Vx4000 3d printer price

Voxeljet VX 4000 3D Printer In-Depth Review

ADVERTISEMENT

8.8Expert Score

Voxeljet VX 4000 3D Printer

This printer is for all the manufacturers who want to offer their clients huge build volumes of parts or functional prototypes by sand 3D printing. So using Voxeljet's VX 4000, you get quality served with quantity.

Affordability

3

Quality

10

Speed

10

Capability

10

Practicality

10

User Expectations

10

PROS

- Highest build volume for sand 3D printing.

- Excellent layer resolution.

- Seamless integration.

- Maximizing productivity.

CONS

- Cost is a huge concern for anyone who is not a well-established player in the 3D printing market for years.

- Also, can this printer system be equally efficiently used for making small parts, as it can be batch productions and big parts, is a concern.

A 3D printer based on Binder Jetting 3D printing technology, Voxeljet VX 4000 is the largest known machine for building sand moulds. It features a ...

Add to wishlistAdded to wishlistRemoved from wishlist 0

Add to compare

|

Table of Contents

Voxeljet is an industrial printer manufacturer in two important categories i. e. Prototyping as well as Serial production. In both of the important categories, there are four 3D printers.

e. Prototyping as well as Serial production. In both of the important categories, there are four 3D printers.

VX 4000 is a serial production type. Voxeljet is also offering 3D Printing Solutions in the categories of Sand Casting, Investment Casting, Architecture and Construction, Polymer Sintering, Mock-Up’s and Models, and Technical Ceramics.

As a company, Voxeljet is also into making parts and functional prototypes with 3D parts on demand.

The company was born from a start-up from the Technical University of Munich and has been supporting its customers with innovative 3D printing solutions for more than 20 years.

The initial years of development of the company were productive for the metal casting industry, but the current applications of the company’s technology extend far beyond.

Currently, the products of this company help streamline conventional, cost-intensive manufacturing processes to more economically attractive, simplify research into new materials as well as lightweight construction developments.

In this article, we are going to state different aspects of the printer such as its features, specifications, print quality, setup, first impression, and a lot more.

ADVERTISEMENT

Features

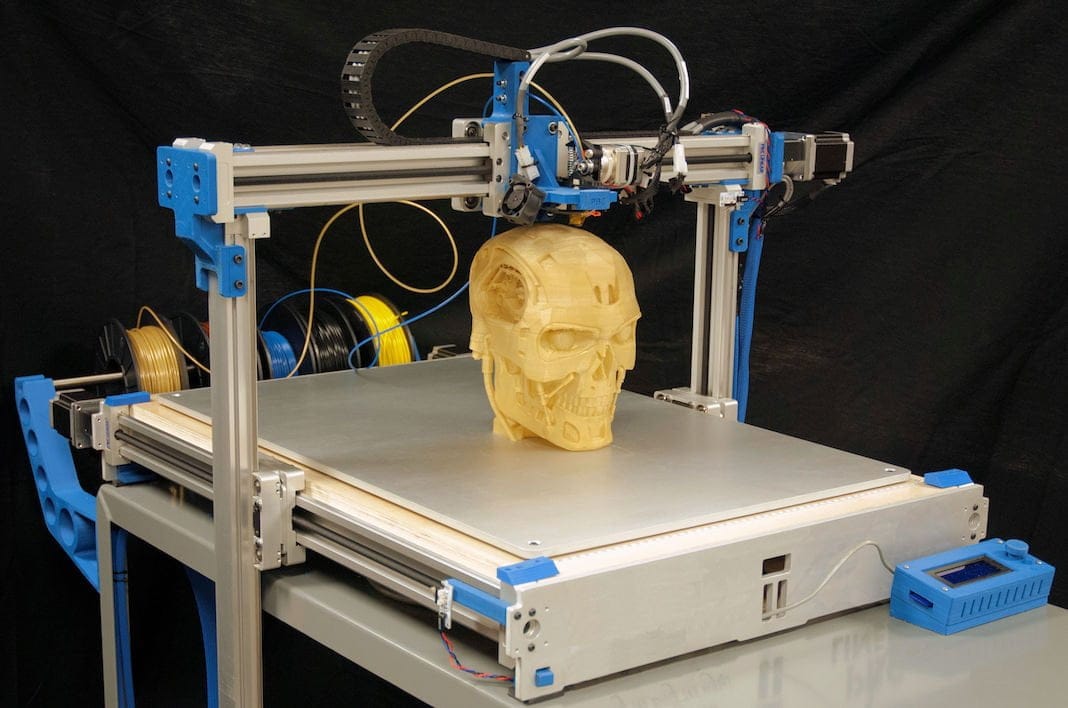

VX 4000 is a large-format 3D printer system manufactured for producing any type of object from particles.

