Uv photocuring lcd 3d printer

ELEGOO Mars UV Photocuring LCD MSLA DLP 3D Printer – ELEGOO Official

ELEGOO Mars UV Photocuring LCD MSLA 3D Printer

$149.99$135.00

Ship FromUSUKEU Countries

Quantity

-5

-5

-5

Technical Specifications

- System: ChiTu L5.5 Series

- Operation: 3.5 Inch Touch Screen

- Slicer Software: ChiTu DLP Slicer

- Connectivity: USB

- Printing Technology: LED Display Photocuring

- Light Source: UV Integrated Light(wavelength 405nm)

- XY Resolution: 0.047mm(2560*1440)

- Z Axis Accuracy: 0.00125mm

- Layer Thickness: 0.01-0.2mm

- Printing Speed: 22.5mm/h

- Power Requirements: 110-220V, 12V5A 60W

- Build Volume: 4.72*2.68*6.1 inches

Resource

Free shipping

1 - Year warranty

Secured payment

Aftersale support

Support Files & Resources:

Download

- 【Fast Slicing Software】ELEGOO Mars comes with the latest version of CHITUBOX Slicing Software which gives you extraordinary user experience.

CHITUBOX takes only 1 minute to slice 30Mb .stl model files while the open-sourced slicing software would take up to 10minutes.

- 【Resin saving and Better Printing】CHITUBOX allows you to hollow out your model before slicing which could save your resin dramatically during photocuring process. Equiped with 40W UV lights and using ELEGOO resin, you can get a better printing result.

- 【Smart and Convenient】3.5'' inch color touch screen equipped with the latest ELEGOO CHITUBOX 5.5 system makes it very easy for off-line printing. The build platform with steel ball balancing structure inside allows you to start printing within 5 minutes after assembly.

- 【High Precision and Resolution】ELEGOO Mars uses a 2560x1440 2K HD masking LCD as to provide accurate printing with XY axis resolution of 0.00185inches / 0.047mm

- 【Warranty and Service】We provide total one-year machine warranty (3 month warranty for FEP and 2K LCD consumable parts) and if you have any questions regarding product operation or software please feel free to contact us

ELEGOO MARS 3D Printer comes with a simple yet well-protect package box which contains all the necessary parts you need to start a perfect printing. Finish Kit Includes:

Finish Kit Includes:

- Resin Tank * 1

- Build Platform * 1

- Metal Scraper * 1

- Plastic Scraper * 1

- User Instruction * 1

- Glove * 3

- Funnel * 10

- UL Adapter * 1

- U Disk(2 GB) * 1

- Backup Screws * 1

- Sillicone rubber seal*1

Unboxing Video: Click here

Review Videos: Click here

Unique Industrial Design

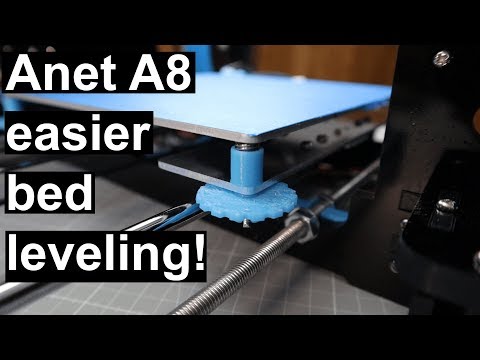

With the unique steel ball design, you only need the Z-axis to return to zero, then lock the leveling screw to start printing.

Large Touch Screen

Large colorful 3.5 inches touch screen. You can preview the model in SD card like you saw pictures in Windows OS. Real-time display printing process.

Speed

ELEGOO Mars comes with the latest version of CHITUBOX Slicing Software that takes only 1 minute to slice 30Mb .stl model files while the open-sourced slicing software would take up to 10minutes. CHITUBOX allows you to hollow out your model before slicing which could save your resin dramatically during photocuring process.

CHITUBOX allows you to hollow out your model before slicing which could save your resin dramatically during photocuring process.

Off-line Printing

The ELEGOO Mars has an integrated computer board for printing directly from USB. You don't need to connect it to the computer while printing.

Precision

ELEGOO Mars uses a 2560x1440 2K HD masking LCD as to provide accurate printing with XY axis resolution of 0.00185inches / 0.047mm

Sturdy Structure

Semi-assembled printer allows you to start printing within 5 minutes.

