3D printers for home business

Best 3D printers of 2022: top choices for work and home use

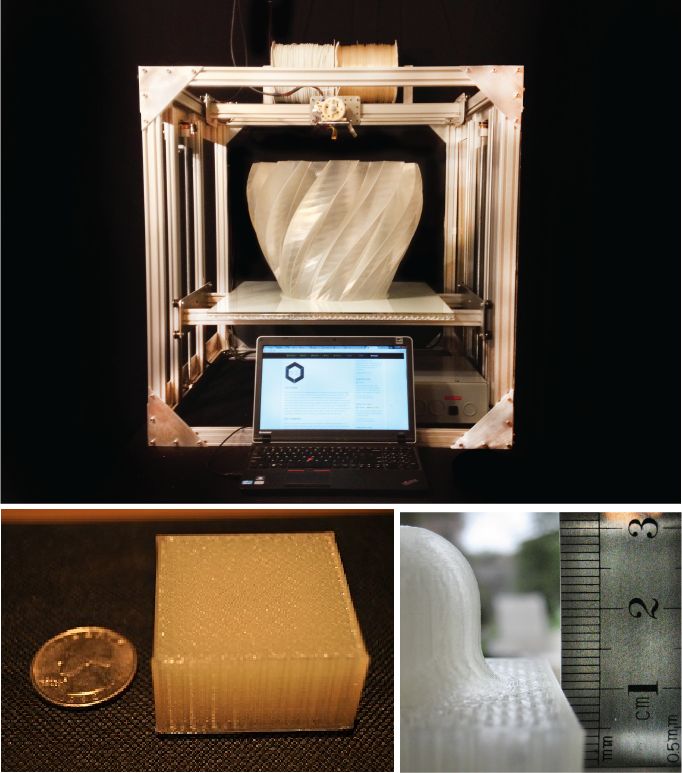

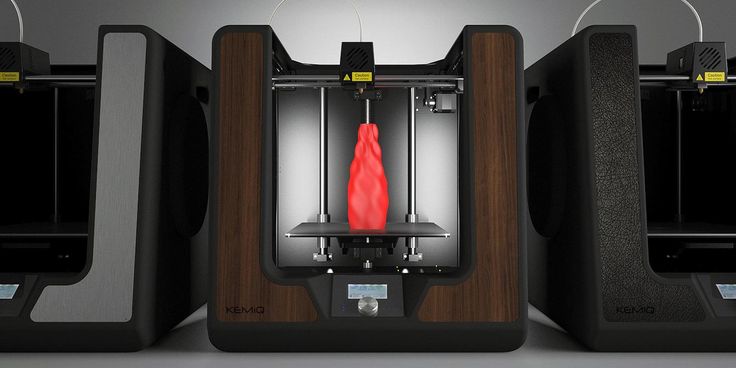

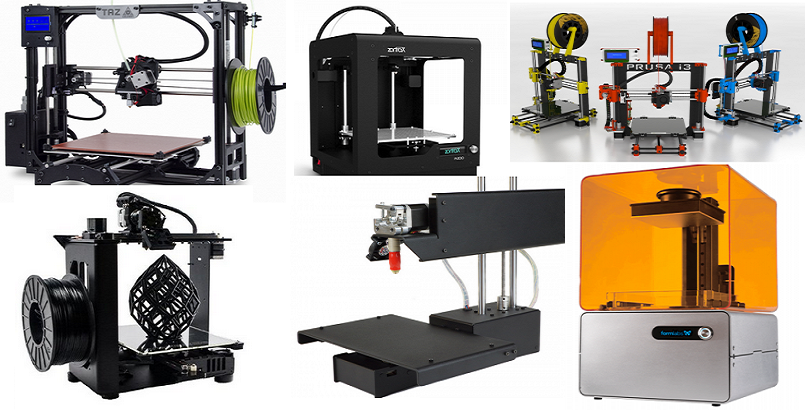

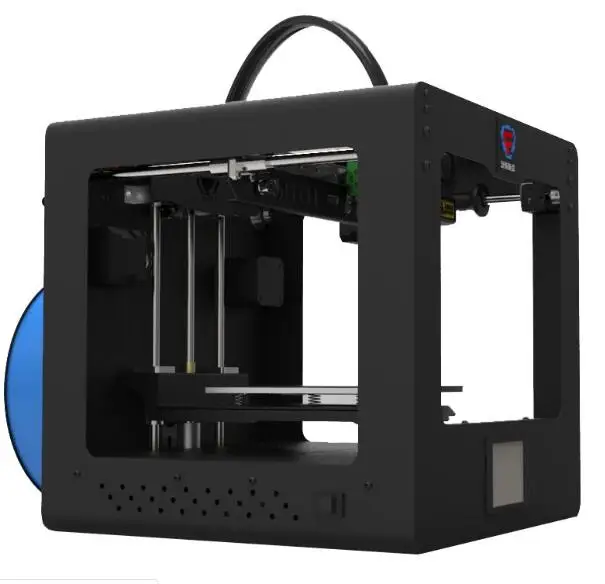

Our list of the best 3D printers contains clear and concise information on all kinds of 3D printers. (Image credit: Future)The 3D printer market is growing at an explosive rate, with new brands and styles of printing making an appearance each year. Where many 3D printers used to be huge, expensive machines, developments in technology and production now mean that many of the best options you can buy are increasingly affordable and can sit on a desk in your home without needing workshop space.

Naturally, this means there's now a massive choice of 3D printers that cater to all sorts of user needs and budgets. While this choice is excellent, picking the best 3D printer for your specific needs can be difficult. However, this guide can help, as we pick some brilliant 3D printers for all uses and budgets, with clear buying advice to help you determine which one you should buy.

Printing hardware has taken off in recent years, so while a handful of filament printers (otherwise known as FDM printers) were all that was once available, there's now a wide variety of different styles to suit your needs across a range of budgets.

Unlike office-style printers that just print ink onto paper, 3D printers turn digital models into real-world objects made from plastic, metal, and wood. FDM printers now come in all shapes and sizes and are well-suited to prototyping and crafting larger objects. At the same time, resin-based (SLA, MSLA, and DLP) allow for much greater detail, typically at a smaller scale, making them a fantastic buy for anyone looking to design jewelry or create tabletop miniatures.

You can use 3D printers to build complete products, make spare parts, or simply create things you’ll find helpful for your home, office, and workshop. And, since 3D printing technology is within the grasp of just about anyone, you don’t have to utilize one to your advantage.