The printer offers six times more build volume than the largest commercially available 3D printer offers.

A wide print head is used inside the printer prints layers in two passes.

Voxeljet VX 4000 ensures speedy manufacturing of individual parts and functional prototypes, as well as small batch production.

Alternately inserted building platforms inside the system design allows the printer to print 24*7. VX4000 has a robust design and is equipped with high-quality technology.

Flexible in producing parts and functional prototypes

Print speed and print flexibility are two of the most competitive areas in which Voxeljet VX4000 provides excellent results.

For ensuring that the parts or functional prototypes are delivered to the market in a faster time, the development is reduced as well as the production times in the design and function is also decreased.

The manufacturing limitations of conventional processes are removed using the additive production method.

All the parts and functional prototypes manufactured on this printer are lighter and more efficient or simply going beyond the limits of what is possible currently in terms of build volume.

There is also a possibility for users to transfer from one VX series to the other while printing parts or functional prototypes of larger or higher dimensions.

Smart to operate and seamless integration

Although the Voxel VX 4000 has many things to do, the operation of this printer system remains simple because of a well-thought-out ergonomic concept across the entire Voxeljet series.

It is the use of foundry-standard materials that allows the molds, parts as well as models to be processed quickly, within a short span of time.

Maximize productivity and making precise parts or functional prototypes

VX4000 is one of the most economical printers that are able to give a productive volume of 139 liters per hour.

This print volume is unmatched in the industry in terms of being huge.

All the parts or functional prototypes printed using this printer has a resolution of 300 dpi.

Even the finest details can be imaged with the highest precision using Voxeljet VX4000.

Larger format components such as four-meter long can be made using this printer.

Flexibility and reproducibility

VX4000 offers both, the installation space, as well as the precision and the speed for producing large-format shapes or smaller parts in series quality, production of these parts and functional prototypes, happens efficiently and in a cost-effective manner.

The printer works with a bidirectional print head technology with which it is able to print parts or functional prototypes as large as a construction field of four meters in length and two meters in width in just two passes.

A robust printer that can operate using foundry-standard materials

VX4000 is capable of producing enormous volumes, because of its innovative as well as adapted printing processes.

It is to be noted how the weight of the operating resources is not transferred to the machine components that are sensitive.

The 3D printed forms can be effortlessly integrated into existing value chains.

VX 4000 uses furan resins for 3D printing parts or a functional prototype.

As mentioned above, the print head of this printer works producing a resolution of up to 300 dpi, which enables the printer to reproduce some of the most complex component geometries that are precisely made up to extremely small design.

Such designs are ideal for supplementing the existing product or even for cushioning volatile production peaks.

ADVERTISEMENT

Specifications

Credit: voxeljet.comUsed for making parts and functional prototypes that are made for mold making, as well as production in the Aerospace, Automotive, and Aviation industry, VX 4000 is based on Binder Jetting 3D printing technology.

The printer has a large scale print volume and was launched in 2011.

It has a closed material system, with a print size metric of 4000 mm * 2000 mm * 1000 mm and a layer resolution of 300 dpi.

Price

For knowing the exact price of this printing system you need to request a quote. But the estimated price of it is more than $250000.

First Impression

Credit: voxeljet.comVX 2000 is claimed as the world’s largest 3D printer for sand. When fitted at a workstation, it appears as a giant beast of a machine system.

A huge print bed comes out and goes in via the print bed shutter which can be seen half opening.

There are transparent windows all over the body of this printing system to let one monitor the printing process when it is going on.

A door is present on the right of the print bed, which is probably for the gas chamber.

Setup

All the setup is completely done by the manufacturers, all you have to do is take some training for understanding the mechanism of this printer and that can be done in many ways.

You should go through the basics of the printer and all the material available for it, via the internet.

Your doubts after going through all this material would be entertained by the technical team of Voxeljet via call, email, as well as personal assistance via Skype too.

