3D printer parts list pdf

3D PRINTER ACCESSORIES User manual

3D PRINTER ACCESSORIES User manual | PDF-MANUALS.com| PDF-MANUALS.com | User manual here! | |

| Operating instructions and pdf manual for use - 3D Printer Accessories | |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

PDF-MANUALS.com - Community administered database of instructions for use and PDF User manual

sitemap.txt alx |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

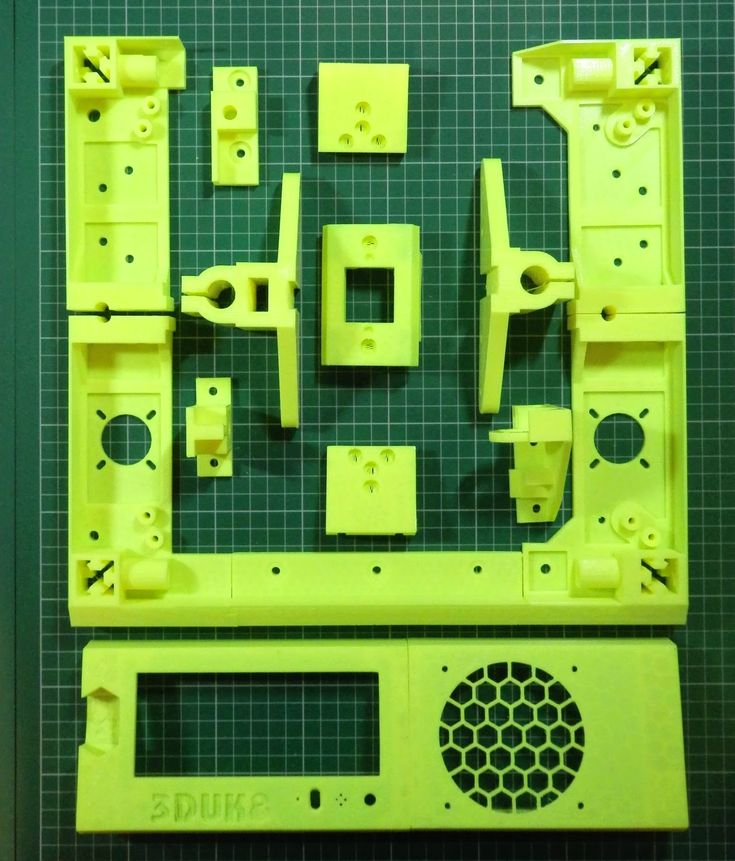

3D Printer Parts: Complete List of 3D Printing Components

ADVERTISEMENT

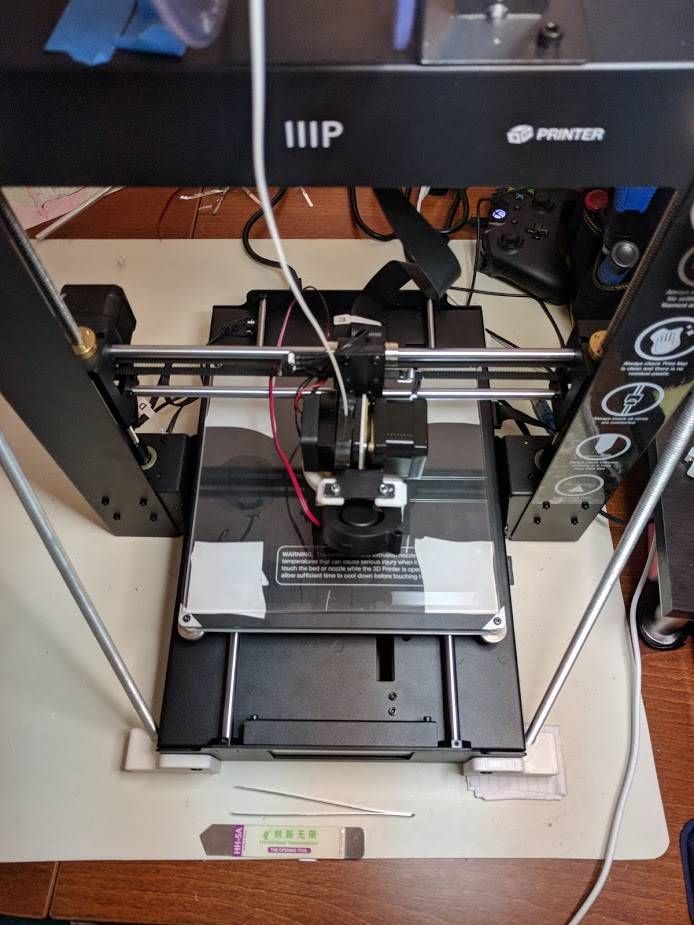

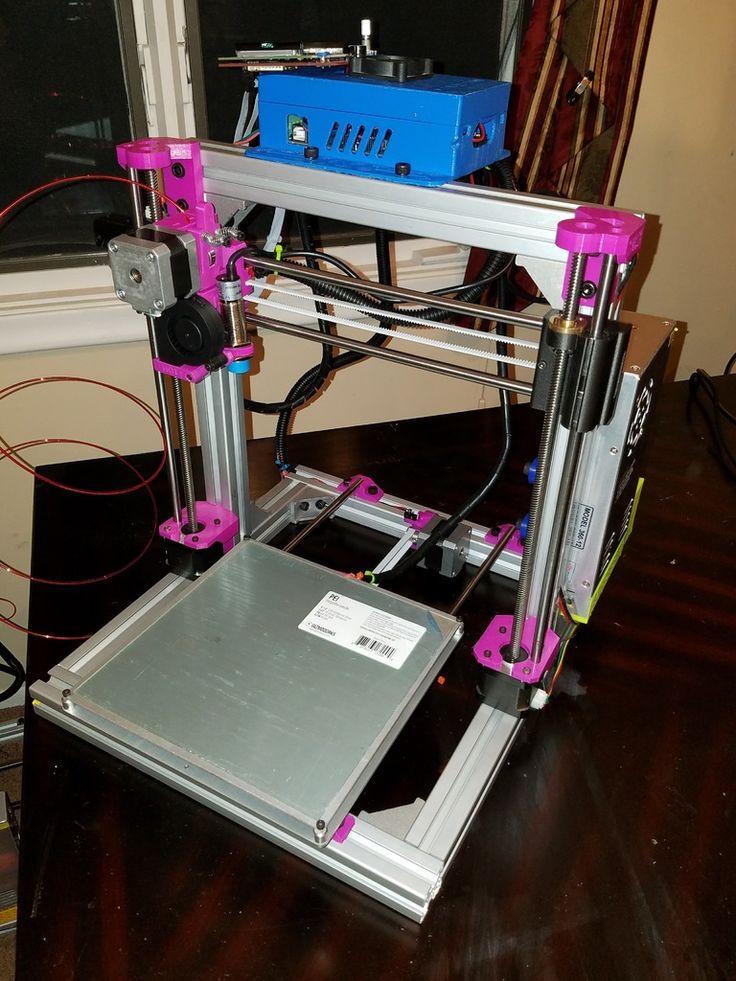

3D printers are becoming popular with time. Some prefer to buy the fully assembled machines while few like to explore a little more with DIY 3D printers.