Whether you’re just getting your feet wet or are an expert, here are the best 3D printers ranges to consider. Our picks wildly vary in price, size, functionality, and use case, so there should be something for you, whatever it is you’re looking for. Remember that the more expensive choices are better suited for professionals, while the best cheap 3D printers are ideal for those just starting.

Remember that the more expensive choices are better suited for professionals, while the best cheap 3D printers are ideal for those just starting.

The best 3D printers

Original Prusa MINI (Image credit: Prusa)1. Original Prusa MINI+

Small, affordable and remarkable 3D printer

Specifications

Print technology: Fused Deposition Modeling

Build Area: 18 x 18 x 18cm

Minimum layer resolution: 50 microns

Maximum layer resolution: 200 microns

Dimensions: 33 x 33 x 38cm

Weight: 4.5kg

Today's Best Deals

Reasons to buy

+

Great value for an FDM printer

+

Easy to use

+

Supports a variety of filament types

Reasons to avoid

-

Reel sits separately

-

Imperfect print quality

-

Calibration can be tricky

This affordable open-frame 3D printer is small enough to sit on your desk and easy enough to assemble yourself without expertise. It comes in kit form and uses FDM (Fused Deposition Modeling) to turn popular modeling materials such as PLA, PETG, ASA, ABS, and Flex into accurate printed products. There’s a Network LAN and USB port for simple connectivity and a user-friendly interface. This entry-level printer should be the first choice for crafters, modelers, and engineering enthusiasts. The Original Prusa MINI+ is a replacement for the Original Prusa MINI (minus the plus), the key advantage being that it now comes with a superPINDA sensor, which is not temperature dependent allowing the first layer calibration to be faster and more reliable.

It comes in kit form and uses FDM (Fused Deposition Modeling) to turn popular modeling materials such as PLA, PETG, ASA, ABS, and Flex into accurate printed products. There’s a Network LAN and USB port for simple connectivity and a user-friendly interface. This entry-level printer should be the first choice for crafters, modelers, and engineering enthusiasts. The Original Prusa MINI+ is a replacement for the Original Prusa MINI (minus the plus), the key advantage being that it now comes with a superPINDA sensor, which is not temperature dependent allowing the first layer calibration to be faster and more reliable.

