Making car parts with 3d printer

How To 3D Print Replacement Car Parts [2022 Guide]

If you're looking to create your own car parts, you can do so with ease. Here is a guide on how to 3D print replacement car parts very cheap.

By Justin Evans

As 3D printing technology grows more popular, hobbyists and automotive industry leaders alike are starting to 3D print car parts as an alternative to expensive repairs and manufacturing.

This may seem unbelievable to people outside of the 3D printing space, but it is true. 3D printers can create all kinds of car parts, and they work just as well as traditionally manufactured parts.

There are plenty of reasons why people do this. They may want to personalize their car, make their car lighter, or just replace a part quickly without needing to pay an excessive amount for it.

For people who want to get into it, it is a lot easier than it looks.

Table of ContentsShow

What Kind of Parts Can You Make With 3D Printers?

There are several types of parts that you can use 3D printing to manufacture:

- Cosmetic customization (rear-view mirrors, cup holders, custom frames)

- Small parts (lids, valves, specialized parts)

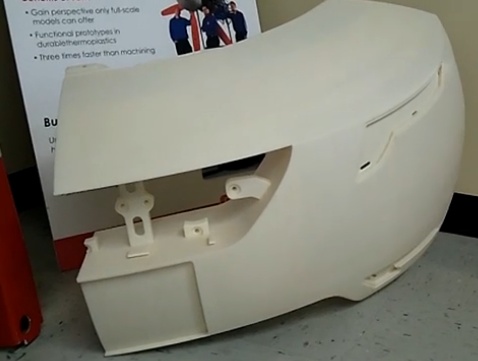

- Larger parts (grills, dashboards)

While you can make powerful parts with 3D printing (like with carbon fiber), it is not recommended for making internal car parts. These parts must deal with excessive heat or pressure and require a specialized manufacturing process.

So long as you keep the part, your intended material, and what that part is used for in mind, the sky is the limit as far as what you can create.

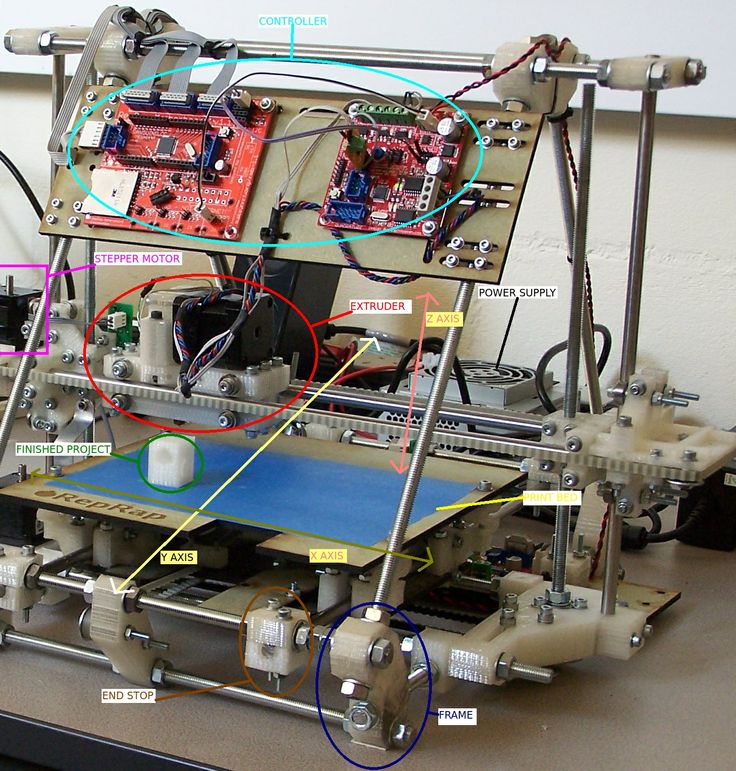

What Kinds of 3D Printers Are Best for 3D Printing Car Parts?

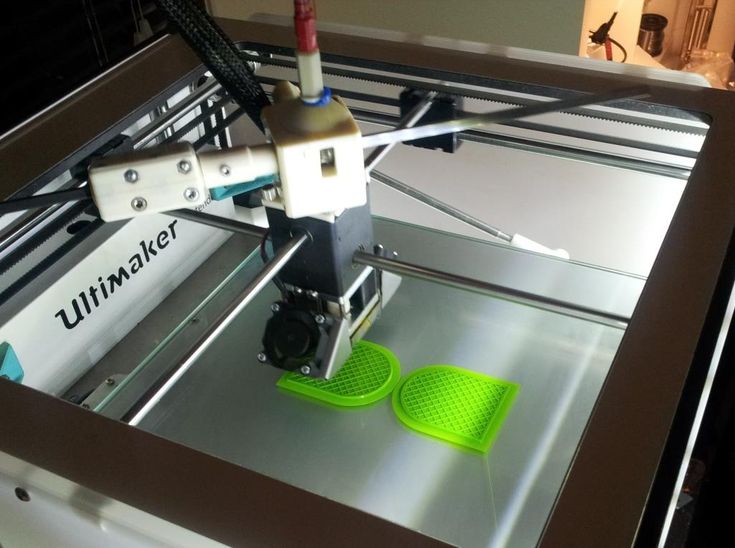

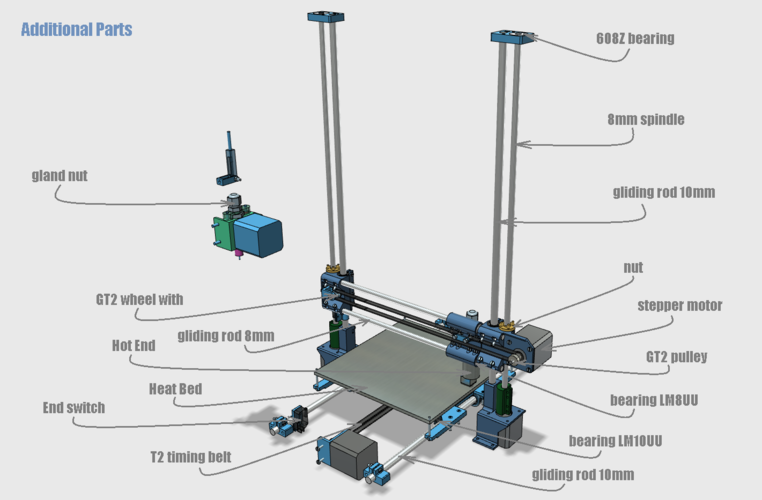

When 3D printing car parts, the ideal printer can vary depending on what you are trying to print.

