3D printed switch holder

Ten 3D Printable Things: Mods and Accessories for the Nintendo Switch - 3DPrint.com

Welcome to Ten 3D Printable Things. Every week I’ll be showcasing 10 fantastic and FREE 3D printable projects, designs and models from all over the web. As always, you can email me your feedback and theme suggestions, and I always love to see what 3D printing projects you’ve been working on. You can also find me on Twitter @SJGrunewald, so say hi and feel free show off what you printed. Tag it #103dpthings and you’ll get a RT.

The Nintendo Switch hybrid gaming system.

This year, legendary video game company Nintendo released their 7th major home video gaming system, the Nintendo Switch. The Switch is a hybrid system that can be used as a mobile gaming device with a touchscreen interface, or plugged into a docking system and played on a television like a standard gaming system. After the lukewarm reception to the Wii U, Nintendo really needed a hit, and with the Switch their habit of taking risks and pushing the boundaries of gaming seemed to have paid off. In just the first 2 weeks Nintendo shipped 1.5 million Switch game systems, making it the fastest selling game console in history.

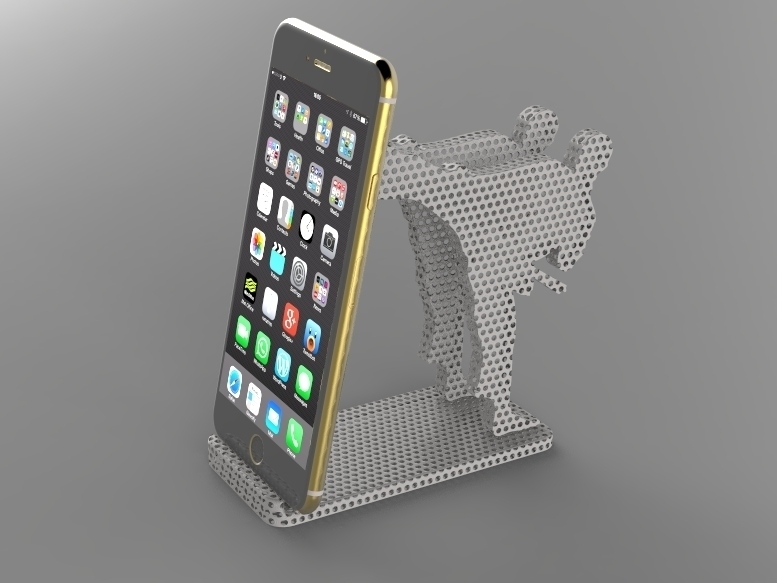

The unique and innovative system, which includes travel capabilities and the multi-use controller that they call a JoyCon, is perfect for customization and personalization using 3D printers. Naturally, the 3D printing community wasted no time in developed some amazing enhancements, accessories and modifications to make the already flexible gaming system even more user-specific.

Here are Ten 3D Printable Things for the Nintendo Switch:

45 DEGREE STAND FOR TABLETOP GAMINGNintendo Switch 45° Stands for JoyCon Channels by andyleer

Found on: Thingiverse

Cost: Free

While the Switch is being used in its tablet mode, it is basically a handheld mobile gaming device. That’s fine for some games, but it can often be uncomfortable for more intensive games. Many users have expressed a desire to be able to set the Switch on a flat surface while gaming, so there are a ton of options available for this exact purpose. These fantastic 45° stands allow the Switch to sit at a comfortable angle on any flat surface, and slide right into the side channels where the JoyCons attach.

These fantastic 45° stands allow the Switch to sit at a comfortable angle on any flat surface, and slide right into the side channels where the JoyCons attach.

The designer created 2 different versions of the stands; the first is smaller and slimmer so it will print quickly and will be easier to take with you on the go. The second raises the Switch up a bit so the charging cable can be plugged in while you play.

ADJUSTABLE ANGLE STANDNintendo Switch – Adjustable Stand by Tim

Found on: MyMiniFactory

Cost: Free

If a 45° angle isn’t the right fit for your personal comfort level, then this handy adjustable stand may be just what you’re looking for. The stand can tilt the Switch at five different angles to suit whatever surface you may be playing on. It is also elevated high enough for the charging cord to be plugged in during use.

The adjustable stand prints in just four simple parts, and should assemble together pretty easily. A few of the parts may need a bit of support, but nothing too difficult to manage.

A few of the parts may need a bit of support, but nothing too difficult to manage.