Sturdy structure of the all-aluminum fuselage plus acrylic cover, which is elegant and durable.

ELEGOO Mars Multi-Language Interface 3D Printer

Last updated date: January 19, 2022

DWYM Score

Why Trust DWYM?

DWYM is your trusted product review source. Along with our in-house experts, our team analyzes thousands of product reviews from the most trusted websites. We then create one easy-to-understand review. Learn more.

Learn more.

Show Contents

Contents

- Our Take

- Features

- Specifications

- From The Manufacturer

- Expert Reviews

- Overall Ranking

- Our 3D Printer Buying Guide

- Our 3D Printer Tip and Advice

We looked at the top 3D Printers and dug through the reviews from some of the most popular review sites. Through this analysis, we've determined the best 3D Printer you should buy.

Overall Take

In our analysis of 44 expert reviews, the ELEGOO Mars Multi-Language Interface 3D Printer placed 11th when we looked at the top 12 products in the category. For the full ranking, see below.

From The Manufacturer

Fast Slicing Software. ELEGOO Mars comes with the latest version of CHITUBOX Slicing Software which gives you extraordinary user experience. CHITUBOX takes only 1 minute to slice 30Mb .stl model files while the open-sourced slicing software would take up to 10minutes. Resin saving and Better Printing. CHITUBOX allows you to hollow out your model before slicing which could save your resin dramatically during photocuring process. Equiped with 40W UV lights and using ELEGOO resin, you can get a better printing result. Smart and Convenient. 3.5” inch color touch screen equipped with the latest ELEGOO CHITUBOX 5.5 system makes it very easy for off-line printing. The build platform with steel ball balancing structure inside allows you to start printing within 5 minutes after assembly. High Precision and Resolution. ELEGOO Mars uses a 2560×1440 2K HD masking LCD as to provide accurate printing with XY axis resolution of 0.00185inches / 0.047mm. Warranty and Service. We provide total one-year machine warranty (3 month warranty for FEP and 2K LCD consumable parts) and if you have any questions regarding product operation or software please feel free to contact us.

CHITUBOX takes only 1 minute to slice 30Mb .stl model files while the open-sourced slicing software would take up to 10minutes. Resin saving and Better Printing. CHITUBOX allows you to hollow out your model before slicing which could save your resin dramatically during photocuring process. Equiped with 40W UV lights and using ELEGOO resin, you can get a better printing result. Smart and Convenient. 3.5” inch color touch screen equipped with the latest ELEGOO CHITUBOX 5.5 system makes it very easy for off-line printing. The build platform with steel ball balancing structure inside allows you to start printing within 5 minutes after assembly. High Precision and Resolution. ELEGOO Mars uses a 2560×1440 2K HD masking LCD as to provide accurate printing with XY axis resolution of 0.00185inches / 0.047mm. Warranty and Service. We provide total one-year machine warranty (3 month warranty for FEP and 2K LCD consumable parts) and if you have any questions regarding product operation or software please feel free to contact us.

Expert Reviews

Expert Summarized Score

6 expert reviews

User Summarized Score

1,913 user reviews

What experts liked

Other Products We Considered

- BestReviews

| Full review

An affordable printer with the quality and performance of a professional machine. It's an excellent 3D printer for both resin printing newbies and enthusiasts alike. High quality prints.

- Tom's Hardware

| Full review

Thanks to its unique steel ball design, you only need the Z-axis to return to zero, then lock the leveling screw to start printing. Its 3.5 inch touchscreen lets you preview the model straight from the SD card.

- Techeblog

| Full review

In addition to the gasket, the Mars Pro also adds a new filter which should help to better contain the noxious fumes.

- ZD Net

| Full review

This printer delivers premium prints without a premium price tag. Marketed at hobbyists, the Mars is easily accessible for both long-time 3D printing enthusiasts and first-time users looking to dip their toes into the world of resin printing.

Marketed at hobbyists, the Mars is easily accessible for both long-time 3D printing enthusiasts and first-time users looking to dip their toes into the world of resin printing.