For most things, an inexpensive basic printer is fine. Plenty of car parts are small and simple and should not need a heavy-duty machine to do the lifting.

If you plan on printing more complex parts or want intricate engravings on your customized parts, you may want to use a higher-end model that can handle that.

What Materials Should You Use?

There are plenty of materials you can use to 3D print your car parts, but the rule of thumb is they should be durable, lightweight, and flexible.

A few standout materials are:

- TPU (shock-absorbent, flexible, and durable)

- Polypropylene (great for airflow and fluid systems)

- Nylon PA11 (great if you are worried about sustainability)

- Polyamide 6 (heat resistant)

What material you use depends entirely on what part you want to make, so always do your due diligence and research what materials work best for each part before you start printing.

How Do You Go About 3D Printing Car Parts?

3D printing car parts seems complex, but when you get down to it, it is a simple process that only requires a few steps.

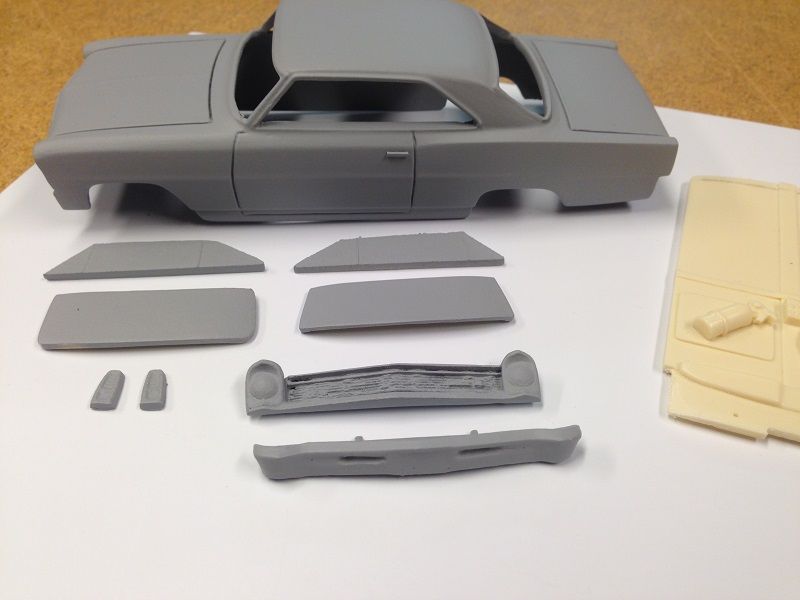

Make or Find a Scale Model

This is the most important step of the entire process. A high-quality 3D printed car part relies on using the proper material and creating it from a good model.

A high-quality 3D printed car part relies on using the proper material and creating it from a good model.

You can set up your scale model in one of two ways. You can make the model yourself using a 3D modeler or find a model online. If you are not confident in your 3D modeling skills, it may be best to find an online model rather than make it yourself.

Many websites offer 3D models for parts that you can download and use with your 3D printer. Make sure the model is from a reputable source for the best results.

Pick Your Material

After picking out your model, the next step is to pick what material you want to use. This will depend entirely on what part you are making and your specific needs.

Remember, materials are not a one-size-fits-all solution. Make sure the material you choose matches your part’s use (heat resistance or flexibility, for example). If you make a part with the wrong material and install it, it can break or damage your car.

Also, keep in mind that just because you can theoretically make engine parts with 3D printing does not mean that you should.

Print the Part

After you have your model and material, it is time to make your part. Make sure the parameters are set the way you want them and double-check everything before printing. Follow the instructions based on your specific printer.

Finishing Touches

Once your part is printed, it is time to add any finishing touches. This is when you paint any small details, like numbers on a knob, or coat the part in another material for a better finish.

You should also use this time to check over the part and make sure everything is up to standard. If there are any defects or issues with the part, you will need to start over.

Install the Part

After printing the part, it is time to install it. This is simple for a part like a cup holder or knob — just pop it in and see if it fits.

If you 3D printed a part like a grill or a dashboard, try going on a test drive first and see how it holds up under a stress test. If it looks like it is not holding up well, it’s time to go back to the drawing board.

What if You Don’t Want to Do It Yourself?

Sometimes 3D printing car parts is not feasible for everyone. A person may want to 3D print a part, but they do not have access to a printer or are not confident in their 3D modeling skills.

In this case, you may want to consider hiring a business that specializes in 3D printing car parts. Be sure to check the business’ rates, selection, and reviews before committing.

Conclusion

3D printing car parts is an easy way to customize and repair your car without breaking the bank. With the right model, materials, and plenty of patience, 3D printing your own parts is a reliable way to take care of your car and make it your own.

There are no limits to what can be done with 3D printing, whether you do it yourself or hire someone else to make the parts for you.

Can You 3D Print Car Parts? How to Do It Like a Pro – 3D Printerly

Many people wonder whether you can 3D print a car or car parts effectively since it’s a very useful manufacturing method. This article will answer some questions about 3D printing car parts, and also walk you through some methods that experienced people do.

This article will answer some questions about 3D printing car parts, and also walk you through some methods that experienced people do.

Before we get into how to 3D print car parts, let’s look at the general question of whether you can 3D print car parts at home, as well as whether you can 3D print a whole car.

Can You 3D Print Car Parts at Home? What Car Parts Can be 3D Printed?

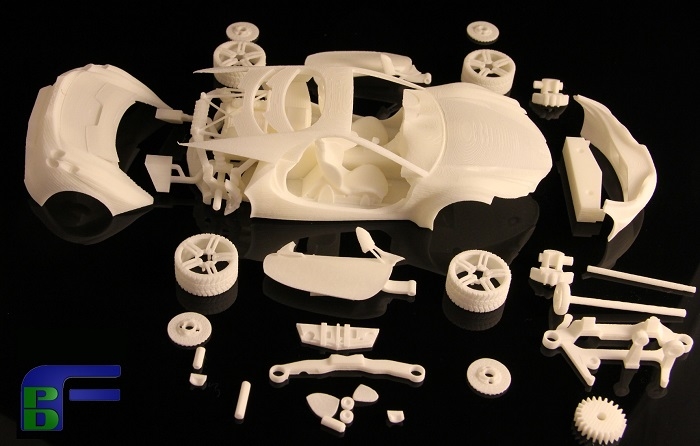

Yes, you can 3D print some car parts from the comfort of your home. You may not be able to 3D print the whole car but there are some car parts that you can independently 3D print and can be assembled or joined to other parts of the car.

