aside the large format nature of the Elegoo Saturn, it’s easy to understand why this machine is in such demand; it’s easy to use, gives good quality results, and the native software doesn’t require tinkering or tweaking.

Print Size Comparison of the Elegoo Mars 2 Pro vs.

Elegoo Saturn

Elegoo SaturnImage 1 of 2

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)The Elegoo Saturn shares many design similarities with the Elegoo Mars 2 Pro, so it makes sense to compare the two 3D printers directly. The Saturn uses a higher resolution masking LCD, but the increased size of the LCD means the XY resolution (pixel size) is .05mm on both machines. This means a part printed on the Mars 2 Pro and Saturn, using the same settings, will result in two parts that should be indistinguishable from one another.

Swipe to scroll horizontally

| Header Cell - Column 0 | Elegoo Mars 2 Pro | Elegoo Saturn |

|---|---|---|

| Masking LCD Resolution | 1620 x 2560 | 3840 x 2400 |

| XY Resolution | .05mm | .05mm |

| Build Dimensions | 5. 08 x 3.15 x 6.3 inches 08 x 3.15 x 6.3 inches | 7.55 x 4.72 x 7.87 inches |

| Build Volume | 100.81 cubic inches | 280.46 cubic inches |

| Printer Dimensions | 7.87 x 7.87 x 16.14 inches | 11.02 x 9.44 x 17.55 inches |

| Printer Volume | 999.66 cubic inches | 1825.70 cubic inches |

| Build / Footprint Ratio (higher is better) | 10.0% | 15.4% |

With a retail price of $500, the Saturn offers nearly 3 times the total build volume (280 cubic inches vs. 100 cubic inches) of the Mars 2 Pro, which retails for $330. If you’re interested in throughput and high-volume printing ability, the Saturn is able to produce a large batch of parts at the same resolution as Mars 2 Pro. However, if you’re looking for a higher resolution finished part and aren’t interested in a large build size, a 4K LCD printer like the Phrozen Sonic Mini 4K would be a better choice.

Image 1 of 2

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)Printing a Large Assembly on the Elegoo Saturn

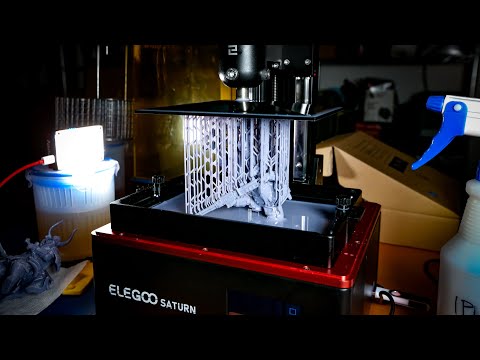

(Image credit: Tom's Hardware)The large build volume and fast per-layer print time of the Elegoo Saturn make it ideal for printing models that would ordinarily be too large or time-consuming to print on a smaller MSLA resin printer like the Longer Orange 10. To test out the ability of the Saturn to print large models in multiple pieces simultaneously, I loaded up the Olympus Rider model from Loot Studios. This model of a winged Pegasus complete with rider armed with a spear prints in six individual pieces and a single large base.

(Image credit: Chitubox)Unfortunately, the auto-placement feature in Chitubox wasn’t able to automatically place all of these parts on the build platform in order to print them in a single piece. After manually rotating the parts myself, I was able to get everything except the base of the model onto a single tray. This would be an ambitious print under the best of circumstances, as it covered a large portion of the surface area of the build platform and would create a large amount of suction when moving the platform up and down. After slicing, Chitubox generated an estimated build time of 7 hours and 10 minutes as well as a material usage of 128 ml. I wasn’t sure if the Saturn could handle a print this ambitious, but I was eager to see if this hard-to-find machine could live up to its reputation.

This would be an ambitious print under the best of circumstances, as it covered a large portion of the surface area of the build platform and would create a large amount of suction when moving the platform up and down. After slicing, Chitubox generated an estimated build time of 7 hours and 10 minutes as well as a material usage of 128 ml. I wasn’t sure if the Saturn could handle a print this ambitious, but I was eager to see if this hard-to-find machine could live up to its reputation.

Image 1 of 2

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)The Saturn printed every single part on the build platform without any defects, and I was genuinely surprised and impressed with how easily the Saturn could handle a large and complex build like this. The Elegoo Water Washable resin created a support structure that was easily removed and left minimal pockmarks on the finished model.