Nintendo Switch controller wall mount by Brent Ed

Found on: MyMiniFactory

Cost: Free

Anyone with a video game console of any kind understands the pain of dealing with extra game controllers. And considering the JoyCon can be separated into different parts, that’s a lot of pieces to keep track of. This cool wall-mounted holder is a great way to keep track of your JoyCon sticks. It has rails on each side, so both JoyCons can be slid into place, with a holder on top for straps or other accessories.

There are 4 different versions of the wall-mounted holder, each labeled “Player 1” through “Player 4”. The mounts can be attached to the wall with a simple double stick adhesive strip so it can be put just about anywhere.

CLIP-ON SUN SHIELDNintendo Switch Sun Shield by reini1305

Found on: Thingiverse

Cost: Free

Phone and tablet manufacturers still haven’t managed to perfect a touchscreen that doesn’t reflect the glare of direct sunlight, often making outdoor gaming difficult at best. Sadly, the Switch suffers from the same malady. But this easy to print sun shield is an excellent solution that doesn’t include scrambling for shade every time the sun shifts.

Sadly, the Switch suffers from the same malady. But this easy to print sun shield is an excellent solution that doesn’t include scrambling for shade every time the sun shifts.

The sun shield clips onto the top of the Switch while still leaving the top buttons accessible. The clearance was designed to be a little wider than the Switch, so you can add on some tape to the parts that touch the screen, preventing any scratches or unnecessary wear and tear. Sadly, the shield doesn’t fold up, so it’s not the most portable accessory, but it’s perfect for gaming in your backyard or out on your patio.

PORTABLE CHARGING STANDNintendo Switch Portable Charging Stand by Ospi

Found on: Thingiverse

Cost: Free

One of the few gripes that new owners of the Switch have had is the inability for it to be charged while it was being used in tablet mode. However this simple print allows the Switch to be held upright so it can be played independent of the dock while being charged.

The designer created 3 different versions, each suited for different angles depending on how and when you’re using the Switch. You can either keep all of them on hand and use each for different scenarios, or just print the version that best suits your needs.

INDIVIDUAL TRAVEL CARTRIDGE HOLDERSNintendo Switch Cartridge covers & Nintendo Switch cartridge holder, key chain. by Brent Ed

Found on: MyMiniFactory

Cost: Free

Unfortunately Nintendo did not give users a lot of options for travelling with their games other than a large, unwieldy box. Thankfully, 3D printing is here to save the day. Your first option is this simple cartridge cover that can be printed in less than 20 minutes. The two parts snap together, so you can toss your games in a pocket or backpack and not have to worry about them collecting dust or getting damaged.

There is also this simple key chain cartridge holder option that allows you to snap a game into place and take it with you, hanging from a backpack or on a set of keys.

Nintendo Switch Mario Hat by Forrest D. Ross

Found on: MyMiniFactory

Cost: Free

If you’re looking for a Switch stand that is a little more whimsical than some of the more utilitarian options on this list, then it’s-a Mario to the rescue. This simple stand looks like a Mario hat, and even includes a small hole in the back to run the charging cable through.

The designer also included 4 different letters that print separately, so you can change the color of the hat and have a Luigi, Wario or Waluigi hat if you’d prefer. The letters just snap in place.

CAR SEAT HEADREST MOUNTNintendo Switch car mount by Joshua Camacho

Found on: MyMiniFactory

Cost: Free

Because the Switch was created specifically so you can take all of your games with you wherever you go, it’s naturally going to be a staple of the long car ride or road trip. Rather than trying to play games while holding the Switch, this great little print allows you to clip it to the back of a car seat, for a hands-free gaming experience.

The mount prints in a single piece and includes a bar at the back that will fit between the car seat and the headrest, so the Switch will sit at about eye-level. There are 3 arms in the front that hold the Switch in place, and you just need to slide it in to get gaming. This print will require some supports, and it’s probably a good idea to do some sanding or painting to prevent scratching.

JOYCON CONTROLLER MODSNintendo Switch Dpad & Nintendo Switch Joystick Extender by EmperorFaiz

Found on: Thingiverse

Cost: Free

Because the JoyCons were designed to be versatile and have many different uses depending on the game, the controller controversially excluded a few features that have become industry standard. The one that I see the most users complaining about is the lack of a proper d-pad. Thankfully, 3D printing can fix that for you. You can just snap 1 of 5 different styles of d-pads onto your left JoyCon and the controller will feel a lot more natural.

The relatively diminutive joysticks on the controllers have also been a point of contention, especially with games that require a lot of very precise movements. This simple joystick extender easily snaps on and makes them easier to use. They can also easily be taken off for social gaming or games that don’t need quite as much precision.

