What are the different types of 3d printer filaments

3D Printer Filament Types and Uses

WHITEPAPER

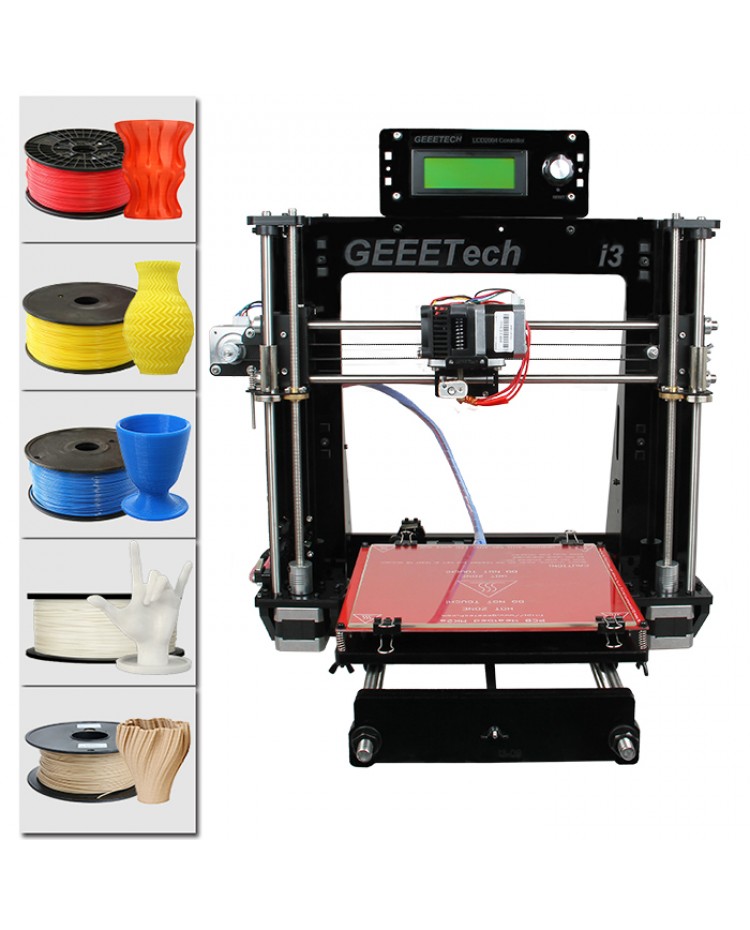

Filament Types

B.Diallo

Signup or download the pdf version to get notified when we publish the latest guides.

Share on facebook

Share on twitter

Share on linkedin

INTRODUCTION

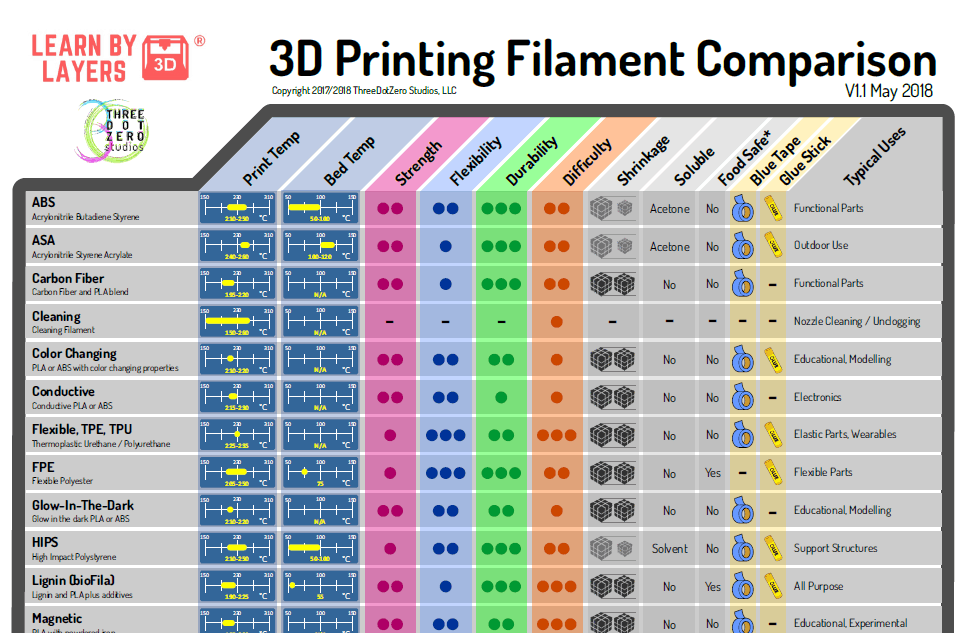

The purpose of this guide is to introduce the different 3D printer filament types that are available and their uses. This can range from producing visual prototypes in industries such as design to helping you pick the right filament when you need to make functional prototypes.The guide is designed to be easy and clear with minimum complexity so it can be quickly referenced when needed.

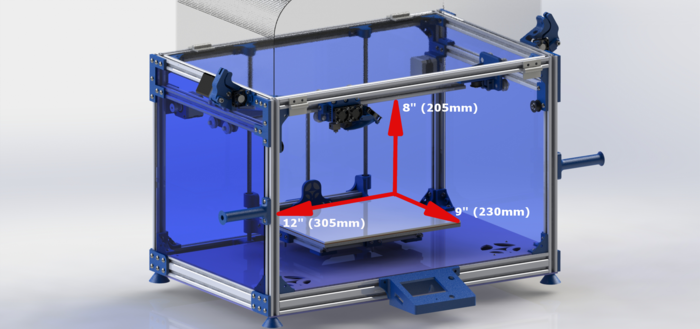

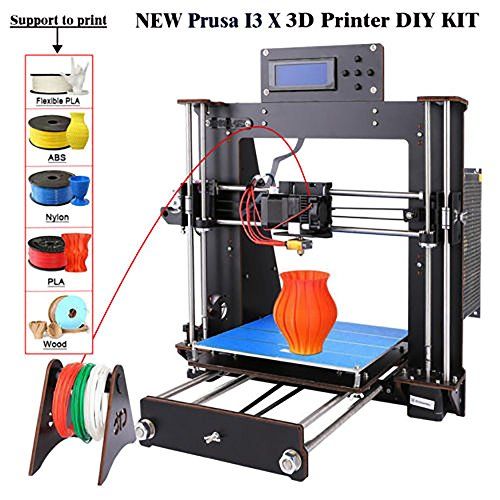

Currently we offer 8 standard filaments which are Engineering PLA, ABS filament , PETG filament , NYLON , a carbon fibre filament composite, PVA, HIPS , Flexible filament (TPU) and Polypropylene. However, due to the implementation of the market leading E3D hot-ends, the Bolt Pro can feasibly print with all current filaments in the market.

The guide will outline the unique characteristics of each filament, including specifications, the mechanical properties of each and how they are used depending on their use case.

The best 3D printer filament in the market is highly dependent on what the application is and each 3D printing material has its own advantages and disadvantages which we will explore in this guide. The main purposes is to have a simple guide to inform users what each filament is capable of and how best to maximise those attributes to achieve better 3D prints.

The guide is intended to be kept up to date to with any developments that occur and we recommend signing up to the white-paper newsletter so we can update you as developments occur.

