3D printer companies best

5 Biggest 3D Printing Companies

DDD, PRLB, and FARO lead the 5 biggest 3D printing companies list

By

Nathan Reiff

Full Bio

Nathan Reiff has been writing expert articles and news about financial topics such as investing and trading, cryptocurrency, ETFs, and alternative investments on Investopedia since 2016.

Learn about our editorial policies

Updated August 01, 2022

Reviewed by

Thomas Brock

Reviewed by Thomas Brock

Full Bio

Thomas J. Brock is a CFA and CPA with more than 20 years of experience in various areas including investing, insurance portfolio management, finance and accounting, personal investment and financial planning advice, and development of educational materials about life insurance and annuities.

Learn about our Financial Review Board

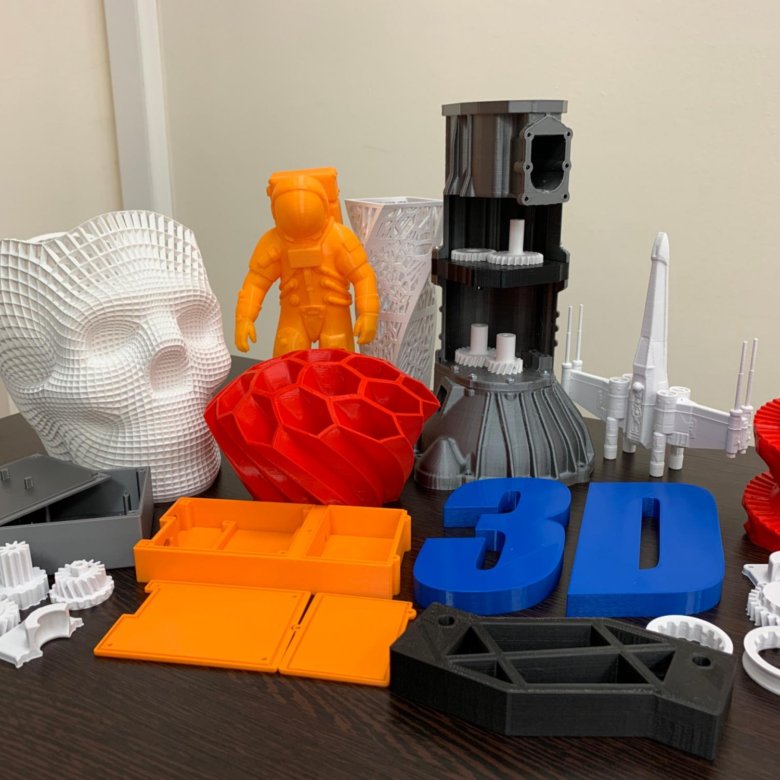

The manufacturing process known as 3D printing is one of the most promising and rapidly developing technologies with applications across a multitude of industries. 3D printing involves the additive layering of thin sheets of material that are fused together to create a physical product from a digital design. While the industry is currently hampered by relatively slow production times, advocates believe that 3D printing ultimately will have the capability to mass produce everything from medical equipment to automotive parts to airline components. Below, we look at the 5 biggest 3D printing companies by 12-month trailing (TTM) revenue. This list is limited to companies that are publicly traded in the U.S. or Canada, either directly or through ADRs. Some foreign companies may report semiannually, and so may have longer lag times. All data are from YCharts as of September 8, 2020.

- Revenue (TTM): $566.6 million

- Net Income (TTM): -$78.4 million

- Market Cap: $632.3 million

- 1-Year Trailing Total Return: -24.6%

- Exchange: New York Stock Exchange

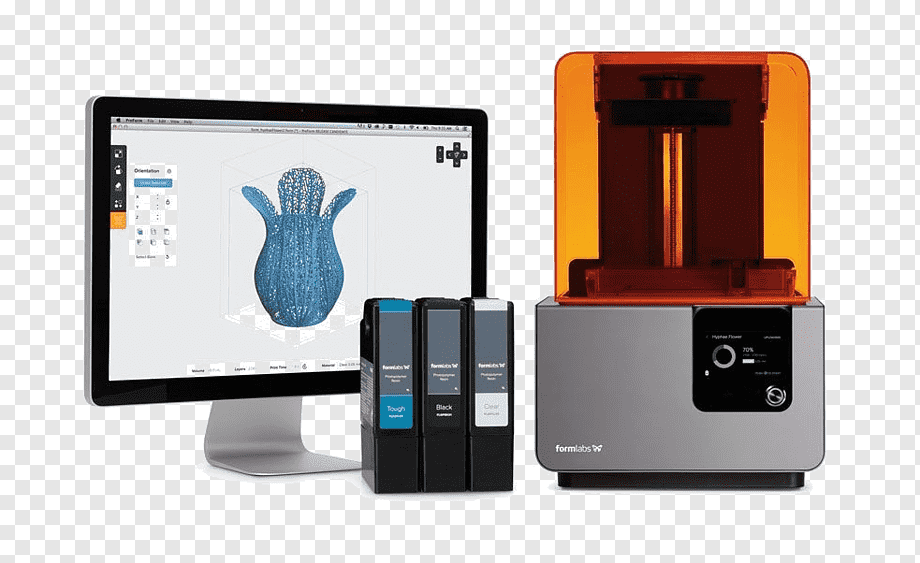

3D Systems invented 3D printing in 1989 with the development and patenting of its stereolithography technology, which uses ultraviolet lasers to help create highly precise parts. DDD built on that by developing new technologies, including selective laser sintering, multi-jet printing, film-transfer imaging, color jet printing, direct metal printing, and plastic jet printing. 3D Systems has three business units: products, materials, and services. The products category offers 3D printers and software and includes small desktop and commercial printers that print in plastics and other materials.

DDD built on that by developing new technologies, including selective laser sintering, multi-jet printing, film-transfer imaging, color jet printing, direct metal printing, and plastic jet printing. 3D Systems has three business units: products, materials, and services. The products category offers 3D printers and software and includes small desktop and commercial printers that print in plastics and other materials.

