Dynamism 3d printer

Dynamism Archives - Perfect 3D Printing Filament

Posted on

Predicting the future is impossible. But that doesn’t stop us at 3D Printing Industry from inviting CEOs, CTOs and other AM experts to give us 3D printing predictions for 2020. If you want to stay up to date with the latest 3D printing news, subscribe to our free 3D Printing Industry newsletter. You’ll be among […]

Posted on

Dynamism has been a retailer of 3D printing technology for over two decades, and the company always does well at keeping up with the latest, most talked-about 3D printers. Currently, one of its featured products is the Ultimaker S5, which was released last year and designed for industrial 3D printing. Another is the Desktop Metal Studio System, released in 2017 and designed for metal 3D printing in an office setting. Both systems exemplify two of the largest trends in 3D printing, more sophisticated desktop systems and binder jetting metals. Dynamism itself is at a crossroads as well. We’ve been talking to resellers around the world these past weeks to figure out what the 3D printing market is like for resellers today. What is a reseller to do? Do they move towards industrial or wait for the consumer market to grow? Dynamism gives us some interesting insight that points to them not only becoming more of business-focused firm but also looking at being more of an integrator.

Both the Desktop Metal and Ultimaker 3D printers have made a big impact on the 3D printing industry since their respective releases, and Dynamism is excited about their futures as well as its own. Recently both were showcased at CES, which wrapped up last week. We were able to talk with Dynamism CEO Douglas Krone about the Ultimaker S5 and its role in manufacturing.

Do you believe that the S5 will be used for manufacturing? What is holding it back from manufacturing now?

“On this point, I’d to point out that both the Ultimaker 3 and S5 are already widely used in manufacturing globally, for producing tools, jigs and fixtures.

To talk about end parts, are early use cases of customers printing end parts used in low volume products like machines or robots—grippers on robotics is a prime example. In these cases companies have looked at their BOMs (Bill of Materials) and found non-critical parts, often replacing metal with advanced 3D printed plastic. This provides short terms savings, but an even larger long-term advantage: far more efficient spare part production, though the life cycle of the product, and beyond. (Even after products are discontinued, companies must maintain a spare parts inventory—usually for years.)

I think that’s where Ultimaker’s Open Material strategy is a big win. These machine/robot producers require specific materials from leading chemical companies (certification, procurement risks) not from 3DP producers themselves (with the resulting lock in). Having said this, Ultimaker is focused prototyping, tools, low volume production and spare parts made on location.”

Do you foresee people using Ultiwalls (clusters of desktop printers) to manufacture parts? Will you need to automate more things on the printer or Ultiwall? Such as part removal?

“The current S5, and what we expect to see next from Ultimaker (the next-generation of ‘concrete floor’ machines), can be deployed in wall-formations.

(And Cura’s CuraConnect supports that use.) But space, health, and safety requirements differ so much per factory and country, it would not make sense for Ultimaker to do a standard ‘Ultiwall’ product. You can expect 3D printing solutions providers like Dynamism to create these types of customized arrangements for larger customers.”

What are instances of Ultimaker adoption in the automotive industry?

“We see almost every automotive company, not just OEMs, but also in second, third and fourth tier now using Ultimaker. Uses are part development, tool design, and tool production. Ford and Volkswagen have especially impressive showcases.”

Are there any product announcements or other news from the show?

“The next news we expect from Ultimaker will be later this year. Look for innovative accessories that will work with all existing Ultimaker S5s, and make a great 3D printer even better. And of course Ultimaker is always iterating and improving Cura.

”

To learn more about Desktop Metal’s Studio System, we spoke with Desktop Metal VP of Product Larry Lyons.

How well is the Desktop Metal Studio System doing?

“As our office-friendly systems are making their way to customers throughout the country, we recently announced the launch Studio System+ and Studio Fleet which together offer enhanced features for metal prototyping and low volume production. Engineers and designers who are looking to push the limits of metal 3D printing with small parts or parts with fine details can now achieve even higher-resolution, with a customizable system configuration for greater process efficiency and throughput right on the shop floor. The new Studio System+ retains all the key features of the original Studio System with advancements that allow customers to build to scale and offer high-resolution printing. Studio Fleet adds a custom-configurable, in-house metal 3D printing solution to support a variety of production scenarios and scales for a wide range of low- to mid-volume applications across industries.

For the first time, on-demand metal 3D printing will be able to deliver accessible and scalable manufacturing that adapts to diverse business needs, part requirements, production volumes and cost constraints. We have received hundreds of reservations for our Studio System and are now shipping in volume to our customers in the USA. The Studio System is available in 45 countries, and we expect to begin international shipments in mid-2019.”

How well (and how) does the system compensate for shrink in all directions in different part sizes?

“Shrinkage is dependent on a number of factors, including alloy used, geometry of the part and size. As part of the Desktop Metal design, printing and sintering process, our software analyzes all of the factors that impact the approximate 18-20 percent shrinkage and automatically adjusts scaling factors in each dimension to yield the intended part size.”

How much can one Desktop Metal Studio System make?

“With one Studio System printer, 12” x 8” x 8” is the maximum build volume, so any part that fits in that box can be printed.

The Studio printer has a maximum print rate of 1 in 3/hr so the throughput of parts printed depends on the volume of the part you are printing. The debinder and furnace have the same build volume, but offer adjustable trays to batch process many parts at once, which is exemplified by our Studio Fleet offering.

