3D steak printing

3D-printed steak, anyone? I taste test this ‘gamechanging’ meat mimic | Food

Across four major cities – London, Amsterdam, Berlin and Tel Aviv – a new meat was born, containing precisely no animal. The London champion of the company, Redefine Meat, is the celebrity chef Marco Pierre White. At Mr White’s in Leicester Square, chefs, investors and barbecue and burger connoisseurs – as well as former winners of MasterChef – gathered to taste it.

The tone of the event was set by the offering of a pipette of “blood” – “Doesn’t it taste like blood, though?” asked an excited waiter. Well, yes. But memo from the world of carnivore: blood is more something we put up with than something we actively want to drink.

“I’ve had vegans complaining that this is too much like meat,” said Redefine Meat’s chief executive and founder, Eshchar Ben-Shitrit. “Personally, I don’t eat meat. I think it’s wrong to kill animals and eat them. But in order to get the flexitarian, it’s better to disregard the opinion of the vegan. ”

Plant-based meat alternatives are nothing new, and the recent boom in demand from part-time vegetarians, or flexitarians, has fed a surge in innovation, from seitan to pea protein products. Yet this is an unarguable technological breakthrough. While a mince texture has been achievable for some time, plant-based whole cuts – which is to say, a cut that has the mouthfeel and the appearance of a steak, or a lamb chop – have long been considered beyond man’s wit.

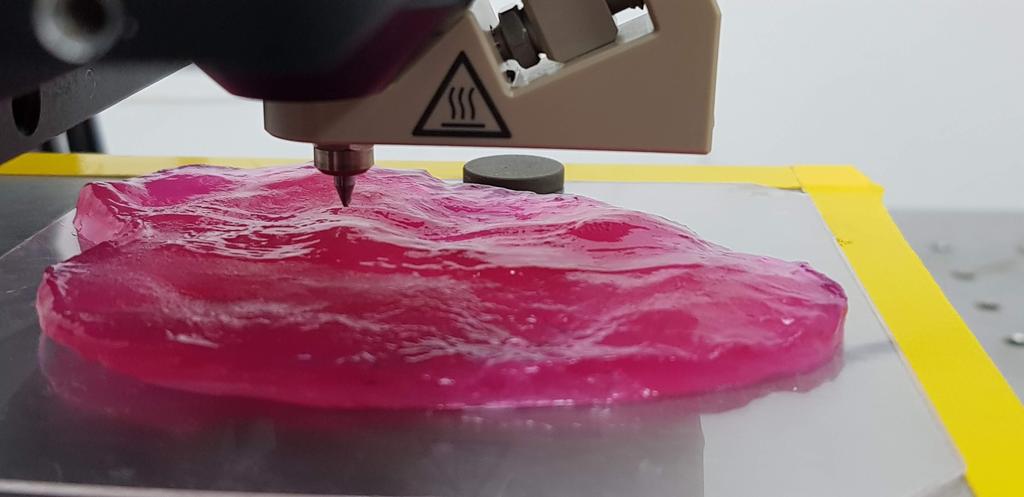

Dishes prepared with Redefine Meat’s plant-based products. Photograph: Amir Cohen/ReutersRedefine Meat is cagey about which protein it uses (investors say it is soy; it also uses pea protein, along with ingredients your grandmother would recognise, beetroot, chickpeas, coconut fat), but is delighted by its method: the “meat” is 3D printed, and the mimicry is extraordinary.

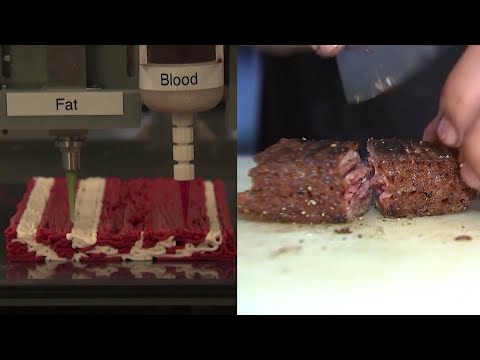

The molecules of difference that create the flavour of beef, as distinct from that of lamb, are few but extremely powerful. This is certainly the closest synthetic approximation yet. Ben Bartlett, a chef and barbecue expert, said: “I judge on taste, texture and appearance – I’ve had so many bland and dull plant products. Then suddenly this came along and I was marking them 9s and 10s.”