(Image credit: Tom's Hardware)After a rinse and cure in the Elegoo Mercury Plus Cure/Wash station, I laid out the parts and assembled the model using DAP RapidFuse CA glue, a favorite of mine for making strong bonds on resin prints like this one. The final result is a finely-detailed print that measures nine inches wide and six and a half inches tall, and it is one of the largest resin MSLA prints I’ve ever made. The 3D model to 3D print process was seamless and easy, and this model earned the Saturn a permanent place on my personal list of all-time favorite 3D printers.

The final result is a finely-detailed print that measures nine inches wide and six and a half inches tall, and it is one of the largest resin MSLA prints I’ve ever made. The 3D model to 3D print process was seamless and easy, and this model earned the Saturn a permanent place on my personal list of all-time favorite 3D printers.

Image 1 of 2

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)Printing Multiple Miniatures Simultaneously on the Elegoo Saturn

(Image credit: Tom's Hardware)One of the key abilities of a large build volume resin MSLA 3D printer like the Elegoo Saturn is the ability to print multiple parts simultaneously. The Saturn is a popular printer for users interested in tabletop gaming, and the large build volume is ideal for printing out multiple miniatures in a single print. Because the print speed is dictated by the number of layers and not the number of miniatures, printing a single miniature or a full build platform full of them takes the same amount of time.

As a test of the printer’s performance, I filled the build platform with some of the enemies from the Loot Studios Ghostly Odyssey release which features a mix of detailed creatures and human 32mm miniatures.

Image 1 of 2

(Image credit: Chitubox)(Image credit: Chitubox)After importing the models into Chitubox, I manually laid them out to prevent the support structure rafts from touching to reduce the overall total surface area of the bottom cross-section. Chitubox handled the slicing of this large tray without breaking a sweat, and I was easily able to fit a mix of models and bases for a total of 12 parts printing simultaneously. Chitubox gave an estimate of 3 hours and 51 minutes, which is an attractive print speed for such a large yield of parts.

The models have a support structure already generated, so after slicing all I had to do was detect and remove the islands (small, unconnected pixels that can cause floating bits of resin) and scroll through the layer view to check for any missing geometry. This is a quick and largely-automated process made possible by the Chitubox app, which I am grateful that Elegoo has internally decided to endorse as opposed to attempting to make their own slicer app which may lack some of this functionality.

This is a quick and largely-automated process made possible by the Chitubox app, which I am grateful that Elegoo has internally decided to endorse as opposed to attempting to make their own slicer app which may lack some of this functionality.

As I expected, the print was completed without incident. Because of the large number of support structures, the first hour or so of the print is just hundreds of tiny cylinders (as seen in the Chitubox preview above). Every time the build platform lifted, it sounded like a Velcro strap being removed as each of the tiny support structures delaminated from the FEP sheet with a tiny pop sound. I couldn’t decide whether the sound was reassuring or not, but in the end, I’m grateful for each pop because it meant the printer was working correctly.

(Image credit: Tom's Hardware)The support structures were easy to remove after a quick soak in hot water, and the models all felt like they had been cured enough to be solid. In particular, the swords and wings on the smaller models were easy to free from the support structure, and I wasn’t concerned with them breaking off or shattering during the cleaning.

In particular, the swords and wings on the smaller models were easy to free from the support structure, and I wasn’t concerned with them breaking off or shattering during the cleaning.

Image 1 of 2

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)Even on these 32mm miniatures, the details were crisp and features like the individual feathers on the harpy model resolved well and could be easily distinguished. If you’ve used a printer like the Anycubic Photon Mono or the Elegoo Mars Pro, this level of resolution (.05mm) is directly comparable with what you’re used to, so the big benefit of the Saturn is being able to increase your output without sacrificing quality.

The Elegoo Saturn is about as hard to find as a PlayStation 5 right now, and it tends to sell out immediately after each restock at Amazon and the Elegoo official store. After using it for this review, it’s clear to me why the printer is in such high demand: it’s fast, relatively inexpensive, and offers a build volume ideal for printing multiple parts simultaneously. The Saturn regularly sells for over $700 on second-hand sites like eBay, so finding one may prove to be a challenge for the foreseeable future.

The Saturn regularly sells for over $700 on second-hand sites like eBay, so finding one may prove to be a challenge for the foreseeable future.

I asked Elegoo to comment on the relative scarcity of the Saturn, and they indicated a combination of high demand and rigorous quality control were to blame for the shortages.