A user mentioned that they have printed replacement bodywork brackets for a BMW. They also mentioned that they have friends printing custom door knobs and accessories.

Many parts of Formula One cars are now 3D printed due to the complex curves achievable as they are expensive if bought from auto shops or online.

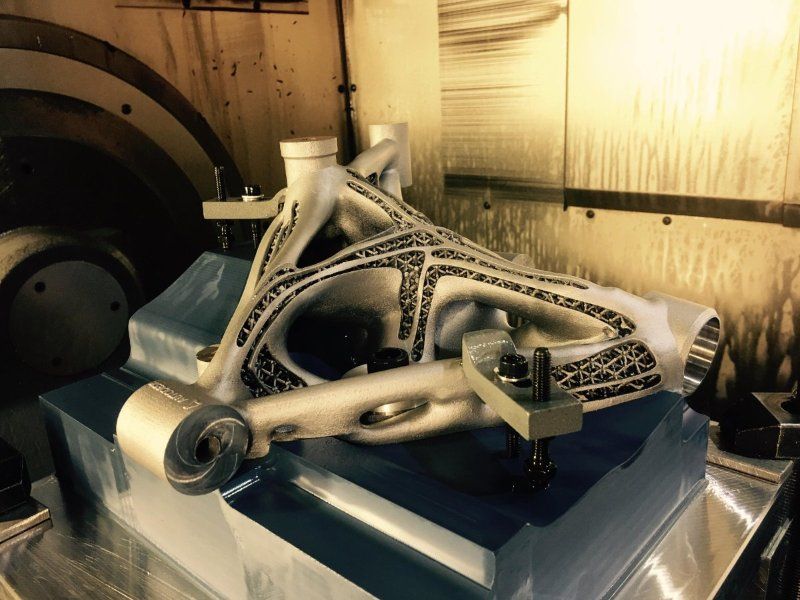

It is also possible to 3D print working engine parts of a car by using metal casting or metal additive manufacturing. Many engine parts are formed this way especially if they are for an old design that is off the market.

Many engine parts are formed this way especially if they are for an old design that is off the market.

Here is a list of car parts that you can 3D print:

- Sunglasses Car Sun Visor Clip

- Bumper Fixing

- 10mm Automotive Body Trim Rivet

- Front Bumper License Plate Cap Inserts CRV Honda 2004

- Porsche Boxter & Cayman “hidden hitch” adapter for utility trailer

- Honda CRV 02-05 Rear Window Wiper Bridge

- Hyundai Elantra Vent Slide

- Wind Shield Clip For BMW Vehicles

- Smartphone Holder for Car

- Seatbelt Cover Renault Super5 R5 Renault5 Safe Belt

- Car Logos

A lot of the parts are usually accessories, but you can 3D print actual car parts with larger 3D printers.

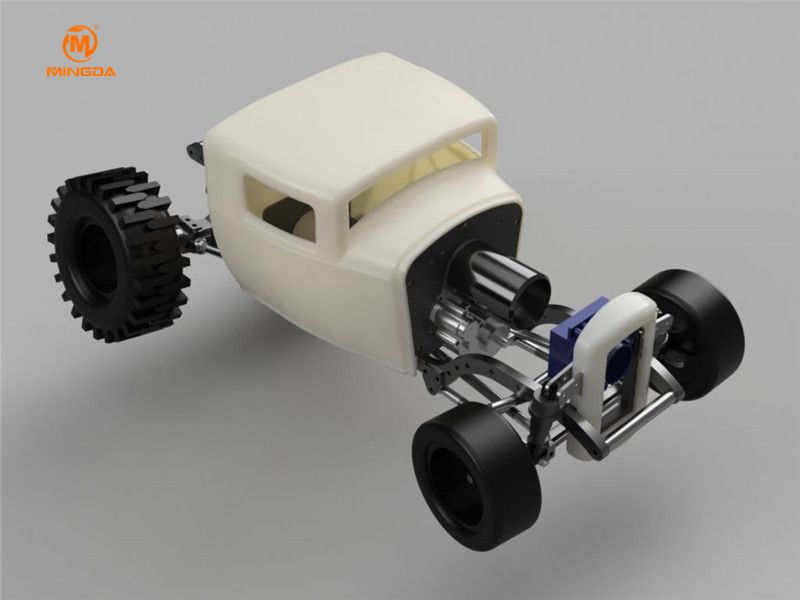

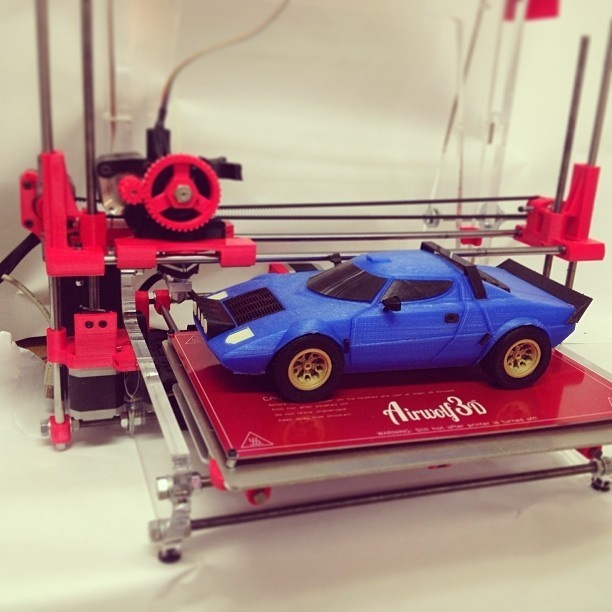

You can also 3D print replica car models like the Tesla Model 3 and RC cars such as The Batmobile (1989) and the 1991 Mazda 787B.

Here’s a video showing a YouTuber 3D printing an RC car for the first time.

The list for 3D printing car parts is endless so you can check out other car models by searching on 3D printer file websites like Thingiverse or Cults.

The video below shows how a brake line clip was 3D printed which further shows that parts of a car can be 3D printed.

Most of the popular car brands that you know 3D print some of their car parts and accessories. When it comes to 3D printing car parts, BMW is the first name you’ll probably hear. They announced in 2018 that they have produced more than a million individual 3D printed car parts.

Their one millionth 3D printed car part is a window guide rail for the BMW i8 Roadster. It took the experts in the company about 5 days to complete the whole part and not long afterward, it was integrated into series production. Now BMW can produce 100 window guide rails in 24 hours.