- Revenue (TTM): $451.0 million

- Net Income (TTM): $58.6 million

- Market Cap: $3.9 billion

- 1-Year Trailing Total Return: 58.2%

- Exchange: New York Stock Exchange

Proto Labs was founded in 1999 with a focus on building automated solutions to develop plastic and metal parts used in the manufacturing process. The company expanded to launch an industrial-grade 3D printing service that allowed developers and engineers to move prototypes into the production process. The company's primary business services include injection molding, sheet metal fabrication and 3D printing.

- Revenue (TTM): $334.7 million

- Net Income (TTM): -$79.7 million

- Market Cap: $1.0 billion

- 1-Year Trailing Total Return: 20.6%

- Exchange: NASDAQ

FARO specializes in 3D measurement and other services for the fields of architecture, engineering, and construction. With a 40-year history, FARO' began before the advent of 3D printing. The company's products include coordinate measuring machines, laser trackers and projectors, mappers, scanners, and software. FARO also serves the aerospace, automotive, and power generation industries.

- Revenue (TTM): $205.3 million

- Net Income (TTM): -$2.7 million

- Market Cap: $1.9 billion

- 1-Year Trailing Total Return: 94.8%

- Exchange: NASDAQ

Belgian company Materialise has a 30-year history providing 3D printing solutions and related software. It provides platforms to facilitate the development of 3D printing applications in industries such as healthcare, automotive, aerospace, and art and design. Some of the company's first 3D printing activities included anatomical models in both dental and hearing aid products. Materialise also produces eyewear and automobile products.

Some of the company's first 3D printing activities included anatomical models in both dental and hearing aid products. Materialise also produces eyewear and automobile products.

- Revenue (TTM): $52.9 million

- Net Income (TTM): -$14.5 million

- Market Cap: $238.2 million

- 1-Year Trailing Total Return: 48.3%

- Exchange: NASDAQ

ExOne specializes in manufacturing 3D printing machines for customers across various industries. It also produces 3D printed products to specification for industrial customers. ExOne 3D printers utilize binder jetting technology, fusing powder particles of materials like metal or sand into molds, cores, and other products.

Article Sources

Investopedia requires writers to use primary sources to support their work. These include white papers, government data, original reporting, and interviews with industry experts. We also reference original research from other reputable publishers where appropriate. You can learn more about the standards we follow in producing accurate, unbiased content in our editorial policy.

You can learn more about the standards we follow in producing accurate, unbiased content in our editorial policy.

YCharts. "YCharts."

3D Systems. "Our Story."

Materialise. "Timeline."

25 Top 3D Printing Companies You Should Know 2022

Think of 3D printing as erosion in reverse. Bodies of water wear substances down layer by near-imperceptible layer; 3D printers build substances up in a similar way. Like all technology, of course, 3D printing isn’t nearly as old as the tides.

The concept dates back to the early ‘80s, when Dr. Hideo Kodama almost patented it in Japan. Due to a bureaucratic issue, though, Kodama’s patent never went through. Consequently, credit for 3D printing typically goes to Charles Hull, an American engineer who founded 3D Systems, the original 3D printing company, back in 1986. It made the first machines that could translate digital designs into 3D cured-resin artifacts.