Some prefer to buy the fully assembled machines while few like to explore a little more with DIY 3D printers.

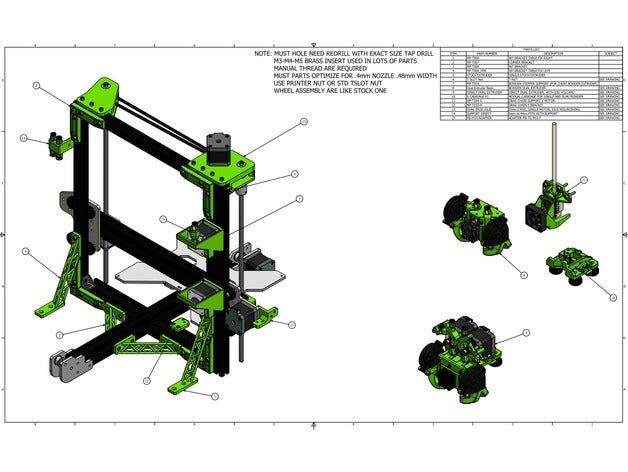

While working with DIY machines, the most exciting part is exploring the different 3D printer parts that make it such a powerful technology. Though it is difficult at times to complete the assembly in few hours, the experience does provide a lot of know-how about the 3D printer anatomy.

By learning about the parts, one gets better understanding of the working of 3D printers. Hence, can utilize the knowledge later when actually printing with the machine.

One can even solve minor to major problems such a nozzle jam and many others, when familiar with the inside out of these 3D printers.

In short, if users are looking forward to a strong career in 3D printing, the right way would be start with the different parts that make up for the most revolutionary technology.

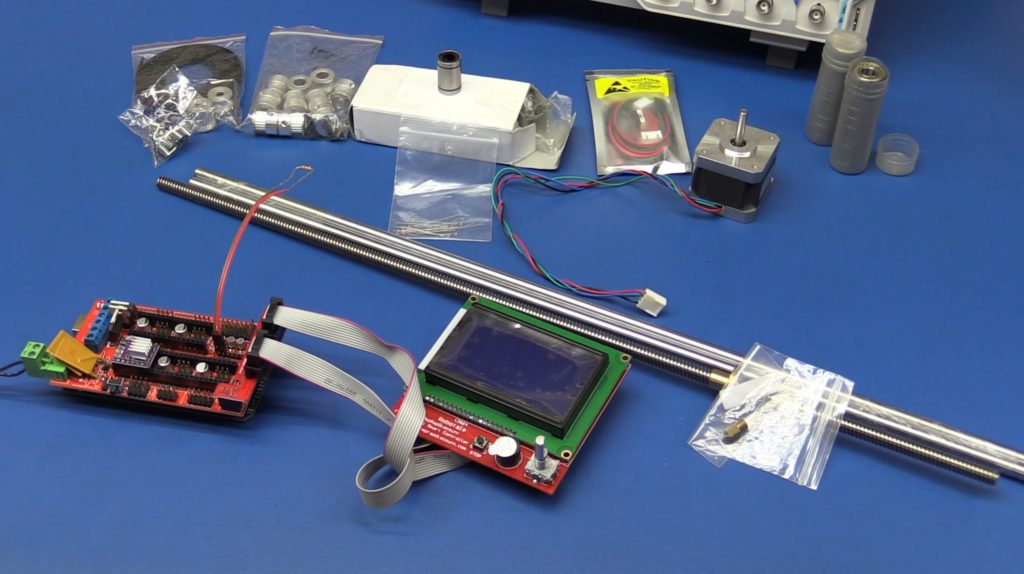

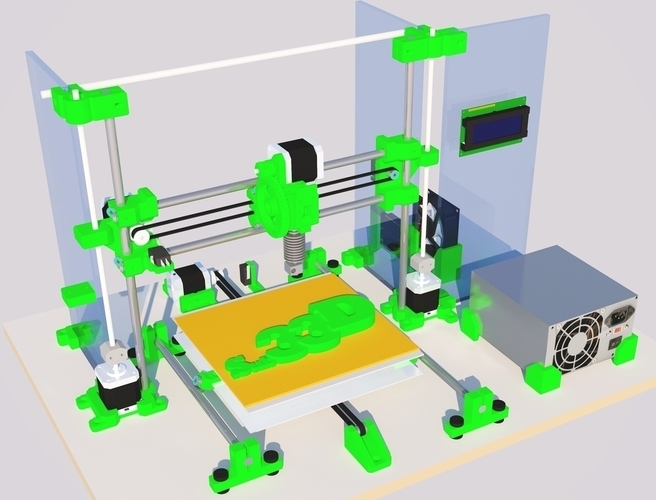

List of Major 3D Printer Parts

3D printers are complex, however, when examined closely, they can be made super easy to understand and work with. The first step must be to check out the 3D printer parts list.

The first step must be to check out the 3D printer parts list.

These components of 3D printers help accomplish tasks from printing smaller to larger parts with ease. The list here contains the component of cartesian printers which are recommended for beginners.