Read the full review: Original Prusa MINI

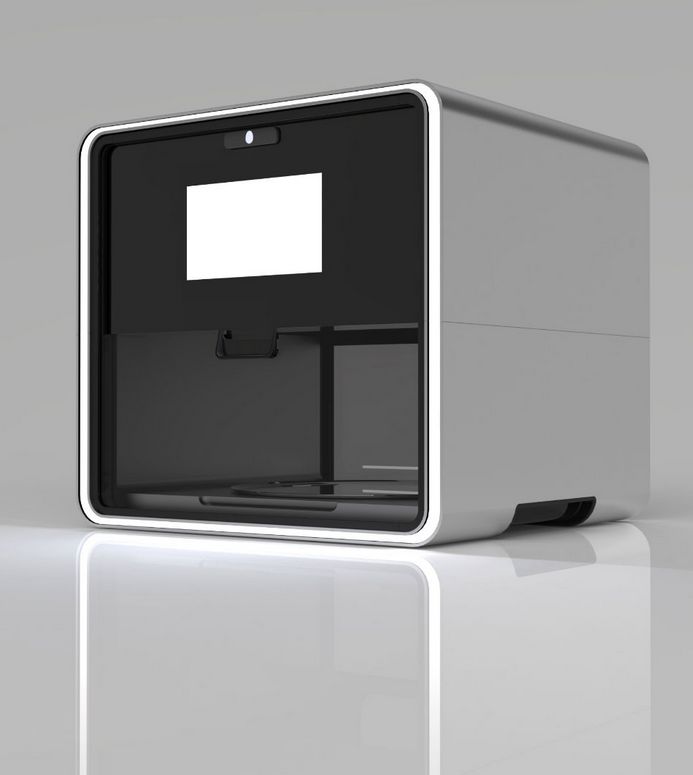

CEL-UK RoboxPro (Image credit: CEL-UK)2. CEL-UK RoboxPro

Best 3D printer for commercial printing

Specifications

Print technology: Fused Deposition Modeling

Build Area: 210 x 300 x 400mm

Minimum layer resolution: 50 microns

Maximum layer resolution: 500 microns

Dimensions: 513 x 508 x 605mm

Weight: 26kg

Today's Best Deals

Reasons to buy

+

Swappable print heads

+

Dual Extruder and auto bed leveling

+

Network ready, no wired needed

Reasons to avoid

-

Large scale printer, not ideal for home use

-

Can be difficult to load filament

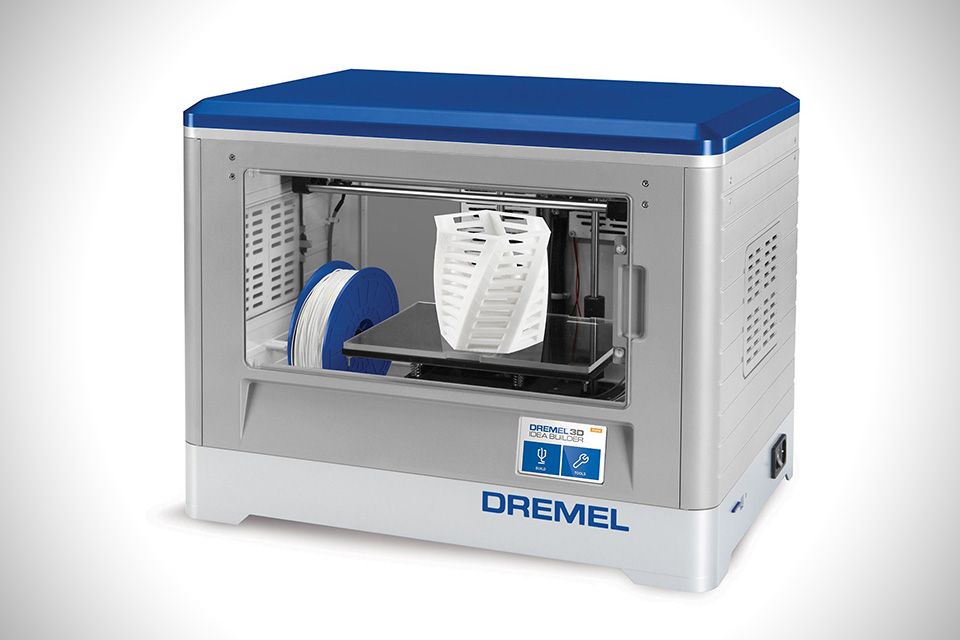

CEL-UK is a leader in 3D Printer innovation, with the original Robox printers introducing many new features to the world of FDM 3D printers. The RoboxPro is Robox on a large scale with a feature set that reads like a 3D print wish list; auto filament loading, auto bed leveling, Wi-Fi, network printing, and swappable tool heads. The main focus of the machine is quality and reliability, designed for anyone wanting a printer that can realize product ideas and get them to market. The enclosed design makes it an ideal choice for commercial and educational use.