ADVERTISEMENT

Print Type/Cost

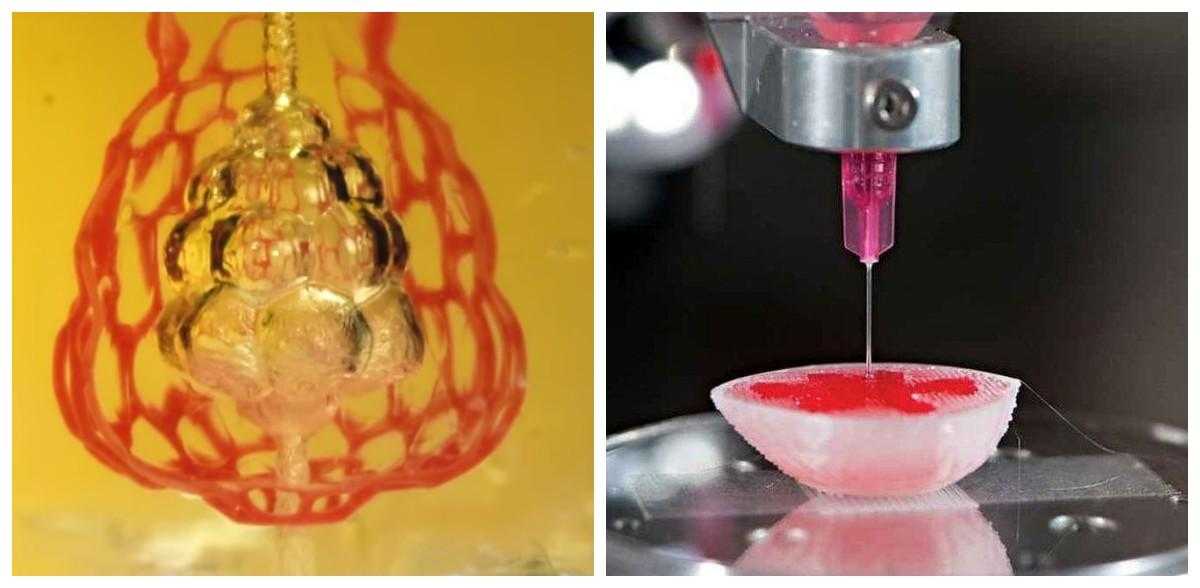

Binder Jetting is an additive manufacturing process on which this printer is based. Here an industrial printhead selectively deposits a liquid binding agent onto a thin layer of powder particles.

It belongs to the class of powder bed fusion, where neither filament spool nor a resin is used for 3D printing parts and functional prototypes, rather powdered material is used.

This powder can be made from metal, sand, ceramics, or composites. These powders are used for building high-value and one-of-a-kind parts and tooling.

The process, as in every 3D printing processes is repeated layer by layer, using a map from a digital design file, until the final object is complete.

Binder Jetting 3D printing technology was developed at the Massachusetts Institute of Technology in the early 1990s.

The company named ExOne obtained the exclusive license to this method of 3D printing in 1996. In 1998, the company launched its first commercial binder jet 3D printer for metals named the RTS-300.

Being the world’s largest sand 3D printer as per Voxeljet’s claims, it uses sand powder for making parts and functional prototypes.

Binder jetting 3D printing technology is unique in the sense that it does not employ heat during the build process.

This technique prints quickly entire layers of many parts that are supported by the loose powder in the job box, eliminating the need for a build plate or supports in most instances, using a wide gantry of printheads.

Thus, binder Jetting is preferred by experts all over the world because it has the ability to print a large number of parts or large parts in a quick and cost-effective manner.

Finally, when the parts are printed in powder, they are sintered together at one time after the shape has been formed, resulting in a high-quality microstructure with superior grain isotropy.

And this is the main reason why experts prefer using this method if they can afford it in their project.

Although the print cost of printing a part or functional prototype using this method is more than other methods, it is worth it, because of the unmatched high quality of parts and functional prototypes produced using this technique.

ADVERTISEMENT

Print Quality

Credit: voxeljet.comAs mentioned in the above paragraph, the quality of parts and functional prototypes printed using binder jetting technology is always high.

It allows one to have a high surface finish as well as a smooth texture that does not need almost any post-processing.

The layer resolution of parts and functional prototypes made by this printer is 300 dpi.

Once the printing process is completed, the printed components can be separated from unglued material.

