What 3d printers does shapeways use

How Shapeways 3D Printing Works

Creating a product has never been easier

1. Design a Product

Use a 3D Printing App

Tweak and tinker your product to perfection using an easy 3D printing app.

Use Your Favorite Software

We support a wide range of programmatic, parametric, sculpting and modeling software.

Hire a Designer

Work with the best 3D modellers in the world to bring your idea to life.

2. Upload to Shapeways

INSTANT PRICING

45+ HIGH QUALITY MATERIALS

AUTOMATED & MANUAL CHECKS

FIXING TOOLS

24/7 GLOBAL SUPPORT

NO MIN ORDER SIZE

Upload Your Model

Experience the journey of a 3D printed product.

Arrow Ring by Courtney, etc.

Run Your Business on Shapeways. You design amazing products, we'll help you reach a global market.

Learn MoreShop the Marketplace

Get feedback and support from a global community, wherever you are in your design process.

First to Try

You're not alone in the creative process. Get support on your early stage product, from your first print through product iteration.

Community Forums

Join hundreds of thousands of Shapeways community members all over the world. Explore our forums and blog.

Get Support Wherever You Are

Whether you're creating a product for the first time or you're an expert, Shapeways has over 150 tutorials to help you along your way.

What our Community is Saying

Many of the things I design are so complex that they would not be possible using traditional techniques, and I love how 3D printing takes jewelry design to the next level.

Maaike van der Horn - MCODE

[Shapeways] is our lemonade stand.Mostly to gain entrepreneurial muscles and work together. And we're having a blast trying it out.

SANTIAGO P. - SUNNY DAY SUPPLIES & CO.

Shapeways is easy to work with, and has the quality level and price that gives me the freedom to realize my creations in the way I want to.

Summer Powell - Summerized

I was able to prototype at such low cost, yet end up with a product that was great. Shapeways enabled me to take a finished product to investors &distributors.

MATT V. - FOUNDER OF BUMPRZ

Getting Started

JEWELERS

PRODUCT DESIGNERS

ARTISTS

ENGINEERS

ANIMATORS

TINKERERS

ENTREPRENEURS

CROWDFUNDING

Shapeways: 3D Printing Service Online

3D Printing Service

Create and customize. Streamline and save. Break down design barriers and scale your business with Shapeways 3D printing services.

Streamline and save. Break down design barriers and scale your business with Shapeways 3D printing services.

Why 3D Printing?

Reduce Assembly Time

Don’t waste time putting products together! Rely on 3D printing to make complex geometries that can be printed as one piece—or consolidated in one build.

Fast Turnaround

Working on a project for a customer that has to be just right? Get models back fast, and 3D print new iterations, if needed, for final feedback and production.

Reliable Quality

Proprietary processes, expert 3D printing operators, and inspections are our secrets to delivering exceptional, quality products every time.

