3D print hot wheels

Hot Wheels Uses 3D Printing to Miniaturize Real-Life Custom Cars - 3DPrint.com

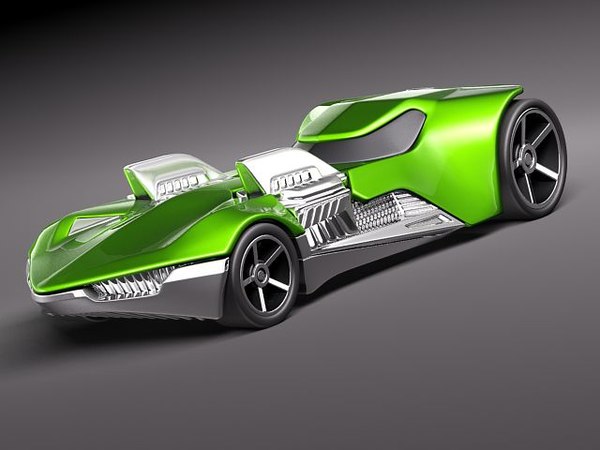

Have you ever wanted your favorite real-life custom car as a Hot Wheel model? Well, the possibility is now within reach. Ever since 2018, Hot Wheels has been conducting its Legends Tour, holding events across the US, for children and adults, to select a chosen fan’s real-life custom car and re-create it as a 1:64 Hot Wheels toy die-cast model.

Hot Wheels, owned by Mattel, has developed over 25,000 unique vehicle designs over the last 50 years, and was looking for distinctly creative and custom-built (not bought) real-life cars as the goal of its Legends Tour. In 2018, the winning design was the 2JetZ from Luis Rodriguez in Las Vegas. In 2019, it was The Nash from Greg Salzillo in Monterey. His custom rat rod, a deliberately worn down hot rod version of the 1957 Nash Metropolitan was selected as the winner from among nearly 5,000 entries in last year’s competition. His real-life custom-made version replaced the chassis, and the original 40 hp engine with a 300 hp block Chevy V-8, including a pair of dice over the air filters, exposed through the hood.

Greg Salzillio with his winning entry and Hot Wheels-made car. Image courtesy of Hot Wheels and Mattel

Traditionally, the creation of a miniature car at Hot Wheels begins with a sketch, followed by physical modeling or sculpting of clay by hand, with various iterations until all details are finalized and then die cast for production.

Image courtesy of Hot Wheels

Typically, the company takes about 12 to 18 months to go from identifying a full-scale vehicle design to having a miniature version in retail stores. Today, the design and manufacturing process includes advanced digital elements, in 3D design, modeling, sculpting and 3D printing.

The real custom car – The Nash. Image courtesy of Hot Wheels and Mattel

To recreate the Nash, Hot Wheels designer and sculptor Manson Cheung initially sought the original blueprints and designs of the Metropolitan so that he could obtain the fundamental shape of the car—much as Salzillo would have done in building the full-scale custom car. The initial sketches serve not only to develop the miniature design from the life-size one, but also to break the car up into the fundamental four pieces of any Hot Wheel model: the body, windows, interiors and the chassis with wheels.

The initial sketches serve not only to develop the miniature design from the life-size one, but also to break the car up into the fundamental four pieces of any Hot Wheel model: the body, windows, interiors and the chassis with wheels.

Fundamental components of a Hot Wheel design. Image courtesy of Hot Wheels and Mattel

For the next step, Cheung doesn’t model using physical clay, but virtual clay, with a 3D Systems Touch X haptic feedback device. He then 3D prints color models using a Stratasys J750 color 3D printer, or for higher-resolution monochrome designs, a Formlabs SLA 3D printer.

The Touch X haptic feedback device allows designers to ‘feel’ virtual 3D models and manipulate the design as if it was a physical model. It combines with Geomagic Freeform or Sculpt 3D software for easy integration with 3D sculpting or modeling tools. Outside of modeling, the device is also used by surgeons to refine their technique, and to provide medical interns with virtual clinical surgery training so they can get the touch and feel of the actual procedure and improve their accuracy prior to entering the live surgical environment.