Ben Bartlett, a chef and barbecue expert, said: “I judge on taste, texture and appearance – I’ve had so many bland and dull plant products. Then suddenly this came along and I was marking them 9s and 10s.”

The starter was “pork sausage” in a thick, umami-ish, Moroccan-tinged sauce of aubergine and yoghurt. It was not quite indistinguishable from the real thing, having a trace of sweetness that hinted at its true nature, but it was unmistakably the “gamechanger” that everyone describes.

But not until the beef dish was the technical achievement really shown off. It resembled a stifado, a slow-cooked Greek stew heaped with baby onions, and the form was judiciously chosen; how much it would look like a steak if it had been flash fried, I don’t know. Yet the resemblance to meat, in the grain, the way it pulls apart, the mouthfeel, is absolutely uncanny. “Many of the traditional meat alternatives are fine,” said Jane Devonshire, the 2016 MasterChef winner, “but you wouldn’t get them past my husband. ” This beef, Mr Devonshire would approve.

” This beef, Mr Devonshire would approve.

White is not quite the unabashed carnivore his early image put across, and spent nine months as a vegan a decade ago. “I went from 20 stone to 15, I became fascinated by the weight loss. Then I started to look at cheeseboards and just hear a voice in my head saying: ‘Eat me.’” Nevertheless, he is associated with a certain mode of eating – fine cuts of noble provenance, a world away from processed or synthetic food. But he appears genuinely to have been won over by Redefine Meat. “I think it’s the cleverest thing I’ve seen in my 45 years in the industry,” he says.

Tom Cenci, the head chef at Stoney Street restaurant in east London, is slightly sceptical about flexitarianism, particularly when it’s done for environmental reasons. “Sometimes you don’t need to reinvent the wheel. If you’re eating asparagus on Christmas Day, or you’re not treating the animal you’ve slaughtered with respect, and eating the whole of it, that’s just as bad for the environment as eating meat,” he says. Yet he notes the importance of this innovation; the vegetarian offering of 10 years ago – a risotto at the bottom of the menu as an afterthought – isn’t cutting it any more.

Yet he notes the importance of this innovation; the vegetarian offering of 10 years ago – a risotto at the bottom of the menu as an afterthought – isn’t cutting it any more.

The genius climaxes with a lamb dish, devised to be very like loin, dressed with peas. You would, no question, be able to tell what animal this was meant to be. It is as different to the “beef” as actual lamb is to actual beef, but still has that trademark, sweet back note. Would you choose it in lieu of lamb, when these 3D cuts are slated to cost about the same? It would take some flexitarian commitment to get you over the line.