These two printers are too hot sale, so they always sold out. In fact, we have arranged more products for Amazon every week, but it sold out when available. In addition, our company will test the machine before selling, so it costs some time.

Elegoo

The high-yield nature of the Saturn makes it ideal for printing multiple miniatures simultaneously, so there’s no doubt this printer will be a hit among hobbyists who are interested in printing custom miniatures. The large build volume also offers the ability to print large parts in a single print, something that smaller machines like the Creality LD-002R aren’t able to accomplish.

The overall trouble-free printing experience of the Saturn makes it appealing to beginners as well as more advanced users, but the $500 retail price (if you can even find it for that) might be a little high for a first printer. If you’re interested in a lower cost alternative, the Elegoo Mars Pro or the Anycubic Photon Mono both offer a similar printing experience at a lower price point.

(Image credit: Tom's Hardware)Andrew Sink first used a 3D printer in 2012, and has been enthusiastically involved in the 3D printing industry ever since. Having printed everything from a scan of his own brain to a peanut butter and jelly sandwich, he continues to dive ever more deeply into the endless applications of additive technology. He is always working on new experiments, designs, and reviews and sharing his results on Tom's Hardware, YouTube, and more.

Product reviews

home

Reviews

Product review:

3D printer Nova 3D Elfin L3132

01. 10.2021

10.2021

Alexander

I chose this 3D printer model because those arranged it. characteristics. This model is inexpensive, but quite functional. The print quality is perfect for me. Prints fast enough.

Product review:

Photopolymer 3D printer Elegoo Saturn Mono 4K

10/01/2021

Sergey

One of the most anticipated MSLA technology consumer 3D printers, and this is no exaggeration. This is an obvious conclusion, which was already pointed out by its predecessor, the half-liter Elegoo Mars.

Product review:

Photopolymer resin Anycubic Basic Black 1L

09/30/2021

Victoria

The quality of the resin is good, the price is pleasant! Now I will only order in this online store and recommend it to others!

Product review:

Photopolymer resin Anycubic Basic 0. 5l Aqua Blue

5l Aqua Blue

09/22/2021

Sergey Kulikov

Very good polymer for 3D printing. Balance of quality and price. At the same time, it is quite liquid. Good balance of strength and light elasticity. It transfers details to the product well.

Product review:

Photopolymer resin Anycubic Basic 0.5l Aqua Blue

09/20/2021

Eugene

Very high quality product! I order from this site not the first time. On a five-point scale, a solid five!

Product review:

Photopolymer 3D printer ELEGOO Mars UV

09/14/2021

Dmitry

Cool 3D printer!!! My expectations are fully justified. Assembling and setting up is not so difficult.

Product review:

Photopolymer resin Anycubic Basic 0. 5l Aqua Blue

5l Aqua Blue

09/09/2021

Buyer

Bought, everything is super. Printing with it is a pleasure!

Product review:

Photopolymer resin Siraya Tech Fast Gray 1L

09/06/2021

Denis

I recently ordered this resin, forked out. Delivered very quickly. Does not smell, hardens quickly.

Product review:

Photopolymer resin Anycubic Basic 0.5l Aqua Blue

09/06/2021

maria

A quality product that can be used with the vast majority of printers. Sufficiently strong, well polymerized, gives high-quality products.

Product review:

Photopolymer resin Anycubic Basic Black 1L

09/01/2021

Elena Bocancea

The cheapest resin. I really liked it because the resin has a high solidification rate, which ensures the strength of finished products and significantly reduces printing time.

I really liked it because the resin has a high solidification rate, which ensures the strength of finished products and significantly reduces printing time.

Product review:

Photopolymer resin Siraya Tech Smoky Black 1L

08/24/2021

Sergey Sheff

Excellent resin! Ordered from Incraft. The quality is good, I liked it!

Product review:

Photopolymer resin Anycubic ECO Black 0,5l

08/18/2021

Konstantin

I want to share a review. The other day I ordered from you ANYCUBIC ECO PHOTOPOLYMER RESIN BLACK 0.5L. I was pleased that the consultants know their business, they clearly told everything, helped to place an order, delivery. Received. I checked, everything was not deceived, the quality is on top. I recommend this store.

Product review:

Photopolymer resin Anycubic Basic 0. 5l Aqua Blue

5l Aqua Blue

08/08/2021

Lina Kalina

I ordered ANYCUBIC resin for my 3D printer. The product turned out to be very good, fit my printer, actually has no smell! I advise!