3D PRINTING GLOSSARY OF KEY TERMS

MATERIAL COMBINATION MATRIX

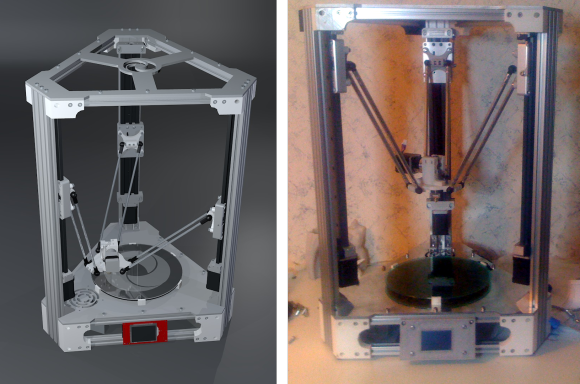

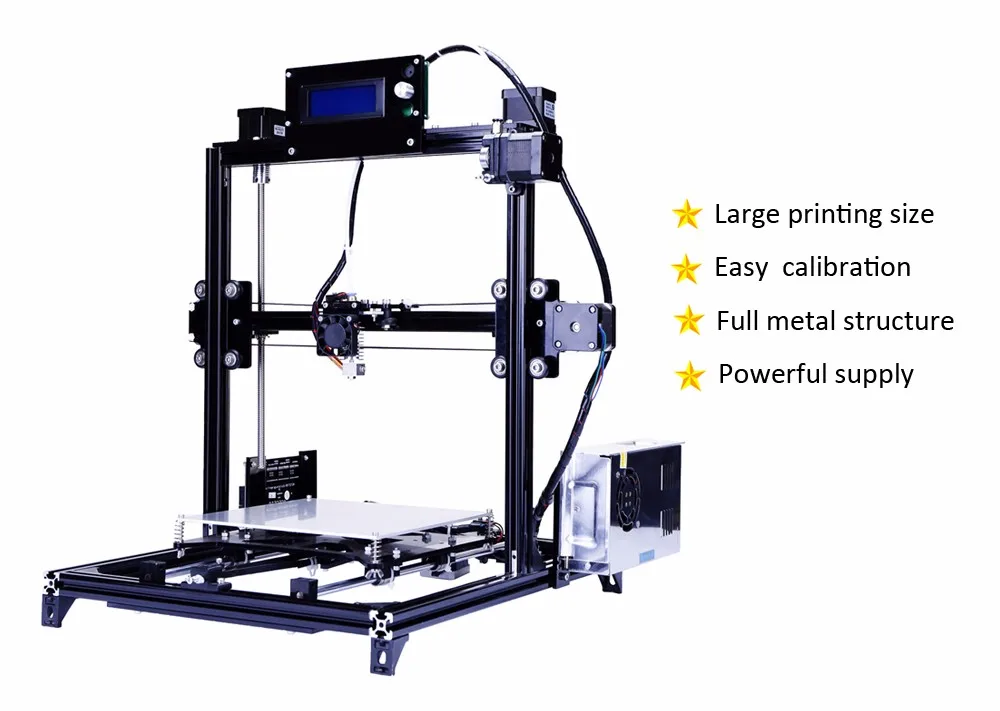

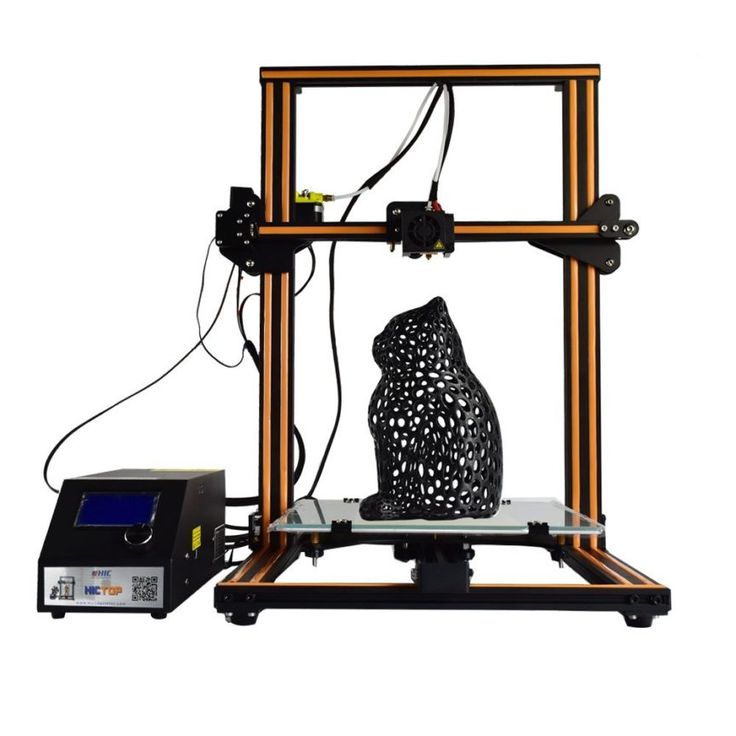

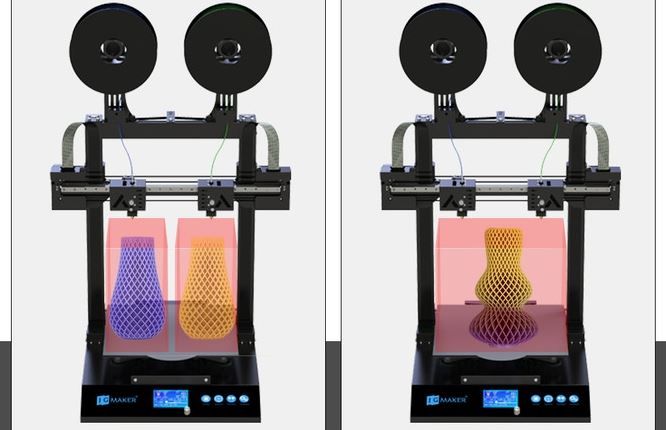

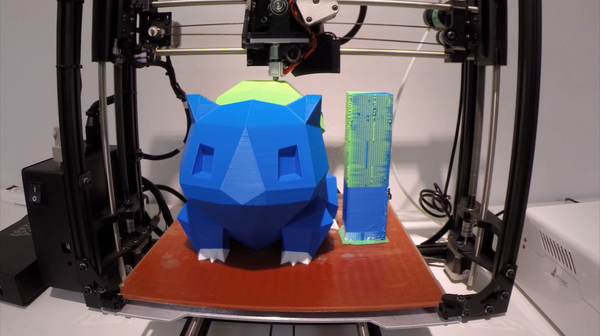

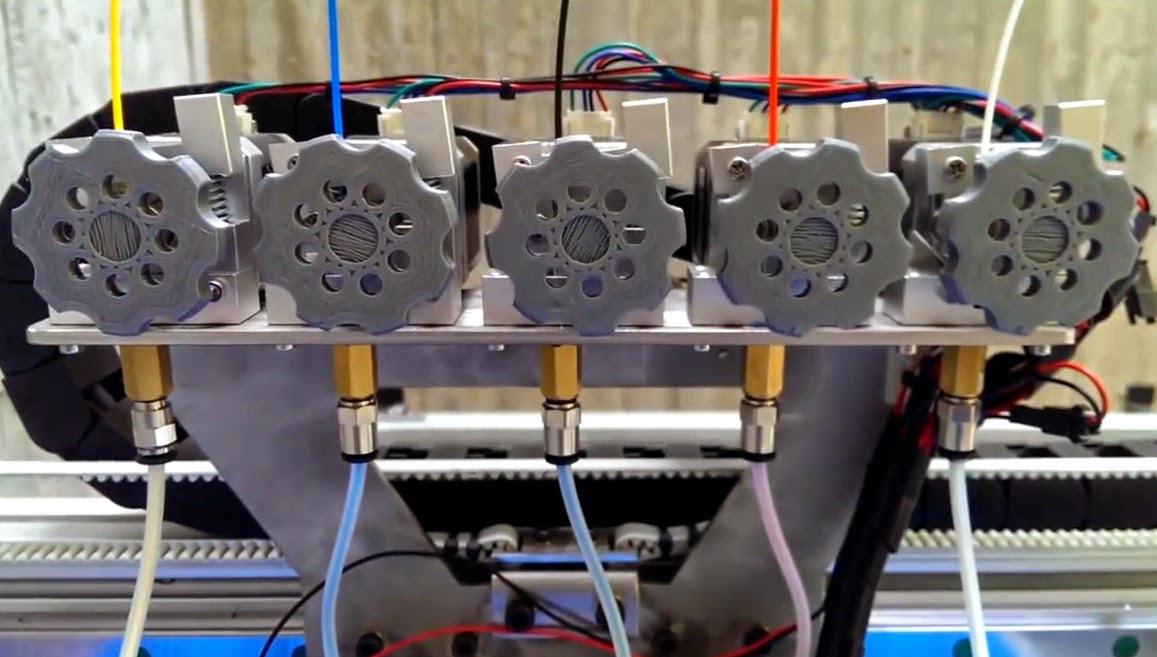

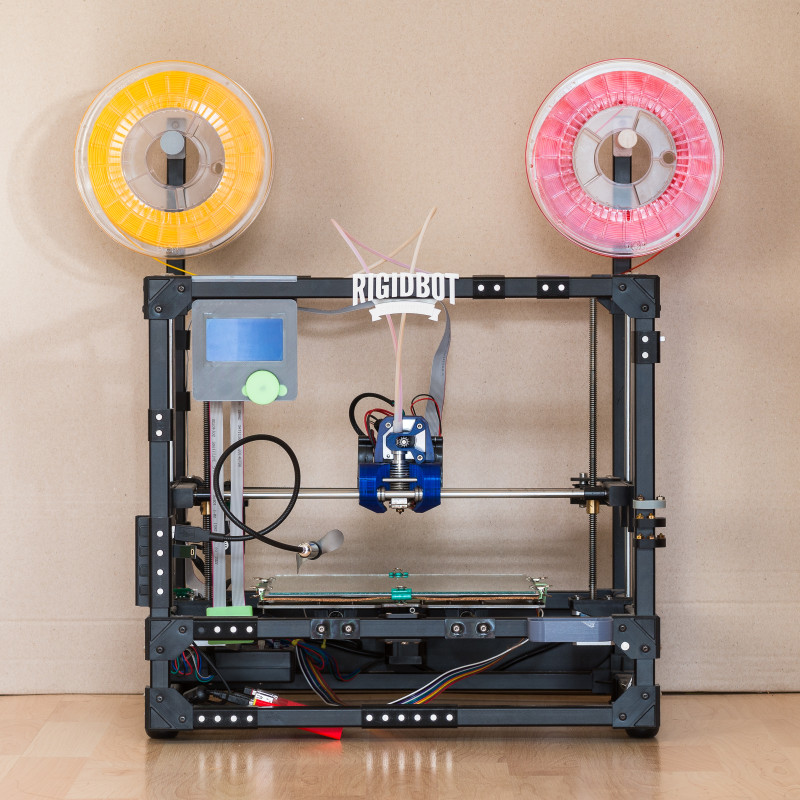

The great advantage of the Bolt Pro 3D printer is it comes with dual independent extruders (IDEX). This means that users have the option of combining two materials to use one as a support or to use different colours of the same material to create unique models.

This means that users have the option of combining two materials to use one as a support or to use different colours of the same material to create unique models.

However, each 3D printing material has unique material properties and these become increasingly important when attempting to combine two different types of filaments.

The matrix below highlights which combinations work well with each other and which 3D printer filament types do not work together and which materials that can be used as breakaway support.

DISTINGUISHING FEATURES EACH 3D PRINTER FILAMENT TYPESEPLA FILAMENT

Aesthetics : Engineering PLA filament can create great visual prototypes with the added option of post processing such as painting or being able to be sanded to create great models.

Ease of use: Engineering PLA is the easiest material to work with that does not have unique work-flow requirements.

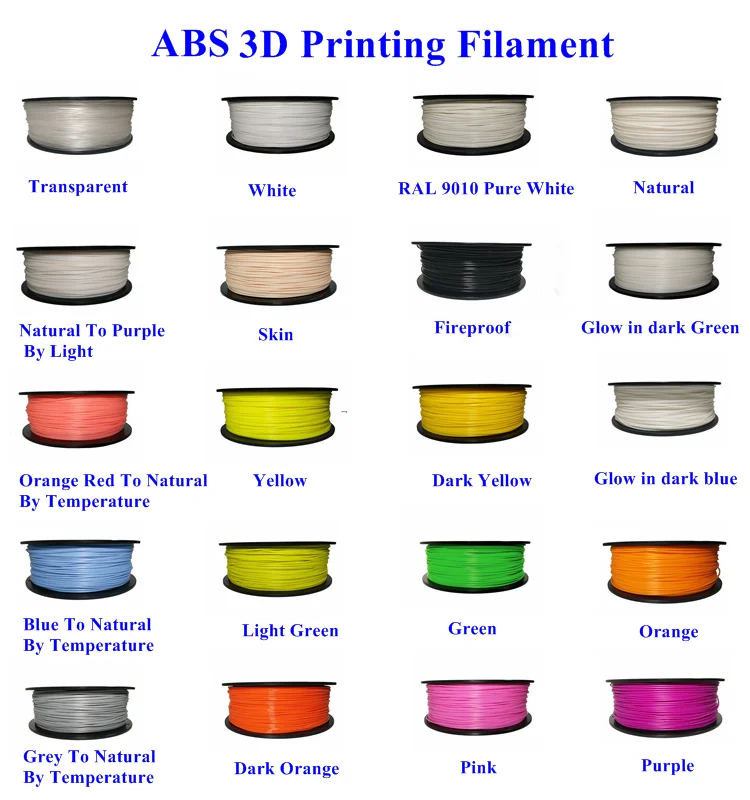

ABS FILAMENT

Heat resistant : ABS has got high heat resistant properties which is useful for functional prototypes

Wear resistant: ABS models do not scratch easily and can last long if stored properly.

High Elasticity: Very flexible and can stretch.

PETG FILAMENT

UV Resistant : Many models degrade if left out in direct sunlight, PETG is the main exception in 3D printing.

Water Resistant : PETG models can be used to store liquids or be submerged without degrading.

PP FILAMENT

Chemical Resistant : PP is highly resistant to chemicals and cannot be combined to anything apart from itself.

Fatigue Resistant : PP models do not break easy from repeated flexural forces.

CARBON FIBRE FILAMENT

High Strength : Carbon is added to a base filament to increase strength and rigidity in the final model.

NYLON FILAMENT

Low Friction : Great for models that require movement without degrading.

FLEX FILAMENT

Elasticity: Elastic parts like phone cases and grips can be made with flex

HIPS FILAMENT

Soluble material : HIPS dissolves in citric based acids.

Impact Resistant : HIPS is highlight impact resistant and can withstand forces for various functional applications.

PVA

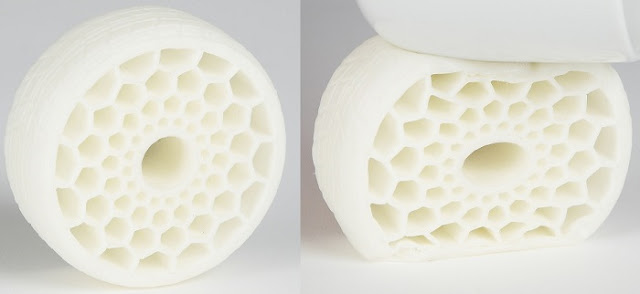

Soluble Support Material : PVA dissolves in water and is used for complex geometric models.

ENGINEERING PLA FILAMENT

ENGINEERING POLY-LACTIC ACID

Engineering PLA is a version of PLA filament formulated to have higher mechanical properties like strength than standard PLA. It is catered to the high demands of current 3D printing industries that need a filament that is both easy to use, sticks well to the print bed and still has the ability to print high-quality prints without much hassle. We highly recommend Engineering PLA for new 3D printing users due to its high predictability when in use.

We highly recommend Engineering PLA for new 3D printing users due to its high predictability when in use.

Material Properties

Strength

Engineering PLA strength is greater than the standard PLA and has great impact resistance for many use cases. Users can create great models and use EPLA to create tooling easily for their enterprise.

Ease

Engineering PLA has a low melting temperature and can benefit aesthetically from active cooling. This makes it a great filament to start with since it isn’t prone to warping like ABS.

Accuracy

EPLA is not prone to warping or cracking like other filaments, therefore tolerances are easier to achieve in comparison to other filaments.

Biodegradable

EPLA is derived from natural sources such as sugar-cane or corn. This makes it biodegradable and will degrade within 6-12 months if it is discarded.

Disadvantage

EPLA has some degradation issues where the colour fades as time passes, especially if it is exposed to direct sunlight.

Disadvantage

EPLA does not have much heat resistant properties and it begins to soften at 60ºC.

Material SpecificationsSpool Information

Outer Diameter200 mm

Centre Hole DiameterWidthThumbscrew TensionFilament Information

Filament Diameter1.75 mm( ± 2%)

Filament WeightFilament LengthSpecific Gravity1.27 g/cm³

PRINTING CHECKLISTExtrusion

Temperature

±210 ºC

Temperature management is key with any print object. If the temperature is too high then the printing process will include a lot of oozing and mess. If instead, prints are not adhering to the bed and you are getting blobs, then the temperature may be too low.

Bed Adhesion

Temperature

±40 ºC

Engineering PLA adheres to the print surface easily. It is one of the few filaments that does so . It doesn’t require a heated bed but it is recommended due to it helping to stabilise the temperature evenly. This is very key in the early stages of the printing process. EPLA doesn’t require a heated bed but it is recommended to

It doesn’t require a heated bed but it is recommended due to it helping to stabilise the temperature evenly. This is very key in the early stages of the printing process. EPLA doesn’t require a heated bed but it is recommended to

use one at temperatures between 40-60 ºC.

Bed

Adhesion

Options

Moisture & Storage

EPLA is not highly hygroscopic and does not require specialised storage set-ups and can be stored in is original filament box, ideally in a sealed bag with a moisture desiccant.

Drying before Printing

EPLA can be dried in an oven if it is not stored properly at a maximum temperature of 50 ºC for 6-12 hours.

Cooling

Cooling works well for EPLA prints because it is less likely to warp significantly in comparison to other filaments.

Your First Layers

EPLA has good inter layer bonding meaning that layer height adjustments mainly affect the aesthetics of the model.

Speeds

There are a number of printing speeds that can be adjusted for the printing process with EPLA which will reduce lead times but can reduce print quality. After gaining experience, this can help you determine how to achieve the desired results at a shorter time frame.

Skirt / Brim

Not required, but helps to reduce issues for larger

parts.

Support

Material

PVA or Breakaway

Priming Pillar

Used when printing with scaffold or dual colour models.

INDUSTRY EXAMPLE PRINT

Aircraft Bracket 3D Model

Engineering PLA parts are a great way to test out the aesthetics of a part. Once printed, parts can be easily painted to create parts with good tolerances to check fit and form for any project.

The part seen here is a topology optimised bracket for a aircraft which was printed using a breakaway support that was easily removed with a pair of pliers.

Engineering PLA has also great dimensional accuracy to test out various designs and how they can fit together to create a final product. It is easy to print and users can create many parts quickly using mirror mode on the Bolt Pro which can print two parts at once.

3D MODEL

FINAL PRINT

Previous

Next

ABS FILAMENT

ACRYLONITRILE BUTADIENE STYRENE

ABS filament is widely used already in standard manufacturing and this is due to it being highly durable and with the benefit of great strength. It is used to create visual prototypes, functional prototypes, tooling and also moulds that can be burnt away.

