What is a 3d printer made of

What Materials Are Used in the 3D Printing Process?

The materials used for 3D printing are as diverse as the products that result from the process. As such, 3D printing is flexible enough to allow manufacturers to determine the shape, texture and strength of a product. Best of all, these qualities can be achieved with far fewer steps than what is typically required in traditional means of production. Moreover, these products can be made with various types of 3D printing materials.

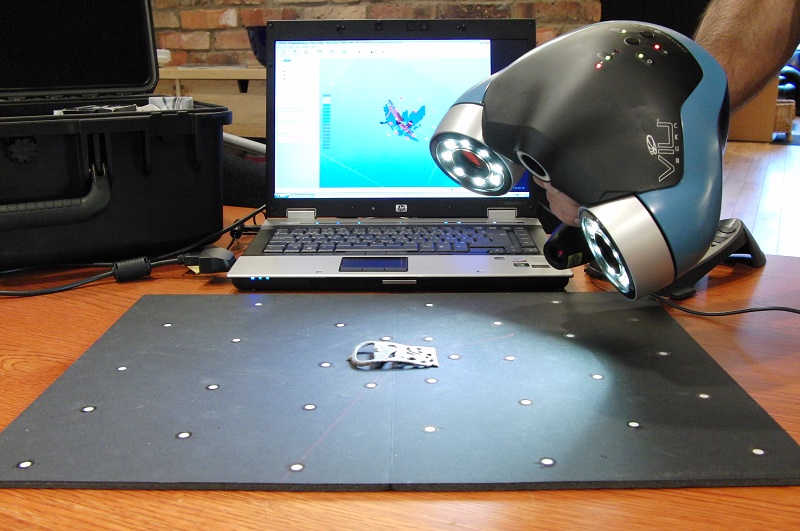

In order for a 3D print to be realized in the form of a finished product, a detailed image of the design in question must first be submitted to the printer. The details are rendered in standard triangle language (STL), which conveys the intricacies and dimensions of a given design and allows a computerized 3D printer to see a design from all sides and angles.

Basically, an STL design is the equivalent of multiple flat designs in one computerized file.

The industry for 3D printing is expected to surpass the 10-figure mark in the near future and plastic is set to be the main material to drive this market. As concluded recently in a SmarTech Markets Publishing study, the market for 3D printing is likely to exceed $1.4 billion before 2020. With an ongoing market expansion, the industry has sought new ways to yield plastics, including the use of organic ingredients like soybean oil and corn. Consequently, plastics are set to become the most environmentally friendly option in 3D printing.

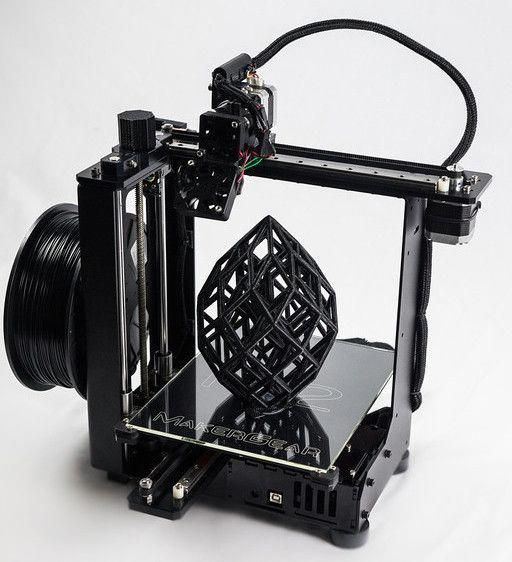

Plastic

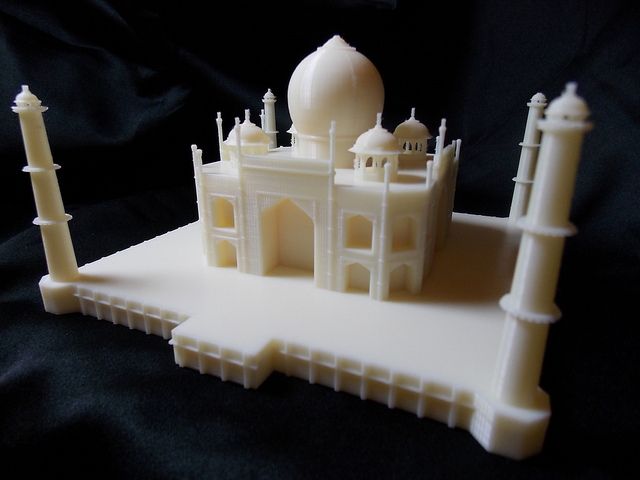

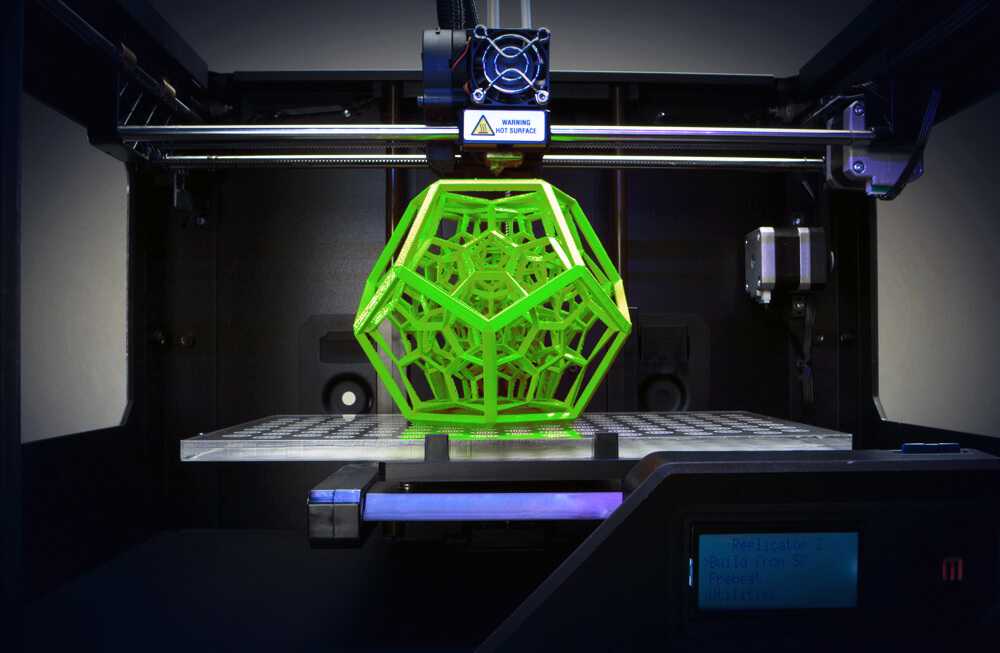

Out of all the raw materials for 3D printing in use today, plastic is the most common. Plastic is one of the most diverse materials for 3D-printed toys and household fixtures. Products made with this technique include desk utensils, vases and action figures. Available in transparent form as well as bright colors — of which red and lime green are particularly popular — plastic filaments are sold on spools and can have either a matte or shiny texture.