The RoboxPro is Robox on a large scale with a feature set that reads like a 3D print wish list; auto filament loading, auto bed leveling, Wi-Fi, network printing, and swappable tool heads. The main focus of the machine is quality and reliability, designed for anyone wanting a printer that can realize product ideas and get them to market. The enclosed design makes it an ideal choice for commercial and educational use.

Read the full CEL-UK RoboxPro review .

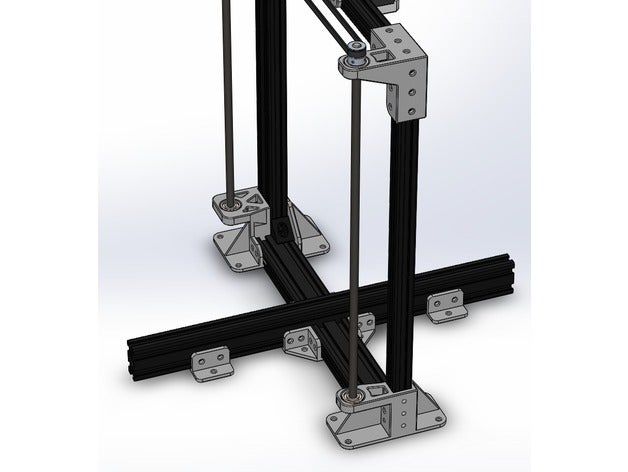

(Image credit: TRILAB)2. TRILAB DeltiQ 2

Distinctive delta design for professional 3D printing

Specifications

Print technology: Fused Deposition Modeling (FMD)

Build area: 25 x 25 x 30cm

Minimum layer resolution: 50 microns

Maximum layer resolution: Variable

Dimensions: 41 x 50 x 81cm

Weight: 10kg

Today's Best Deals

Reasons to buy

+

Elegant design

+

Easy expansion

Reasons to avoid

-

Not suitable for all materials

-

Fully open design

This elegant delta design should get your attention if you’re looking for a professional 3D printer for fairly large and complex projects. It uses FDM technology to build 3D models from rolls of filament. Still, instead of the more common cartesian printers, the TRILAB DeltiQ 2 has a fixed round build plate with the extruder suspended between three arms that move the print head along three axes. It gives this model a fairly small footprint, while its high tower design ensures it can print some quite large pieces.

It uses FDM technology to build 3D models from rolls of filament. Still, instead of the more common cartesian printers, the TRILAB DeltiQ 2 has a fixed round build plate with the extruder suspended between three arms that move the print head along three axes. It gives this model a fairly small footprint, while its high tower design ensures it can print some quite large pieces.

And unlike most 3D printers, it has two extruder options, one for standard PLA and PETG and the other for flexibles. It just requires a little retooling to swap between them. The TRILAB DeltiQ 2 uses some of the best components available in its construction, and the interface is a smartphone running a dedicated app. This handsome, high-end workshop printer would sit well in any laboratory, studio or classroom.

Read our full TRILAB DeltiQ 2 review .

Original PRUSA SL1 (Image credit: PRUSA)3. Original PRUSA SL1S SPEED

The best MSLA printer just got better

Specifications

Print technology: Stereolithography

Build area: 320 x 450 x 500mm

Minimum layer resolution: 25 microns

Maximum layer resolution: 100 microns

Dimensions: 400 x 237 x 225 mm

Weight: 4. 5kg

5kg

Today's Best Deals

Reasons to buy

+

Rapid printing

+

Great build quality

Reasons to avoid

-

High maintenance

-

Limited build volume

Prusa Research revolutionized the FDM 3D printer market, and this model looks set to do the same for SLA printers. While this printer uses stereolithography technology, it's a slight variant known as MSLA. This uses a monochrome LCD and UV LED to expose the resin, which is cheaper than precision lasers but just as accurate. The SL1S SPEED replaces the outgoing SL1, and as you might have guessed from that model name, it’s faster – around ten times faster and with a vastly improved print quality. The speedy new model looks set to lead the SLA market with support from the excellent PrusaSlicer software and a huge open-source community.

