Solder 3d printer

3d Printing Solder | Hackaday

March 10, 2016 by Bob Baddeley

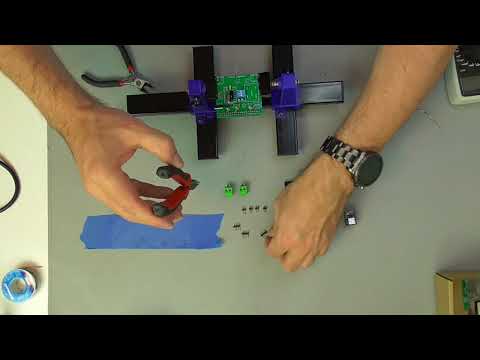

The general process of circuit board assembly goes like this: You order your PCBs. You also order your components. For surface mount components, you apply solder paste to the pads, put the components on top, and then heat the board up so the solder paste flows and makes a bond. Then for through hole components you put the leads through the holes, and solder them with an iron or a solder wave or dip. Then you do an inspection for defects, program any microcontrollers, and finally test the completed board to make sure everything runs.

The tricky part is in volumes. If you’re only doing a few boards, it’s usually easiest to assemble them by hand. In the thousands you usually outsource. But new tools, and cheap hacked tools, have made it easier to automate small batches, and scale up into the thousands before outsourcing assembly.

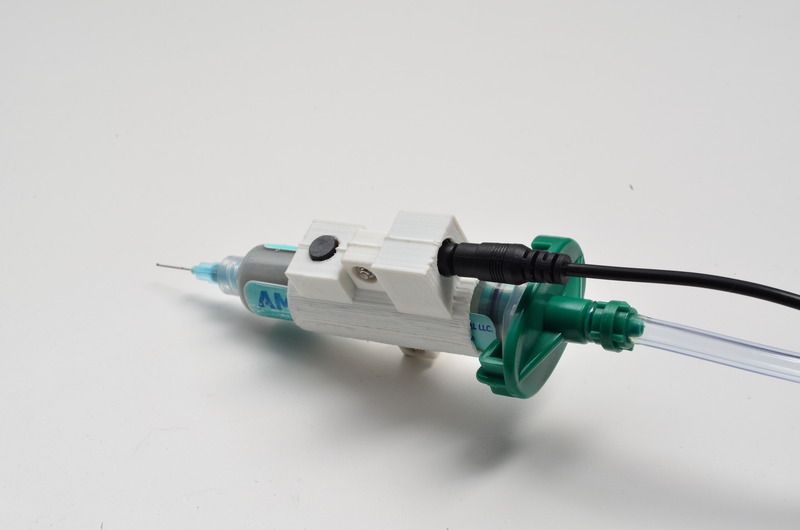

In this new series which we’re calling Tools of the Trade we’ll be covering a variety of tools used for building products, and we’re starting with circuit board assembly. Let’s investigate our tools of the trade: solder paste dispensing. Continue reading “Tools Of The Trade – Solder Paste Dispensing” →

Posted in Hackaday Columns, Slider, Tool HacksTagged 3d printed circuits, 3d printing solder, circuit board, pcb, pcb assembly, smd soldering, solder paste, solder paste dispenser, solder stencil, Tools of the TradeNovember 7, 2013 by James Hobson