ADVERTISEMENT

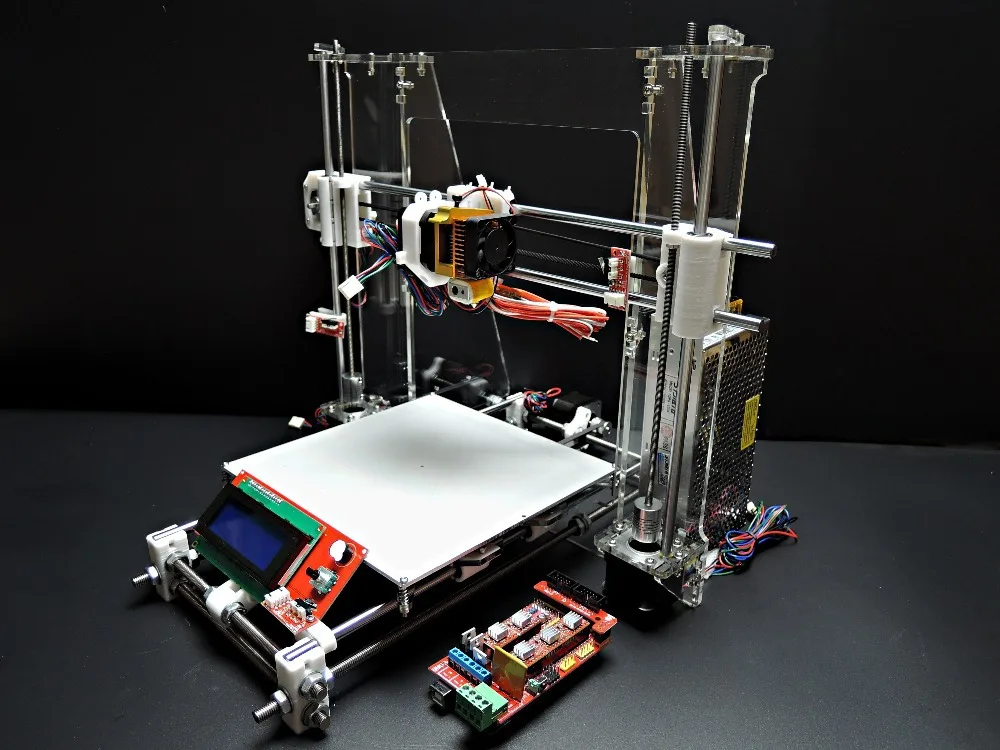

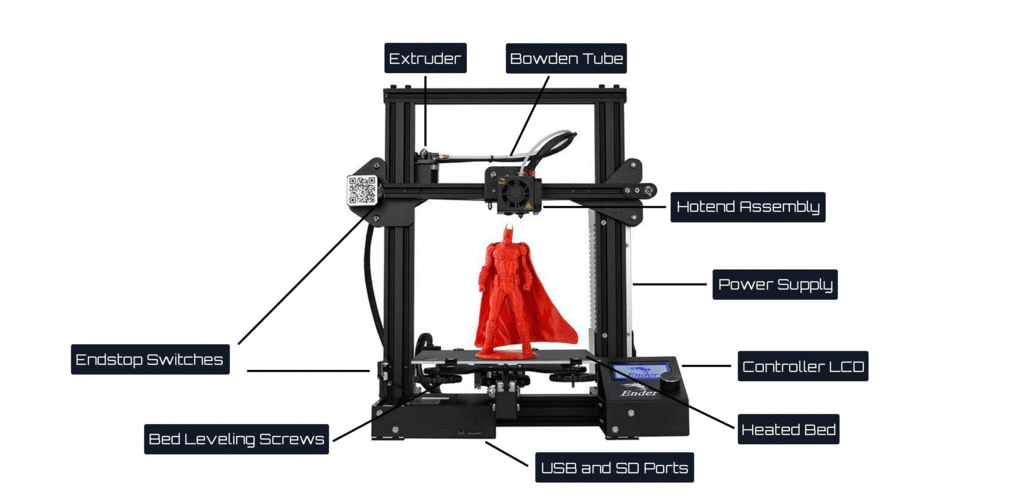

MotherBoard or Controller Board

The motherboard which is also known as mainboard or control board. As the name suggests, this component is responsible for maintaining the smooth processing of the machine.

Being responsible for all the fundamental operations, motherboard works as the brain of the 3D printers. It directs the motion components as per the instructions sent from a computer and at the same time, interprets signals from the sensors.

You must have guessed how crucial it is to have a great quality controller board for achieving high performance from a 3D printer. Even if you put every best part in your machine, while ignoring the controller board, your 3D printer would be worthless.

