Spectra 3d printer

Arcam EBM_Spectra H_Machine | GE Additive

Arcam EBM Spectra H

Spectra H’s high-heat capability enables users to incorporate new alloys into production to expand their offerings, including high-temperature, crack-prone materials.

request a virtual demo

High heat for high-temperature alloys

With Spectra H’s high-heat capability, users can incorporate new alloys into production to expand their offerings, including high-temperature, crack-prone materials. The Spectra H has the capability to produce parts at temperatures exceeding 1,000 °C. The machine’s enhanced capacity is opening up new opportunities to produce high-integrity parts larger and faster than ever before. As part of a system that simplifies operation and maximizes output, Spectra H is the evolution that's helping the industry take the next step forward.

BUILD VOLUME: 250 x 430 mm (Ø/H)

ELECTRON BEAM POWER: 6kW

DOWNLOAD BROCHURE

AVAILABLE MATERIALS

- Arcam EBM Ti6Al4V Grade 5, P-Material datasheet

- Arcam EBM TiAl, D-Material

- Arcam EBM Nickel alloy 718, D-Material

- Arcam EBM Highly Alloyed Tool Steel, D-Material

Powder Recovery Station 30

GE Additive offers a comprehensive powder handling system to support EBM machines, including the Spectra H, both pre- and post-build. Learn about the PRS 30 for efficient, automated recovery of additive powder from builds on the Spectra H.

learn more

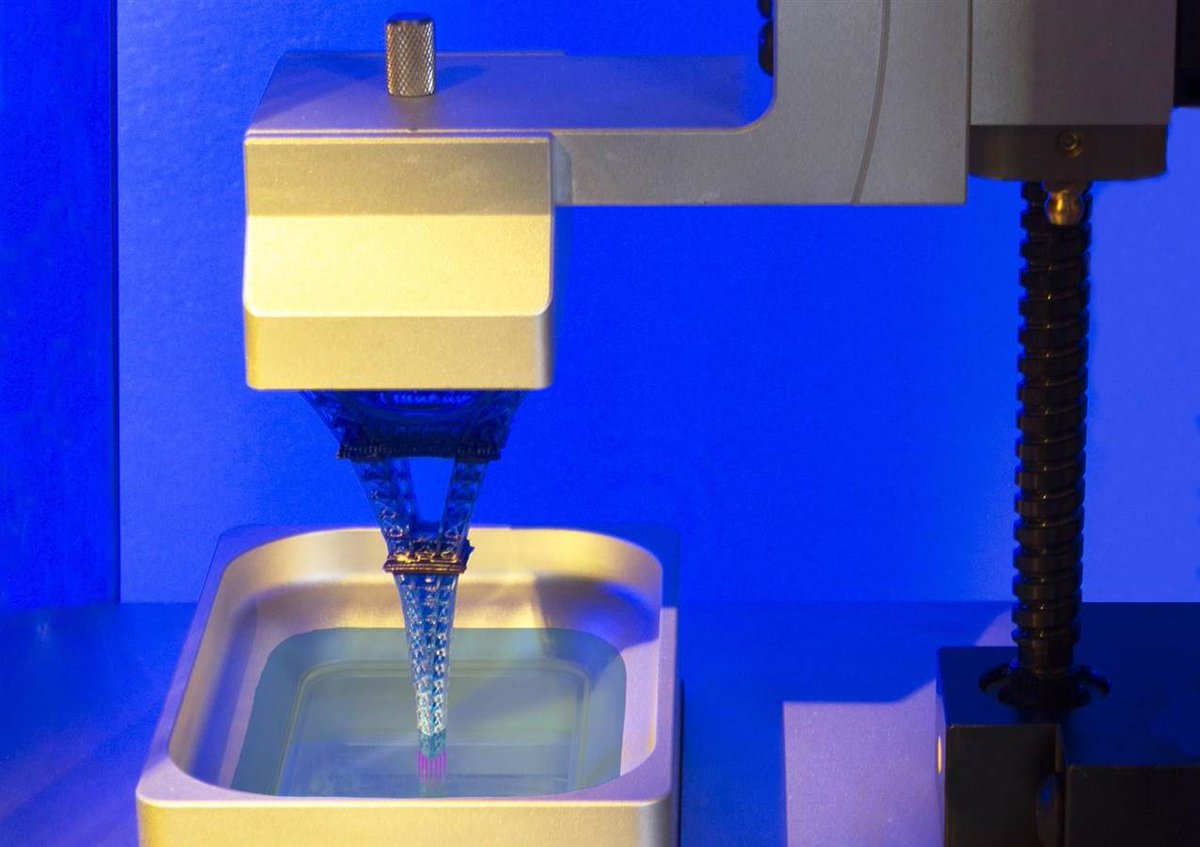

The EBM process at work

The EBM process utilizes a high-power electron beam that generates the energy needed for high melting capacity and high productivity. The hot process allows you to produce parts with no residual stress and the vacuum ensures a clean and controlled environment.

watch video

Arcam EBM Spectra L:

Largest EBM build envelope for high-volume production of quality parts

LEARN MORE

Arcam EBM Q10plus:

Optimized for serial production of orthopedic implants

LEARN MORE

Arcam EBM Q20plus:

For cost-efficient production of large, distortion-free aerospace components

LEARN MORE

Arcam EBM A2X:

Advanced process and material development in a clean and controlled environment

LEARN MORE

explore all machine solutions

Are you ready to create metal parts using

high-temperature, crack-prone alloys?

Tomas Kellner

19 September 2019

Where to buy - Spectrum Filaments

-

Choose country

- Australia

- Austria

- Belgium

- Brasil

- Bulgaria

- Canada

- Croatia

- Cyprus

- Czech Republic

- Denmark

- Estonia

- Finland

- France

- Germany

- Great Britain

- Greece

- Hungary

- Israel

- Italy

- Lithuania

- Malta

- Netherlands

- Norway

- Poland

- Portugal

- Romania

- Slovakia

- Slovenia

- South Africa

- Spain

- Sweden

- Switzerland

- Tunisia

-

Choose country

- Australia

- Austria

- Belgium

- Brasil

- Bulgaria

- Canada

- Croatia

- Cyprus

- Czech Republic

- Denmark

- Estonia

- Finland

- France

- Germany

- Great Britain

- Greece

- Hungary

- Israel

- Italy

- Lithuania

- Malta

- Netherlands

- Norway

- Poland

- Portugal

- Romania

- Slovakia

- Slovenia

- South Africa

- Spain

- Sweden

- Switzerland

- Tunisia

Australia

Bilby3D Sydney – Kingsgrove

Unit 7, Kingsgrove Business Park

192 Kingsgrove Rd,

Kingsgrove, 2208

Visit website

Bilby3D Brisbane – Spring Hill

Shop 2, “The Edwardian” 474 Upper Edward St

QLD, 4000 Brisbane

Visit website

Bilby3D Melbourne – Clayton

A5, “Hallmarc Business Park”, 2A Westall Rd

3168 Clayton

Visit website

Bilby3D Perth (Showroom)

Unit 3, 158 Francisco St

Belmont, 6104

Visit website

Austria

3DJake. at

at

Saaz 99

8341 Paldau

Visit website

Belgium

Labo3D.be

Rue du tige 174

4450 Juprelle

Visit website

Ets Lo Manto 3D

Boulevard Hector Denis 22

4000 Liege

Visit website

3djake.be

Saaz 99

8341 Paldau

Visit website

Bulgaria

Innovative Pro Engineering

4002 Plovdiv

Visit website

3Dpro.bg

str. Karamfil 36B ap.27

9000 Varna

Visit website

Canada

3D Printing Canada

36 Ditton Dr., Unit #3

Hamilton, Ontario

L8W 0A9

- +1 (905) 963-9066

-

Napisz do nas

contact@3dprintingcanada.

