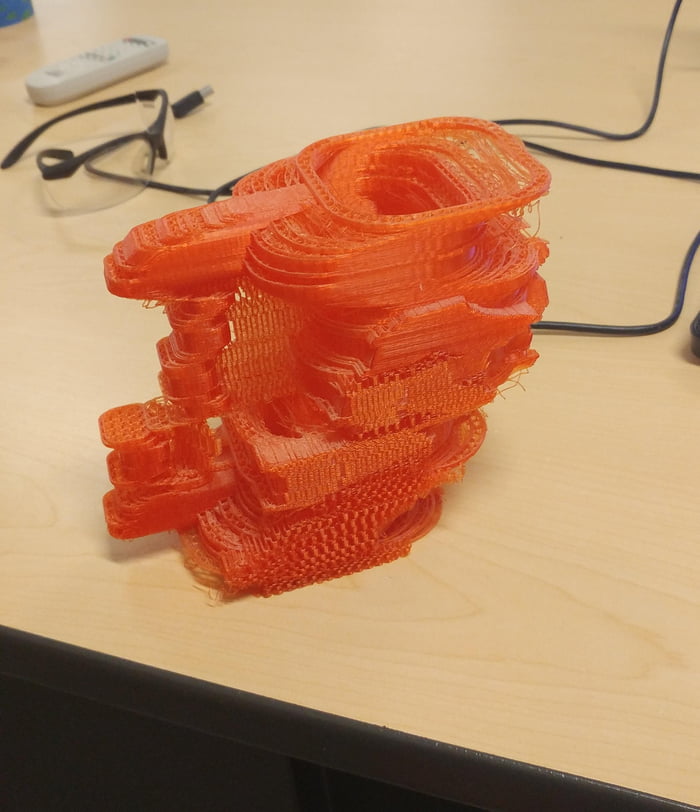

3D printer mess

Blobs and Zits

Blobs and Zits

During your 3D print, the extruder must constantly stop and start extruding as it moves to different portions of the build platform. Most extruders are very good at producing a uniform extrusion while they are running, however, each time the extruder is turned off and on again, it can create extra variation. For example, if you look at the outer shell of your 3D print, you may notice a small mark on the surface that represents the location where the extruder started printing that section of plastic. The extruder had to start printing the outer shell of your 3D model at that specific location, and then it eventually returned to that location when the entire shell had been printed. These marks are commonly referred to as blobs or zits. As you can imagine, it is difficult to join two pieces of plastic together without leaving any mark whatsoever, but there are several tools in Simplify3D that can be used to minimize the appearance of these surface blemishes.

Common Solutions

Retraction and coasting settings

If you start to notice small defects on the surface of your print, the best way to diagnose what is causing them is to watch closely as each perimeter of your part is printed. Does the defect appear the moment the extruder starts printing the perimeter? Or does it only appear later when the perimeter is completed and the extruder is coming to a stop? If the defect appears right away at the beginning of the loop, then it’s possible your retraction settings need to be adjusted slightly. Click on “Edit Process Settings” and go to the Extruders tab. Right below the retraction distance, there is a setting labeled “Extra Restart Distance.” This option determines the difference between the retraction distance when the extruder is stopping and the priming distance that is used when the extruder is restarting. If you notice a surface defect right at the beginning of the perimeter, then your extruder is likely priming too much plastic. You can reduce the priming distance by entering a negative value for the extra restart distance. For example, if your retraction distance is 1.0mm, and the extra restart distance is -0.2mm (note the negative sign), then each time your extruder stops, it will retract 1.0mm of plastic. However, each time the extruder has to start extruding again, it will only push 0.8mm of plastic back into the nozzle. Adjust this setting until the defect no longer appears when the extruder initially begins printing the perimeter.

You can reduce the priming distance by entering a negative value for the extra restart distance. For example, if your retraction distance is 1.0mm, and the extra restart distance is -0.2mm (note the negative sign), then each time your extruder stops, it will retract 1.0mm of plastic. However, each time the extruder has to start extruding again, it will only push 0.8mm of plastic back into the nozzle. Adjust this setting until the defect no longer appears when the extruder initially begins printing the perimeter.