After that, they are prepared for further processing, wherein because Voxeljet uses a resource-friendly material and unglued powder residues can be fed back into the production cycle, depending on the material system used.

Software

Credit: voxeljet.comThe system software, during the binder jetting process, breaks down the shape that is defined in the CAD data into thousands of thin layers that make up the mold.

This goes even for the complex bionic internal structures as well as for the products linked with each other without contact.

Even such parts or functional prototypes can be produced using Binder jetting process.

Customer Support

The support and services department at Voxeljet consists of Voxeljet Academy, Material Certification Lab, Financing, Refurbished 3D Printing Systems, and Distribution Worldwide.

The first one can be an answer to all your questions regarding any printer system that you’ve purchased from the company.

If you want you can also reach out to the manufacturer via phone, email, Skype, or in person.

ADVERTISEMENT

Parameters Influencing Buying Decision

When you are out there in the market, you are probably looking for a comparison chart that can be used for finding out the best one suited for your 3D printing operation.

That is when the below-mentioned factors can be handy.

3D Printer Cost: Very expensive.

3D Print Speed: VX 4000 can build 139 liters per hour.

3D Printer Quality: The layer resolution of parts or functional prototypes build on VX 4000 is 300 dpi.

3D Printer Capability: VX 4000 can be used to print various types of sands such as classic quartz/silica sand GS14, GS15, GS19, GS25, Cerabands, and Chrome Ore.

3D Printer Practicality: The printer system can be used for developing special and individual shapes, medium series production, as well as supplementary production.

3D Printer User Expectations: The printer system primarily targets huge industrialists in the field of the 3D printing industry and is also able to fulfill their expectations. A proof of this is the case study mentioned on the webpage dedicated to this printer on the printer manufacturer’s website.

The Verdict

In a nutshell, this printer is for all the manufacturers who want to offer their clients huge build volumes of parts or functional prototypes by sand 3D printing.

Build by Voxeljet, and compatible with all the VX series by the same manufacturer, this printer is a gem of a machine when it comes to building objects for an application that demands hugeness.

It should be also not how the printer offers flexibility, and how it is based on the binder jetting technology which offers high-resolution parts and functional prototypes.

So, you get quality served with quantity while using Voxeljet’s VX 4000.

voxeljet’s VX4000: The Largest Industrial 3D Printer Arrives & Ready to Report to Work in North America - 3DPrint.com

Voxeljet’s arrival near Detroit most surely did not go unnoticed early last year, with a 50,000-square-foot facility opening in Canton, allowing many in the area to hope for a bright economical boost in in a state now famous for its financial struggles. And whether or not their presence has helped the area is still an unknown quotient, but voxeljet of America, Inc. has most certainly added to the industrial 3D printing manufacturer’s revenues as well as kept the momentum moving impressively forward regarding their entry into the North American commercial market.

And whether or not their presence has helped the area is still an unknown quotient, but voxeljet of America, Inc. has most certainly added to the industrial 3D printing manufacturer’s revenues as well as kept the momentum moving impressively forward regarding their entry into the North American commercial market.

The word is that the Canton service center will be operating at the same capacity as voxeljet’s Friedberg facility, and if that’s not true already, their latest developments should push that plan into action with the stateside arrival of the VX4000, which holds the title as the world’s largest industrial 3D printer—allowing the Motor City area now to boast further about exciting happenings via the high-tech manufacturer.

The VX4000 will be a focus in the Canton service center as they roll out on-demand parts and more. This printer has so many exciting features that it’s hard to know where to start. Speed and user-friendliness are a good place to begin, however, for this huge machine capable of production of sand molds on any level—and continuous production of them. From large individual molds to small series parts, cost-effective production is promised to their long list of clientele in the automotive, aviation and aerospace, film and entertainment, art and architecture, engineering, and consumer product end markets.

From large individual molds to small series parts, cost-effective production is promised to their long list of clientele in the automotive, aviation and aerospace, film and entertainment, art and architecture, engineering, and consumer product end markets.

Featuring a build space of 4,000 x 2,000 x 1,000 mm, the largest industrial printer in the world also ensures productivity and flexibility on the same grand level. Both build speed and build volume can be adjusted, convenient during such processes as building often required stable side walls. High volume output is a key benefit, obviously, with resolutions of 300 dpi possible. There is, quite simply, no other industrial machine like this—and the company itself compares the massive build space of their machine to that of a VW Golf vehicle—just to give one an idea.