Other car companies that 3D print their car parts include:

- Rolls-Royce

- Porsche

- Ford

- Volvo

- Bugatti

- Audi

For car companies such as these to have 3D printed their car parts, this shows that 3D printing car parts are possible.

Jordan Payne, a YouTuber, was able to make a new logo for their Datsun 280z using their Creality Ender 3 with ABS filament for added heat resistance. He mentioned that he used a program called Fusion 360 as a result of its high-quality software.

You can watch the full video below to get more insight into how he was able to 3D print the car logo.

Can You 3D Print a Car?

No, you can’t 3D print every part of a car, but you can 3D print a significant amount of the car such as the car’s chassis, the body, and the interior structure of the vehicle. Other parts like the engine, battery, gears, and similar parts could have some 3D printed metal parts but not ever part can be 3D printed.

One of the biggest examples of a 3D printed car is the Strati car, the world’s first 3D printed car. It took 44 hours to 3D print and is created in one single piece to reduce the number of parts and increase the likelihood of printing success.

Here’s a video of the Strati car actually being test-driven.

A father who got rewarded with a new Aventador from Lamborghini 3D printed a replica of the Aventador with his son. It took them almost one year and a half but they were able to complete the project and print the car replica.

The father got a 3D printer worth $900 and also found a diagram of the car model online. They printed separate panels from durable plastic and soldered them together. Also, they used Nylon with Carbon Fiber filament to make the car’s interiors.

However, when they realized that they may not be able to 3D print movable parts such as wheels and small electrical parts, they purchased them online. After a lot of trial and error, they were able to create a replica of the Lamborghini’s Aventador car.

3D printers are good at printing out shapes and not so good at printing complex parts or components as they are made from a lot of different materials. This is why most acclaimed 3D printed cars don’t have all their parts 3D printed.

You can watch the video to see how the Aventador came out.

On the other hand, you can 3D print a half-size mock-up of a car using a hybrid technology such as a 3D printer and half robot. José Antonio who is the coordinator of the project stated that the model can be used to showcase the style and design of a car.

The system mixes 3D printing with a robot that allows the curving of materials since pure 3D printing systems can only manufacture small pieces.

You can watch the video below to learn more.

Many people believe that while a 3D printer may still improve, it cannot provide better methods of construction for critical car parts such as engines or tires, though some smaller car models create basic tires out of flexible TPU filament.

How to 3D Print & Make Car Parts

Now that you know that some car parts can be 3D printed, you probably want to know how the car parts can be 3D printed. It’s often easier to get started with a 3D scan of parts when printing car parts.

Most people often start by finding an existing car part design on platforms like Thingiverse or Cults, or by designing their own car parts or scanning an existing car part.

TeachingTech, a 3D printing YouTuber 3D printed a custom air box for their car, which is basically the filter that air passes through to let your car engine breathe.

The first step the user took was to move their airflow meter to create more space for the air box. He took some reference photos with a ruler in place to help his measurement so he can position the key features accurately in CAD.

He modeled it in CAD to the basic dimensions and then modeled up the two mating surfaces of the air box, designed to grip the rubber gasket of the panel filter.

He also designed a simple but robust feature for clamping the two halves together yet still removable without any tools.

The pattern was modeled to match the airflow meter that it needed to bolt to. Both halves of the engine box were designed to be printed without any support material and the finished parts came out well.

Here’s the video on how the air box was modeled and 3D printed.

Scanning parts can be tricky if you are doing it for the first time because it requires a little experience. You want to get some practice scanning more basic objects before you start scanning complex car parts.

You want to get some practice scanning more basic objects before you start scanning complex car parts.

It’s important to move your 3D scanner slowly so it can pick up the features and details of the part, as well as find new features relative to the location of the parts it has already scanned when rotating the part.

Due to the specifications of some scanners, they may not be able to accurately scan small features so you may have to accentuate these features so the scanner can find them.

Here is a video on how to 3D scan your car part and some of the scanners you can use to get a high-quality result so you can check it out.

The video below shows more explicitly how you can design and 3D print car parts.

How Much Does a 3D Printed Car Cost?

A 3D printed electric car called the LSEV costs $7,500 to produce and is fully 3D printed except for the chassis, tires, seats, and windows. The Strati car is known to cost between $18,000-$30,000 to originally produce, but they are no longer is business. The 3D printed Lamborghini costed about $25,000.

The cost of a 3D printed car is largely dependent on the materials used in building the car. It also depends on the volume of the car that is 3D printed.

If most parts of the car are 3D printed, the car will be relatively cheaper.

Best 3D Printed Car Models (Free)

The designer stunner2211 on Thingiverse has created a Car Gallery of some amazing 3D printed car models that you can download and 3D print yourself:

-

Saleen S7

-

Mercedes CLA 45 AMG

-

Ferrari Enzo

-

Bugatti Chiron

-

Ferrari 812 Superfast

-

Hummer h2

These are all downloadable for free, so definitely have a look.

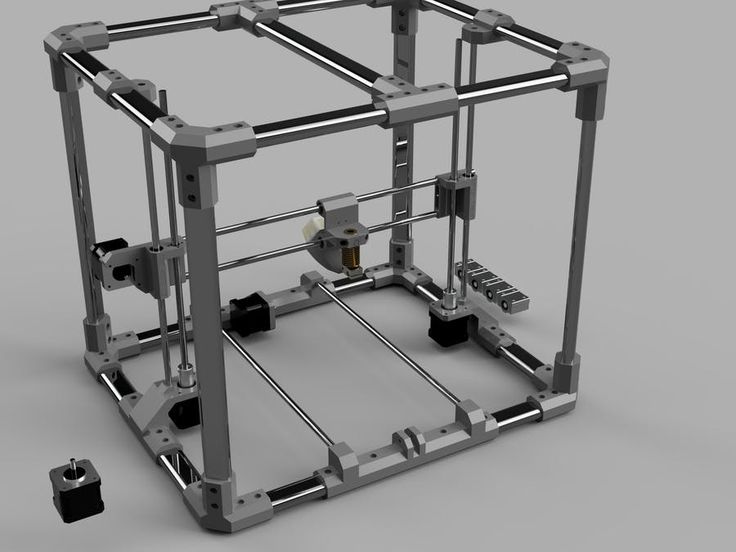

Best 3D Printer for Car Parts

Now that we have established that some car parts can be 3D printed, let’s take a look at the best 3D printer to print them. The best 3D printers for car parts that I have found are the Creality Ender 3 V2 and the Anycubic Mega X.

They have been found to print high-quality and durable car parts with high precision and accuracy.