For customers needing a higher throughput, Studio Fleet is a custom-configurable solution for in-house metal 3D printing—supporting a range of applications for low to mid-volume production. Built to scale, it leverages Studio System+ technology—including a software-controlled workflow and stackable shelving for batch processing—for the rapid production of high-quality, complex metal parts. For the first time, on-demand metal 3D printing will deliver accessible and scalable manufacturing that adapts to diverse business needs, part requirements, production volumes, and cost constraints. The Studio Fleet is available to be built in two configurations:

For automotive, what kinds of parts are your customers targeting?

“Our automotive customers are targeting parts across all stages of product life cycle.

For Studio, most applications are in the product development, prototyping and tooling (jigs/fixtures/molds) areas where lower volumes and quick turnaround times match well with the Studio’s capabilities. For the Production System, which will be available to ship in 2019, early applications we are seeing are in the replacement / aftermarket parts, customization and serial production where volumes requirements range from mid-to-high throughput. Many customers are developing end-use parts that will appear in new cars that have yet to hit the market and will deliver higher performance at a lower cost than the traditional manufactured alternative in today’s cars.”

How much faster is it than MIM? How much cheaper is it than MIM?

“For the Studio System, the time it takes to produce the initial part is 2-3 days. This compares to several weeks or even months with MIM due to the mold that needs to be designed and manufactured before the MIM process can begin.

This allows customers to dramatically accelerate the time it takes to get an initial prototype for testing and validation work compared to the traditional MIM process. It also allows customers to iterate on their design and test each iteration before ordering the mold to be manufactured, which can save thousands in costly mold changes if a change is needed.

Because of the expense associated with manufacturing the mold in MIM, most MIM companies will not bid on any job that is less than 10,000 units due to the mold cost making the parts too expensive. The Studio System provides a more cost-effective solution for low-to-mid volume applications in the MIM industry, especially when leveraging the throughput and cost advantages of a Studio Fleet installation.”

What kinds of part sizes can I reliably print with the Desktop Metal Studio?

“With the Studio System printer, 12″ x 8” x 8” is the maximum build volume, so any part that fits in that box can be printed.

In addition, we recently introduced a new swappable high resolution printhead with supporting software profiles allows for smaller parts with finer features and animproved surface finish. This creates opportunities for new geometries and applications with the ability to print parts similar to those produced with metal injection molding (MIM)—parts featuring sintered voxels as tiny as 240um in XY by 45um in Z, which is smaller than a grain of table salt—making it ideal for a variety of applications such as parts for consumer electronics, medical devices and automotive.”

Discuss this and other 3D printing topics at 3DPrintBoard.com or share your thoughts below.

Posted on

This week at CES 2019 in Las Vegas, production-grade stereolithography 3D printer manufacturer Nexa3D will be displaying its new NXE400 3D printer for the first time in North America. The NXE400 is impressive indeed, with reported print speeds of up to six times faster and 2. 5 times the build volume of comparable hardware, making it the fastest large-format 3D printer in the industry.

5 times the build volume of comparable hardware, making it the fastest large-format 3D printer in the industry.

Water pump housing

Like the other 3D printers in the company’s newest line, the NXE400 leverages Nexa3D’s proprietary Lubricant Sublayer Photo-curing (LSPc) technology and patented structured light matrix, and can continuously print up to 16 liters of parts at high speeds of up to 1Z centimeter a minute. This lowers the production time for prototypes and other functional parts from hours to just minutes, at injection molding levels of tolerance, repeatability, and quality, which also saves on money.

The new, highly accurate NXE400 comes with integrated sensors and cognitive software, which combine to offer continuous print monitoring, optimize part performance, and give detailed diagnostics. In addition, it also comes equipped with tough materials in order to enable ultra-fast 3D printing of production tooling, casting patterns, functional prototyping and end-use parts, and dental restoration.

Speaking of the dental industry, Nexa3D is planning on commercializing its new NXE 3D printer series this year through a multi-channel arrangement with its current partners: 3D printer manufacturer XYZprinting and digital and traditional dental materials provider BEGO. The three-way collaboration will go a long way in transforming the world of digital dentistry, as it will access the demand for expensive digital dentistry printers and industrial production, and the partnership could also end up being a major dental competitor to both EnvisionTEC and 3D Systems.

Various parts and assemblies 3D printed by the NXE400. Electrical assembly, pull handle, GoPro mount, bracket assembly, topology optimized brackets designed by ParaMatters

But the dental industry isn’t the only one that Nexa3D is interested in – the company is also collaborating with Techniplas, a global design and automotive manufacturing provider. Nexa3D joined its open innovation program as a partner a year ago in an effort to expand its presence in the automotive industry, and at this week’s CES show, Techniplas will be showcasing a concept vehicle that features 3D printed parts produced by Nexa3D, along with its growing generative design capabilities.

At CES 2019, Nexa3D will be exhibiting a range of its 3D printers, including the new NXE400, at the Techniplas booth #9320 in the North Hall’s Vehicle Technology zone in the Las Vegas Convention Center (LVCC), and also at the Dynamism booth #32020 in the 3D Printing Marketplace in the LVCC’s South Hall.

Izhar Medalsy, the Chief Product Officer for Nexa3D, said “After more than two years of intensive research and development, our team is proud to exhibit the results of our painstaking work at CES 2019 with our significant partners Techniplas and Dynamism, two go-to-market collaborators that are helping us validate the marketplace impact and build access to new products.”