Parts 3D Printed

3D Printing Technologies

Materials and Finishings

Countries Shipped

Customers Served

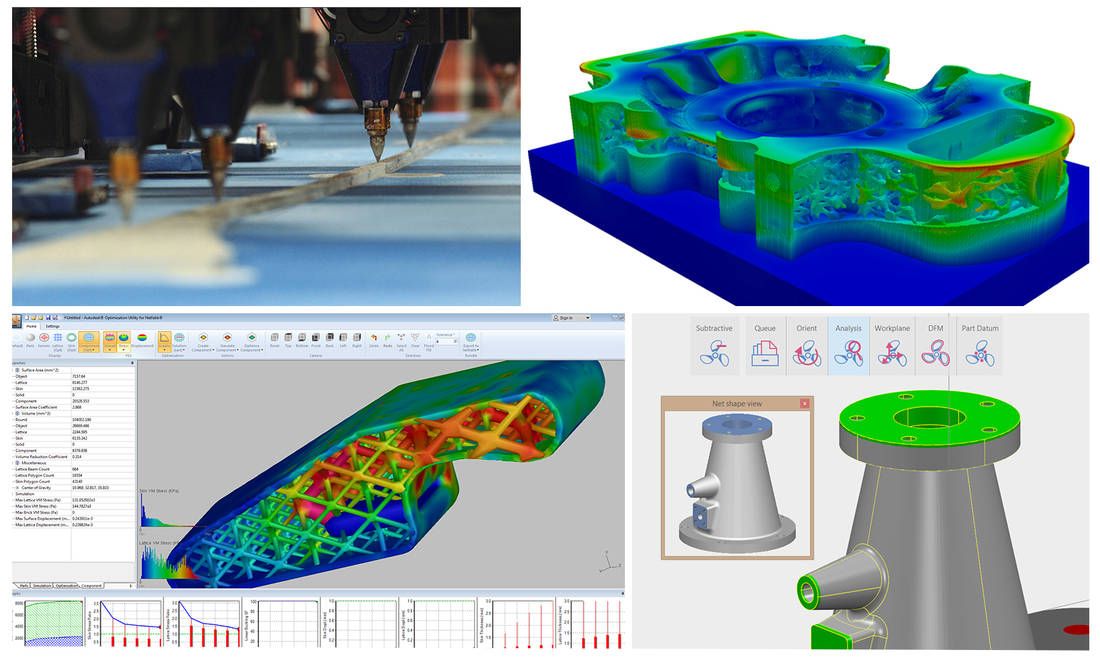

Cutting Edge Technologies

Manufacture high-quality products in over 90 of the best materials and finishes, from plastics to metals.

HP Multi-Jet Fusion

- Nylon 12 with a smooth and finished surface

- Exhibits incredible strength, durability and stiffness

- Supports complex geometries and thin features HP Technologies

Our Services

Production Parts

Upload customized models for 3D printing service—ensuring durability and strength in materials that result in end-use products meant to last. Our Services

Rapid Prototyping

Take the guesswork out of product development with 3D printing services for high-performance models used in meetings, testing, and perfection of final parts. Prototyping Service

E-commerce Integrations

Launch your business through our marketplace by connecting to the Shapeways platform through our API, Shopify, or Etsy E-commerce Integrations. E-commerce Integrations

Professional Design Services

Bring your idea to life with 3D file design and optimization. Through our partnership with ZVerse, every customer has access to expert 3D Design solutions for any project need. Design Service

Design Service

Rapid Prototyping

Our high quality printing enables you to assess factors such as ergonomics, usability, manufacturability, and material testing. Prototyping Service

E-commerce Integrations

Launch your business through our marketplace by connecting to the Shapeways platform through our API, Shopify, or Etsy E-commerce Integrations. E-commerce Integrations

Materials

Nylon 12 [Versatile Plastic]

