3D scanner definition

What is 3D Scanning? | Laser Design

First of all, let’s be clear that 3D laser scanning is not magical. True, the technologies that make it possible are very advanced and quite amazing. But behind the mirrors—found in the laser probe (without any smoke)—there is a lot of know-how and experience that makes the laser scanning experience seem so easy to Laser Design customers.

Read on or watch our video on What is 3D Scanning?

What is 3D Scanning?

3D Laser Scanning is a non-contact, non-destructive technology that digitally captures the shape of physical objects using a line of laser light. 3D laser scanners create “point clouds” of data from the surface of an object. In other words, 3D laser scanning is a way to capture a physical object’s exact size and shape into the computer world as a digital 3-dimensional representation.

3D laser scanners measure fine details and capture free-form shapes to quickly generate highly accurate point clouds. 3D laser scanning is ideally suited to the measurement and inspection of contoured surfaces and complex geometries which require massive amounts of data for their accurate description and where doing this is impractical with the use of traditional measurement methods or a touch probe.

The 3D Scanning Process:

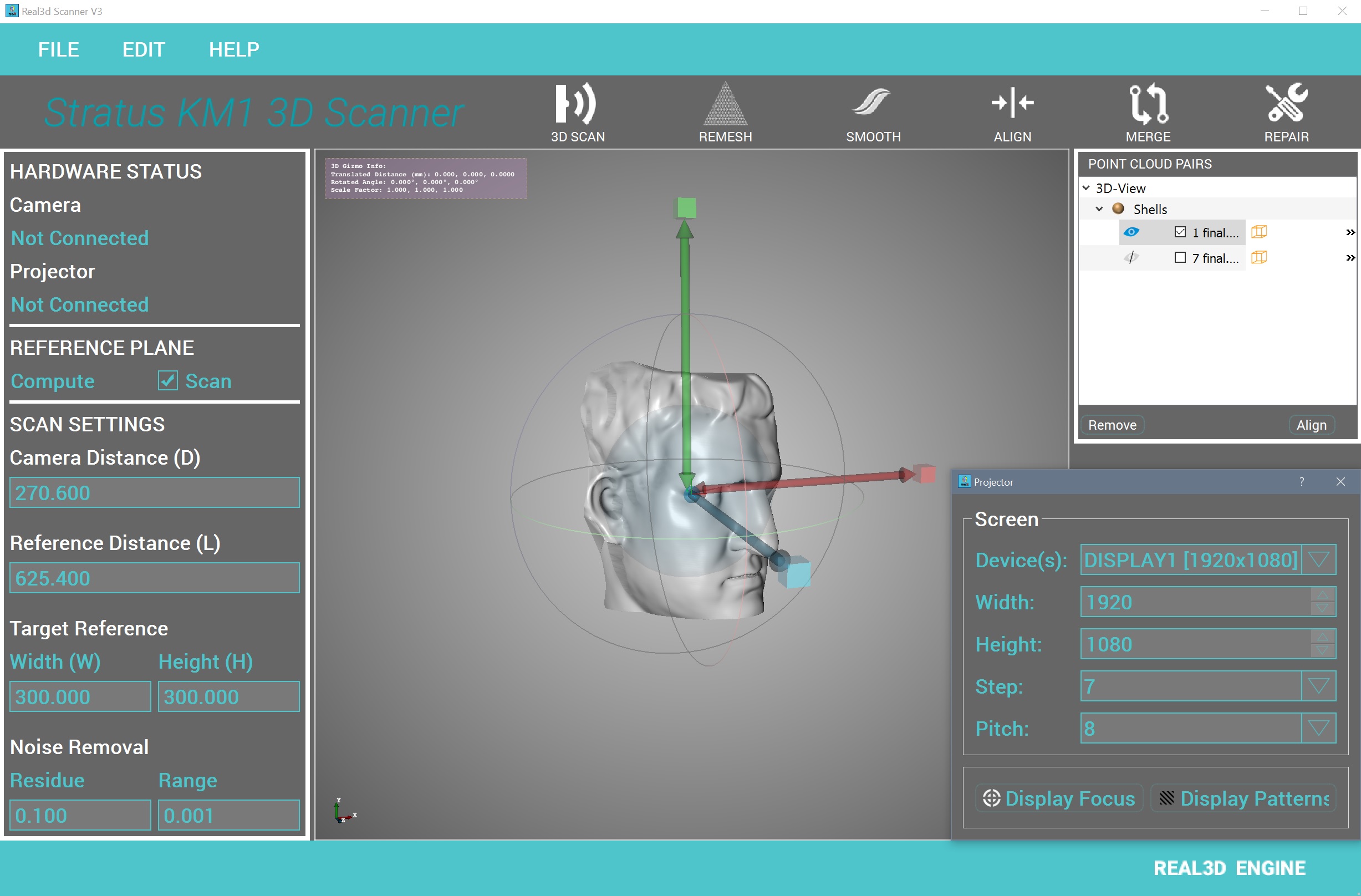

Data Acquisition via 3D Laser Scanning

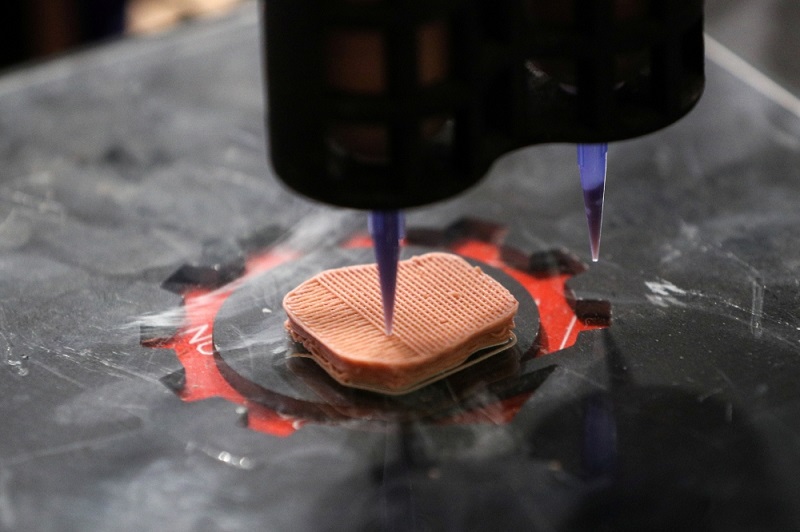

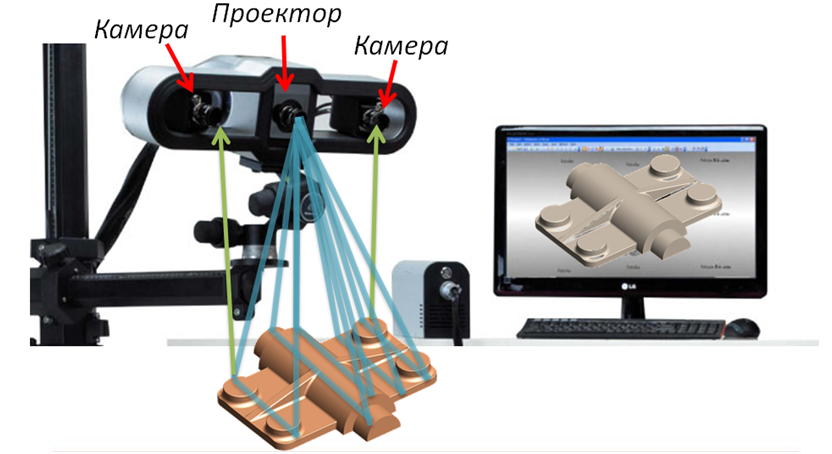

3D Laser Scanning Process An object that is to be laser scanned is placed on the bed of the digitizer. Specialized software drives the laser probe above the surface of the object. The laser probe projects a line of laser light onto the surface while 2 sensor cameras continuously record the changing distance and shape of the laser line in three dimensions (XYZ) as it sweeps along the object.

Resulting Data