I wrote an article called 7 Best 3D Printers for Automotive Cars & Motorcycle Parts for more depth, but below are some quick choices that work well.

Creality Ender 3 V2

Here are some qualities that make the Creality Ender 3 V2 a go to for 3D printed car parts.

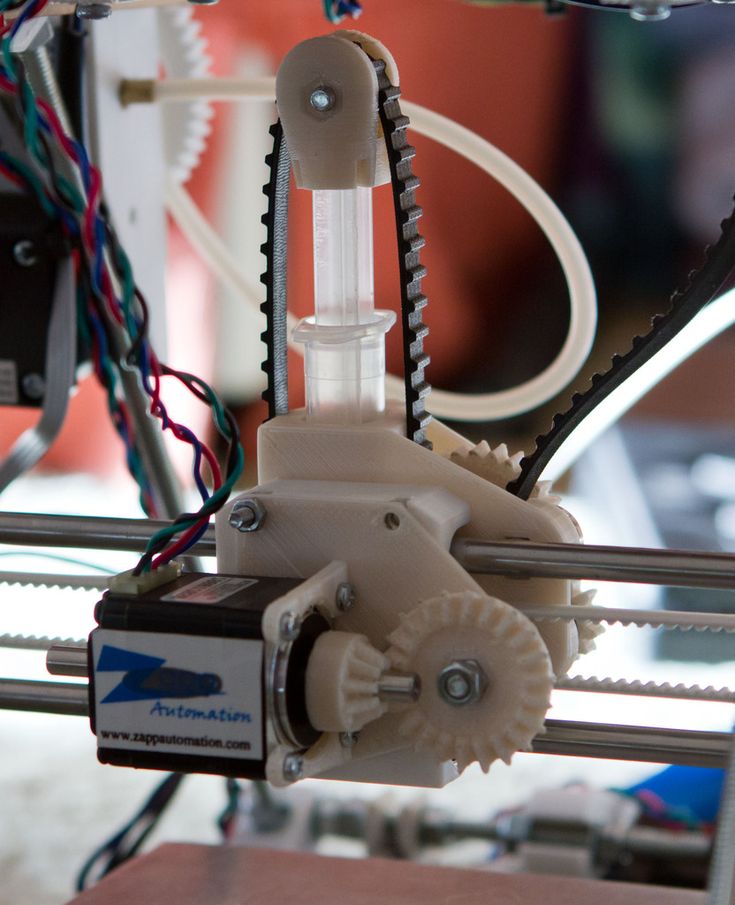

- Well assembled direct extruder/hot end

- Supports major files such as STL and OBJ

- Slicer software that can be pre-installed on the thumb drive

- Has a silent motherboard

- Has automatic bed leveling feature

- Quick heating hotbed

- Supports PLA, TPU, PETG, and ABS

- Quick and easy assemble

One of many amusing features of this 3D printer is that if there is any sudden electrical power failure or outage, printers can resume printing from the last layer, saving time and reducing waste.

You don’t have to start all over again as you can start right from where you stopped. Also, the voltage spike does not affect the printer as a result of its high and safe power supply.

For better performance, the printer comes with a silent motherboard which facilitates faster printing at lower noise levels. You can print your car parts in your home with minimal noise.

You can print your car parts in your home with minimal noise.

The Carborundum Glass Platform that comes with the Creality Ender 3 V2 contributes to the quick-heating hotbed feature. This helps print stick better to the plate and provides a smoothness for the first print layer.

Anycubic Mega X

As its name implies, the Anycubic Mega X comes in a large size and with high quality and durability. It is powerful and can work on a long stretch without breaking down.

Here are some of the notable qualities of the printer:

- Large Printing Volume and Size

- Dual X and Y Axes Dual Screw Rod Design

- Resume Printing Feature

- Powerful Extruder with Stable Rotation Speed

- 3D Printer Kits

- Powerful Extruder

- Strong Metal Frame

With the Anycubic Mega X, you can reload the filament with a single tap if it runs out. The 3D printer will turn on a smart alarm and automatically pause printing so you can resume from where you paused.

This means that you don’t have to start all over again if your filament runs out while printing.

You can also use TPU and PLA to get great print results.

A user mentioned that the printer came very close to being fully assembled and only took about 5 minutes to set up, and another 10-20 to tighten, level, and adjust to their liking. They said the part printed perfectly without much work at all.

They also said the printer is relatively quiet, easy to work with, the software is included, and there is a lot of online support.

A lot of users mentioned how easy it was to assemble the printer because it comes with so many spare parts and tools they sent with each printer, so you can open the box, assemble it and print something.

Best Filament for Car Parts

Car parts should be able to withstand heat so when 3D printing car parts, the material or filament used should not be the type that can melt easily under the sun or heat.

ASA Filament

The best filament that I have found highly effective for car parts is Acrylonitrile Styrene Acrylate (ASA). It is well known for its high UV and heat resistance and can be used to produce functional parts for automotive applications.

It is well known for its high UV and heat resistance and can be used to produce functional parts for automotive applications.

Here are some of the qualities that make ASA the best filament for car parts.

- High UV and weather resistance

- Special matte and smooth finish

- High temperature resistance of about 95°C

- High water resistance

- High level of durability with resistance to impact and wear

You can get a spool of Polymaker ASA Filament from Amazon, a pretty popular brand known for its high quality. It’s currently rated 4.6/5.0 at time of writing with over 400 reviews.

Many users who used PLA+ switched over to this ASA and were surprised that a filament like this even existed. They specifically wanted to make things that could survive outside and in the heat of a car on a hot summer’s day.

Their PLA+ was warping in and outside of their car, and they didn’t have a lot of luck with PETG. They came across this filament in an online video of it being used in the inside of a car engine bay, and used as a shroud for an air filter which worked well.

One of the best things about ASA filament is just how easily it prints. The user didn’t have a heated enclosure and still experienced no issues with warping. They said it prints just like PLA but works as good as ABS (the less weather resistant version).

If you need a functional and durable filament with great heat resistance at a respectable price, you should definitely try out Polymaker ASA Filament from Amazon.

Another user who used this filament said that once they figured out ASA printing, it became easy for them to use. They also said it has less of a smell compared to ABS, and it’s stable inside a hot car environment.

Many other users have testified to how the ASA filament was easy to use for them.

Polycarbonate Filament (PC)

Polycarbonate Filament (PC) is another good option for car parts. Many users have described this filament as one of the best materials for automotive use.