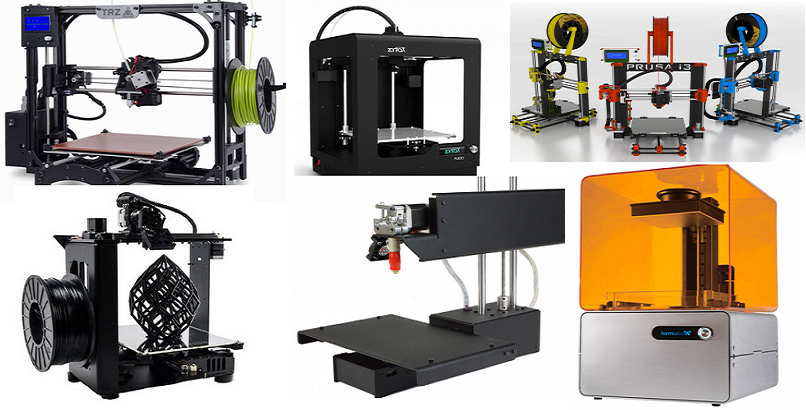

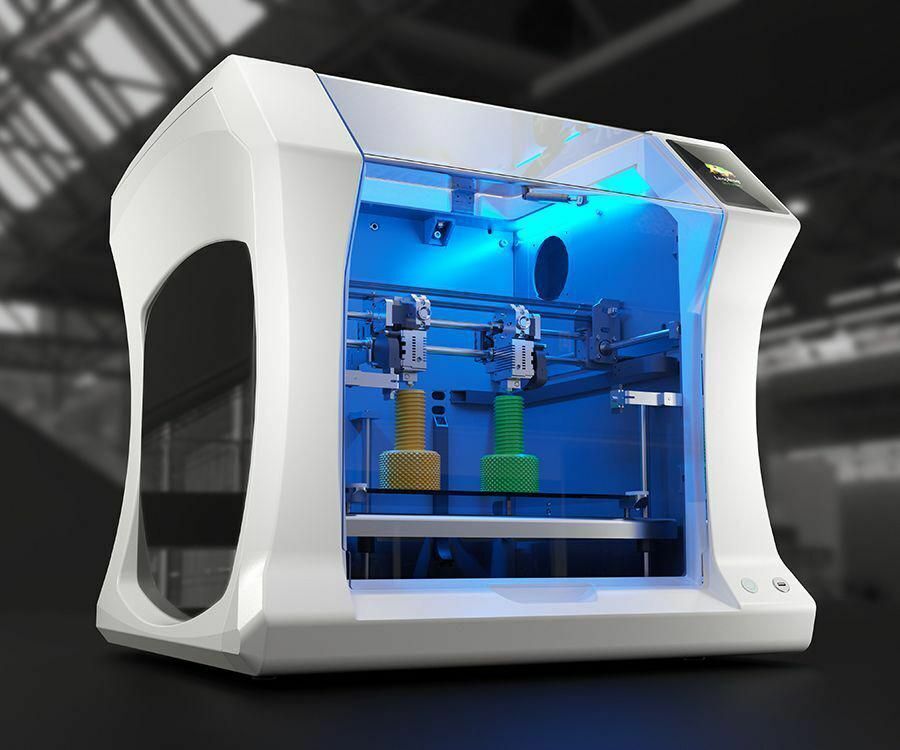

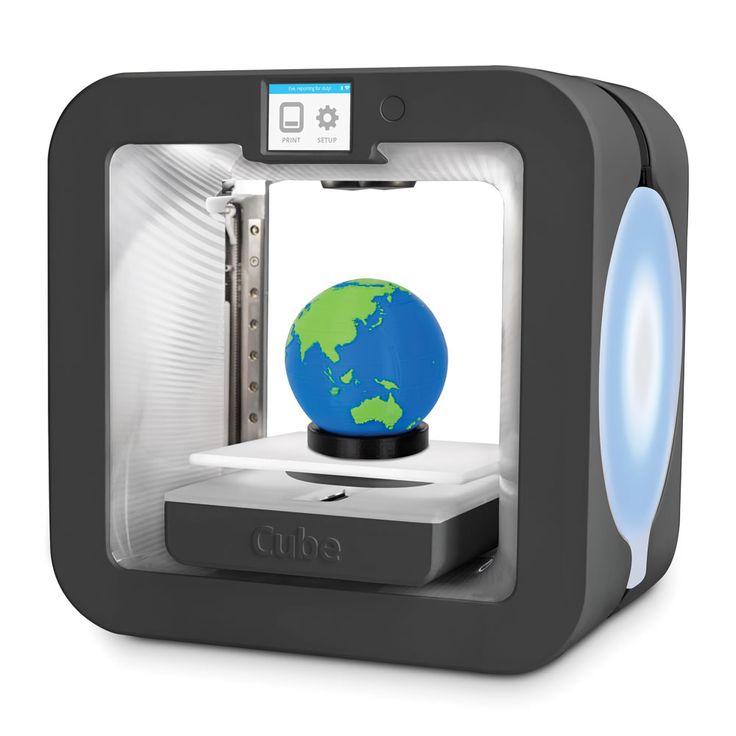

Nowadays, 3D printing is a thriving industry. Modern printers range from desktop models to industrial giants to “bioprinters,” which can create human tissue. That’s not to mention the 3D-printing software, where objects get designed and optimized, and on-demand printing shops.

Modern printers range from desktop models to industrial giants to “bioprinters,” which can create human tissue. That’s not to mention the 3D-printing software, where objects get designed and optimized, and on-demand printing shops.

Here are 25 companies that are thriving in the 3D printing space.

Top 3D Printing Companies to Know

- GE

- HP

- Carbon, Inc.

- Glowforge

- Fast Radius

- 3D Fortify

- Markforged

- SprintRay

- Desktop Metal

- Divergent

25 3D Printing Companies to Know

Location: Boston, Massachusetts

The GE Additive team specializes in hardware, software and consulting services for 3D-printed metal parts. Utilizing direct metal laser melting and electron beam melting processes, the company’s additive machine hardware melt and layer metal powders to build custom part solutions. GE Additive products have created parts for use in orthopedic implants, aircrafts, automobiles and industrial manufacturing tools.

Location: Palo Alto, California

Known for its PC and related hardware, HP also offers personal 3D printers as well as 3D-printing software, services and varied materials. HP’s Jet Fusion printer series are multi-material compatible and scalable to manufacturing needs, with its Jet Fusion 5210 model able to print approximately 550 parts per week. The company’s 3D printing services have come in handy for industries ranging from aerospace to consumer goods and electronics.

Location: Boston, Massachusetts

3D Fortify relies on a magnetic system that arranges reinforcement fibers with a digital light processor. By arranging the fibers in the object, 3D Fortify can create high-strength tools for engineers. So far, the company’s products include FLUX printers, materials, software and applications.

Location: Somerville, Massachusetts

Formlabs makes various 3D printers, which range from desktop to industrial formats. The Form 3 and Form 3L, two of the smaller styles, rely on laser light and a flexible tank of resin to print quickly and precisely. Both can create features as narrow as one thousandth of an inch, which comes in handy for printing New Balance’s new midsoles. Made from a substance called Rebound Resin, these bouncy creations look less like traditional foam and more like sprays of Spiderman’s webbing.

The Form 3 and Form 3L, two of the smaller styles, rely on laser light and a flexible tank of resin to print quickly and precisely. Both can create features as narrow as one thousandth of an inch, which comes in handy for printing New Balance’s new midsoles. Made from a substance called Rebound Resin, these bouncy creations look less like traditional foam and more like sprays of Spiderman’s webbing.

Location: Watertown, Massachusetts

Many 3D printers use plastic filament, but not those made by Markforged. Its industrial printers can print hardier substances, including nylon, carbon fiber and even metal — hence the “forge” in Markforged. (Continuing the metal theme, it also makes AI manufacturing software called Blacksmith.) Integrated into factories worldwide, this company’s printers reportedly have helped transform supply chains by accelerating prototype and replacement part manufacturing.

Location: Gaithersburg, Maryland

Xometry began as a way to simplify prototyping. Its software eliminated the need for companies to slowly and laboriously gather quotes from manufacturers. Instead, they could access six different types of 3D printers on demand and at instantly-quoted rates. That model has attracted high-profile clients like car manufacturer BMW, which relies on Xometry for custom trim, logos and other unique and tooling-heavy touches that are printed from carbon fiber tubing.

Its software eliminated the need for companies to slowly and laboriously gather quotes from manufacturers. Instead, they could access six different types of 3D printers on demand and at instantly-quoted rates. That model has attracted high-profile clients like car manufacturer BMW, which relies on Xometry for custom trim, logos and other unique and tooling-heavy touches that are printed from carbon fiber tubing.

Location: New York, New York

Focused less on 3D printing hardware than software, nTopology’s NTop Platform can be integrated into 3D printing engineering workflows. A standout feature: It can autonomously tweak and streamline existing designs, removing clunkiness and excess weight so designers can focus on more important problems and avoid busywork — whether they’re printing medical devices or rocket nozzles.