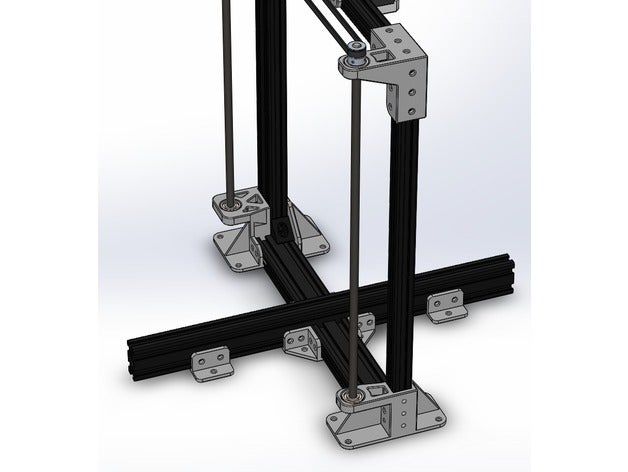

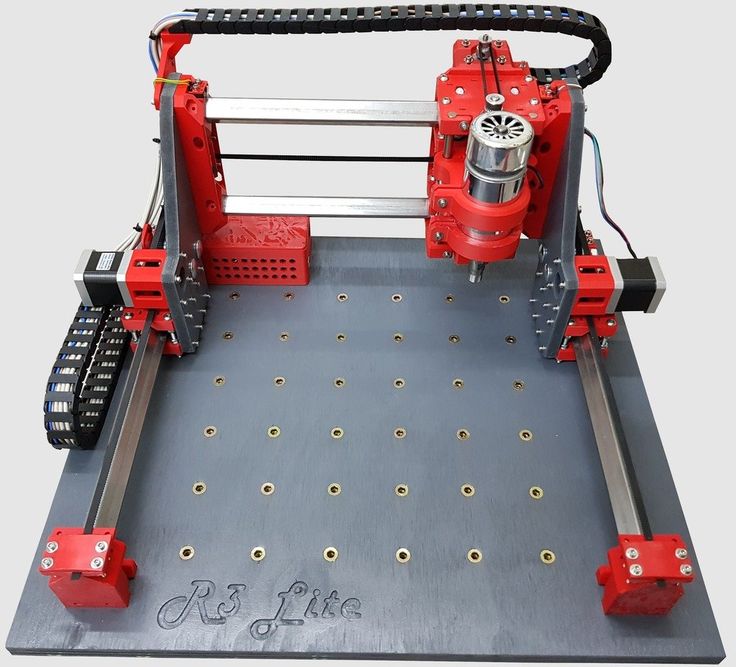

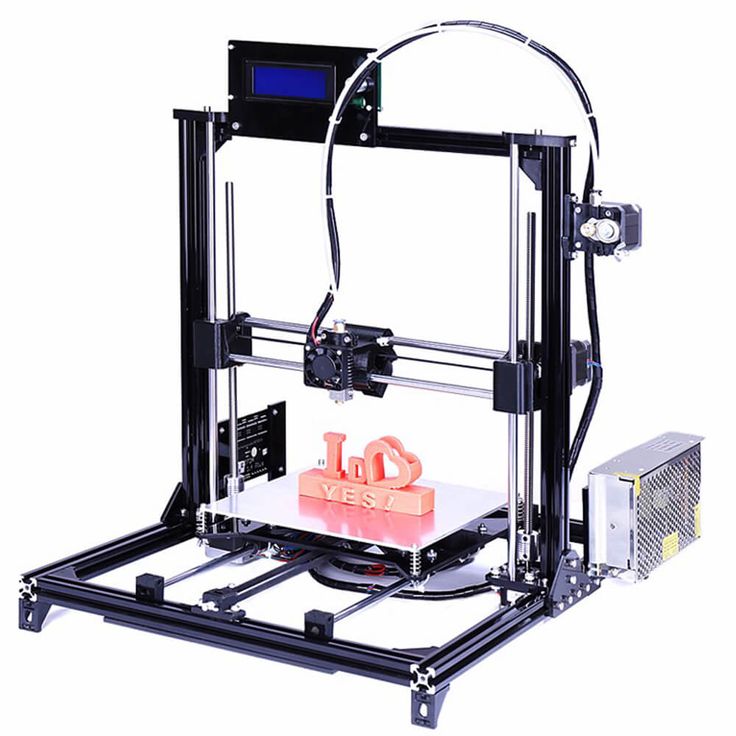

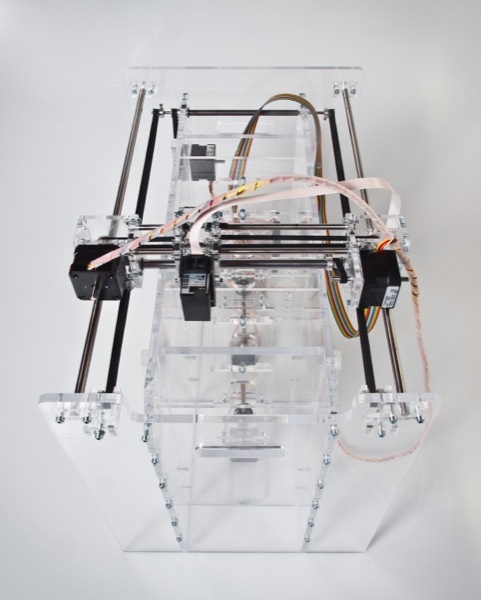

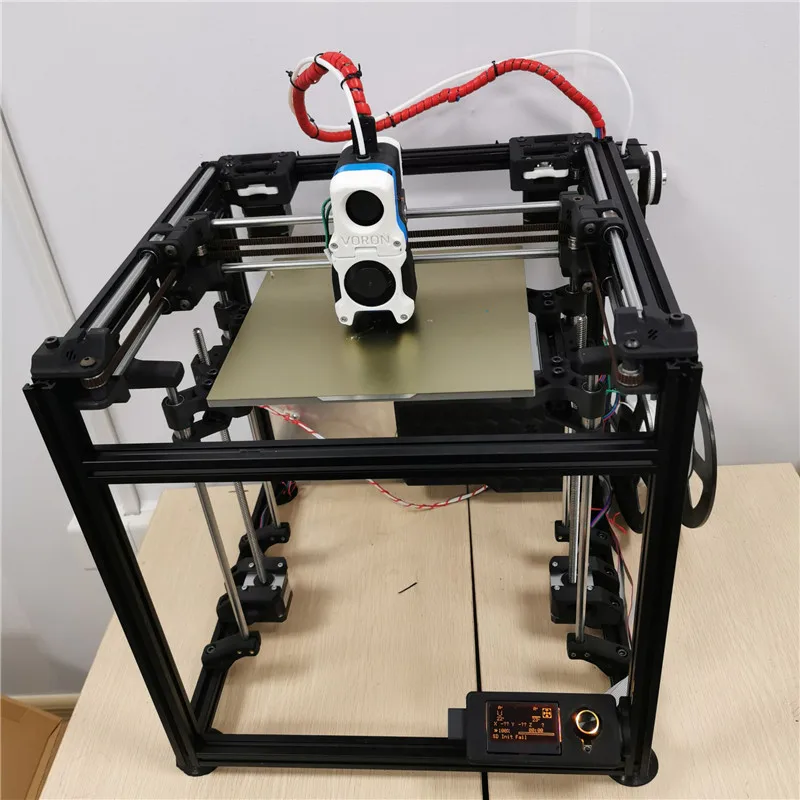

Frame

Frame helps keep all the other components of your 3D printer together at one place. It also maintains the stability of the entire machine. If your frame is robust, you will have a more durable 3D printer.

Companies use different materials and the most common ones are the metal and acrylic. In old days, wood was used for the frame of the consumer 3D printers.

However, to maintain the highest stability, one must choose the metal body. These printers aren’t always expensive as well.

For example, Monoprice offers budget 3D printers under $300 with aluminium frame. Yes, you heard it right. With limited budget, you can still own a metal frame 3D printer.

When talking about frames, the open and closed frame designs also make a difference. A closed frame offers better results by maintaining consistent temperature around the print space. There are few printers that also offer semi-enclosed frames.

ADVERTISEMENT

Print Material

Filament is used for the FDM 3D printers. Filaments are available in spools. These are heated to certain temperature and are liquified to be deposited on the print bed.

Filaments are available in spools. These are heated to certain temperature and are liquified to be deposited on the print bed.

This happens in layers. The objects created by 3D printers are made of these filaments. There are many types of filaments used for 3D printing. And, each one of them have different properties. They have their own advantages and limitations.

When getting a printer, one must take care of the compatibility with different filaments. Not all printers allow multiple filament compatibility.

Some can process only one kind of filaments, mostly PLA. And, others can work with multiple choices of filaments including PLA, ABS and many others.

There are other 3D printers that only accept the proprietary filaments. Hence, you must be aware of your 3D printing needs before opting for a 3D Printer and the filaments it supports.

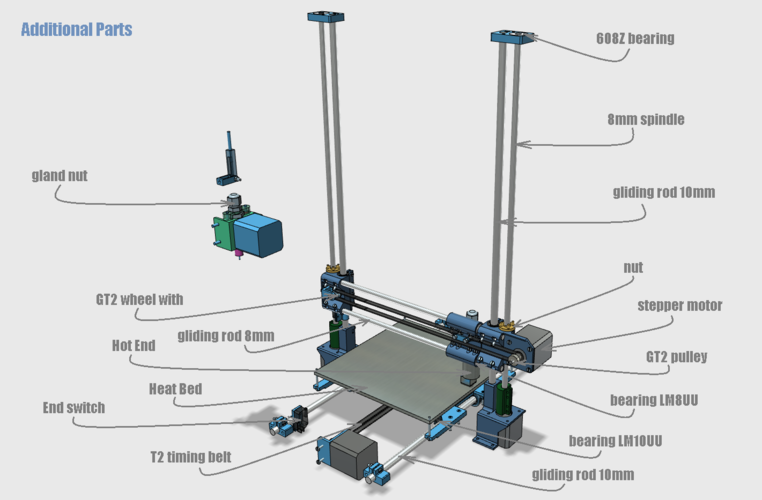

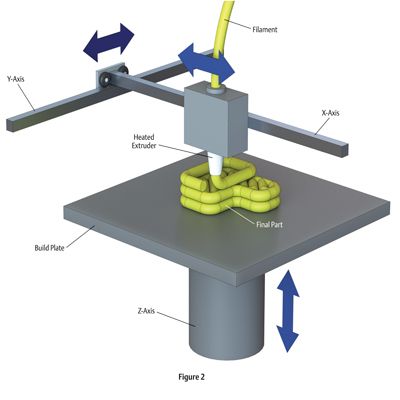

Motion Controllers

You must know that the 3D printers, as the name suggests works along the three axes. Motion controllers receive instructions from the mother board about the movement they must make, while they are the ones who perform the actual movements.