Although popular, ABS does have some caveats that need to be taken into consideration. It produces fumes when melted and needs to be enclosed during the printing process. Additionally, it is highly prone to warping due to high shrinkage during cooling and requires a heated print bed.

Material Properties

Strength

ABS offers great strength for parts and is often used to create tooling. It is more durable than EPLA and is often chosen because of this despite it having more stringent print settings.

Heat Resistant

Another desired property that ABS offers is it is highly heat resistant, which makes it ideal for a wide range of engineering needs.

Impact Resistant

ABS offers parts that are less brittle than EPLA parts. It is slightly more ductile, which creates parts that can withstand high impact situations.

Rigid

ABS printed parts are also highly rigid and do not bend easily. This property compounded with its strength properties means that parts can withstand stresses far more than EPLA.

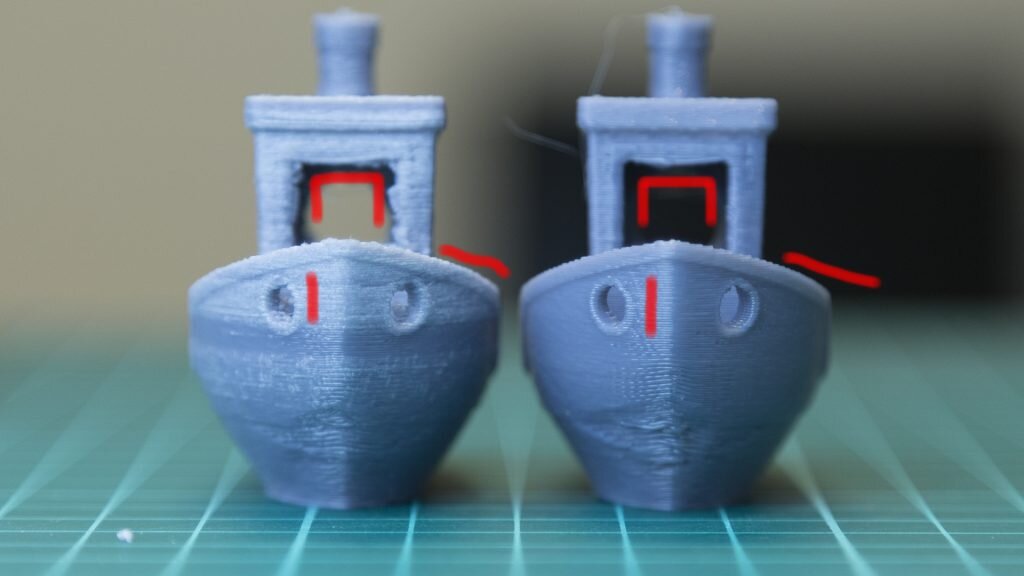

Disadvantage

ABS can warp significantly during the printing process. This is especially pronounced at the edges of your model as some areas cool faster than others which can pull the model of the print bed. This can be mitigated with proper adhesion techniques.

Disadvantage

Due to shrinkage, ABS has lower dimensional accuracy in comparison to EPLA or HIPS for example.

Material SpecificationsSpool Information

Outer Diameter200 mm

Centre Hole DiameterWidthThumbscrew TensionFilament Information

Filament Diameter1.75 mm( ± 2%)

Filament WeightFilament LengthSpecific Gravity1.04 g/cm³

PRINTING CHECKLISTExtrusion

Temperature

±230 ºC

ABS requires higher temperatures to be extruded. It is more sensitive to temperature during the printing process. One thing to note is ABS produces fumes when heated and requires printing with the enclosure closed.

Bed Adhesion

Temperature

±90 ºC

ABS has significant shrinkage when it is cooled. Because of this , it can causes warping where certain areas cool faster, shrink and pull on the layer structure when it is still molten. A heated print bed allows for these areas to remain temperature stable and reduces shrinkage. The addition of the flex-plate gives you the feature of easily being able to remove parts without damage. Printing larger parts can also face significant warping, therefore the best approach is to print parts using the enclosure after you ensure that the first layer is optimised. This will involve accurate bed levelling and using skirts and brims to help check that the extrusion process is proceeding accordingly.

A heated print bed allows for these areas to remain temperature stable and reduces shrinkage. The addition of the flex-plate gives you the feature of easily being able to remove parts without damage. Printing larger parts can also face significant warping, therefore the best approach is to print parts using the enclosure after you ensure that the first layer is optimised. This will involve accurate bed levelling and using skirts and brims to help check that the extrusion process is proceeding accordingly.

Bed

Adhesion

Options

Moisture & Storage

ABS is hygroscopic and requires to be stored away from open air. A good indication of too much moisture in the filament is excess fumes and oozing occurring while printing. Storing it with Silica bags will aid in the removal of excess moisture.

Drying before Printing

Although the filament softening temperature for ABS is at 80 ºC, the spool holder can be a different material and using an oven for 6-16 hours at 50 ºC should sufficiently dry the ABS filament and keep the spool intact.

Cooling

Considering that ABS has significant shrinkage during cooling, you should not use any cooling settings when printing otherwise your print will warp excessively.

Your First Layers

Increasing layer height may produce more visible plateauing because the effect of increasing layer heights which in the same vain increases the extrusion volume. This therefore needs to be taken into consideration when printing smaller parts.

Speeds

There are a number of printing speeds that can be adjusted for the printing process. For ABS it is good to keep speeds consistent during the printing process which will improve print quality.

Skirt / Brim

Recommended for ABS parts, both large and small.

Recommended for large surface area parts.

Support

Material

When printing with a support material, ABS goes best with HIPS due to the similar extrusion temperature. When printing is complete, HIPS is soluble in d-limonene and the model can be submerged in it where the HIPS dissolves away.

Priming Pillar

Required when using two materials such as HIPS as a support for ABS or a dual colour print.

INDUSTRY EXAMPLE PRINT

EDUCATIONAL MOLECULE PRINT

The model here was printed with ABS and HIPs as a support material. Although it is great for functional prototypes, it is also effective for visual parts because it can be post processed to achieve better visual fidelity.

Parts can be dropped and withstand various stresses which is great for long lasting prototypes or in this case a part that can be used for education demonstrations where it would likely face some wear and tear.

3D MODEL

FINAL PRINT

Previous

Next

PETG FILAMENT

POLYETHYLENE TEREPHTHALATE + GLYCOL

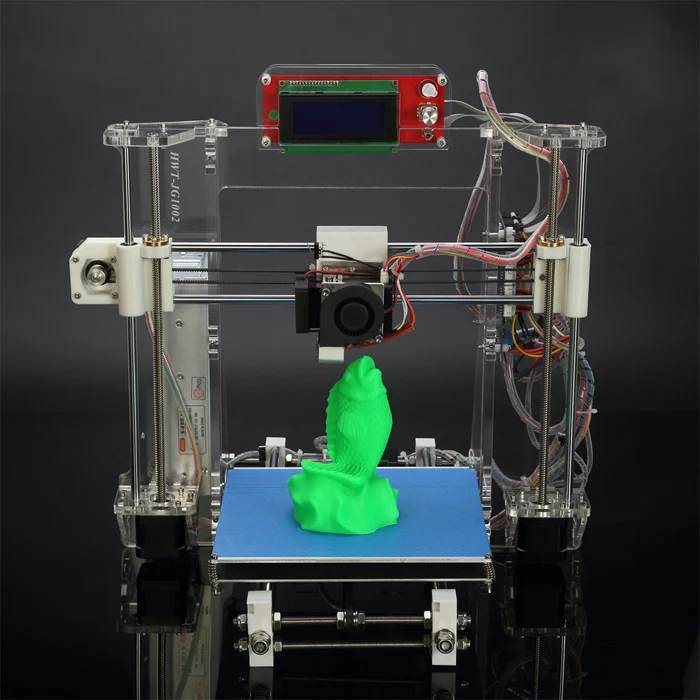

PETG is a very durable and a great material for a wide range of engineering requirements. Outside 3D printing, it is the most widely used plastic that is often used to create plastic liquid bottles.

Outside 3D printing, it is the most widely used plastic that is often used to create plastic liquid bottles.

This is due to its great ability to last and withstand abrasion. It offers parts that are strong and when printed with less infill, the parts are slightly flexible just like standard water bottles.

Material Properties

Strength

PETG is very strong and this allows it to withstand high pressures in comparison to other filaments. This is especially pronounce in load bearing applications.

Chemical Resistant

Considering its use in the creation of various containers, PETG is not affected by a wide selection of chemicals and this property is useful in certain engineering projects.

Impact Resistant

PETG has very high impact resistant properties with the added benefit of being ductile. This means its less brittle than ABS/EPLA and won’t break easily if a force is applied.

UV Resistant

In contrast to ABS, PETG parts aren’t affected as much by UV radiation and can withstand it better.

Disadvantage

Although strong, PETG parts scratch easy in comparison to other materials like PP.

Disadvantage

PETG can string a lot during the printing process.

Material SpecificationsSpool Dimensions

Outer Diameter200 mm

Centre Hole DiameterWidthThumbscrew TensionFilament Information

Filament Diameter1.75 mm( ± 2%)

Filament WeightFilament LengthSpecific Gravity1.27 g/cm³

PRINTING CHECKLISTExtrusion

Temperature

±230 ºC

PETG has a relatively high melting temperature. When it is molten, it has more elasticity properties than other non flexible filaments.

Bed Adhesion

Temperature

±70 ºC

PETG may have adhesion issues with standard beds, therefore it is recommended to use a heated bed. This will ensure proper adhesion and reduce warping during the printing process. To aid with adhesion, using a brim can help reduce possible warping especially with large surface area parts.

To aid with adhesion, using a brim can help reduce possible warping especially with large surface area parts.

Bed

Adhesion

Options

Moisture & Storage

PETG is highly resistant to liquids, this is not the same as being hygroscopic which PETG is and not storing it in a sealed air tight bag can affect print quality. A print with blobs and oozing is an indicator of this.

Drying before Printing

Similar to ABS, PETG has a high melting temperature but should be dried for 6-16 hours at 50 ºC if it is not stored properly to reduce moisture content.

Cooling

Cooling PETG is not required and is only beneficial for smaller parts with complex geometries.

Your First Layers

Layer height for PETG is a dependent on the requirement of the model. Smaller layer heights improve the overall aesthetics of the object.

Speeds

Optimising print speeds also can improve surface finish and how glossy the model becomes. PETG is prone to oozing and stringing therefore slower speeds can help. Furthermore, it is difficult to get good bridging with PETG because of this and needs to be taken into consideration when choosing what model to print.

PETG is prone to oozing and stringing therefore slower speeds can help. Furthermore, it is difficult to get good bridging with PETG because of this and needs to be taken into consideration when choosing what model to print.

Skirt / Brim

Not require, but if your model has issues adhering to the print bed, this may aid in reducing warping issues.

Support

Material

PVA or PETG breakaway.

Priming Pillar

Used when printing dual colour or with breakaway support.

INDUSTRY EXAMPLE PRINT

FUNCTIONAL PROTOTYPES

PETG is most associated with the production of bottles or containers because of its great chemical resistant properties. Apart form that however it has many other uses cases, especially in additive manufacturing.

One use case is to print outdoor brackets for various applications where a part is needed to withstand the effects of wear and tear where other thermoplastics would degrade rapidly if exposed to similar conditions.

Furthermore, it can also be used to create snap to fit components because PETG is ductile, especially when parts are thinner, while increasing infill makes it more stiff and rigid.

3D MODEL

FINAL PRINT

Previous

Next

NYLON FILAMENT

POLYMIDE

Nylon filament is a material that offers high durable and strong printed parts. Additionally, when printed at lower infill amounts, it can create slightly flexible parts.

Although similar to PETG, it offers far greater durability for engineering functional parts with the slight advantage of offering very low coefficient of friction parts.

Material Properties

Strength & Durability

Nylon is one of the strongest and most durable filaments on the market. It offers parts that can resist wear and tear and also offer great tensile strength.

Low Friction

Having a low coefficient of friction means that Nylon is a great material for producing parts like gears or parts that require motion.

Impact Resistant

Nylon parts have great impact resistance and can absorb impact forces with minimum deforming. They give users versatile options for prototyping applications.

Heat Resistant

Nylon allows for the creation of various engineering parts that can withstand high temperatures. Combining this attribute with the low friction feature can create strong functional prototypes.

Disadvantage

Achieving optimum bed adhesion can be challenging when printing with Nylon.

Disadvantage

Nylon is highly hygroscopic which will affect print quality if the filament is not dried properly.

Material SpecificationsSpool Information

Outer Diameter200 mm

Centre Hole DiameterWidthThumbscrew TensionFilament Information

Filament Diameter1.75 mm( ± 2%)

Filament WeightFilament LengthSpecific Gravity1.08 g/cm³

PRINTING CHECKLISTExtrusion

Temperature

±250 ºC

Nylon has a high extrusion temperature but be mindful of this since it can string and ooze more if the temperature is too high. If the temperature is too low, then it will have trouble adhering to the print bed.

If the temperature is too low, then it will have trouble adhering to the print bed.

Bed Adhesion

Temperature

±90 ºC

Due to its material properties, Nylon does not adhere well with most surfaces including BuildTak and needs higher heated bed temperatures. Nylon can warp significantly during the printing process and requires J8567 stickers to keep the first layer stuck to the build-plate.