Location: New York, New York

Shapeways 3D prints designs on demand in a choice of more than 50 materials, including plastic, sandstone and platinum. Customers simply log in to the site, upload a design and place an order, which prints in one of the two Shapeways factories and arrives via mail. It’s online shopping, really, but instead of browsing the wares, shoppers design them. Shapeways also has a team of designers on hand to help users bring their visions to fruition.

Customers simply log in to the site, upload a design and place an order, which prints in one of the two Shapeways factories and arrives via mail. It’s online shopping, really, but instead of browsing the wares, shoppers design them. Shapeways also has a team of designers on hand to help users bring their visions to fruition.

Get Alerted for Jobs from 3D Systems Corporation

More on 3D PrintingPros and Cons of 3D Printing

Location: Rock Hill, South Carolina

The original 3D printing company remains on the cutting edge of the field. 3D Systems Corporation makes a broad spectrum of 3D printers, which work via stereolithography, a liquid-to-solid process, and a powder to solid process called selective laser sintering. Printers make everything from metal artifacts to plastic filaments to custom dental implants. 3D Systems also offers a constellation of related products, like 3D scanners and design software.

Get Alerted for Jobs from 3D Systems Corporation

Location: Seattle, Washington

This company’s namesake 3D printer, Glowforge, can print with almost any material. Kid-friendly and intended for home use, it creates custom designs from plastic, wood and even chocolate. Though it allows for creativity, that’s not required; the hardware comes pre-loaded with a catalog of cool designs for everything from monogrammed macarons to a wooden Settlers of Catan game board.

Kid-friendly and intended for home use, it creates custom designs from plastic, wood and even chocolate. Though it allows for creativity, that’s not required; the hardware comes pre-loaded with a catalog of cool designs for everything from monogrammed macarons to a wooden Settlers of Catan game board.

Location: Chicago, Illinois

Fast Radius has replaced old-school, centralized factories with a network of smaller “manufacturing lighthouses” — a move for which the company was named one of the globe’s leading factories by the World Economic Forum. At each of its fabrication plants, the company 3D-prints and injection-molds parts for industrial use and quickly ships them off. Its partnership with UPS, paired with the company’s distributed structure, means it can often offer next-day delivery, even on custom builds.

Location: Redwood City, California

This startup has a minimal web presence — it’s still in stealth mode — but it focuses on 3D printed buildings. Specifically, Mighty Building makes tiny-house-esque “backyard studios” with a massive printer that barely fits in a warehouse. The company offers three studio models so far, which max out at less than 600 square feet. That’s smaller than many studios, but the pint-sized standalone structures are surprisingly stylish and functional, outfitted with floor-to-ceiling windows and working bathrooms.

Specifically, Mighty Building makes tiny-house-esque “backyard studios” with a massive printer that barely fits in a warehouse. The company offers three studio models so far, which max out at less than 600 square feet. That’s smaller than many studios, but the pint-sized standalone structures are surprisingly stylish and functional, outfitted with floor-to-ceiling windows and working bathrooms.

Location: Redwood City, California

Every 3D printing process involves fusing layers into a whole, but Carbon has reinvented the fusing process. Called Digital Light Synthesis, the technique smooths away the “seams” that 3D printing often produces. This creates a seamless finish, and a stronger product — traditionally 3D-printed objects’ strength can vary, depending on whether the nozzle moved clockwise or counterclockwise in production.

Location: Los Angeles, California

Divergent 3D aims to streamline and decentralize car manufacturing. That means moving production out of multi-million-dollar factories and into a networked cluster of 3D printing shops. In these smaller, warehouse-like spaces, the Divergent 3D team relies on end-to-end design software and industrial printers to create light, safe, fast cars. As of 2017, the company had prototyped two vehicle models: a motorcycle called the Dagger, and a sleek low-riding sports car called the Blade. (Cutting-edge, indeed!)

That means moving production out of multi-million-dollar factories and into a networked cluster of 3D printing shops. In these smaller, warehouse-like spaces, the Divergent 3D team relies on end-to-end design software and industrial printers to create light, safe, fast cars. As of 2017, the company had prototyped two vehicle models: a motorcycle called the Dagger, and a sleek low-riding sports car called the Blade. (Cutting-edge, indeed!)

Location: Los Angeles, California

SprintRay is a 3D printing company specializing in dental products. The company’s RayWare software is specifically designed with dental professionals in mind as it pairs CAD automation and allows for connection to SprintRay’s printers, making modeling dental products more streamlined. The software also allows users to save edited models and export to other CAD services. In addition, SprintRay offers a host of 3D dental printers as well as cloud solutions that reduce the need for hardware and allow for more mobile printing.

Location: Burlington, Massachusetts

Desktop Metal condensed a steel mill into a box smaller than a refrigerator that easily fits through an office door. No special ventilation is required, and there’s no open flame, laser light or loose powder involved. It just needs power and an internet connection to 3D-print with steel. More specifically, this company’s printer extrudes rods of a powdered steel alloy, wax and polymer binder. (The company is developing copper and nickel filaments, too.) The printer first cooks away the binding. It then welds steel layers together in its furnace. Though it’s a very contained process, it’s also transparent — users can watch it unfold via livestream.

More on 3D PrintingFive 3D Printing Applications in Construction

Location: Waltham, Massachusetts

Nano Dimension’s combines 3D printing products with AI to create streamlined 3D-printed circuits and devices. Imbued with its DeepCube neural network, the company’s printers are able to detect and correct manufacturing errors in real-time, improving part quality and reducing material costs. In addition, Nano Dimension hosts surface-mount technology hardware and software for automated assembly needs.

In addition, Nano Dimension hosts surface-mount technology hardware and software for automated assembly needs.

Get Alerted for Jobs from Nano Dimension

Location: Solana Beach, California

With 3D-printed tissue, this company takes lab testing to the next level. Organovo’s bioprinting technology builds fabricated multicellular tissues, giving a wider three-dimensional view of cellular function and structure in comparison to views in a two-dimensional petri dish. Specialists can utilize these tissue creations to assess pharmacology and structural factors of a disease, and have already been able to simulate liver, kidney, bone and other cellular environments.