With its firmness, flexibility, smoothness and bright range of color options, the appeal of plastic is easy to understand. As a relatively affordable option, plastic is generally light on the pocketbooks of creators and consumers alike.

As a relatively affordable option, plastic is generally light on the pocketbooks of creators and consumers alike.

Plastic products are generally made with FDM printers, in which thermoplastic filaments are melted and molded into shape, layer by layer. The types of plastic used in this process are usually made from one of the following materials:

- Polyastic acid (PLA): One of the eco-friendliest options for 3D printers, polyastic acid is sourced from natural products like sugar cane and corn starch and is therefore biodegradable. Available in soft and hard forms, plastics made from polyastic acid are expected to dominate the 3D printing industry in the coming years. Hard PLA is the stronger and therefore more ideal material for a broader range of products.

- Acrylonitrile butadiene styrene (ABS): Valued for its strength and safety, ABS is a popular option for home-based 3D printers. Alternately referred to as “LEGO plastic,” the material consists of pasta-like filaments that give ABS its firmness and flexibility.

ABS is available in various colors that make the material suitable for products like stickers and toys. Increasingly popular among craftspeople, ABC is also used to make jewelry and vases.

ABS is available in various colors that make the material suitable for products like stickers and toys. Increasingly popular among craftspeople, ABC is also used to make jewelry and vases. - Polyvinyl Alcohol Plastic (PVA): Used in low-end home printers, PVA is a suitable plastic for support materials of the dissolvable variety. Though not suitable for products that require high strength, PVA can be a low-cost option for temporary-use items.

- Polycarbonate (PC): Less frequently used than the aforementioned plastic types, polycarbonate only works in 3D printers that feature nozzle designs and that operate at high temperatures. Among other things, polycarbonate is used to make low-cost plastic fasteners and molding trays.

Plastic items made in 3D printers come in a variety of shapes and consistencies, from flat and round to grooved and meshed. A quick search of Google images will show a novel range of 3D-printed plastic products such as mesh bracelets, cog wheels and Incredible Hulk action figures. For the home craftsperson, polycarbonate spools can now be purchased in bright colors at most supply stores.

For the home craftsperson, polycarbonate spools can now be purchased in bright colors at most supply stores.

Powders

Today’s more state-of-the-art 3D printers use powdered materials to construct products. Inside the printer, the powder is melted and distributed in layers until the desired thickness, texture and patterns are made. The powders can come from various sources and materials, but the most common are:

- Polyamide (Nylon): With its strength and flexibility, polyamide allows for high levels of detail on a 3D-printed product. The material is especially suited for joining pieces and interlocking parts in a 3D-printed model. Polyamide is used to print everything from fasteners and handles to toy cars and figures.

- Alumide: Comprised of a mix of polyamide and gray aluminum, alumide powder makes for some of the strongest 3D-printed models. Recognized by its grainy and sandy appearance, the powder is reliable for industrial models and prototypes.

In powder form, materials like steel, copper and other types of metal are easier to transport and mold into desired shapes. As with the various types of plastic used in 3D printing, metal powder must be heated to the point where it can be distributed layer-by-layer to form a completed shape.

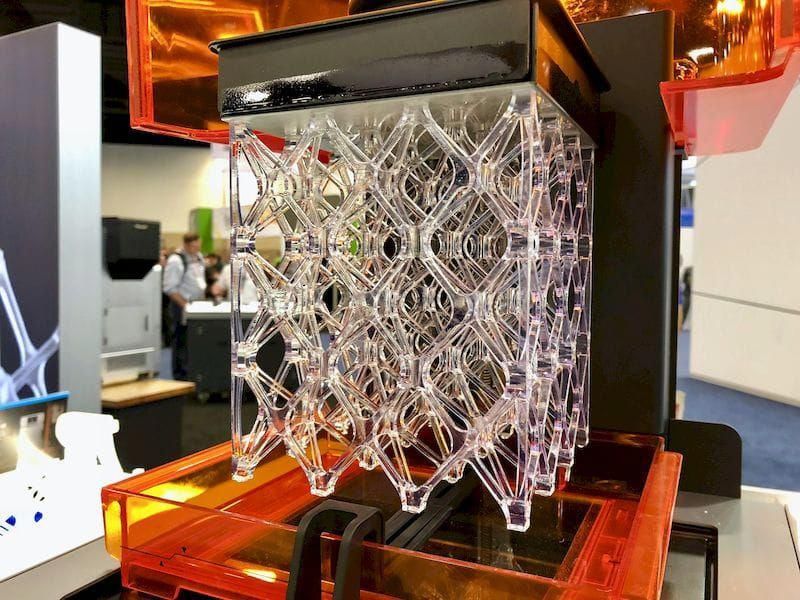

Resins

One of the more limiting and therefore less-used materials in 3D printing is resin. Compared to other 3D-applicable materials, resin offers limited flexibility and strength. Made of liquid polymer, resin reaches its end state with exposure to UV light. Resin is generally found in black, white and transparent varieties, but certain printed items have also been produced in orange, red, blue and green.

The material comes in the following three categories:

- High-detail resins: Generally used for small models that require intricate detail. For example, four-inch figurines with complex wardrobe and facial details are often printed with this grade of resin.

- Paintable resin: Sometimes used in smooth-surface 3D prints, resins in this class are noted for their aesthetic appeal. Figurines with rendered facial details, such as fairies, are often made of paintable resin.

- Transparent resin: This is the strongest class of resin and therefore the most suitable for a range of 3D-printed products. Often used for models that must be smother to the touch and transparent in appearance.

Transparent resins of clear and colored varieties are used to make figurines, chess pieces, rings and small household accessories and fixtures.

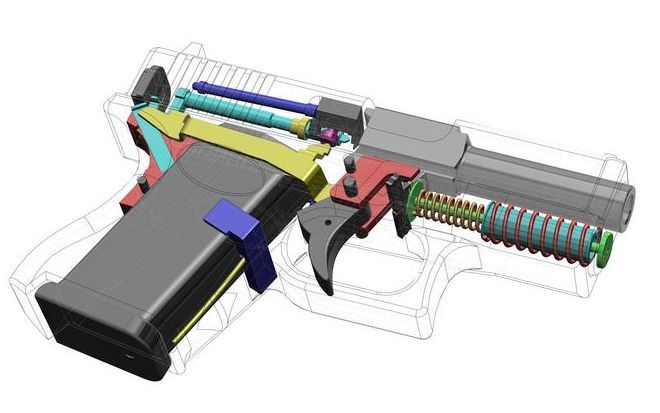

Metal

The second-most-popular material in the industry of 3D printing is metal, which is used through a process known as direct metal laser sintering or DMLS. This technique has already been embraced by manufacturers of air-travel equipment who have used metal 3D printing to speed up and simplify the construction of component parts.