The shape of the object appears as millions of points called a “point cloud” on the computer monitor as the laser moves around capturing the entire surface shape of the object. The process is very fast, gathering up to 750,000 points per second and very precise (to ±. 0005″).

0005″).

Modeling Choice Depends on Application

After the huge point cloud data files are created, they are registered and merged into one three-dimensional representation of the object and post-processed with various software packages suitable for a specific application.

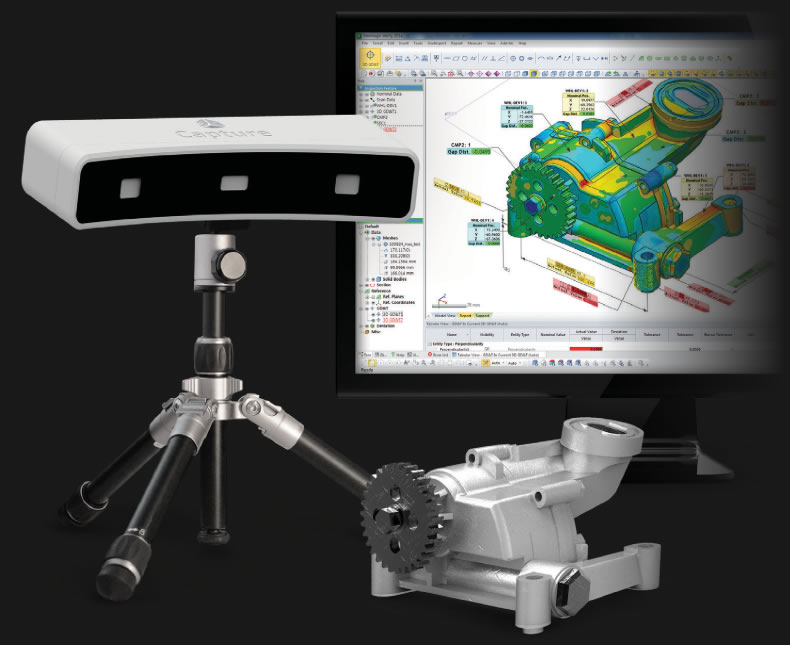

Point Cloud Data for Inspection

If the data is to be used for inspection, the scanned object can be compared to the designer’s CAD nominal data. The result of this comparison process is delivered in the form of a “color map deviation report,” in PDF format, which pictorially describes the differences between the scan data and the CAD data.

CAD Model for Reverse Engineering

Laser scanning is the fastest, most accurate, and automated way to acquire 3D digital data for reverse engineering. Again, using specialized software, the point cloud data is used to create a 3D CAD model of the part’s geometry. The CAD model enables the precise reproduction of the scanned object, or the object can be modified in the CAD model to correct imperfections. Laser Design can provide a surface model or the more complex solid model, whichever results are needed for the application.

Laser Design can provide a surface model or the more complex solid model, whichever results are needed for the application.

Have additional questions? Check out our Glossary, sign-up for our eNewsletter, watch the 3D Laser Scanning Video or ask a question of your own!

What is 3D Scanning? – Definition, Advantages and Uses

3D scanning involves collecting data about the shape and appearance of a physical object, structure, environment or person and then using that data to construct digital 3D models. 3D scanners are used to analyze objects and environments, collect the data and construct the model.