It is suitable for demanding prototyping requirements, tools, and fixtures. It’s also suitable for the manufacturing of various types of mechanical equipment and electrical parts such as shields, insulating connectors, coil frames, etc.

It’s also suitable for the manufacturing of various types of mechanical equipment and electrical parts such as shields, insulating connectors, coil frames, etc.

The filament comes with great toughness, strength, and durability that car parts need to last well.

A user mentioned that they have tried out other filaments such as PLA and PETG but they could not survive the heat of their car. Polycarbonate has a glass transition temperature of around 110°C which is more than enough to withstand the heat within a car and even in direct sunlight.

One of the biggest pros of PC filament is that it actually prints fairly easily with the right 3D printer, and has a high heat resistance, strength, and durability.

You can get a spool of Polymaker Polycarbonate Filament from Amazon for a competitive price. It’s carefully winded during manufacturing to ensure there aren’t any tangling issues, and it’s dried and vacuum sealed to reduce moisture absorption.

Production of parts according to drawings from polymers and non-ferrous metals in Moscow

Manufacture of parts from polypropylene 3D printing of plastic parts Printing auto parts on a 3D printer 3D printing Production of parts from polyacetal Production of parts from ultramolecular polyethylene (UHMWPE) Production of parts from PTFE Production of parts from caprolon Production of parts from polyamide

Order

The company "SHIK POLYMER" performs 3D printing of auto parts from different types of plastics. We offer a fast and affordable solution for the manufacture of worn, failed or lost parts and components.

We offer a fast and affordable solution for the manufacture of worn, failed or lost parts and components.

When is the best time to order 3D printed parts?

3D printing allows you to create auto parts that exactly match the original parts. Such a solution will allow you not to wait for the missing part for several weeks and not to ring up auto-dismantling in search of used components.

3D printing will help out if a small and insignificant part of an expensive car assembly has broken. Most often, small parts are very difficult to find or they are not sold separately at all. In order not to buy a new assembly, you can simply print the broken element.

Which car parts can be printed?

Our equipment allows you to print components for car components and assemblies, body parts, dashboard parts. The material is selected depending on the type of auto parts and operating conditions.

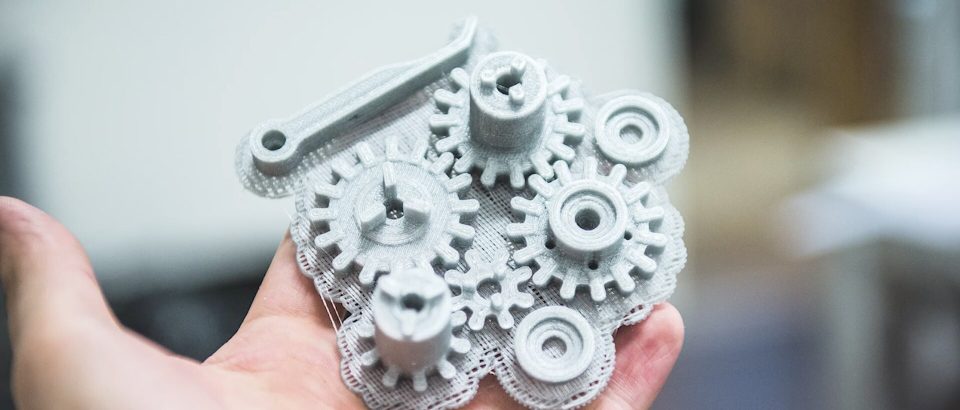

Most often, 3D printing services are ordered for the manufacture of interior elements, wheel caps, car emblems. You can also print gears, washers, guides, fasteners and other details.

You can also print gears, washers, guides, fasteners and other details.

You can provide us with a sketch, drawing or original part, including broken ones. Our engineers will develop a product model and prepare it for printing. The price of 3D printing of automotive components depends on the type of plastic, size and complexity of the product.

Printing auto parts on a 3D printer can be ordered with delivery in Moscow and other Russian cities. Both piece production and small-scale production are possible.

Procedure for work

You leave an application for

by the site or by calling

We clarify the questions,

We approve the technical

task, we get

Prepayment

We make parts,

We prepare them for shipment,

We report on readiness

specified address or

waiting for you for pickup

Our partners

Our advantages

- Own production on modern machines of world brands

- Average production time of parts - 15 working days

- Discounts for large orders

- Delivery throughout Russia by transport companies

5 ways 3D printing is changing the automotive industry

Photo source all3dp. com

com

An article from formlabs.com adapted and expanded for you by Top 3D Shop.

You can't buy a fully 3D printed car in a car dealership yet, but additive technologies have been used in the development of cars for many years. Every year, especially in recent years, 3D printing is taking an increasingly important place at all stages of production. This is evidenced by the rapid growth of 3D printing market share in automotive manufacturing, which is projected to reach $2.5 billion by 2023.

For example, luxury car companies including Bentley, Porsche, BMW and Ferrari are using 3D printing to create custom car interior parts. GM, Volvo, Ford are using 3D printing to produce tooling to save money, improve designs and reduce delivery times.

Source 3dprinting.com

3D printing is constantly emerging with new opportunities, it is becoming more accessible. If the first 3D printers cost about $20,000, now you can find 3D equipment for $100. Now companies can, with the help of additive technologies, produce the necessary components directly at their own enterprises and not depend on suppliers.

Now companies can, with the help of additive technologies, produce the necessary components directly at their own enterprises and not depend on suppliers.

With new materials, 3D printers can print high-precision, functional end parts. Additive technologies facilitate the production of custom products and increase productivity.

But this is only the beginning of the journey. Here are five key ways 3D printing is driving innovation in the automotive industry, from car design to production. Plus one bonus.

1. Changing the prototyping process

It was with the production of prototypes that the use of 3D printers in the automotive industry began. 3D printed prototypes took much less time than traditional methods required.

Using Raise3D 3D printers and ideaMaker software, Crazy Grandpa Garage was able to automate the process of creating custom car parts. Production costs have been reduced by 50%, design reliability has improved significantly, and lead time has been reduced by 83%. The parts now come out very well fitted to the car.

The parts now come out very well fitted to the car.

Source: facebo ok.com

Using 3D printing, car designers can quickly prototype individual parts or assemblies, from interior detail to dashboard, or even full-size car models. Thanks to 3D prototyping, the initial idea quickly turns into a physical embodiment of the concept - a conceptual model. The concept can then be developed into full-featured, high-fidelity prototypes, and after several validation steps, mass production begins. For the automotive industry, getting through these steps quickly is vital, and the entire downtime of an automobile production line in just an hour is very costly for the company.