- 3D Printing Industry

| Full review

A budget-friendly UV LCD 3D printer that is user-friendly and offers ceaseless ingenuity. The printer only takes five minutes to assemble and begin printing. For those afraid of the initial set up, which is challenging with some other models, the ELEGOO is a great option. The ease of set up and initial printing classifies it as a ‘plug-and-play’ 3D printer.

- Pirate 3D

| Full review

What experts didn't like

Loud beeping throughout beginning and end of printing process.

- Tom's Hardware

| Full review

Unfortunately, I found the gasket's fit and finish isn't perfect.

- ZD Net

| Full review

With a modest but typical printing volume of 120x68x155 mm, the Mars is limited in its output to jewellery, tabletop miniatures, pop-culture paraphernalia and small mechanical prototypes.

- 3D Printing Industry

| Full review

Slightly messy. Can produce an odor. Not the fastest print time.

- Pirate 3D

| Full review

1. EcubMaker TOYDIY USB 3-Layer 3D Printer

Overall Score: 10.0

2. Sovol SV01 Alloy Steel Removable Glass Plate 3D Printer

Overall Score: 9.6

3. ANYCUBIC Personal Computer Compatible Anti-Clogging 3D Printer

Overall Score: 9.5

4. R QIDI TECHNOLOGY X-Plus Ventilating Stable 3D Printer

Overall Score: 9.4

5. Geeetech A10M 2-In-1 LCD Display 3D Printer

Overall Score: 9.4

6. Comgrow Creality Ender 3 Pro Aluminum 3D Printer

Overall Score: 9.2

7. Artillery Sidewinder Easy Install 3D Printer

Overall Score: 9. 1

1

8. Dremel Digilab Polylactic Acid 3D Printer

Overall Score: 9.1

9. FlashForge Finder Non-Heated Build Plate 3D Printer

Overall Score: 8.3

10. ANYCUBIC Large Screen High Resolution 3D Printer

Overall Score: 8.0

11. ELEGOO Mars Multi-Language Interface 3D Printer

Overall Score: 7.7

12. XYZprinting da Vinci Nano STEM User-Friendly 3D Printer

Overall Score: 7.0

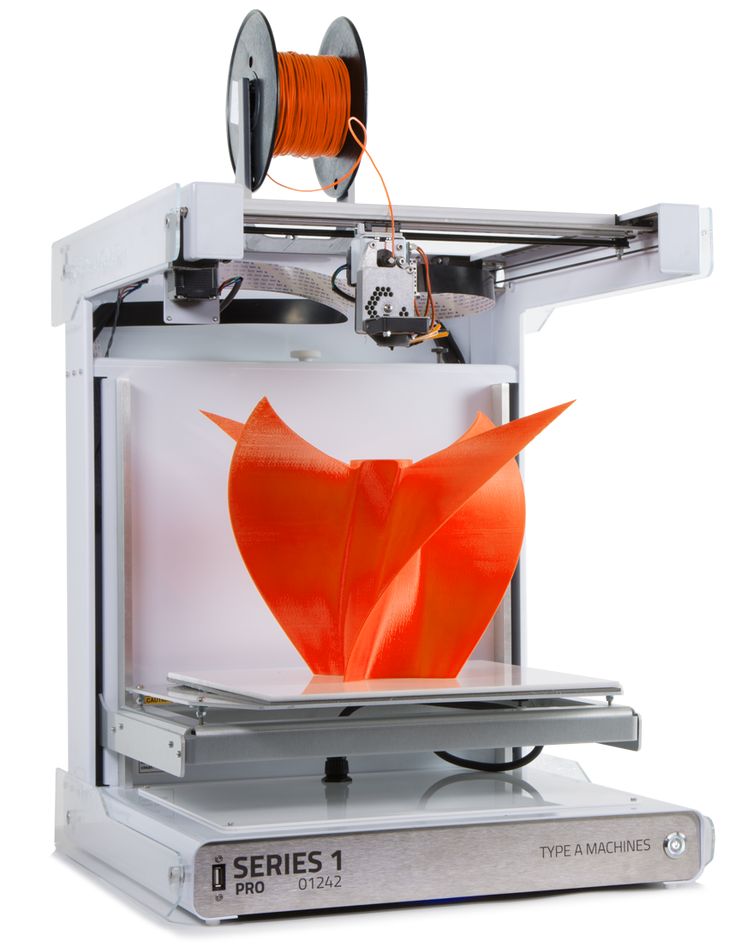

A 3D printer is a marvelous piece of technology that is taking businesses and home offices by storm. In a short amount of time and with the right designs, you have the ability to print almost anything. For example, you can print useful household items like bowls and plates if you accidentally break a piece of your dinnerware. You can print a planter for your new herb garden, or even a simple stationary holder for your desk. If you want to print a small set of cutlery for taking to work or school, you can print out a unique fork, knife and spoon from your 3D printer as well.