DMLS printers have also caught on with makers of jewelry products, which can be produced much faster and in larger quantities — all without the long hours of painstakingly detailed work — with 3D printing.

Metal can produce a stronger and arguably more diverse array of everyday items. Jewelers have used steel and copper to produce engraved bracelets on 3D printers. One of the main advantages of this process is that the engraving work is handled by the printer. As such, bracelets can be finished by the box-load in just a few mechanically programmed steps that do not involve the hands-on labor that engraving work once required.

The technology for metal-based 3D printing is also opening doors for machine manufacturers to ultimately use DMLS to produce at speeds and volumes that would be impossible with current assembly equipment. Supporters of these developments believe 3D printing would allow machine-makers to produce metal parts with strength superior to conventional parts that consist of refined metals.

In the meantime, the use of 3D parts is taking flight in the aerospace industry. In what has been the most ambitious push of its kind, GE Aviation plans to print engine injectors at an annual rate of 35,000 units by 2020.

The range of metals that are applicable to the DMLS technique is just as diverse as the various 3D printer plastic types:

- Stainless-steel: Ideal for printing out utensils, cookware and other items that could ultimately come into contact with water.

- Bronze: Can be used to make vases and other fixtures.

- Gold: Ideal for printed rings, earrings, bracelets and necklaces.

- Nickel: Suitable for the printing of coins.

- Aluminum: Ideal for thin metal objects.

- Titanium: The preferred choice for strong, solid fixtures.

In the printing process, metal is utilized in dust form. The metal dust is fired to attain its hardness. This allows printers to bypass casting and make direct use of metal dust in the formation of metal parts. Once the printing has completed, these parts can then be electro-polished and released to the market.

Metal dust is most often used to print prototypes of metal instruments, but it has also been used to produce finished, marketable products such as jewelry. Powderized metal has even been used to make medical devices.

When metal dust is used for 3D printing, the process allows for a reduced number of parts in the finished product. For example, 3D printers have produced rocket injectors that consist of just two parts, whereas a similar device welded in the traditional manner will typically consist of more than 100 individual pieces.

Carbon Fiber

Composites such as carbon fiber are used in 3D printers as a top-coat over plastic materials. The purpose is to make the plastic stronger. The combination of carbon fiber over plastic has been used in the 3D printing industry as a fast, convenient alternative to metal. In the future, 3D carbon fiber printing is expected to replace the much slower process of carbon-fiber layup.

With the use of conductive carbomorph, manufacturers can reduce the number of steps required to assemble electromechanical devices.

Graphite and Graphene

Graphene has become a popular choice for 3D printing because of its strength and conductivity. The material is ideal for device parts that need to be flexible, such as touchscreens. Graphene is also used for solar panels and building parts. Proponents of the graphene option claim it is one of the most flexible of 3D-applicable materials.

The use of graphene in printing received its largest boost through a partnership between the 3D Group and Kibaran Resources, an Australian mining company. The pure carbon, which was first discovered in 2004, has proven to be the most electrically conductive material in laboratory tests. Graphene is light yet strong, which makes it the suitable material for a range of products.

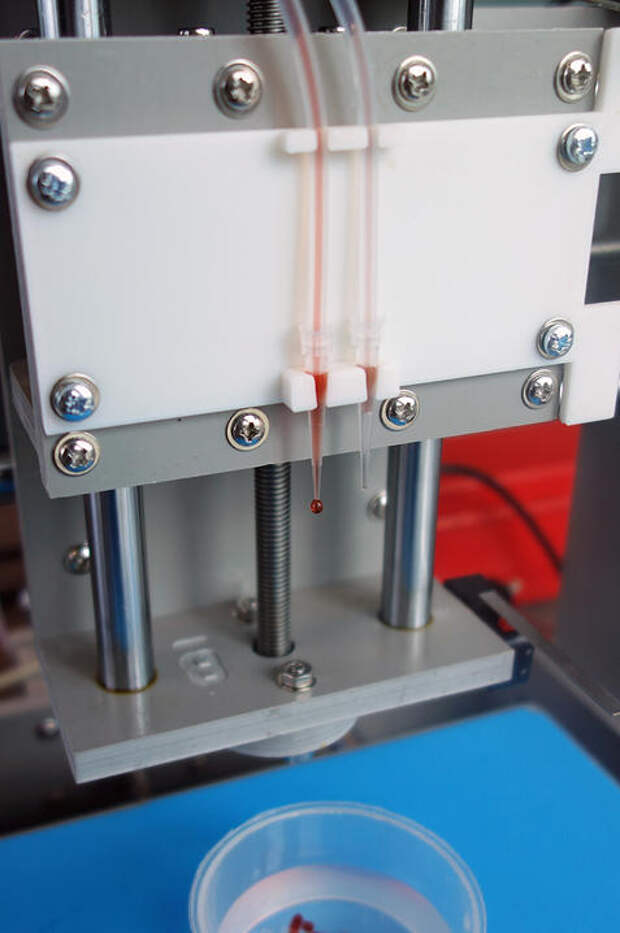

Nitinol

As a common material in medical implants, nitinol is valued in the 3D printing world for its super-elasticity. Made from a mixture of nickel and titanium, nitinol can bend to considerable degrees without breaking. Even if folded in half, the material can be restored to its original shape. As such, nitinol is one of the strongest materials with flexible qualities. For the production of medical products, nitinol allows printers to accomplish things that would otherwise be impossible.

Even if folded in half, the material can be restored to its original shape. As such, nitinol is one of the strongest materials with flexible qualities. For the production of medical products, nitinol allows printers to accomplish things that would otherwise be impossible.

Paper

Designs can be printed on paper with 3D technology to achieve a far more realistic prototype than a flat illustration. When a design is presented for approval, the 3D-printed model allows the presenter to convey the essence of the design with greater detail and accuracy. This makes the presentation far more compelling, as it gives a more vivid sense of the engineering realities should the design be taken to fruition.

Get 3D Plating From Sharretts Plating Company

For more than 90 years, Sharretts Plating Company has offered prompt, affordable, high-quality plating services. Operating from our 70,000-square-foot Pennsylvania production facility, we offer services to customers across North America and abroad. As one of the most globally recognized names in the plating industry, our customizers know they can trust us for plating, metal finishing and other solutions.