Israeli company unveils lab-grown beef chunks

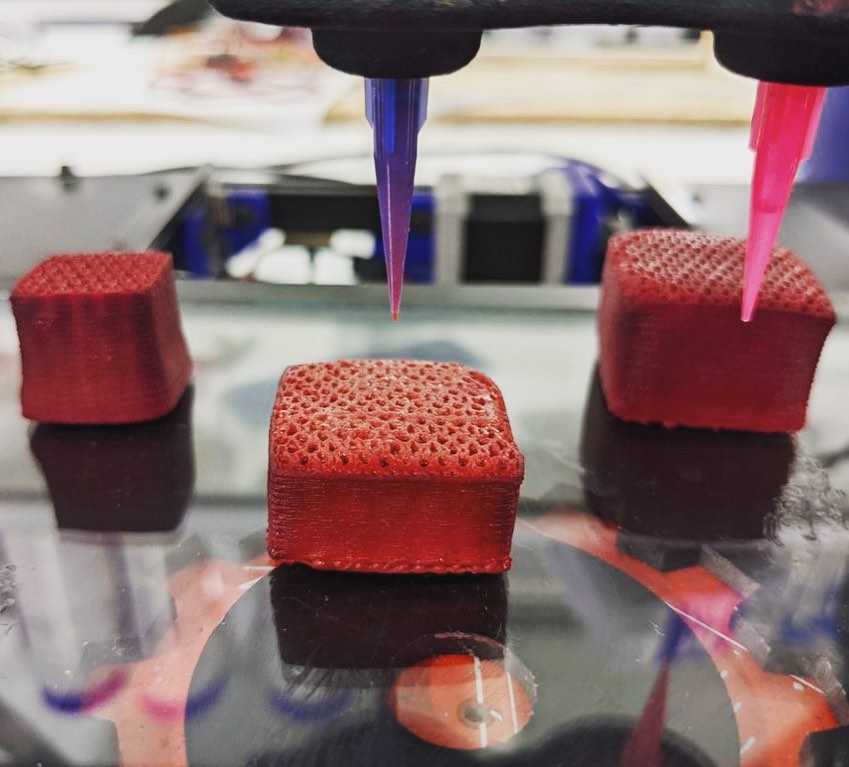

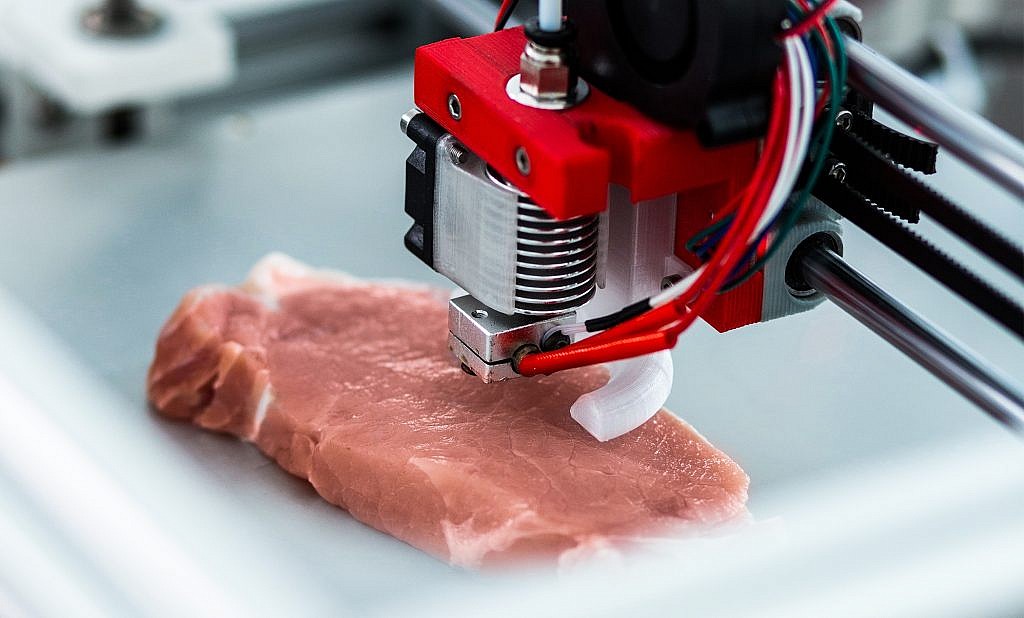

Craving your next serving of steak? These 3D-printed and sumptuous beef morsels may have you surprised.

This cutting-edge company is on a mission to mass produce cultured beef—real beef sourced from cows without any slaughtering involved, that further undergoes 3D printing.

Researchers suggest that lab-made beef is bound to reduce the environmental toll from conventional meat production methods. But, does the public feel ready to embrace these up-and-coming cuisines?

But, does the public feel ready to embrace these up-and-coming cuisines?

Rare or well done?