JOYCON WAND ACCESSORYNintendo Switch Joy-Con Wizard Accessory by fotis mint

Found on: MyMiniFactory

Cost: Free

“The wand chooses the wizard, Mr. Potter” …unless Harry had himself a 3D printer, that is. I really don’t need to say much about this cool JoyCon accessory, because it’s a wand. Everyone wants a wand, especially one that can actually be used to play games. The wand simply slides into the channel on the side of the detached JoyCon, making it perfect for multiplayer games.

Depending on the size of your 3D printer, the wand can be printed as a single part, standing up on its end, or cut into two parts that simply need to be glued together. You can choose to print your wands to match the colors of your JoyCon, but personally I think using a wood-based filament and staining it would look much cooler.

You can choose to print your wands to match the colors of your JoyCon, but personally I think using a wood-based filament and staining it would look much cooler.

Wands up! Now get to a 3D printer and get to work!

That’s it for this week, see you next week and as always thanks for reading. Discuss in the Nintendo Switch forum at 3DPB.com.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 103dpthings • 3d print nintendo • 3D printable game accessories • 3d printed game accessories • 3d printed gaming accessories • 3d printed video game accessories • free 3d models • harry potter • JoyCon • Legend of Zelda • myminifactory • nintendo • Nintendo Switch • personalization • Super Mario Bro • Ten 3D Printable Things • ten 3d printed things • thingiverse • video games • Wands • Wario

Please enable JavaScript to view the comments powered by Disqus.

The Best Free 3D-Printed Nintendo Switch Accessories

New to Shacknews? Signup for a Free Account

Already have an account? Login Now

- Guide

- Modojo @ Shacknews

Mount the Switch to your car or to your face with these readily-available Switch accessory design plans.

0

The Nintendo Switch is big and only getting bigger, and players across the globe have fallen in love with its adaptable hybrid design and library packed with fantastic games. Be it on television, kicked back on a flat surface, or even in the palm of players' hands, the Switch offers gamers huge amounts of freedom to play their way. Robust as those options are, some players have looked beyond pre-manufactured accessories and dreamt up unique accessories that allow even greater options for Switch gameplay. Best of all, they've uploaded their designs in a few different places across the web, and those with 3D printers sitting around their homes can use them to craft some surprisingly-imaginative accessories.

If you or someone you know has a 3D printer and a Nintendo Switch, check out our picks for some of the best and most interesting 3D-printed Nintendo Switch accessories available for free.

Nintendo Switch Attachable Grip

Switch players who do a lot of their gaming in docked or tabletop mode are likely well familiar with the Joy-Con Grip, which provides some added ergonomics and old-school feel when compared to using two Joy-Con controllers separately. Unfortunately, there's no standard option for better ergonomics when playing the system with the Joy-Con controllers attached to the Switch. That's why user MottWorks3D found a workaround, and with his Attachable Grip designs, players can attach the Joy-Cons to the Switch system and still enjoy feeling like they've got a standard controller in their hands. Even better, the Attachable Grips also function when disconnected from the Switch itself. Players can find the plans over on MyMiniFactory.

Adjustable Stand For Nintendo Switch

One of the biggest complaints players raise against the Switch is that the devices bottom-mounted USB C port doesn't allowed for the console to be charged when kicked back playing in tabletop mode. Naturally, there's an easy solution in the form of this simple accessory — it raises the Switch off tables and other surfaces just enough to allow room for its charging cable. Even better, the basic-but-thoughtful design allows the Switch to be kicked back at various angles. Players can find the plans, which were developed and uploaded by user Snuffypot11, over on MyMiniFactory.

Nintendo Switch D-Pad Mod

Some Nintendo fans were quite surprised to discover that the Switch Joy-Cons don't feature a standard directional pad. Nintendo is frankly famous for its peerless D-pads, so ditching the traditional cross shape and using round buttons ruffled a few players' feathers. No worries though, because user EmperorFaiz has a fix for this issue, and has provided designs for a stick-on D-Pad that comes in a selection of different old-school and new-school inspired styles. Switch owners can find the plans for the latest version, D-Pad Mod 1.6, over on Thingiverse.

Switch owners can find the plans for the latest version, D-Pad Mod 1.6, over on Thingiverse.