If the defect does not occur until the end of the perimeter when the extruder is coming to a stop, then there is a different setting to adjust. This setting is called coasting. You can find it right below the retraction settings on the Extruder tab. Coasting will turn off your extruder a short distance before the end of the perimeter to relieve the pressure that is built up within the nozzle. Enable this option and increase the value until you no longer notice a defect appearing at the end of each perimeter when the extruder is coming to a stop. Typically, a coasting distance between 0.2-0.5mm is enough to have a noticeable impact.

Typically, a coasting distance between 0.2-0.5mm is enough to have a noticeable impact.

Avoid unnecessary retractions

The retraction and coasting settings mentioned above can help avoid defects each time the nozzle retracts, however, in some cases, it is better to simply avoid the retractions all together. This way the extruder never has to reverse direction and can continue a nice uniform extrusion. This is particularly important for machines that use a Bowden extruder, as the long distance between the extruder motor and the nozzle makes retractions more troublesome. To adjust the settings that control when a retraction takes place, go to the Advanced tab and look for the “Ooze Control Behavior” section. This section contains many useful settings that can modify the behavior of your 3D printer. As was mentioned in the Stringing or Oozing section, retractions are primarily used to prevent the nozzle from oozing as it moves between different parts of your print. However, if the nozzle is not going to cross an open space, the oozing that occurs will be on the inside of the model and won’t be visible from the outside. For this reason, many printers will have the “Only retract when crossing open spaces” option enabled to avoid unnecessary retractions.

For this reason, many printers will have the “Only retract when crossing open spaces” option enabled to avoid unnecessary retractions.

Another related setting can be found in the “Movement Behavior” section. If your printer is only going to retract when crossing open spaces, then it would be beneficial to avoid these open spaces as much as possible. Simplify3D includes an extremely useful feature that can divert the travel path of the extruder to avoid crossing an outline perimeter. If the extruder can avoid crossing the outline by changing the travel path, then a retraction won’t be needed. To use this feature, simply enable the “Avoid crossing outline for travel movement” option.

Non-stationary retractions

Another extremely useful feature in Simplify3D is the ability to perform non-stationary retractions. This is particularly useful for bowden extruders that build up a lot of pressure inside the nozzle while printing. Typically when these types of machines stop extruding, the excess pressure is still likely to create a blob if the extruder is standing still. So Simplify3D has added a unique option that allows you to keep the nozzle moving while it performs its retraction. This means you are less likely to see a stationary blob since the extruder is constant moving during this process. To enable this option, we have to adjust a few settings. First, click “Edit Process Settings” and go to the Extruder tab. Make sure that the “Wipe Nozzle” option is enabled. This will tell the printer to wipe the nozzle at the end of each section when it stops printing. For the “Wipe Distance”, enter a value of 5mm as a good starting point. Next, go to the Advanced tab and enable the option labeled “Perform retraction during wipe movement”. This will prevent a stationary retraction, since the printer has now been instructed to wipe the nozzle while it retracts. This is a very powerful feature and a great option to try if you are still having trouble removing these defects from the surface of your print.

So Simplify3D has added a unique option that allows you to keep the nozzle moving while it performs its retraction. This means you are less likely to see a stationary blob since the extruder is constant moving during this process. To enable this option, we have to adjust a few settings. First, click “Edit Process Settings” and go to the Extruder tab. Make sure that the “Wipe Nozzle” option is enabled. This will tell the printer to wipe the nozzle at the end of each section when it stops printing. For the “Wipe Distance”, enter a value of 5mm as a good starting point. Next, go to the Advanced tab and enable the option labeled “Perform retraction during wipe movement”. This will prevent a stationary retraction, since the printer has now been instructed to wipe the nozzle while it retracts. This is a very powerful feature and a great option to try if you are still having trouble removing these defects from the surface of your print.

Choose the location of your start points

If you are still seeing some small defects on the surface of your print, Simplify3D also provides an option that can control the location of these points. Click on “Edit Process Settings” and select the Layer tab. In most cases, the locations of these start points are chosen to optimize the printing speed. However, you also have the ability to randomize the placement of the start points or align them to a specific location. For example, if you were printing a statue, you could align all of the start points to be on the backside of the model so that they were not visible from the front. To do this, enable the “Choose start point that is closest to specific location” option and then enter the XY coordinate where you want the start points to be placed.