“Touch X haptic devices allow a user to feel 3D on-screen objects by applying force feedback on the user’s hand, and the Touch X delivers expanded, true-to-life sensations with a more fluid feel and lower friction. Its durability, affordability, and accuracy make the Touch X haptic device ideal for commercial, medical, and research applications, especially when compactness and portability matter.”

In making the virtual clay model, Cheung points out that “it is very much like sculpting by hand because you have that arm movement, you can feel the digital clay.”

The real-life custom car and the Hot Wheels model do have differences, as features and detail are reduced or eliminated to produce the Hot Wheels miniature. Cheung does try to capture as much detail as he can, saying, “I tried to replicate everything in the interior. It had heated leather seats and the back of the seats had some detail, so I tried to include that in there. Sometimes in production, we lose that, but I put that in, in case we can get it. We sent it off to our Asian counterparts to deal with production. Sometimes they use thicker or thinner material. There were some slight changes. Some engine detail was lost because of those production issues. The cockeyed dice were one such casualty. That was lost because of tooling issues.”

Cheung does try to capture as much detail as he can, saying, “I tried to replicate everything in the interior. It had heated leather seats and the back of the seats had some detail, so I tried to include that in there. Sometimes in production, we lose that, but I put that in, in case we can get it. We sent it off to our Asian counterparts to deal with production. Sometimes they use thicker or thinner material. There were some slight changes. Some engine detail was lost because of those production issues. The cockeyed dice were one such casualty. That was lost because of tooling issues.”

Iterations using 3D printed prototypes. Image courtesy of Hot Wheels and Mattel

To develop a physical model from this, the virtual model is sent to a farm of ten 3D printers used by Mattel, with colors specified.

As 3D printing specialist at Mattel, Shane Thompson, explains, “For the majority of requests, we’ll print using our Stratasys J750 color printer which can print more than 500,000 color combinations including Pantone colors.

This process is called PolyJet printing which uses 4 print heads that have 2 rows of microscopic nozzles on each head that the resin gets jetted out from. This machine prints in layers of about .001 of an inch which gives us really good resolution and surface finish. The build frame for this machine is 19.3″ x 15.4″ x 7.9″ so we can print many parts at once.”

To 3D print the Hot Wheel models, which are typically two to three inches long, up to 35 resins can be used to develop accurate miniature prototypes. Once the design is virtually sculpted and prototyped, and the final design is developed and crash-tested. Yes, Hot Wheels crash tests its models for stability and strength. Files are then shipped for manufacturing and production in Asia. With this digital workflow, the design process for the Nash took only 40 hours, and Cheung says this would normally take him 50-80 hours.

The Hot Wheels Nash model, which won last year, will now be available in stores this December. While Salzillo paid nearly $10,000 to build his real-life custom car, the Nash Hot Wheel model will be available for $1.09.

While Salzillo paid nearly $10,000 to build his real-life custom car, the Nash Hot Wheel model will be available for $1.09.

Image courtesy of Hot Wheels and Mattel

In addition to the Legends Tour, Mattel has long been investing in 3D design and manufacturing technologies to improve their design and manufacturing process, and to bring new toys, personalized products and customization to its traditional customer base. In 2016, they had unveiled their $300 3D printer, the ThingMaker, that was developed in partnership with Autodesk, for kids to make their own toys via a basic smartphone design app.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3D printed miniaturization • 3d printed toys • 3D Systems Touch Haptic 3D Stylus • custom car design • Formlabs 3D printer • Geomagic Freeform • geomagic sculpt 3d modeling software • hot wheels • Manson Cheung • mattel • Mattel’s ThingMaker 3D printer • Stratasys J750 3D printer

Please enable JavaScript to view the comments powered by Disqus.