Get Alerted for Jobs from Organovo Holdings

Location: Miami, Florida

Rokk3r has helped more than 30 companies streamline their business plans with “exponential technologies.” (That means tech that helps them outperform competition by a factor of at least ten. ) Those technologies include blockchain, Internet of Things connectivity, and, you guessed it, 3D printing. The latter can exponentially reduce the number of parts required in complex manufacturing, which accelerates and simplifies the whole process.

) Those technologies include blockchain, Internet of Things connectivity, and, you guessed it, 3D printing. The latter can exponentially reduce the number of parts required in complex manufacturing, which accelerates and simplifies the whole process.

Get Alerted for Jobs from Rokk3r Labs

Location: New York, New York

Though MakerBot printers have many industrial applications, the company also makes a newbie-friendly desktop printer, the Replicator+, that’s found in more than 7,000 classrooms. Makerbot complements that popular hardware with free lesson plans that incorporate 3D printers and are available via download or book form. In one suggested earth science lesson plan, for instance, students print models of different cloud types to literally grasp the distinction between cumulus and cirrus. And that’s just one of the new options Replicator+ opens up for students who learn best through touch and action.

Get Alerted for Jobs from MakerBot

Location: San Mateo, California

This company specializes in 3D printing for gamers. Whether clients want custom board game pieces or 3D-printed replicas of their ship in the Star Trek video game, Mixed Dimension’s printer can make it happen. Capable of more than 10 million colors, it’s high-resolution enough for photo-caliber projects. Users can upload screenshots or CAD designs of their desired spaceship, or work with staff artists to turn imagined gaming tableaus into 3D realities.

Whether clients want custom board game pieces or 3D-printed replicas of their ship in the Star Trek video game, Mixed Dimension’s printer can make it happen. Capable of more than 10 million colors, it’s high-resolution enough for photo-caliber projects. Users can upload screenshots or CAD designs of their desired spaceship, or work with staff artists to turn imagined gaming tableaus into 3D realities.

Get Alerted for Jobs from Mixed Dimensions

Location: Eden Prairie, Minnesota

Stratasys has been in the 3D printing industry since 1988 — almost as long as 3D printing has existed. During that time, it has racked up more than 250 granted or pending patents worldwide. Today, the company helps clients like Audi and Lockheed Martin perfect their manufacturing process with 3D printing. It also manufactures printing hardware for Hewlett-Packard as well as its own brands. Ever the industry leader, Stratasys remains on the cutting edge, especially when it comes to recycling. Clients can send used cartridges, print engines and other parts back to the company for green disposal.

Clients can send used cartridges, print engines and other parts back to the company for green disposal.

Get Alerted for Jobs from Stratasys

Location: Cambridge, Massachusetts

CELLINK focuses on “bioprinting,” the 3D printing of bone, cartilage, and, maybe someday, functioning human organs. Any and all of that is possible with the company’s patent-pending universal bioink — a soup of stem cells and alginate derived from brown seaweed. More than 700 labs worldwide currently use the substance. The company also makes complementary technology: 3D printers, software and specialty inks designed for specific types of tissue.

Get Alerted for Jobs from CELLINK

Location: Maple Plain, Minnesota

Protolabs speeds up the manufacturing process. As its name suggests, the business began as a quick-turnaround prototyping company. In 2014, however, it added a 3D printing shop to speed the transition between the prototyping phase and small batch testing. That shop now has more than 100 printers that can print metal, plastic and other materials.

That shop now has more than 100 printers that can print metal, plastic and other materials.

Get Alerted for Jobs from Protolabs

Location: Leuven, Vlaams-Brabant, Belgium

Materialise focuses on 3D printing software, which makes complex printing hardware accessible to engineers, healthcare professionals and even fashion designers. Designer Anoul Wipprecht, for example, used Materialise software to print a surreal, bubble-wrap-like dress that also tracks the wearer’s mood. The company’s comprehensive digital suite includes tools for drafting and optimizing designs, controlling printers mid-job and managing 3D printing workflows.

Get Alerted for Jobs from Materialise

Top 10 3D printing companies listed on the stock exchange

So, we present to your attention the ranking of 3D printing companies in terms of annual turnover.

Stratasys: $750 million

Industry leader Stratasys grew 54% over the past year with sales exceeding $750 million. This is partly driven by demand for the new Object500 Connex3 model, as well as the traditionally popular PolyJet and industrial FDM 3D printers. Another growth driver was the acquisition of other companies such as Solid Concepts and Harvest Technologies (now part of Stratasys Direct Manufacturing). At the same time, the American-Israeli company (which includes, among other things, MakerBot Industries and SolidScape) recorded a net loss of $119 in its financial statements.million. This figure is more than four times higher than last year, which is also due to active acquisitions and investments. The forecast for 2015 is positive, it is expected that the revenue will be $940 million. If Stratasys manages to beat expectations by 6%, it could become the first pure 3D printing company to reach $1 billion in revenue.

This is partly driven by demand for the new Object500 Connex3 model, as well as the traditionally popular PolyJet and industrial FDM 3D printers. Another growth driver was the acquisition of other companies such as Solid Concepts and Harvest Technologies (now part of Stratasys Direct Manufacturing). At the same time, the American-Israeli company (which includes, among other things, MakerBot Industries and SolidScape) recorded a net loss of $119 in its financial statements.million. This figure is more than four times higher than last year, which is also due to active acquisitions and investments. The forecast for 2015 is positive, it is expected that the revenue will be $940 million. If Stratasys manages to beat expectations by 6%, it could become the first pure 3D printing company to reach $1 billion in revenue.

3D Systems: $650 million

Although 3D Systems' revenue rose 27% to a record high, the company still lost the top spot to Stratasys last year. The head of the company, Avi Reichental, said he was not entirely satisfied with how the company realized the potential of its technology portfolio. 3D Systems has some of the most advanced 3D printing technology in the industry, but hasn't shown enough willingness to go mainstream. However, according to 3D Systems financial statements, the company turned out to be in positive territory with a net profit of $1.6 million at the end of the year. Although the forecast for 2015 is generally positive, it is likely that 3D Systems will again be behind Stratasys, with revenues of $850-900 million.