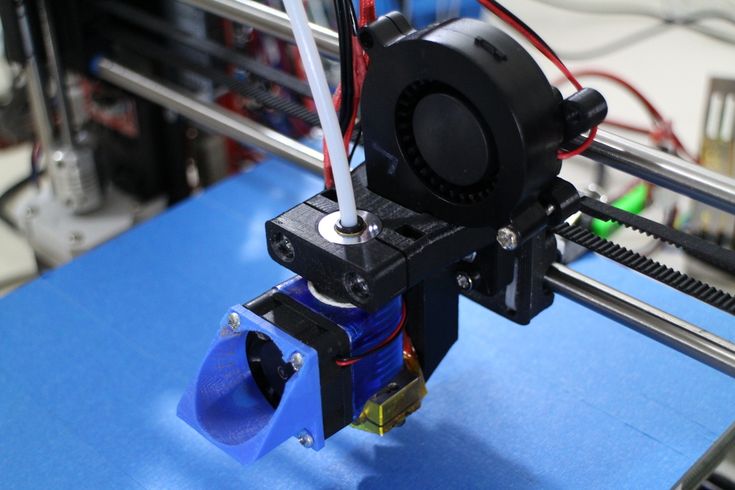

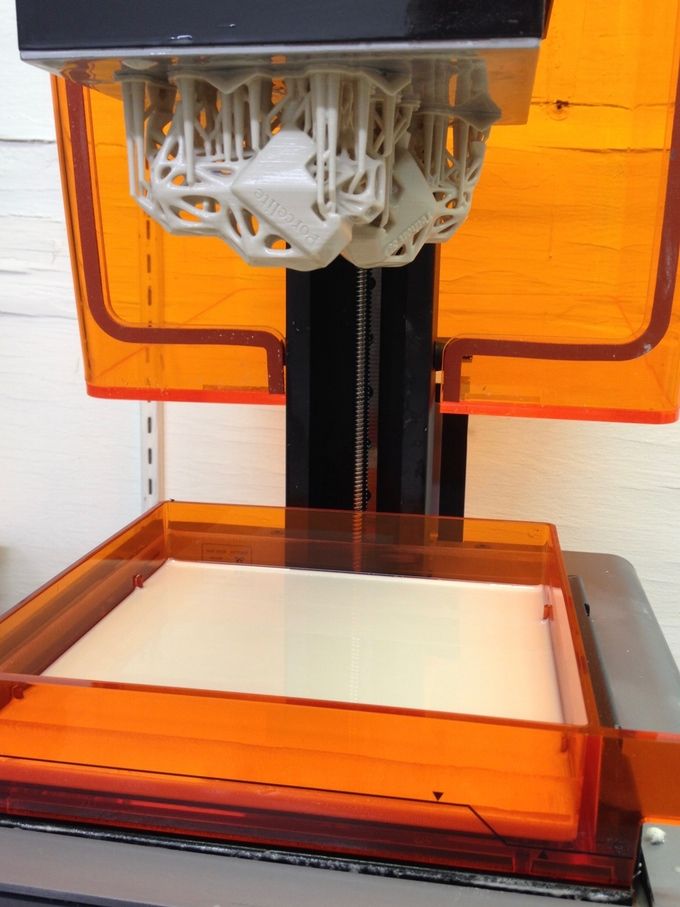

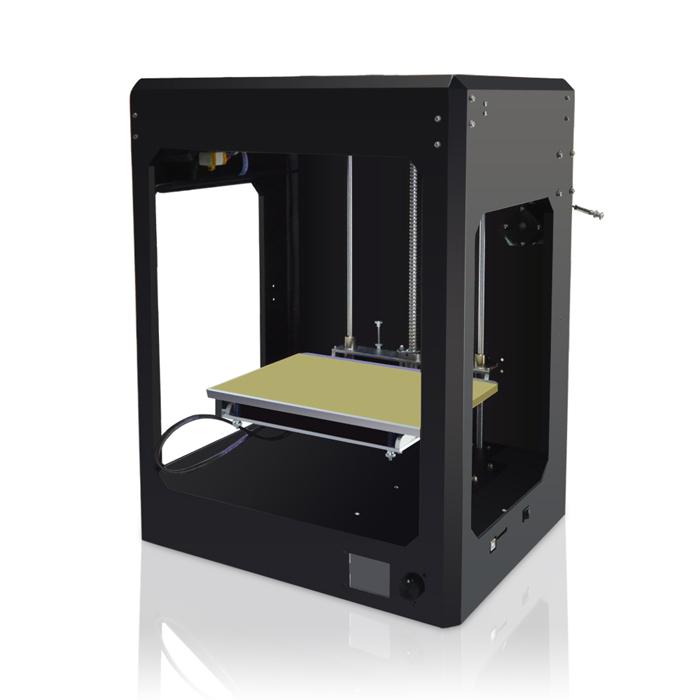

[Bam] from the LulzBot forums has successfully printed metal using his 3D printer and a Budaschnozzle 1.1 hot end. Well, solder to be specific — but it’s still pretty awesome!

He’s making use of 3mm solder purchased from McMaster (76805a61), which has a blend of 95.8% tin, 4% copper and 0.2% silver. It took quite a few tries to get it extruding properly, and even now it seems to only be able to print about 15mm before jamming up — a more specific hot end with a larger thermal mass might help. He plans on trying a thinner filament (1.75mm) as it might help to keep it at the proper extrusion temperature, which in this case is around 235C.