Nexa3D wants to invite all qualified resellers, strategic partners, and industry practitioners to check out its new NXE400 3D printer, priced at $49,950, at CES 2019 this week. If you’re unable to make it out to Las Vegas for the show, you can see the 3D printer in action in the video below:

Discuss this news and other 3D printing topics at 3DPrintBoard.com or share your thoughts in the Facebook comments below.

[Images provided by Nexa3D]

Posted on

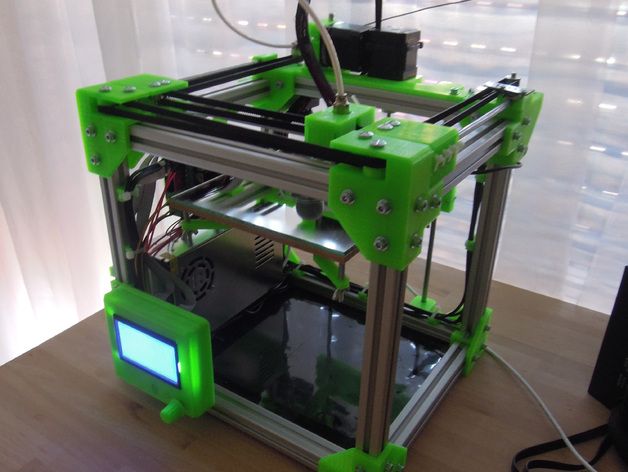

At Hannover Messe this past April, desktop 3D printing leader Ultimaker introduced its first new 3D printer in two years – the S5, an expansion to its professional 3D printer portfolio. Ultimaker reseller Dynamism showcased the new S5 at RAPID + TCT that same month, as did Ultimaker itself. The desktop system, with a 330 x 240 x 300 mm build volume, has all kinds of great features, including dual extrusion, an intuitive touchscreen integrated into the front panel, and an enclosed front with tinted glass doors…so imagine my excitement when I learned that Dynamism would be shipping me a review unit!

Full disclosure – while I’ve completed 3D prints before at Dayton’s 3D printing bar, this would be my first time setting up and operating a 3D printer all on my own. So when the gigantic box, and a smaller one of extra filament, arrived on my porch, I was a little…okay, a lot…intimidated. In fact, I was so concerned about not having anything pull focus from the unboxing and set-up process that the gigantic carton just sat in my dining room for a few days until the opportune moment. At 3DPrint.com we do not charge money for reviews. This is my own experience and my own opinion.

So when the gigantic box, and a smaller one of extra filament, arrived on my porch, I was a little…okay, a lot…intimidated. In fact, I was so concerned about not having anything pull focus from the unboxing and set-up process that the gigantic carton just sat in my dining room for a few days until the opportune moment. At 3DPrint.com we do not charge money for reviews. This is my own experience and my own opinion.

I’ll say this – the S5 was extremely well packaged. I was amazed at the sheer amount of used packing material I had at the end of the process, but also not surprised; I was dealing with precious cargo, after all. Another thing I will say, with complete honesty, is that while I write about technology all day every day, handling it is not my personal forte. So the fact that I was able to get this machine out of the box and set up with relatively few hiccups means that anyone can. The provided instructions were easy to follow, and if I needed more information, I just checked out the Ultimaker Resources.

The S5 came with a test print and a box of hardware accessories and tools, including two print cores, several nozzle covers, the glass build plate, a 2 mm Hex screwdriver, a glue stick, spool holder with a material guide, XY calibration sheets, a power cable, and a USB drive. The 3D printer also came with Tough PLA and PVA support material, the latter of which I am in love with…but more on that later.

Keeping my cats and dogs away!

I found it fairly straightforward to set up most of the hardware, but I had a bit of trouble using the clips to secure the Bowden tubes; however, I think that was more user error than anything else. I had no issues installing the Cura software, or updating the firmware once the 3D printer was fully up and running, though it took me a couple of tries to get the 3D printer to connect to my WiFi. While there were no problems loading the materials, I had a harder time installing the BB 0.4 print core. I think this was mainly due to the fact that I was so insanely aware of just how expensive this machine was and was treating it with kid gloves, and a firmer hand is sometimes required when installing hardware. Luckily, the more I used the 3D printer, the more comfortable I became.

Luckily, the more I used the 3D printer, the more comfortable I became.

Speaking of actually using the 3D printer, when the time finally came to test it out, I got a little too excited and forgot about a very important step: calibration. I very quickly realized that there was a problem, as the print was stringing and not adhering to the build plate, even though I’d applied a thin layer of glue, and stopped the job about three minutes in. While I was sad that my first print was far from a resounding success, I resolved to make it right.

I again waited a bit to try calibrating the S5, partly because I was busy but mainly because I was intimidated by it all over again. But once I took the time to sit down and figure it out, the calibration sheet that came with the 3D printer was a breeze to use, and I was on my way once again, ready to try 3D printing something that wasn’t just the calibration grid of straight lines.

My first successful attempt was one of the two sample prints that came on the included USB drive, which printed very quickly. I love the intuitive touchscreen on the front of the S5 – it’s very user-friendly, and I quickly figured out how to pull up a rough image of what the print would look like once it was complete, so I’d know that it was printing correctly. Once I pried the tiny print off of the plate (a very easy task thanks to a layer of glue underneath), I put it in a small container of water and let it sit overnight, so I could see how long it took to dissolve the PVA support structures.

I love the intuitive touchscreen on the front of the S5 – it’s very user-friendly, and I quickly figured out how to pull up a rough image of what the print would look like once it was complete, so I’d know that it was printing correctly. Once I pried the tiny print off of the plate (a very easy task thanks to a layer of glue underneath), I put it in a small container of water and let it sit overnight, so I could see how long it took to dissolve the PVA support structures.