The head of the company, Avi Reichental, said he was not entirely satisfied with how the company realized the potential of its technology portfolio. 3D Systems has some of the most advanced 3D printing technology in the industry, but hasn't shown enough willingness to go mainstream. However, according to 3D Systems financial statements, the company turned out to be in positive territory with a net profit of $1.6 million at the end of the year. Although the forecast for 2015 is generally positive, it is likely that 3D Systems will again be behind Stratasys, with revenues of $850-900 million.

Materialize: $81 million

Materialize is one of Europe's leading 3D printing service providers and a developer of innovative 3D printing software. In 2014, the company's revenue amounted to $81 million, which is 18.4% more than last year. The company's net profit reached $1.8 million, half of what it was in 2013, but still significant. Materialize's core business is the development and sale of 3D printing software (22% of sales) and medical 3D printing services (37%). The industrial segment, including the i.materialise 3D printing service, generated 40% of the company's total revenue. Materialize is expected to grow by 20% next year and reach €100 million in annual turnover.

The industrial segment, including the i.materialise 3D printing service, generated 40% of the company's total revenue. Materialize is expected to grow by 20% next year and reach €100 million in annual turnover.

ExOne: $43.9 million

Last year, ExOne grew by 10% with revenues of approximately $43.9 million. The main contribution to this result was made by the fourth quarter, during which sales increased by 50%. This state of affairs resulted in a gross profit of $10 million, but ExOne's operating costs were $21 million. This was mainly due to investments in the expansion of the company (new production facilities in Russia and Italy), as well as research and development (more than $8 million). In addition, ExOne announced the creation of a new large-scale 3D printer, Exerial.

Arcam: $39 million

Arcam, a Swedish manufacturer of electron beam melting (EBM) systems, recorded revenues of approximately $39 million. Thus, sales grew by 70% in a year, and profits exceeded $6 million. However, it is likely that in the financial markets such results were considered too good to be true. Compared to a record high at the end of 2013, Arcam shares are down more than 70% and are now trading for around $17.

Thus, sales grew by 70% in a year, and profits exceeded $6 million. However, it is likely that in the financial markets such results were considered too good to be true. Compared to a record high at the end of 2013, Arcam shares are down more than 70% and are now trading for around $17.

SLM Solutions: $36 million

Germany's SLM Solutions posted similar results to Arcam, with record earnings of approximately $36 million and 56% growth in 2014. At the same time, the company's shares fell from a record high of €21 to €18. However, SLM Solutions boasts a more stable stock price than most other members of the 3D printing industry. At the moment, for the past period of 2015, SLM Solutions reports an increase in the number of orders twice year-on-year.

Alphaform: $30 million

German company Alphaform offers rapid prototyping services. Alphaform made its first steps in the consumer market as part of the Artshapes project to apply 3D printing to the arts. The company reported record revenue of $30 million in 2014, up 11.6%. While Alphaform lost more than $3 million in the same period, this is a significant improvement from $6.5 million in 2013.

The company reported record revenue of $30 million in 2014, up 11.6%. While Alphaform lost more than $3 million in the same period, this is a significant improvement from $6.5 million in 2013.

voxeljet: $17-18 million

Analysts have criticized the German company voxeljet for not selling enough devices while offering special deals to customers to increase orders. However, it should be taken into account that voxeljet manufactures large industrial equipment, the print volume of which reaches 8 cubic meters - in other words, the company occupies a very specific niche. Estimated revenue for 2014 (updated data will be available at the end of March) is $17-18 million. In addition, according to voxeljet forecasts, the company expects to grow by almost 50% this year.

Organovo: $0

Organovo is the only listed biomaterials 3D printing company. However, most of Organovo's activities are still research and the first commercial product, exVive3D human liver tissue, was released just recently. The company has created its own bioprinter and uses it to 3D print organic tissues, which it then sells to major pharmaceutical companies for research purposes. The company's annual operating costs are approximately $20 million. At the same time, Organovo is confident that its products can bring more than $100 million in profit in the foreseeable future.

The company has created its own bioprinter and uses it to 3D print organic tissues, which it then sells to major pharmaceutical companies for research purposes. The company's annual operating costs are approximately $20 million. At the same time, Organovo is confident that its products can bring more than $100 million in profit in the foreseeable future.

Renishaw: data not available

Rounding out the top ten was British company Renishaw, which recorded $520 million in revenue and $100 million in marginally lower profits. As of now, Renishaw has yet to disclose earnings for its 3D printing business, limiting itself to commenting that "demand has been solid." The stability of demand can be judged by the fact that, having entered the market with the AM250 device operating on SLM technology, in 2014 the company has already introduced a new EVO system.

Tags: Stratasys, 3D Systems, Materialize, ExOne, Arcam, SLM Solutions, Alphaform, voxeljet, Organovo, Renishaw. The first prototype of such a device was born back in 1984. The idea of the invention belongs to the American Charles Hull, he received a patent for it only two years after development. The printer was a rather massive industrial installation and, despite many inaccuracies and shortcomings in operation, the technology was used.

The first prototype of such a device was born back in 1984. The idea of the invention belongs to the American Charles Hull, he received a patent for it only two years after development. The printer was a rather massive industrial installation and, despite many inaccuracies and shortcomings in operation, the technology was used.