“The market for cast parts in the US has always focused on size. With the VX4000, we not only produce the largest sand molds in the world, but can also combine these with smaller mold components,” said David Tait, Managing Director of voxeljet America, as he commented on the expanded capacities of the voxeljet equipment fleet and range of services in the US.

“The resulting flexibility provides for rapid delivery times and cost-efficient production.”

The VX4000 benefits the foundry industry—made up of factories traditionally responsible for metal castings or molds—in particular. They are a major consumer of voxeljet’s services, now able to see manufacturing of items like large turbines and rotors being printed, with all the rewards of the new technology, from speed in production to much greater affordability—not to mention virtually unlimited customization options for any part or design, with those of large volume in mind. Any company involved in casting and molds will find benefit in this technology, however, as it is not exclusive to the foundry industry only.

Another major benefit of the large-scale printer to be enjoyed is layer building. With this method, the print head is actually raised as each layer is applied. This allows the VX4000 to bear the weight of the building platform, which is substantial—and it can also be expediently replaced with a rail. The voxeljet team points out that with this, nearly permanent printing is offered.

The voxeljet team points out that with this, nearly permanent printing is offered.

Those outside of the highly industrial arena may be quite curious about the element of sand as a primarily material—quartz sand to be specific—which is bound together with a special agent. The molds are fabricated from CAD data, offering detail and precision, not to mention post-processing ease as the molds just require unpacking and dusting off. This is a process growing in demand, along with that for plastic models. The US is currently the largest growth market for 3D printing, and that is only expected to expand.

“We decided to place our largest printing system in the US in order to service growing demand in the US market directly on location. Our objective is to strengthen our most important growth market with a diversified portfolio of machines, materials and processes,” said Rudolf Franz, COO of voxeljet AG, in regards to the US market and its obvious potential. “Indirect beneficiaries of this high-end technology are the automotive industry, the special machine building sector and the spare parts industry in particular.

”

Other features to note which make use of voxeljet’s technology highly beneficial:

- Economical production is allowed as sand molds and cores are printed all in one piece.

- Nearly unlimited geometries and even undercuts can be implemented.

- Precise sand molds and cores with high surface quality can be attained, with 300 µm thin quartz sand layers.

- Familiar features are offered with quartz sand and furan resin with series-comparable mold and casting properties.

- The process is suitable for sand-casting all castable metals, such as aluminum, brass, magnesium, iron and steel casting as well as all common alloys.

- 3D printed cores can be combined with traditional sand molds, and vice versa.

- Simple core removal is allowed as a low binder content means that the behavior during outgassing and core removal is similar to traditional methods.

- Express delivery is available in only three working days from the service center.

Large companies with complex needs are able to pinpoint numerous reasons to use 3D printing over traditional methods, noting the general elimination of tool costs and the ability to print in low volume more efficiently. Shorter times for production and less labor in post processing all add up to a much more attractive scenario over conventional techniques, along with the ability to fabricate prototypes rapidly.

Voxeljet is a leading manufacturer of large-format and fast 3D printing systems. As we were glad to report, they also recently received the coveted ‘Component of the Year’ flagship award from the British Cast Metals Federation (CMF) as part of a joint project.

See the video below for a more in-depth look at how the VX4000 operates and offers so many industrial benefits. What are your thoughts on a 3D printing service center in Michigan? Discuss in the VX4000 3D Printer Comes to Canton forum over at 3DPB.com.

Adam Robertson (left) of the Precision Casting Centre and Kevin Smith, Sales Director of voxeljet UK, with the ‘Component of the Year’ award, presented by the Cast Metals Federation.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d printed sand molds • 3d printing foundry • British Cast Metals Federation • Canton • industrial 3d printing • Michigan • voxeljet • voxeljet canton facility • VX4000 3D printer

Please enable JavaScript to view the comments powered by Disqus.

voxeljet VX4000 3D Printing System - SMARTPRINT

The VX4000 is the world's largest sand mold industrial 3D printing system. It has a single build space measuring 4000 x 2000 x 1000mm (LxWxH). This machine can be used to cost-effectively produce very large individual molds, many small serial components, or a combination of both. With its uniquely large volume, the VX4000 maximizes productivity and flexibility.