He plans on trying a thinner filament (1.75mm) as it might help to keep it at the proper extrusion temperature, which in this case is around 235C.

During our research we found another user from the RepRap blog who has also been experimenting with printing low-melt point alloys — and he’s even successfully created an Arduino compatible Sanguino board using the printer!

If you want to try this yourself, you’ll need a nozzle you don’t care about, bored out to about 1mm — any smaller and it won’t extrude at all. Be warned though, the solder will corrode brass and aluminum, and [Bam] notes that after going through 1lb of solder, the nozzle was closer to 2mm in diameter when he was done! Oh and for the love of hacking — use ventilation!

Stick around after the break to watch a video on a professional version of this system — which is essentially a repurposed welding robot, using electron beam direct manufacturing. These technologies can’t make nicely finished parts, but they excel when considering they can make near net-weight parts, requiring only a small amount of machining to finish.

Continue reading “3D Printing With Metal… At Home!” →

Posted in 3d Printer hacksTagged 3d printing metal, 3d printing solder, lulzbotSoldering best 3D printing files・Cults

Wall Holder for Parkside lidl soldering iron

€0.56

TS100 Case and Holder (Heavy Duty)

Free

Mini electronic workshop in a box

€2.50

Solder Spooler Holder w/ 608 Ball Bearings - MG Chemicals and Kester

Free

Fume Extractor DIY

Free

Solder Tip Case

€1.18

Tool for easy soldering

€0.90

Sortimo L-Boxx inlay for TS100

€3. 75

75

Tool Holder for Table - Modular

Free

Buck Converter Cover

€0.50

Pegboard Solder Holder

Free

Soldering Iron Tip Cleaner Case

€1.89

Bench Top Vise Clamp On Adjustable Ball and Socket

Free

Hakko FX-888 soldering sponge template

Free

Fume extractor for 80mm fan (soldering)