Israel-based Steakholder Foods, previously known as MeaTech 3D, has unveiled what it calls Omakase Beef Morsels.

As the name implies, these are bite-sized meat chunks developed using a 3D printing process that operates on lab-grown beef.

Steakholder's cultured beef morsels (Steakholder Foods)As opposed to being sourced from slaughtering livestock, the beef for these morsels is derived from "starter cells" or STEM cells of the animal that are left to grow in a petri dish or flash under human-made conditions.

"Omakase Beef Morsels are an innovative culinary and technological achievement inspired by the marbling standard of Wagyu beef and designed as a meat lover’s delicacy for premium dining experiences," explains Steakholder Foods.

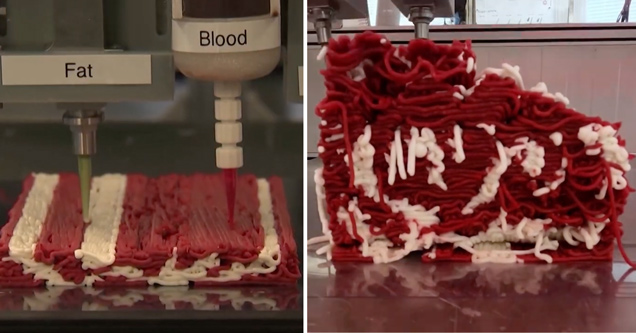

"The product is made up of multiple layers of muscle and fat tissue which have been differentiated from bovine stem cells. It can be printed in a variety of muscle-fat layer sequences and with any desired marbling ratio, shape or width."

It can be printed in a variety of muscle-fat layer sequences and with any desired marbling ratio, shape or width."

As innovative as Steakholder's new "patent-pending breakthrough" may seem, 3D-printed meat is actually nothing new—at least when it comes to vegan versions.

In 2020, another Israeli company, Redefine Meat announced the launch of its plant-based 3D printed meat product, apparently also "patent-pending," with its primary protein sources being soy and peas.

Redefine's vegan-friendly meat mimic has been dubbed "gamechanging," with its "extraordinary" taste and texture, been declared "certainly the closest synthetic approximation yet."

Steakholder's 3D printed beef, on the other hand, uses lab-grown steak that the company unveiled in December 2021 as the world's "largest" cultured steak chunk weighing almost 4oz (110 grams)—making it closest to real steak sourced from slaughtering cows.

The following video explainer dives deeper into the production process and how scientists had to "grow" both fat and muscle tissue of the meat in the lab:

Prior to Steakholder's innovation, Aleph Farms, yet again Israel-based, is credited with producing the world's first lab-grown beef steak in 2018.

From environment to ethics: adoption among public

As for whether lab-grown meat is better for the environment, as touted by the industry gamechangers, researchers largely state so but there's more to be learned.

A 2019 report from the University of Oxford suggests "cultured meat" grown using tissue engineering techniques produces up to 96% less greenhouse gas emissions than the conventional process.

"What our study found was that the environmental impacts of cultured meat could be substantially lower than those of meat produced in the conventional way," Dr. Hanna Tuomisto of Oxford University's Wildlife Conservation Research Unit, who led the research, has previously said.

"Cultured meat could potentially be produced with up to 96% lower greenhouse gas emissions, 45% less energy, 99% lower land use, and 96% lower water use than conventional meat. "

"

Additionally, producing meat without having to raise and slaughter cattle may work out better for ensuring animal welfare and overall health.

However, an earlier publication on European Union (EU)'s website suggested not all artificial meat production methods may be energy efficient, and the choice of meat source (chicken, beef, pork, or plant) had a role to play.

"One study shows that artificial meat could have less environmental impact than beef, and possibly pork, but more than chicken and plant-based proteins (Smetana et al., 2015)." [1, 2].

"However, these [lifecycle analyses] are speculative as they are all based upon hypothetical models of what form cultured meat production might take (Stephens et al., 2018). Further monitoring of associated technological developments is needed to complement these speculative models."

