Uvu 3d printing lab

Art Computer Lab | Department of Art & Design

Lab Hours

GT 334

Open lab hours

M-W 8a - 11a, 4:30p -8p

T-Th 5p - 8p

F Available upon request

GT 511e

Open lab hours

M-W 8a - 10a, 3:30p -7p

T-Th 8a - 10a

F Available upon request

GT 511g

Open lab hours

M-W 8a - 10a, 12:30p -4p

T-Th 8a - 10a, 3:30p - 7p

F Available upon request

GT 516c

(A&D Print Lab)Open lab hours

M-W 8a - 4p, 4:30p -8p

T-Th 9a - 11:30a, 12:30p -8p

F 10:30a-3:30p

GT 537

Open lab hours

M-W 8a - 10a

T-Th 8a - 4p

F 10a - 2:30p

GT 539

Open lab hours

M-W 8a -10a, 12:30p - 4p, 6p - 8p

T-Th 9a - 10a, 12:05p - 1p, 3:05p - 4p, 6:05p - 8p

F 10a - 2:30p

GT 543

Open lab hours

M-W 10a - 2p, 4p - 5p, 7p - 8p

T-Th 8a - 11:30a, 1:30p - 2:30p, 4:20 - 8p

F 10a - 2:30p

Adobe tutors available:

Adobe tutors are available on Mondays and Wednesdays from 2p - 4p and Fridays from 10:30 -3p.

For more information about Adobe tutors and to sign up, inquire in Art & Design print lab, gt516c. (801 863-6930)

Linked in Learning instructional videos are also available for UVU students. For information about UVU's Linked in Learning, use this weblink: https://www.linkedin.com/learning/

UVU Student computing is a great resources for students to gain Mac & PC computer access with the Adobe software. UVU Student Computing information.

Art & Design Labs Closure Dates:

- September 5 - Labor Day

- October 13-15 - Fall Break

- November 21-26 - Thanksgiving Holiday

- All Art & Design computer labs and print lab will close at 4p on Thursday December 11, 2022 for Fall semester and will not reopen until Monday January 9, 2023.

These dates are based off of the: 2022 UVU Fall Schedule

*hours are subject to change without notice.

Window Mat Cutting for students is available by appointment.

Window Mat Cuts are available by appointment. Window cuts cost $1.00 per window. Mat boards need to be cut down to their outer dimensions and students will need to know the dimensions of their window sizes that they need cut prior to appointment. Here is a pdf file that can be used to fill in the width and heigth of the mat boards and window cuts: matboard window cut template.

For window mat cutting appointments, please contact Phil Ah You via this link: Message Phil or you can find his contact info from this link: Phil Ah You's UVU professional page.

A&D Lab Software

current Lab Software

- Adobe Creative Suite

- Cinema 4D (students can purchase subscription via UVU.

onthehub.com.)

onthehub.com.) - ZBrush

- Microsoft Office

Adobe Software Info

To access student Adobe software use this page: https://www.uvu.edu/desktopsupport/adobe.html

Lab Rules

General

- No food or drink in the labs (water is a drink).

- Lab use is for currently enrolled A&D students and for A&D course/project use only.

- No children in labs or hallways (with or without adult supervision).

- Use headphones when your course projects involve noise/sound.

- Store your files on removable media NOT on lab devices.

- Please Log Out or Shut Down your computer when you are through.

Internet Use

- Do not misuse the internet.

- No non-related A&D project-related internet use. No computer games, use of peer-to-peer networks, Torent or other media content downloads, and no personal social networking.

- No copying of software (onto, or off of computers).

Lab Use During Courses

- Use only during class time if you are currently enrolled in the course being taught.

- Use devices only for direct in-class activities and only with instructor approval.

Art & Design print lab information (GT 516c)

- Accepts credit cards and Debit Cards only (no cash or checks).

- UVU Print Credits can be used only for letter sized black & white.

- Print and save work 15 minutes prior to labs closing.

A&D Computer Lab Mission and Objectives

Printing of specialized substrates such as labels and transparencies must have manufacture box and be approved by lab manager.

All printing must be paid for with debit or credit card, (no cash accepted).

Ink-jet prints must be paid for prior to printing.

The Art Print lab is intended to support art students and Art & Design projects. The Lab manager, area coordinator, and department chair must approve printing projects that are in question. (Faculty shows, event posters, and print for promoting the department)

All department printing must have an approval form signed by Lab Manager, Area Coordinator, and Department Chair, as well as an approved banner number.

Faculty and staff personal work must either be approved by Department Chair for faculty development funds or paid for with credit/debit card.