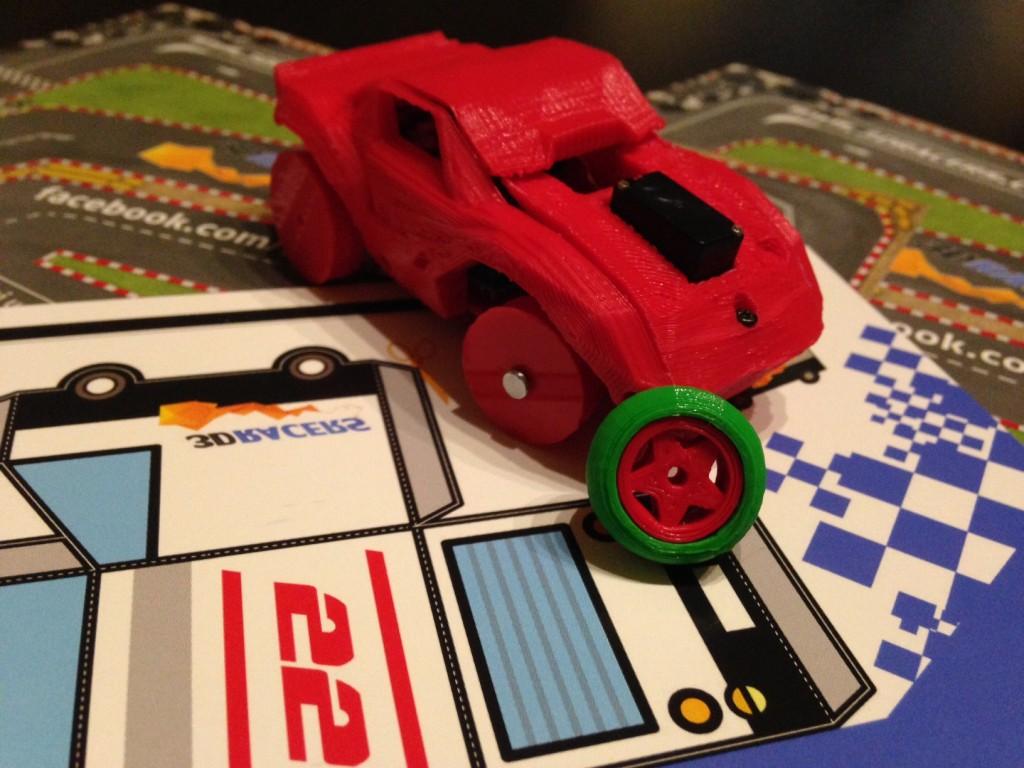

Custom 3D Printed Hot Wheels Track Turns

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

-

Item in the photo is in Quantity: 4 x Single Lane

Option selected!

This option is sold out.

-

Item in the photo is in Quantity: 1 x Single Lane

Option selected!

This option is sold out.

-

Item in the photo is in Quantity: 2 x Single Lane

Option selected!

This option is sold out.

Click to zoom

266 sales |

5 out of 5 starsfrom €12.74

Loading

VAT included (where applicable), plus shipping

Quantity

Select an option 1 x Single Lane (€12. 74) 2 x Single Lane (€19.11) 4 x Single Lane (€31.86) 1 x Double Lane (€19.11) 2 x Double Lane (€31.86) 4 x Double Lane (€50.98)

74) 2 x Single Lane (€19.11) 4 x Single Lane (€31.86) 1 x Double Lane (€19.11) 2 x Double Lane (€31.86) 4 x Double Lane (€50.98)

Please select an option

Quantity

123456789101112131415161718192021222324252627282930313233343536373839404142434445464748495051525354555657585960616263646566676869707172737475767778798081828384858687888990919293949596979899

Explore related categories & searches

Listed on Jun 18, 2022

111 favorites

Report this item to Etsy

Choose a reason…There’s a problem with my orderIt uses my intellectual property without permissionI don’t think it meets Etsy’s policiesChoose a reason…

The first thing you should do is contact the seller directly.