In addition to household items, a 3D printer can also print out toys for your kids. Whether they are into dinosaurs or blocks, you can find patterns to print for numerous playthings. From whistles to fidget spinners to toy cars, almost any toy can be created using a 3D printer at home. Plus, you can also print accessories for yourself, like a wallet or orthotics for your shoes. There are endless possibilities to take advantage of when you have a 3D printer.

There are several different types of 3D printers on the market, each with their own advantages. A fused deposition modeling (FDM) printer is a basic one that is loved by beginners to 3D printing. It works by heating a filament and shaping it along X, Y and Z axes. Within this category, there are two different types of FDM printers: cartesian and delta. A Cartesian FDM printer moves the printing bed on the Y axis, while the other two axes move with their own motors. Most FDM printers work this way as it is highly precise. A delta FDM printer has three motors on individual rods, which is not a common model.

Stereolithography (SLA) printers use a process that involves a chemical reaction to form layers of print. It is a highly precise result with smooth prints. This kind of model is perfect for printing items that require extremely fine printed details. A similar model is the digital light processing (DLP) printer. It works by using light, which targets a specific area of the resin and hardening it into a sculpture.

Both SLA and DLP models produce exceptionally smooth prints as compared to an FDM model, which can have rougher results. If you want to print industrial parts, then a selective laser sintering printer is a good choice. The process it uses involves laser precision, and is good for highly complex designs and detailed items.

In addition to the type of 3D printer you need, you’ll also have to consider what kind of printing materials are best for the objects you want to create. If you’re going with a printer that uses filament, you have a couple of options. Polylactic acid (PLA) is a kind of plastic made from plants. It can be useful for creating items for indoor use. However, it does deteriorate after a lot of sun exposure, so you shouldn’t use it for any items that are kept outdoors. Polyethylene terephthalate glycol (PETG) is a food-safe plastic. If you want to use it to create items like plates or cutlery, you will still need to finish it with a food-grade epoxy. Acrylonitrile butadiene styrene (ABS) is a a highly sturdy plastic that is perfect for items that will be used outdoors.

Polylactic acid (PLA) is a kind of plastic made from plants. It can be useful for creating items for indoor use. However, it does deteriorate after a lot of sun exposure, so you shouldn’t use it for any items that are kept outdoors. Polyethylene terephthalate glycol (PETG) is a food-safe plastic. If you want to use it to create items like plates or cutlery, you will still need to finish it with a food-grade epoxy. Acrylonitrile butadiene styrene (ABS) is a a highly sturdy plastic that is perfect for items that will be used outdoors.

If your are going with a SLA or DLP printer that uses resin, then you can choose the quality of liquid resin you need based on what you’re making. Standard resin is a good option for small gadgets like pencil holders. Professional resin is best for engineering applications that will see high impact and high usage. Medical-grade resin is often used for making custom dental work or hearing aids.

- The type of 3D printer you need will really depend on the kinds of objects you want to print.

That’s why it’s best to consider the range of needs you have before purchasing a printer. For example, if you primarily want to print household objects for indoor use, then you can use an FDM printer. For objects that you will be using outdoors, the type of filament is what will make a difference. You have to use an ABS filament that can withstand the sun. If your goal is to print artwork with your 3D printer, then it’s best to use a resin printer, which will be able to handle the delicacy of your designs, unlike an FDM printer. For tools, opt for an FDM for home use. For professional-grade tools, then you will need to use a resin-based 3D printer.