Lab-grown beef may seem to be a more ethical alternative to slaughtering animals. Prominent animal welfare groups like UK's Vegan Society have expressed support for the product as it helps "reducing animal suffering and the environmental impact of animal agriculture" while still upholding the fact that cultured meat is not vegan.

But the ethics of production process itself may leave people divided.

A controversial aspect of lab-grown beef is that it uses Fetal Bovine Serum (FBS) as a substance for supporting STEM cell growth. FBS is derived from an unborn fetus of a slaughtered cow which may not sit well with all consumers.

"In layman's terms, it's baby cow blood," explains Dr. Celia Homyak, co-director of Alternative Meats Lab at UC Berkeley in the video.

Scientists are working to eventually replace FBS with another substance that will eliminate dependence on cow fetuses.

"Steakholder Foods is committed to removing fetal bovine serum (FBS), a costly animal-derived ingredient used in cell culture media that feeds stem cells as they undergo differentiation into muscle cells and fat cells. We have already developed processes that don't require this component and are working to phase it out as soon as possible," says the company.

"Our plans are that [FBS] shouldn't be part of any at-scale commercial activity," Simon Fried, a former Steakholder executive has previously said.

Homyak also implied that the actual environmental impact from mass-producing cultured beef may only become known as production is scaled up.

"We don't know what the carbon footprint looks like to actually scale these up, and the amount of space and energy it will take."

Time will tell who wins the race of mastering meat mass-production—cultured or vegan. More than just being food as fuel, culinary habits and preferences can be deeply personal and engrained across cultures and belief systems. More than just pioneering technological innovation, the bigger challenge for the evolving food tech lies in winning over people's perceptions and preferences, and that too, organically (no pun).

Note: Neither BleepingComputer nor the author is affiliated with any of the companies and/or their associates and/or the larger meat production industry in any manner and is not receiving any material or financial favors from the publication of this piece.

How does a 3D printer steak taste? - such a question is no longer from the category of fantasy.

Israeli startup Redefine Meat has learned how to 3D print steaks that look like real meat. In mid-February, the startup completed another round of funding to start shipping its printers around the world. According to the plan, the expansion was supposed to begin last year, but the pandemic prevented it: the startup intends to promote the product first through restaurants.

Israeli startup Redefine Meat has learned how to 3D print steaks that look like real meat. In mid-February, the startup completed another round of funding to start shipping its printers around the world. According to the plan, the expansion was supposed to begin last year, but the pandemic prevented it: the startup intends to promote the product first through restaurants. Many companies produce artificial meat from soy and pea protein, coconut fat, sunflower oil, natural colors and flavors. But even if they taste like real minced meat, they lack the main thing: the texture and look of the steak. Redefine Meat founder Eshkhar Ben-Shitrit figured out what to do with it. His printer prints three types of voxels, or millimetric three-dimensional pixels. Some copy muscle, others fat, others blood. Each stake consists of an example of 3 million voxels. By changing the recipe and collecting them in different sequences and proportions, you can reproduce tenderloin, ribeye, picanha and other types of steaks. And most importantly - they copy not only the taste, but also the type of meat, and even sensations. “A steak is basically muscle, fat and blood in a complex structure that affects how it feels in the mouth and how it is cooked. The taste depends on how the marbled veins of fat melt when you cook,” Ben-Shitrit told Israel21c online.

And most importantly - they copy not only the taste, but also the type of meat, and even sensations. “A steak is basically muscle, fat and blood in a complex structure that affects how it feels in the mouth and how it is cooked. The taste depends on how the marbled veins of fat melt when you cook,” Ben-Shitrit told Israel21c online.

How Ben-Shitrit met cows

Ben-Shitrit grew up on a kibbutz where his mother ran a dairy farm. He loved meat since childhood. And at the age of 13, he learned how to cook the perfect steak when he went to work part-time at his uncle's restaurant in Tel Aviv in the summer.