No drop of printing, except for the Epson P7000. All Files must be print ready.

The Lab does not provide for color correction and color adjustment. Test prints are recommended for ink-jet printers.

A&D Print Lab Location & Contact

The A&D Print Lab is currently located in GT516c.

Phone: 801 863-6930

Lab Print Pricing

Laser Print Pricing

28lb Bright laser paper:

8.5 x11 = .15 11 x 17 = .20¢

8.5 x 11 (B&W) = .20¢ 2 sided =.30¢

11 x 17 (B&W) = .35¢ 2 sided = .50¢

8.5 x 11 = .25¢ 2 sided =.35¢

11 x 17 = .35¢ 2 sided = .50¢

Card Stock/ 80# Cover:

8.5 x 11 = . 28¢ 11 x 17 = .35¢

28¢ 11 x 17 = .35¢

12 x 18 = .38¢

8.5 x 11 = .35¢ 2 sided = .60¢

11 x 17 = .50¢ 2 sided = .70¢

12 x 18 = .55¢ 2 sided = .75¢

(No discount for Cardstock B&W)

XYRON

8.5 x 11 = $1.00

11 x 17 = $2.00

Photo Sleeve

8.5 x 11 = 25¢

11 x 14 = 35¢

13 x 19 = 45¢

16 x 20 = 65¢

Ink Jet Print Pricing

LASAL Luster/Matte = 4¢ Per square inch

Entrada/Satine = 41/2¢ Per square inch

Ink Only = 3¢ Per square inch

Plotter Epson Matte= 31/2¢ Per square inch

Precalculated Costs by Size

5 x 7 = $2.05 (Lab paper) or $1.05 (Ink only)

6 x 9 = $2.62 (Lab paper) or $1.62 (Ink only)

8 x 10 = $3.20 (Lab paper) or $2.40 (Ink only)

11 x 17 = $7.48 (Lab paper) or $5.61 (Ink only)

12 x 18 = $8. 64 (Lab paper) or $6.48 (Ink only)

64 (Lab paper) or $6.48 (Ink only)

13 x 19 = $9.80 (Lab paper) or $7.41 (Ink only)

16 x 20 = $12.80 (Lab paper) or $9.60 (Ink only)

Test Prints 2"x2" @ $.20 ea

Coil Binding

Coilbinding = $2.00

Metal Foil

Metal foil = .50¢ Per square inch + plus laser print cost.

Vinyl Cutting

50¢ Per inch

Blank PHOTO Paper Pricing

Luster/Matte

8.5 x 11 = $1.00 13 x 19 = $1.90

Entrada/Satine

8.5 x 11 = $1.60 13 x 19 = $3.20

EZ Mount

12 x 24 = $1.00

Mat Board Pricing

Black

16 x 20 = $4.00 32 x 40 = $12.50

Natural

16 x 20 = $4.60 32 x 40 = $16.50

13 x 16 = $3.15

Hinging Tape

16" = 70¢

PHOTO CORNERS

Full square (8) = $2.00

half square (4) = $1.00

window Mat cuts

(By appointment only)

$1. 00 per window cut

00 per window cut

Step 2: Nail the Solution | Entrepreneurship

Destination 3: Product Development

Summer Acceleration Program

Launch & Accelerate will take place from May 16, 2018 to August 1, 2018 with a final pitch event on August 8, 2018. Classes will be held weekly on Wednesdays from 9-Noon, including instruction, workshops, and one-on-one consultations with instructor Ralph Little and others. Everyone admitted to the program will have access to the free student incubator space in the Business Resource Center (BRC) located just south of UVU behind the Hampton Inn. Free parking will be provided at the BRC.

Learn More

ENTR 4300: Strategic Innovation

Focuses on developing every element needed to create an actionable business plan, with a special emphasis on business model generation, marketing, and finance. Emphasizes writing a comprehensive business plan and should be able to competently manage a small business or start their own with a minimum risk of failure.

Emphasizes writing a comprehensive business plan and should be able to competently manage a small business or start their own with a minimum risk of failure.