- We also have a ranking of the best 3D scanners.

3D scanning is used across a wide range of industries, from architecture and engineering to medicine and entertainment. By allowing workers in these industries to examine objects digitally,

3D scanning can help make their work more accurate and efficient. 3D scanning is also compatible with 3D printing and CAD (computer-aided design), and it can even be used for reverse engineering.

That’s a very basic explanation of 3D scanning, but there’s a lot more to learn about this important process. This guide covers everything you need to know about 3D scanning, including the different techniques, advantages, limitations, applications and how 3D scanning works.

- We also have a ranking of the best DIY 3D scanners.

What is 3D Scanning? The Basics

While there are a variety of different 3D scanning techniques, they all rely on the same principles. All 3D scanners use a sensor, which may be a physical probe, laser or light, to measure the distance between a camera and an object.

3D scanners are able to identify 3D points, calculated from photos and depth measurement using triangulation, with each point appearing on the screen individually. Altogether, these 3D points form a point cloud, which appear like in the image below. The process of extrapolating the shape of a subject from points is known as reconstruction.

Once the scanner has created the point cloud, it then meshes it to turn it into a 3D model made up of surfaces. Meshing essentially means you are connecting the dots of the point cloud to produce a complete model. A mesh is a collection of vertices and faces, along with information of how the vertices make up the faces. Rather than valuing each point equally during the meshing process, you can deprioritize some of the points to create a mesh that isn’t extremely complex and therefore is easier to work with.

Meshing essentially means you are connecting the dots of the point cloud to produce a complete model. A mesh is a collection of vertices and faces, along with information of how the vertices make up the faces. Rather than valuing each point equally during the meshing process, you can deprioritize some of the points to create a mesh that isn’t extremely complex and therefore is easier to work with.

Finally, the mesh is textured. In the context of 3D scanning, texture refers to an image painted upon a service, and applying a texture to a surface is called texture mapping or UV mapping. Textured images are stored in a special file where every pixel with U and V coordinates has a corresponding color. Many 3D scanners have a special camera for capturing texture that allows them to collect color information at each point. Bright and uniform lighting is required for optimal results, unless the scanner is equipped with a flash.

Generally, several scans are required in order to create a complete model, as the scanner needs to collect information from every side of the subject. Scans are brought together into a common reference system, a process known as alignment or registration. The scans are then merged to create a 3D model. The whole 3D scanning process is known as the 3D scanning pipeline.

Scans are brought together into a common reference system, a process known as alignment or registration. The scans are then merged to create a 3D model. The whole 3D scanning process is known as the 3D scanning pipeline.

3D Scanning Techniques & Advantages

There are a wide variety of different 3D scanning methods, each with its own advantages and disadvantages. Here’s a look at the main 3D scanning techniques.

Contact-based 3D Scanning

As the name suggests, with this technique a scanner collects data on an object through physical touch. The object either rests on a surface plate or is held in place by a fixture as it is probed by the scanner, and the software used with the probe will detect how and where the probe touches the object’s surface and record the 3D location of the surface. A coordinate measuring machine (CCM) is an example of a contact-based 3D scanner.

Contact-based 3D scanning is often used in manufacturing, particularly for performing quality control of parts during maintenance operations or after fabrication. This technique is very precise and can be used to 3D scan transparent or reflective surfaces, but on the downside, it is slower than most other 3D scanning techniques and isn’t well suited to scanning freeform shapes.

This technique is very precise and can be used to 3D scan transparent or reflective surfaces, but on the downside, it is slower than most other 3D scanning techniques and isn’t well suited to scanning freeform shapes.

Laser Triangulation 3D Scanning

This type of 3D scanning uses either a single laser point or a laser line to scan an object. The laser is cast by the 3D scanner and reflects off the subject, modifying its initial trajectory. The change in trajectory is recorded by a sensor and allows the system to calculate the specific angle of deviation using trigonometric triangulation. With enough laser scans, the scanner can map the subject’s surface and create a 3D scan.

Laser triangulation is a highly accurate 3D scanning technique that produces high resolution scans. Its main limitation is that it isn’t ideal for scanning objects with transparent or shiny surfaces. Laser triangulation scanners are often used to probe the environment.

Structured Light 3D Scanning

Like laser triangulation scanners, structured light scanners also use trigonometric triangulation to create scans. However, rather than using a laser, this technique projects a series of linear patterns of light onto an object. Two sensing cameras analyze the light patterns, examining the length of each line to calculate the distance to the subject. The scanner can then calculate exact X-Y-Z coordinates to create extremely accurate 3D models.

However, rather than using a laser, this technique projects a series of linear patterns of light onto an object. Two sensing cameras analyze the light patterns, examining the length of each line to calculate the distance to the subject. The scanner can then calculate exact X-Y-Z coordinates to create extremely accurate 3D models.

As well as being highly precise, structured light 3D scanning is fast, produces high resolution scans, and is suitable for scanning people. On the downside, it is highly sensitive to lighting conditions, so it doesn’t work well outside.

Laser Pulse-based 3D Scanning

Also known as time-of-flight scanning, this method creates scans using the speed of light and sensors rather than triangulation. Laser pulse-based 3D scanners do this by measuring how long a casted laser takes to reach an object and come back via reflection. The laser and sensor hardware is rotated by a mirror, which allows the software to collect 360 degrees worth of data and capture the information needed to create a 3D model.

The main benefit of laser pule-based scanning is that it can be used to scan very large objects, structures and environments. It is, however, a slow method in comparison to other 3D scanning techniques.