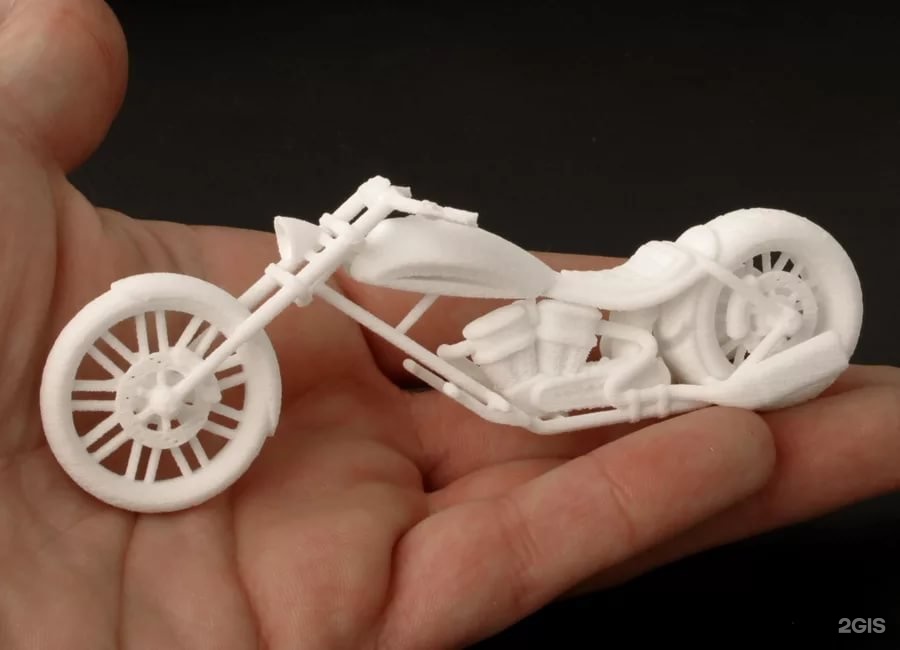

Nylon 12 [Versatile Plastic] is a durable nylon plastic that can be used for a wide range of applications, both for prototyping and for end products. Printed using Selective Laser Sintering (SLS) 3D printing services, when thin, it's flexible enough for hinges and springs and when thick, strong enough for structural components. Material Details

Accura 60

Accura 60 is a translucent and rigid acrylate-based plastic. Shapeways 3D prints this material using a large-format Stereolithography (SLA) printer capable of producing small to large parts with high resolution and detail as well as smooth surfaces with limited layer lines. Material Details

Material Details

Stainless Steel 316L

Stainless Steel 316L is manufactured using ExOne’s ‘Triple Advanced Compaction Technology’ with Binder Jetting. Unlike our Steel that is infused with bronze, this material is a single alloy, composed of pure Stainless Steel. Material Details

Nylon 12

Nylon 12 (Versatile Plastic) is a durable nylon plastic that can be used for a wide range of applications, both for prototyping and for end products. Printed using Selective Laser Sintering (SLS), when thin, it's flexible enough for hinges and springs and when thick, strong enough for structural components. Material Details

Accura 60

Accura 60 is a translucent and rigid acrylate-based plastic. It is 3D printed using a large format stereolithography (SLA) printer capable of producing small to large parts with high resolution and detail as well as smooth surfaces with limited layer lines. Material Details

Stainless Steel 316L

Stainless Steel 316L is manufactured using ExOne’s "Triple Advanced Compaction Technology" with a binder jetting system. Unlike our Steel that is steel infused with bronze, this material is a single alloy, 100% Stainless steel 316L. Material Details

Unlike our Steel that is steel infused with bronze, this material is a single alloy, 100% Stainless steel 316L. Material Details

Testimonials

I like the ease of use in the Shapeways platform, being able to 3D print on-demand orders for the first time, and most of all–being able to scale my business. In the beginning years ago I basically had the change in my pocket and a credit line at my bank so I couldn’t order a ton of things, and you never know what’s going to sell.”

Steven Jaworski

Owner | Voytek Medical

During the process, we used Shapeways capabilities to 3D print many prototypes. That meant we had the option to iterate very quickly, print objects, and test them to see if they were working correctly in terms of complexity, or too much complexity.”

Yonatan Assouline

Manager & Co-Founder | Flamingo Works

Shapeways was really great when we worked together before, which led us to reach out again. It’s been so helpful to talk with them about what we could do in every aspect of 3D printing and finishing, and it saved us a lot of time in experimentation. ”

”

Nathan Lachenmyer

Director of Technology | Sitara Systems

I like the ease of use in the Shapeways platform, being able to 3D print on-demand orders for the first time, and most of all–being able to scale my business. In the beginning years ago I basically had the change in my pocket and a credit line at my bank so I couldn’t order a ton of things, and you never know what’s going to sell.”

Steven Jaworski

Owner | Voytek Medical

During the process, we used Shapeways capabilities to 3D print many prototypes. That meant we had the option to iterate very quickly, print objects, and test them to see if they were working correctly in terms of complexity, or too much complexity.”