Register Today

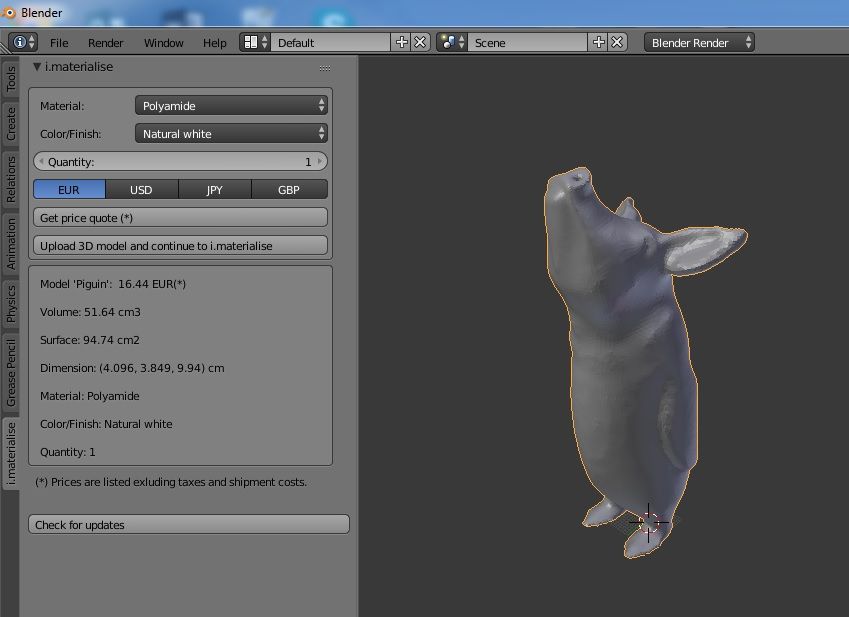

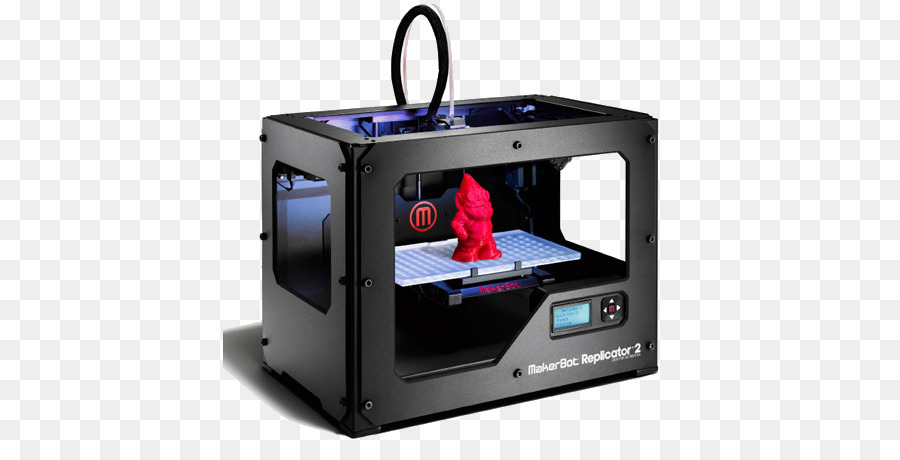

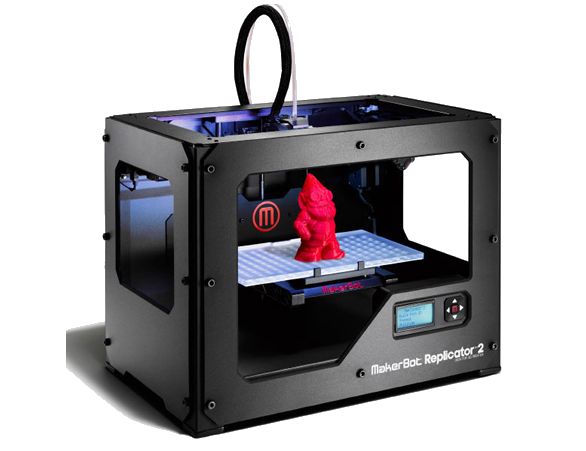

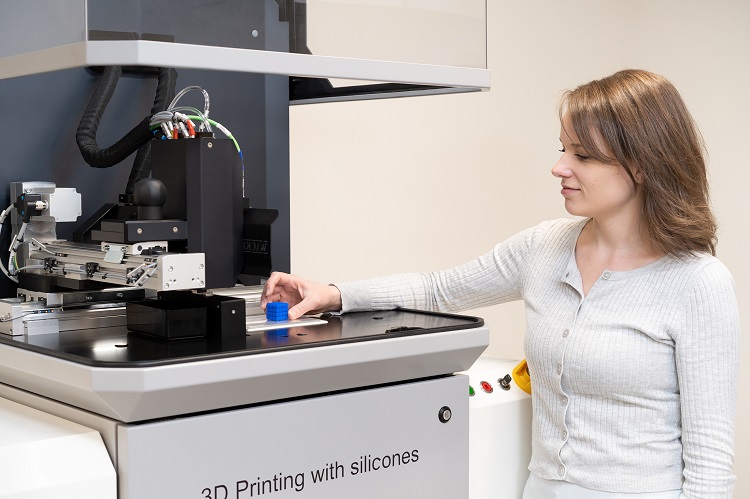

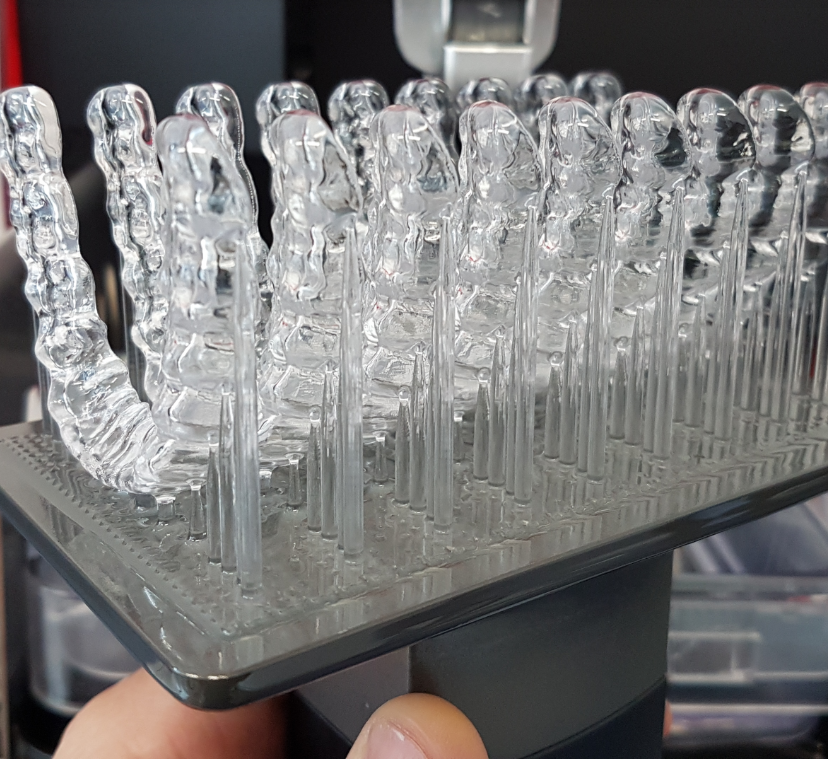

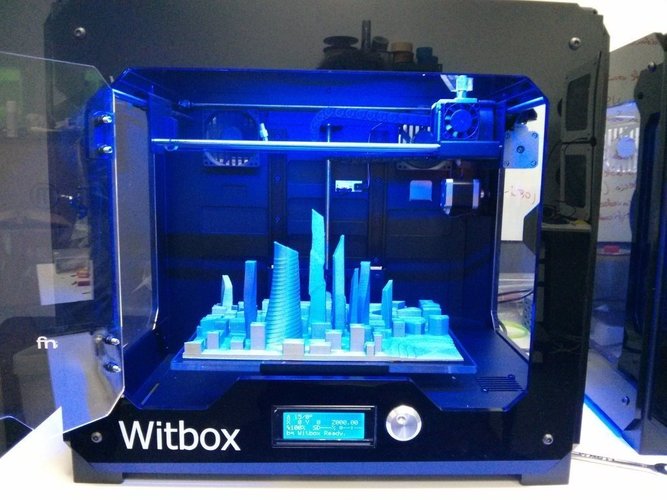

UVU 3D Printing Lab

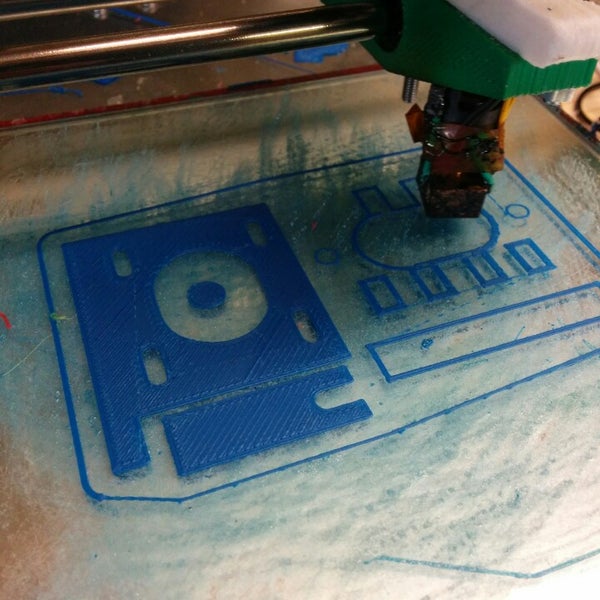

Making prototypes can help you, your target market, and potential investors visualize your idea. We have 3D printing, scanning, and laser cutting we can offer to all students at UVU to help them prototype their products and designs. The lab is happy to help with any digital modeling you require as well. Our students are the drafters and designers using this technology in industry.