Click on “Edit Process Settings” and select the Layer tab. In most cases, the locations of these start points are chosen to optimize the printing speed. However, you also have the ability to randomize the placement of the start points or align them to a specific location. For example, if you were printing a statue, you could align all of the start points to be on the backside of the model so that they were not visible from the front. To do this, enable the “Choose start point that is closest to specific location” option and then enter the XY coordinate where you want the start points to be placed.

Related Topics

Stringing or Oozing

Stringing or Oozing

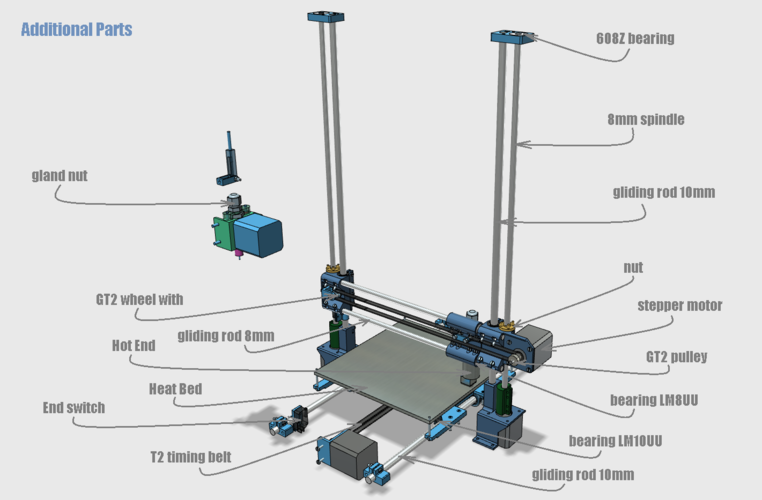

Stringing (otherwise known as oozing, whiskers, or “hairy” prints) occurs when small strings of plastic are left behind on a 3D printed model. This is typically due to plastic oozing out of the nozzle while the extruder is moving to a new location. Thankfully, there are several settings within Simplify3D that can help with this issue. The most common setting that is used to combat excessive stringing is something that is known as retraction. If retraction is enabled, when the extruder is done printing one section of your model, the filament will be pulled backwards into the nozzle to act as a countermeasure against oozing. When it is time to begin printing again, the filament will be pushed back into the nozzle so that plastic once again begins extruding from the tip. To ensure retraction is enabled, click “Edit Process Settings” and click on the Extruder tab. Ensure that the retraction option is enabled for each of your extruders. In the sections below, we will discuss the important retraction settings as well as several other settings that can be used to combat stringing, such as the extruder temperature settings.

The most common setting that is used to combat excessive stringing is something that is known as retraction. If retraction is enabled, when the extruder is done printing one section of your model, the filament will be pulled backwards into the nozzle to act as a countermeasure against oozing. When it is time to begin printing again, the filament will be pushed back into the nozzle so that plastic once again begins extruding from the tip. To ensure retraction is enabled, click “Edit Process Settings” and click on the Extruder tab. Ensure that the retraction option is enabled for each of your extruders. In the sections below, we will discuss the important retraction settings as well as several other settings that can be used to combat stringing, such as the extruder temperature settings.

Common Solutions

Retraction distance

The most important retraction setting is the retraction distance. This determines how much plastic is pulled out of the nozzle. In general, the more plastic that is retracted from the nozzle, the less likely the nozzle is to ooze while moving. Most direct-drive extruders only require a retraction distance of 0.5-2.0mm, while some Bowden extruders may require a retraction distance as high as 15mm due to the longer distance between the extruder drive gear and the heated nozzle. If you encounter stringing with your prints, try increasing the retraction distance by 1mm and test again to see if the performance improves.

Most direct-drive extruders only require a retraction distance of 0.5-2.0mm, while some Bowden extruders may require a retraction distance as high as 15mm due to the longer distance between the extruder drive gear and the heated nozzle. If you encounter stringing with your prints, try increasing the retraction distance by 1mm and test again to see if the performance improves.