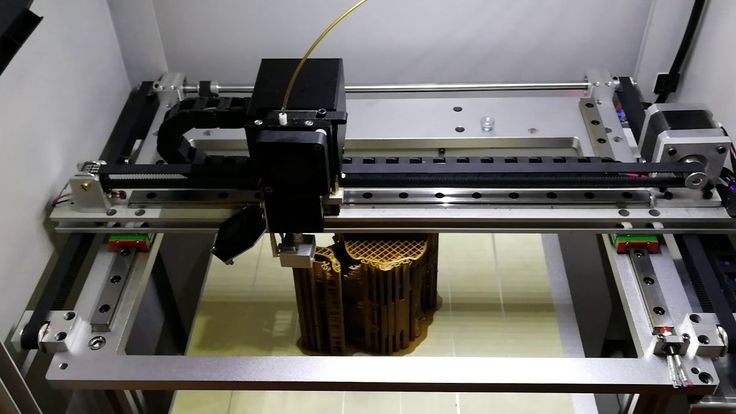

Hal co-founded 3dsystems, a leader in industrial 3D printers. However, this material is not dedicated to these large machines. 3D printing is becoming more and more part of everyday life. Thus, the technology is used to create unique toys, various models, figurines, packaging, clothes, shoes and jewelry. For these purposes, it is not at all necessary to purchase a large-sized printer. You can get by with a small device. It has a compact size, and its technology is completely identical to the industrial one. Heated plastic is fed through the nozzle (spout) of the device, which is laid out on the surface in accordance with the drawing specified in the program. And if earlier such a device was a luxury that only a few can afford, today a 3D printer is available to everyone.

And if earlier such a device was a luxury that only a few can afford, today a 3D printer is available to everyone.

Top-10 rating according to KP

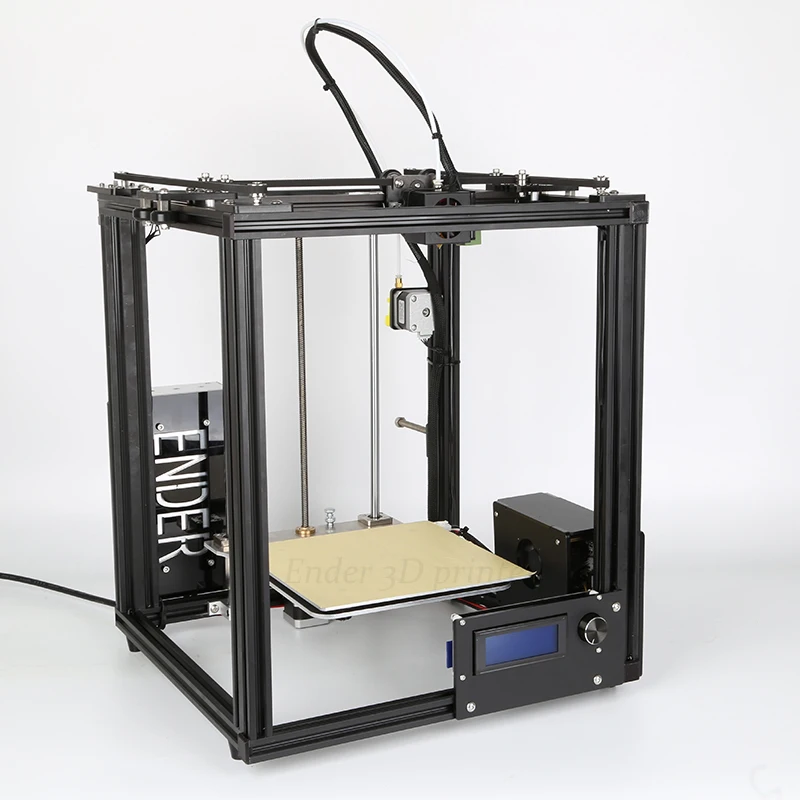

1. Creality3D Ender 3

Creality3D Ender 3. Photo: market-yandex.ruOur rating opens with a model from the world's largest manufacturer of 3D printers. The Ender 3 features an elegant and thoughtful design, excellent print quality and a wide build area. Manufacturers have provided a good arrangement of wires that do not get confused during operation. The small control unit of the device is located to the right of the work surface. The gadget prints perfectly with various types of plastic. In particular, we are talking about varieties of ABS, PLA, TPU and PETG. The scope of this printer is quite wide. It can be used to produce minifigures, do artistic modeling, and make small prototypes of parts and functional elements.

Pros and cons

Possibility of using various types of plastic, high quality of parts, reliable design

A small display that displays only basic information

2.

FlashForge Adventurer 3 FlashForge Adventurer 3. Photo: market-yandex.ru

FlashForge Adventurer 3 FlashForge Adventurer 3. Photo: market-yandex.ru The model from the Chinese developer FlashForge took the second position in our rating. The device is equipped with a Wi-Fi receiver, a removable heated pad for printing. In addition, manufacturers have provided a built-in webcam, a closed case and a color touch-screen display. The latter, although it does not support the Russian language, is intuitively understandable. The ergonomics of the device is provided by the filament sensor: if the printer runs out of plastic, it automatically goes into standby mode and does not idle.

Despite the rather wide functionality, this model is hardly suitable for an experienced printer or a small production due to the small area of the working space, high price

3. FlyingBear Ghost 5

FlyingBear Ghost 5. Photo: market-yandex.ru from FlyingBear is ideal for semi-professional use. Uniform supply of filament (plastic) provides good opportunities for creating three-dimensional figures with a fairly high resolution. High productivity is achieved thanks to the transparent Dual Drive extruder with BMG double drive. The gadget has a body closed on three sides. Its walls are made of heat-resistant non-toxic ABS plastic. This protection prevents the accumulation of dust on the working parts of the device, which greatly facilitates the maintenance of the printer. The device is controlled using a 3.5-inch color TFT display.

High productivity is achieved thanks to the transparent Dual Drive extruder with BMG double drive. The gadget has a body closed on three sides. Its walls are made of heat-resistant non-toxic ABS plastic. This protection prevents the accumulation of dust on the working parts of the device, which greatly facilitates the maintenance of the printer. The device is controlled using a 3.5-inch color TFT display. Short power cord, inaccuracies in the Russian-language menu, weak airflow system.

4. Anet N4

Anet N4. Photo: market-yandex.ru The budget model from the Chinese manufacturer Anet N4 is equipped with all the necessary functions for a small domestic production. The base of the device is made of cast aluminum alloy. The weight of the gadget does not exceed 9kg. A transparent tinted hood protects the work surface from external sources of ultraviolet radiation. It can be removed to remove the finished product and clean the printer. Also, manufacturers have provided a removable resin bath and a working platform, which greatly facilitates the use of the device.

It can be removed to remove the finished product and clean the printer. Also, manufacturers have provided a removable resin bath and a working platform, which greatly facilitates the use of the device.