Want to learn how to use modeling software? EGDT 1071 is a course with no prereqs that teaches students how to use the modeling software for mechanical and product design.

Learn More

Additional Resources

Websites

- https://Wix.com - Build a website or online store

- https://Weebly.com - Build a website or online store

- https://www.squarespace.com/ - Build a website or online store

Other

- https://www.fiverr.com/ - Get cheap help developing whatever you need developed

Organizations

- Business Resource Center - The BRC has several resources to help community members start their businesses

Go to Step 3: Nail the Go-to-Market Strategy

Let's do it!

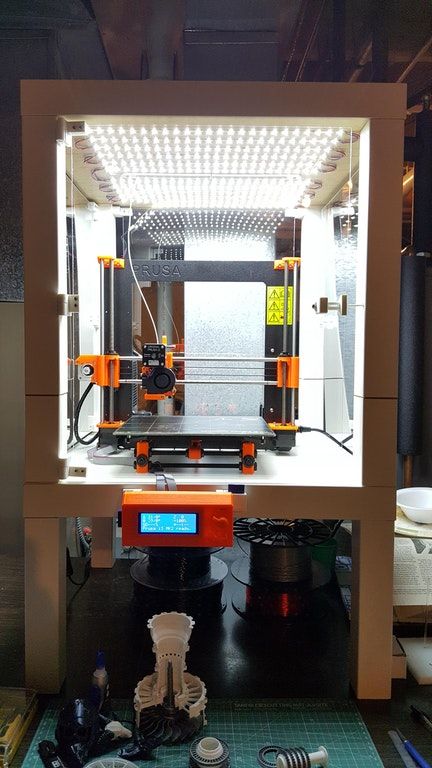

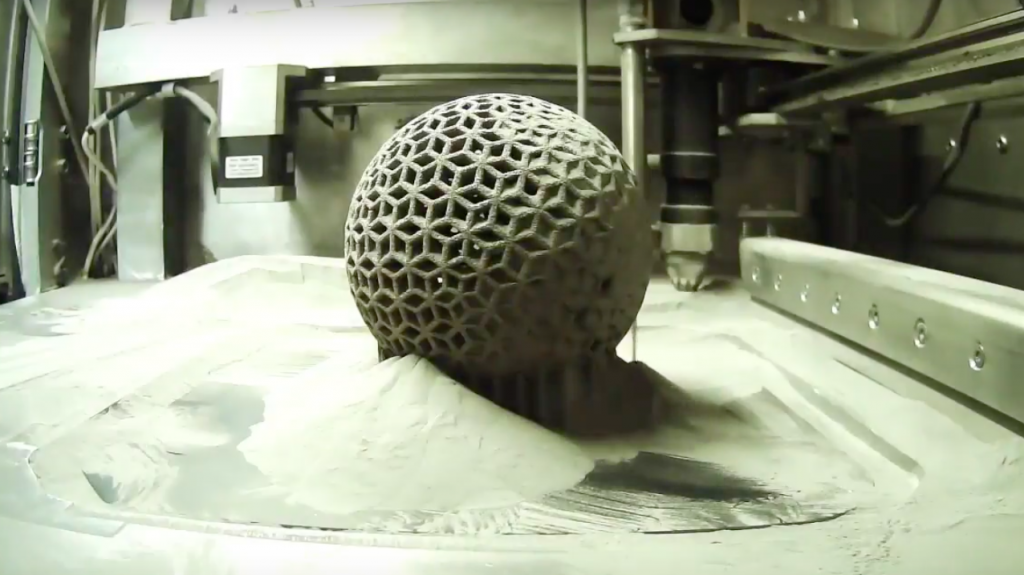

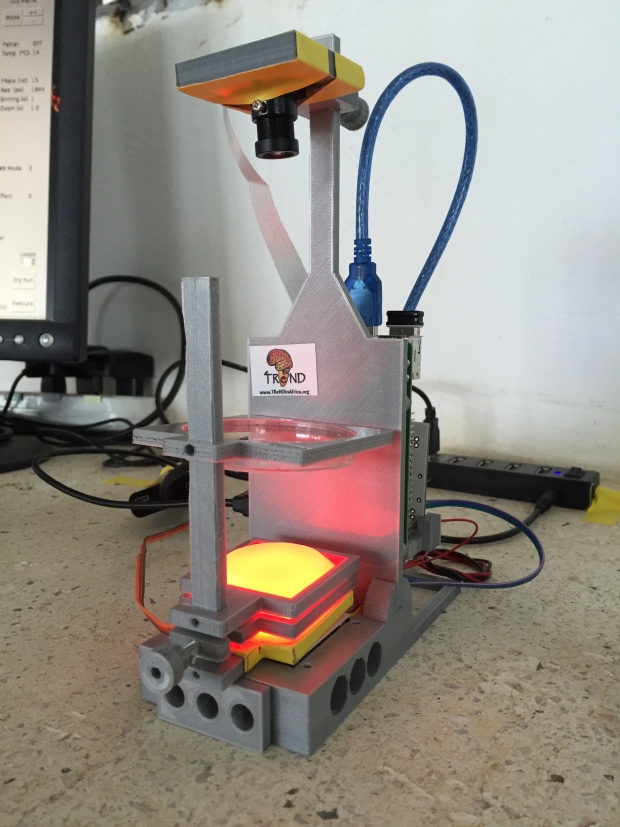

3D printing laboratory - All about plastics - education, technology, perspectives

Prototyping and modeling using 3D printers has recently become more and more widespread. This is due not only to the development and cheapening of equipment for creating three-dimensional models, the emergence of new polymeric materials for three-dimensional printing, but also the emergence of the need for such modeling for medical products, aircraft parts, instrumentation, automotive and aircraft manufacturing, as well as souvenirs. and other areas. The use of polymeric materials for structural purposes for prototyping made it possible to produce not only models, but also small batches of technical products.