Yonatan Assouline

Manager & Co-Founder | Flamingo Works

Shapeways was really great when we worked together before, which led us to reach out again. It’s been so helpful to talk with them about what we could do in every aspect of 3D printing and finishing, and it saved us a lot of time in experimentation. ”

”

Nathan Lachenmyer

Director of Technology | Sitara Systems

Previous Next

Recent Articles

Trusted by Businesses Around the World

Review of leading companies in the field of 3D printing services / Habr

I got the impression that in Russia there is a stereotype that there are only two ways to make money on 3D printers:

1) Become a dealer of an international company / set up the production of your own 3d printers

2) buy several 3d printers and take orders from architects/doctors/military

0007 designer people are lower than they seem, and the future, which is unevenly distributed / distributed not quite in Russia, is already here.

Under the cut you will find a brief overview of the three giants of the European and American 3d printing industry, which do not specialize in the production of their own 3d printers, but develop communities, create a "marketplace", act as platforms for startups, designers, etc. After the review of the "big three" follows a review of the most interesting projects created around these giants.

After the review of the "big three" follows a review of the most interesting projects created around these giants.

Some projects are commented by Konstantin Ivanov (consst), who attended European (3DPrintShow) and American (Inside 3D Printing) conferences.

Three giants in 3D printing marketplaces from USA and Europe

www.shapeways.com

en.wikipedia.org/wiki/Shapeways

The company, organized in 2007 in the Netherlands (originates from the Philips business incubator), but is headquartered in New York. The company employs 90 people. At the moment, it has attracted about $40 million in investments. It has two full-fledged productions in the Netherlands and in New York. The number of ordered products has exceeded one million.

Konstantin: “World and US market leader Shapeways. Successfully located its head office in Queens, NY, becoming a Mecca among the creative people. For a pretty decent history of its existence, Shapeways has gathered a huge community of designers, at the end of 2013 - 300,000 people.Of course, the number of active and prolific designers is much smaller, but the total number and products on the marketplace cannot fail to impress.

With each of the active designers, Shapeways community managers (they are usually called community managers, which is rather rare in Russia so far) work a lot, communicate, and help resolve any issues: high-quality photography of products, placement on the marketplace, correction of 3d models. In general, the community is the heart of Shapeways.

A huge knowledge base they have collected on the forum and in the Tutorials sections of the site allows you to find the answer to almost any question that arises when working with 3d models for printing. Storehouse of knowledge.

Some of the people from Shapeways (former community managers, production managers) are already creating their own separate businesses in the field of 3d printing. Shapeways encourages and develops an entrepreneurial culture.

However, competitors really, really dislike Shapeways for dumping the market.

Indeed, their prices for 3d printing from many different materials are almost always lower than competitors from Europe. They can afford it, with so many investments involved)

Shapeways have created and are developing an excellent powerful API for developers of various online 3d model customizers, which can also be made through them. As a result, in addition to the marketplace, they work as a production and API, which is very convenient.

They completely stopped delivering to Russia since last year, citing problems at customs. By the way, I must say that the experience of ordering 3D printing from them in NY is also not ideal: they missed the delivery time for samples, I had to write to support, but the issue was quickly resolved.”

A few videos and articles in English for a deeper understanding

Video about the company. Keanu Reeves is there too.

Number of unique pieces made from 2008 to 2013

Founder Peter Weijmarshausen

Forbes article (10/10/2011)

Wired article by Bruce Sterling (10/3/2011)

BusinessInsider article (12/19/2012)

Another performance by Peter Weijmarshausen

www. sculpteo.com

sculpteo.com

en.wikipedia.org/wiki/Sculpteo

French startup launched in 2009. Raised several million investments, has a small fleet of its equipment

Strengths: a very interesting online service, with the ability to not only analyze your model, but also prepare it online for printing. There is a mobile application 3DPcase

Konstantin: “Guys from France who started after Shapeways hit the market. Small team, own small production (industrial 3d printers) in Paris.Like many other players in the market, part of their production capacity is outsourced. This is quite logical, since to control a huge production, including from metals, ceramics, etc. - Pretty messy story.