Retraction speed

The next retraction setting that you should check is the retraction speed. This determines how fast the filament is retracted from the nozzle. If you retract too slowly, the plastic will slowly ooze down through the nozzle and may start leaking before the extruder is done moving to its new destination. If you retract too quickly, the filament may separate from the hot plastic inside the nozzle, or the quick movement of the drive gear may even grind away pieces of your filament. There is usually a sweet spot somewhere between 1200-6000 mm/min (20-100 mm/s) where retraction performs best. Thankfully, Simplify3D has already provided many pre-configured profiles that can give you a starting point for what retraction speed works best, but the ideal value can vary depending on the material that you are using, so you may want to experiment to see if different speeds decrease the amount of stringing that you see.

Thankfully, Simplify3D has already provided many pre-configured profiles that can give you a starting point for what retraction speed works best, but the ideal value can vary depending on the material that you are using, so you may want to experiment to see if different speeds decrease the amount of stringing that you see.

Temperature is too high

Once you have checked your retraction settings, the next most common cause for excessive stringing is the extruder temperature. If the temperature is too high, the plastic inside the nozzle will become less viscous and will leak out of the nozzle much more easily. However, if the temperature is too low, the plastic will still be somewhat solid and will have difficulty extruding from the nozzle. If you feel you have the correct retraction settings, but you are still encountering these issues, try decreasing your extruder temperature by 5-10 degrees. This can have a significant impact on the final print quality. You can adjust these settings by clicking “Edit Process Settings” and selecting the Temperature tab. Select your extruder from the list on the left, and then double-click on the temperature setpoint you wish to edit.

Select your extruder from the list on the left, and then double-click on the temperature setpoint you wish to edit.

Long movements over open spaces

As we discussed above, stringing occurs when the extruder is moving between two different locations, and during that move, plastic starts to ooze out of the nozzle. The length of this movement can have a large impact on how much oozing takes place. Short moves may be quick enough that the plastic does not have time to ooze out of the nozzle. However, long movements are much more likely to create strings. Thankfully, Simplify3D includes an extremely useful feature that can help minimize the length of these movements. The software is smart enough that it can automatically adjust the travel path to make sure that nozzle has a very short distance to travel over an open space. In fact, in many cases, the software may be able to find a travel path that avoids crossing an open space all together! This means that there is no possibility to create a string, because the nozzle will always be on top of the solid plastic and will never travel outside the part. To use this feature, click on the Advanced tab and enable the “Avoid crossing outline for travel movement” option.

To use this feature, click on the Advanced tab and enable the “Avoid crossing outline for travel movement” option.

Movement Speed

Finally, you may also find that increasing the movement speed of your machine can also reduce the amount of time that the extruder can ooze when moving between parts. You can verify what movement speeds your machine is using by clicking on the Speeds tab of your process settings. The X/Y Axis Movement Speed represents the side-to-side travel speed, and is frequently directly related to the amount of time your extruder spends moving over open air. If your machine can handle moving at higher speeds, you may find that increasing this settings can also reduce stringing between parts.

Related Topics

How the Federal State Educational Standards, the Unified State Examination and reports created a mess in education

Many adults believe that Soviet education was many times better. Our new blogger Sergei Rutskikh discusses why modern education leaves much to be desired. He believes that there are several reasons why our education is getting worse.

He believes that there are several reasons why our education is getting worse.

Educational business

Is there a mess in today's educational organization? Convinced: there is! What does it start with? With excessive commercialization. It is attractive because it allows everyone who cares in one way or another to improve education to earn money. How beautifully everything was arranged by the pioneers of the educational business. If you read innovative teachers at the end of the 80s (I won’t mention their names, they are too famous), then most of them suggested switching from teaching methods to teaching technologies. AT 90s, "creative teams" were formed that trained and attracted teachers to the educational business.

An endless stream of new curricula, new textbooks, new workbooks, articles, recommendations, versions of the Unified State Examination, teaching methods and technologies, and so on and so forth. One of the main arguments was this: “Enough of monotony! You provide a variety of textbooks, curricula and learning technologies!” Nobody remembered the former Soviet main motto: “Children are not bags for stuffing with knowledge!”.

There was a real hurricane of good, average and frankly bad teaching materials. For the consumer, an endless process of replacing one with another was established. It doesn't matter that yesterday's good is being replaced today by bad and terrible, because tomorrow it will be replaced anyway. How much was written and sold. Today in Russia, the commercialization of education is at the highest business level.