Read our full Original Prusa SL1S 3D printer review .

4. AnyCubic Vyper

The best beginner friendly FDM 3D printer

Specifications

Print technology: Fused Deposition Modeling

Build area: 245 x 245 x 260mm

Dimensions: 508 × 457 × 516mm

Weight: 10kg

Colour

Black

Condition

New

Today's Best Deals

Reasons to buy

+

Built-in accessories drawer

+

Reliable automatic bed-leveling

+

Great value for the features you get

Reasons to avoid

-

Excessive initial stringing

-

Questionable build quality in places

-

Cura profile needs fine-tuning

If the world of 3D printing ever seemed too intimidating for you, look no further than the AnyCubic Vyper. While perfect for beginners with its auto-leveling feature and minimal assembly, seasoned printing hobbyists will also appreciate what it can offer, albeit with a few adjustments.

As the 'automatic leveling' might imply, the AnyCubic Vyper removes the need to align your build plate manually should you want to move the machine to a different location. It's fast and accurate, saving time when setting up your first print, which makes setting up and getting started a breeze.

Read our full AnyCubic Vyper review.

Raise3D E2 (Image credit: Raise3D)5. Raise3D E2

The best workhorse 3D printer

Specifications

Print technology: Fused Deposition Modeling

Build area: 330 x 240 x 240mm

Minimum layer resolution: 20 microns

Maximum layer resolution: 250 microns

Dimensions: 607 x 596 x 465mm

Weight: 35kg

Colour

Black

Condition

New

Today's Best Deals

Reasons to buy

+

High-resolution print capability

+

Innovative ouch screen interface

+

Dual Extruder system can work independently

Reasons to avoid

-

Huge and heavy, not ideal for home use

-

Careful placement of bed required

-

Needs manual assistance for filament loading

3D printing has come of age, and machines like the Raise3D E2 bring high-end FFF printing to the home, education, and business. This dual extrusion printer goes head-to-head with the RoboxPro and will fulfill most companies' design and development needs with slick business and network integration. Home and educational users will benefit from a simple interface and near-faultless reliability. The only drawback of this machine is its size and weight.

This dual extrusion printer goes head-to-head with the RoboxPro and will fulfill most companies' design and development needs with slick business and network integration. Home and educational users will benefit from a simple interface and near-faultless reliability. The only drawback of this machine is its size and weight.

Read the full Raise3D E review .

(Image credit: Anycubic)6. Anycubic Photon M3

Detailed 3D modelling for beginners

Specifications

Print technology: Stereolithography (SLA)

Build area: 18 x 18 x 18cm

Minimum layer resolution: 50 microns

Maximum layer resolution: 200 microns

Dimensions: 18 x 16.4 x 10cm

Weight: 7kg

Colour

Yellow

Condition

New

Today's Best Deals

Reasons to buy

+

Good value

+

Detailed models

Reasons to avoid

-

Print size is small

-

Poorly placed USB port

The Anycubic Photon M3 is the ideal entry-level resin printer to introduce you to 3D printing. It’s relatively easy to set up and operate, and the box includes everything you need to get started except for the UV resin. This compact model will fit easily on your desk in a well-ventilated room, though the build volume is somewhat limited at 180 x 163.9 x 102.4mm or 7 x 6.5 x 4-inches.

It’s relatively easy to set up and operate, and the box includes everything you need to get started except for the UV resin. This compact model will fit easily on your desk in a well-ventilated room, though the build volume is somewhat limited at 180 x 163.9 x 102.4mm or 7 x 6.5 x 4-inches.

This modest machine can turn out surprisingly detailed models for printing small plastic parts or artistic pieces. The interface is a 7.6-inch panel, and the software will help you print your project and slice it. If you want to make larger models, you should consider one of Anycubic’s larger 3D printers, but this is a great place to start for $299 (about £275 / AU$480).

Read our full Anycubic Photon M3 review .