Joy-Con Drink Holder

Look, it's a drink holder for a Nintendo Switch, what more explanation is needed? With user sanzliot's design, players can enjoy their Switch experience right alongside their favorite beverages, which could technically extend gaming sessions for those fueled by the likes of sugar and caffiene. Now pausing for lubrication is a concern of the past, and players can find plans for the Joy-Con Drink Holder at this link at Thingiverse.

Nintendo Switch Car Seat Headrest Mount

It's not that Nintendo appeals mainly to children — children of all ages, more like — it's just that many Nintendo fans happen to be children. And since the Switch can go anywhere, many younger players find themselves enjoying their favorite Nintendo titles in the car. Enter the Nintendo Switch Car Seat Mount, which puts the action front-and-center for little backseat gamers. Uploaded by user camachoisboss, players can find the free plans for the headrest mount over at MyMiniFactory.

Uploaded by user camachoisboss, players can find the free plans for the headrest mount over at MyMiniFactory.

Joy-Con Ergo Pro Handle

In order to alleviate concerns of slinging controllers across the room, Nintendo started offering wrist straps with Wiimotes. However, the Switch has tiny little Joy-Con controllers that pose a similar risk for losing grip. Fortunately, a solution for the issue is simple — just add a little bit of bulk and toss in some finger grooves for good measure. Such is the case with the Ergo Pro Handle, a simple to print and easy to use accesory that also helps keep hands more comfortable during extended bouts of gameplay. Designed by user HLS, these no-nonsense plans can be found over on MyMiniFactory.

Single Hand Joy-Con Adapter

As is the case with many other accessories we've featured here, the Single Hand Joy-Con Adapter was ultimately crafted for convenience. Unlike others on this list, however, it was created with one-handed gamers and other disabled players in mind. This simple controller accessory puts each Joy-Con at a right angle to the other, allowing just one hand to access both Joy-Cons and all necessary buttons. Designed Created specifically for a one-handed friend and uploaded by users Vexelius, players can find the designs for this cool accessory on Thingiverse.

This simple controller accessory puts each Joy-Con at a right angle to the other, allowing just one hand to access both Joy-Cons and all necessary buttons. Designed Created specifically for a one-handed friend and uploaded by users Vexelius, players can find the designs for this cool accessory on Thingiverse.

Kevin Tucker is a core component of Shacknews' powerful guide development team. For questions, concerns, tips, or to share constructive criticism, he can be reached on Twitter @dukeofgnar or through e-mail at [email protected].

Filed Under

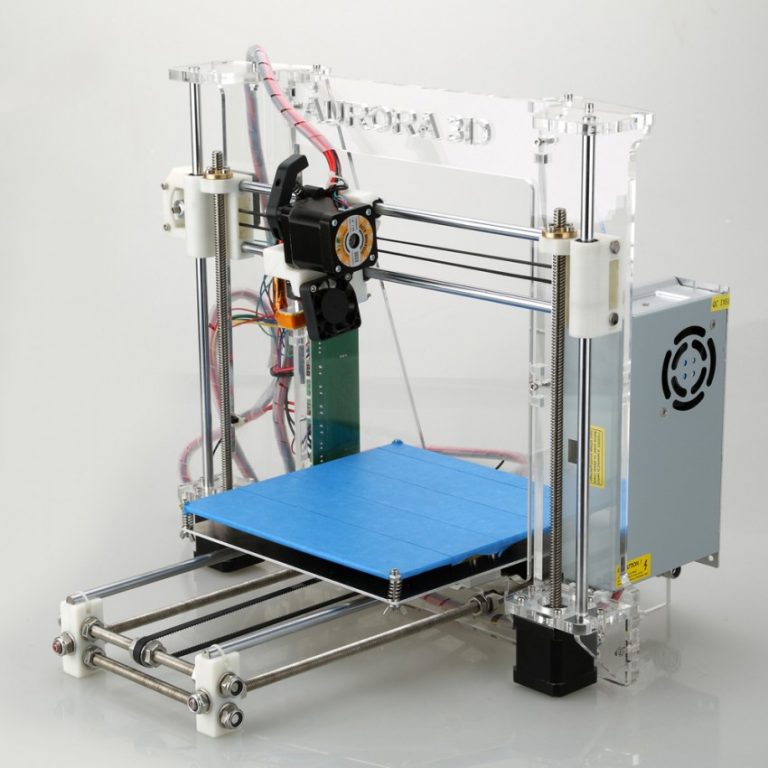

JG Maker is a worthy alternative to inexpensive 3D printers for beginners / Sudo Null IT News Everyone determines their own budget for themselves, and then the search begins for this cost of the printer, reviews are read, communities are considered ... As a result, the cheapest ones become the most common, as the threshold for entering 3D printing decreases from year to year. And if at the dawn of 3D printers they were assembled by enthusiasts from improvised spare parts, then acrylic constructors appeared, and then kits using extruded aluminum profiles began to appear en masse.