With its uniquely large volume, the VX4000 maximizes productivity and flexibility.

The unique and patented layering process has been specially adapted for this printer. Instead of lowering the build platform during the printing process, the print head and coater are raised with each layer. As a result, the machine can support the enormous weight of the building platform, which can be quickly replaced with a rail, allowing for almost continuous printing. Sand is used as the particulate material. The VX4000 printhead system can achieve resolutions up to 300dpi. The layer applied in one cycle has a thickness of 300 µm. nine0003

- Powerful 3D printing system for fast and economical production of medium sized individual molds, cores and low-volume components

- Largest bonded build space for sand molds available on the market: 4000 x 2000 x 1000 mm

- Large production volume for high performance and flexibility

- Unique printing concept for optimum capacity utilization

- Resolution up to 300 dpi

| DIMENSIONS/WEIGHT | |

|---|---|

| External dimensions LxWxH | 19. 000 x 9.300 x 4.300 mm 000 x 9.300 x 4.300 mm |

| Installation space LxWxH* | 24.000 x 16.100 x 4.500 mm |

| Weight | - |

*Installation space includes ref. equipment

| PROCESS nine0031 | SAND |

|---|---|

| Building size LxWxH | 4.000 x 2.000 x 1.000 mm |

| Print resolution x, y | up to 300 dpi |

| GENERAL | |

|---|---|

| Ambient temperature | 22 ± 2 °C |

| Relative humidity | 55 ± 5% |

Like all voxeljet 3D systems, the VX4000 is ideal for creating complex components and prototypes fully automatically and without tooling. It meets the optimal prerequisites for fast and flexible production in industrial environments thanks to its continuous printing process and high build speed. Its robust construction gives the VX4000 a particularly long service life. The machines are designed and built in Germany.

Its robust construction gives the VX4000 a particularly long service life. The machines are designed and built in Germany.

The VX2000 is a 3D printer for industrial applications. It is a particularly good choice for economical casting of large format parts using sand cores and molds. The VX2000 can also be used for cost effective production of low volume components. nine0003

voxeljet 3D printers can be used to economically and efficiently produce sand molds and cores for metal casting. Molds are made by applying powdered material in layers and selectively bonding it with a binder. Silicate sand is used as a powder material.

Plastic 3D printing is the ideal solution for cost-effective and time-saving injection molding and design models. Models are made by applying particulate material in layers and selectively bonding it with a binder. PMMA (polymethyl methacrylate), an acrylic plastic, is used as the particulate material. nine0143

4 000 mm (157 in)

2 000 mm (79 in)

8 000 L (2 113 GAL)

Description

The VX4000 is the world's largest sand mold 3D printing system covering an area of 4 x 2 x 1 meter. The VX4000 is unmatched in build volume. Unlike smaller voxeljet 3D printing systems, the VX4000 uses an innovative and patented layering process that ensures consistent changeover times, maximum component precision and quality, even in high volume production and low component batches. In terms of flexibility and reproducibility, the VX4000 is in a class of its own. Whether large format special shapes or small serial quality parts are required, the VX4000 offers both the space to install and the precision and speed to produce them efficiently and economically. With bi-directional print head technology, the VX4000 is able to print an entire construction field 4 meters long and 2 meters wide in just two passes. By using foundry-standard materials, 3D printed molds can be easily integrated into existing value chains. The VX4000 uses a 3D printing optimized furan resin and standardized silica sand/silica. The print head works with a resolution of up to 200 dpi and can therefore accurately and accurately reproduce even the most complex part geometries.

The VX4000 is unmatched in build volume. Unlike smaller voxeljet 3D printing systems, the VX4000 uses an innovative and patented layering process that ensures consistent changeover times, maximum component precision and quality, even in high volume production and low component batches. In terms of flexibility and reproducibility, the VX4000 is in a class of its own. Whether large format special shapes or small serial quality parts are required, the VX4000 offers both the space to install and the precision and speed to produce them efficiently and economically. With bi-directional print head technology, the VX4000 is able to print an entire construction field 4 meters long and 2 meters wide in just two passes. By using foundry-standard materials, 3D printed molds can be easily integrated into existing value chains. The VX4000 uses a 3D printing optimized furan resin and standardized silica sand/silica. The print head works with a resolution of up to 200 dpi and can therefore accurately and accurately reproduce even the most complex part geometries.

build size

build size