Motion controllers receive instructions from the mother board about the movement they must make, while they are the ones who perform the actual movements.

- Belts: The belts connected to motors are responsible for moving X-axis and Y-axis. The movement happens from side to side. This movement does affect the print speed and precision, hence are very crucial for the attaining best results. One must ensure that the belts aren’t loose or the print may ruin. For this, one can use tensioners.

- Stepper Motors: These are responsible for the mechanical movement of the device and are controlled by Stepper driver. These motors connect with X, Y as well as Z axis. These motors help in driving the print head, print bed, along with the leadscrews. Because the rotations are made in steps, they are called Stepper motors.

- Threaded rods: Threaded rods are connected to the stepper motors. With the movement of threaded rods, the print head moves in upward and downward directions.

In few 3D printers, the print bed movement also relies on threaded rods. So, the Z axis movement is dependent on Threaded rods. Although these could be used for the movement along the X and Y axis, being expensive, majority of the printers use belts. Belts are faster and lighter alongside being cheap.

In few 3D printers, the print bed movement also relies on threaded rods. So, the Z axis movement is dependent on Threaded rods. Although these could be used for the movement along the X and Y axis, being expensive, majority of the printers use belts. Belts are faster and lighter alongside being cheap. - End Stops: End stops ensure that the end points are marked along the three axes when the movement of components take place. It identifies the range of movement of each component.

ADVERTISEMENT

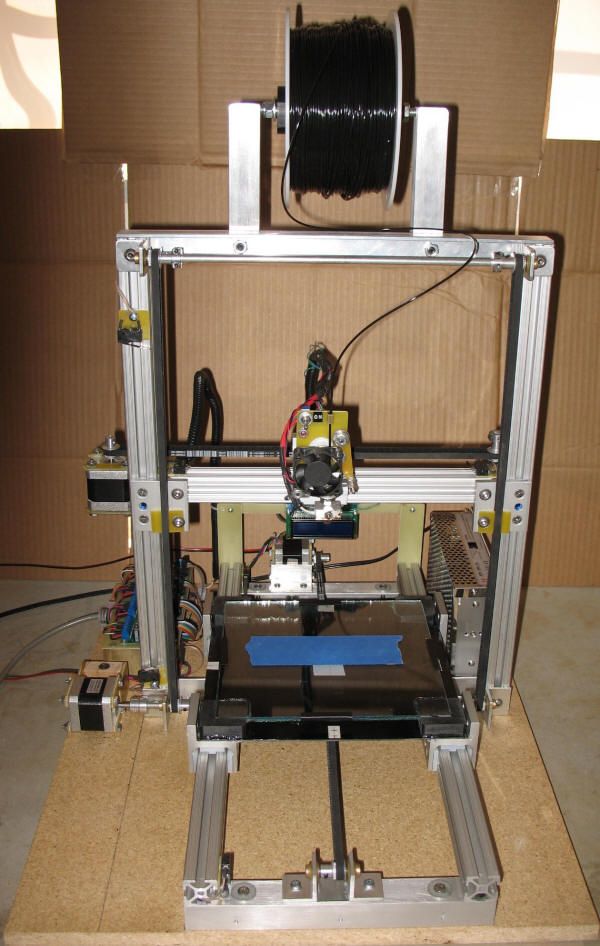

PSU

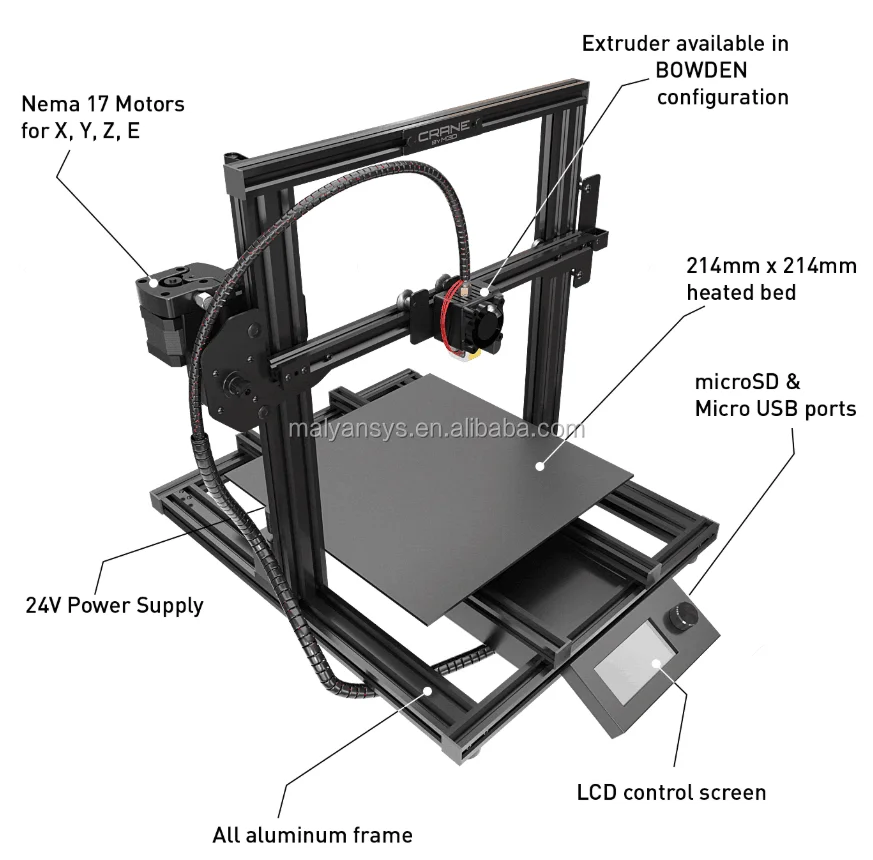

PSU, abbreviated as Power Supply Unit helps in supplying power for a smooth operation of 3D printer. You can find the PSU mounted on the frame. Or, it can also be available separately along with another controller box. However, mounted one provides compact look and occupies less space.

PSU strength would decide what temperature your 3D printer is capable of working with. For advanced materials, one must choose the one with higher temperature range allowance.

Print Bed

Mostly, anyone who has worked with 3D printer would know what a print bed is. This is the component where the models are created.

The filaments are deposited on the print bed, one layer at a time for building the entire object. One of the major 3D printer parts that does decide the quality and surface finish of the printed object.