Now there are already affordable solutions with factory metal parts and a minimum of plastic solutions, which raises the quality of such kits to a new level.

Now there are already affordable solutions with factory metal parts and a minimum of plastic solutions, which raises the quality of such kits to a new level. One of these printers is JG-maker from a fairly well-known company, which was one of the first to start production and sale of kits for assembling 3D printers.

I will not hide, the printer was provided for review, but I will try to tell everything honestly about it. From the moment I was offered to test it and before the courier delivered it to me, 4 days passed. This means that the printers are already in stock in Moscow and, if desired, they can be received faster than waiting from a warehouse in China. But, in practice, this slightly increases the cost. To whom it is critical, look from which warehouse the delivery takes place.

The printer arrives in this branded box. She, as I mentioned above, was brought by the courier home and handed over personally.

We open the package and see the instructions and a bag with various useful little things.

The instruction manual is duplicated from English into Russian. But the assembly instructions also have two languages, but one is Chinese and the other is English.

Thankfully everything is illustrated step by step. Yes, and collecting here is not particularly difficult. Slowly for an hour, you can easily meet.

The following was found in a small package:

- Cable for connecting the printer to a computer or flashing the board. The board, by the way, is still based on Arduino. The solution is time-tested and very reliable, but many are already switching to 32 bits, although this again affects the cost.

- PLA Probe

- Several bags of screws

- Z-axis end cap

- Filament Sensor

- X-axis belt tensioner

- X-axis belt

- Set of keys and hexagons

- Palette knife (now put instead of a spatula)

- Card reader with 8 GB memory card inside

- And spare parts in the form of ties, nozzles, fittings and other hardware

Further, on the top cover of the inner package there is an inscription that it is better to look at the instructions on the memory card before assembling. The manual is actually there, it is in PDF format. But paper is more than enough.

The manual is actually there, it is in PDF format. But paper is more than enough.

Actually, here are the main parts of the printer.

The movable table, control board and cables connecting it to the main components are one large module in a steel case. It is necessary to fasten the guides of the X and Z axes to it, as well as the holder for the coil, which is also made of metal. Everything is very reliable.

One of the main elements of any printer is its print head, where the hot end with the cooling system and the airflow of the printed area are located.

The extruder here is quite simple and unpretentious. This is one of the latest models of budget extruders with improvements that allow you to print with relatively soft plastics. For very soft plastics, such an extruder is not suitable. If the task is to print with soft TPU, TPE or Flex plastics, the extruder will need to be replaced.

The table has an additional layer with a rough coating, to which all plastics stick well. This coating was not glued directly to the surface of the table, but was glued to a thin textolite, which makes it easy to remove large printouts. It is enough just to remove and bend the table so that the part peels off.

This coating was not glued directly to the surface of the table, but was glued to a thin textolite, which makes it easy to remove large printouts. It is enough just to remove and bend the table so that the part peels off.

One of the main elements of interaction with the printer is the card reader. It is designed for a standard SD card. Inside there is a spring-loaded latch. To remove the card, you need to click on it.

Power socket with internal fuse. There is a 230-110V switch on the power supply. The connector was sealed with a warning sticker so that you definitely do not forget to check in which position the switch is. Although maybe the sticker should have been nearby. But the case is covered with powder dye, to which stickers do not adhere well. I tried to re-glue this one, but it fell off by itself after a few minutes.

I noticed a nice nuance - a PTFE tube flared inside. This solution allows the rod to easily enter the tube without getting stuck and easily enter the hot end. Nice little thing.

Nice little thing.

The table, also known as the Y axis, moves along cylindrical guides - shafts. The shafts are fixed with metal clamps. The belt spool is in a plastic cradle. But the plastic is moulded, and should last a long time, there are no complaints about this knot.

Before starting the review, I looked at what the previous owners and bloggers had to say about the printer. The main claim was to the table. Since the wires were not fixed in any way + the table had a regular connector. As a result, the wires either broke from constant movement or there was a bad contact in the connector, and it burned. This model already has a modification of this node and, as can be seen above, the wires are not only fixed, but also securely soldered.

Under the hood of the printer is the control board and power supply. Well, the block, as usual, from the LED strip. But high-quality, with active cooling. But the board seems to be its own design from JG Aurora.