For example, the assembly plant of the American car manufacturer General Motors claims to have saved more than $300,000 by purchasing a 3D printer in 2016.

Ringbrothers designers and engineers are not dependent on third parties to implement laser stereolithography (SLA) in their facility. The cost is reduced, the development time is reduced. Source: formlabs.com

The cost is reduced, the development time is reduced. Source: formlabs.com

Tailpipes for BMW M4 by Eventuri, Source: ultimaker.com

Traditional prototyping was time consuming and costly, in part because the product went through more iterations. With 3D printing, you can create high-quality prototypes in one day and at a much lower cost. More examples.

The Ford Fiesta ST with 3D printed parts, ext. SEMA 2016, ultimaker.com

For example, General Motors has partnered with Autodesk to produce low cost, lightweight automotive parts using 3D printers. Tools, fixtures and fittings can now be produced at a fraction of the cost, according to Autodesk. For example, a 3D printed tool used to align engine and transmission ID numbers costs less than $3 at General Motors. A traditionally produced instrument will cost $3,000. In addition, downtime due to faulty tools can be significantly reduced as new tools are produced in-house.

2. Creating custom and complex parts

Daihatsu, the oldest car manufacturer in Japan, launched a project in 2016 to customize its Copen model.

Source: 3dprint.com

In partnership with Stratasys, Daihatsu customers can design and order custom 3D printed panels for their front and rear bumpers, with a choice of over 15 basic patterns in 10 different colors.

Source: 3dprint.com

In Europe, the BMW MINI brand also uses 3D printing to create personalized car parts. Since the beginning of 2018, MINI customers have been able to personalize various trim elements such as the instrument panel, LED treadplates and illuminated bumpers, as well as choose from different colors and textures. These parts are then 3D printed using a range of technologies from DLS Carbon to SLS.

Source: formlabs.com

Volkswagen Motorsport's I.D. R Pikes Peak is designed with over 2000 3D printed test parts.

Source amfg.ai

The use of 3D printers makes it possible to experiment in the development of non-standard designs, reduces the cost of their production. Long production processes for custom-made products are becoming much shorter.

Long production processes for custom-made products are becoming much shorter.

Ringbrothers uses 3D printing to create customized end pieces such as ventilation grilles. Source: formlabs.com

Large companies are merging 3D printing technologies with traditional manufacturing methods. Volkswagen has recreated its iconic 1962 Microbus by replacing the petrol engine with a 120 hp electric one. The Type 20 concept electric minivan has received many improvements using 3D printed parts. These improvements include cast aluminum wheels. Even the wheel hubcaps, while looking like stamped steel, are actually printed on a Formlabs SLA 3D printer, then electroplated and polished.

Source: formlabs.com

Formlabs Form 2 SLA Specifications

Source: top3dshop.ru

The Bentley Speed 6 is another example. Bentley has used cutting-edge metal 3D printer technology to produce a grille, side vents, door handles and exhaust pipes much more complex than those used on current production models.

Bentley used metal 3D printing to create intricate micron precision parts. Source: formlabs.com

A prime example is Bugatti's monobloc brake caliper. For some components, Bugatti would have preferred titanium due to its high performance, but processing this metal with traditional methods is expensive and difficult. 3D printing has allowed Bugatti to produce a titanium alloy brake caliper. Due to the thin walls, the caliper turned out to be very light - almost two times lighter than forged aluminum. At the same time, the strength of the 3D-printed monoblock is superior to that of aluminum. The 3D printed titanium monoblock has a tensile strength of 1250 N/mm2. This means that a force of just over 125 kg will be applied per square millimeter of this titanium alloy without tearing the material. The new titanium caliper is 41 cm long, 21 cm wide and 13.6 cm high and weighs only 2. 9kg compared to currently used aluminum, which weighs 4.9 kg.

9kg compared to currently used aluminum, which weighs 4.9 kg.

The Bugatti Brake Monobloc is the industry's largest functional 3D printed titanium vehicle component. Source: formlabs.com

3. Tool and fixture making

A variety of fixtures help make manufacturing and assembly processes easier and faster, and improve worker safety. Automotive factories and component suppliers use a large number of non-standard tooling that is specifically designed and optimized for end use. As a result, a lot of non-standard equipment and tools are made, which increases production costs.

This 3D protective wheel disc was purchased for 800 euros but can now be printed for just 21 euros. Tool development time has been reduced from 56 to 10 days.

Source: ultimaker.com

Outsourcing custom tooling and fixtures to service providers who machine parts from solid metal or plastic stock can delay production by weeks.

For example, the development and prototype of a commutator motor using traditional manufacturing methods can take up to four months and cost about half a million dollars. Thanks to 3D printing, Ford was able to develop several variants in just 4 days and 99.4% cheaper - only $3,000.

Additive technologies allow you to complete the task in a few hours and significantly reduce costs compared to ordering from a third-party enterprise. Since increasing the complexity of a 3D printed model does not incur additional costs, products can be better optimized for their application. New elastic materials for 3D printing in many cases allow you to print plastic parts instead of metal or create prototypes on a 3D printer to test the tool before using it in production.

Gradually, the production of 3D printed accessories and tools is becoming one of the largest applications of additive technologies.

Pankl Racing Systems uses 3D printed fixtures to fasten workpieces to a conveyor belt. Source: formlabs.com

For example, Pankl Racing Systems uses multiple Formlabs SLA 3D printers to make critical manufacturing tools. The multi-stage production of parts for transmissions on automatic lathes requires a series of fixtures and tools designed for each specific part.

With the help of 3D printing, Pankl's engineers have reduced the production time for the aids by 90%, from 2-3 weeks to around 20 hours. Costs were also reduced by 80-90%, saving $150,000.

The transition to 3D printing has enabled Volkswagen Autoeuropa to cut tooling development costs by 91% and tooling time by 95%.

4. Solving problems with spare parts

Spare parts have always been a problem for the automotive industry. The demand for them is either there or not, so the production of spare parts is not economically viable, and the storage of pre-fabricated replacement components is also costly. But if there are no repair parts available, difficulties arise and the main product becomes less valuable.

But if there are no repair parts available, difficulties arise and the main product becomes less valuable.

3D printing could solve the problem of parts in the automotive industry in many ways. The main factors are printed materials, which can match the characteristics of traditional materials used in parts and be cost-effective. There are prerequisites for this.

Using computer-aided design, drawings of all parts can be stored digitally, so there is no need to store the parts themselves. The parts needed by the client can be printed on a 3D printer right in the workshop.