Different 3D Printers boasts different kinds of print bed. You can find heated as well as non-heated print beds. A non heated print bed may be enough for PLA, however, for advanced filaments, heated beds are recommended. These helps in enhancing adhesion and stability for first layer of the print.

Also, the print beds are designed using different materials. For example, aluminium and glass print beds. Both have its own benefits and limitations. Aluminium print beds heat up faster and glass print beds, being flatter, provides better finish and are easy to maintain as well.

Some 3D printers offer automatic calibration of print beds. However, users need to level the bed manually in some.

However, users need to level the bed manually in some.

ADVERTISEMENT

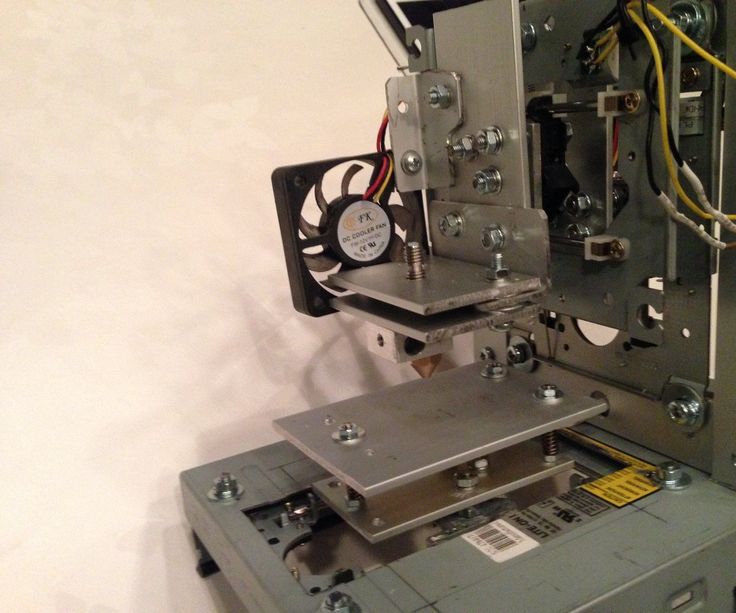

Extruder

The extruder, also known as print head extrudes the filament and deposit it on the print bed. The extruder can be categorized in two sections. One is called the cold end while the other is known as the hot end.

The job of the cold end is to lock the filament while pushing it gradually downwards to the hot end.

The hot end that has a nozzle attached to it at the end, maintains a high temperature greater than the melting point of the filament. The hot end melts the filament which is further deposited on the print bed.

The extruder itself is made of different parts.

- The Filament Drive Gear: Also known as extruder drive gear is responsible for pushing the filament into the hot end.

- The Heat Sink: The heat sink along with the heat Sink Fan ensures that the material is still in solid state until it reaches the nozzle.

- The Heater Cartridge: This is the component that works to heat up the filament.

- The Thermocouple: To maintain the right temperature, the extruder uses a temperature sensor. This is used for the hot end.

- The Cooling Fan: Once the melted filament is deposited, it must be cooled down for setting before the next layer gets deposited. The job of the cooling fan is to ensure the same.

- Nozzle: This forms the tip of the extruder. The filament is melted and it comes out of the nozzle for deposition. There are different sizes of nozzles that the printers use. 0.4 mm is the most common one. By keeping the smaller diameter of nozzle, one can achieve finer details with greater accuracy. And, larger nozzle helps in printing at a higher speed.

Some 3D printers are equipped with dual extruders as well. With a dual extruder, one can print simultaneously with two different filaments. Dual extruders have two kinds of setup. Either both the nozzles are included in one print head or connected with two different print heads.

Either both the nozzles are included in one print head or connected with two different print heads.

ADVERTISEMENT

Feeder System

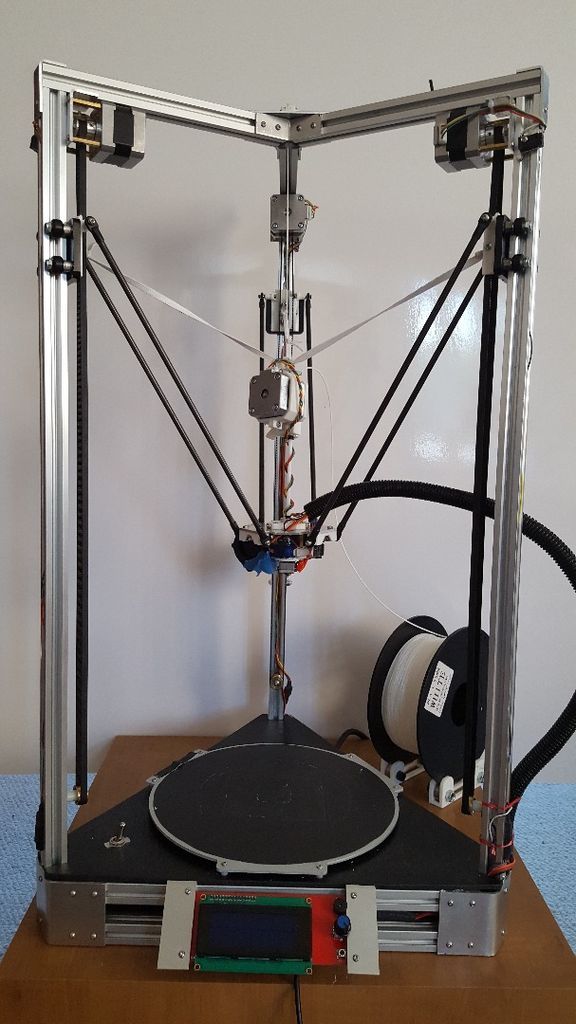

There are two most common feeder system used in 3D printers: Bowden feeder system and Direct feeder system. In a Bowden setup, there are different locations for cold and hot ends.

While a filament tube is used to direct the filament towards the hot end. This setup can dramatically increase the print speed as the extruder becomes lighter.

When talking about the direct setup, the cold end and the hot end are directly connected. The direct feeder system is most common among the users who work with flexible filaments.

Connectivity

When it comes to connectivity with other device, 3D printers differ a lot. Some provide only the ethernet or USB port for connection. However, many new 3D printers are now available with Wi-Fi setup as well.

The interface can also help connect the mobile phone or laptop through Wi-Fi connection to your 3D printer. The file transfer can also be done using any of the three options.

For a standalone experience, many 3D printers also come with SD card slots. These slots are used for file transfer while the printer works without a need for any other device.

User Interface

These days, most of the 3D printers, even the budget ones, comes with an LCD user interface. With the help of this interface, one can control the printer settings without a need for computer.

Hence, these machines can work as standalone machines. The majority of the 3D printer has a mounted interface. However, you may find some models with separate controller box including the LCD interface.

This interface can help check and set the machine parameters. You can also use this interface to initiate the loading or unloading of filament. Moreover, an auto-leveling system can be initialized with the help of this small screen on the 3D printer.