com

com

Visit website

Croatia

3djake.hr

Saaz 99

8341 Paldau

Visit website

Czech Republic

Botland.cz

Vratimovska? 681/80

71900 Ostrava ? Kunc?ice

- +420 234 280 990

- Napisz do nas [email protected]

Visit website

Filamentia.cz

Altajská 1568/2,

100 00 Praha 10

- +420 234280650

-

Napisz do nas

info@filamentia.

cz

cz

Visit website

Majkl3D.cz

K Samotám 411

340 04 Železná Ruda

- +420 774 223 133

- Napisz do nas [email protected]

Visit website

Smart3D.cz

Německého 621

59231 Nové Město na Moravě

Visit website

materialpro3d.cz

Blatného 1803/18

61600 Brno

Visit website

Kondik.cz

Švermova 268/76

460 10 Liberec

Visit website

Cadmiaprint. cz

cz

Nadrazni 1958/48d

78501 Sternberk

Visit website

3DSystem

Kukucinova 400/66

02001 Puchov

3djake.cz

Saaz 99

8341 Paldau

Visit website

Denmark

Techbitshop

Stadionvej 9

9550 Mariager

Visit website

ALLNET NORDIC

Borupvang 3

2750 Ballerup

Visit website

3DStore.dk

Gilmoseparken 62

7400 Herning

Visit website

3DEksperten.dk

Voerbjergvej 40

9400 Norresundby

Visit website

Estonia

Oomipood.ee

Peterburi tee 90F

11415 Tallinn

- +372 641 0850

-

Napisz do nas

info@oomipood.

ee

ee

Visit website

Oomipood – J?HVI

Puru tee 1

41534 J?hvi

Oomipood – PÄRNU

Papiniidu 8

80010 Pärnu

Oomipood – RAKVERE

Haljala tee 4

44415 Rakvere vald

Oomipood – TALLINN

Peterburi tee 90f

13816 Tallinn

Oomipood – TARTU

Ringtee 75

50501 Tartu

Finland

ALLNET NORDIC A/S

World Trade Center

Aleksanterinkatu 17

00100 Helsinki

Finland

VAT no. 26115744

- +358-942705050

Visit website

France

Filimprimante 3D

2 route de Melesse, Park Emeraude, cellule 18

35520 LA MEZIERE

Visit website

3djake. fr

fr

Saaz 99

8341 Paldau

Visit website

Germany

Comprise IT Systeme

Jütrichauer Strasse 3

39261 Zerbst

- +49 3923 7589710

- Napisz do nas [email protected]

Visit website

SYNERGY21

Maistrasse 2

82110 Germering

Visit website

OPITEC

Hohlweg 1

97232 Giebelstadt

Visit website

Pollin Electronic

Max-Pollin-Straße 1

85104 Pförring

Visit website

Printbay

Albertstrasse 16

78065 Villingen-Schwenningen

Visit website

FILAMENTWORLD

Pfaffenweg 35

89231 Neu-Ulm

Visit website

Innet

Am Eichenschlag 28

82294 Oberschweinbach

Visit website

Allknow

Am Friedrichshain 22

10407 Berlin

Visit website

ALLNET

Maistrasse 2

82110 Germering

Visit website

BFI

Otterichweg 7

90411 Nürnberg

Visit website

3djake. de

de

Saaz 99

8341 Paldau

Visit website

Great Britain

3djake.uk

Saaz 99

8341 Paldau

Visit website

Greece

Thes3D – Athens

25is Martiou 6

12132 Peristeri

Visit website

Thes3D – Thessaloniki

Zaimi 43, Triandria

55337 Thessaloniki

Visit website

Hungary

3djake.hu

Saaz 99

8341 Paldau

Visit website

3Dipar.hu

Valto Utca 4

2142 Nagytarcsa

Visit website

Italy

3djake.it

Saaz 99

8341 Paldau

Visit website

Lithuania

3DBonum

Zietelos 3

LT-03160 Vilnius

- +37068468826

-

Napisz do nas

hello@3dbonum.

com

com

Visit website

3DBonum

Molo 2A-9

92277 Klaipeda

- +37068468826

- Napisz do nas [email protected]

Visit website

Malta

PATRICK PRINTS

TRIQ KARMEN MICALLEF BUHAGIAR

HAZ-ZEBBUG ZBG3971

MALTA

Mob: +356 9980 1277

- +35699801277

-

Napisz do nas

infopatrickprints@gmail.

com

com

Visit website

Netherlands

Wembley’s

Sonatestraat 8

7323 KP Apeldoorn

Visit website

3DCopyCenter

Sibeliusstraat 7

3816MK Amersfoort

Visit website

3djake.nl

Saaz 99

8341 Paldau

Visit website

Norway

Polyalkemi.no

Trondheim

Norway

- +47 94072324

Visit website

ALLNET NORDIC A/S

World Trade Center

P.O. Box 2874, Solli

255 Oslo

Norge

VAT no. 26115744

- +47-21984288

Visit website

Poland

CENTER3DPRINT Sp. z o.o.

z o.o.

Gęsia 8/205

Kraków

- +48124004646

Visit website

Revo 3D

Rynek 2

41-250 Czeladź

Seb-Comp Katowice

ul. Chorzowska 108 lok 16

40-001 Katowice

Godziny pracy:

pn. – pt.: 8:00 – 16:00

sobota: zamknięte

- 883 633 611

- Napisz do nas [email protected]

Visit website

Seb-Comp Lublin

ul. Bociania 6/1a

20-542 Lublin

Godziny pracy:

pn. – pt.: 8:00 – 18:00

sobota: 10:00 – 14:00

- 696 811 833

-

Napisz do nas

lublin@seb-comp.

pl

pl

Visit website

Seb-Comp Warszawa

al. Jana Pawła II 43a lok. 22a

01-001 Warszawa

Godziny pracy:

pn. – pt.: 8:00 – 17:00

sobota: 10:00 – 14:00

- 883 336 444

- Napisz do nas [email protected]

Visit website

Seb-Comp Wrocław

ul. Swobodna 37 lok 10.3

50-088 Wrocław

Godziny pracy:

pn. – pt.: 10:00 – 18:00

sobota: 10:00 – 15:00

- 790 388 308

-

Napisz do nas

wroclaw@seb-comp.

pl

pl

Visit website

Softgraf

Plebiscytowa 51G

43-109 Mikołów

ZADAR.pl

ul. Sapiechy 69

31-644 Kraków

- 792600065

- Napisz do nas [email protected]

Visit website

TwojSklep3D.pl

WIZJER

Krańcowa 8B

75-236 Koszalin

Visit website

Kingfil

Kosmiczna 18

42-274 Konopiska

Visit website

Komax

Mickiewicza 29

38-500 Sanok

Visit website

LAMA PLUS

Bielska 206

43-400 Cieszyn

Visit website

Morele. net

net

Fabryczna 20A

31-553 Kraków

Biurowe.pl

Ściegiennego 7

40-114 Katowice

BOTLAND

Gola 25A

63-640 Bralin

Visit website

Electropark.pl

Aleksandra Ostrowskiego 30a

53-238 Wrocław

Visit website

Fiber3D.pl

Księcia Bogusława X 16/9

70-246 Szczecin

Visit website

Hobby-Store

al. Zwycięstwa 96/98

81-451 Gdynia

Visit website

Iffland / Uprinto

Starolubańska 26,

59-800 Lubań

Visit website

INK3.de

Maltańska 1

61-131 Poznań

Visit website

Enoztech

Śląska 50/16

81-310 Gdynia

Visit website

3Drukarki. pl

pl

Warszawska 37

05-152 Czosnów

Visit website

3D-SHOP.PL

Katowicka 29

46-200 Kluczbork

Visit website

AEMCA

al. Jana Pawła II 22

00-133 Warszawa

Visit website

Aeris

Skłodowskiej Curie 25/2

05-800 Pruszków

Visit website

B3D

Dereniowa 4

61-306 Poznań

Visit website

3Drukarki.pl – Sosnowiec

Modrzejowska 24/3

41-400 Sosnowiec

Visit website

3DReaktor.pl

Konstruktorska 6

02-673 Warszawa

Visit website

3djake.pl

Saaz 99

8341 Paldau

Visit website

2B3D

Czajkowskiego 42/8

51-171 Wrocław

Visit website

Portugal

Corexy. pt

pt

Rua Cândido de Sousa, 9 R/C

4710-503 Braga

- +351 967 969 966

- Napisz do nas [email protected]