USE, GEF and reports

What about the officials? They subjugated the entire cohort of creative teaching staff. How? Yes, reports! Our officials are responsible people. They participate in the active educational life of the country! Can they afford to be left out of the picture in the face of a thriving education business? Of course not. They constantly create such conditions for the educational process for teachers, parents and students so that no one can doubt their significance.

Just imagine what would happen if there were no USE? Well, only an idiot can imagine his absence. What kind of irresponsible minister of education and enlightenment will allow you to be free with regard to student grades? The USE is an exam for teachers, parents, and students, personally organized by the Minister of Education and Enlightenment.

What kind of irresponsible minister of education and enlightenment will allow you to be free with regard to student grades? The USE is an exam for teachers, parents, and students, personally organized by the Minister of Education and Enlightenment.

The Minister brings to a common denominator the whole mess of the educational process in Russia. It doesn't matter how and what they taught - it is important how they passed the exam

GEF is a reinforcement for the USE. Who's to say it's not healthy? I, as the author of the post, simply admire the logic of organized reporting within the system of the current government policy. Everything is fine with reporting, you won’t find fault! What claims can be made against the "center"? Mind is not enough.

Unprofessional personnel

And what does our real economy think about education? Do they lack workers? They are not very literate engineers? Well, gentlemen! We (education officials) are doing everything to raise education in Russia to the world level! Someone says that children do not know how to apply the acquired knowledge? And how do you prove it? Well, yes, students have no practice! But we are not in the Soviet Union with its training departments at every enterprise where we organized the practice of students.