The Conclusion

The 3D printing technology is growing with leaps and bounds. Doesn’t matter if are from a technical background or a non-technical one. Users can definitely learn to operate 3D printers because of all the help available online.

And, to know a little more than what others know, would certainly put you in a better place. So, why not start with the components of 3D printers?

3D printers are housed with many smaller and larger parts. Every part has their own role to play. Some tackles the movement while some work for accuracy various other important jobs.

These parts work in conjugation to provide a stable and uniform precision. The objects printed with a 3D printer bear varying properties and quality, depending on the difference in these parts and components.

However, all of these components have equal share when it comes to the operation of the 3D printers. Knowing about these 3D printer parts is a great way to start the journey towards 3D printing.

Who knows, you can someday, be able to create your own 3D printer. Possibilities are endless and when basics are strong, one can dream for higher goals.

3D printer models

Looking for 3D printer models? The Internet is filled with sites that offer them for free. We have collected the TOP 10 catalogs that you can use to search and download free models in STL format. We hope you can find what you are looking for.

- Yeggi

- Yobi 3D

- STLfinder

→ myminifactory.com

My Mini Factory is a 3D model depository operated by iMakr, an online store that sells 3D printers and accessories. It also has one of the biggest 3D printer shops in Central London. The site contains 3D models designed by professionals, and all models stored on it are checked for quality. You can also make a request for the desired model, which their designers will create and put in the public domain. Billing itself as a 3D printing social network, MyMiniFactory is a thriving community of makers who love to showcase their creations. Users vote for the best models, which allows popular creations to rise to the top of the list and gain popularity. The site presents models that are stored on its social network, as well as outside it, for example, on the Thingiverse and YouMagine sites.

Users vote for the best models, which allows popular creations to rise to the top of the list and gain popularity. The site presents models that are stored on its social network, as well as outside it, for example, on the Thingiverse and YouMagine sites.

→ thingiverse.com

The most popular and famous site among 3D printer users, Thingiverse is owned by MakerBot Industries, the creator of the popular Replicator 3D printer series. The site allows users to store and share 3D model files that are used with 3D printers. It's a very popular site and has a large community of people hosting various categories of files on it. So if you're looking for "cool" printable stuff, Thingiverse is worth a visit. It is a portal designed to provide its users with ways to share their designs and to help print 3D creations. The site has a system that tries to find out what you like. The more you interact with the site, downloading and evaluating various developments, the better its recommendations will be.

→ 3dshook.com

Another online community for 3D printing hobbyists showcasing interesting 3D printer accessories, electronics and most importantly 3D models. The site contains many very interesting models of cars and buildings, as well as various add-ons and spare parts for your 3D printer. A huge catalog of paid and free models for a 3D printer. There are original unique products. Convenient search, navigation, rubricator. 3DShook has over 40 categories and adds over 100 new models to its collection every month. On 3DShook you can always find something for your home, animals, kids or something special for yourself.

→ youmagine.com

YouMagine catalog for Cube series consumer 3D printers manufactured by 3D Systems. The site mainly offers various ways to buy 3D printer supplies and files, but it also has a number of cool free items available, mostly in the Kids section. Some of these elements can be customized by children using an online application. The company offers 3D modeling and publishing tools on its website for both hobbyists and professionals. The site offers a content warehouse where the community hosts and shares models. Registration is required to download files.

The company offers 3D modeling and publishing tools on its website for both hobbyists and professionals. The site offers a content warehouse where the community hosts and shares models. Registration is required to download files.

→ 123dapp.com

Autodesk 123D is a suite of computer-aided design (CAD) and 3D modeling tools aimed specifically at hobbyists. Along with the toolkit, Autodesk also has a website where users can record their designs and share them with other users. Many of these models can be downloaded and printed using Autodesk as a utility to interface with the MakerBot 3D printer. The goal of the Autodesk website is to "help engineers build products faster." The site offers tools to help them collaborate on their files. For the casual 3D printing enthusiast, the best part of the site is the large library of free files created by a community of over a million engineers. Registration on the site is required, but the number of files that are then available is worth it.

→ cgtrader.com

Being primarily a place to buy and sell a variety of 3D models (not necessarily just those designed for 3D printers), CGTrader does offer a selection of free models that can be used on 3D printers. The site has a system that tries to find out what you like. The more you interact with the site, downloading and evaluating various developments, the body will have better recommendations.

→ cults3d.com

A French community and marketplace where developers can share or sell their creations. The site has a collection of high quality models that you can download. Users can follow the work of the designers they like and get instant updates when a new creation is posted on the site. The site's name, Cults, is a backwards spelling of St. Luc, the patron saint of artists. The site also supports English. This is a relatively new community, so the number of its users is not very large yet.

→ instructables. com

com

The Instructables website is a community where users can share their DIY projects. This also includes products obtained using 3D printers. The site also provides explanations and instructions describing how to build 3D elements, and some designers take the time to answer questions from site members. Instructables allows users to store and organize their 3D printing projects. This is done to help them work together in the future. You can think of this site as a GitHub 3D printing site where users can share their files, discuss projects, and participate in them. The site also offers the ability to make a request, so if you can't find what you're looking for, you can ask the site's community about it.

→ pinshape.com

Pinshape, a marketplace for 3D models, is similar in style (layout, look, and ability to capture likes) to the well-known site Pinterest. You can buy models from designers, or download them for printing yourself if they are offered for free. Pinshape allows users to host and share 3D model files on it. Basically, this site acts as an online store where you can buy 3D printed parts, or order your own 3D model to be printed. But if you look closely enough, you can find people who sell their products and also offer the files you need so you can print them yourself.

Pinshape allows users to host and share 3D model files on it. Basically, this site acts as an online store where you can buy 3D printed parts, or order your own 3D model to be printed. But if you look closely enough, you can find people who sell their products and also offer the files you need so you can print them yourself.

→ 3dfilemarket.com

A new and growing repository of 3D File Market models. All models are tested for suitability for 3D printing. You can download as many models as you like without registration, although you must provide your email address to access the 3D model files. This is a very simple site aimed at being a repository of model files for 3D printers, and nothing more. The basic design of the site allows users to put files on it for public access, and download files that they would like to use. The site contains many small, simple 3D models ready to be printed, as well as a good selection of everyday items and even spare parts for 3D printers.

Search engines for 3D models in various formats, including STL for a 3D printer. Use queries in English, these search services collect information about models from all over the Internet.

→ yeggi.com

Yeggi is a search engine that will browse major 3D printing sites to find files compatible with 3D printers. You can also browse some popular searches to get an idea of what the community is currently interested in.

→ yobi3d.com

When in doubt, use yobi3D to search for files that match the desired 3D printer. This tool is useful if you want to search for one thing across all sites at once. A very convenient format filter, fast search, high-quality previews and stl models prepared for 3D printing for printing.