Visit website

RepRap.pt

Rua Do Cobre, 539 R/C

2750-322 CASCAIS

Visit website

Khameleton.pt

Rua Joao Lino, Lote 35, Armazem 20E – Barreiro

2830-222 Barreiro

Visit website

Evolt.pt

Avenida De Sao Mateus 263

3870-059 Bunheiro-Murtosa

Visit website

3djake.pt

Saaz 99

8341 Paldau

Visit website

Romania

FORMWERK

Str. Prof. Dr. Ion Athanasiu 33, sector 5

Prof. Dr. Ion Athanasiu 33, sector 5

50676 Bucharest

Visit website

Slovakia

Justcreate.sk

Bajkalská 9

83104 Bratislava

Visit website

Profi-filaments sk

Allendeho 2735/24

5951 Poprad

Visit website

3dskladom.sk

Orechová 4/600

91927 Brestovany

Visit website

3djake.sk

Saaz 99

8341 Paldau

Visit website

Slovenia

3djake.si

Saaz 99

8341 Paldau

Visit website

South Africa

Kemtek Imaging Systems

Fortune Street, Unit 5b

2049 City Deep

Spain

ALLNET Ibérica

Rúa Río Anllóns, 2 – 4 Bajo

15100 Carballo – A Coru?a

- +34 981 75 31 41

-

Napisz do nas

pedidos@allnet.

es

es

Visit website

Maker Store by ALLNET

Rúa Río Anllóns, 2 – 4 Bajo

15100 Carballo – A Coru?a

- +34 881 98 21 70

- Napisz do nas [email protected]

Visit website

3djake.es

Saaz 99

8341 Paldau

Visit website

Sweden

ALLNET NORDIC A/S

World Trade Center

Klarabergsviadukten 70

Stockholm SE-111 64

Sweden

VAT no. 26115744

- +46-840836320

Visit website

3djake. se

se

Saaz 99

8341 Paldau

Visit website

Switzerland

3d-printerstore.ch

Weststrasse 15

CH-8570 Weinfelden

Visit website

Tunisia

Celetronix.com

Magasin N° 16 et 17 Centre SAID

2033 Mégrine

Visit website

Not sure what filament to choose?

Compare

Selected:

CompareClear

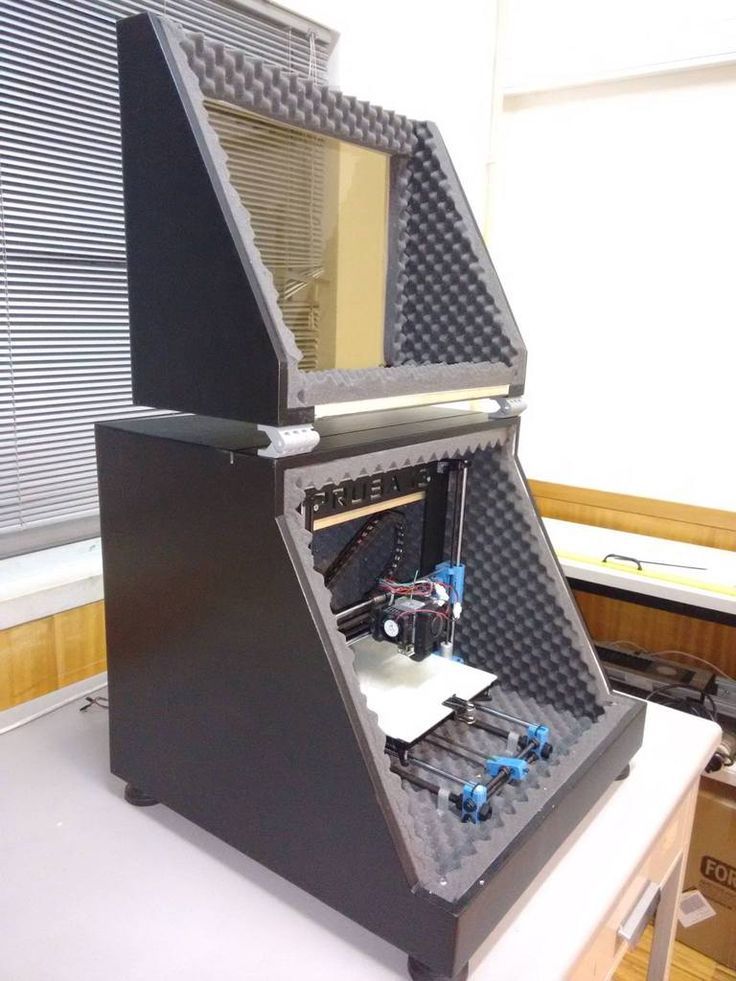

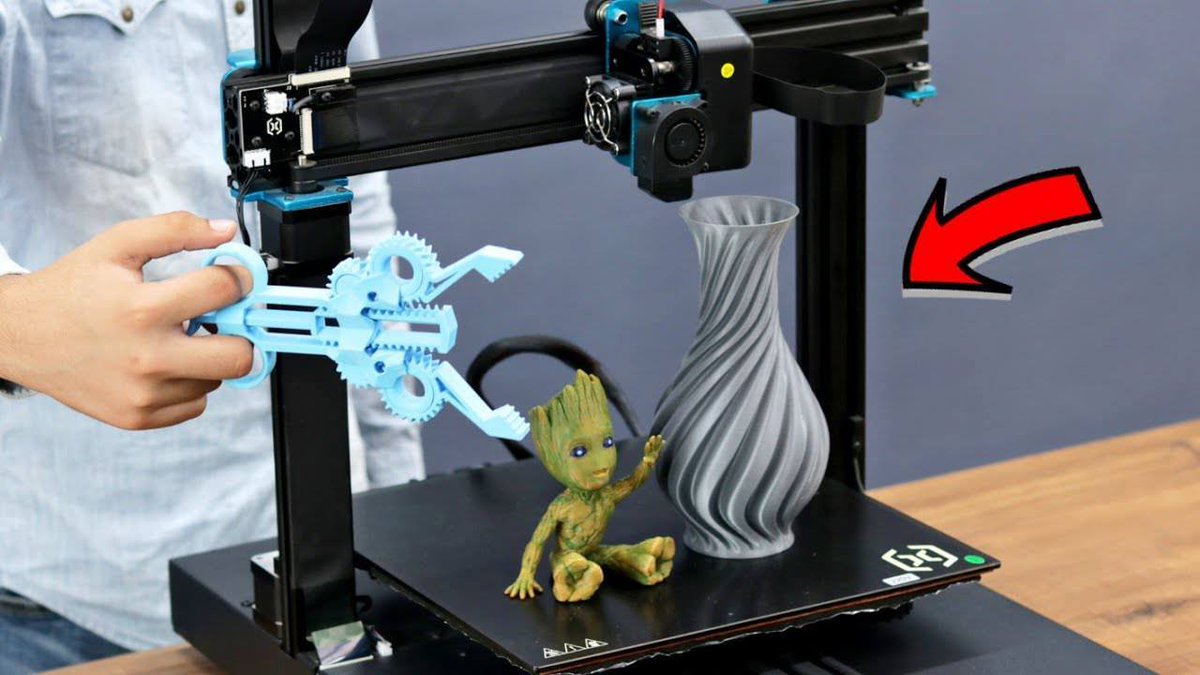

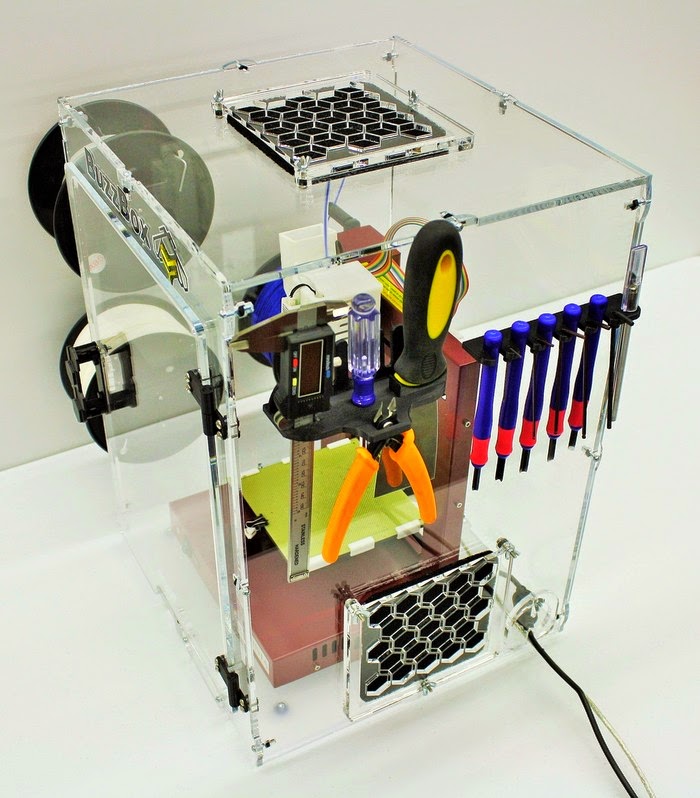

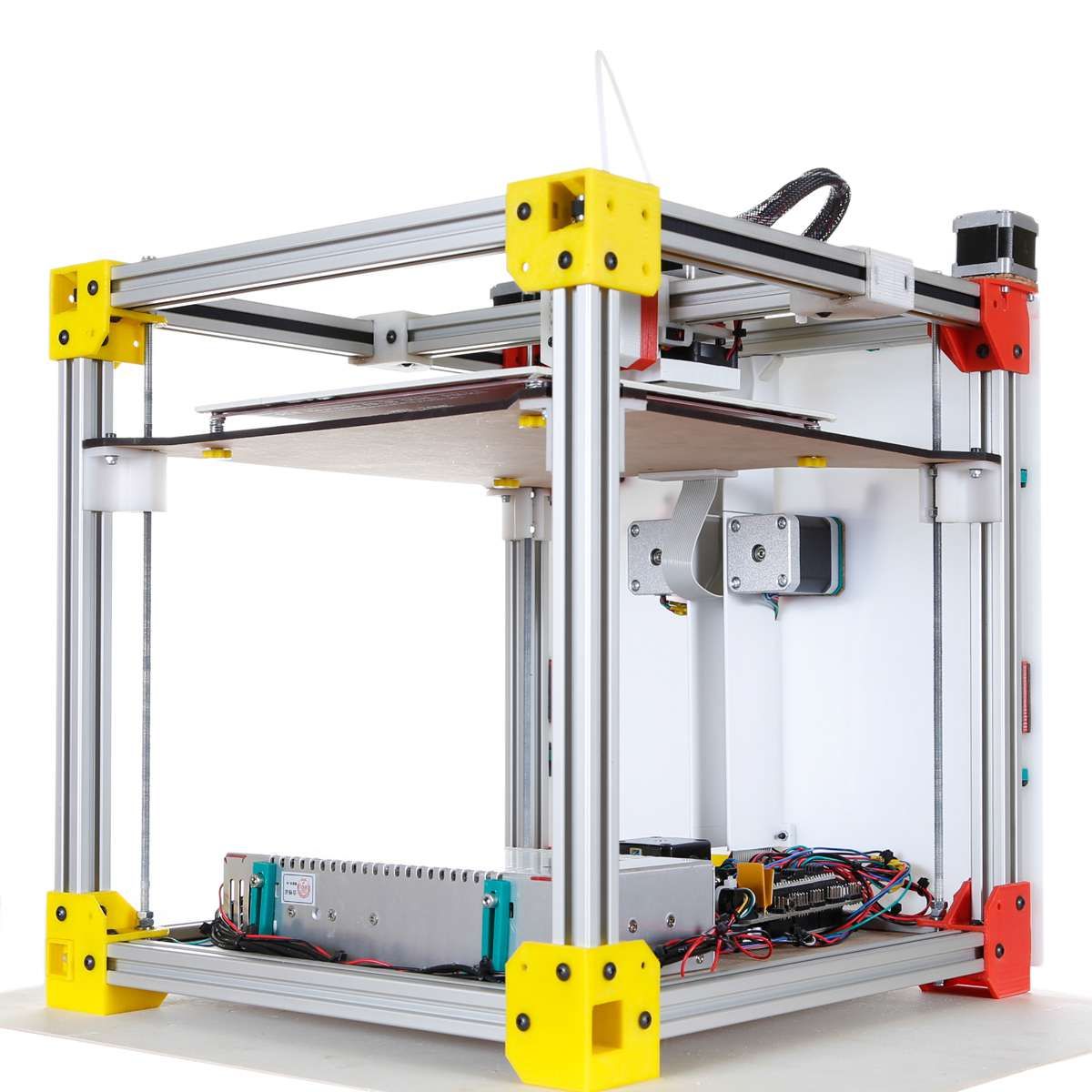

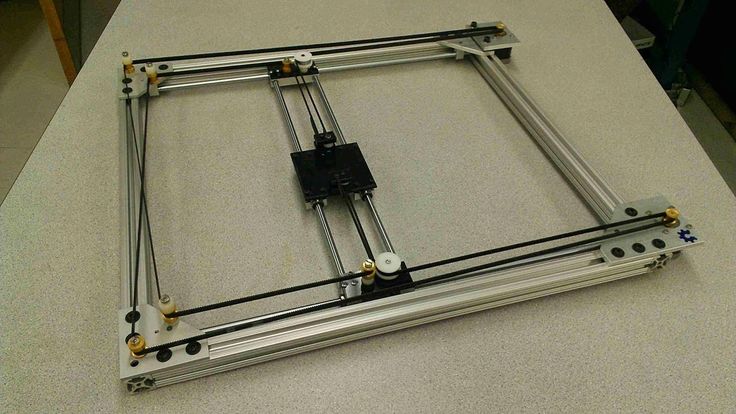

SkyOne 3D printer MFP

SkyOne 3D printer MFP

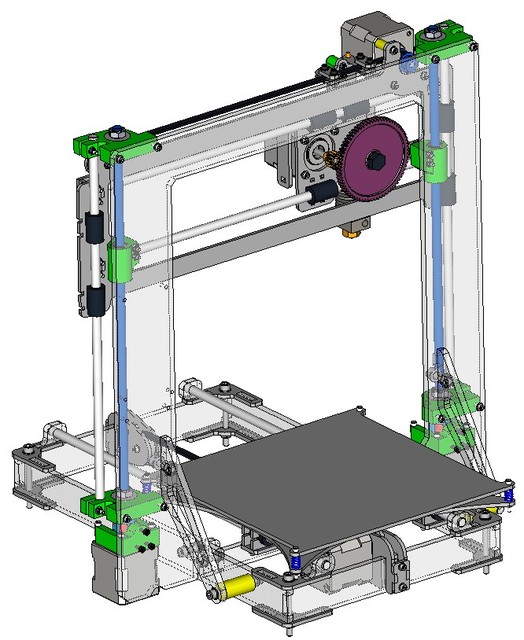

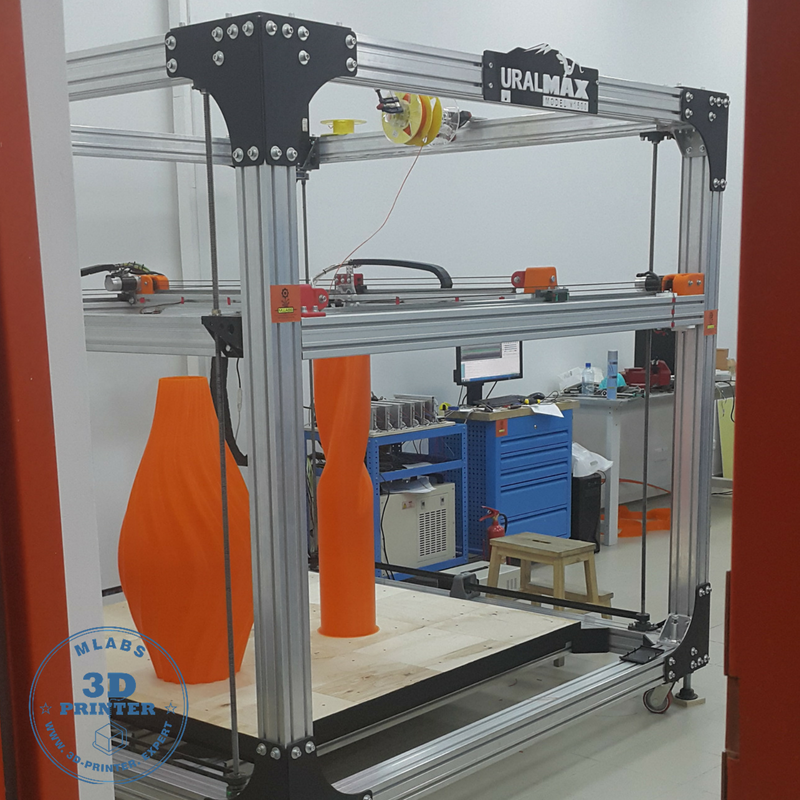

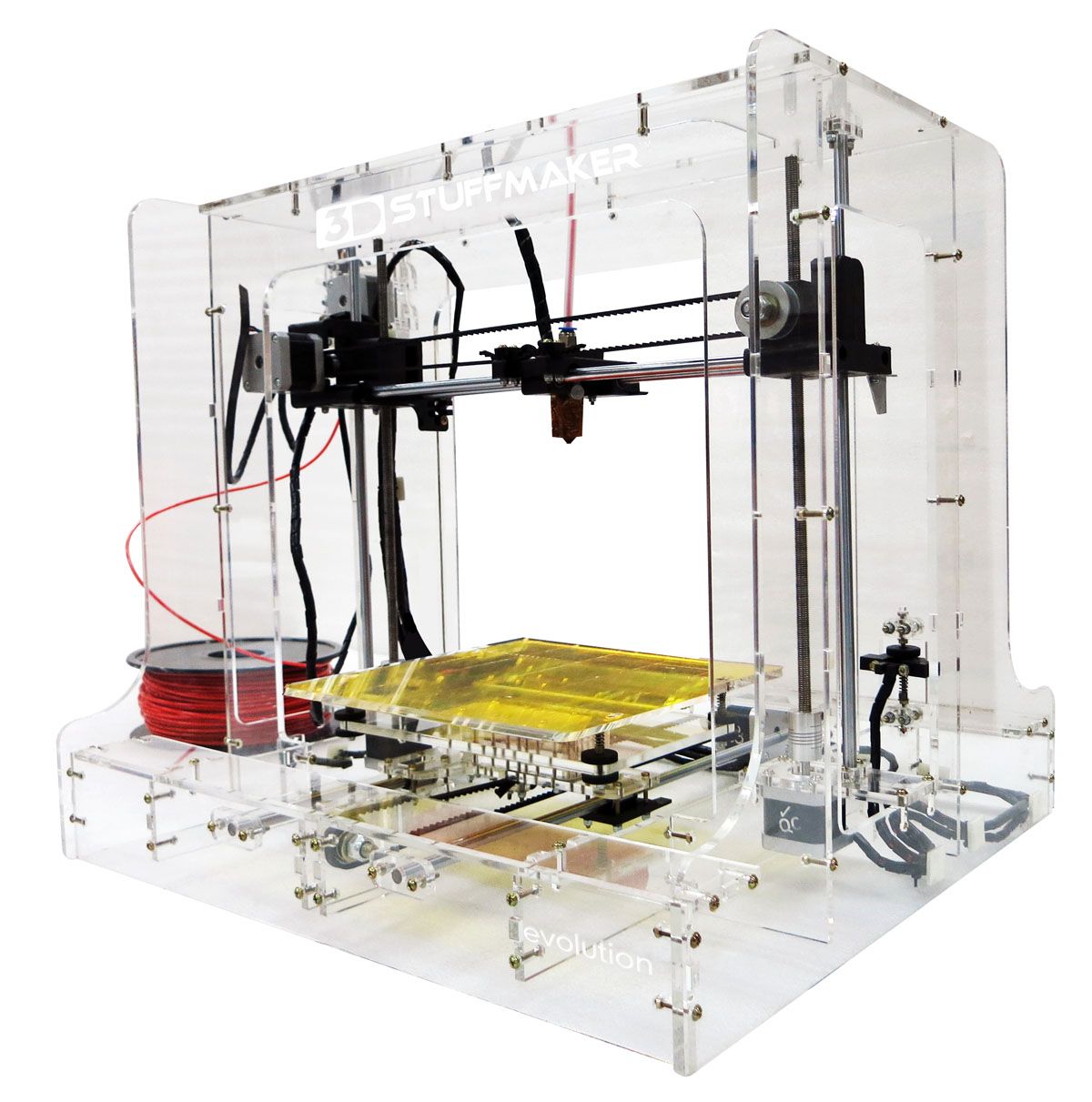

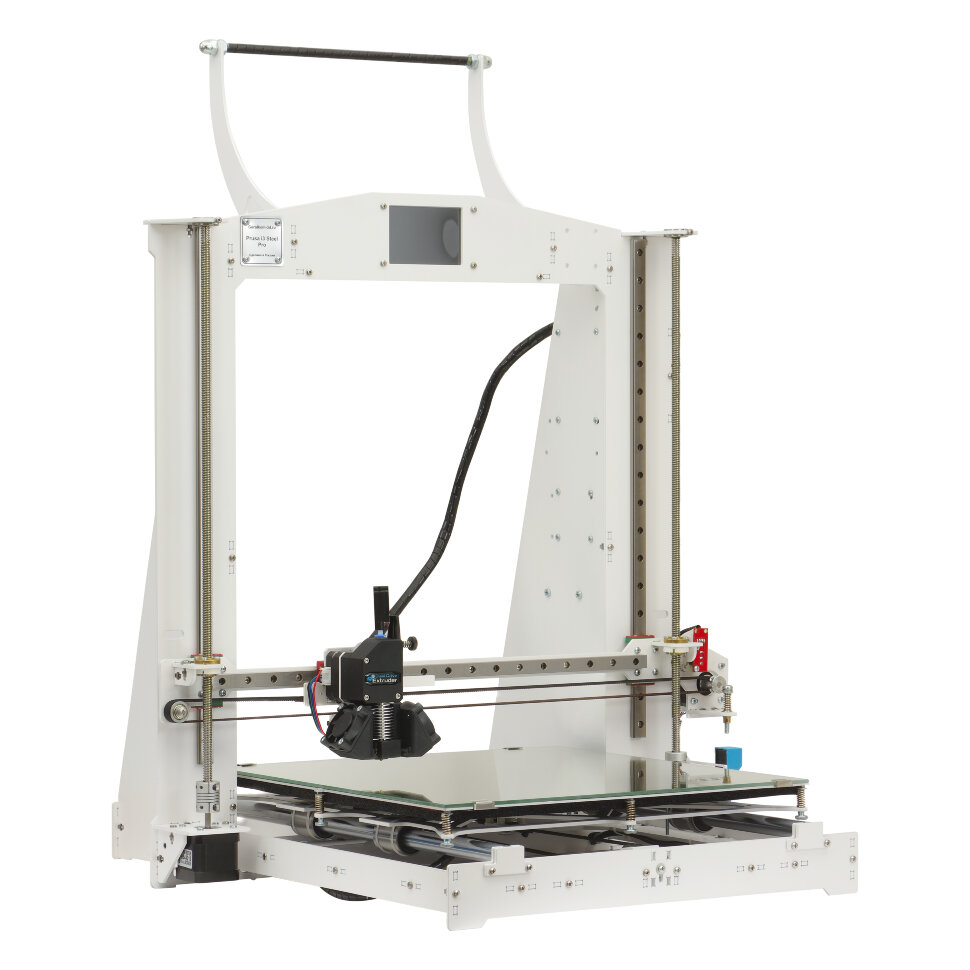

We offer a novelty in the world of three-dimensional technologies - SkyOne 3D printer MFP. Unlike most similar printers, SkyOne has advanced features that allow you to solve a wide range of tasks. SkyOne is universal coordinate a machine that has the ability to work as a 3D printer, engraver, CNC milling machine. Thanks to easily replaceable extruder and adaptive design of the 3d printer, it is possible to install a tool suitable for performing various tasks such as spindle, dispenser, vacuum gripper or pneumatic marker.

Thanks to easily replaceable extruder and adaptive design of the 3d printer, it is possible to install a tool suitable for performing various tasks such as spindle, dispenser, vacuum gripper or pneumatic marker.

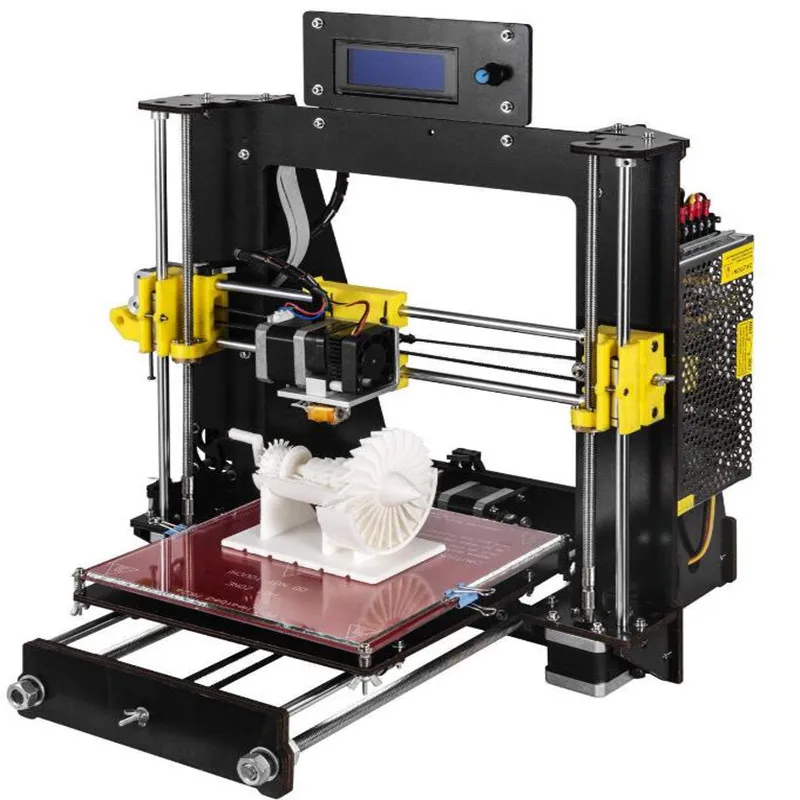

The rapid development of additive technologies has led to the high popularity of 3D printing. Quality and beautiful 3d printing opens up great opportunities for us. 3D modeling and prototyping is the newest way receiving high-quality small-scale industrial products, three-dimensional images and figures. 3D printers are widely are used in design, construction and industry. A full copy of the future development saves time and means to avoid inaccuracies and errors.

SkyOne is a versatile and functional 3D printer.

SkyOne Benefits

Multifunctionality. SkyOne 3d printer is also engraving and milling car.