I loved the Ultimaker water soluble PVA. It was just so easy – pop the print in water and let the material work its magic. It’s possible to simply crunch and pull the supports off by hand as well, but the immediate effect wasn’t as clean. Obviously, the larger and more complicated the prints were, the longer I had to let them sit in water, and I learned that unless I felt like getting gummy residue stuck to my fingers, it was best to just wait until the supports had 100% completely dissolved. It was also a little tough cleaning the build plate, as the PVA sort of bonded with the glue and became hard to scrub off. But I followed the advice of the Dynamism team and got a soft, non-abrasive sponge to help with this task.

But I followed the advice of the Dynamism team and got a soft, non-abrasive sponge to help with this task.

My next two prints were included Cura files: a star trophy and a rocket ship. Both of these were fairly straightforward prints, and gave me a chance to try out an extra form of bed adhesion with the addition of a brim; I can tell you now I much prefer a skirt, but I figured I would just give it a shot.

The first print I completed that wasn’t already included in Cura or the USB drive was a Harry Potter Logo by Cults3D user 3DNaow, which turned out great. It’s definitely my favorite 3D print from this review, mostly because I love Harry Potter. Because I majorly scaled it down, the print took a lot less time to complete as well.

I’m going to take a moment here to rave about the remote monitoring. I didn’t download the app, but I did not have the S5 set up in my office. I live in an older Cape Cod house, and my office is in the half story upstairs, which doesn’t have great ventilation. So I decided it would be better to put the 3D printer on a table in my dining room, which is in a much more open part of the house. But this meant that I couldn’t keep my eye on it during the day. Having the option to monitor my print jobs from upstairs, thanks to Cura and the camera located above the auto-leveling bed, provided me with peace of mind.

So I decided it would be better to put the 3D printer on a table in my dining room, which is in a much more open part of the house. But this meant that I couldn’t keep my eye on it during the day. Having the option to monitor my print jobs from upstairs, thanks to Cura and the camera located above the auto-leveling bed, provided me with peace of mind.

I would have called this adorable Low Poly T-rex by Thingiverse user slavikk my favorite, had I not screwed it up so badly. I had been messing around in the custom settings in Cura, just to try and put the system through its paces by changing up things like the infill and layer height, and I somehow managed to change the support material from Extruder 2 – the Natural PVA – to Extruder 1 – the Tough PLA. It took me about a quarter of the way into the print to realize my mistake, and by then it was too late. So this dino is still pretty cute, but I think he will be much better-looking when I take the time to get an X-Acto knife and cut away the black supports from the front.

In completing my small collection of low poly animals from Thingiverse, I chose to 3D print a Low Poly Cat – another print by slavikk – and a Low Poly Stanford Bunny by johnny6. I put both the cat and the bunny on the build plate at the same time for a 7.5 hour print. This is where things started to get a little rocky.

About four hours in, an error message popped up on the touchscreen: “One material appears to be empty. Please change it to a new material to continue printing.” I wasn’t home (this became the only time I left the house during a print job) and my husband texted me about it, but said that it didn’t appear that the filament was empty. Once I got home and took a look, it was definitely very obvious that neither filament was empty, so I just took a shot in the dark and pressed ‘Ok’ below the error message to confirm that I had changed to a new material, even though I hadn’t, just to see if it would start up again.

I got lucky and the prints resumed…for about 20 minutes. Then, the same thing happened again, I tried the same fix, and things continued on, though the support material was looking pretty stringy. About an hour later, the connection went out and I lost the monitor view upstairs, but the S5 just kept rolling along.

Then, the same thing happened again, I tried the same fix, and things continued on, though the support material was looking pretty stringy. About an hour later, the connection went out and I lost the monitor view upstairs, but the S5 just kept rolling along.

My next print was an STL file that the Dynamism team had sent me of a generic sample spare part, which took about 15 hours to print, with no supports, when scaled to 100%. It was a good illustration of just how important professional 3D printers, like the S5, can be for businesses in need of prototypes or models. The level of quality and accuracy of the prints produced on the S5 is just stellar, in my opinion. Maybe you should take my opinion with a grain of salt, because as I noted earlier, I’m not an expert on using 3D printers, but that’s up to you.

Realizing that not a single one of the items I’d 3D printed so far were at all useful, I went back to Thingiverse and found this batman earphones holder by itlaor, which quickly printed without any supports and is now being used by my husband, with great appreciation, to keep his earbuds from getting tangled up all the time.

I also decided to 3D print this very detailed Eagle Sculpture by Thingiverse user 3DWP for my husband, who is an Eagle Scout and has a small collection of eagle figurines and sculptures. With this one, I couldn’t get my computer upstairs to connect to the 3D printer downstairs. I turned the WiFi off on both the computer and the printer and then immediately back on, and still nothing. So in the interest of saving time, I simply saved the STL file to the USB drive and printed it that way. About 10 hours in to the 16.5 hour print, I got the same error message I’d received with the low poly animals, and “fixed” it the same way. It seemed to only occur on prints with PVA supports for some reason.

I enjoyed trying out the Ultimaker S5 3D printer from Dynamism. I had it for far longer than I planned, but thoroughly enjoyed using it. What I knew already from writing about this technology daily, and have now had the chance to truly experience for myself, is that 3D printing takes time, which is something I don’t always have in the evenings – I do a decent amount of church and theatre volunteer work. So I kept searching for quick print jobs to try with the S5 because I just do not often have 15-24 hours where I am at my house the entire time. But as for the quality and ease of use – that was top notch.