If you’ve already done that, your item hasn’t arrived, or it’s not as described, you can report that to Etsy by opening a case.

Report a problem with an order

We take intellectual property concerns very seriously, but many of these problems can be resolved directly by the parties involved. We suggest contacting the seller directly to respectfully share your concerns.

If you’d like to file an allegation of infringement, you’ll need to follow the process described in our Copyright and Intellectual Property Policy.

Review how we define handmade, vintage and supplies

See a list of prohibited items and materials

Read our mature content policy

The item for sale is…not handmade

not vintage (20+ years)

not craft supplies

prohibited or that use prohibited materials

not properly labeled as mature content

Please choose a reason

Tell us more about how this item violates our policies. Tell us more about how this item violates our policies.

Tell us more about how this item violates our policies.

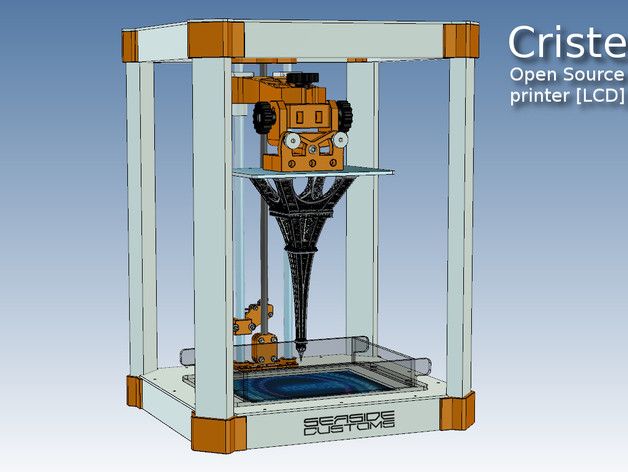

3D printing — Worldskills Russia national team

“

3D printing technology was invented back in the 80s of the last century, but became popular not so long ago. With this printing method, the material is layered on top of each other, forming a finished product, and not just a two-dimensional image. Thanks to this, the possibilities of 3D printing are almost limitless: you can produce both a small high-precision part and an entire structure! In this tutorial, we'll walk through the entire 3D printing process from start to finish.

Glossary

In order to successfully master the material, we recommend that you study the following concepts:

Apparatus that works on the principle of additive manufacturing. The finished product is, as it were, “grown” from a certain material

The principle of production, in which the finished product is formed by gradually adding material to the base

Programs that allow you to cut STL models into layers and, based on this, generate a G-code in which commands are written for 3D printer

Video Lecture

Abstract

Additive Manufacturing Technologies

There is a huge variety of 3D printing technologies in the world today, from the oldest and simplest FDM technology to the emerging 3D bioprinting technology.

SLA (Stereolithography)

Technology for the production of models from liquid photopolymer resins. The polymerization of the resin occurs due to irradiation with an ultraviolet laser at the points of contact of the material with the beam. Upon completion of the contour construction, the working platform is immersed in a tank with liquid resin for a distance equal to the thickness of one layer. After leveling the surface of the liquid material, the process of building the next layer begins. The cycle is repeated until the complete model is built.

The main advantage of stereolithography is its high printing precision. The minimum layer height can be as low as 25 microns.

Among the shortcomings, it is worth noting the high cost of manufactured models due to the high price of consumables.

Here is an example of a printed part with mechanical supports.

SLS (Selective Laser Sintering)

In this manufacturing process, a laser selectively sinters polymer powder particles, fusing them together to create layer after layer.

This technology provides high precision, detail and allows the production of parts with good and stable mechanical properties, unlike FDM and SLA. And printing in the volume of consumables allows you to print parts of even the most complex shape without mechanical supports.

Here is an example of a part printed using this technique.

MJP (Multi Inkjet 3D)

This technology is based on the layering of an object from a wax-based photopolymer to build supports and a resin with properties selected for the part itself.