Compact. Dimensions 275x250x400 mm with print area 140x190x200 mm.

High speed, quick preparation for printing. Coordinate machine quick release extruder, allows promptly prepare the printer for milling and engraving.

Rich equipment and a choice of one of two colors solutions.

In the 3dlaboratorio online store you can buy a SkyOne multifunctional 3D printer and all the necessary consumables materials at a bargain price. The basis of our company's activity is the production of high-quality three-dimensional printers and sale of consumables. We are also happy to offer you:

- Engraving sets.

- Durable and easy to machine plastics.

- Varnish for printing from the manufacturer.

- Training in the latest 3D technologies.

- Accessories for 3D printers.

- Prompt delivery of SkyOne 3D printer and accessories.

Having a high quality and fast 3D printer is only part of the success. Correct selection of consumables materials plays a key role in obtaining the desired result. When choosing, it is important to be guided by the properties and purpose plastics for printing. It is important to note that each plastic has individual properties and is suitable for certain areas of application. For example, PLA+ is a biodegradable plastic and is great for food, medical spheres, while FLEX is resistant to wear, neutral to oils and gasoline.

We invite you to free training in 3D printing. We teach our clients 3D technologies and share last achievements in a surprisingly interesting field. Free training is a great opportunity to join popular and rapidly growing field of 3D modeling.

Employees of our company will help you choose plastic for solving any problems. By working with us, you get the ability to organize a constant supply of high-quality accessories for printing at competitive prices.

Events

-

3D printing festival in St. Petersburg