This is due not only to the development and cheapening of equipment for creating three-dimensional models, the emergence of new polymeric materials for three-dimensional printing, but also the emergence of the need for such modeling for medical products, aircraft parts, instrumentation, automotive and aircraft manufacturing, as well as souvenirs. and other areas. The use of polymeric materials for structural purposes for prototyping made it possible to produce not only models, but also small batches of technical products.

According to the recent study “3D Printing Market (2013-2020)” published by Markets and Markets (“M&M”), between 2013 and 2020, the annual growth of the 3D printing market will be 23%, resulting in will grow to 8.4 billion US dollars by 2020 (http://www.orgprint.com/wiki/3d-pechat/obzor-tehnologij-3D-pechati).

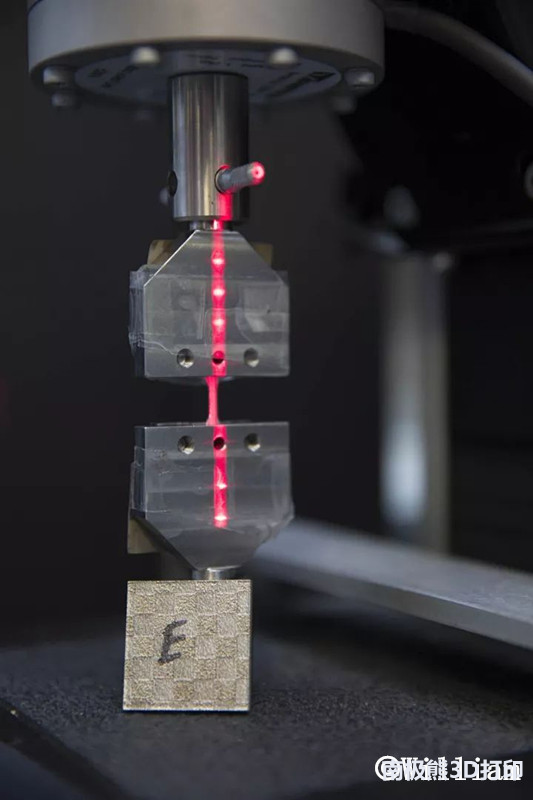

3D printing is a technology for creating three-dimensional objects from a digital sample (CAD) by layer-by-layer application of additive materials. 3D printing methods include stereolithography (SLA), powder laser sintering (SLS), electron beam melting (EBM), layer-by-layer printing with molten polymer thread (FDM), formation of three-dimensional models from layer-by-layer sheet material (LOM) and others.

3D printing methods include stereolithography (SLA), powder laser sintering (SLS), electron beam melting (EBM), layer-by-layer printing with molten polymer thread (FDM), formation of three-dimensional models from layer-by-layer sheet material (LOM) and others.