That’s why it’s best to consider the range of needs you have before purchasing a printer. For example, if you primarily want to print household objects for indoor use, then you can use an FDM printer. For objects that you will be using outdoors, the type of filament is what will make a difference. You have to use an ABS filament that can withstand the sun. If your goal is to print artwork with your 3D printer, then it’s best to use a resin printer, which will be able to handle the delicacy of your designs, unlike an FDM printer. For tools, opt for an FDM for home use. For professional-grade tools, then you will need to use a resin-based 3D printer. - An important factor to note for 3D printers is resolution. The resolution for 3D printers is measured in a unit called microns. For example, an FDM printer, which is most common for individual use, has a resolution of 25 microns. Resin-based 3D printers, which are common for professional applications, have a resolution of 100 microns.

This means that you will get much finer details on a resin printer. Consider the kind of details you need printed and how smooth the object needs to be. The higher the microns, the higher the precision of the printer.

This means that you will get much finer details on a resin printer. Consider the kind of details you need printed and how smooth the object needs to be. The higher the microns, the higher the precision of the printer. - In addition to the hardware of the actual 3D printer, you’ll also need software to create the printer files. The software program for your computer, on which you create the 3D printing files, is referred to as a slicer. Popular slicing software includes Cura and Slic3r. There are other slicer software options available as well. Be sure to read reviews online before landing on a 3D printing software for your computer.

- Making a 3D printed object can take time. During the printing process, your printer may be interrupted by a number of issues. As a result, the object that you’re printing can be ruined in progress, wasting resources and time. In order to reduce the amount of unexpected interruptions during the 3D printing process, look for a printer that has a print resume feature.

This will ensure that your print isn’t ruined partway through as a result of an issue. If the printer does have to pause, it can easily pick up where it left off with your object.

This will ensure that your print isn’t ruined partway through as a result of an issue. If the printer does have to pause, it can easily pick up where it left off with your object. - The first layers of your printed object are like the foundation of a house. Everything else rests on those layers, and it’s is critical that they are well-formed, stable and staying in place. In order to ensure that the bottom layers of your print are solid, you will need a heated bed. Different types of filament have specific temperatures they require in terms of heat, so you may need to experiment to find what is right for you.

- An intuitive user interface will make all the difference on your 3D printer. If you have one that is manual, such as one with a rotary knob, it can be difficult to navigate. Even a touchscreen that is confusing can cause unnecessary problems with your printing process. Look for a streamlined touchscreen user interface that is easy to understand and doesn’t require complex instructions.

- When you first start using your 3D printer, you may have to adjust the tension of the X, Y or Z axes by tightening or loosening them. Having a printer where the tension belt is easy to access and adjust will make life a lot easier. Otherwise, you will have to figure out how to remove specific components in order to access the tension belt, which require time and intricate knowledge of the printer hardware. Plus, if you aren’t able to put everything back in place the right away, it will cause further issues.

Checkout Our Other Buying Guides

LCD 3D printer MSLA Longer Orange10 UV curing photocuring resin printing 98 x 55 x 140 mm print size

Share to:

- Description

- Reviews (0)

- Delivery and payment

- Bulk request

Descriptions Longer Orange10

Key Features:

• High precision finish

Combine with high stability and incredible precision, allowing you to create parts in detail

• Stand auto-generation

One-click generation grid supports structures, support generation tool makes it easy to add, change or delete

• offline printing

Support printing by transferring print job file data from TF Card

• Touch panel

2. 8-inch color touch screen, friendly interactive interface, allowing you to view the printing status in real time, without the need of a linked computer

8-inch color touch screen, friendly interactive interface, allowing you to view the printing status in real time, without the need of a linked computer

• Easy to align

With universal joint design structure, easy to level the platform with a screw, let you start printing project efficiently

• Fast slicing

Professional slicer software can complete 100mm slice file within 1 minute, faster than software open source, about 30 times.

Print technology: LCD

Features:

Assembly size: 98mm (L) x 55mm (W) x 140mm (H)

Layer thickness: 0.02 - 0.1 mm

Build speed: up to 30 mm/h

LCD resolution: 854 x 480

LCD size: 115 µm

Z-axis resolution: 0.625 µm

Light source: 405nm UV LED Matrix

Material: Resin

Operating Software: Longer than

Operating System: Windows 7/8/10 64bit

File Format: STL

Connection Mode: TF Card

Touch Screen: 2.8 inch color touch screen

Power input: 100 - 240 V AC, 50/60 Hz, 1. 6 A

6 A

Output power: 12V/DC, 6A

Rated power: 41W

Operating temperature: 20 - 30 degrees Celsius

Relative humidity: 30 - 60PCT

Specification

- All (0)

- Photo (0)

- Video (0)

- Sort by: All

All Popularity Most Helpful Most Recent

-

Translate into English

Get G points! Be the first to write a review!