Even obsolete parts whose drawings have not survived can in principle be recreated by making a 3D scan of existing parts of this type and applying reverse engineering (reverse engineering). You can read more about this on our blog. Old projects can take on new life. There are many lovers of vintage cars, with the help of 3D printing it would be possible to create parts for them.

Ringbrother 3D printed the Cadillac emblem for a custom built old car. Source: formlabs.com

Source: formlabs.com

5. Production of standard parts

As 3D printers and materials for 3D printing become more affordable, a gradual transition to the production of mass-produced automotive parts using additive technologies is possible.

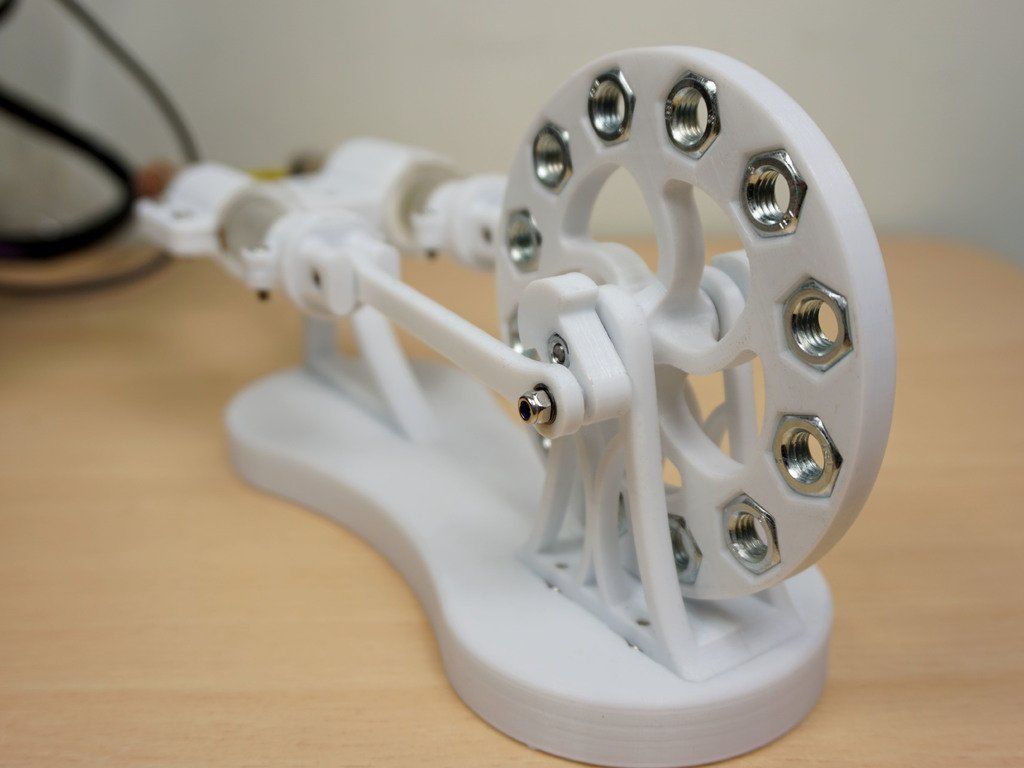

3D printing makes it possible to combine components into a single whole. Let's say there is a mechanism assembled from six or seven car parts that can be combined into one printed part. It will save time and assembly costs. With 3D printing, it is also possible to reduce the weight of the combined assembly, as a result, the car will use fuel more efficiently.

3D Systems has developed an advanced exhaust pipe for a sport bike. In the image below, you will see 20 sheet metal and hydroformed parts needed to assemble the original exhaust pipe. On the right is a monolithic exhaust pipe that does not require assembly, made using metal 3D printing.

Source: designnews.com

The 3D printed tube was produced using Grade23 titanium in just 23 hours, compared to three weeks for traditional production. Design development time reduced from 6 weeks to 6 days. Additive manufacturing also eliminates the need for tooling, fixtures, multiple welding and multiple inspections.

Design development time reduced from 6 weeks to 6 days. Additive manufacturing also eliminates the need for tooling, fixtures, multiple welding and multiple inspections.

Geometry optimization has reduced the amount of material required for maximum productivity. All elements of the original exhaust pipe are incorporated into the new design and, when printed with a typical wall thickness of 0.5mm, the 3D printed exhaust pipe is about 25% lighter than the original one.

A wide range of 3D printing materials is beginning to meet the requirements of various vehicle components. Since additive methods reduce costs compared to traditional methods (such as molding and injection molding), it makes a lot of sense from a production and financial point of view to further introduce 3D printing into the production of basic parts.

Volkswagen, one of the world's largest and most innovative car manufacturers, is using an HP Metal Jet 3D printer to produce high-performance functional parts with special design requirements, such as shift knobs and mirror mounts. Volkswagen's long-term plans to work with HP include accelerating the production of mass-customized parts such as key rings and exterior nameplates.

Volkswagen's long-term plans to work with HP include accelerating the production of mass-customized parts such as key rings and exterior nameplates.

+1. 3D Printed Cars

Although complete 3D printed cars have not hit the market yet, some interesting designs and concepts are suggestive of where the automotive industry might go.

Light Cocoon. German engineering firm EDAG was clearly inspired by nature to create the 3D printed supporting structure of the Light Cocoon concept car. The frame resembles the veins of a tree leaf or its branch. Despite the fact that the design of the EDAG took less material than a conventional frame, all the strength requirements for structurally significant components are met. Outside, the case is covered with a lightweight and durable waterproof fabric.

The cover protects the EDAG Light Cocoon from the weather and gives the car a unique personality. Source: formlabs.com

Source: formlabs.com

Blade . Blade ("Blade") announced as "the world's first 3D-printed supercar." It meets supercar standards but is made from inexpensive materials: carbon fiber tubes and aluminum rods, combined with 3D printed metal parts. Blade turned out to be very light and does not take long to assemble.

The world's first 3D printed Blade supercar. Source: formlabs.com

Strati . The American company Local Motors 3D printed and assembled the Strati electric car right at the exhibition stand, in just 44 hours. Most of the components were printed - the body, seats, interior parts. A car is made up of less than 50 assemblies, far fewer than the thousands of parts that go into a traditional car. The company intends to reduce the print time to 10 hours.

The Local Motors Strati consists of less than 50 individual parts*. Source: formlabs.com

LSEV . Developed by the Italian company XEV, the LSEV could be the first in the 3D printed electric vehicle market when it goes on sale.