Photogrammetry

Photogrammetry is a technique for obtaining measurements and other dimensional information of objects and environments from high resolution photographs. Photogrammetry can be done using aerial or handheld cameras which are used to take a series of overlapping photos of the subject. Photogrammetry software is then able to create 3D models by point matching the geometric intersection of light rays and using triangulation to decipher information like camera angles, locations and characteristics of the subject.

- We also have a ranking of the best photogrammetry software.

- We also have a more in-depth guide to photogrammetry.

This technique is used across a range of industries and is particularly important in land surveying, engineering, agriculture and forestry. It has numerous advantages, including high accuracy, affordability and the ability to access difficult locations, but it’s also affected by the weather and environmental restrictions.

It has numerous advantages, including high accuracy, affordability and the ability to access difficult locations, but it’s also affected by the weather and environmental restrictions.

3D Scanning Applications

3D scanning is used across a huge range of industries, and as scanning and software capabilities continue to develop, it is becoming ever more important across various sectors. Here are the main applications of 3D scanning.

Entertainment

3D scanning is used to create 3D models in the movie, television and video game industries. In TV and film, it is often used in virtual cinematography, where it can be used to quickly scan real-world objects Artists commonly sculpt physical models and then 3D scan them, rather than manually create digital models with 3D modeling software.

3D scanning plays a similar role in the gaming industry, where it’s used in the creation of characters, props and landscapes, but it is also used in the development of virtual reality gaming. It can be used to create lifelike 3D representations of objects, people and spaces, so it’s very useful for creating immersive and interactive virtual gaming environments.

It can be used to create lifelike 3D representations of objects, people and spaces, so it’s very useful for creating immersive and interactive virtual gaming environments.

Medicine

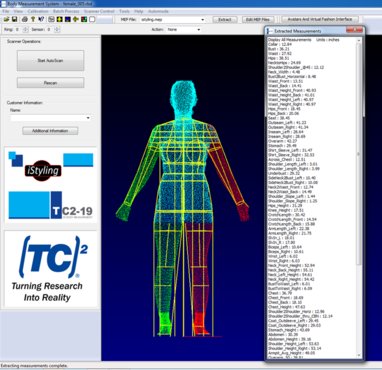

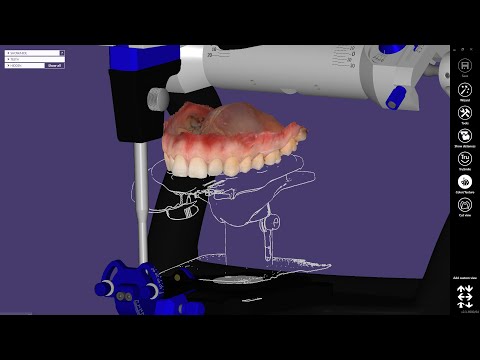

3D scanning is becoming increasingly important in the medical world. One of the main benefits is that it can be used in the creation and customization of prosthetics, implants and wearable devices such as casts and braces. For example, prosthetics can be designed with great accuracy, increasing patient comfort, and 3D printing means they can be produced quicker and cheaper than traditional methods. 3D scanning is particularly common in dentistry for creating dental implants and other objects.

- We also have a feature story on 3D printed prosthetics.

- Check out our feature story on dental 3D printing.

Another notable use of 3D scanning in medicine is 3D ultrasound, where the technique can be use to create 3D images in obstetrics.

Architecture

3D scanning can be used to scan and analyze entire buildings in precise detail, which is hugely beneficial to architects. Like in construction, the point clouds produced by 3D scanners can be used to highly accurate measurements and visualizations. Doing this via 3D scanning and CAD software is far cheaper and quicker than traditional methods. 3D scanning is also useful to architects for reverse engineering of aspects of buildings, from exteriors to internal future.

Like in construction, the point clouds produced by 3D scanners can be used to highly accurate measurements and visualizations. Doing this via 3D scanning and CAD software is far cheaper and quicker than traditional methods. 3D scanning is also useful to architects for reverse engineering of aspects of buildings, from exteriors to internal future.

- We also have a ranking of the best architecture software.

- Also check out our general ranking of the best 3D CAD software.

Construction & Engineering

3D scanning has a wide range of use in the construction and engineering fields. Aerospace was one of the first industries to use 3D scanning, but now it’s used in most construction, manufacturing and engineering processes. For example, in construction it’s useful for site modeling, the documentation of historical sites and quantity surveys, while in engineering it can be used to inspect equipment and for reverse engineering.

- We also have a feature story on 3D printing in construction.

Reverse engineering is a particularly interesting use of 3D scanning. Parts produced several decades ago are generally only described via two-dimensional drawings, which can make accurate reproductions both difficult and time consuming. However, with 3D scanning, data of the shape of the object can be collected with great accuracy, and that data can then be used to create a new 3D model.

This model can then be used to create new molds and tooling, allowing manufacturers to create brand new parts with the same dimensional characteristics of the original. These reverse-engineered models can also be used to 3D print duplicates of the original. For example, 3D scanning can be used to restore classic car parts that aren’t available anymore. As 3D scanning removes much of the guesswork and is much faster than traditional reverse engineering, the process is extremely streamlined and results are highly accurate.

Archiving & Historical Analysis

3D scanning is increasingly popular among historians, art historians and archaeologists as a method of documentation and analysis. 3D scanning creates reproducible, highly accurate 3D models of artifacts and works of art, so it’s an important technique in archiving and curating. In addition, it allows for the sharing of accurate copies across the research and teaching communities.

3D scanning creates reproducible, highly accurate 3D models of artifacts and works of art, so it’s an important technique in archiving and curating. In addition, it allows for the sharing of accurate copies across the research and teaching communities.