In principle, this is a fairly simple board with inexpensive drivers. These drivers aren't the quietest, but the printer doesn't make much noise. In addition, they do not heat up so much, which allows them to be used without radiators at all. But, if you have a desire to replace the drivers with fashionable 2208, then you will have to change the control board at the same time. The price of the printer affects, let me remind you that it is in the most affordable niche.

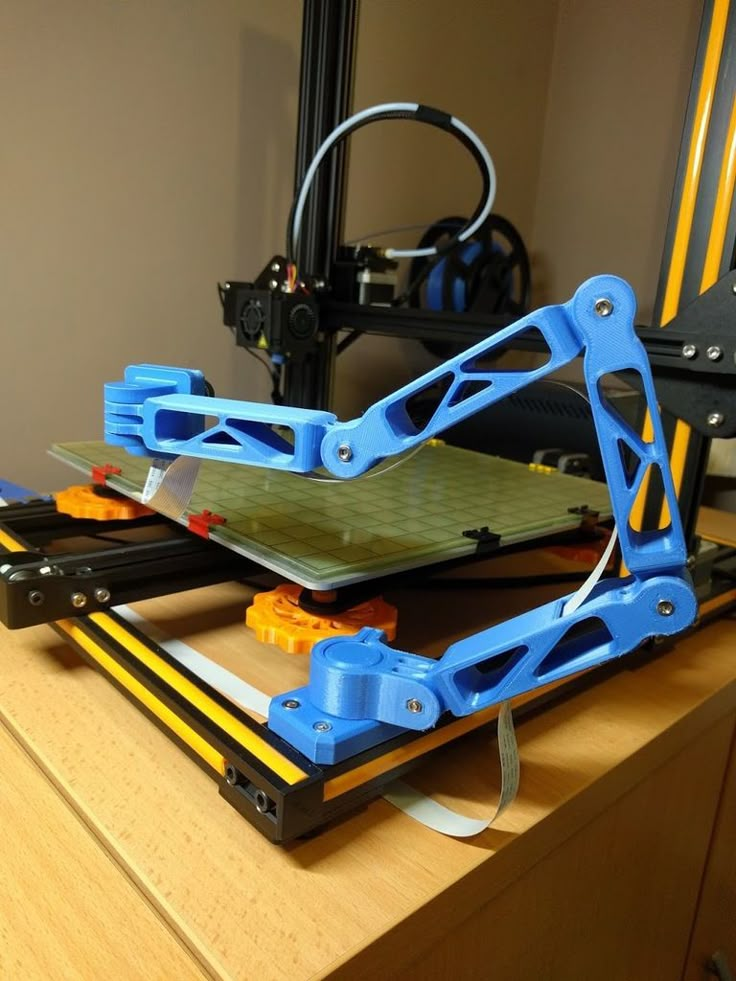

We assemble the Z and X axes. To do this, unpack the aluminum rails.

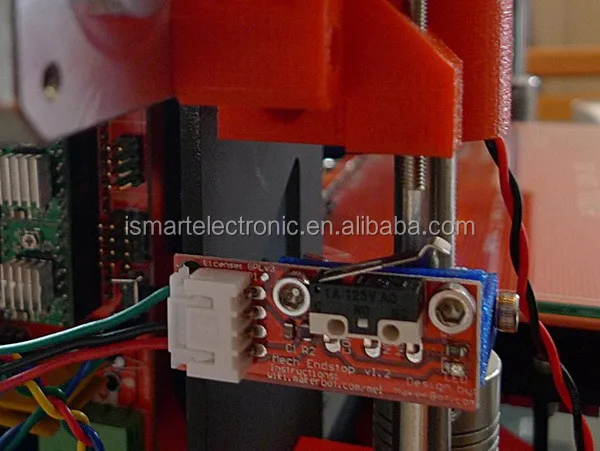

First, screw the Z-axis motor and limit switch. The end cap doesn't need to be over tightened. After assembling the printer, it will need to be moved a little more.

We screw 2 vertical guides ...

And proceed to the assembly of the X axis. There is a feature here, you need to correctly position the elements relative to the guide, in accordance with the recesses. There are different distances from the edges to them.

There are different distances from the edges to them.

Next, tighten the belt.

After fixing the belt in the “head” clamps, you need to adjust its tension. The belt should not be stretched like a string, but at the same time it should not sag. The roller on the left is responsible for the tension. It is necessary to loosen its clamp, insert something between the roller and the frame, slightly tighten and tighten the screws.