Initially, 3D printing was used exclusively for prototyping objects, but recently a radical step has been taken towards production. Automotive, aerospace, medical, and consumer products are among the industries that are actively embracing 3D printing. According to M&M, 3D printing in medicine and aerospace will grow exponentially in the near future. 3D printing has significant growth potential, it is indispensable where piece production of personalized products is needed.

This article touches upon some aspects of 3D printing, which is carried out by layer-by-layer printing with a melted polymer thread (rod).

Layer-by-layer printing with a molten polymer thread , also known as Fused Deposition Modeling or simply FDM, is used to obtain single products that are close in their functional characteristics to serial products, as well as for the manufacture of investment molds for casting metals.

The main polymer materials used in FDM technology in Russia are ABS plastic, PLA (polylactide), to a lesser extent polyamide (PA-12 or PA-11), TPU, PET-G and a number of other polymers. Almost all polymeric materials are imported.

High impact polystyrene (HIPS) is used as support polymers. This material is used for printing ABS plastic, PMMA, PET-G. Polyvinyl alcohol PVA (PVOH, PVA or PVAL) is also used as a support polymer, however, due to the water solubility of this polymer, it is more difficult to obtain a thread from it, modification of the standard technology is required.

At the Interplastica-2018 exhibition, work was announced on the synthesis of special grades of structural polymer materials for 3D printers at the Kabardino-Balkarian State University (PSU, PFS, etc.). In the report of KNRTU (Kazan), the topic of using PP filament for 3D printing was mentioned, which is not surprising, since in the Republic of Tatarstan a wide range of PP grades is produced by Nizhnekamskneftekhim PJSC. The problem with polyolefins in printing is associated with poor adhesion to the 3D printer substrate and high shrinkage when cooled.

The problem with polyolefins in printing is associated with poor adhesion to the 3D printer substrate and high shrinkage when cooled.

FDM printing technology is as follows: a polymer thread is fed into a heated head with a controlled temperature, in the head it is heated to a melt state and the resulting thermoplastic modeling material is fed with high precision in thin layers onto the working surface of a 3D printer. The layers are applied on top of each other, joined together and cooled, gradually forming the finished product.

The diameter of the nozzle through which a thread with a diameter of 3 or more often 1.75 mm is fed is 0.3-0.4 mm in the first case, and 0.1-0.3 mm in the second case. Therefore, the requirements for a polymer thread should be quite stringent in terms of sizing (thickness variation), stability of rheological properties (melt flow), melt purity (presence of impurities or contaminants).

1 shows the scheme of printing polymer thread FDM

1. Flow chart of 3D printing by FDM polymer filament printing.

Flow chart of 3D printing by FDM polymer filament printing.

The production of thread (rod) for FDM technology is carried out on extrusion plants for extruding rod, including a dryer, an extruder, usually a single-strand extrusion head, a calibrator (if necessary), a cooling bath, a gauge for the thickness (diameter) of the thread, 2 (rarely 4 -x positional) bar winder on the coil. There is a lot of information on the Internet about homemade filament extruders, as a rule, of low productivity and low quality filament. However, the production of thread must be carried out on specialized extrusion lines.

A diagram of such a line is shown in fig. 2.

Fig. 2. Extrusion plant for the production of polymer thread

I would like to note that for the wide development of FDM technology in our country, it is necessary to clearly define the characteristics of polymer materials that determine the possibility of their use in 3D printing technology with a polymer thread, as well as to synthesize or modify industrial polymers in order to obtaining material with the required characteristics. In particular, both thermophysical properties (for example, the thermal diffusivity coefficient, which determines the cooling rate of the material), and rheological properties (fluidity at different temperatures), as well as temperature parameters of the weldability of layers depending on the properties of the feedstock, etc., should be taken into account.

In particular, both thermophysical properties (for example, the thermal diffusivity coefficient, which determines the cooling rate of the material), and rheological properties (fluidity at different temperatures), as well as temperature parameters of the weldability of layers depending on the properties of the feedstock, etc., should be taken into account.