MJP is somewhat similar to SLA technology: both use photopolymer resins and UV lasers. But MJP is distinguished by more detailed printing and the presence of wax supports, which, in turn, allows you to completely get rid of the post-processing of the model.

This is what a part made using this technology looks like.

CJP (colour inkjet)

The principle of printing is to apply powdered materials layer by layer, after which a binder polymer is applied. The peculiarity of the technology is that polymers of different colors can be used, which makes it possible to create multi-colored and textured parts.

The peculiarity of the technology is that polymers of different colors can be used, which makes it possible to create multi-colored and textured parts.

This technology is used to create realistic prototypes of buildings, clothes and shoes, human organs in medicine, and to make scanned human figures.

FDM (Fusion Deposition Modeling)

This technology is printed by fusing the material layer by layer.

Although FDM technology is the oldest printing technology, it has become widespread relatively recently. It includes ease of study and use, availability on the market of additive technologies and an excellent ratio between price and quality of finished products.

FDM technology allows you to use different types of media for printing. Each material differs in its properties and printing parameters. These can be:

- simple plastics: ABS, PLA;

- engineering plastics: PetG, ePeek;

- special materials: PVA, Hips, Flex.

Making a part on a 3D printer

Safety precautions

- During the operation of the 3D printer, do not put your hands in the working area where printing is being done.

- Protective goggles and gloves should be worn when handling photopolymer printers that use photopolymer resin.

- Wear respiratory and eye protection when using printers that use powder media.

What we need

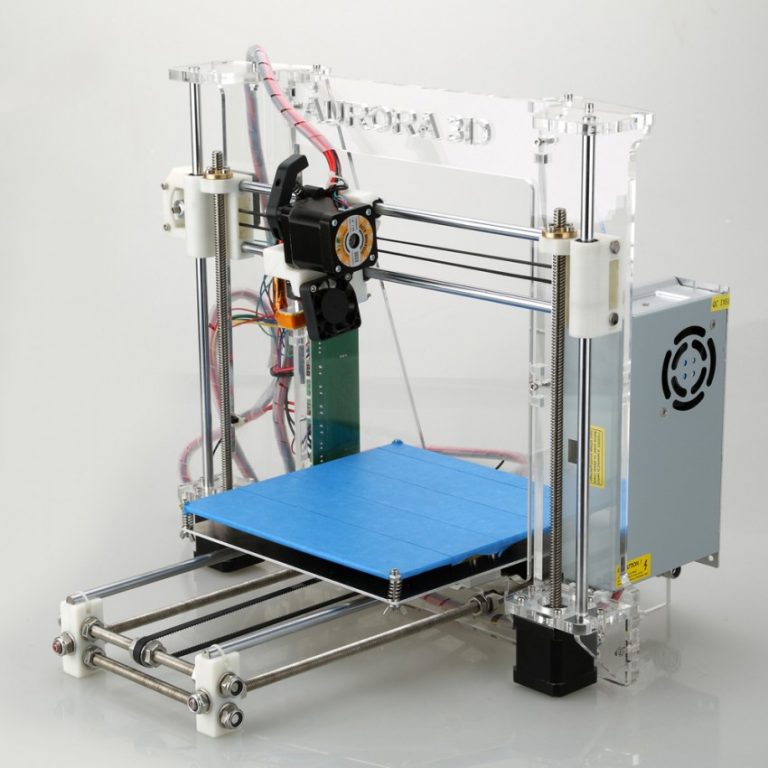

3D printer

3D printing plastic

Computer with

slicer installed0102USB stick

Special adhesive for 3D printing

Napkins

Making settings for printing

2. We position the model in such a way as to minimize the number of supports.

3. Set print options. Set the height of the layer. It should not exceed the diameter of the nozzle installed on the printer. The higher the layer height, the faster the print, but the surface quality of the model suffers.

It should not exceed the diameter of the nozzle installed on the printer. The higher the layer height, the faster the print, but the surface quality of the model suffers.