As one of the most globally recognized names in the plating industry, our customizers know they can trust us for plating, metal finishing and other solutions.

With each passing decade, SPC has remained at the forefront of innovation in the world of plating. Now, with 3D printing technology approaching maturity, we are determined to meet the demands of this exciting and revolutionary new form of product creation.

At SPC, our extensive background with plating applications has allowed us to apply these capabilities to 3D-printed parts. In recent years, we have applied surface finishing to 3D parts manufactured by electronics and automotive companies as well as in numerous other industries. Regardless of your industry, we can customize a process that will suit your products.

Ultimately, companies that master this technology are bound to have an edge over their competition. Browse our 3D-print plating page to learn more about the options and contact us today for a free quote.

What Materials Are Used in 3D Printing?

Published Date

Author Jeff Yoders- Plastic is still the most popular material used for 3D printing.

- As the 3D-printing market value increases, the list of what materials can be used also grows.

- Raw materials such as metal, graphite, and carbon fiber are commonly used for 3D printing, though at-home use is mostly limited to PLA for now.

Ice cream. Molecules for medicine. Even human skin. The list of what materials are used in 3D printing grows longer—and much more interesting—by the day. And expanding it is a multibillion-dollar material arms race right now.

A recently released 3D-printing market study found that the worldwide market for 3D-printing products was valued at $12. 6 billion in 2020 and was expected to grow to $37.2 billion by 2036. That means a huge increase in the materials those machines use.

6 billion in 2020 and was expected to grow to $37.2 billion by 2036. That means a huge increase in the materials those machines use.

What Is The Most Common Material Used for 3D Printing?

Plastic still reigns supreme in the 3D printing. According to a Grand View Research report, the market size for 3D printing plastics globally was valued at $638.7 million in 2020 and was expected to grow to $2.83 billion by 2027.

This material isn’t just your “everyday” plastic. Two types of plastic are most commonly used in 3D printing:

- PLA: Poly Lactic Acid (PLA) is the most popular 3D-printing material. It’s a biodegradable plastic made from renewables such as cornstarch. Its low melting point makes it easy to use at home.

- ABS: Acrylonitrile butadiene styrene (ABS) is best suited for parts that require strength and flexibility, like car components or household appliances. It’s also known for its low cost.

But it doesn’t stop there in the 3D-printing materials world.

1. Metal

Used for: Ready-to-install parts, finished products, prototypes

If there is a runner-up to plastic, it would be metal. Direct metal laser sintering (DMLS) is the technique and, unlike printing plastics, it can be used to make either a finished industrial product or a prototype. The aviation industry is already an early proponent and consumer of DMLS printing to streamline operations and manufacture ready-to-install parts. There are even already mass-market DMLS printers for creating 3D-printed jewelry.

The growth and popularity of 3D printing metals holds the potential to manufacture and create more effective machine parts that currently cannot be mass-produced onsite. This could lead to better conductors, tensile strength, and other attributes of laboratory metals than “mined-and-refined” metals such as steel and copper.

In the aerospace industry, the materials question is largely answered, and creating volume of parts is the Holy Grail. GE Aviation began printing fuel nozzles for its LEAP jet engine in 2016, ramping up to 30,000 parts in less than three years and printing its 100,000th nozzle in 2021. The LEAP’s successor, the RISE, will also incorporate 3D-printed parts.

GE Aviation began printing fuel nozzles for its LEAP jet engine in 2016, ramping up to 30,000 parts in less than three years and printing its 100,000th nozzle in 2021. The LEAP’s successor, the RISE, will also incorporate 3D-printed parts.

Used for: Electronics, lighting

Australian-listed graphite and nickel miner Kibaran Resources has partnered with 3D-printing company 3D Group to share development costs on a research-and-development venture called 3D Graphtech Industries.

The partnership is pursuing patents to investigate 3D printing graphite and graphene, a pure form of carbon first created in a laboratory in 2004. Graphene conducts electricity better and is stronger, easier to insulate, and lighter than other conductors on the market today. It outperforms even the best conductors several times over. Because it must be created in a lab, it is a good case study for just what kind of mass production of metals additive manufacturing can accomplish.

Because it must be created in a lab, it is a good case study for just what kind of mass production of metals additive manufacturing can accomplish.

Materials for research and development are sourced from Kibaran’s Tanzanian mines, where graphite with high crystallinity and a purity of 99.9% carbon has been found. This is incredibly well-suited to the production of graphene.

The semiconductor industry is interested in producing large quantities of graphene, as well. For example, IBM found a way to use it for LED lighting in 2014. The ability to 3D print sheets of material for use in LEDs could seriously cut lighting production costs.

3. Carbon FiberUsed for: Bearings, parts, electrical cable installation

Related to graphite, carbon fiber (which undergoes an oxidation process that stretches the polymer) can be added to the more traditional plastic to create a composite that can be as strong as steel but less intensive to use than aluminum, says Markforged. The company’s large-format 3D printers are designed to print stronger parts more quickly and at significantly lower costs.

The company’s large-format 3D printers are designed to print stronger parts more quickly and at significantly lower costs.

Meanwhile, startup Impossible Objects has also been exploring carbon fiber, as well as glass, Kevlar, and fiberglass. The company’s printer can also work with PEEK (polyether ether ketone) thermoplastic polymers, which are typically used for bearings, piston parts, and electrical cable installation.

New 3D Printing Materials

The 3D-printing industry is experimenting with a wide variety of innovative, novel approaches such a bio-based resins made from corn and soybean oil, powders, nitinol, and even paper.

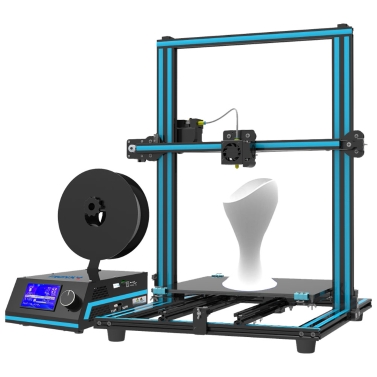

Do I Need a New 3D Printer for These Materials?As the list of materials grows, what does this mean for the actual hardware? Right now, on the consumer level, plastic is about as good as it gets. For example, the $1,399 Dremel 3D40 Flex is limited to PLA.

Today, several printers are focused entirely on DMLS, including the 3DSystems DMP Flex 350 and several models from Stratasys, but these currently cost upward of $100,000 each because DMLS printers burn much hotter than their plastic counterparts, as the powders and metals they create have higher melting points. Stronger housings and more powerful industrial smelting tools increase their costs significantly.