Next, place the X axis on the vertical guides.

It turns out like this.

At this point, you can already adjust the Z-axis stop. I advise you to tighten the slightly spring-loaded table screws and then adjust the stop so that the nozzle just barely touches the table. Then, by releasing the screws, it will be possible to easily adjust the gap of the first layer.

We screw the upper rod.

And install the decorative element on top. In addition to beauty, it also protects the upper groove of the profile from dust. It is not very convenient to wipe it there, and with such a cap it will be a little easier to keep the printer clean.

It is not very convenient to wipe it there, and with such a cap it will be a little easier to keep the printer clean.

We insert the trapezoidal screw into the nut on the X axis.

And fix it in the clamp on the stepper motor. Next, we screw the motor with the extruder and the bar presence sensor.

We insert the signed connectors into the desired slots. We screw the holder for the coil and the printer is completely assembled.

Next, you need to adjust the table gap. To do this, we put the head in turn in each corner of the table and adjust the height of the gap with the lamb under the table. Here, as usual, you need to place a piece of paper between the nozzle and the table and clamp it until it moves with little friction. It is better to repeat the procedure a couple of times in a circle at each corner. Since there are four screws, and the plane is easier to set when there are three of them. With four screws, it doesn't align perfectly the first time, as the diagonal screws offset each other a little, and by raising one edge, the other can drop a little. This is another non-critical minus. In principle, four screws are placed on the table in most printers. And in such printers with a moving table, the third screw will also be very difficult to adjust.

This is another non-critical minus. In principle, four screws are placed on the table in most printers. And in such printers with a moving table, the third screw will also be very difficult to adjust.

There is already a sliced file on the memory card. Through the G-code viewer we look at what is there. There is a test cube. He is on the raft. but the raft is not separable. In addition, for some reason it is cut with adaptive layers. Some are very thin, some are standard. But it prints fine. I did not use the test PLA, but immediately applied the proven PLA PRO. It has stable diameter and excellent quality.

Launching another model. And here it turns out that the holder is not very suitable for this type of coils. The coil is inserted very tightly there because of the high side on the edge of the holder. It is better not to risk it, otherwise you can not remove it later. I use a separate holder.

Prints smoothly and steadily. All without complaints.

All without complaints.

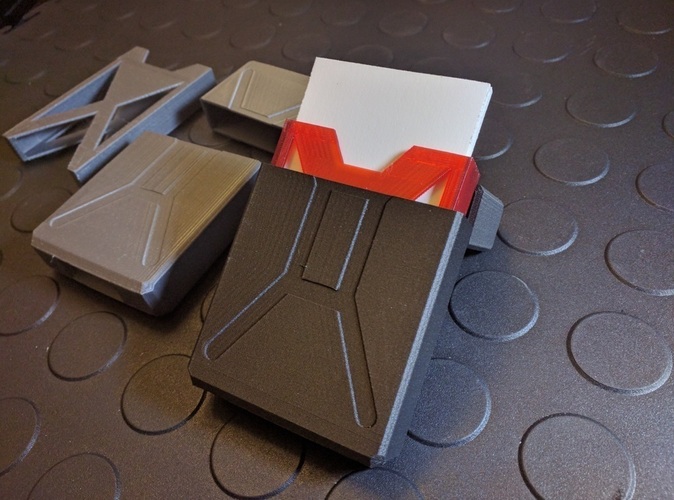

After about 12 hours, we have a ready base for the brain puzzle.

There are slight irregularities in the layers in the direction of the Z axis. But, as for me, they are not very critical.

Next, in red again, print the puzzle pieces.

The puzzle is quite difficult to assemble. Well, the model has the opportunity to print the assembled version and it is already easier to assemble according to the sample.

After a couple of days, Yorick is ready. The puzzle pieces took about 16 hours to print on one half of the brain.

What is the result?

The printer turned out worthy for the money. In the initial segment of 3D printers, the choice has become wider, which is good. Everyone chooses for himself what he likes best.

This printer has the following specifications.

Printable area: 220x220x250 cm. The default nozzle is 0. 4 mm. Spare of the same diameter. The trapezoidal screw allows you to make a minimum step in height of 0.02 mm, I recommend cutting layers in the same multiple of this value.

4 mm. Spare of the same diameter. The trapezoidal screw allows you to make a minimum step in height of 0.02 mm, I recommend cutting layers in the same multiple of this value.