3D modeling is also useful for historical analysis; for example, it’s often used in the modeling of facial features of humans’ evolutionary ancestors by scanning fossils. Other examples of the use of 3D scanning of historical artifacts include the scanning of sculptures by Michelangelo, the Kasubi Tombs in Uganda and Cuneiform tablets.

Design

Rapid prototyping and reverse engineering are very important to the design process of many products, so 3D scanning it a useful tool for many designers. When designers look to mimic natural materials, 3D scanning provides a fast, accurate way to study complicated arrangements and create new designs. In addition, 3D scanning provides great accuracy with complex parts and shapes, allows for shared web scans, and allows for coordinated product design using parts from various sources.

Forensics

3D scanning is now also a very important forensics tool for law enforcement officials. It’s valued for its ability to create highly accurate models of crime scenes, accidents, bullet trajectories and then bloodstain patterns. 3D scanning is useful for both documentation and analysis in this context.

3D Scanning Accessibility

If you’re interested in 3D scanning yourself, you’ll be glad to know that the technology is accessible to beginners, students and hobbyists, even if you’re on a tight budget. There are many small, handheld scanners suitable for home use which can be purchased for just a couple hundred dollars. Of course, the more you’re willing to pay, the higher quality scanner you’ll be able to get your hands on. The best 3D scanners, used by professionals, cost tens and even hundreds of thousands of dollars.

Conclusion

3D scanning is a technique for creating digital 3D models of objects, structures, environments, and even people. 3D scanners do this by collecting data about the shape and appearance of a subject, using calculations to construct a point mesh from the data, and then meshing and texturing to create a complete 3D model.

3D scanners do this by collecting data about the shape and appearance of a subject, using calculations to construct a point mesh from the data, and then meshing and texturing to create a complete 3D model.

There are several different 3D scanning techniques, including contact and laser scanning methods, each with their own advantages and disadvantages. However, all 3D scanners are able to create highly accurate 3D models. The fact that they can often do this in a faster, cheaper way than traditional methods means 3D scanning is used across a wide range of industries, from entertainment and medicine to architecture and forensics.

3D scanning technology is constantly evolving and the last two decades have seen it becoming of increasing performance across a variety of sectors, and its importance is sure to increase even further in the coming years. There have even been strides made to incorporate laser scanning technology with smartphone apps, and it’s likely that someday we’ll be able to simply record videos on our phone and create 3D models from then, so the future is certainly bright for 3D scanning.

Other articles you may be interested in:

- The best 3D scanners

- The best DIY 3D scanners

- The best low-cost 3D scanners

- Top 3D scanner apps for iOS and Android

- Structured light 3D scanning vs laser scanning

- 3D body scanners: a guide

04/16/2021

Content

-

- What is 3D scanning and why it is used by

- How 3D scanner

- 3D scan technologies

- Methods 3D

- Contact 3D scanners

- Non-contact 3D scanners

- Types of 3D scanners according to the principle of use

- Advantages and disadvantages of 3D scanners

- Things to consider when choosing a 3D scanner

- Applications

Currently, few people are not familiar with such a concept as 3D printing. Many companies are using modern 3D printers with might and main, recreating layouts of various shapes and sizes with their help. There are also those that recreate whole objects - not only small ones (for example, phone cases, souvenirs, sneakers), but also large ones (houses, engine parts, etc.). But all this would not be possible without 3D scanners. It is they who allow you to accurately copy almost anything - from huge buildings and structures to humans, animals, small objects and much more.

There are also those that recreate whole objects - not only small ones (for example, phone cases, souvenirs, sneakers), but also large ones (houses, engine parts, etc.). But all this would not be possible without 3D scanners. It is they who allow you to accurately copy almost anything - from huge buildings and structures to humans, animals, small objects and much more.

What is 3D scanning and what is it used for

Three-dimensional scanning is a technology that appeared in the 60s of the 20th century. It was created in order to transfer the physical parameters of the object into a digital format in the form of a three-dimensional model. The need for this naturally arose when people around the world increasingly began to use computers both in everyday life and in production.

The first samples of 3D scanners were quite simple and did not have wide functionality. Gradually, they became more complex and improved, making it possible to achieve an ever clearer image of the object. This has become especially relevant with the advent of lasers.

This has become especially relevant with the advent of lasers.

3D scanners allow you to transfer object data into digital format

3D scanning has opened up new opportunities in various areas of human activity - from the automotive industry and the military industry to design, medicine and cinema.

How a 3D scanner works

A 3D scanner is a device that examines an object by digitizing it using sensors and using the information received to create a three-dimensional model. In fact, a 3D scanner creates a digital copy of a physical object of any configuration and complexity. In this, it fundamentally differs from its predecessors - conventional scanners that can only read information from documents and photos.

The scanning process itself can take place in different ways - depending on the type of 3D device and the technology used, as well as on what object you want to process with it - moving or static.

3D Scanning Technologies

There are 2 main types of 3D scanners - laser and optical. Their fundamental difference lies in how and with the help of what the “removal” of data takes place. Let's take a closer look at both.

Their fundamental difference lies in how and with the help of what the “removal” of data takes place. Let's take a closer look at both.

Laser 3D scanning, as the name implies, uses a laser and can be carried out both at short and long distances from the object.

Laser Scanner

For the most part, 3D laser scanners work on the principle of triangulation, when the camera finds a beam on the surface of an object and measures the distance to it, after which a cloud of points is created, each of which has its own coordinates in space, and a 3D model is built. Their "advantages" are affordable price and ease of use combined with high scanning accuracy. Of the "minuses" - there are restrictions on the remoteness and size of the object.