Key Features

| Print Technology | LCD | |

| Applications | Home/DIY Professional | 30 mm/h |

Pros and cons

Ability to use photopolymer resins from any manufacturer, high polymer curing speed

Small work surface, slightly inferior to competitors in some parameters

900bic5 Anycubic5 Anycubic5 5. S. Photo: market-yandex.ru In the middle of our rating is the Anycubic Photon S model. It is equipped with an advanced optical system and a large working camera. The device has a matrix light source that provides a uniform luminous flux over the entire plane of the desktop. This allows a very high curing speed of the layers to be achieved. In addition, the printer has an original function that allows you to simultaneously print eight identical models. According to the developers, the target audience for this device are orthodontists and jewelers. Most parts of the device are made of plastic. This factor significantly reduces the weight of the device and makes it convenient to transport.

According to the developers, the target audience for this device are orthodontists and jewelers. Most parts of the device are made of plastic. This factor significantly reduces the weight of the device and makes it convenient to transport.

6. ELEGOO Mars Pro

ELEGOO Mars Pro. Photo: market-yandex.ru This model is significantly different from its predecessor Elegoo Mars. Thanks to the advanced Z-axis mechanics and directional UV light from the diode array, it is suitable not only for hobbies, but also for fields of activity such as dentistry and jewelry. In addition, the developers moved the USB connector to the front of the device. Now there is no need to constantly rotate the gadget in the process. The weight of the device is only 7. 5 kg, which makes it very convenient for transportation. A translucent plastic cover will reliably protect against extraneous radiation and will allow you to monitor the production process.

5 kg, which makes it very convenient for transportation. A translucent plastic cover will reliably protect against extraneous radiation and will allow you to monitor the production process.

pluses and disadvantages

Convenient production, low fabric 7. Two Trees Bluer Two Trees Bluer. Photo: market-yandex.ru

This is one of the most popular home models of 3D printers. It is ideal for getting acquainted with technology, various experiments, training and prototyping. Distinctive features of Two Trees Bluer are: "quiet" drivers, which are the engine of the device, a heated table, two-way airflow and a thread break sensor. The mechanics of the printer is quite simple, and at the same time very effective. The open type case will be very convenient when cleaning the work surface. The firmware of the device provides the functions of auto-calibration and automatic resumption of printing in case the power was accidentally turned off.

Pros and cons

Low price, easy and convenient to use

Lack of protection for the work surface, poor quality of spare parts

8. Wanhao Duplicator i3 Mini

Photo: market-yandex.ruMiniature 3D printer does not look like other devices. However, this feature does not affect its technical characteristics. The plastic spool is located on the right side of the bracket. Wanhao branded coating is pasted over the table. There is no platform heating, so it is recommended to use PLA plastic for printing. The manufacturer clearly states in the manual that the printer is designed to work only with PLA material and nothing else. The body of the gadget is made of sheet steel. The memory card slot and all printer control elements - a monochrome liquid crystal display, a universal knob-button and a Reset micro-button - are placed on the front panel of the printer.

004 mm

004 mm Pros and downsides

Good price

Lack of heating and protecting the working surface, high probability of problems with a working coat

9.0094.094 9009.094. Arntillery.

Artillery Genius. Photo: market-yandex.ruThe base of the device consists of an aluminum case, in which all the electronics are hidden. An aluminum portal is also attached to it. The latter is also a guide for the moving parts of the printer. At the top of the portal is a plastic jumper to which the spool holder and filament sensor are attached. As for the control screen, its functionality is seriously curtailed. However, it is sufficient for simple tasks, but it is impossible to configure the printer.

Pros and cons

Spacious work surface, robust housing

Little functionality for a rather high price, lack of work surface protection, few functions on the control screen.

10.

Tianfour Sparkmaker Tianfour Sparkmaker. Photo: market-yandex.ru

Tianfour Sparkmaker Tianfour Sparkmaker. Photo: market-yandex.ru This model is ideal for beginners, as it does not require additional settings at all before starting work. Externally, the printer has the shape of a cylinder with a height of 27.5 cm and a diameter of 17 cm. The realistic contours and smooth curves of the figures are ensured by LCD technology. The printer works with any photopolymer resins for 3D printing with a flash length of 405nm.

How to choose a 3D printer

Choosing a 3D printer is not such a difficult task as it might seem at first glance. Despite the relentless interest in 3D printing and the incredible number of devices on the market, the basic requirements for models remain unchanged. Komsomolskaya Pravda turned to Svyatoslav Vulf, a blogger and host of a YouTube channel about modern technologies and experiments, for help in this matter. He regularly monitors new products on the 3D technology market and tests them at home.

Product size

Initially, you should decide what size of products you expect to receive in the end. The required area of the working surface depends on this. Note that the price of the device also depends on the size of the latter. For work at home, there will be enough indicators: 200 × 250 × 200 (WxHxD).

Technology

Today, there are several technologies for printing on a 3D printer. They differ significantly from each other. Let's consider some of them.

SLA-technology — works on the basis of liquid photopolymer, which under the influence of laser light changes its physical properties and hardens. It allows you to create figurines with the highest precision of microforms.

DLP technology is an alternative SLA method. However, instead of laser systems, LED projectors are used here, which significantly reduce the cost of 3D printers. When using this technology, the future prototype is formed layer by layer.

The FDM method is ideal when prototypes are required that will be actively used and not just sitting on a shelf. Here, high-strength industrial plastics will be used for production. Please note that there are other technologies, but they are very similar to the above.

Material

Before buying a printer, you should also pay attention to what materials it works with, as they have significant differences from each other. For example, ABS can take many different polymeric forms. This is a very durable plastic. It is easily sanded and processed. PLA plastic is considered more environmentally friendly. It is made from agricultural products - corn, potatoes, beets and others. In its original form, it is transparent and can be colored. PLA is just as strong but tougher than ABS. The ductility and heat resistance of SBS make it the material of choice in engineering and mechanical applications.

Noise level and drivers

An important factor when choosing a 3D printer are drivers - device engines (not to be confused with software).