This issue also transfers to the later stages of the printing process and can lead to cracking as some layers peel away from others. To reduce this issue, we recommend printing with the enclosure closed to reduce temperature changes and prevent cracking.

Bed

Adhesion

Options

Moisture & Storage

If Nylon filament is not stored correctly, printed models will have a rougher texture and you may face lots of oozing. You may hear popping or cracking sounds that indicate that it has absorbed too much moisture.

Drying before Printing

If the quality of your models are low, then drying Nylon filament in an oven for a period of 6-16 hours at 50 ºC and this should remove most of the exess moisture that has been absorbed.

Cooling

Nylon does not require cooling which can cause cracking due to shrinkage .

Your First Layers

Nylon does not have any layer height requirements apart from aesthetics. However, Nylon parts can crack, therefore increasing the shell layers can help reduce this.

Speeds

Nylon can warp and crack during the printing process and this can be reduced if inter layer bonding is increased. This is done with slower printing speeds that gives the filament time to bond correctly. Printing at higher speeds can create print failures more often.

Skirt / Brim

Not required, but helps to reduce issues, for larger parts.

Support

Material

It is recommended to use breakaway support with Nylon.

SPORT NYLON PRINT

As mention, Nylon parts have very low friction properties making it a great choice for a surfboard fin prototype. A part printed with Nylon also has the added benefit of being able to withstand high stresses which makes it ideal for tooling and functional parts that can be tested to gauge how well a design can perform in controlled situations.

3D MODEL

FINAL PRINT

Previous

Next

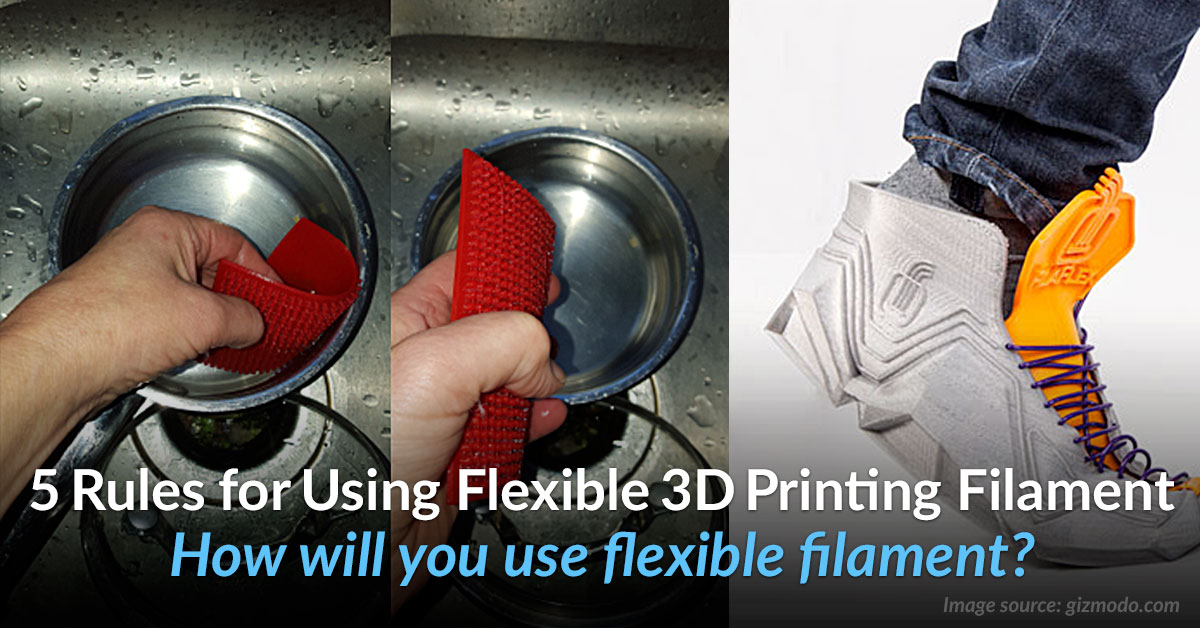

FLEX FILAMENT

Thermoplastic polyurethane (TPU)

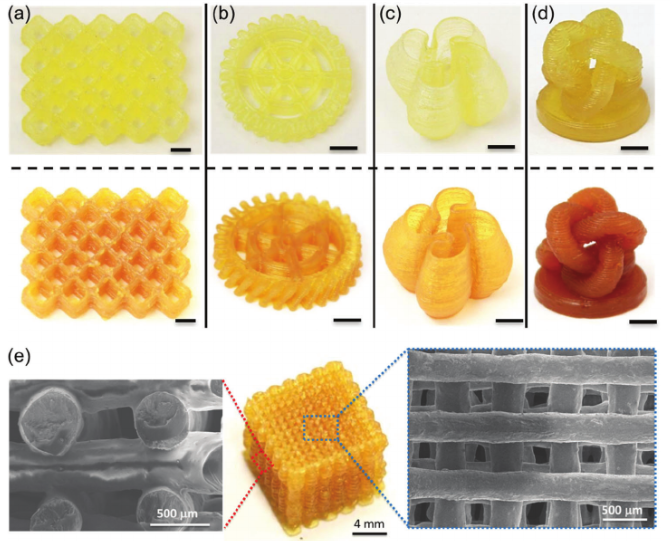

Flexible filament (TPU) is created by combining a standard polymer with rubber. This creates a filament that is very similar to what is used in standard manufacturing for parts in automobiles and many household items.

The printed objects that can be created are not only flexible, but have higher elasticity than most of the other slightly flexible filaments available.

Material Properties

Elasticity

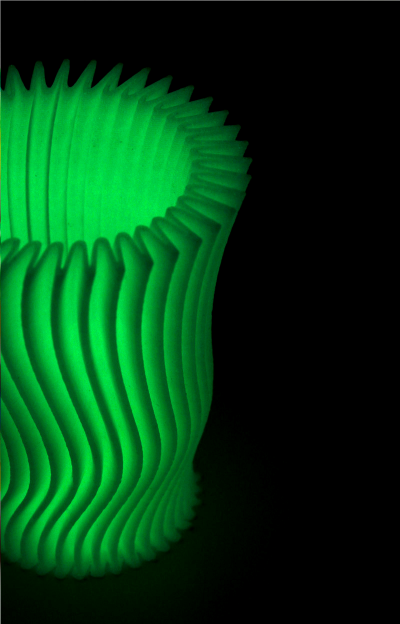

TPU parts are both highly elastic and flexible which offers a unique combination of 3D printing applications for both visual and functional prototypes.

Chemical Resistant

Parts produced with TPU are resistant to most standard chemical solutions which opens it up for a range of uses to create long lasting parts.

Impact Resistant

Flex parts are highly impact resistant due to its elastic rubber like properties.

Heat Resistant

Due to its abrasion resistant properties, coupled with the elasticity, flex parts will last and endure various stress depending on the build direction.

Disadvantage

TPU is challenging to print with because it strings significantly and can ooze. This is due to its elasticity properties making it harder to work with.

Disadvantage

TPU prints cannot be post processed after printing which can be a minus for visual prototypes.

Material SpecificationsSpool Information

Outer Diameter200 mm

Centre Hole DiameterWidthThumbscrew TensionFilament Information

Filament Diameter1. 75 mm( ± 2%)

75 mm( ± 2%)

1.20 g/cm³

PRINTING CHECKLISTExtrusion

Temperature

±230 ºC

Printing with Flex may involve some testing with the optimum temperature. Due to its properties, it may string if the temperature is to high and create messy prints.

Bed Adhesion

Temperature

±70 ºC

Flex filament may face some adhesion issues when printing and requires a relatively hot heated bed to ensure the filament stays on the print surface.

Bed

Adhesion

Options

Moisture & Storage

TPU absorbs moisture very easily and requires drying before printing. Additionally using a poly-box during the printing process will also aid in keeping the material dry during the printing process which is crucial for parts that require longer lead times.

Drying before Printing

To dry TPU, it should be heated in a oven for 12 hours to reduce moisture content at 50 ºC.

Cooling

It is recommended to use cooling for TPU since it is very viscous when molten and needs to be cooled to set it during the printing process.

Your First Layers

TPU is a challenging material to print with. It has higher risk of being plagued with blobs and oozing which can create rough parts. Additionally, it has poor bridging characteristics and prints better with objects that require consistent extrusion where there are less stops and starts of the extrusion process.

Speeds

TPU prints better with slow speeds. This again is due to its ability to stretch without breakage when molten which causes oozing and stringing. Faster speeds can lead to this and slower speeds allows the material to adhere better and settle per layer .

Skirt / Brim

Not require, but helps reduce issues, for larger parts.

Support

Material

PVA but take into consideration that objects with too many overhangs will be difficult when printing with Flex.

Priming

Pillar

Required when printing with support.

INDUSTRY EXAMPLE PRINTPRODUCT ACCESSORIES FLEX PROTOTYPE

TPU is often used to create parts that need to be elastic. One great use case is printing phone covers but it can also be used on other industries for example in the creation of car panel designs, shoe designs and for medical devices.

3D MODEL

FINAL PRINT

Previous

Next

PP FILAMENT

Polypropylene

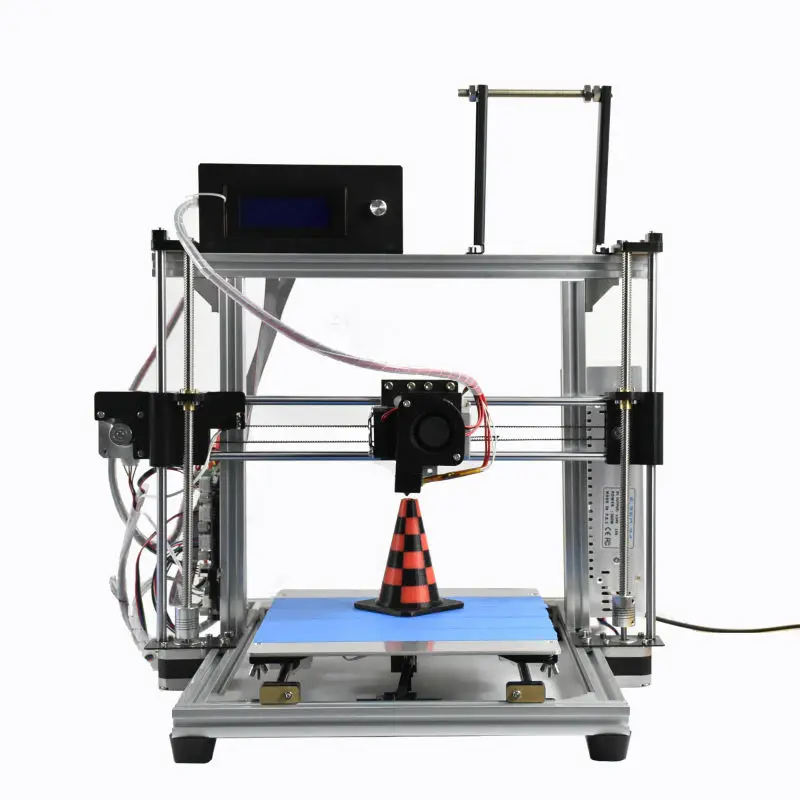

PP is a recent addition in the 3D printing world and offers some unique properties that make it an important material for engineering purposes. It is a semi crystalline polymer which means on a molecular level, once the material cools, it retains its molecular structure which has attributes of added strength and durability.If printed with lower infill settings, it can create flexible parts that have almost no bending failure properties, while increasing infill can create more rigid parts , but both types retain their material properties.

Material Properties

Heat Resistant

PP has great heat resistant properties meaning it is ideal for engineering applications. This mainly due to its melting temperature which is at 164 ºC.

Chemical Resistant

PP is not affected by most solvents and is often used to create containers for various chemicals.

Impact Resistant

Because off the semi-crystalline structure, PP is highly resistant to impacts. The flexibility features also make it useful since it is often used to create hinges in standard manufacturing.

Heat Resistant

PP is highly resistant to wear and can create parts that do not erode easily with heavy use. Furthermore, parts created are strong while being lightweight.

Disadvantage

PP does not bond well with any other material and this means it is not possible to print with standard adhesion methods apart from PP based adhesive products

Disadvantage

PP models cannot be post processed due to its adhesion issues.

Spool Information

Outer Diameter200 mm

Centre Hole DiameterWidthThumbscrew TensionFilament Information

Filament Diameter1.75 mm( ± 2%)

Filament WeightFilament LengthSpecific Gravity0.89 g/cm³

PRINTING CHECKLISTExtrusion

Temperature

±220 ºC

PP quickly settles back to its original molecular structure once it cools and therefore printing with it requires high temperatures. This ensures it flows smoothly during the printing process.

Bed Adhesion

Temperature

±80 ºC

Polypropylene is semi-crystalline which means it doesn’t adhere to any other material well. This brings about a problem because it won’t adhere to any print surface, other than its own. Therefore printing with PP requires the use of Tesa PP 57167 tape but not directly on the BuildTak Surface. Instead if you remove the Flex Plate and flip it around and use the tape on the sheet metal side to print on.

Instead if you remove the Flex Plate and flip it around and use the tape on the sheet metal side to print on.

Bed

Adhesion

Options

Moisture & Storage

PP is highly resistant to a lot of things . Although it is not hygroscopic its still recommended to store PP away from moisture. Keep your filament dry and away from direct sunlight.