4. Adjusting the filling percentage. They affect the occupancy rate of the model: the higher the percentage, the stronger the model. But at the same time, material consumption and printing time increase.

5. Perform support settings. The main ones are the gaps between the model and the support body during printing. When setting supports, you must take into account the height of the layer.

6. Perform adhesion settings. They allow you to create "skirts" around the models, which increase the contact area of the model with the table. The smaller the contact area, the wider the "skirt" should be.

7. After setting all parameters, press Slicing.

8. Save the job and send it to the printer.

Preparing the printer

1. Loading material into the printer.

2. In the program, go to the "Plastics" section, select the "Plastic Loading" item and set the type of plastic you want to load.

3. Calibrating the printer. To do this, go to the "Service" section, select the "Desk settings" item and follow the instructions on the screen.

4. The job can be run in one of the print speed profiles: Draft, Standard, or Quality. Each profile is labeled with an estimated print time. Select the required profile.

5. Apply the 3D printing adhesive to the napkin and spread it evenly on the table.

6. We start the job and wait for the part to be printed.

Finished product measurement and post-processing

1. Printing completed. Let the model cool down and remove it from the table.

Important

Do not remove the finished model from the table immediately, as this can ruin the model itself or even damage the table

2. We are reviewing the finished product. We take the dimensions of the physical model and compare them with the dimensions of the three-dimensional model.

3. We evaluate the surfaces of the model. Very slight roughness is the norm for FDM printing. To achieve ideal surfaces, the model needs further post-processing.

“

In this lesson, we went through the entire path of a 3D printer operator and figured out the steps that go into it. And now consolidate your knowledge by completing a small task.

Interactive task

To reinforce your knowledge, take the test

| Let's start! |

| Next |

| Check | 0226

Sorry, you answered all the questions incorrectly

Read the lecture and watch the video again

| Go again |

| Go again |

Excellent!

You did a great job. Now you can get acquainted with other competencies

| Go Again |

What is the strongest material for 3D printing?

3DPrintStory 3D printing process What is the most durable material for 3D printing?

While the 3D printing process seems like a great alternative to traditional manufacturing methods, the parts produced can be fragile and unusable. As a rule, this is the result of using standard materials that are not designed for strength and durability. But there is a solution: use durable materials! Durable 3D printing materials can greatly enhance your options, as you can print parts and assemblies for small projects without fear of breakage.

But there is a solution: use durable materials! Durable 3D printing materials can greatly enhance your options, as you can print parts and assemblies for small projects without fear of breakage.

In this article, we will look at the three most durable types of 3D printing materials. However, before that, we will take a closer look at what strength means in terms of filament materials.

What is strength and how do we evaluate it?

The strength of a material can be measured and evaluated in different ways. In this article, we will mainly use tensile strength (stress before something breaks). We will list the tensile strength of each 3D printing material in pounds or pounds per square inch (PSI).

Despite the obvious amount of pounds the material can support, there is still a margin of error depending on how the part was printed. We've compiled research from a variety of sources to make sure these three materials are the strongest.

You must also understand that the material itself is not the only factor that affects the strength of the finished product. The design itself, post-processing and the 3D printing process also affect the strength of the part.

The design itself, post-processing and the 3D printing process also affect the strength of the part.

Polycarbonate

Polycarbonate (PC) is considered by many manufacturers and reviewers to be the strongest 3D printing filament available. In particular, it is possible to achieve high strength of polycarbonate products by 3D printing with an all-metal hot end and a 3D printer in a case that is isolated from the influence of the external environment.

Some Numbers

Airwolf 3D, after many filament tests, have come to the conclusion that polycarbonate is the best choice of durable filaments for desktop 3D printers. They were able to hang up to 685 pounds on a polycarbonate printed hook and found that this material had a tensile strength of 9800 psi. In contrast, the same part printed in PLA could only support 285 pounds.