Quite often you can meet them at exhibitions. The last time, while talking with them at 3DPrintShow in London and Inside3DPrinting in New York, the guys shared their opinion on the pace of market development in Europe and the USA and a little more about competition in Europe, where Shapeways is also actively going.

The main focus of Sculpteo's development is applications, their own online software for calculating, correcting and even preparing 3d models for printing. This is very impressive, none of the competitors do this. For comparison, Shapeways uses only half of its software, the second part is Netfabb's software.

Sculpteo is great for those who already know how to work with 3d models in many ways and use 3d printing for prototyping.

The team is also developing its API. Delivery to Russia, according to the director of the company Clement, they do, but in fact this is not possible.”

Once they kept their blog on Habré, with some quite useful articles, for example, the translation of the article about the “Industrial Revolution” 1, 2, 3, 4, 5.

Konstantin: has an office both in Belgium and, for example, in Ukraine. The main activity is prototyping of industrial, engineering, medical, aviation, etc. products.However, the company also has its own consumer direction, which was named i.

Materialise. The marketplace and community are also being developed. If you look closely, they very much follow the example of their American colleagues, up to copying interface elements, which is quite logical - the usability in Shapeways is really very good.

Recently launched the so-called Boutiques, separate shops for selected designers. Continue their movement to the consumer segment.

A number of important advantages: its large production with the most experienced staff and a large number of different technologies, printers and post-processing. Completely own software that works well with models (but no better than Sculpteo does). And, of course, the API, which they are actively developing and connecting more and more partners to it.

I also offer a white label option for companies that don't want their customers to know exactly where their products are made.”

A little video about Materialise

Videos (in English)

How the largest stereolithographic machine

How to earn 3D printing without 3D printer

Aggregators:

3DHubs.com - allow owners to register their 3d printer in the database. Thus, it becomes possible for any person to find either the nearest 3d printer, or exactly the printer that is needed (all over the world).

Plus, they can collect useful statistics and publish monthly trend reports. They take a commission of 15-20%

Konstantin: “One of the investors from a London fund introduced me to the founders of a fairly recent startup 3dhubs, who also invested in the company. Brian and Bram came up with and are making a great international story that actually makes life easier for those who need to print something “close to home”.The service works all over the world and even a little in Russia. The guys are attentive to the customer service inside, help each client if one of the hub owners has problems with printing. Very comfortably.

Coming to each new city or to an exhibition, they do the so-called unlock of the city and open new hubs with printers there.

This was also the case at the exhibition in London last year.”

makeXYZ.com

Texas Entrepreneurs Project. Allows you to search for 3d printers and 3d designers. Received investment from Intel.

Standing on the shoulders of giants

www.sols.co

Allows you to create personalized insoles.

Konstantin: “A great example of how, growing inside a small start-up company, Sols founder Kegan Schouwenburg caught the entrepreneurial spirit and started her own project to produce custom 3D printed orthopedic insoles!Kegan was one of the people who did the entire production of Shapeways from scratch, which is truly a huge job.

Her company has now raised about $8 million in funding from the same investors who invested in Shapeways and is actively building its business. At the same time, he uses polyamide (nylon) for the manufacture of the base for the insoles and makes all samples using Shapeways.

Proper collaboration and collaboration.”

mixeelabs.com

An online application that allows you to create figurines ($25), molecules, key chains for dogs, cufflinks and wallets for cards.

Konstantin: “Second success story in the 3d printing business, also from a former Shapeways employee. Nancy Yi Liang is the founder of product customizer Mixeelabs, who makes money from his brainchild and lives in New York.In our last meeting with her, she told how well things are going with the sale of her products from the site (80% of sales), a little worse from the Shapeaways marketplace (20% of sales), but at the same time, the very first viral effect gave her the same Sad Keanu, which she invented and distributed perfectly everywhere.