Product review:

Photopolymer resin Anycubic Basic 0.5l Aqua Blue

07/29/2021

The buyer bought

, everything is super I recommend everyone to buy from you

Product review:

Photopolymer resin Anycubic ECO Black 0,5l

07/15/2021

Konstantin

A couple of days ago, I ordered ANYCUBIC ECO PHOTOPOLYMER RESIN BLACK 0.5L. I would like to share my experience with the store. The sellers helped with the choice and arranged everything, they know their business, this is a big plus. Placed an order, everything came on time, the quality of the goods did not disappoint. I recommend this store to everyone.

I recommend this store to everyone.

Product review:

Xiao Genshin Impact

07/08/2021

Buyer

The model looks much cooler than the picture, beautiful straight pose, though without turning the head. I want to put this on the shelf. I love the character and bought the figurine :)

Photopolymer resin Anycubic ECO Black 0,5l

06/16/2021

Buyer

Surprisingly, the resin almost does not smell. I love black. I'm just learning how to make figurines, so I don't attach pictures. I think in the future it will be my hobby. I ordered resin in other colors. I'm waiting to be delivered.

Product review:

Photopolymer resin Siraya Tech Smoky Black 1l

05/29/2021

Z.P.

The store works very quickly. I made 2 orders, one came to Krasnodar on the third day, the second - on the fourth.

I made 2 orders, one came to Krasnodar on the third day, the second - on the fourth.

Product review:

Photopolymer 3D printer Anycubic Photon Mono

05/20/2021

Buyer

On ali 20700)) so it's cheaper, as you have indicated in the advertisement

Product review:

Photopolymer resin Anycubic Basic Black 1L

04/30/2021

Dmitry

Good resin. Low viscosity requires slightly longer exposure time for good cure.

Formlabs Jewelry Resins material properties characteristics

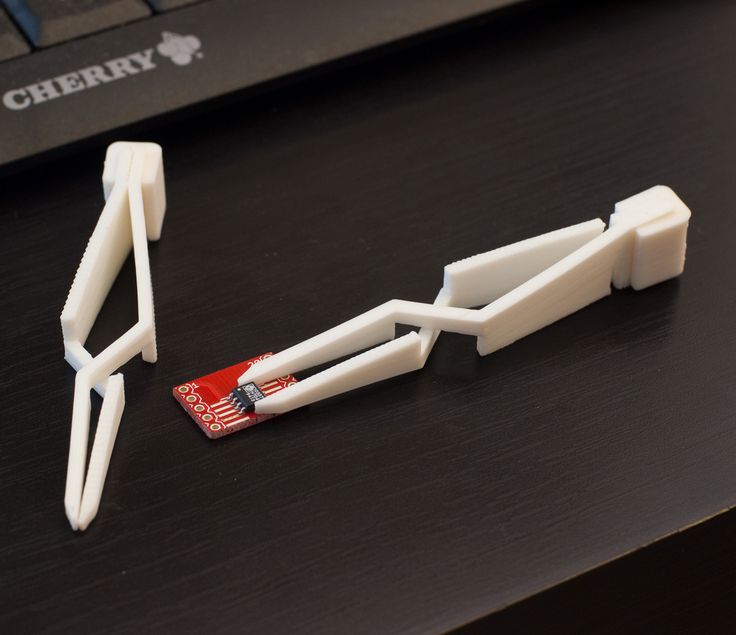

Jewelry resins are specially developed by Formlabs for jewelry 3D printing. They create highly detailed prints for designing and making jewelry.

These resins are easy to work with. After all, they really accurately reproduce precise settings, sharp protrusions, smooth rods and fine surface details. By using Formlabs Jewelry Resins on the world-renowned Formlabs Form 3 Automated Desktop Stereolithography 3D Printer, you can be sure of the result of printing and casting. Resins are designed to mimic working with wax. They burn cleanly and residue-free with a controlled burn-out schedule and are suitable for traditional jewelry manufacturing methods. Thus, 3D printing with Formlabs jewelry resins fits into your traditional jewelry manufacturing workflow, accelerating and scaling it.

By using Formlabs Jewelry Resins on the world-renowned Formlabs Form 3 Automated Desktop Stereolithography 3D Printer, you can be sure of the result of printing and casting. Resins are designed to mimic working with wax. They burn cleanly and residue-free with a controlled burn-out schedule and are suitable for traditional jewelry manufacturing methods. Thus, 3D printing with Formlabs jewelry resins fits into your traditional jewelry manufacturing workflow, accelerating and scaling it.