Do you want to buy Longer Orange10 in bulk? Please submit your wholesale Longer Orange10 inquiry below. Please note that we usually don't provide free shipping on bulk orders of Longer Orange10, but the wholesale price will be a big deal.

Your target price:

Quantity ordered:

Country

Your name:

Your phone number:

Your email address:

Company name:

Inquiry details:

Your recently viewed items

Pre-Sales Support

ELEGOO MARS 3 Pro Mars4 ULTRA 3K Mono LCD 3D Printer User Manual

Document

ELEGOO MARS 3 Pro Mars4 ULTRA 3K Mono LCD 3D Printer

Thank you for purchasing the ELEGOO Mars 3 3D Printer.

Please unpack and inspect the printer upon receipt.

If you have questions about the printer. please contact us at [email protected]. please contact us at [email protected] facebook and ins.

Please read the instructions carefully before using the printer.

Software and multilingual instructions available

download from www.elegoo.com/download.

- Keep the Mars 3 3D Printer and its accessories out of the reach of children.

- The first time you use the printer, you will need to set it up before printing (unpack and test).

- If printing fails, you will need to empty the resin tank and replace the resin, otherwise your printer may be damaged.

- Resin capacity in the tank must not exceed the MAX line position.

- Use ethyl alcohol 95% (or higher) or isopropyl alcohol to wash your model, unless you are using water-washable resin.

- Use the printer indoors, away from direct sunlight and dust.

- Please keep the printer away from water or damp environment.

- Please put on a mask and gloves before use and avoid direct skin contact.

- If you want to print models with sharp edges, be careful when removing it from the build platform.

What to take with you

Printer components

- Turning handle

- Axis

- Build the platform

- Smolatank

- SECROUSE

- ,0005 9000

-

006

- de INTRACT

Technical characteristics of Mars 3

- System: EL3D-3.0.1

- Operation: 3.5 inch

- SLISER with a touch screen

- Software: Chitabox 9000,

- Possibilities: USB

- Press Press

- Print Specification

7cm (D) * 22.7cm (W) * 43.85cm (H)

7cm (D) * 22.7cm (W) * 43.85cm (H) - Physical

Leveling

- Carefully lift the printer out and remove the plastic film.

- Turn on the printer.

- Insert the work platform, fasten the rotary handle and loosen the screws (see figure 1).

(Picture 1) - Remove the resin tank and place an A4 size paper between the build platform and the 4K LCD screen and click "Move Z Axis to Zero" (see Figure 2). When the work platform stops, push it down with one hand and make sure it is in the center position, then secure it with the hex wrench.

(see figure 3)

- Since tightening the mounting plate screws will change the tension when pulling A4 paper, you need to calibrate the Z-axis height again a little. If there is no or little resistance when pulling A4 paper, press to lower the Z-axis by a distance of 0.

1 mm. If the paper is not pulled out or the resistance is very high, press to raise the Z-axis by 0.1mm. axis. (See Figure 4)

1 mm. If the paper is not pulled out or the resistance is very high, press to raise the Z-axis by 0.1mm. axis. (See Figure 4) - After the above alignment is completed, set the current Z-axis position as the starting height for the first print layer. The operation is as follows: Return to the previous interface and click "Set Z=O". At this time, a message will appear on the screen as shown in the picture. Then click "Confirm" to complete (see Figure 5).

- Press "10 mm" - then press "up" 10 times, after which the Z-axis will rise by about 1 mm (see fig. 00).

- (Figure 7) 8. Check the light by clicking "Tool" - "Exposure" - "Next" (see Figure 7). If the 4K screen can display the full "ELEGOO TECHNOLOGY www.elegoo.com" then the UV light works perfectly.

Print test

Model print (cover machine with UV protection).