Dear colleagues! We are pleased to announce the participation of SkyOne at the 3D Printing Festival in St. Petersburg. Come, your Attention will be presented to practical examples of using a 3D printer - milling cutter.

You will demonstrated how can be successfully printed and milled! The festival will take place on 9February 2019, from 10:00-19:00, at the address: Saint Petersburg, Congress Center "PetroCongress", st. Lodeynopolskaya, 5. See you!

You will demonstrated how can be successfully printed and milled! The festival will take place on 9February 2019, from 10:00-19:00, at the address: Saint Petersburg, Congress Center "PetroCongress", st. Lodeynopolskaya, 5. See you! -

New company development - plastic dryer

3DLaboratorio presents a new innovative development - a dryer for plastic

-

Participation in the exhibition "3D Print Expo"

We invite you to visit us at the exhibition "3D Print Expo" in Sokolniki, booth E17, 13 and 14 October.

-

Participation in the exhibition "Interplastica 2017"

24-27 January HTW we invite you to visit our booth at the exhibition "Interplastica 2017".

-

Best Innovative Company 2016 Award

According to the results of the 3D Pint Expo, the HTW team received an award "Best Innovative company 2016" for own development - 3D printer / engraver / router SkyOne.

-

Preparing for the exhibition "3D Print Expo"

Our company is in full swing preparing for the 3D Print Expo, at which we will present coordinate machine SkyOne, a milling kit for it and plastics for printing.

-

RosUpack Exhibition

SkyOne printer presented at the booth of "Electroprivod" company at the annual exhibition "RosUpack".

-

Engraving and milling kit

Passing the final tests of the milling and engraving kit. Exit to sale scheduled for August 2016.

-

Color range

The SkyOne 3D printer is on sale in white and silver.