So I kept searching for quick print jobs to try with the S5 because I just do not often have 15-24 hours where I am at my house the entire time. But as for the quality and ease of use – that was top notch.

The Ultimaker S5 is available for purchase on the Dynamism website starting at $5,995.

Discuss this and other 3D printing topics at 3DPrintBoard.com or share your thoughts below.

[Images taken by Sarah Saunders for 3DPrint.com]

Dynamism Showcases Leading 3D Printers at RAPID + TCT - 3DPrint.com

New advancements in 3D printing are giving manufacturers better options to improve efficiency. To save time and costs, companies are increasing utilization of 3D printing for jigs, figures, and creating parts in-house rather than outsourcing them to third-party manufacturers.

Dynamism offers many of these leading edge 3D printers, with expert pre-sales advice, installation and training, and ongoing technical support. Customers can select printers that use different types of materials to create parts and products, depending on their needs.

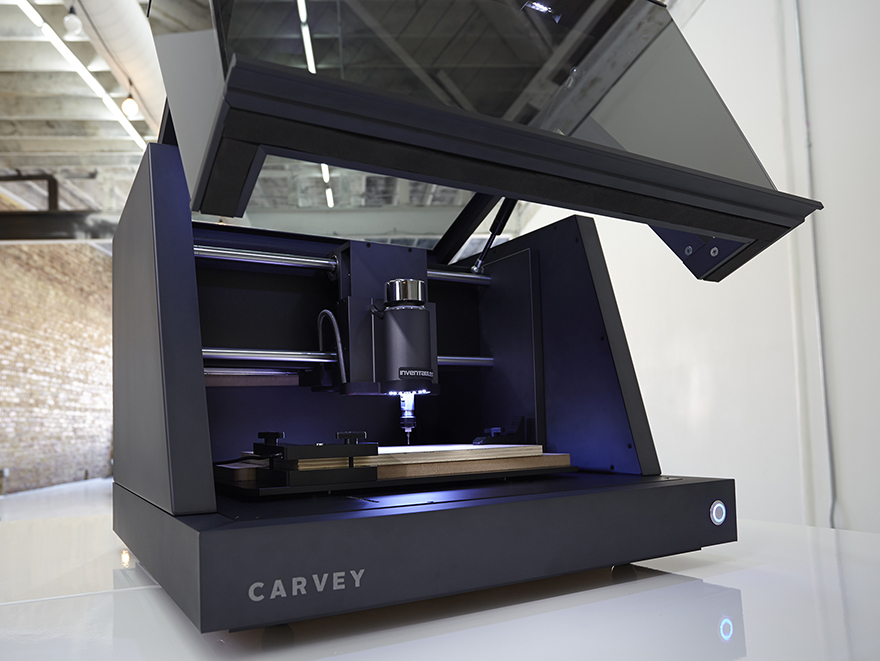

In metal printing (including jigs, fixtures, tools, or prototyping), Desktop Metal is leading a transformation. Its Studio System drastically decreases product development timelines, with rapid prototyping of metal parts. Its Production System portends a revolution in manufacturing.

The Desktop Metal Studio System is currently being used by pioneer customers including, Google’s Advanced Technology and Products Group and the US Navy. Customers can reserve their own system today.

In manufacturing, the upcoming Desktop Metal Production System will move mass production into the age of 3D printing. With that, designers and engineers will have more freedom to design new types of parts and features that are impossible with current manufacturing techniques. To help that transition, Desktop Metal has realized its remarkable (and imagination-inspiring) Live Parts software.

Dynamism is a leading 3D printing solutions provider that helps customers integrate these 3D printing options into their businesses. Many manufacturers have also found success with PLA, ABS, and Nylon printing.

In Europe, Volkswagen Autoeuropa was able to cut its development of special parts down from 56 days to just 10 days by using the Ultimaker 3D printers to create tools, jigs, and fixtures for its Scirocco and Sharan model cars. The cost of production also dropped drastically, with parts that were typically outsourced for €800 being 3D printed in-house for just €21.

Ultimaker has just released its latest flagship product, the Ultimaker S5, which features a wealth of new innovations. The manufacturer has just announced a partnership, with leading chemical companies, to standardize material profiles to provide enterprises using Ultimaker printers with access to a wide range of high-level engineering plastics and composites. Members of the alliance program include DSM, BASF, Sabic, Dupont, Owens Corning, Mitsubishi, Henkel, and Clariant.

Dynamism is now showcasing the Desktop Metal Studio System and the Ultimaker S5 at the Rapid + TCT Show in Ft. Worth, Texas.

Discuss this and other 3D printing topics at 3DPrintBoard.com or share your thoughts below.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: desktop metal • DM Studio System • Dynamism • Studio System • ultimaker • Ultimaker S5 • Volkswagen Autoeuropa

Please enable JavaScript to view the comments powered by Disqus.

3D printing in the creation of modern implants

Implementation stories

Medicine

Author: Semyon Popadyuk

Author: Semyon Popadyuk

Cooperation for the best result | Implants that stimulate bone growth | Application possibilities for 3D printed implants | Model for the future

Spinal implant manufacturer K2M expands its capabilities through a strategic 3D printing partnership with 3D Systems. The specialists of the two companies will jointly develop innovative implants for the treatment of diseases of the spine and explore new ways to create customized implants. nine0003

Effective partnerships arise when each party brings something unique to the project, making the result of cooperation become something more than the totality of the introduced elements. The partnership between K2M and 3D Systems is an ideal example of such collaboration and is based on the two companies' common goal of improving innovation processes and results.