He graduated with a law degree from the Hebrew University of Jerusalem, worked for a year and a half as a clerk of the Israeli Supreme Court, and in 2011 changed careers to become a product manager for Hewlett-Packard. Responsible for printing on cardboard boxes. His next job was at the Israeli company Highcon, specializing in cardboard packaging. In 2015–2017 he was its vice president of marketing.

So, Ben Shitrit loved meat. But when his first child was born, he was surprised to find that he could no longer eat beef. There were memories of his childhood on a dairy farm, where he saw firsthand how cows take care of their calves. Ben-Shitrit tried many meat substitutes, but none of them looked like a real steak. Then he had the idea to print meat on a printer to copy its texture. He quit and in February 2018 founded Jet-Eat, which was later renamed Redefine Meat.

“The company was engaged in R&D for almost two years before [in the fall of 2019] we first raised serious investments and recruited a team - in nine months the staff grew from 6 to 25 people,” Ben-Shitrit told Business Insider and last July . Now, judging by the information on the startup's website, it employs 36 people.

The startup developed its products in collaboration with scientists from the Israeli Institute of Technology Technion, using its laboratories for experiments. In September 2019The company received $6 million in seed funding from CPT Capital, a venture fund that also includes stakes in other artificial meat producers, Impossible Foods and Beyond Meat. In February of this year, Redefine Meat raised $29 million in a Series A round in which new investors joined CPT Capital - Losa Group, Sake Bosch, K3 Ventures.

In February of this year, Redefine Meat raised $29 million in a Series A round in which new investors joined CPT Capital - Losa Group, Sake Bosch, K3 Ventures.

1/5 cow per day

Redefine Meat already has something to boast about. Last June, the company officially unveiled the world's first plant-based 3D printed steak, then began testing its product in high-end restaurants in Israel, and Ben-Shitrit became a hero in the Israeli media with the phrase "We print steaks on a 3D printer ".

True, the fastest printer at his disposal prints about 6 kg of meat per hour. With three cartridges to recharge (artificial meat, fat and blood) and maintain the machine, on good days it produces about 90 kg of meat per day. Beef cows can weigh about half a ton, but meat can account for 60–70% of the total weight.

No meat in meat, no milk in chocolate

Not only meat becomes vegan. In mid-February, Nestle announced that it would launch the first vegan milk chocolate, called KitKat V. The product will roll out to several countries, including the UK, and if successful, will expand to other markets. It took about two years to develop the bar. The main problem was that soy and almond substitutes do not mix well with cocoa and sugar, and as a result, the desired creamy structure is not obtained. KitKat V replaced milk with rice mix. This is not the first product to replace animal ingredients. Last year, Nestle launched meat-free sausage, veggie ground meat, dairy-free ice cream, and animal food with insect protein and bean and millet meat protein substitutes.

The product will roll out to several countries, including the UK, and if successful, will expand to other markets. It took about two years to develop the bar. The main problem was that soy and almond substitutes do not mix well with cocoa and sugar, and as a result, the desired creamy structure is not obtained. KitKat V replaced milk with rice mix. This is not the first product to replace animal ingredients. Last year, Nestle launched meat-free sausage, veggie ground meat, dairy-free ice cream, and animal food with insect protein and bean and millet meat protein substitutes.

The startup is currently completing the construction of the first production line, which will assemble a new printer model designed for 10 kg of meat per hour. “It’s not yet an industrial machine, we call it semi-industrial,” Ben-Shitrit told Business Insider.

Machines will be installed directly at customers' premises to enable them to sell fresh meat. The technology that Redefine Meat is developing could disrupt the global food supply chain, Ben-Shitrit shared his thoughts with The Times of Israel online edition. 3D printers that produce meat near the points of sale make it unnecessary to buy meat in other countries, he said.

3D printers that produce meat near the points of sale make it unnecessary to buy meat in other countries, he said.