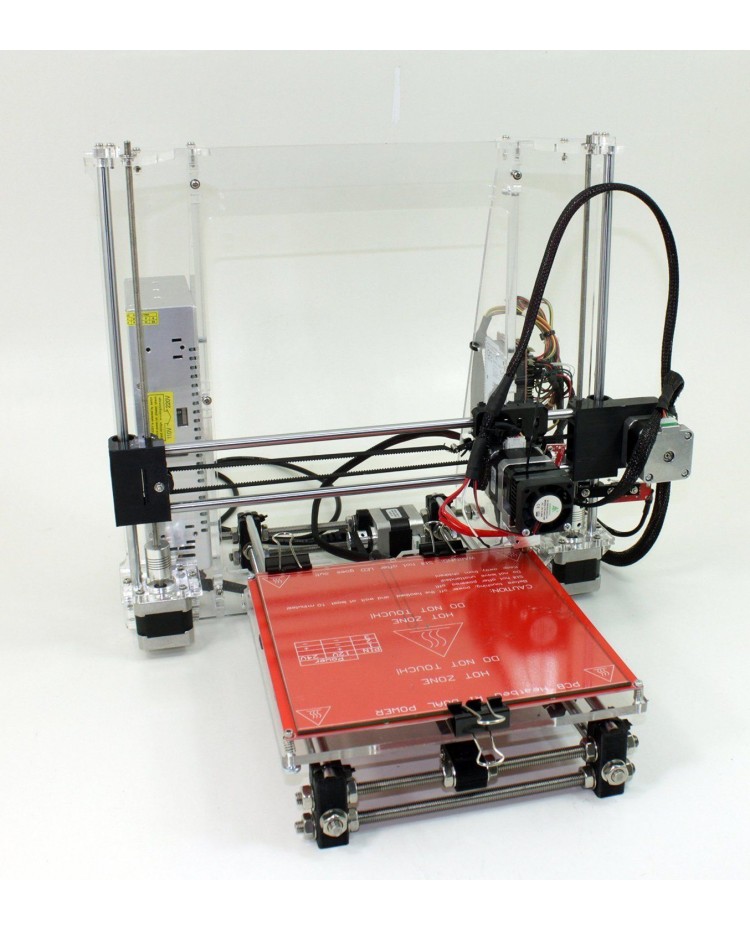

21 3D Printing Case Studies [Part 2]

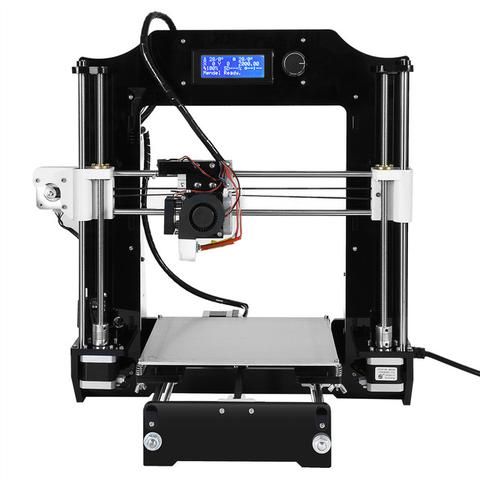

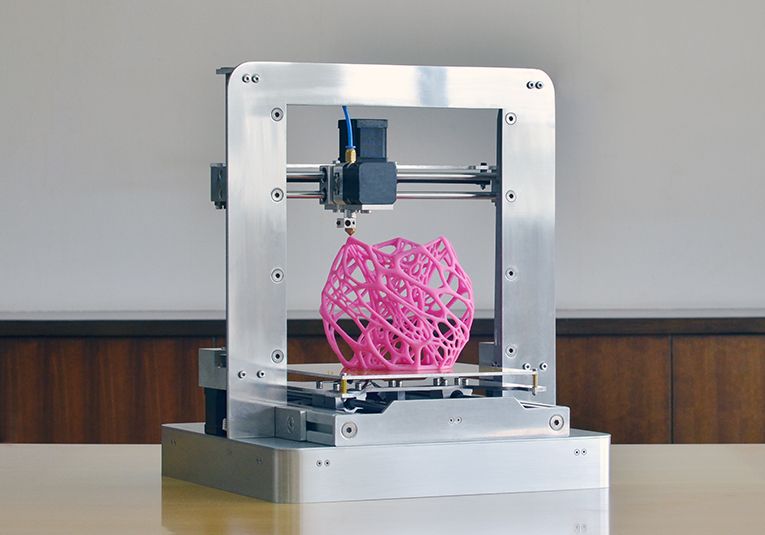

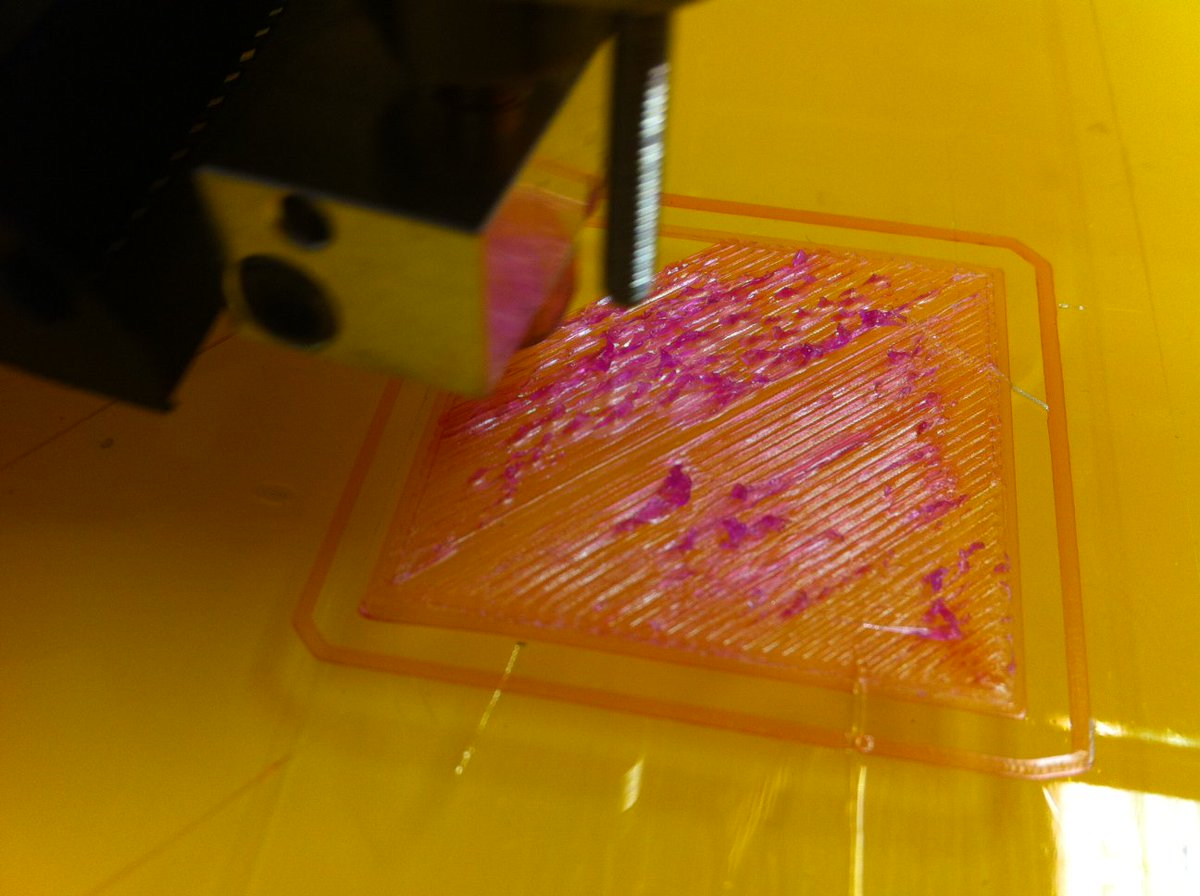

3D printing is a manufacturing process that creates a physical object from a digital model file. The technology works by adding material layer by layer to create a complete object.