K2M is a world leader in comprehensive and minimally invasive spinal solutions based on the 3D Total Body Balance™ concept. Surgeons around the world use the company's products to treat the most complex pathologies of the spine. nine0003

As part of its desire to expand the range of solutions offered, K2M has attempted to combine its own experience in the treatment of spinal pathologies with the experience accumulated in the industry in the manufacture of high-precision medical devices. 3D Systems was one of the first to join this endeavor.

The company has been one of the leaders in 3D technology for over 30 years and often provides surgeons, healthcare professionals, medical device manufacturers and medical schools with high-precision solutions, including virtual reality surgical simulators, 3D printed anatomical models, Virtual Surgery Planning (VSP®) technology, as well as customized 3D surgical guides, instruments and implants. nine0003

iQB Technologies experts recommend the article: Additive technologies in medicine: how to reduce risks to patients' health

Using the 3D Systems ProX DMP 320 printer and proprietary Lamellar 3D Titanium Technology™, K2M manufactures the CASCADIA™ Interbody Systems series of implants with surfaces that combine both porosity and roughness to promote bone growth

Collaboration for a Better Result

The partnership between K2M and 3D Systems is based on the technological developments that the parties share as well as the cultural values they share, according to Jim Ham, director of marketing for the K2M Total Spine Solutions Group.

“We know everything about the spine, and 3D Systems knows everything about 3D printing, but there are a lot of opportunities for synergy in the way we do our business, in our pursuit of innovation, in our shared corporate goals and desire to improve the lives of patients.” nine0003

K2M started out as a developer of new technologies and devices for the treatment of spinal deformities. The introduction of 3D printing has allowed the company to expand beyond deformity treatment into the rapidly growing market for products for the treatment of degenerative spinal diseases using minimally invasive procedures.

“We need the capabilities of 3D printing to further develop our portfolio of degenerative pathologies and minimally invasive procedures, and 3D Systems has provided us with these capabilities,” explained Mr. Ham. “The partnership with 3D Systems has strengthened our leadership position in 3D printed spine products, allowing us to tap into a wider market and fueling our growth over the past few years.” nine0003

K2M 3D printed products are manufactured using 3D Metal Printing (DMP) technology developed by 3D Systems. While this technology is new to K2M, it is well established in precision medicine, explained Tim van Kleinenabrugel, director of healthcare business development at 3D Systems in Leuven, Belgium.

“More than a decade of experience and 500,000 manufactured pieces prove that metal 3D printing using a laser beam is very well suited for the manufacture of organically shaped spinal implants with a porous structure,” Van Kleinenbrügel said. nine0003

Bone stimulating implants

3D Systems provides design consulting, 3D printing and post-processing services for the FDA-certified K2M CASCADIA family of vertebral implants. In 2016, CASCADIA's rapidly growing product line was recognized by Orthopedics This Week with its annual Spine Technology Award. nine0003

CASCADIA implants are manufactured using ProX DMP 320 printers and K2M's latest Lamellar 3D Titanium Technology™. Using traditional technologies, such products cannot be produced.

Metal 3D printing (DMP) technology is an excellent solution for creating porous structures and natural shapes similar to those used in K2M vertebral implants

Implants are made from titanium powder by selective action of a high-energy laser beam - in this way, porosity and surface roughness are simultaneously achieved, ensuring bone tissue growth. Although the products have the strength of titanium, they transmit X-rays, allowing surgeons to better see how the implant interacts with adjacent body tissues. nine0003

K2M products using Lamellar 3D Titanium technology include CASCADIA TL, AN, Lateral, AN Lordotic Oblique and Cervical Interbody Systems implants. The manufacturing process used by 3D Systems to manufacture them includes not only 3D printing, but also post-processing - heat treatment, surface treatment, cleaning and laser marking - that is, everything that is necessary to obtain a finished product.

Tom Morrison, a neurosurgeon at the Polaris Center for Neurosurgery and Spine Surgery in Atlanta, Georgia, has been using CASCADIA Interbody Systems implants for over a year. nine0003

“Lamellar 3D Titanium technology never ceases to amaze me,” says Dr. Morrison. “Porosity and surface roughness are of great importance from a biological point of view, and the results of long-term follow-up of my patients confirm my impressions. I am very enthusiastic about the use of CASCADIA Interbody Systems implants and will be very excited about the new possibilities of using K2M's Lamellar 3D Titanium technology to stimulate bone growth. ” nine0003

TASK

- Creation of innovative methods for the treatment of diseases of the spine.

SOLUTION

- A global partnership that combines K2M's extensive experience in the creation of spinal implants with 3D Systems' advanced metal 3D printing technologies.

RESULTS

- Manufacturing a rapidly growing line of CASCADIA™ Interbody Systems implants with porous and rough surfaces that promote bone growth. nine0062

- Using Virtual Surgery Planning (VSP®) and 3D printing an experimental device for a patient with no other treatment option.

- Enabling development of other areas, such as innovative custom spinal implants.

Application options for 3D printed implants

A recent example of effective collaboration between K2M and 3D Systems is a project in which 3D Systems provided Virtual Surgery Planning (VSP®) and, together with K2M, created an experimental device used in those rare situations where there are no certified alternative treatments for the patient. nine0003

The process began when Sean Reynolds, project manager at K2M, spoke about the company's latest developments with Dr. Michael Finn, a neurosurgeon at the University of Colorado who specializes in spine disorders.