Another type of laser scanner works by measuring the response time of a beam from the surface of an object - the so-called laser range finder. They are widely used where it is necessary to create 3D models of various buildings and structures. It is not advisable to use them at short distances, since in such cases the response time is very short and the accuracy of the data is reduced. Otherwise, this type of scanner is characterized by high scanning speed and the ability to read all the details.

It is not advisable to use them at short distances, since in such cases the response time is very short and the accuracy of the data is reduced. Otherwise, this type of scanner is characterized by high scanning speed and the ability to read all the details.

The disadvantage of laser scanners is the impossibility of their use on moving objects. Then optical 3D scanners come to the rescue, which shoot with one or more cameras from different angles an object illuminated by a special projector. Based on the received image, a three-dimensional image is built.

Optical scanner

A "contraindication" for the use of this technology are reflective and translucent surfaces - shiny, mirror or transparent. But when scanning a person, they are simply irreplaceable.

3D scanning methods

Any object can be digitized both by contact and non-contact methods. In the first case, active interaction with the subject is necessary, in the second, accordingly, no. Both of these methods have their advantages and disadvantages.

Both of these methods have their advantages and disadvantages.

Contact 3D scanners

They have a mechanical probe with a special sensor that measures parameters and transmits the collected information to the device. To do this, the object under study is placed on a special surface and fixed (if necessary). Such tight physical contact makes it possible to determine and then build a 3D image as accurately as possible, however, there is a small risk of damage to the prototype.

Non-contact 3D scanners

This category includes all devices capable of scanning at a distance. This is especially true for objects located in hard-to-reach places.

Non-contact 3D scanner

A stream of radiation (it can be ultrasound, light, X-rays or a laser) is directed to the object and reflected from it, it is recognized by the 3D scanner. They are similar in principle to a video camera and may require the use of additional devices for better lighting.

Non-contact 3D scanners come in 2 types:

-

Active - work with the help of a laser beam or structured light directed at an object, which, when reflected, give information about the location of the object in the form of coordinates.

-

Passive - use time-of-flight rangefinders that read the time and distance that the laser beam travels to the object, and so - for each point in space, which ultimately allows you to accurately recreate its three-dimensional image.