€0.99

8586 / 858D Rework soldering iron tip Holder

Free

Solder Wire Clamp

Free

SMOKE EXTRACTOR V2

Free

Solder Holder

€0. 90

90

Pi Camera Soldering Scope

Free

TS 100 Soldering Iron Case - with magnets

Free

Hakko T12 Handle (clone) Holder

Free

Soldering iron tip cleaner ball holder 55mm ID

Free

Soldering iron tip cleaner pad holder 35x50mm

Free

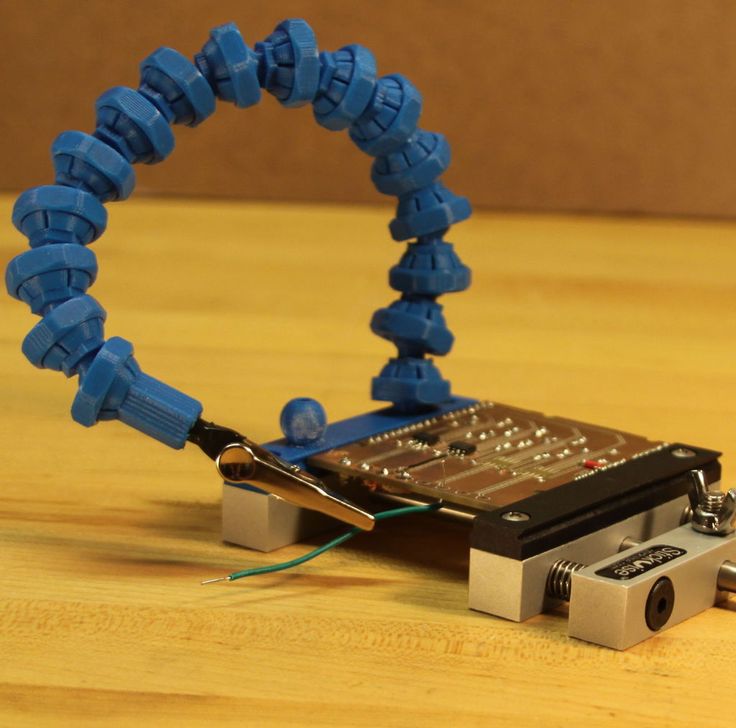

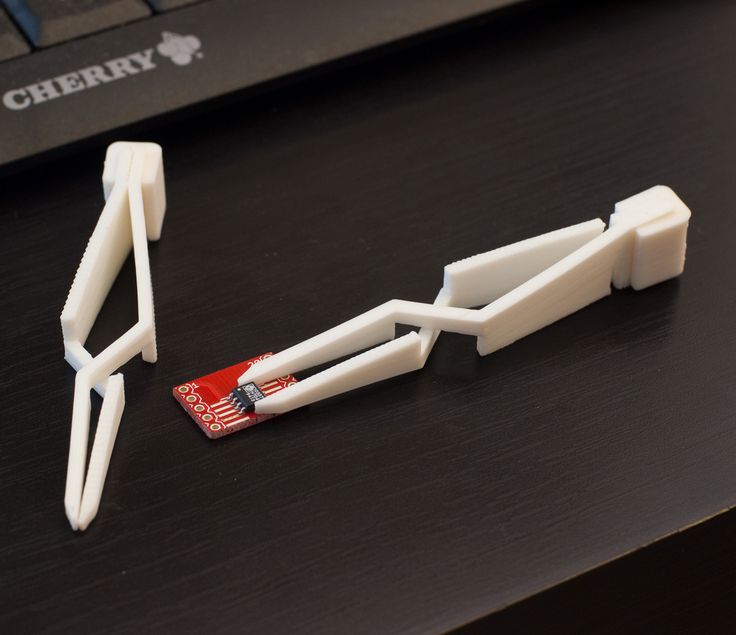

Adjustable PCB Holder - 3D Print for Printed Circuit Board Soldering and Desoldering

€1.04

Husqvarna Automower Cable Guide Junction Box for Silicon

Free

Weller Soldering Support Spacer

Free

Weller PH70 Style Safety Base, for Weller Soldering Iron

€1.42

Solder station - third hand - helping hand v3

Free

clamps to hold

€1. 03

03

3/4 inch Conduit Insert press

Free

Bender Solder Dispenser

Free

Brass insert tool holder

Free

18650 Alignment Helper Solder Rig

€0.94

Convert Dremel 220 press to Threaded insert tool NEW!

Free

Soldering stand

€1

Convert Dremel 220 press to Threaded insert tool

Free

Magnetic Multi clamp for PCB soldering etc.

Free

Solder spool holder magnetic

Free

Magnetic PCB solder fixture for steel work plate

Free

Soldering fingers for wire splicing

Free

Solder Fume Extractor 8mm threaded Rod foot

Free

PCB SteadyGrip v2

€1. 44

44

3D Printed Egg Splatter Neon Sign

Free

Soldering iron cleaner

€1.02

Motorized Solder Dispenser

Free

Rolling Pegboard Solder Spool Holder

Free

KSGER T12 OLED controller soldering station case

Free

Solder dispenser. Another one, "at the request of the workers";)

There were some interesting suggestions and comments in the dispenser's past review. I carefully read them all, thought it over, and here it is, our answer

Perinsky, and to all commentators.

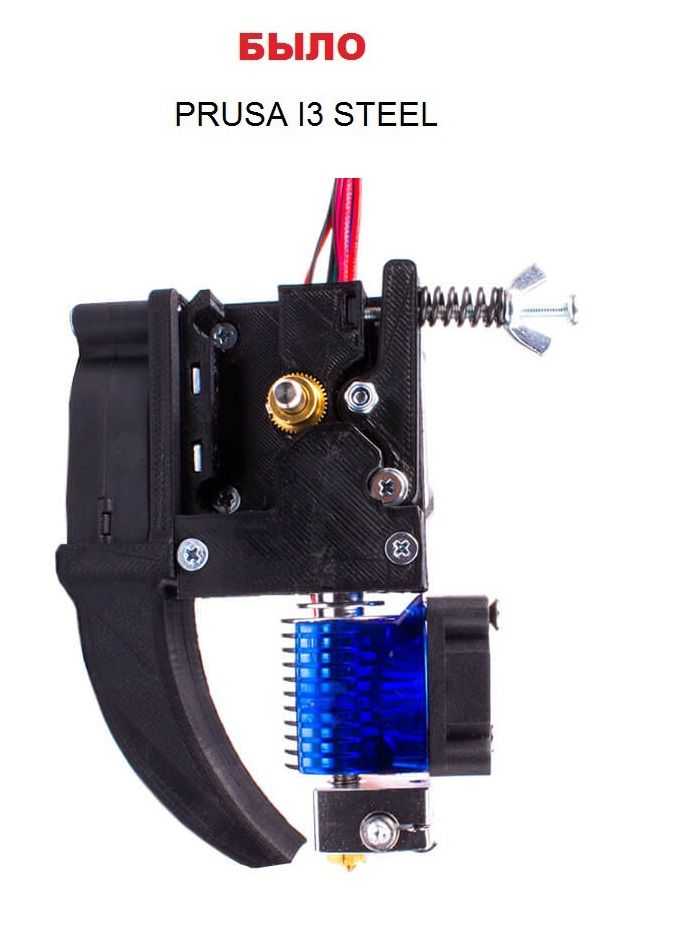

So, one of the options “on the topic” was this photo

As it turned out, the author’s name is Valery Perinsky and he lives on thingiverse, and this model is here.