The 3D printing process was developed in the 1980s and was originally called "rapid prototyping". It allowed companies to develop prototypes faster and more accurately than other methods. After more than 30 years of innovation, its use is much more varied today. Businesses, engineers, designers, educators, healthcare professionals and hobbyists are using this technology for a variety of purposes.

After more than 30 years of innovation, its use is much more varied today. Businesses, engineers, designers, educators, healthcare professionals and hobbyists are using this technology for a variety of purposes.

This is the second part of the article, before reading we advise you to read the first part in our blog.

New developments in the space industry

The use of 3D printing reduces the cost of expensive and specific prototypes, tools and machines for space and allows small companies to innovate in the space industry.

Relativity, an aerospace company, is testing aluminum rocket motors using additive manufacturing. If successful, this development will drastically reduce the costs and practical difficulties of space travel, opening the space to new business.

Masten Space Systems is another company driving change in the aerospace industry: Founded in 2004, the company specializes in VTOL and VTOL rockets. Using 3D printers, Masten made plastic rocket motors for research testing.

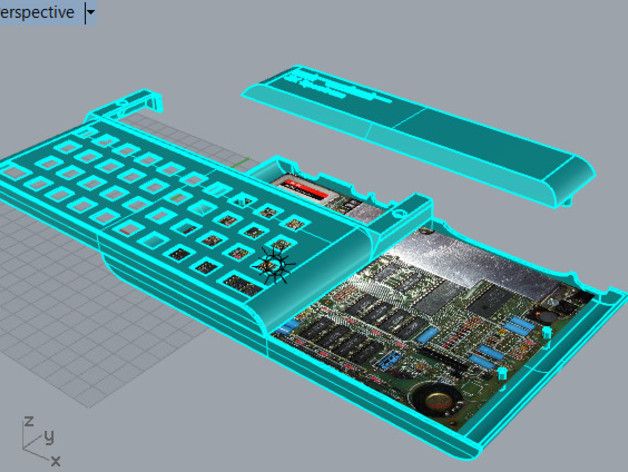

Generative design

Generative Design - Uses the power of artificial intelligence to develop new high-performance product design iterations that help solve complex problems, reduce component weight and manufacturing costs, expand customization options, and optimize performance.

Brackets and posts where forces are well defined are common parts for generative design.

3D printing is great for creating complex, organic objects. With a wide range of material properties tailored to specific applications, you can expect designs you've never seen before. Engineers can use artificial intelligence to find and test complex new designs quickly, efficiently, and at scale, dramatically reducing research and development time for new products. Then, using their own 3D printer, they can bring the complex shape to life to hold and test.

Improving the delivery of educational material

In addition to training the future workforce in CAD and 3D printing, universities are beginning to see the benefits of using 3D printers in a wide range of academic disciplines.

The University of Massachusetts Lowell has upgraded its sculpture and 3D design courses. Yuko Oda, who joined the university in 2017, started by ordering a lot of 3D printers.

Yuko has been able to bring her passion for art and technology into the classroom, and she currently teaches sculpture, 3D modeling and animation. Most students know that they need to understand 3D animation and 3D modeling for future careers in various fields, including film sculpture design. For artists, 3D modeling has become a necessary skill.

One of the most promising new advances in sculpture is the integration of 3D printing and virtual reality (VR). This is especially true for students who are intimidated by 3D design. VR is rapidly lowering the barriers to 3D design, allowing artists and students to create with their hands in software such as Oculus Medium. Yuko taught eighth graders how to create 3D objects in 30 minutes in VR and then print them out on a 3D printer. Even for experienced sculptors, VR shortens the time it takes to move from an idea to a physical object, potentially opening up new areas of experimental art.

Endangered bird rescue

When zookeepers at the ZooTampa Zoo in Florida were doing a routine checkup on a 25-year-old great hornbill, they found an injury at the base of the saddlecloth, a yellow, helmet-like growth on the top of the bird's head. Further examination revealed that the bird, named Crescent Moon, was suffering from life-threatening cancer.

The cancer located next to the bird's skull could not be removed because it contained part of the bird's sinuses. The zoo team wanted to know if it was possible to remove the cancerous tumor and replace the base of the bird's saddle with a 3D printed copy made especially for it. 3D printed prostheses and patient-specific devices have already been used in human procedures, but never for hornbills.

A successful 3D printed "reserve beak" was created using BioMed White Resin material. It is an opaque white material for biocompatible systems requiring long-term skin contact or short-term mucosal contact.

Spare parts and custom parts

Left controller with Fuse 1 3D printed buttons, right with injection molded buttons.

One of the problems with custom-made parts is that these orders tend to be made in low volumes and must change with OEM updates. But with the rise of private 3D printing, custom manufacturing has taken off in many industries.

Battle Beaver Customs specializes in custom game controllers. Their modifications make controllers more responsive and more competitive, allowing players to increase their gaming potential and achieve peak performance in various games. Rapid prototyping with a 3D printer allows the company to quickly change mount and button designs. When creating custom-made consumer goods, fast lead times can pay dividends for companies looking to stay ahead of their competitors. According to Michael Crunell, head of research and design at Battle Beaver Customs, "The Fuse 1 3D printer is great for making changes quickly, from concept to final part. Our competitors can't keep up."

Making interesting bath bombs

With 928 stores in 48 countries, Lush Cosmetics is known around the world for creating creative and eye-catching products such as body oils, bath bombs and more, and attributes its success to its ability to quickly respond to trends and customer demand.

To bring new, industry-defining, highly detailed beauty products to life, the company had to turn to 3D printing. They have invested in a next generation additive manufacturing center to create molds, tooling and final parts.

Lush Cosmetics produces vacuum molds using 3D printers.

"We use our 3D printers to create molds, tooling and final parts. Having these capabilities means we don't have to share designs with other companies because we own the entire product development process," says Damien Carter, Head of Innovation Lab at Lush Cosmetics.

Real mass customization

3D printing opens up new business opportunities such as mass customization. What used to be too complex, prohibitively expensive, or impractical to produce with traditional methods is now available at no extra cost with digital technology, giving designers full control and opening the door to fully customizable consumer products.

A good example of this is Gillette's Razor Maker program, which allows customers to personalize their razor handle by choosing different patterns or colors.

"For Gillette, the Razor Maker pilot project represents an important step towards customization, where new technologies and new business models must come together to provide unique products to our consumers," said Donato Diez, Global Brand Manager for Gillette and Razor. Maker.

Dental Printing

Desktop 3D printers are increasingly found in dental laboratories and clinics. In fact, the popular 3D printed clear aligners are perhaps the most successful application of 3D printers we have seen so far.

Over the past ten years, 3D printing has advanced so much in dentistry that now no new dental lab opens without using some form of digital dentistry. 3D printing materials are so good that they can be used to produce crowns, dentures and more.

3D printing technologies thrive in an environment where our unique bodies require custom solutions. As a result, the dental industry is undergoing a rapid digital transformation, with digital workflows delivering increased efficiency, consistent high quality, and reduced costs for dental labs and clinics.

3D printed gorgeous glasses

Marcus Marienfeld AG has distinguished itself from the conventional spectacle frame industry by using different and unique manufacturing techniques to create its frames. They recently started introducing 3D printers to their eyeglasses production line in their workshop.

"When you have a 3D printer, you become very inventive and creative. I can create things with minimal effort that I wouldn't even try to create if I didn't have a 3D printer," says Markus Marienfeld.

Infinite Possibilities

As workflows have evolved over the past few years and taken hold across industries, we are starting to see the revolutionary potential of 3D printing emerge.

From dentistry and healthcare to consumer products, architecture and manufacturing, society is increasingly interacting with 3D printed products. Creating bespoke parts, reducing lead times and overheads, and empowering customers to personalize products - we can only expect the impact of 3D printing to expand further.