Stronger housings and more powerful industrial smelting tools increase their costs significantly.

Although many 3D-printer manufacturers are offering metal 3D-printing services, it will be some time before the economies of scale that helped bring down the cost of plastic 3D printing affect the DMLS market. And 3D-printing systems with graphite/carbon fiber are just now starting to gain traction in the marketplace.

The diversity of applications that industries are exploring for 3D printing makes for an exciting but tumultuous time. From jet parts to lighting to rapid prototyping, the new (and “old”) 3D printing materials will deliver even more opportunities for how and what industries print.

This article has been updated. It was originally published in November 2014.

About the Author

Jeff Yoders has covered IT, CAD, and BIM for Building Design + Construction, Structural Engineer, and CE News magazines. He has won six American Society of Business Publications Editors awards and was part of the reporting team for the 2012 Jesse H. Neal Award for best subject-related series of stories.

Neal Award for best subject-related series of stories.

Follow on Twitter Content by Jeff Yoders

Techno Print 3D Company

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them. Many will say that it is wrong to compare them or Read more→

XYZprinting, best known for its daVinci line of desktop 3D printers, is bringing five new devices to the professional and industrial environment. One will use laser sintering technology, the second full color inkjet printing and three DLP machines. First of all, the novelties will be of interest to dentists and jewelers. Read more→

One will use laser sintering technology, the second full color inkjet printing and three DLP machines. First of all, the novelties will be of interest to dentists and jewelers. Read more→

Cleaning the nozzle of a 3D printer is a fairly common process that any user of such a device has to deal with. This is not at all a complicated procedure that anyone can handle. You can complete this task in 15 minutes, using only handy tools and accessories. Read more→

Acetone steam polishing of ABS plastic is a process for smoothing the surface of 3D printed models. The result of this treatment makes your printed products look as if they were made by a professional mold casting method. If you want to understand how this is done correctly, then read this article. Aceto Read more→

3d printer (design, types, manufacturers) | Wiki 3DP

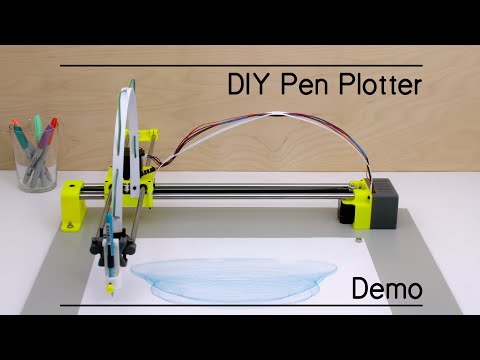

The 3D printer is a peripheral device that 3D prints by layering a physical object from a given 3D digital model.

Due to a certain simplicity of the basic design of equipment that allows 3D printing, development in this area is carried out as ordinary people - 3d printing enthusiasts (in fact, anyone can build their own 3d printer with their own hands) , as well as large industry companies and development centers.

Modern 3D printers can print both various polymer materials (the main share of consumables), and metal, specialized building compounds, food and bio-materials.

3D printers are already used today for both domestic and professional prototyping of objects. Today, in addition to conditionally “standard” equipment, there are developments and designs that print food, printers used in medicine and printers capable of printing low-rise buildings and small structures.

We also note that 3D printers in particular and 3D printing in general are actively used in education, robotics and a number of other socially significant and innovative and promising areas.

It should be noted that 3d printers are one of the few categories of equipment that have a real ability to self-reproduce (in particular, project RepRap ). [1]

Types of 3d printers

3D printers are classified according to several key parameters, the main ones being: the applied 3d printing technology; print material; the level of quality and dimensional stability of the resulting products.

In the latter case, a distinction is made between home (desktop) 3d printer and professional grade 3d printer , showing more stable size of printed objects, improved performance (printing speed) and prototyping quality. Professional-class equipment is actively used in various design bureaus (to create models and prototypes of products or structures being developed), as well as for the purposes of small-scale production of a wide range of products (souvenirs, individualized electronics cases, etc. ).

).