A collaboration between K2M and 3D Systems has resulted in a 3D-printed experimental metal implant that could serve as a model for new applications for metal 3D printing. nine0003

Dr. Finn had a patient who he thought would be a good candidate for a 3D printed implant. The patient had previously undergone surgery, but the recovery process was slow and the patient suffered from limited mobility. At that time, there were no alternative products on the market that could help the patient. Dr. Finn concluded that removing the implant from the last operation and replacing it with a 3D printed implant would be the best treatment tactic. nine0003

“This part of the body is under significant stress, so the patient did not recover well,” Dr. Finn explained. “I thought that a 3D-printed implant would give the patient the best chance of recovery.”

Based on the results of the spine scan and a web consultation with K2M and Dr. Finn, 3D Systems developed a virtual surgical plan. As a result of the cooperation of the three main project participants, the implant design was developed and the type of screws for its fastening was selected. nine0003

From Dr. Finn's point of view, the operation was a success, and the collaboration between K2M and 3D Systems is one example of success: “I was impressed by the dynamism of both companies. They really focused on building this product in a timely manner. K2M is able to develop innovative solutions for complex surgical procedures, and 3D Systems has a lot of experience in solving such problems, so this project was not too difficult for them.”

nine0026 Model for the future For Sean Reynolds and K2M, the collaboration between the two companies at a critical stage in pre-surgery was an exciting prelude to a promising new line of work - the provision of surgical planning services and the manufacture of customized implants for the treatment of complex degenerative diseases of the spine.

Although experimental devices are rarely used, the approach used in the case described above may in the future become a model for the manufacture of individualized implants for a particular patient. These will be implants approved by the US Food and Drug Administration for production within certain specifications based on the needs of the patient. nine0003

“Based on our experience with 3D printing, we believe that in the future, 3D printed custom-made spinal implants will be widely used in the treatment of not only complex cases, but also degenerative diseases,” said Reynolds. “We are very pleased and excited about the prospects for future collaboration with 3D Systems.”

Translation from English. The original of this material is on the 3D Systems website.

nine0002Article published on 04.12.2017, updated on 04.03.2022

French 3D Printing Designers to Watch in 2017・Cults

Have you just bought a 3D printer and don't know which 3D models to download to work with it? At Fichier3D. fr we have compiled a small list of top French 3D designers who are doing really cool and creative things with their 3D modeling software . All French designers were selected from among the members of the French platform Cults . If you'd like to suggest other profiles, feel free to post them in the comments. This is a list of 20 artists and is by no means a ranking. Indeed, the universes are very different from each other, so it would be unthinkable to rank them :)

1 - Cirion, a photography-inspired designer.

This designer from Rennes offers 3D files inspired by his work as a photographer. In terms of 3D printing, he works a lot with wood effect, which gives his creations a very natural style. Some of these projects are based on the city and animals. You can download Cyrion's STL files from his Cults3D page, or follow his projects on the Tumblr blog. nine0003

2 - Yoda3D, Yoda 3D printing.

A true fan of the Star Wars universe, Cedric Lohier (real name) doesn't limit himself to designing 3D Yodas, but invents and creates real characters from a universe close to science fiction. If you are an action figure collector or just want to bring a little fantasy to your little cousin's toy box, we advise you to download Yoda3D 3D Models immediately. You can also check out his YouTube channel to see his turntables. nine0003

3 - Thierry3D, actor bust specialist.

Are you a movie buff and want to have a bust of your favorite actor on your desk? Then don't wait any longer, go and visit Thierry 3D's 3D Files on Cults, maybe you will find what you are looking for! The faces are very realistic, so much so that it looks like they were scanned in 3D. Mythical actors such as Harrison Ford or Arnold Schwarzenegger can be seen next to fictional characters such as Frankenstein or Nosferatu. The only thing that is a pity is that there are no photos of prints, only renders. nine0003

4 - Dantego, 3D printed game kit.

Dantego, aka Hugo Parinello, is a young designer who is very active in the world of 3D printing. He divides his time between 3D modeling and his Dagoma 3D printer, on which he makes many prints and tests. His universe is inspired by video games as well as Egyptian mythology. Super creative, Dantego is not shy about sharing his talent by offering live videos on his Twitch channel. His video game related work can be seen on his blog and his 3D files can be downloaded from his Cults page. A designer we should definitely keep an eye on in 2017! nine0003

5 - 3DVision, superheroes in all their states.

French designer 3DVision offers many 3D models with cool renderings. This freelance graphic designer has a passion for 3D and stress tests for Sculpteo. The cool thing is that it combines both fan art and usefulness. For example, there are many stands for tablets or phones in the colors of Batman or Superman. The series where Angry Birds characters intersect with the Transformers universe is just hilarious! Go to 3DVision's company profile to download their quality 3D models. We also look forward to photos of his prints :)

6 - OM3D, a designer who brings everyday objects to life.

Olivier is a very sweet French designer who often has fun using ordinary objects to create original and poetic creations. For example, a headphone coil will suddenly take on the appearance of a bone, or a toothpick holder will naturally turn into a cactus. Full of humor and ease of 3D printing, free OM3D 3D models can be downloaded from his Cults page. A designer you simply have to discover! nine0003

7 - Jean-Fabric, the art of creating STL files without support!