Cooling

Cooling is not required for PP parts unless they are small and have complex geometries.

Your First Layers

PP can warp significantly during the printing process. Using larger layer heights increase the likely-hood of this since at the edges, the stresses that are created as the material cools can cause more warping with larger heights. Smaller layers create less stress and improve interlayer bonding.

Speeds

Printing with Polypropylene at higher speeds creates rough edges and parts that have poor adhesion between layers .Although this is true for all filaments, the effects are more pronounced with PP due to its material properties.

Skirt / Brim

Not required, but helps to reduce issues, for larger parts.

Support

Material

INDUSTRY EXAMPLE PRINTAUTOMOTIVE INDUSTRY PRINT

Carbon filament parts in 3D printing are often used as functional prototypes or as housings for models that need to withstand high impact forces. It is also often used to create levers because of its increased rigidity which is due to small carbon bits added to the base material in the spool.

3D MODEL

Research at Brigham Young University (CMR@BYU),

FINAL PRINT

Previous

Next

PVA FILAMENT

Scaffold

PVA is used as a soluble support material during printing complex parts. It works as a bridge material between open areas of the print which would otherwise deform.

Although it is possible in slicer software to use the same material as support, this often requires extra post processing to remove the break-away support and with some objects, this can create rough 3D prints.

PVA gives more flexibility and options for complex parts and can aid in producing complex parts in one pass unlike other manufacturing processes.

Material Properties

Water Soluble

PVA is soluble in water which means post processing is relatively easy. Depending on the amount used, all that is needed is to submerge the model in water for a few hours and the PVA melts away.

Great for Overhangs

Parts that require large overhangs for example arches, will need the use of PVA to support the print.

Disadvantage

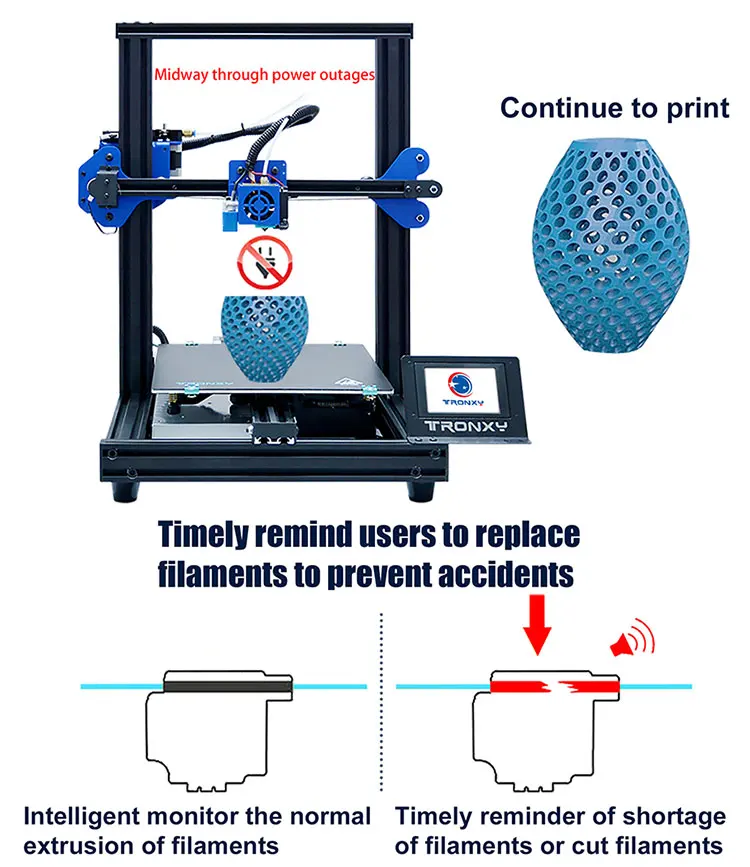

PVA needs to be stored in a airtight container because it is highly hygroscopic which will make the printing process difficult.

Disadvantage

PVA can cause clogging of the nozzles during the printing process. This is especially pronounced when the printing process requires the heated extruder to remain stationary for long periods of time.

Material SpecificationsSpool Information

Outer Diameter200 mm

Centre Hole DiameterWidthThumbscrew TensionFilament Information

Filament Diameter1. 75 mm( ± 2%)

75 mm( ± 2%)

1.19 g/cm³

PRINTING CHECKLISTExtrusion

Temperature

±215 ºC

PVA extrudes at a temperature slightly higher than EPLA which makes it the ideal material to use as for support. This is due to both materials being able to adhere to each other without issues. Larger temperature differences may cause issues when printing with support materials.

Bed Adhesion

Temperature

±40 ºC

As mentioned before, PVA and EPLA go well together and PVA adheres well with the print bed at around 40 ºC.

Bed

Adhesion

Options

Moisture & Storage

PVA is highly hygroscopic and this makes it prone to oozing during the printing process. This can affect your model significantly by blocking paths that the extruder has to work on and resulting in deformed parts.

Drying before

Printing

PVA has a relatively low melting point and needs to be dried if necessary at 45 ºC for 4-6 hours to dry.

Cooling

It is recommended to use cooling for PVA which helps to solidify it quicker so as to aid as a support structure during printing.

Prime Pillar

The purpose of a Prime pillar is twofold. It is a rectangular 3D part that is printed at the front of a model. It is only used when printing with two materials using the two extruder and is printed each time the extruder change. Its purpose is to prime the extruder to ensure they are properly heated and extruding properly. Additionally, it cleans the nozzles to remove excess dried filament, especially for material that oozes easily.

Skirt / Brim

Recommended

Support

Material

1. E-PLA works well, especially for large parts

2. TPU

3. PET/Co-polyesters

PVA SUPPORT PRINTEPLA MOLECULE MODEL WITH PVA SUPPORT

There are various separate settings that can be adjusted in your slicer software for support structures. You add your own or the software can automatically plot them for you. As you gain experience, you will start to understand different aspects so you can use less support depending on your model.

You add your own or the software can automatically plot them for you. As you gain experience, you will start to understand different aspects so you can use less support depending on your model.

SUPPORT MODEL

FINAL PRINT

HIPS FILAMENT

High Impact Polystyrene

HIPS is a filament that can both be used as a support material and also to create 3D prototypes. In terms of mechanical properties, it is very similar to ABS where it is often used as a support material due to the similar temperature properties allow both materials to stick to each other.

With HIPS you can create parts with great dimensional accuracy and like ABS , it can be machined further or painted in the post processing stage.

Material Properties

Dissolves in D-Limonene

HIPS dissolves in citrus based acids like D-Limonene where it can be used as a support material for complex parts that are made from namely ABS.

Great for ABS Overhangs

HIPS is a great support materials for complex ABS geometric 3D prints in the same way how PVA works well with PLA. This is due to it being able to adhere well to ABS during printing allowing for smooth parts once removed.

Impact Resistant and Easy to Print

HIPS is highly impact resistant and can be used to create proof of concept functional parts. HIPS creates great looking 3D prints and it is also inexpensive, which means it is ideal for rapid prototyping models.

Durable, Strong & Lightweight

HIPS is highly strong and also lightweight meaning it can be used to create a variety of functional prototypes.

Disadvantage

HIPS can face warping issues that can make it challenging to print.

Disadvantage

HIPS is hygroscopic and needs to be stored in a airtight bag.

Material SpecificationsSpool Information

Outer Diameter200 mm

Centre Hole DiameterWidthThumbscrew TensionFilament Information

Filament Diameter1. 75 mm( ± 2%)

75 mm( ± 2%)

1.03 g/cm³

PRINTING CHECKLISTExtrusion

Temperature

±230 ºC

HIPS has a high melting temperature and this makes it a great support material for ABS parts which would normally melt PVA support.

Bed Adhesion

Temperature

±90 ºC

HIPS can warp and in order to help it adhere to the print bed, a high temperature setting will allow it to remain fixed during the printing process.

Bed

Adhesion

Options

Moisture & Storage

With any filament, it is highly recommended to store HIPS in a sealed bag since it will allow for the material to last and create better prints.

Drying before Printing

HIPS has a low sensitivity to moisture but if not stored properly then it should be dried in a oven for a period of 6-12 hours at 50 ºC.

Cooling

HIPS does not require cooling, however when printing smaller parts it can be beneficial.

Your First Layers

HIPS is relatively easy to print with and works similar to EPLA in terms of easy of use apart from the higher temperature requirements.

Speeds

TPU prints better with slow speeds. This again is due to its ability to stretch without breakage when molten which causes oozing and stringing. Faster speeds can lead to this and slower speeds allows the material to adhere better and settle per layer .

Skirt / Brim

Recommended for large parts and parts with a narrow base.

Support

Material

HIPS can be used as a support material for ABS prints.

Priming

Pillar

When using HIPS as a support material, the best process is to use a prime pillar which helps with ensuring extrusion settings and temperature settings are correct during each new layer pass. This is due to the switching of the extruder hot-ends for each new layer.

ENGINEERING ABS PRINT WITH HIPS

HIPS as a support material has various settings similar to PVA apart from the extrusion temperature. One key though that is different is that HIPS is also great as a prototyping material which can create great models. It has a smooth finish and great mechanical properties which means you can achieve functional prototypes with it as well.

3D MODEL

FINAL PRINT

Previous

Next

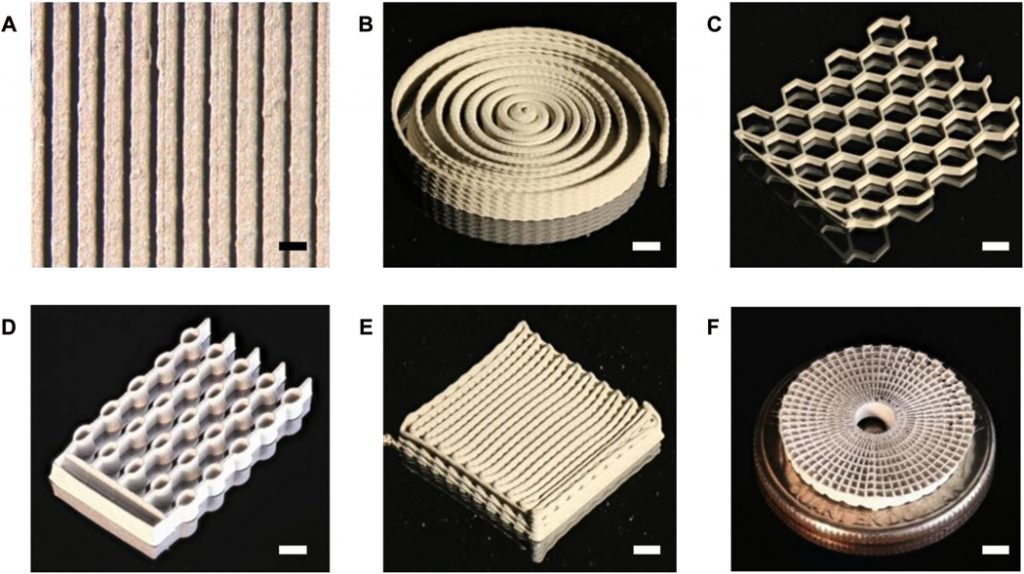

CARBON FILAMENT

PETG+Carbon

One key distinction that needs to made is that Carbon filament is not the same as standard carbon fibre. Carbon filament is created by combining shorter carbon fibre with another common material like PetG which is then used to create the carbon filament spool. Despite this, the printed object still benefits from the strength properties while still remaining lightweight. It has improved tensile strength and can create really rigid parts.

It has improved tensile strength and can create really rigid parts.

One key note before printing is carbon filament requires the Bolt Pro NozzleX hot-ends which are abrasion resistant. Using standard nozzles will damage them and lead to clogging.

Material Properties

Strength

Carbon printed parts offer really high strength parts that are stiff and very rigid. These parts can be used with great effect for functional prototypes.

Lightweight

The added benefit of using carbon filament is in conjunction with the strength properties, parts are also extremely lightweight which opens up a wide range of use cases for engineering.

Impact Resistant

Parts produced with carbon filament have impact resistance which is comparable or even exceeds other printing materials in the market.

Durable and Heat Resistant

Unlike ABS and PLA, carbon printed parts have the additional benefit of being very abrasion resistant which offers longer lasting parts that look good and function well with great heat resistant.

Disadvantage

Carbon filament is abrasives and can clog and ruin non specialised nozzles.

Disadvantage

Carbon prints are an abrasive finish and cannot be post processed.

Material SpecificationsSpool Information

Outer Diameter200 mm

Centre Hole DiameterWidthThumbscrew TensionFilament Information

Filament Diameter1.75 mm( ± 2%)

Filament WeightFilament LengthSpecific Gravity1.19 g/cm³

PRINTING CHECKLISTExtrusion

Temperature

±230 ºC

Since the carbon filament is mixed with PETG, the print settings mostly reflect the same setup. One thing to be mindful is carbon can clog a lot and requires specialised metallic nozzles.

Bed Adhesion

Temperature

±70 ºC

Carbon has an average chance of warping during the printing process and requires the printing environment to be enclosed to maintain a constant temperature. The bed temperature settings are similar to PETG again as that is the base material in the filament spool and needs to be high enough to adhere properly to the build surface.

The bed temperature settings are similar to PETG again as that is the base material in the filament spool and needs to be high enough to adhere properly to the build surface.