The printer has an all metal body and 95% metal parts. All critical components are made of metal, this will increase the service life. Plastic parts to a minimum, but those that are made by casting in the factory. The printer is easy to assemble and ready to print within an hour of getting your hands on it. I put in an hour for assembly. Can be collected faster.

Minor cons: The spool holder does not fit some types of spools. Namely, under 750 grams from the FD-layer. The same spools are used for the welding rod... Here you need to either sharpen the holder or use a free-standing spool holder. You can also print your version. Another disadvantage, but not critical, I would include the absence of eccentrics on the guide wheels. True, I haven’t touched them on my other printer for 2 years already and everything prints smoothly, without straying. And here it is straight from the factory.

And here it is straight from the factory.

How we decided to make a modular 3D printer

As you know, Master Kit has developed and manufactures several models of 3D printers. Each of these models is assembled from a large number of parts using a noticeable amount of fasteners - screws, nuts, etc. Detailed assembly instructions are attached to each set. As practice shows, we do not like to read instructions, our character is not the same.

To help our users, we are releasing video assembly instructions.

And then one evening, discussing the scenario of shooting such instructions for assembling the MC7 Prime Mini printer, we realized that we were walking through some kind of dark forest. Long, tedious, and the end of this forest is not visible. After all, everyone who has at least a little bit of a screwdriver and pliers will still assemble parts of the printer in their own way, which tells them their own experience.

Maybe, we thought, we should break the assembly process into logical parts and end each part with the appearance of a complete functional unit, for example, an X-axis unit, a plastic feed unit, etc. ? The idea seemed attractive, and the script began to turn from a continuous tightening of screws and nuts into logical parts that could be filmed separately.

? The idea seemed attractive, and the script began to turn from a continuous tightening of screws and nuts into logical parts that could be filmed separately.

And that's when it dawned on us... But what if we pre-assemble these nodes and put them assembled in the same box? How many of these nodes will there be, and how easy is it to connect them into a finished printer? Will the parts fit in the box provided?

Experimented. Yes, the pre-assembled units are completely included in the box, even with the power supply. The final assembly requires a minimum number of operations, and they are not difficult. In addition, the knots packed in the box look very aesthetically pleasing!

This is how Master Kit got two kits instead of one: a completely disassembled MC7 Prime Mini for those who are interested in building a device from scratch, and a pre-assembled 3D-START for those who want to start typing as soon as possible. The first one can be offered, among other things, as a tutorial for assembling mechanics such as a CNC machine or developing skills in fine metalwork, the second will be attractive for those who want to quickly master the principles of 3D modeling and printing.

3D-START modular kit assemblies in packaging without lid

Let's see what components are included in the pre-assembled printer.

X-axis drive unit (extruder). This is the horizontal axis along which the extruder moves in this kinematic scheme. The assembly includes: a stepper motor with a toothed belt, toothed gear and bearing; X-axis linear bearings with guides with a diameter of 6 mm; Z-axis linear bearings; limit switch along the X axis; Z-axis limit switch pusher; fully equipped extruder E3D V6.

X-axis drive

Y-axis (table) drive unit. This is also the horizontal axis along which the table with the printed model moves. Composition: base; stepper motor, gear and belt, bearings; linear bearings with guides 8 mm; Y-axis limit switch, glass with holders and four adjustment springs.

Y-Axis Drive

Z-Axis (Extruder) Drive Assembly. This is the vertical axis along which the extruder moves. It consists of a stepper motor, a flexible coupling and an M5 threaded stud.

Z-axis drive

Base with plastic feed unit. Consists of a plywood frame that serves as a connecting element for all printer assemblies, fixed to it by the plastic feed unit and fastening parts for the Z-axis guides. A bundle of Arduino Mega 2560 + RAMPS 1.4 with installed stepper motor drivers is mounted on three parts to the Z-axis rails. A Z-axis limit switch is also fixed to the node.

Electronics assembly

Rails and fasteners. Two 8mm rails, which are mounted on the base frame, in turn mount the X-axis drive assembly and the electronics assembly. Compared to the previous completely disassembled version of the printer, the number of screws and nuts that need to be used for the final assembly of the printer has decreased significantly!

8 mm rails and fasteners

Printer mechanical assembly can now be described in one paragraph:

with six screws and nuts we connect the base, the Z-axis drive and the table drive; we insert two 8 mm guides, passing them through the base parts intended for this, the linear bearings of the X-axis drive unit and the electronics mounting parts; then, with four screws and nuts, we connect the frame with electronics to the other two parts of the mount, tighten the six screws of the fastening parts of the guides.