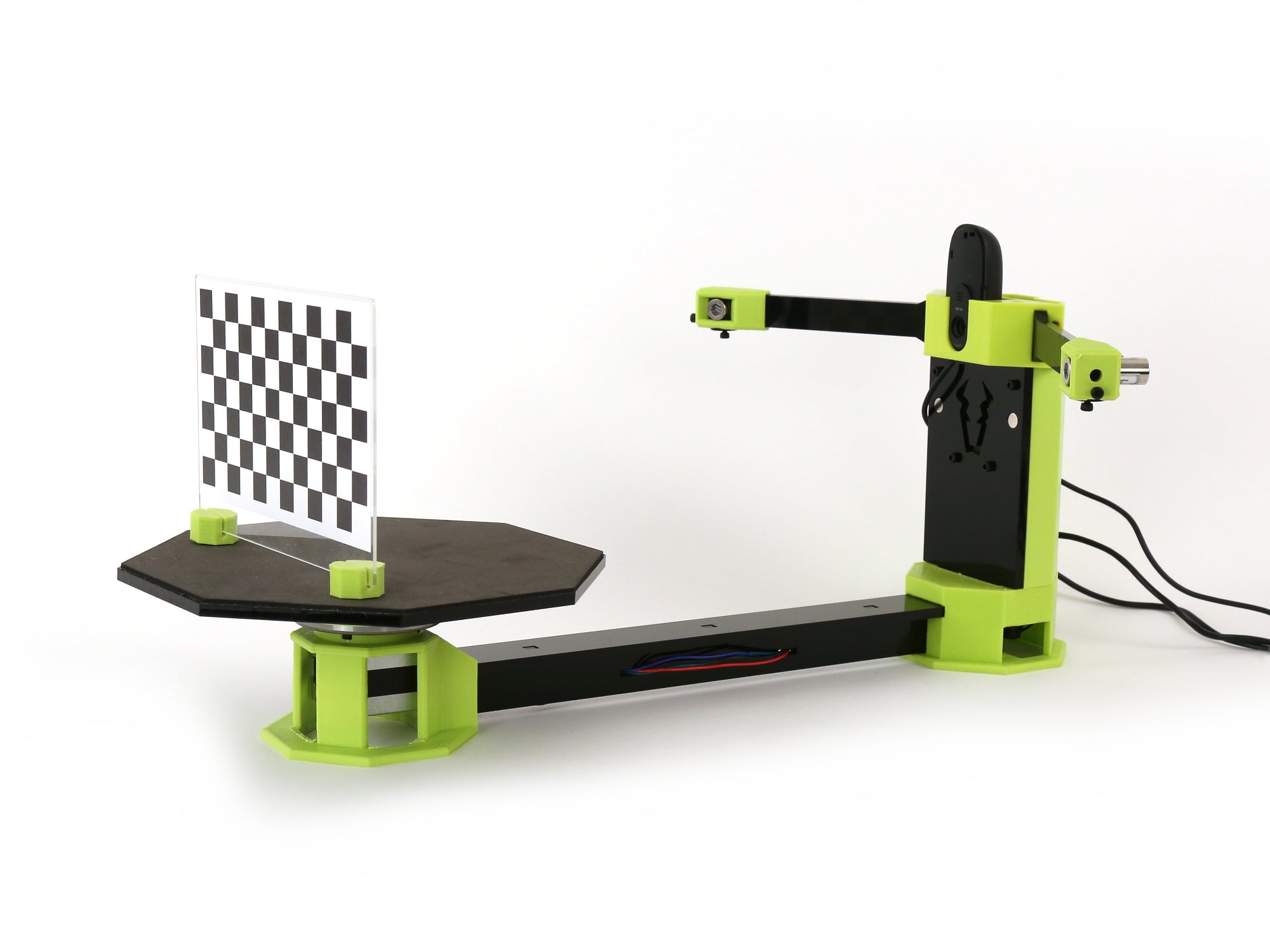

Desktop 3D scanners are very popular and widespread, since they are mostly simple and safe to use, do not require any special technical skills and are quite cheap. The EinScan-SE 3D scanner is one such example. It can be used both at home and in the office. It has access to the API of many popular 3D printers, which makes it possible to immediately print the created three-dimensional model.

Add to compare

Product added to compare Go

| Manufacturer | Thor3D |

Add to compare

Product added to compare Go

| Manufacturer | Shining 3D |

Add to compare

Product added to compare Go

| Manufacturer | Shining 3D |

Add to compare

Product added to compare Go

| Manufacturer | Range Vision |

Types of 3D scanners according to the principle of use

There is also a variety of species here. Let's highlight the main ones:

Let's highlight the main ones:

-

Manual: The are handy and simple models that are easy to use as they are quite compact and do not require special skills. True, their technical capabilities may be somewhat limited.

-

Portable: are mainly used for field work, they are convenient to take with you.

-

Desktop: have extended functionality and are used to create high-quality 3D models. Most often used in offices.

-

Stationary: are used, as a rule, in production, various enterprises, as they can scan a large number of objects of the same type at once. Mounted on special turntables.

Handheld 3D Scanner Calibry

Such a choice of products allows you to select the right model for a specific task. In some cases, scanners independently measure objects, in others - with the help of a person who sequentially moves the device until all the necessary information is collected.

Such options for hand-held 3D scanners as Calibry are in high demand among buyers. Despite the apparent simplicity of execution, it has a high resolution and scanning accuracy, due to which it is able to digitize objects with a length of 0.2 to 10 meters. Objects that have a non-standard surface - dark or shiny, with a large number of corners and small details will not become a problem either. Among other things, its undoubted advantage is its low weight, only 900 grams.

Advantages and disadvantages of 3D scanners

Surely, many of the potential buyers are wondering: do you really need a 3D scanner to invest a lot of money in it? What can this acquisition give and will such an investment be justified?

3D scanning has become an integral part of any modern manufacturing process

In order to understand how much you need this equipment, we will list its advantages and disadvantages.

Benefits:

-

They make it possible to scan objects located at a remote distance and in places inaccessible to the presence.

-

They have the ability to "read" not only colors and images, but also to convey the texture of the surface.

-

Significantly speed up the process of "taking" data from any object, even a very complex one with a large number of planes.

-

A variety of models allows you to choose the most convenient version of the scanner, including manual or portable, which can be easily taken with you.

Weaknesses:

-

Some scanners are unable to recognize transparent or black and white objects. In this case, their preliminary preparation (treatment with a special composition) is required.

-

I do not always display complex objects correctly, with a large number of inserts and partitions.

-

To obtain a high-quality result, they require skills and abilities to work with certain computer programs for creating 3D models.

-

If the rules of operation are constantly violated, it may become necessary for expensive repairs to the equipment.

If you need high-precision and high-quality three-dimensional copies of objects, then you cannot do without a 3D scanner. It makes it possible to work in almost any conditions - indoors and outdoors, and with any objects by type and size. It is not surprising that now these devices are in great demand, which gives rise to the annual release of a large number of models, from which you can always choose the one that suits you in terms of quality and price.

What to consider when choosing a 3D scanner

The computer equipment market offers a huge amount of all kinds of equipment, including devices for three-dimensional scanning. Navigating that variety is sometimes not at all easy: some buyers are only concerned about the cost, others are interested in the number of options (sometimes completely useless), but the most far-sighted look at the ratio of the first and second.

Choosing the right 3D scanner is a big deal

It is not always easy to take into account all the technical points that can significantly affect what result will be ultimately achieved. We will tell you what you should pay attention to if you are thinking about buying a 3D scanner.

We will tell you what you should pay attention to if you are thinking about buying a 3D scanner.

Focus on the following parameters:

-

How high is the accuracy of the 3D scanner. This is one of the most important features. It needs to be targeted first.

-

Resolution also plays an important role. It follows from the first, since the accuracy of measurements and the quality of copying depend on the resolution.

-

In what range the device operates, how close / far it can be from the scanned object.

-

The scanning field is the parameters of that object, thing that it is able to process in 1 session.

-

Does the scanner capture various atypical types of surfaces with complex terrain - channels, partitions, holes, etc.).

-

Portability, mobility of the device - how easy it can be moved if desired, taken with you, its size.

-

The time it takes to prepare for work, as well as the duration of the digitization process itself.

-

The range of possibilities in terms of copying: are there any restrictions on shapes, textures, material, as well as operating conditions - temperature, light, etc.

Of course, the better the quality of the 3D scanner, the more expensive it is. However, you should focus primarily on the tasks that you face, and only then take into account everything else.

Applications

Three-dimensional scanners are in demand in many areas of human life. They are irreplaceable both in the industry, and for household needs. The range of their application is so wide that it is possible to list for a very long time. It's easier to say where they are not needed.

The most common areas of use are, of course, medicine, industry, architecture, construction, film industry and design.