Innovations

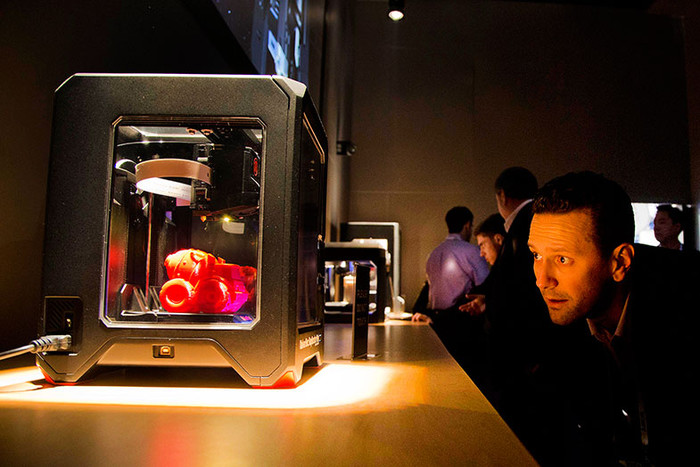

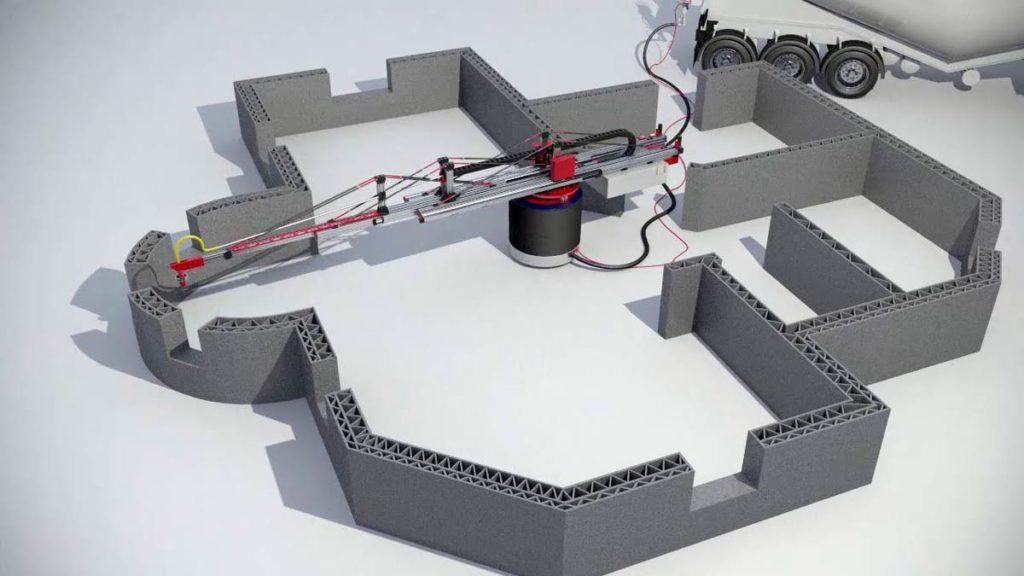

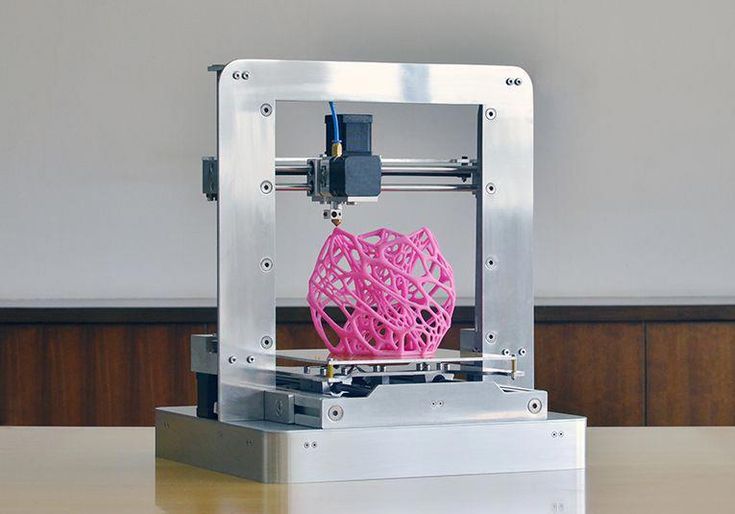

3D printers are being introduced everywhere to educate children from the age of ten. Is this not the most modern level for you? Here we will not allow anyone to lag behind the West. What if the child does not develop with him, but only watches how this melted plastic printer glues parts? The child, on the other hand, turns on the computer, the program of which controls this ultra-modern device, he also learns and at the same time gains the competence to control a 3D printer. And then he takes Lego pieces and makes a robot out of them. Well, isn't this development?

And what if the child is deprived of the development of coordination of physical movements and sensations, but, like a cool engineer, he controls modern technology. And this is ten years old! Then we will load it with theoretical knowledge and after graduation we will understand that it cannot compete with a robot that performs the same functions.

But these are his personal problems. True, today they are created by the content and method of educating children and youth, but no one is to blame for this. And this is the most important thing for officials!

True, today they are created by the content and method of educating children and youth, but no one is to blame for this. And this is the most important thing for officials!

Officials do not know and do not want to know how to change education. They can endlessly listen to criticism and evaluation of education, but they will never admit it, since huge money is spinning in education and there is accountability! This means that everyone responsibly fulfills their bureaucratic duties! A mess in education? Prove it! Do not agree!

You are in the "Blogs" section. The opinion of the author may not coincide with the position of the editors.

Illustration: Shutterstock (TeraVector)

How a colleague made a home alarm from Nokia 2100, but its operation led to unexpected consequences

To make the story itself, its ending and the actions of the "heroes" understandable, we will have to write a small introductory part.

At the end of the last century, I got a new job in the department where Sergey already worked. We pretty quickly, if not friends, then certainly became friends. He is a good man, simple, not evil, always ready to help, and absolutely disinterestedly. An excellent specialist a la Kulibin, who repairs printers and monitors at the enterprise. I was always amazed by his ability to disassemble a laser printer, for example, down to the last screw, and then reassemble it. And even if after the assembly there were "extra" spare parts, the printer still started working. To myself, I call him "sermyaga" (kindly). He is absolutely unpretentious in everyday life and is very tight-fisted. He does not care what he eats, what to wear, whether he is shaved today or not, whether he has washed and ironed clothes on him, etc. This is neither good nor bad. He's just the way he is. He always rode a bicycle to and from work. Whether rain, snow, ice, snowstorm, scorching sun - only a bicycle. On principle, he does not travel by bus, because he will have to pay for the fare, but he feels sorry for the money for this business.