Redefine Meat was supposed to hit restaurants late last year, but the coronavirus got in the way. During the pandemic, Redefine Meat signed contracts with several organizations interested in introducing artificial meat into the assortment. For example, in January of this year, Redefine Meat announced a strategic agreement with Israeli meat distributor Best Meister. The partner will supply not only to restaurants in Israel, but also to butcher shops. The agreement was signed after a blind tasting of alternative meats in Tel Aviv (both companies claim that it was the largest in the world - it was attended by about 600 people), which showed that 90% of meat eaters like fake meat. The company wants to conduct the same test with chefs in other countries and is preparing to enter markets in Europe, Asia and North America later this year. “This is a step towards becoming the world's largest alternative meat company by 2030,” Ben-Shitrit told The Times of Israel.

What the startup hopes for

Ben-Shitrit is going to sell his meat at the price of the real one. He believes that now is the best time to bring the product to market - many large meat companies are investing in meat alternatives for vegans, flexitarists, etc.

According to Euromonitor, global sales of meat substitutes reached $19.5 billion in 2018. In 2019, investment bank UBS predicted that the plant-based meat market would reach $85 billion by 2030. And Barclays named meat substitutes as the fastest growing segment of the food industry and estimated their market by 2030 at $ 140 billion. A large contribution to its popularity is the demand from people concerned about healthy eating, animal cruelty and climate change. Ben-Shitrit says that his equipment can in the future create analogues with the structure of chicken, pork, lamb and tuna. But he started with beef for two reasons. “Beef has the biggest business potential, it's the $500 billion industry, and it's the most environmentally damaging,” he told Food Ingredients First online. “In the beef category, there is a wide variety of products for which alternative meat is not used, mainly minced meat and sausages.” He says that the 20,000 liters of water and 25 kg of feed needed to produce 1 kg of meat is a terrible inefficiency and waste. In addition, the meat produced by his startup contains almost no cholesterol and boasts a high fiber content.

“In the beef category, there is a wide variety of products for which alternative meat is not used, mainly minced meat and sausages.” He says that the 20,000 liters of water and 25 kg of feed needed to produce 1 kg of meat is a terrible inefficiency and waste. In addition, the meat produced by his startup contains almost no cholesterol and boasts a high fiber content.

Media news2

Is advertising distracting? With a subscription you won't see it on the siteMeat for printing: how startups prepare steaks in a 3D printer :: RBC Pro

Pro Project partner*

TV channel

Pro

Investments

Events

RBC+

New economy

Trends

Real estate

Sport

Style

National projects

City

Crypto

Debating club

Research

Credit ratings

Franchises

Newspaper

Special projects St. Petersburg

Petersburg

Conferences St. Petersburg

Special projects

Checking counterparties

RBC Library

Podcasts

ESG index

Policy

Economy

Business

Technology and media

Finance

RBC CompanyRBC Life

Material section Main

Management · Global business trends

Articles Bloomberg

The global market for meat substitutes has already reached $14 billion. But so far, such products are more expensive than real pork or beef, and their texture is far from the original. Startups from Israel and Spain promise to solve both problems with a 3D printer0003

But so far, such products are more expensive than real pork or beef, and their texture is far from the original. Startups from Israel and Spain promise to solve both problems with a 3D printer0003

Photo: Baptiste Virot for Bloomberg Businessweek

The walls of the Redefine Meat laboratory in Rehovot, Israel are decorated with stucco moldings in the shape of different types of steaks, among which, of course, there are tibon and ribeye. There are books about meat on the shelves, and refrigerators are literally bursting with packages of minced meat and tenderloin, or something very similar to minced meat and tenderloin.

Technicians and researchers here are downright obsessed with their work. And no, the main goal of a startup is not at all to sell customers the perfect beef tenderloin. The company wants to create high-quality plant analogues. Redefine Meat is currently working on a 3D printer that, according to the creators, will be able to print steaks so juicy and full of flavor that even the most demanding meat eaters will not be able to distinguish them from real ones.