For example, in dentistry, these devices allow you to create ultra-precise three-dimensional models of dentures. One type of such a scanner is Shining 3D's AutoScan DS-EX PRO, which does a great job with a variety of tasks while being quite affordable and reliable.

Medical 3D Scanner

In engineering, such technologies are also indispensable. Digital building prototypes are now much easier and faster to obtain than in the past, when it required multiple manual measurements and then entered into a database. Any physical object can now be recreated in three-dimensional form, moreover, in the shortest possible time and with a minimum error.

In cinemas, we can see with our own eyes "revived" fantastic characters, which were created using motion capture technology, which made them as realistic and impressive as possible. This would not have been possible without 3D scanners.

A few decades ago, it was even difficult to imagine all the things that we use all the time today. And in many ways this has become achievable thanks to three-dimensional digitization. This approach provides huge advantages in work (especially for technical specialists - engineers, designers, designers), however, in order to use them to the maximum, it is also necessary to understand computer programs for 3D scanning.

We will talk more about this topic in one of our next articles. And if you want to know more about it, stay tuned.

#Useful

Expert in the field of additive and subtractive technologies, 3D equipment and CNC machines with over 10 years of experience.

Share

all materials

3D laser scanning - definition, characteristics

Your city: Moscow

Right?

× Choose the city closest to you:

Moscow Saint Petersburg Vladivostok Novosibirsk Ekaterinburg Kazan Nizhny Novgorod Chelyabinsk Omsk Rostov-on-Don Samara Krasnoyarsk Voronezh Perm

Volgograd Krasnodar Saratov Tyumen Tolyatti Izhevsk Barnaul Ulyanovsk Irkutsk Khabarovsk Makhachkala Yaroslavl

▼ Show more

Deselect

3D scanning is a technique used to capture the shape of an object with a 3D scanner. The result is a 3D object file that can be saved, edited, and even printed in 3D. Some 3D scanners can collect shape and color data at the same time. 3D scanning is compatible with computer-aided design (CAD) software, as well as 3D printing after a little training in the relevant programs.

Some 3D scanners can collect shape and color data at the same time. 3D scanning is compatible with computer-aided design (CAD) software, as well as 3D printing after a little training in the relevant programs.

3D scanning technologies:

- Photogrammetry – 3D modeling from photographs. The principle of photogrammetry is to analyze several photographs of a static object taken from different viewpoints and automatically detect pixels corresponding to the same physical point. The input required from the user is camera parameters such as focal length and lens distortion. Photogrammetric technology is also capable of reconstructing objects of various scales photographed from the ground or from the air. The main advantages of 3D photogrammetry scanning technology are its accuracy and speed of data collection.

- Structured Light 3D Scan Structured Light 3D Scan technology works by projecting a series of linear patterns onto an object.

The system is then able to examine the edges of each line in the pattern and calculate the distance from the scanner to the surface of the object. The structured light used for 3D scanning can be white or blue and is generated by numerous types of projectors such as digital light processing (DLP) technology. The projected pattern is usually a series of light rays, but can also be a random dot matrix. The main advantages of structured light technology for 3D scanning are speed, resolution and the ability to 3D scan people.

The system is then able to examine the edges of each line in the pattern and calculate the distance from the scanner to the surface of the object. The structured light used for 3D scanning can be white or blue and is generated by numerous types of projectors such as digital light processing (DLP) technology. The projected pattern is usually a series of light rays, but can also be a random dot matrix. The main advantages of structured light technology for 3D scanning are speed, resolution and the ability to 3D scan people. - 3D Laser Triangulation Scanning Technology – Laser triangulation based 3D scanners use either a laser line or a single laser dot to scan an object. Using this method, digitization begins with the emission of a rectilinear laser beam, which deforms upon contact with the object. Using a camera, the 3D scanner analyzes the deformation of the line emitted by the laser on the reliefs of the object in order to determine its position in space using trigonometric calculations.

The angle formed between the camera and the laser beam, the distance from the camera to the object, and the distance from the laser source to the object (known from the calculation of the time it takes the laser to go around) are parameters. which allow you to determine the spatial coordinates of the object. The advantages of laser triangulation technology for 3D scanning are resolution and accuracy.

The angle formed between the camera and the laser beam, the distance from the camera to the object, and the distance from the laser source to the object (known from the calculation of the time it takes the laser to go around) are parameters. which allow you to determine the spatial coordinates of the object. The advantages of laser triangulation technology for 3D scanning are resolution and accuracy. - Laser pulse based 3D scanning technology is a 3D scanning technology based on calculating the time it takes for a laser to reach the surface and return. Each measurement made by a 3D scanner reports a point on a surface, and the operation must be performed hundreds of thousands of times over the entire surface. This 3D scanning technology includes laser pulsed 3D scanners and phase shift 3D scanners. They, in addition to modulating the amplitude of the laser beam used for 3D scanning, also modulate its phase. These systems offer superior performance by combining the two types of modulation.

Advantages of pulsed laser 3D scanners: the ability to scan large objects and the environment.

Advantages of pulsed laser 3D scanners: the ability to scan large objects and the environment. - 3D Contact Scan uses contact between a probe and an object to reveal surface information measured by probe deformation. This is done using a touch probe, also called a probe or probe, connected to a 3D scanner. The probe is usually connected to a structure (for example, a robotic arm) capable of registering its deformations. The main advantages of contact technology for 3D scanning are its accuracy and the ability to 3D scan transparent or reflective surfaces.

Recommended equipment

- 3D equipment

- Accessories

3D equipment

Accessories

Application for 3D scanning

I have read the Privacy Policy and agree to the processing of my personal data.

Service Request

I have read the Privacy Policy and agree to the processing of my personal data.