We pretty quickly, if not friends, then certainly became friends. He is a good man, simple, not evil, always ready to help, and absolutely disinterestedly. An excellent specialist a la Kulibin, who repairs printers and monitors at the enterprise. I was always amazed by his ability to disassemble a laser printer, for example, down to the last screw, and then reassemble it. And even if after the assembly there were "extra" spare parts, the printer still started working. To myself, I call him "sermyaga" (kindly). He is absolutely unpretentious in everyday life and is very tight-fisted. He does not care what he eats, what to wear, whether he is shaved today or not, whether he has washed and ironed clothes on him, etc. This is neither good nor bad. He's just the way he is. He always rode a bicycle to and from work. Whether rain, snow, ice, snowstorm, scorching sun - only a bicycle. On principle, he does not travel by bus, because he will have to pay for the fare, but he feels sorry for the money for this business. Short, stocky, strong, but very eager for vodka. He can drink himself unconscious, and the next day ask everyone what happened yesterday ("restore events", as he says). He can drink a bottle, and then immediately ride a bike to the stadium and run ten kilometers to cheer up or pull himself up on the horizontal bar about twenty times. He drank often and a lot, which did not cause any joy in his wife, to put it mildly, but on the contrary. She is a stern woman, and when her husband's drunkenness completely got her, she could give him cuffs. Serega, although it would not have been difficult to twist her into a "ram's horn" at such a moment, endured the executions of his wife humbly, probably understanding and accepting his guilt. They lived with his wife, too, very "non-trivial" (in my opinion). In a private house, together, but everyone is absolutely on their own, like neighbors in a communal apartment (their children have long since left for other cities). They had a separate family budget (according to the principle - what I earned is mine, how much is none of your business, but where and on what I spend it is already mine).

Short, stocky, strong, but very eager for vodka. He can drink himself unconscious, and the next day ask everyone what happened yesterday ("restore events", as he says). He can drink a bottle, and then immediately ride a bike to the stadium and run ten kilometers to cheer up or pull himself up on the horizontal bar about twenty times. He drank often and a lot, which did not cause any joy in his wife, to put it mildly, but on the contrary. She is a stern woman, and when her husband's drunkenness completely got her, she could give him cuffs. Serega, although it would not have been difficult to twist her into a "ram's horn" at such a moment, endured the executions of his wife humbly, probably understanding and accepting his guilt. They lived with his wife, too, very "non-trivial" (in my opinion). In a private house, together, but everyone is absolutely on their own, like neighbors in a communal apartment (their children have long since left for other cities). They had a separate family budget (according to the principle - what I earned is mine, how much is none of your business, but where and on what I spend it is already mine). The products were bought by each for himself and stored in different refrigerators. They also cooked for themselves. They ate together, but each had their own food. Managed their earnings as they wanted. Utilities were also paid separately. He is for electricity and gas, she is for water and telephone (by agreement), etc. A wife could go to her daughter in another city for a week and not warn her husband. He could go on a spree in the company of drinking companions for several days and not tell her anything either. No one worries or worries about anyone, no one reports to anyone and does not report on their plans. Anyway. Someone else's family - darkness. They are satisfied and thank God. Well, somehow ...

The products were bought by each for himself and stored in different refrigerators. They also cooked for themselves. They ate together, but each had their own food. Managed their earnings as they wanted. Utilities were also paid separately. He is for electricity and gas, she is for water and telephone (by agreement), etc. A wife could go to her daughter in another city for a week and not warn her husband. He could go on a spree in the company of drinking companions for several days and not tell her anything either. No one worries or worries about anyone, no one reports to anyone and does not report on their plans. Anyway. Someone else's family - darkness. They are satisfied and thank God. Well, somehow ...

And now the story itself. It happened in the year, probably so, in two thousand and five. Thefts in private sector houses in the area where Sergey lived became more frequent. Once climbed up and to him. There is nothing special to take from them in the house, but the door lock was broken, inherited, they made a mess in the house - not very pleasant. The wife somehow drove off once again to her daughter, there is no one to "guard" the house when Seryoga is at work. He decided to install an alarm on the front door in order to know if someone breaks into the house again during his absence. Buy an alarm? Well, no, it's Seryoga! After all, money will have to be paid for it - and this is against his "homemade" principles. He had an old Nokia 2100 (a small one with a "milky" screen).