Bed

Adhesion

Options

Moisture & Storage

Storage of carbon requires it to be sealed and stored away from sunlight to uphold its quality.

Cooling

Carbon does not require cooling when printing.

Your First Layers

As with PETG, layer heights are highly dependent on the type of model that is being printed. This is mainly due to the combination of both materials that can create varying results during the printing process. Another matter to note is the size of the hot-end needs to be at least 0.4mm which is due to the carbon fibres that can build up with smaller nozzle sizes and create clogs during the printing process.

Speeds

Carbon prints work well with lower speeds and may not have the same fast speed settings that are available with filaments like ABS and PLA. This is mainly due to the fibres that can clog the extruder, especially if they build up.

This is mainly due to the fibres that can clog the extruder, especially if they build up.

Skirt / Brim

A skirt or brim is recommended when printing carbon

Support

Material

Breakaway support is recommended for carbon filament.

INDUSTRY EXAMPLE PRINTTOOLING PRINT EXAMPLE

PP is very strong and durable plastic that has great fatigue resistant properties. For this model, we chose to print a compliant pliers designed by BYU CMU which operates without the use of multiple parts to create a functional tool or part. This is a great use case for PP because it has great wear and tear resistance and can be both ductile and more stiff when printed with higher infill to create a wide range of different parts.

3D MODEL

FINAL PRINT

Previous

Next

Share on facebook

Facebook

Share on twitter

Twitter

What Are the 6 Different 3D Printer Filament Types?

Consumer 3D printers are no longer restricted to ABS and PLA filaments. The popularity of additive manufacturing technology has led to the influx of many engineering plastics. Although ABS and PLA remain popular, many 3D printing enthusiasts have switched to newer materials.

The popularity of additive manufacturing technology has led to the influx of many engineering plastics. Although ABS and PLA remain popular, many 3D printing enthusiasts have switched to newer materials.

So, here is everything you need to know about different 3D printing filaments and how to choose one for your specific needs.

How to Choose a 3D Printing Filament

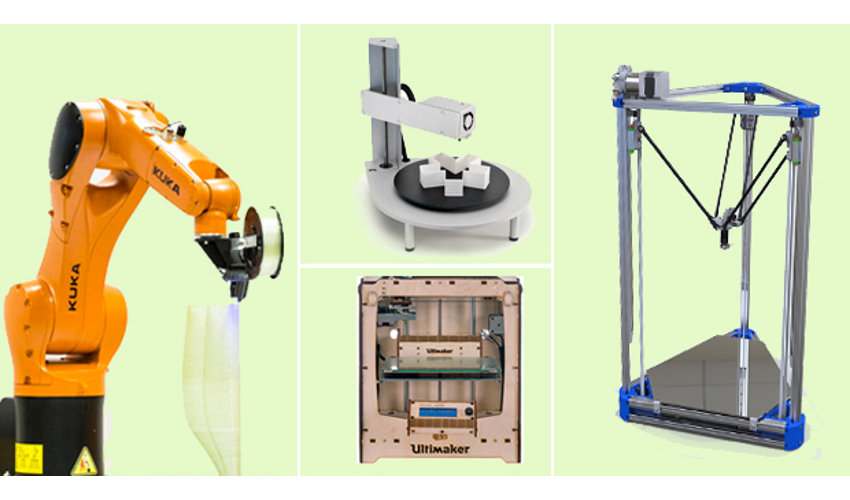

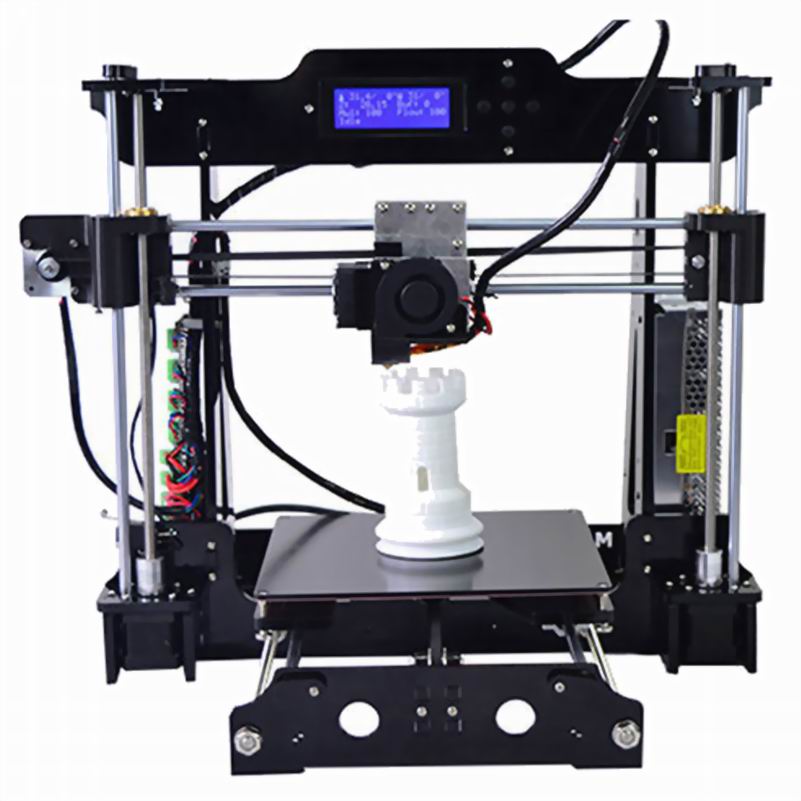

3D printing is unlike most run-of-the-mill hobbies. It involves sophisticated robots creating complicated objects using exotic materials. Like all advanced engineering endeavors, 3D printing relies on the users’ ability to read and follow technical data sheets. Knowing how to make sense of these documents is key to knowing which 3D printing filament to use for specific applications.

Image Credit: Nachiket Mhatre There’s no need to bother with this if your 3D printing needs are restricted to cosmetic prints because PLA is all you will ever need. Printing functional parts, however, needs an understanding of various filament parameters, such as tensile strength, toughness/flexibility, heat resistance, durability, creep, and warping.

So, what are the best 3D printing filaments, and when should you use one over another?

1. PLA (Polylactic Acid)

Polylactic Acid is to 3D printing what training wheels are to bicycles. It’s incredibly easy to print on even the cheapest 3D printers. With print temperatures beginning as low as 180°C, you don’t need an all-metal hot end to print this filament safely. PLA doesn’t even require a heated bed, as long as the ambient room temperature is maintained above 20°C.

Image Credits: Nachiket MhatreThe material practically doesn’t warp and can bridge extremely well if you give adequate part cooling. Not sure what all those terms mean? Check out our Ender-3 upgrade guide to learn more about all-metal hot ends and 3D printer safety.

The bottom line: it’s incredibly difficult to ruin a PLA print. This allows beginners to gradually learn the many complicated aspects of 3D printing without hitting the brick wall of repeated print failures. As a beginner, sticking to PLA makes it easy to grasp the fundamentals of bed adhesion, first layer calibration, overhangs, and bridging. PLA is the optimal way to test the limits of 3D printing without having to second-guess your printer calibration and slicer settings.

PLA is the optimal way to test the limits of 3D printing without having to second-guess your printer calibration and slicer settings.

PLA Filament Properties

- Printability: Excellent

- Color Selection: Excellent

- Heat Resistance: Poor

- Tensile Strength: Excellent

- Toughness: Poor

- UV Resistance: Excellent

- Moisture Resistance: Excellent

- Creep Resistance: Poor

When Should You Use PLA 3D Printing Filament?

PLA is great for cosmetic 3D prints but not so much for anything else. Despite its high tensile strength, it lacks toughness because the material is too hard to flex. This makes it brittle and susceptible to cracking in applications requiring impact resistance and bending. Its low-temperature printability also translates into poor heat resistance. PLA prints warp when subjected to direct sunlight or in-car conditions due to the material’s low glass transition temperature of 57°C.

PLA prints warp when subjected to direct sunlight or in-car conditions due to the material’s low glass transition temperature of 57°C.

PLA’s tendency to creep, or to permanently deform under load at room temperature, makes it unviable for any functional print that either uses fasteners or serves any load-bearing purpose. Consequently, most 3D printing enthusiasts move to other materials once they have mastered slicer settings and 3D printer tuning with PLA.

2. PETG (Polyethylene Terephthalate Glycol)

PETG should ideally be your second filament challenge once you have mastered PLA. It is quite similar to the plastic found in water bottles and food containers, except for the addition of glycol to improve printability. PETG is better than PLA in most important parameters. It’s slightly tougher, significantly more heat resistant, exhibits excellent creep resistance, and is therefore suitable for functional 3D printing.

Image Credit: Nachiket Mhatre However, it is also slightly more difficult to print. That isn’t entirely a bad thing. While it is virtually impossible for a well-tuned printer to mess up PLA prints, getting PETG right requires a better understanding of slicing software and first layer calibration. This makes the filament a safe way to learn these concepts, which are vital to mastering other technically challenging 3D printing filaments.

That isn’t entirely a bad thing. While it is virtually impossible for a well-tuned printer to mess up PLA prints, getting PETG right requires a better understanding of slicing software and first layer calibration. This makes the filament a safe way to learn these concepts, which are vital to mastering other technically challenging 3D printing filaments.

PETG is also quite hygroscopic, so drying it before printing is necessary if you live in a humid area. The prints themselves aren’t prone to moisture absorption, but a wet filament will cause extrusion and print quality issues. The material can bond permanently to most 3D printing surfaces if the first layer is printed too close to the build surface.

The sticky, viscous nature of the molten filament also makes it a poor choice for bridging and steep overhangs. However, that also translates into the best layer adhesion despite its low printing temperature.

PETG Filament Properties

- Printability: Good

- Color Selection: Good

- Heat Resistance: Average

- Tensile Strength: Good

- Toughness: Good

- UV Resistance: Excellent

- Moisture Resistance: Poor

- Creep Resistance: Good

When Should You Use PETG 3D Printing Filament?

PETG is the perfect compromise between PLA and the much superior ABS filaments. While it lacks the higher temperature resistance of ABS, it is still good enough for prints to be used outdoors or car interiors. It is also considerably tougher than PLA and ideal for applications where impact resistance is desired. PETG’s resistance to creep also makes it ideal for functional prints and 3D printer components alike.

While it lacks the higher temperature resistance of ABS, it is still good enough for prints to be used outdoors or car interiors. It is also considerably tougher than PLA and ideal for applications where impact resistance is desired. PETG’s resistance to creep also makes it ideal for functional prints and 3D printer components alike.

3. TPE/TPU/TPC (Thermoplastic Elastomer/Polyurethane/Copolyester)

TPE comprises a number of plastics with rubber-like properties. Such filaments are used in applications where flexibility is desired. Regular flexible filaments marketed as TPE are available in various shore hardness, which is a measure of flexibility. In fact, TPE incorporates a broad category of filaments, including urethane-based TPU, which is slightly more rigid to improve printability. TPC is a copolyester-based variant with improved resistance to heat, UV, and chemical agents.

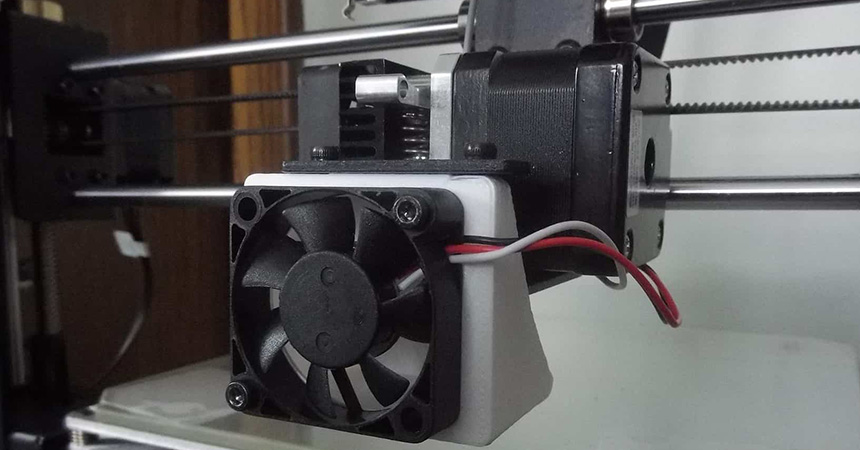

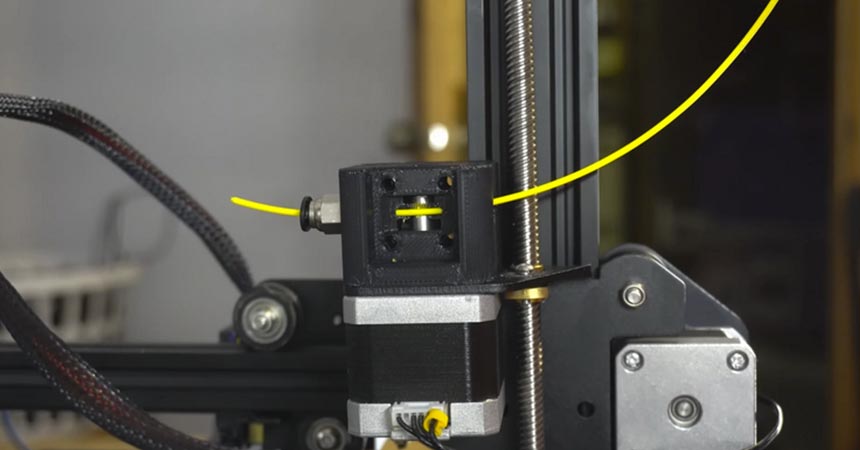

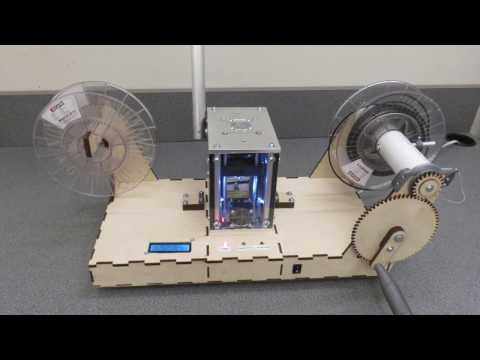

Printing with TPE and its variants are challenging due to the inherent flexibility of the filament. These filaments are particularly difficult to print with Bowden extruders since the lack of rigidity makes it difficult to push the filament through the nozzle. Therefore, direct drive extruders, with a short filament path between the extruder gears and nozzle, are recommended for reliable printing.