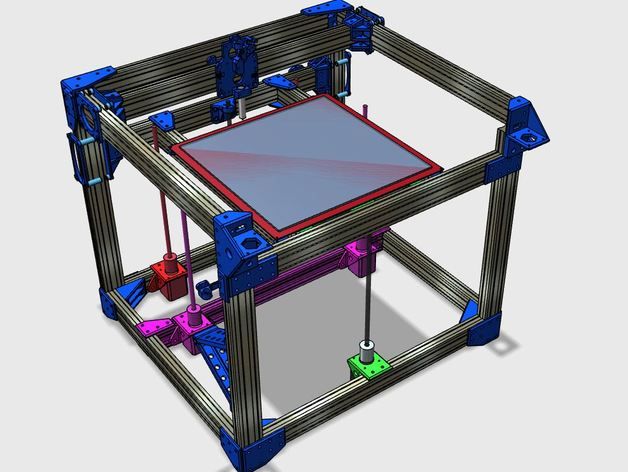

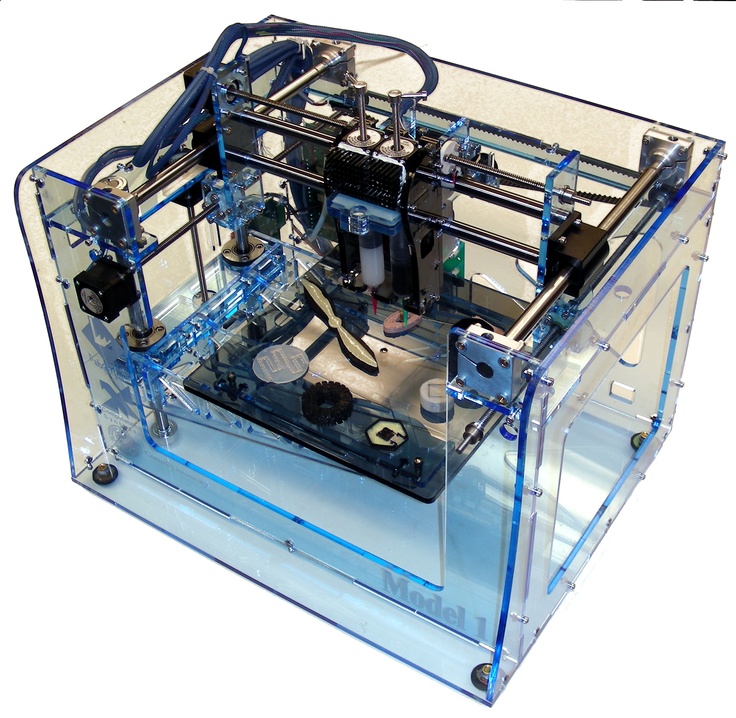

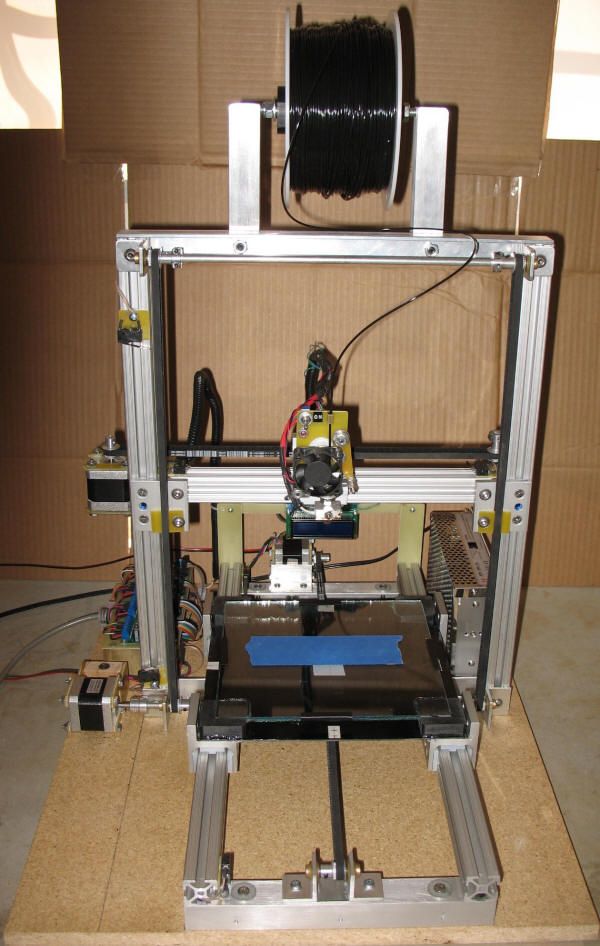

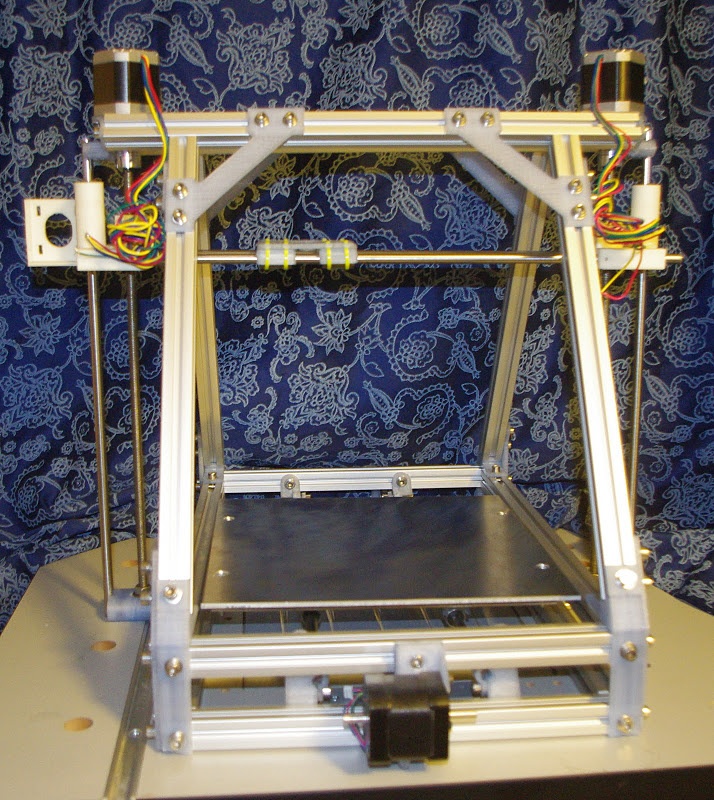

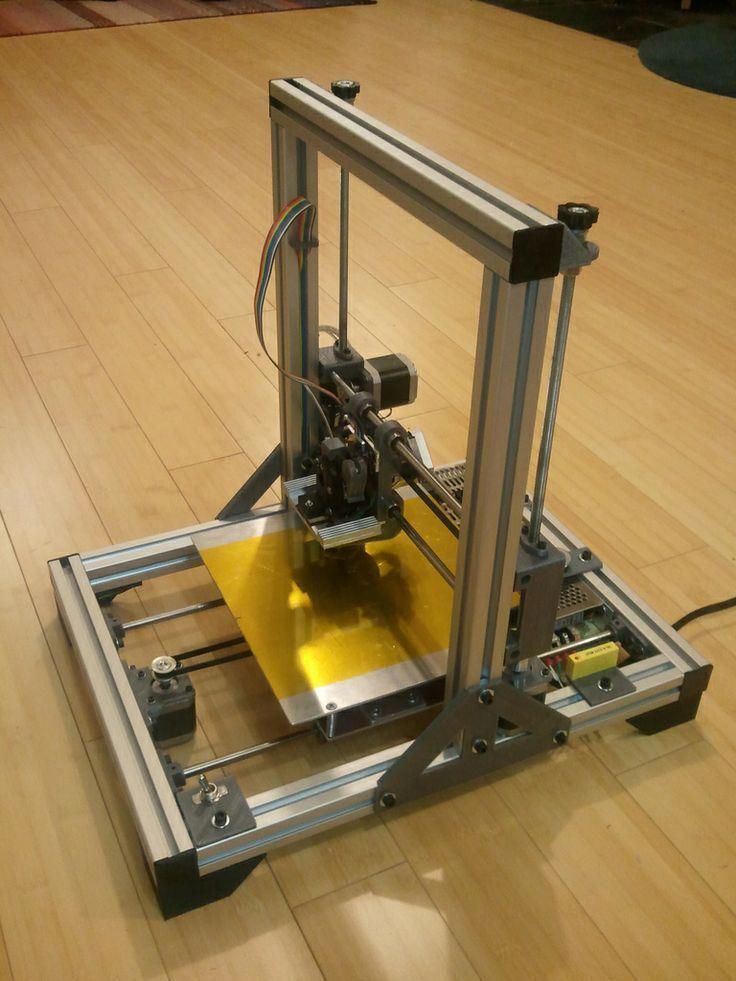

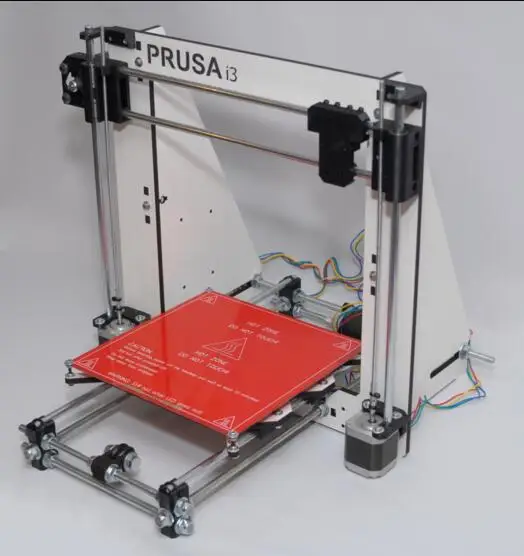

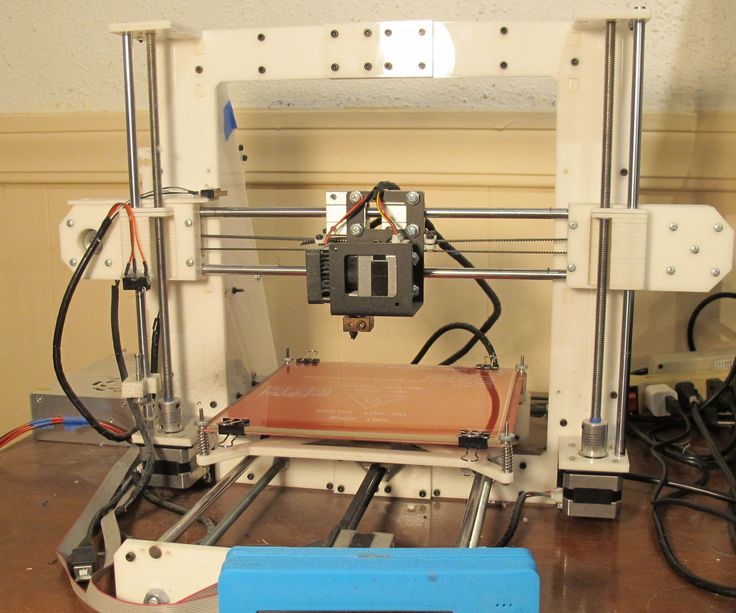

Typical design of a 3D printer

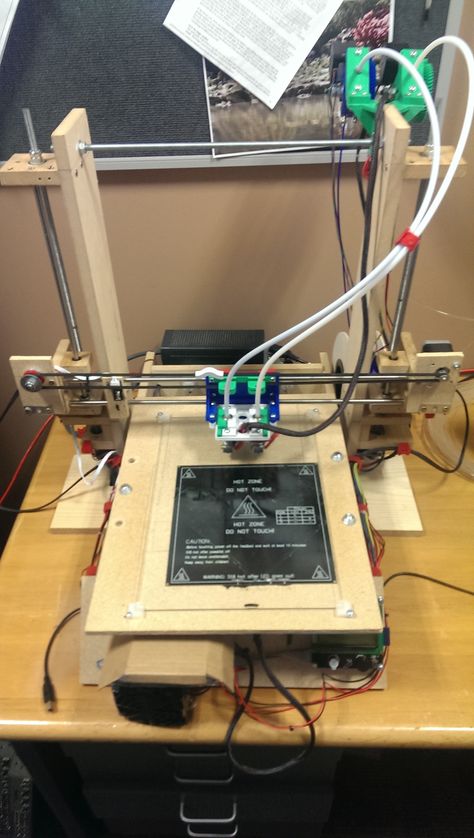

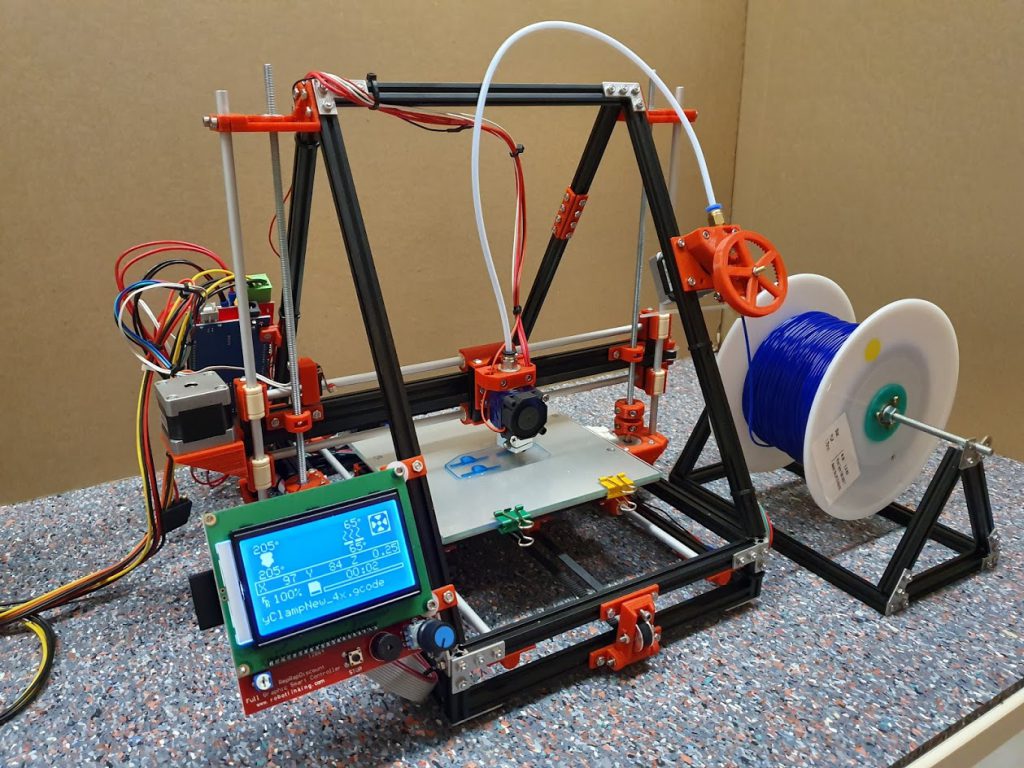

The 3D printing industry is currently experiencing a period of rapid growth and development, which has led to the fact that today there is an extremely wide and very diverse range of equipment on the market: from amateur printers , assembled by hand in a single copy from auxiliary parts and elements, to industrial designs capable of creating high-precision copies of objects with very complex geometry.

In general, 3D printers are actually not very complex. The main challenges in printer manufacturing are to ensure assembly accuracy and further positioning accuracy in all axes for the extruder to ensure print quality.