Jean-Fabrique first worked as a machining technician before moving on to 3D design. Therefore, he creates fun creations straight from his artistic mind with great spirit and impeccable dedication. We especially like the copy of the Tegenaria Domestica spider, which is sure to inspire the biggest pranksters. What we love about Jean-Fabric's 3D models is that they can be printed without support and tested on his Prusia i3 3D printer. The staging of his 3D files is also smart with all those GIFs that add dynamism and fun to his work! nine0003

8 - Seb2583, your 3D garden friend.

Sebestyen's creations are an absolute must for any self-respecting geek gardener! This DIYer, passionate about his garden, has created a series of 3D printed seedling indicators to help you navigate all your plans. Indeed, the problem is to remember what is planted in which pot and with which paper, because if it rains, they wither or fly away. There are 3D files for several fruits and vegetables such as carrots, cabbage, beans, broccoli, etc. We also like the watering can apple, which is very practical if you need to repair your watering can. All STL models of Seb2583 can be downloaded from his Cults page. nine0003

9 - Mageli, Pirate Designer

Trained as an engineer, Maelig Pommere, whom we interviewed, expresses all his creativity under the anagrammatic pseudonym Mageli. The general theme of his work is centered on subjects related to childhood. He announces his desire to show his children that there is an alternative to disposable consumption, he is working more and more on 3D printing as a way to reuse, transform, diversify products using a minimum amount of thread. All of these great free 3D files can be found on his Cults page. nine0003

10 - ThomasDC, your office ally.

If you want to increase the comfort of your work, Thomas De Cicco's 3D models are for you! This former student at the Gobelins school in Paris created stands that allow you to lift your computer and thus get a slightly tilted keyboard. The dual pen hinge is also super ingenious and will come in handy if you want to impress in the gallery with your embossed notes :) To see more of his design work, you can visit his personal website here or just download his STL files at Cults. nine0003

11 - PLP, low poly pug specialist.

French designer PLP has a passion for his dog, a pug named IODA, and has created a series of key rings and figurines that look like stylized, low-poly pugs. It looks like a scarecrow of a brand or a cartoon character, this creation is so charismatic. We also particularly like how Pierre-Louis adapted the special shape of the gorilla into 3D. In short, take a look at the PLP arch, you won't regret it! One of the 3D designers to keep an eye on this year. nine0003

12 - JJB, Geo Trouvetou from 3D printing.

Jean-Jacques Bodin is a very prolific 3D designer who comes up with a range of cool and useful gadgets that can be 3D printed. On his Cults profile, you'll find tons of 3D files to download, from eyeglass holders to Montcuuc city magnets and F1 helmet-shaped pencil holders! One of his most notable creations is the 3D adaptation of the Tintin rocket, which is an outstanding achievement both in terms of 3D modeling and printing! nine0003

13 - JP-Design, jeweler for your 3D printer.

This French 3D designer loves to create 3D models with elegant lines that are perfect for 3D printed jewelry. There are Voronoi style rings, wire rings and bubble rings. The artist plays with a variety of geometric shapes, varying 3D files of rings, pendants and even cups with original designs. We highly recommend that you visit his Cults page to check out all of his 3D models. nine0003

14 - Objets Imprimés, connect your furniture with 3D printing.

Objets Imprimés is a young home furnishings brand that uses 3D printing to create unique and original creations. Objets Imprimés' 3D models seek to take advantage of this technology by bringing all of its precision into the small, intricate details that make up the structural components of products. Thus, we find fasteners to create a soliflor or a lamp using tansy. The STL files designed by Jean-Baptiste Riccutte can be found on his Cults profile. nine0003

15 - Making Perso, a real crazy inventor.

He defines himself as a craftsman, a jack of all trades, who is not afraid of the cold, and it's not for us to argue with him! Fabrication Perso's creations are the work of a true craftsman who draws his inspiration from the world around him. Nothing scares him and he makes great prints! If you want to see what a creative craftsman's desktop looks like, check out Fabrication Perso's digital curiosity cabinet - you won't be disappointed! nine0003

16 - BoxPlyer, a playful tinker.

BoxPlyer is a very prolific French 3D designer and creator. It offers us a lot of free 3D models, each as perfect to print as the other. We can feel a passion for old-fashioned toys like this gorgeous bilbock brought up to date, or fun little puzzles to pass the time, or just little 3D spinners. But that's not all, because in this real digital garage you can find a lot of useful and ingenious items, such as parts for drones, sand yachts or clothes hangers! nine0003

17 - KreaPrint3D, elegant designs of the highest quality.

KreaPrint3D defines itself as a new 3D printing enthusiast and uses its Ultimaker for custom 3D printing as a side business. Visit her personal website for a list of her services. Great idea as KreaPrint3D also offers very subtle and applied designs for download. Proof of this is a series of trophies for laborers, his baroque chairs or cabaret-style corsets. See all of his other STL files on his Cults profile. nine0003

18 - Proxia, French manufacturer.

Patrick Robin is a well-established designer who makes a wide range of products, from decorative items to parts and games. We especially remember his wonderful fun that allows you to personalize table football players with a effigy of Darth Vader or a stormtrooper. As you can see, Proxya is full of ingenuity and talent, so we highly recommend you check out its library of 3D printer files. nine0003

19 - Cromagnon, flag bearer of the electronic factory.

Jean-Charles Rodinger is not only a talented designer, but also a person who has his own vision, his own philosophy regarding the society in which we live. We invite you to get to know its movement and the Cromagnon brand on the spot. Luckily, he was willing to share some of the 3D fantasy objects he designed.