Her project is a great example of how, having come up with an interesting and quite viral thing, you can earn money on it in the long run.”

joshharker.

com

Joshua Harker — Artist, sculptor, musician, digital adventurer, imagination architect, troublemaker

Konstantin: later he went into business, opened his own company, developed his own unique and recognizable style (which was later copied by many others) and showed how to effectively apply new design approaches to 3d printing.I could not resist and decided that the worse we are, we will make one for ourselves. Here is the result:

www.minetoys.com

For all Minecraft fans. Prints your character from the game.

www.twikit.com

The service allows you to customize gifts and jewelry made of plastic and metal.

n-e-r-v-o-u-s.com

Konstantin: “Nervous are practically gods in 3d printable design, they come up with new shapes and structures and constantly impress.

In addition to the beautiful futuristic design, they came up with an incredible online thing that creates amazing kinetic structures right in the browser, right in front of you.All this is flexible and allows you to actually make wearable objects made using 3D printing.

Photos of works from Nervous System

Octopussy which I myself printed a year ago (report on Habré)

Blokify.com

A mobile application that makes it very easy to create a 3d model and send it to print. Convenient for working with children.

Video and a couple of photos

draw

materialize

WhiteClouds.com

»Submit your ideas (even on a napkin). We will bring them to life."

The company does not require its customers to be able to handle a computer: you can send a simple sketch made by hand, and the company's specialists will turn it into a digital three-dimensional model, print it on a 3D printer and send the finished product to the customer.Once, they even sent a cardboard model to the company, asking them to print a copy on a 3d printer, and the order was completed.

Portfolio under spoiler

A little zombie:

Russian projects

The following picture speaks eloquently about the state of affairs in Russia:

3D Printing Map of the Worldparable on the topic

One company once sent a shoe salesman to an African city.

Shortly after arriving in Africa, he wrote to the office:

“You can take me back. Here everyone walks barefoot.

They returned him to his homeland.Then they sent another shoe seller.

Almost immediately upon arrival, he sends an urgent telegram to the office:

“Send all the shoes you have.Here everyone walks barefoot!

zdravprint.ru

A service for the creation of individual fixators, which are printed on a 3D printer and are designed to replace plaster at certain stages of recovery.

Konstantin: “My good friend Fedor Aptekarev at the last Yandex Startup Camp launched a project to create plaster using 3d printing. With such a cast, the fracture can be endured a little easier.”What awaits us in the future

Me : Konstantin, while collecting materials for this post, I came across some skeptical statements by very respected people (for example, the director of Epson) about the future of 3d printing, but you, in turn, You have been actively developing this industry in Russia for a year already, holding training seminars, developing a community, holding competitions for designers, planning to launch an API for your project, what is the basis for your confidence that this is worth doing?

Konstantin: Glad you asked.Let's clarify what exactly the head of Epson said. Something like this: “There is no big future for plastic 3D printing at home. We will only make commercial 3D printers.” He talks about building an industrial design printer. Epson itself is going to develop industrial printers. And I completely agree with them.

My opinion is that industrial 3d printing technologies, which we also use, can really take 3d printing to a new consumer level. Here you need to immediately make a reservation that the head of Epson is talking about home printing, but he only means FDM technology (plastic filament melting), as the most popular home 3d printing technology. At the same time, do not forget that after the end of the patent for SLA technology (stereolithography), for example, a completely “home” Formlabs 1 printer appeared, which gives a very acceptable quality. Yes, of course, it can not be compared with the industrial one.

I'm talking about the fact that rather than home 3d printing, there is no future, but FDM technology.

She will live herself. It is suitable for too narrow an application and the quality is very, very low.

I am sure that what we are doing now will create (and is already creating it abroad) a new market and new opportunities for consumers and designers, will speed up the solution of many problems and, of course, will become more accessible. Confidence is fully confirmed by the facts, the results of communication with colleagues from abroad and in Russia, and, of course, by the numbers, which are constantly growing.

Me: Konstantin, after talking with the CEO of the world's leading companies and having “visited the future a bit”, what will the world expect in the coming years?