3D printing of teeth and other products

Home

Top 3D Shop Dental Laboratory

Top 3D Shop Dental Laboratory

Top 3D Shop Laboratory manufactures a full range of dental products using additive and classical methods, materials and equipment from leading manufacturers: crowns and implants, bridges and caps abutments, inlays, frames and beams, clasp, veneers, caps, surgical templates, models. templates

implants

Bugels

We take STL files with any intraoral scanners:

9000 9000 9000 9000

Workpiece materials:

- Wax

- Titanium

- Ceramic

- Cobalt Chrome

- Zirconia

- Polyetheretherketone

- Polymethyl methacrylate

- Composites and specialty materials from leading manufacturers

Implant systems:

- ABDental

- Adin

- AlphaBio

- Ankylos

- Antogyr

- Astra

- Bego Semados

- BioHorizons

- Biomet 3i

- Biotech

- Conmet

- CSM

- C-Tech

- Dio

- Impla Conical

- ImplaSchutz

- Implantium

- Impro

- LIKO-M

- Medentix

- Megagen

- Mis

- NeoBiotech

- NIKO

- Nobile Active

- Nobel Branemark

- Nobel Conical Connection

- Nobel_Replace

- Osstem

- OT Medical

- Radix

- Renova

- Sic

- Sin

- Sky Bredent

- TBR

- Xive

- Zimmer

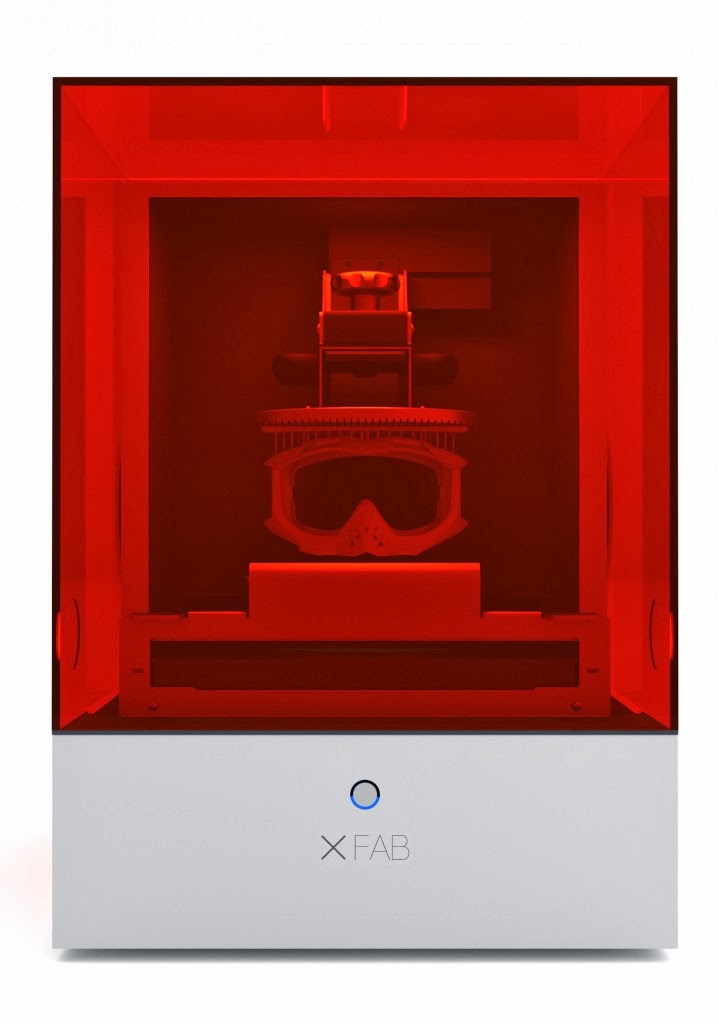

3D dentistry - new in the world of dental technology

A prosthesis on a 3D printer is no longer a fantasy, but a completely familiar and ordinary solution to many issues related to prosthetics. Now, many modern advances are used in dental clinics, thanks to which it is possible to solve problems as simply as possible and much cheaper than it was before. Unfortunately, not everyone has access to 3D dentistry, since such equipment requires additional costs and the ability to work with special equipment. But our services can be considered a way out of the situation, because we represent the whole range of work that a dental laboratory can perform. Our only difference is the 3D technologies used, thanks to which it is possible to print almost any products and designs.

Now, many modern advances are used in dental clinics, thanks to which it is possible to solve problems as simply as possible and much cheaper than it was before. Unfortunately, not everyone has access to 3D dentistry, since such equipment requires additional costs and the ability to work with special equipment. But our services can be considered a way out of the situation, because we represent the whole range of work that a dental laboratory can perform. Our only difference is the 3D technologies used, thanks to which it is possible to print almost any products and designs.

The production of abutments, crowns or bridges can be quite time consuming using classical methods. The manufacture of dentures and other products in a modern laboratory equipped with appropriate equipment is a completely different direction, which allows you to reduce the cost of the process as much as possible, but not reduce the quality of the products obtained. Even artificial gums, thanks to printing in a private clinic, are not a problem - all activities in our dental laboratory are carried out quickly and professionally.