I tried to print this dispenser and I had a few questions. in particular - what for was it to break the coil into THREE parts? At least the middle one can be combined with the top one. Moreover, the author used two magnets - one 10mm in diameter and 4 thick, and the second - 9 mm in diameter and 5 thick. I must say that this is quite some kind of rare earth magnet. In the sense that you will not find it in every land. On Ali, in particular, I found such a miracle from only one seller, and I didn’t like the price with delivery. The second question is how, in fact, to unwind the solder ?! Reel rotation? Hmm... but that's not our method!

Next, we watch this video and admire the idea, we are impressed by the implementation:

Hmm... And if we combine brands? ©

At first I wanted to fix the existing model, and then I decided that it would be easier to redraw from scratch. Almost. We take a sketchup…

Well, we print. I printed, as is easy to see, in a mirror image. Coil:

The dispenser itself.

We need a wheel from a lighter and a plate made of something springy, like brass, which needs to be bent at an angle of about 120 degrees somewhere around 0.3mm). Well, cut the M3 thread in the housing for the screw securing the cap. You can go through the holes for the wheel axle with a drill - they may turn out slightly out of size, they are small. Well, it is possible that the wheels themselves come in different sizes - this is China ... These wheels are also directional, but in my opinion there is no difference in this application.

Actually, I liked it so much that I printed another one so as not to rearrange the solder.

As you can see, there are no magnets. They are already ordered, but everything works in principle without them. How exactly - look at the video

IMHO the result turned out to be quite sensible. It is both aesthetically pleasing and comfortable to use. Thanks to everyone who pointed me to these dispensers (both on Singivers and on YouTube), thanks to the authors of the developments, and use it to your health.

File here

ATTENTION! The file has been re-uploaded, for some reason there was an error in the original. Moreover, I edited the model again and ran it through netfabb for the lucky owners of simplify version 4