Konstantin: In the very near future, I can say with complete confidence, the following awaits us:

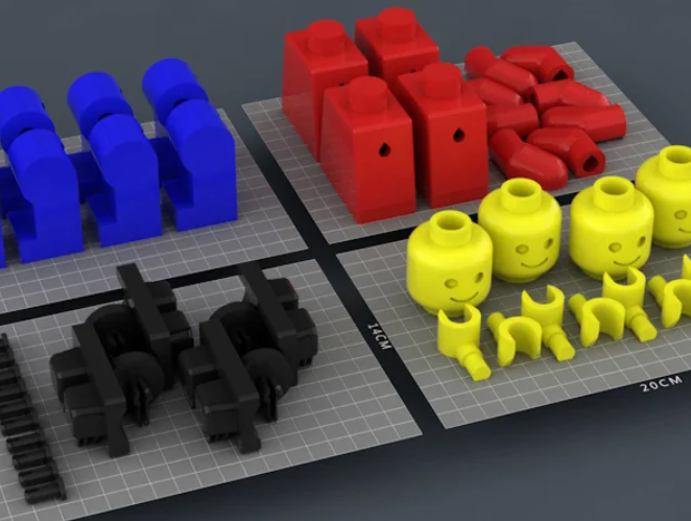

- the widespread integration of the "print on a 3d printer" button into all conceivable and unthinkable applications, programs, games, and so on. We will print both in 3d printing services and for enthusiasts on home 3d printers- the end of patents for the main industrial 3d printing technologies (SLA (already), SLS, 3DP, DMLS) will lead to a more serious development of smaller and less expensive printers, respectively, the growth of both industrial technologies and quality will also skyrocket

- Google , actively introducing 3D scanners into their phones, will also contribute to the growth of the market, since many people will have the most important thing for the market - a model for printing.

And to create it, you only need a phone number

- finally, the alliance of 3D Systems and Google in the Ara project will give a significant jump in the development of 3d printing speed and it is likely that we will finally see how an entire custom goods production line will finally be made using 3d printing. This is what is called mass customization

P.S.

Model Databases:

Thingiverse.com (free models, project by MakerBot, over 100,000 models downloaded, 21 million downloads)

Threeding.com (paid and free models, project from Bulgaria, plans to release an app for Apple iOS and Android, commission 8.5%)

3DPrintWise.com ()

CGtrader.com (paid models, received investment from Intel. 35,000 3d designers posted over 45,000 3d models)

Who wants to participate in the API test for the 3d printing service - write to me magisterludi or Konstantin consst

Classification of 3D printers / Sudo Null IT News

ISS, organs, houses and more.

Foreign technology publications are beginning to say that 3D printing is able to resurrect the industry in the states, and the shapeways service, before our eyes, is showing interesting growth rates, albeit far from industrial ones. With such an abundance of laudatory texts about the impending revolution in production, the thought comes to mind that the Russian segment is practically free, but is it so easy to achieve industrial scale with the assurance of the printers themselves and the emergence of open source projects? It's up to you to decide, but food for thought on the topic under the cut.

I’ll make a reservation right away that the standards in the industry are very conditional, so far. But a brief overview with the order of prices can be generated now. And so, let's get started.Consumer

A type of printer intended primarily for personal use. Supplied in the form of a designer, or assembled. The vast majority of printer models of this type are derived from the open source RepRap project.

Since they have basically the same platform, their characteristics are also very similar.

Designed with an eye on the average user and equipped with a fairly simple and intuitive interface. Printed, as a rule, ABS and PLA plastic. Complex and high-precision objects will be quite problematic to print, but they print ordinary crafts with ease, albeit for a long time.Price range: $500 - $3500

Target audience:

Designers / artists / inventors who work from home.Personal

An edge class of printers that is home but also the lower rung of industrial business printers. These devices have much in common with their consumer-grade brothers, but have the higher quality and precision of printing that is inherent in professional 3D printing systems. The appearance of such printers is rather a reaction of large manufacturers to the growing market for home systems. Given the low accuracy of the consumer class, vendors have offered reduced models of professional systems with performance close to them.