Please put on the face mask and gloves first (to avoid direct skin contact), then slowly add the resin to the maximum line of the tank, and the resin should not exceed the maximum line, cover it with a lid to protect it from UV. light it up and make sure the printer is level and doesn't wobble, connect the USB to the printer, select the model file "Rook.ctb" and start printing.

light it up and make sure the printer is level and doesn't wobble, connect the USB to the printer, select the model file "Rook.ctb" and start printing.

(Figure 8)

If you find that there is not enough resin during printing to complete the model, you can press the "Pause" button and add more resin to the tank, and then press "Print" to continue printing.

Wash the print and empty the tank

After printing is complete, wait for the resin on the build platform to stop dripping. Loosen the rotary knob and remove the work platform. Use a scraper to remove the model and wash it 95% (or higher) ethyl alcohol if you are using a standard resin or an ABS-like resin. (See picture 9)

- Install ChiTu Box

ELEGOO ChiTu Box is stored in U disk. Choose the appropriate version and install it on your computer, or you can download the latest version from www.elegoo.com/download if you prefer. - How to use the chitu box

After the installation is completed, launch the ChiTu software, click File-Open File, then open your own 3D model files (type . stl) or you can download several samples from our website www.elegoo.com . You can control and change the view angle, size and position of the model by left-clicking the model and using the options in the left menu.

stl) or you can download several samples from our website www.elegoo.com . You can control and change the view angle, size and position of the model by left-clicking the model and using the options in the left menu.

ELEGOO ChiTu Box

Other operations:

- Press and hold the left mouse button and drag the model to the desired location.

- Scroll the mouse wheel to zoom in or out on the model.

- Click and hold the right mouse button to see different perspectives of the model.

ChiTu box setup

Click "Settings" and select

ELEGOO Mars 3 as the default printer (see fig. 10).

build Volume

Below are the default settings and you don't need to change them. If the model is larger than the build volume of the printer, you will need to resize it with a locked factor (see Figure 10).

Resin parameter (see picture 11).

Resin density: 1.1 g/ml

Resin cost: You can enter the cost of the resin and after cutting you will see how much it costs for your model.

Parameters (see fig. 11).

Layer height: The recommended height is 0.0–5 mm, but you can set it between 0.01–0.2 mm.

The higher you set, the longer it will take to expose each layer.

Number of coats: Set as 3-6 coats.

Exposure time: Can be set to 1.5-3 s depending on layer height and model complexity, the thicker the setting, the more the bottom will stick to the build platform. Bottom exposure time: can be set from 20s to 40s, the longer the setting, the stronger the bottom will stick to the build platform.

Transition: Default setting and should not be changed.

Transition type: The default parameter is linear and should not be changed.

Print process standby mode: The default setting is static and should not be changed. Rest time after retraction: Default setting if it is 0 and should not be changed. Bottom lift distance: When printing bottom layers, it is recommended to set the build plate lift distance to 3mm.

Lift Distance: When printing normal layers, it is recommended to set the build plate lift height to 3 cm.

Lift Speed: When printing normal layers, it is recommended to set the table lift speed to 110 mm/min.

Retraction speed: When printing lower layers, it is recommended to set the build plate retraction speed to 280mm/min.

Save model

After setting all the parameters, click "slicing", and when finished, click "export slicing". files to U disk or SD card", then connect the U disk to the printer and start printing. (See picture 12)

FAQ

- Model does not stick to build platform

Exposure time of bottom layer too short, set exposure time longer.

The bottom of the model has very little contact with the build platform, so add more bottom layers. Alignment is not done correctly and this will result in the first layer being too thick or one side being very thick and the other very thin.

- Model layer break

The printer shakes while printing.

The protective film is very loose due to long-term use and needs to be replaced.

Build platform or resin tank not secured. - Mars 3 can't work

We offer a full one year printer warranty and a 6 month screen warranty.

If your printer is not working, please contact us at [email protected]. and in order to better help and solve problems for you, please add your order ID to your email address. - Printing error

If the model did not print completely or failed, there may be residue left in the printer.

resin that can be filtered out with a funnel when you save the remaining resin back into a sealed bottle. If you don't filter out the leftovers, the platform may damage the 4K screen the next time you print. As for the remaining resin on the platform and tank, you can clean and wipe them with wipes. - Maintenance

- If the Z-axis continues to make friction noise, apply some lubricant to it.

Learn more

- If the Z-axis continues to make friction noise, apply some lubricant to it.