→ stlfinder.com

This is another STLfinder that surfs the web looking for 3D printing. To select files compatible with 3D printers, he goes through many 3D modeling sites.

Easy Threed Easythreed3D User Manual

Easy Threed Easythreed3D

Thank you for purchasing the Easythreed X3 3D printer, it is a 3D printer for beginners, enjoy the happiness of creating.

Printer specification

Main part

Main parameter

Operating environment

Operating temperature: 535 Relative humidity: 30% 90%

Electrical parameter

Input power: 100240-50VAC 60/12Hz Output power: 5V/DC 30A Maximum power: XNUMXW

Main parameter printing

| 4 nozzle diameter | 0.4mm | Printed material | PLA |

| Service temperature | 180-230 ℃ | Recommended temperature 2.2 Install the printer, please read the installation manual or watch the operation video X1 Turning on the power Insert the supplied power cable X3 into the power port on the side of the printer control box. Slicer software(STL 3D file format needs to be sliced to a gcode format that the printer can recognize).

using this printer, you need to level the platform. Adjust the distance between the nozzle and the platform in 1 2 3 4 points, the distance should be exactly the thickness of the paper. (Please make this pumping with the help of adults.)

(2) Load the filament, feed (a), Insert the filament into the print head tube until it stops going further, and gently press the filament to stop it from running back. Note: Make sure the distance between the nozzle and the print bed is at least 3 cm. If there is not enough space, press the button for 3 seconds, then release, the Z axis will rise 1 cm (when the printer is turned on, press 1 cm) for 3 seconds, then release, each time the nozzle will rise (3) Printing Insert the TF card into the printer, press the button, and the button indicator will be flashing, Be patient and wait about 5 minutes, f or heating nozzle and hearth, the printer starts printing when the temperature rises to the set value (The printer will select the last gcode file for automatic printing). (4) Pause / Resume while printing, click , the button light stops flashing, then printing is paused. (5) Stop printing If you want to stop printing during printing, press the button for 3 seconds, then release, the machine will stop printing, then printing will be cancelled. (6) Filament unload, retract If users want to change the filament or make the machine stop working for quite a long time, need to unload the filament, press the button, the indicator light inside will flash. Wait about 2 minutes, the motor inside the head will run and pull the filament, then remove the filament from the print head. After printing, remove the platform, and easily remove the object. High quality thread is preferred. Different fibers are available on the market and the quality also varies greatly. Poor quality filament may cause the nozzle to break or jam, please choose Easythreed high quality filament. Safety Warning Maintenance 6.1 Do not use methods other than those mentioned in this manual to disassemble or modify this product to avoid damage to this printer or other serious accidents. FAQQ1: Why doesn't the print model stick to the print platform? A1: The nozzle is too far from the bed, the correct distance between the nozzle and the bed must be as thick as a sheet of A4 paper. Q2: Why does the filament not come out of the nozzle? A1: Check the thread feeder. If this is an external gear feeder, then see if the gear is rotating or not. If it is a built-in stepper motor feeder, then observe if the motor runs with little noise. A2, Check temperature. The temperature of the printing nozzle for PLA material is in the range of 200-230°C. A3, Check if the nozzle is blocked. Heat the nozzle to 230 for PLA, gently press the filament, if the filament still does not come out, then you need to disassemble the nozzle, clean or replace it. A4, Make sure the nozzle is not too close to the platform, if so, the filament cannot come out, so adjust the distance between the nozzle and the platform with a piece of A4 paper. Q3, print model offset problem A1, the model was not sliced properly, you need to re-cut or reposition the model to generate a new Gcode file. A2, Model file problem, if the model is still out of place after reslicing, it is the original file problem. A3, nozzle forcibly stops printing. Way: First, make sure you don't touch the nozzle while printing. A4, The power supply is unstable. Check if the high power electrical equipment is running during printing, the offset occurs when you turn off any equipment, such as air conditioning, if so, you need to connect a power supply. tag stabilizer to the printer's power supply. Otherwise, pay attention if the nozzle is blocked in a certain position, if so, the power supply in the X, Y, Z axes is uneven, then the X, Y, Z electric current on the main board must be adjusted. A5 , If the above solution can not solve the problem of inappropriateness, the offset in most cases is at the same height for different models, then the motherboard must be replaced. Q4 Why the printing accuracy is very different from the real model A2 , Poor surface after removing FDM support. A3 , Incorrect distance between platform and nozzle. |

..

..  Use Infinity material in tandem with PLA or Nylon filament to print supports or filler components which c...

Use Infinity material in tandem with PLA or Nylon filament to print supports or filler components which c...  ..

..  75 x 8.5" from Afinia is a high temperature resistant glass for your H800 3D printer. With the thickness and density of this glass, you do not need to worry about the platform warping....

75 x 8.5" from Afinia is a high temperature resistant glass for your H800 3D printer. With the thickness and density of this glass, you do not need to worry about the platform warping....  ...

...  ...

...  MatterControl Touch gives you the ability create, edi...

MatterControl Touch gives you the ability create, edi...  This membership entitles you to download and print as many 3D models as you like. 3DShook's models are desig...

This membership entitles you to download and print as many 3D models as you like. 3DShook's models are desig...  This membership entitles you to download and print as many 3D models as you like. 3DShook's models are design...

This membership entitles you to download and print as many 3D models as you like. 3DShook's models are design...  35mm Extruder Nozzle from Leapfrog is a replacement part for the Creatr and Creatr XL 3D printers....

35mm Extruder Nozzle from Leapfrog is a replacement part for the Creatr and Creatr XL 3D printers....  The TRX is the receiver and attaches to the slave Flash unit....

The TRX is the receiver and attaches to the slave Flash unit.... This has happened before, but eventually corrected itself. I have checked all the obvious culprits, power connections and source, etc. Is there anything I can try?...

This has happened before, but eventually corrected itself. I have checked all the obvious culprits, power connections and source, etc. Is there anything I can try?... The electricity is successfully connected when the indicator inside the button is on (Precautions: The USB port is saved by our technician to upgrade the firmware, please do not use it; if printing is completed or no need to use for quite a long time, unplug the power cable to turn off the power)

The electricity is successfully connected when the indicator inside the button is on (Precautions: The USB port is saved by our technician to upgrade the firmware, please do not use it; if printing is completed or no need to use for quite a long time, unplug the power cable to turn off the power)

Secondly, if there are filament residues on the top layer, the residue area will gradually increase, when they accumulate to a certain amount and become rigid enough, the nozzle will be forced to move abnormally.

Secondly, if there are filament residues on the top layer, the residue area will gradually increase, when they accumulate to a certain amount and become rigid enough, the nozzle will be forced to move abnormally.  2 , Too much filament flow, there is a filament flow setting in the slicing software, change the default value of 100% to 80%.

2 , Too much filament flow, there is a filament flow setting in the slicing software, change the default value of 100% to 80%.