These filaments are particularly difficult to print with Bowden extruders since the lack of rigidity makes it difficult to push the filament through the nozzle. Therefore, direct drive extruders, with a short filament path between the extruder gears and nozzle, are recommended for reliable printing.

The tendency of the filament to compress and elongate also makes retractions unreliable. This leads to excessive stringing in prints, which requires expertise to mitigate. It is also recommended to print these flexible filaments on an unheated bed, preferably with a release agent, such as a glue stick or hairspray. Failure to do that often results in the prints permanently bonding to the build surface.

TPE Filament Properties

- Printability: Average

- Color Selection: Average

- Heat Resistance: Average

- Tensile Strength: Average

- Toughness: Excellent

- UV Resistance: Good

- Moisture Resistance: Poor

- Creep Resistance: Good

When Should You Use TPE/TPU/TPC 3D Printing Filament?

These flexible filaments are excellent in applications where impact resistance, bendability, wear, and grip are more desirable than rigidity. TPE and TPU are regularly used to 3D print gaskets, phone covers, and wristbands for wearable devices. TPC is a more expensive alternative that offers additional temperature and chemical resistance suitable for harsh environments.

TPE and TPU are regularly used to 3D print gaskets, phone covers, and wristbands for wearable devices. TPC is a more expensive alternative that offers additional temperature and chemical resistance suitable for harsh environments.

4. ABS (Acrylonitrile Butadiene Styrene)

ABS, in its injection molded avatar, is found in most consumer products in the form of automobile dashboards and switchgear, toys, pipe fittings, and as the chassis of most consumer durables. Not surprisingly, its familiarity, price, and availability made it the material of choice for the commercial 3D printing industry. It’s a terrific material with an unmatched price-to-performance ratio and good heat resistance.

Image Credit: Nachiket Mhatre Its heat resistance makes it incompatible with the cheap PTFE-lined hot ends. Most ABS filaments require nozzle temperatures of around 250°C. This makes all-metal hot ends mandatory for safe printing. The filament also off-gasses harmful VOCs (volatile organic compounds) such as styrene, which are known to negatively impact health. Learn how ABS compares to PLA in our ABS vs. PLA comparison.

Learn how ABS compares to PLA in our ABS vs. PLA comparison.

ABS filament’s tendency to warp makes it difficult to print unless you own a printer with a heated enclosure, like the Voron series of DIY 3D printers. Delamination, bed adhesion, and warping are persistent issues on large ABS prints on unenclosed printers. Having said that, most modern ABS filament blends print fine, as long as you keep the build volume enclosed and use the heated bed as a passive heat source. Carbon fiber and glass fiber-enhanced ABS composite filaments mitigate these issues to a great extent.

ABS Filament Properties

- Printability: Average

- Color Selection: Average

- Heat Resistance: Good

- Tensile Strength: Good

- Toughness: Good

- UV Resistance: Average

- Moisture Resistance: Good

- Creep Resistance: Excellent

When Should You Use ABS 3D Printing Filament?

ABS exhibits good tensile strength and toughness, which makes it ideal for functional prints and even some engineering applications. The material can be used in high-temperature applications such as 3D printer hot end components and functional prints for car interiors. Any engineering scenario that demands resistance to heat, impact, and wear can be met cheaply with ABS.

The material can be used in high-temperature applications such as 3D printer hot end components and functional prints for car interiors. Any engineering scenario that demands resistance to heat, impact, and wear can be met cheaply with ABS.

5. ASA (Acrylonitrile Styrene Acrylate)

ASA is a modified form of ABS that is easier to print and exhibits improved UV resistance. Large ASA prints are easier thanks to their tendency to warp less than ABS. Most ASA filaments also tend to off-gas less VOCs while printing.

And all this is achieved while maintaining the strength, toughness, and temperature resistance comparable to ABS. We see no reason to choose ABS if you can afford the slight premium commanded by ASA filaments.

ASA Filament Properties

- Printability: Good

- Color Selection: Average

- Heat Resistance: Good

- Tensile Strength: Good

- Toughness: Good

- UV Resistance: Excellent

- Moisture Resistance: Good

- Creep Resistance: Excellent

When Should You Use ASA 3D Printing Filament?

ASA can be used for the same applications as ABS, with the added versatility of maintaining durability and color integrity despite heavy exposure to sunlight.

6. PA (Polyamide or Nylon)

Polyamide, better known as its brand name Nylon, is found in consumer durables in the form of gears, hinges, and sliding components—basically in any application that calls for extreme wear resistance, low friction, excellent toughness, and some degree of temperature tolerance. PA is indispensable in powder-sintered 3D printing processes employed in commercial SLS 3D printers.

Image Credit: Nachiket MhatreNylon also exists in the FDM 3D printing space in various blends offering different compromises between heat resistance, toughness, durability, and creep resistance. The latter is important because the material exhibits a tendency to heat creep in its natural state. Therefore, most engineering applications require PA blended with carbon or glass fiber to improve tensile strength, creep resistance, and temperature tolerance.

The material’s high glass transition temperature and an innate tendency to warp make it difficult to print on cheap, unenclosed printers. Furthermore, PA’s chronic tendency to absorb moisture requires filament dryers that can reliably maintain 80°C chamber temperatures. In fact, successful printing also requires the filament to be routed through a dry box while printing. It’s a great engineering filament that demands a capable printer and an experienced operator.

Furthermore, PA’s chronic tendency to absorb moisture requires filament dryers that can reliably maintain 80°C chamber temperatures. In fact, successful printing also requires the filament to be routed through a dry box while printing. It’s a great engineering filament that demands a capable printer and an experienced operator.

PA Filament Properties

- Printability: Poor

- Color Selection: Poor

- Heat Resistance: Good

- Tensile Strength: Good

- Toughness: Excellent

- UV Resistance: Average

- Moisture Resistance: Poor

- Creep Resistance: Average

When Should You Use PA 3D Printing Filament?

Functional PA prints work well as mechanical parts, such as gears, hinges, and levers. The material is also tough enough to be used to manufacture custom tools and prototypes requiring strong meshing parts subjected to friction and impact. Various glass fiber and carbon fiber blends can also be used to modify the rigidity and flexibility of the material to suit different engineering demands.

Various glass fiber and carbon fiber blends can also be used to modify the rigidity and flexibility of the material to suit different engineering demands.

6. PC (Polycarbonate)

PC is one of the strongest 3D printing filaments accessible to consumer 3D printers. How strong, you ask? Well, the material is used to manufacture everything from bullet-proof glass to fighter jet canopies. PC can withstand temperatures as high as 110°C, with some blends even outperforming that impressive figure.

PC has the unique distinction of exhibiting high tensile strength while also being extremely impact resistant. This gives it the distinction of excelling in applications where even Nylon falls short. However, these physical properties make PC challenging to print. It isn’t uncommon for some PC blends to require nozzle temperatures of 300 °C, with the heated bed maintained in excess of 100 °C.

The material is also prone to excessive warping and only adheres well to polycarbonate build surfaces or polyimide tape. However, like Nylon, PC is available in various blends, making it more printable.

However, like Nylon, PC is available in various blends, making it more printable.

PC Filament Properties

- Printability: Poor

- Color Selection: Poor

- Heat Resistance: Excellent

- Tensile Strength: Excellent

- Toughness: Excellent

- UV Resistance: Excellent

- Moisture Resistance: Poor

- Creep Resistance: Excellent

When Should You Use PC 3D Printing Filament?

PC is employed in various industrial, automotive, and electrical applications—especially those requiring high strength and temperature resistance. The inherent optical clarity of the material also makes it ideal for transparent prints, as long as the wall thickness is kept minimal.

Choose Your 3D Printing Filament Wisely

Now that you have a handy means to compare various physical properties and performance parameters of consumer-grade filaments, choosing the right one is a matter of evaluating which parameters are best suited to your particular applications.

If you are new to 3D printing, we recommend starting with PLA and graduating to PETG before taking on more challenging materials such as ABS and Nylon.

What is the best plastic for 3D printing? Let's figure it out together!

Plastic for 3D printing

After purchasing your own FDM 3D printer, as well as in the course of choosing it, it becomes necessary to choose the right plastic for 3D printing. But how to do this if you are new to 3D printing and have little to no understanding of this issue? Plastic for printing on a 3D printer is in most cases the main component of successful product reproduction. Therefore, we will not save on knowledge, and will tell you how to choose the best plastic for 3D printing.

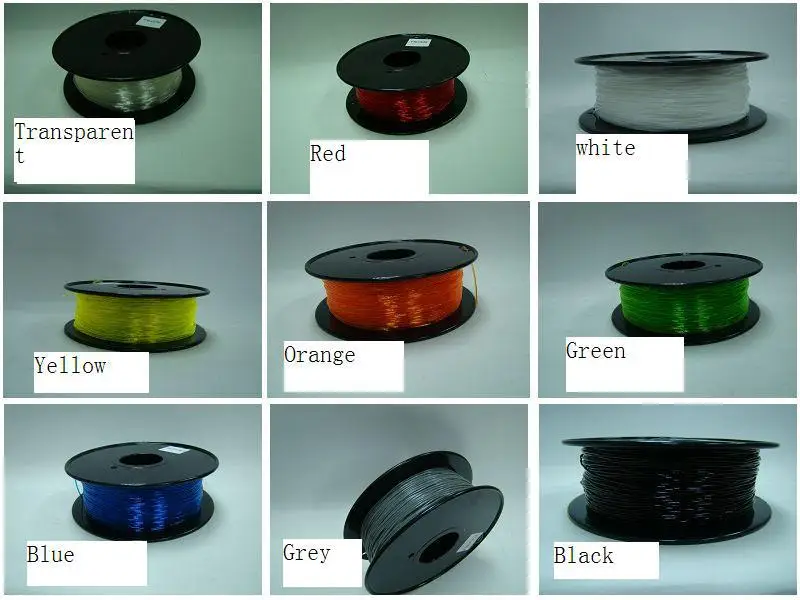

Types of plastic for a 3D printer

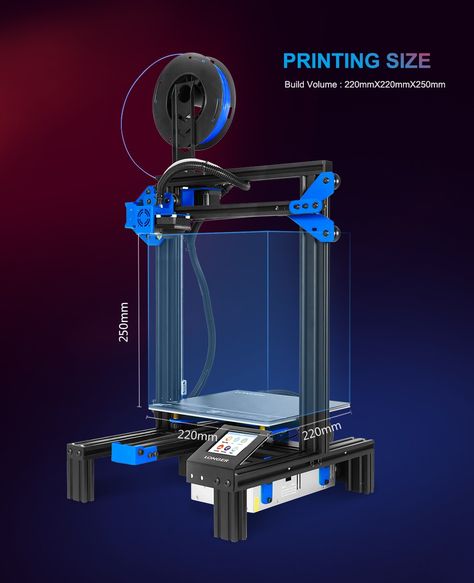

First of all, we need to consider the types of plastic for a 3D printer. Plastic for 3D printing, or filament, is produced in the form of a thin thread with a diameter of 1.75 mm and 3 mm. Most often, filaments with a thickness of 1. 75 mm are used in the basic configuration, but some manufacturers of 3D printers provide the ability to install a 3 mm plastic feed system. Plastic for 3D printing has many varieties, among which the most common are ABS and PLA plastic.

75 mm are used in the basic configuration, but some manufacturers of 3D printers provide the ability to install a 3 mm plastic feed system. Plastic for 3D printing has many varieties, among which the most common are ABS and PLA plastic.

Plastic for 3D printing: varieties

By popularity in the Ukrainian market, the following types of plastic for 3D printing can be distinguished:

- PLA (PLA) or polylactide. Organic and short lived. Suitable for 3D printing of decorative products, but not able to withstand high mechanical loads;

- ABS (ABS) or acrylonitrile butadiene styrene. It has a long life and excellent mechanical properties. Heat-resistant and used for industrial purposes. Shrinks on cooling. It is recommended to print in ventilated areas;

- PVA (PVA) or polyvinyl alcohol. A water-soluble material that is used as a support;

- Nylone (Nylon). An alternative to ABS plastic, suitable for many engineering structures. When printing with nylon, it is recommended to ventilate the room;

- HIPS (High Impact Polystyrene).

In terms of physical properties, it is a cross between PLA and ABS. May also emit toxic fumes when printed.