The wife somehow drove off once again to her daughter, there is no one to "guard" the house when Seryoga is at work. He decided to install an alarm on the front door in order to know if someone breaks into the house again during his absence. Buy an alarm? Well, no, it's Seryoga! After all, money will have to be paid for it - and this is against his "homemade" principles. He had an old Nokia 2100 (a small one with a "milky" screen).

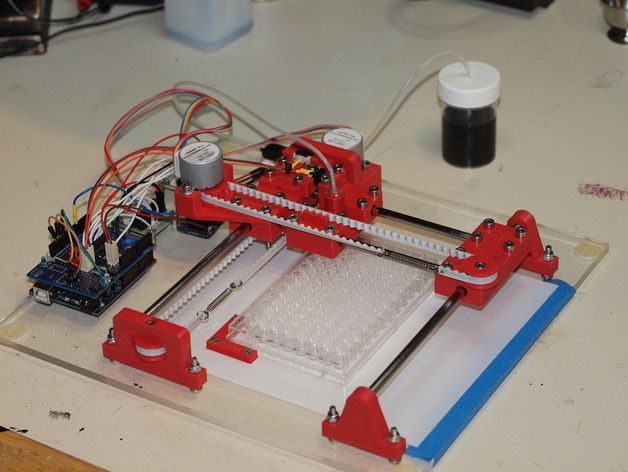

And on the basis of this "apparatus" Serega got himself a home alarm system. I myself have not seen his creations, but I will describe the principle of operation of the alarm from his words. Above the front door, from the side of the street, behind a beam, he put his Nokia (who doesn't know - he won't see or find it). From it, the charger wire was stretched into the house and the charger was inserted into the outlet. Seryoga attached something like a mikrik to the door. When the door opens, the normally open contacts of the mic close. From the contacts of the mikrik there are two wires to Nokia, which are soldered (or maybe they were glued, I don’t know exactly how he stuck the wires to the board) to the pad of the button on the mobile phone board, on which he scored the mobile number in speed dials, which was always with him. Leaving the house, he closed the door, turned on the Nokia and hid it behind the timber. If in Sergey's absence the door was "unauthorized" opened, then the contacts of the mikrik were closed, simulating pressing the speed dial button and from the "Nokia alarm" number, there was a call to the mobile phone that was with him.

Leaving the house, he closed the door, turned on the Nokia and hid it behind the timber. If in Sergey's absence the door was "unauthorized" opened, then the contacts of the mikrik were closed, simulating pressing the speed dial button and from the "Nokia alarm" number, there was a call to the mobile phone that was with him.

And then, one fine day, we were sitting in the office at work and Seryoga received a call from his self-made alarm system. That's it, the house is being robbed again. He called the police, reported on the intruders, jumped on his bike and rushed home. He returned to work two hours later upset and with a fresh black eye. It turned out that this wife returned home from her daughter (and she did not know about the alarm that Seryoga installed). Fifteen minutes later, in her own house, she was "received" by the arriving police outfit, and soon Seryoga pulled himself up. That the lady in the house is not a thief was quickly figured out. The outfit left, and after that Seryoga immediately got in the eye from his missus. Deserved, according to his wife. The situation with the detention by the police in her own house really pissed her off. On the same evening, the alarm system invented by Seryoga was dismantled by him, so to speak, out of harm's way.

Deserved, according to his wife. The situation with the detention by the police in her own house really pissed her off. On the same evening, the alarm system invented by Seryoga was dismantled by him, so to speak, out of harm's way.

News

Publications

Maibenben M547 is a simple, work laptop with a Ryzen 7 4700U processor and 16 GB of RAM that will allow you to perform basic tasks: office software, browsing, watching movies. But thanks though...

One of the most outstanding mobile DACs in recent times I can safely call the Ikko ITB03. Yes, and there is a reason, for filling it is charged as a solid portable: XMOS chip to USB, two converters...

We continue our walk around St. Petersburg. In the last post, we walked from the Moscow railway station along Ligovsky Prospekt to the Obvodny Canal. Then along the embankment we reached Bagrationovsky...

Often Chinese comrades do not pay due attention to high-quality translation into Russian or forget about localization in principle.