Using a similar test, MatterHackers studied the tear strength of this type of thread, as well as a number of other materials. They were able to hang an average of 409 pounds on the polycarbonate hook, while the PLA parts had a significantly lighter average weight of just 154 pounds.

They were able to hang an average of 409 pounds on the polycarbonate hook, while the PLA parts had a significantly lighter average weight of just 154 pounds.

Finally, well-known 3D printing YouTuber Thomas Sunladerer reviewed several polycarbonate materials and gave very positive feedback on the strength of the material.

3D printing with polycarbonate

It is worth noting that the quality of 3D printing with polycarbonate is not very good. Compared to other materials, protrusions and small details may not turn out as well as using the same PLA.

According to Rigid.Ink, polycarbonate is mostly sold in clear color. This 3D printing material has excellent heat resistance as well as impact resistance. But note that you will have to print at high temperatures. As mentioned above, it is better to use an enclosed 3D printer and a solid metal hotend.

Polycarbonate pluses: super strong, excellent thermal and impact resistance.

Cons of polycarbonate: does not cope well with protrusions and small details of a 3D model, requires a body and an all-metal hot end, a limited number of colors.

Nylon

Next on our list of durable 3D printing materials is nylon. This material is considered by many to be the most reliable for desktop 3D printers. Nylon is inferior in strength to polycarbonate, but still clearly stronger than other competitors such as PLA and ABS.

Some numbers

A hook printed with nylon (910) thread had a breaking strength of 7,000 psi, while the same ABS hook only had a tenacity of 4,700 psi, according to Airwolf 3D. Airwolf 3D also noted that the nylon filament-printed clip holds 485 pounds.

MatterHackers posted similar results and noticed that a hook printed with their NylonX material can hold an average of 364 pounds before it breaks. Rigid.Ink also reviewed some nylon threads and gave them a four out of five rating for strength and a five for durability. For comparison: the strength and durability of PLA is three conventional units.

3D printing with nylon

Nylon is slightly easier to print than polycarbonate, but it's still not PLA. Nylon filament is quite hygroscopic, so it must be kept dry and requires a high printing temperature of 220-270°C. This material is prone to slight warpage, but is also resistant to impact, fatigue, and high temperature.

Nylon filament is quite hygroscopic, so it must be kept dry and requires a high printing temperature of 220-270°C. This material is prone to slight warpage, but is also resistant to impact, fatigue, and high temperature.

Nylon pros: impact resistance, fatigue resistance, heat resistance, easier to print than polycarbonate.

Nylon 9 cons0129 : hygroscopic, warping, very high hot end temperature required.

Composites

Finally, composite threads, although not essentially a single material, can be extremely strong. Composites are threads with certain additives that affect the properties of the material, including to increase strength. The names of these threads usually have the words "pro", "reinforced" (reinforced) or "infused" (infused), since they are usually a mixture of different materials.

For this reason, it is impossible to assess where the composite fibers are compared to the two previous materials. Some composites, such as Carbonyte, can compete with nylon threads for strength, while some composites are less durable.

It all depends on what the composite thread consists of. Durable is usually a high strength material such as nylon impregnated with another high strength material such as carbon fiber or glass.

Speaking of carbon fiber, this is also a very strong filament that is sometimes used for 3D printed bicycles. However, some composite fibers are stronger than many pure carbon fibers, so they are not in the top three, but deserve special mention as composite fibers.

Some numbers

We will use nylon with carbon fiber and nylon with glass fiber as examples. MatterHackers has determined that hooks printed on these materials can hold an average of 349and 268 pounds respectively.

Rigid.Ink gave the fiberglass nylon filament four out of five ratings for strength and five for durability. They also gave the carbon fiber nylon a five out of five rating for both strength and durability. In comparison, PLA and ABS were in the top three for strength.

3D printing with composites

Composites vary in the way they are 3D printed, but they are generally relatively similar to their base material.

Read the lecture and watch the video again

Read the lecture and watch the video again