Printing precision and resin resin applications Formlabs

1| Compatible with printer | Bath compatible | Layer height, micron | Features and Applications | |

| Castable Wax | Form 2 Form 3 Form 3B | Form 2 Standard Form 2 LT Form 3 Tank V1 Form 3 Tank V2/V2.  1 1 | Form 2, Form 3/3B - 25, 50 µm | Accurate settings, sharp teeth, smooth shafts, fine surface details Photopolymer with 20% wax No post-curing required |

| Castable Wax 40 | Form 2 Form 3 | Form 2 LT Form 3 Tank V2.1 | Form 2, Form 3 - 25.50 µm | Photopolymer with 40% wax Heavy Statement Jewelry Pendants & Medallions Custom Wedding Jewelry |

1 Data as of March 2021 Even the finest details are clearly reproduced and a clean casting every time. The photopolymer, which contains 20% wax, is specially formulated for reliable casting with 0% ash residue and clean burnout. Castable Wax Resin faithfully reproduces intricate details and offers the smooth surfaces that stereolithographic 3D printing is known for. 1 Material properties may vary depending on part geometry, print orientation, print settings and temperatures. 2 Data was obtained from parts printed on a Formlabs Form 2 3D printer, Castable 50 µm Fine Detail setting and washed without post curing. The Burnout Standard Chart is designed to give the highest possible investment strength and complete burnout of the finest details when using R&R Plasticast or similar investment materials. Use this schedule as a starting point and make adjustments as needed. – Castable Wax 40 Resin contains a 40% mixture of solid and liquid waxes, which gives this polymer a low coefficient of expansion. The resin is available in a wide range of investment casting conditions and is compatible with leading plaster moulders. Parts printed with Castable Wax 40 have excellent detail and clean burnout across a wide range of workflows and casting conditions. Castable Wax 40 offers the easiest workflow on the market for 3D printing and casting tasks with a highly detailed design. With more flexible casting parameters and burnout, this resin ensures that casters of all skill levels can produce high quality resin jewelry. Formlabs jewelry resins 1 Material properties may vary depending on part geometry, print orientation, print settings and temperatures. 2 Data was obtained for green parts printed on Form 3 3D printer, 50 micron, Castable Wax 40 Resin setting, no post-cure. The following burn-in chart is designed to reduce the thermal expansion of the resin in the mold while still allowing full burn-out of thick jewelry pieces. Formlabs Recommends Certus Prestige Optima 9 Investment Powder0427 TM

• Castable Wax V1 •

Material Properties

Castable Wax by Formlabs

Green 1 Method Tensile properties 2 Tensile Strength 11.6 MPa ASTM D 638-10 Tensile modulus 220 MPa ASTM D 638-10 Elongation at break 13.0% ASTM D 638-10 Burnout properties 2 Temperature at 5% weight loss 249 °C ASTM E 1131 Ash content (TGA) 0.0-0.1% ASTM E 1131

Formlabs Standard Burnout Chart

Castable Wax

• Castable Wax 40 V1 •  Does not require additional polymerization.

Does not require additional polymerization. Formlabs jewelry resins. Material Properties

Castable Wax 40

Green 1 Method Burnout properties 2 Temperature at 5% weight loss 249 °C ASTM E 1131 Ash content (TGA) 0.0-0.1% ASTM E 1131

Formlabs Standard Burn-In Chart

Castable Wax 40

| Phase | Time | °C graph | ||

| A | After the setting period of the investment material (30-60 min), place the flasks in the stoving oven | Hold | 180 min | 55 °C |

| B | Thermal junction Wax sprue extends to the outside, increasing air flow to the resin pattern.  The wax in the resin ends up in the investment. The wax in the resin ends up in the investment. Burn-in starts gently, destroying the structure without much expansion | Heating | 48 min | 2 °C/min |

| Hold | 180 min | 150 °C | ||

| Heating | 75 min | 2 °C/min | ||

| Hold | 180 min | 300 °C | ||

| C | Burnout Removes resin and ash residues in the package | Heating | 108 min | 4 °C/min |

| Hold | 180 min | 732 °C | ||

| D | Casting temperature Cool the flask to the casting temperature of the selected metal | Heating | 44 min | -5 °C/min |

| Molding window | Up to 2 hours | Desired casting temperature |

Wash Information:

Rinse Castable Wax 40 prints in isopropyl alcohol (IPA) for several minutes.

.jpg?x-oss-process=image/resize,p_100/format,webp)