Operating printers of this class is just as simple and boils down to loading an image and pressing the start button. At the same time, this limits the possibilities in terms of various advanced printing options.

Suitable for use in offices, however, the noise and high temperature conditions of some models require their placement at some distance from the working area. The ease of cleaning output objects was not carried over to this class from industrial models, so it would be logical to place them in a separate workspace.Price range: $7,000 - $40,000

Target audience:

Small business with a small budget, but who needs occasional 3D printing. It can be engineering companies, design studios, marketing agencies.

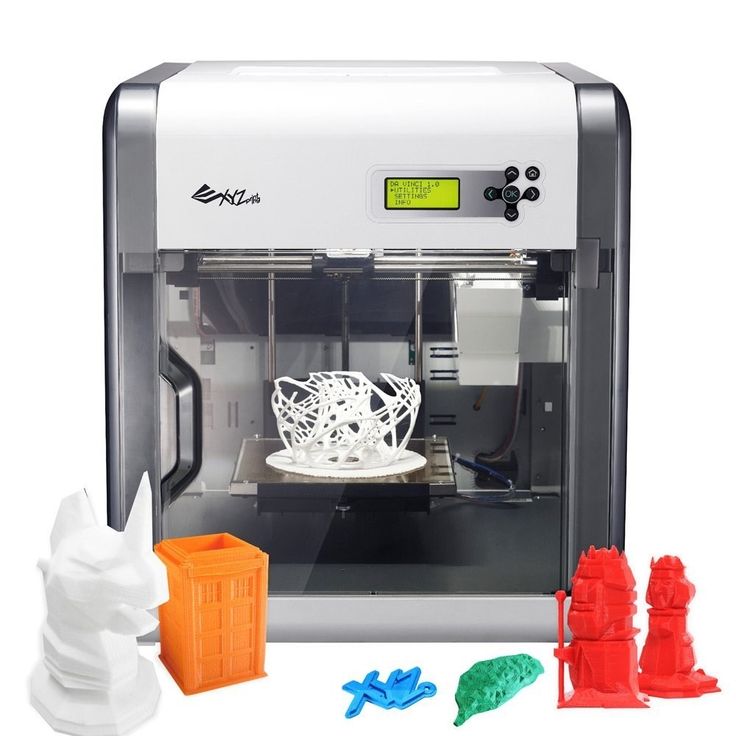

Professional

Systems in this class no longer look compact, but rather look like large refrigerators. This is the basis of 3D printing technology, which includes all the achievements and possibilities available to the industry.

The purpose of professional systems can be very different, from prototyping to full-scale production, which in turn makes them an excellent option for both large businesses and high-tech companies with a small staff. ShapeWays, by the way, uses printers of this class.

Unlike their small brothers, these printers, due to the large number of modes and additional options, already require certain skills to work with them, so you cannot do without an operator.

In terms of the workspace, everything is not so simple here either. They are very large and noisy, so they require a separate room with good ventilation. Space requirements vary, but the space should be something like a laboratory and have a high-voltage line connected.

As a result, we get a universal 3D printing machine that provides the highest print quality and increased product sizes compared to the lower grades. ShapeWays, for example, collects several objects per print cycle, placing them at some distance from each other, which ultimately has a positive effect on the speed of order processing.

Price range: $30,000 - $750,000

Target audience:

Companies that have a constant need for prototyping, modeling, manufacturing of various kinds of objects with high quality and accuracy.

Production

The name of the class speaks for itself. These machines combine the precision and quality of professional printers, large print area, high level of automation and process control. On them, as well as on professional installations, it is possible to print not only prototypes, but also the final consumer product.

Systems of this kind are not intended for ordinary users, and the amounts that will have to be invested in such production will make you logically want to hire an experienced operator who will make the whole mechanism work 24 hours a day without downtime.

Small spaces are no longer enough. Here you need to clearly plan the future line and take care of the supply of the high-voltage line and gas pipe.

The result is a high-tech production that can quickly change the profile and use materials from ABS plastic to titanium.![]()

Learn more