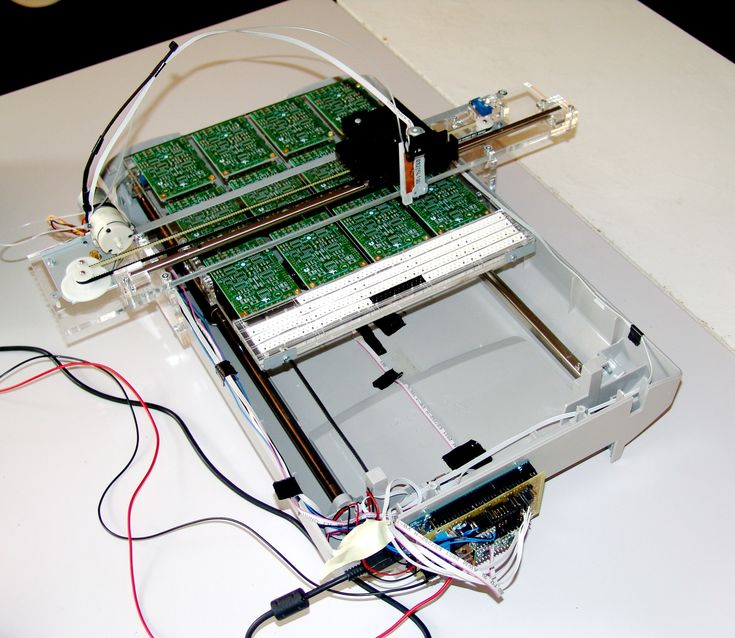

3D solder printed microchip from parts from DVD

4square

✩✩✩✩✩✩✩

- #1

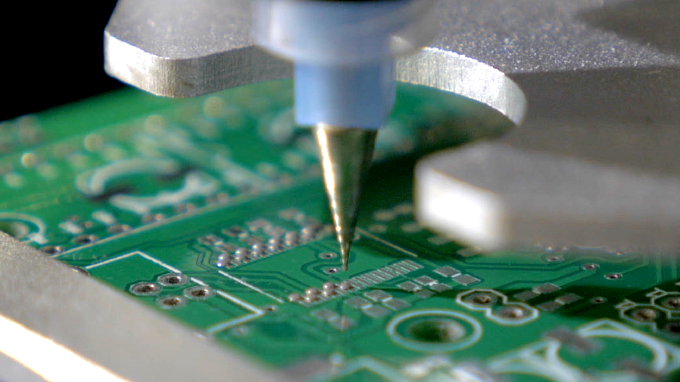

Attach an auto-feed soldering iron with solder for tinning or "quick" wiring diagram printing to the DVD printer. For example, first mark the tracks in the textolite with an engraver or laser, and then fill them with solder on a DVD printer.

For example, first mark the tracks in the textolite with an engraver or laser, and then fill them with solder on a DVD printer.

Modified:

4square

✩✩✩✩✩✩✩

- #2

Manual soldering gun... Print the circuit diagram by fixing the syringe head with flux in the printer. "Textolite" (the basis for printing) first smear "vaseline" (or varnish, or stick a film), with a thin layer, then go through the scheme "along the varnish" with an engraver, then with a flux ... Coat with "varnish" (put on a table), engraver , flux, solder, rinse with alcohol (remove the film), varnish. Textolite non-foil...

Textolite non-foil...

-

solderinggun.png

554.4KB Views: 27

Modified:

KennyUA

★✩✩✩✩✩✩

- #3

Light drug addiction)

Reactions:

Shalom4square

✩✩✩✩✩✩✩

- #4

Rosin "pencil". .. Oh, that smell of lilac... Mix copper powder with rosin. We need an adhesive base... BF-2... Just print on it with solder... Glue with ultraviolet curing...

.. Oh, that smell of lilac... Mix copper powder with rosin. We need an adhesive base... BF-2... Just print on it with solder... Glue with ultraviolet curing...

-

flusflomaster.png

56.4KB Views: 12

Modified:

4square

✩✩✩✩✩✩✩

- #5

"Magnetic" rosin...

-

magnitcanifole.png

21.6KB Views: 8

KennyUA

★✩✩✩✩✩✩

- #6

I want to reveal a terrible secret: 10 boards in China cost 5 bucks + a stencil 8 bucks. I scattered the components and blew out with a hairdryer (Either at the IR station from the spotlight

I scattered the components and blew out with a hairdryer (Either at the IR station from the spotlight

I assembled the same one for myself, already 80 pieces of boards are soldered)

Your theory has the right to life, but management software is not taken into account. Here you have a board, you can generate a pick-n-place file with coordinates, pull tracks from gerberas, but how to convert it into a machine view so that the miracle of the DVD player processes it) right, no way, more precisely, no one will do this due to inexpediency. But I recommend an IR oven)

Modified:

Reactions:

Shalom and 4square4square

✩✩✩✩✩✩✩

- #7

It still seems to me that all such operations can be put into the framework of a simple milling program. .. Software is a business...

.. Software is a business...

Modified:

KennyUA

★✩✩✩✩✩✩

- #8

But why?)

4square

✩✩✩✩✩✩✩

- #9

Well, so that in the arsenal of the do-it-yourselfer there is another affordable simple technology for "quick" obtaining the finished product. And, besides, do-it-yourselfers are not only electronics engineers, right? There are still artists and other audiences... Well, in China (it used to be in Greece), as a famous character said, there is everything! Ah, that's a gorgeous vidosik, thanks! We will know! I wonder if clay can be baked with this thing? An electrical circuit on ceramic paste (clay) ... ... Software is a thing to come: if there is a method, there will be software ... but with solder (tin) can you draw a picture on copper?

And, besides, do-it-yourselfers are not only electronics engineers, right? There are still artists and other audiences... Well, in China (it used to be in Greece), as a famous character said, there is everything! Ah, that's a gorgeous vidosik, thanks! We will know! I wonder if clay can be baked with this thing? An electrical circuit on ceramic paste (clay) ... ... Software is a thing to come: if there is a method, there will be software ... but with solder (tin) can you draw a picture on copper?

Modified:

4square

✩✩✩✩✩✩✩

- #10

Here.

.jpg?x-oss-process=image/resize,p_100/format,webp)