In terms of physical properties, it is a cross between PLA and ABS. May also emit toxic fumes when printed.

Other questions and answers about 3D printers and 3D printing:

What is the best plastic for a 3D printer?

In fact, there are many more types of plastic for 3D printing. This can include flexible, fluorescent and luminescent filament, wood and metallized materials. But in practice, such consumables are rarely used and are needed for narrowly specific purposes. Metallized plastics are interesting in their own right, but they are at the initial stage of development and are inferior in performance to ordinary reinforced materials. “And what plastic is best for a 3D printer?” - you ask. You should choose based on specific goals. If you intend to print decorative elements that will not be subject to payload, you can look at PLA plastic. If your goal is to print gears, structural parts and other things, look at reinforced materials for 3D printing.

What plastic to print with?

Please note that not every printer supports the full range of 3D printing materials. Before buying a specific filament, check the specifications of your own device to avoid wasting money. The rest is up to you and your imagination. A huge range of colors and shades of plastic is available for sale, matte and glossy, semi- and fully transparent materials. Such a variety will allow you to make almost any product to your taste.

Before buying a specific filament, check the specifications of your own device to avoid wasting money. The rest is up to you and your imagination. A huge range of colors and shades of plastic is available for sale, matte and glossy, semi- and fully transparent materials. Such a variety will allow you to make almost any product to your taste.

Remember that if you need to buy plastic for 3D printing - 3DDevice store is at your service! We offer a wide range of different materials in all possible color options and are ready to provide advice when choosing a filament.

If you have additional questions that we have not covered, write to us by e-mail and we, if necessary, will add your questions! Best regards, 3DDevice team. We also provide 3D modeling, 3D scanning and 3D printing services. We work all over Ukraine! If you have any questions, please contact us in any way convenient for you. Contacts are listed here. We look forward to collaborating!

Back to Home

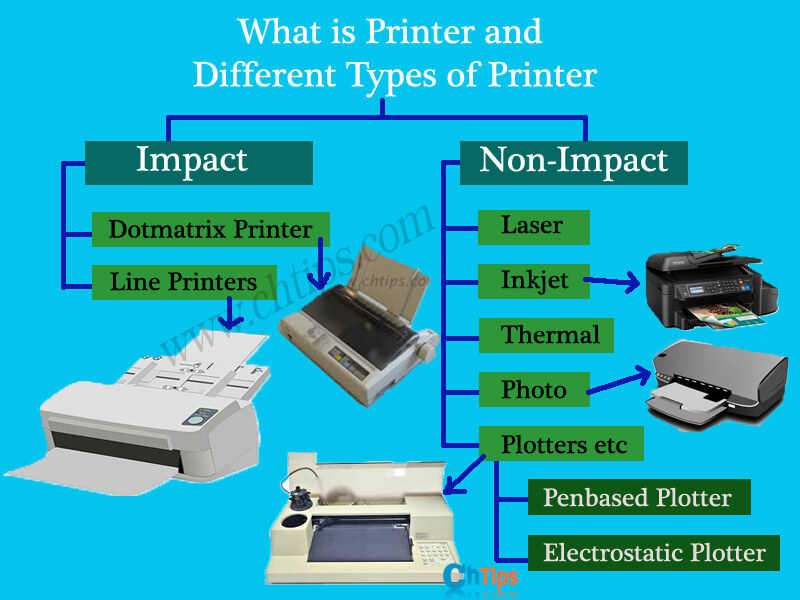

Types of 3D Printer Plastic Filament

3D Printer Plastic Filament is one of the most important materials for 3D printing, as no 3D object can be created without it. Threads come in different types, their choice should depend on the model you want to print.

Threads come in different types, their choice should depend on the model you want to print.

Filament or 3D Filament is a 3D printer plastic that is used for 3D printing. In 3D printing, the most popular filaments are ABS (acrylonitrile butadiene styrene) and PLA (polylactic acid).

However, besides ABS and PLA , there are many more threads.

Types of 3D Printing Filament

Here is a list of different types of 3D printing filaments:

#1. ABS 3D Printing Filament

Acrylonitrile Butadiene Styrene, also known as ABS filament , is the most popular 3D printer filament. In fact, this filament is used in a wide variety of applications because high quality ABS is impact resistant.

This plastic for 3D printer is strong and slightly flexible, making it a good material for 3D printing. In addition, ABS is easy to extrude.

Printing temperature range: 210°C - 250°C

ABS plastic can be used to make some moving parts, some automotive parts, electronics cases. In production, it is used to create protective headgear (helmets), various musical instruments, even Lego constructors are made of this plastic.

In production, it is used to create protective headgear (helmets), various musical instruments, even Lego constructors are made of this plastic.

| ABS Pros | Cons of ABS |

|

|

#2. PLA

3D Printing Filament Polylactic Acid or PLA filament is another popular 3D printing filament that is often compared to ABS. PLA plastic is a biodegradable thermoplastic that is made from corn starch, sugar cane, tapioca roots, and potato starch.

This 3D printing filament is more environmentally friendly than other thermoplastics. Because of this, and more specifically because of its low toxicity, PLA is often chosen over ABS. Therefore, it is the most popular plastic for 3D printing.

Unlike ABS , PLA filament does not produce a toxic odor during printing, so it is safer to use at home or in class at school.

Printing temperature range: 180°C - 230°C

PLA filament has the ability to degrade in the human body to harmless lactic acid, and due to this property it is used in medical suture and surgical implants. Surgically implanted screws, pins, rods or meshes naturally break down in the human body within 6 months to 2 years.

In addition, PLA filament is considered safe. Thus, this thread is used for the manufacture of food packaging, candy wrappers, disposable tableware, as well as hygiene products.

| Pros of PLA | Cons of PLA |

|

|

#3. PVA

3D Printing FilamentPolyvinyl alcohol, better known as PVA filament, is another great 3D filament. PVA is a special water-soluble plastic. This type of filament is based on polyvinyl alcohol, so it has quite good properties such as non-toxicity and biodegradability.

PVA is easy to print and can serve as a good support during the printing process for slanted models or models with projections that cannot be printed without supports.

Printing temperature range: 180°C - 230°C

PVA is commonly used as paper adhesive, thickener, packaging film, etc. This material is also used in sport fishing, when bags of PVA filled with bait are thrown into the water. The bags dissolve quickly and release the bait to attract fish.

The bags dissolve quickly and release the bait to attract fish.

| PVA Pros | Disadvantages of PVA |

|

|

#4. Filament for 3D printing PET

Polyethylene terephthalate or PET is another popular plastic bottle filament. It is durable and harmless plastic. It does not produce unpleasant odors and is completely recyclable.

PET thread in its original state is colorless and crystal clear. However, when exposed to heat or cold, the material changes its transparency.

If you let it cool down slowly after printing, it will have a crystalline structure. PET has different versions, including PETG .

This modification is a transparent thermoplastic with the possibility of thermoforming the product after printing.

Printing temperature range: 220°C - 250°C

PET filament is ideal for packaging because of its vapor barrier and durability. This 3D filament is often used for phone cases and mechanical parts requiring flexibility and impact resistance.

| PET Pros | Cons of PET plastic |

|

|

#5. Filament for 3D printing PETG

PETG Filament is a variation of the very popular PET filament with the addition of "modified glycol", hence the name PETG. It is a really durable material, extremely durable and odorless.

It is a really durable material, extremely durable and odorless.

PETG filament provides strength and impact resistance superior to PET as the latter tends to become cloudy and brittle when overheated. The addition of glycol eliminates these limitations, giving PETG yarn the following properties: low shrinkage, no warpage, and strength but not brittleness.

Printing temperature range: 220°C - 245°C

PETG filament is best suited for printing products that are subject to sudden or continuous stress, such as protective components (mobile phone cases) or mechanical parts. Contact with food is also safe.

| PETG Pros | Cons of PETG plastic |

|

|

#6. 3D Printing Filament PETT

Polyethylene-co-trimethylene terephthalate ( PETT ), is another popular 3D printer filament. This material is colorless and transparent.

This type of 3D printing filament is non-biodegradable but recyclable.

Printing temperature range: 210°C - 230°C

PETT are polymers that make it safe for direct food contact. PETT is used to make food containers as well as bottles.

| PETT Pros | Cons of PETT plastic |

|

|

#7. HIPS

3D Printing FilamentHigh impact polystyrene material ( HIPS ) is biodegradable and bright white. It has no side effects when in close contact with human skin and is safe for pets.

HIPS is very similar to ABS, only it uses limonene as a solvent. In addition, like PVA filament, HIPS filament is also an excellent support material for 3D models. In fact, HIPS is a great support material when printing with ABS filament on a dual extrusion printer.

Printing temperature range: 210°C - 250°C

The specific application of HIPS filament is not manufacturing, but supporting the object itself. This filament is popular as a recycled material in dual extrusion 3D printers to provide structural support for a complex object. In addition, HIPS is widely used in the food industry (packaging). This filament is also used to make medicine trays.

In addition, HIPS is widely used in the food industry (packaging). This filament is also used to make medicine trays.

| HIPS benefits | Cons of HIPS |

|

|

#8.

Nylon 3D Printing FilamentPolyamide, better known as nylon filament, is a popular synthetic polymer that is also used in many industrial applications. This 3D printer filament is made of eco-friendly plastic. It is strong, lightweight, flexible and wear resistant.

Nylon is the best 3D printer filament, due to its strength and high melting point, suitable for mechanical and functional parts.

Printing temperature range: 210°C - 250°C

Due to its strength, durability and flexibility, nylon is used in a wide variety of applications. This engineering grade filament is ideal for some machine parts, mechanical components, structural parts, gears and bearings, and toys.

This engineering grade filament is ideal for some machine parts, mechanical components, structural parts, gears and bearings, and toys.

| Nylon thread pros | Cons of nylon thread |

|

|

Another weakness of nylon is its sensitivity to moisture. It easily absorbs moisture. In fact, it can absorb over 10% of its weight in just 24 hours, which is pretty bad. Thus, you must be very careful when storing. You should keep it dry for good 3D models by storing it in an airtight container along with dehumidifier or silica gel bags. In addition, nylon has adhesion problems.

In addition, nylon has adhesion problems.

#9. Wood 3D Printing Filament

If you are tired of working with plastic and want to try something new in your next 3D project, you can unleash your creativity with wood based materials using FDM Filament ( Fused Deposition Modeling ), also known as Wood Filament.

Wood Filament contains a blend of recycled wood with a resin binder. This way you can create a 3D object that looks like wood and smells like wood.

Due to the fact that the printed object will be wooden, it will be difficult to tell that this object was printed on a 3D printer. So, if you want to achieve that perfect wooden look, get Wood 3D Printer Filament . The use of wood filament is similar to the use of thermoplastic filament such as ABS and PLA.

When using this thread, the temperature must be between 175°C and 250°C. Otherwise, you will not achieve the perfect look.

Printing temperature range: 195°C - 220°C

Wood threads are often used in decors or materials that must be made from wood. In addition, you can use it to print a wooden box, a figurine, tables, chairs, cups, and the like.

In addition, you can use it to print a wooden box, a figurine, tables, chairs, cups, and the like.

| Wood Filament Pros | Cons Wood Filament |

|

|

#10. Sandstone 3D Printing Filament

3D Printing Filament Sandstone is another great material that will help you achieve a unique result. This thread combines fine chalk powder with PLA for a stone-like color and texture.

With Sandstone 3D Printer Filament , you can achieve smooth or rough surface with different characteristics by changing the extrusion temperature during 3D printing. If you are looking for printable filaments with a unique finish then this is the material for you.

If you are looking for printable filaments with a unique finish then this is the material for you.

Printing temperature range: 165°C - 210°C

This thread is ideal for architectural, museum or landscape models.

| Sandstone Pros | Cons Sandstone |

|

|

#11. Metallic 3D Printing Filament

Another interesting 3D printer filament that you should definitely try is Metal PLA . This material is categorized as PLA combined with metal powder. Using metallic filament, you'll be making 3D printable models that look like they're made of bronze, brass, or copper.

Print temperature range: 195°C - 220°C

Since Metallic PLA produces metal-like products, this 3D printer material is great for making jewelry, statues, and replica artifacts.

| Pros Metal PLA | Cons Metal PLA |

|

|

#12. 3D Printing Magnetic Iron

Magnetic filament is made by infusing finely ground iron powder into a base material. Theoretically, any material can be used as a base, for example, PLA. When PLA is used, this material is usually referred to as magnetic PLA.

Magnetic Iron PLA is another great 3D printer filament that you will surely love. This thread strongly attracts magnets such as neodymium, iron-boron (NdFeB) or samarium-cobalt (SmCo). This filament contains iron and is sealed in a desiccant bag.

This thread strongly attracts magnets such as neodymium, iron-boron (NdFeB) or samarium-cobalt (SmCo). This filament contains iron and is sealed in a desiccant bag.

Printing temperature range: 195°C - 220°C

This type of 3D printer filament is great for decors like fridge magnets and the like. In addition, it is also used to make sensors, actuators, and educational projects.

| Advantages of magnetic iron | Minuses of magnetic iron |

|

|

#13.

Conductive 3D Printing Filament The 3D printer with PLA conductive filament opens up new possibilities for your next 3D printing projects. This material includes conductive carbon particles, allowing low-voltage electronic circuits to be printed for simple items such as LEDs and sensors.