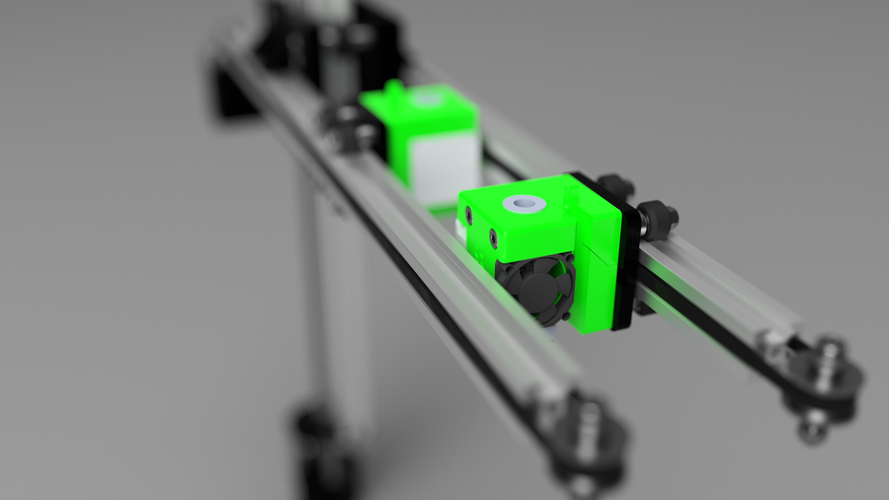

In order to present a typical design of a 3D printer, let's consider the most common (currently) 3D printing technology - FDM (layer-by-layer deposition method) .

Typical design of a Fused Deposition 3D Printer (FDM). (Visualization: 3D Today)

3d printer consists of :

- Housing , acting as a skeleton for mounting structural elements ;

- Guides , for relatively free movement of the print head in a given space ;

- Print head (extruder) - a group of parts that feeds, heats and extrudes ( extrusion ) the consumable through the nozzle onto the work surface ;

- Stepper motors - structural elements of a 3D printer responsible for uniform movement of the print head in a given space ;

- Worktable – 3D printer construction platform, on which the direct creation of a three-dimensional object is carried out;

- Electronics - a set of elements responsible for managing and coordinating the printer during the printing process .

Let's take a closer look at some (most important) elements of the basic design of the 3D printer [2] .

Extruder (print head) 3d printer

The most important design element of this type of equipment. The extruder of a 3D printer is a unit that provides the supply of molten plastic to the working area of the machine. To date, there are already a huge number of different design solutions.

In particular, there are samples of equipment equipped with interchangeable nozzles of various diameters. There are also options for printers with two extruders in the design. Such samples are capable of printing in two colors or printing supports with soluble plastic PVA or HIPS .

Maintenance of the 3D printer extruder consists in cleaning it from the outside of plastic pieces adhering during the printing process. Sometimes, usually when working with low-quality consumables, the extruder nozzle can become quite clogged - in this case, you have to clean it.

3D printer worktable

The table can be heated or not. To calibrate the table, either automatic drives ( automatic calibration ) or spring-loaded bolts ( manual adjustment ) are used. It is usually covered with glass, although there are options for 3D printers with a perforated platform. For a heated table, a heated element is also added.

Maintenance of this component consists of its calibration and regular cleaning of the surface.

Electronics and control

Control board can be located in the housing. Most 3d printers have a board based on RAMPS . But there are also options with their own solutions. Usually it is enough to check whether the cooling cooler is working (if it is necessary in this design).

As for the control screen 3D printer, it should be noted that it is not present on all models of this category of equipment. Usually it is where it is possible to print from an SD card.

Usually it is where it is possible to print from an SD card.

The principle of operation of a 3D printer

As already noted, today in the industry there are already several subspecies of 3D printing methods, as well as a very extensive set of related equipment and structures.

In order to consider the principle of operation of a 3D printer, let's turn to its key element (the extruder head) and the 3D printing method using plastic filament.

3D printing process :

Thread ( filament ) enters the print head (extruder), after which the filament is heated to its liquid state. Next, the resulting mass is squeezed out through the extruder nozzle. At the same time, stepper motors, using toothed belts, drive the Extruder, which moves along the guides in a given direction and applies plastic to the platform layer by layer according to a given model. [3]

3d printer manufacturers

On the one hand, 3D printing technology is still at the stage of its inception and development, on the other hand, it is based on highly developed technological solutions from a number of other areas (in particular, polymer extrusion). These circumstances, together with the development of the Internet, which has significantly accelerated and simplified the exchange of information on a global scale, have led to the fact that many companies around the world can boast of some success in the development, design and production of equipment for 3d printing.

These circumstances, together with the development of the Internet, which has significantly accelerated and simplified the exchange of information on a global scale, have led to the fact that many companies around the world can boast of some success in the development, design and production of equipment for 3d printing.

The vast majority of such companies (today) assemble equipment from prefabricated structural elements according to freely available design schemes with minimal changes and innovations. However, the market already has its own leaders - relatively large companies, relatively (considering the age of the 3D printing market itself) have been working in this area for a long time. Below is a list of the most notable ones.

Top manufacturers :

- 3D Systems (USA) ;

- EnvisionTEC (Germany) ;

- Stratasys (USA) ;

- MX3D (Netherlands) ;

- Rapid Shape (Germany) ;

- DWS s.

r.l. (Italy) ;

r.l. (Italy) ; - Wuhan Binhu Mechanical & Electrical (China) ;

- MakerBot Industries (US) ;

- RepRapPro (UK) ;

- Magnum (Russia) ;

- Ultimaker (Netherlands) ;

- PICASO 3D (Russia) .

In general, there are developers and (or) manufacturers of 3D printers in almost every civilized country in the world. According to various estimates of experts and analysts, today in the world you can buy a 3d printer from at least 300 companies .

In Europe (as can be seen from the above list) German, Dutch and Italian companies occupy a central place, which is quite correlated with the position of local polymer processing equipment manufacturers in the international market. The United Kingdom also occupies a prominent place in the world market of additive technologies, where, according to various estimates, there are at least 15 companies that develop and manufacture equipment for 3D printing.

In Asia the undisputed market leader is Chinese companies. However, besides them, there are notable players from other countries of the region: India, Japan, South Korea, Taiwan, and even Thailand and Hong Kong.

In the post-Soviet space the undisputed leader in the number of industry companies working in the development and manufacture of 3d printers and auxiliary equipment is the Russian Federation, on the territory of which (according to various estimates) fit at least 36 enterprises, the main ones which are presented above. It should also be noted that there are industry firms in Ukraine, Belarus, Lithuania and Latvia.

In North America , in addition to the world leader - the United States, its functionaries in the field of development, production and implementation of 3dp printing equipment are also present in Canada.

In conclusion, we note that there are manufacturing companies in countries such as Israel; Brazil, New Zealand and Australia, although they can literally be “counted on the fingers” and they (at the moment) do not have a noticeable impact on the world market.