Snapmaker 2.0 A350 (Image credit: Snapmaker)7. Snapmaker 2.0 A350

Best 3-in-1 3D printer

Specifications

Print technology: Fused Filament Fabrication, CNC, Laser

Build area: 350 x 350 x 350mm

Minimum layer resolution: 50 microns

Maximum layer resolution: 300 microns

Dimensions: 645 x 480 x 580mm

Weight: 29kg

Today's Best Deals

Reasons to buy

+

3D printer, CNC, and Laser cutter in one

+

Solid design and build quality

+

Easy to understand software

Reasons to avoid

-

Switching between uses takes time

-

Enclosure purchased separately

-

Very noisy when printing

A true 3-in-1 machine makes sense because 3D printers, CNC, and Laser cutters all use the same basic mechanics and technology. The original Snapmaker has a dedicated following, so it is no surprise that Snapmaker 2.0 builds on its predecessor's reputation and features. The A350 is the largest of three models and proves proficient in all disciplines. Swapping between the three heads and beds does take time to reconfigure and calibrate for the prince and features it's worth it.

The original Snapmaker has a dedicated following, so it is no surprise that Snapmaker 2.0 builds on its predecessor's reputation and features. The A350 is the largest of three models and proves proficient in all disciplines. Swapping between the three heads and beds does take time to reconfigure and calibrate for the prince and features it's worth it.

Read the full Snapmaker 2.0 A350 review .

Best 3D Printers: How did we test them?

3D printers are tested using a collection of bespoke benchmarks that help show the strengths and weaknesses of each model that, after time, can be compared against other products. These will differ depending on printer type, but a filament printer will be tested for stringing, bridging, and speed, as well as additional commentary on detail, achieved, and noise levels.

This will be done fairly, with dues given to different materials and printer types, with resin printers being subject to smaller, more detailed models to replace the stringing test. Design, price, and performance will also be explored as sections within the reviews.

Design, price, and performance will also be explored as sections within the reviews.

All our tests are conducted from the perspective of the printers target market where possible, so expect to see a lot of tabletop miniatures and figurines alongside the usual 'benches' (test models that are also dubbed as 'torture tests' to see where a printer needs to be better optimized for future prints).

- We've also featured the best printers

Round up of today's best deals

Anycubic Vyper

$429.99

View

See all prices

Raise3D E2

$3,499

View

See all prices

Reduced Price

Anycubic Photon M3

$699

$569

View

See all prices

powered by

Collin is the B2B Hardware Editor for TechRadar Pro. He has been in journalism for years with experience in both small and large markets including Gearadical, DailyBeast, FutureNet and more.

He has been in journalism for years with experience in both small and large markets including Gearadical, DailyBeast, FutureNet and more.

CEL-UK RoboxPro review | TechRadar

Skip to main contentTechRadar is supported by its audience. When you purchase through links on our site, we may earn an affiliate commission. Here’s why you can trust us.

(Image: © Future)

TechRadar Verdict

Dual extrusion, PEI build platform, wireless, scalable these are all desirable 3D printer features and are all part of the formidable RoboxPro. Aimed at the commercial market, this large scale FFF printer balances quality, ease of use and value like no other.

TODAY'S BEST DEALS

Why you can trust TechRadar Our expert reviewers spend hours testing and comparing products and services so you can choose the best for you. Find out more about how we test.

3D printers aren't known for being discrete, but some do at least try to blend in, like the compact RoboxDual . However, others are on another scale and can't help but stand out, like the formidable CEL-UK RoboxPro.

However, others are on another scale and can't help but stand out, like the formidable CEL-UK RoboxPro.

The printer was created to fulfil the demand from professional users, who liked the features of the RoboxDual but wanted an upscaled version for larger prints.

While the RoboxPro reflects many of the features of the RoboxDual, it's been fine-tuned for the commercial market and incorporates additions that better enable the machine to integrate with the workplace directly out of the box.

Networking, touch screen control and three interchangeable print heads come as standard, and as with the RoboxDual, you get a host of features designed to make life easier.

Quick change HeadLocks, magnetic print platform, intelligent filament reels and comprehensive software means that the RoboxPro looks set to offer the complete package.

While many of the features will appeal to the home market, the company is aiming this 3D printer at the commercial sector. This is a machine that is designed to be used as a workhorse in any workshop or product design studio.

CEL-UK has established itself as a manufacturer of compact and expandable 3D printers, where it excels. However, are those points that excel with the convenient RoboxDual in homes and schools going to be quite so successful on a larger scale, and appeal to a commercial user base?

(Image credit: Future)If you're familiar with the RoboxDual, then you'll know it's a machine with high-quality production values. It's a true product with none of the usual 3D printed parts that show homage to the open-source 3D print community.

In stark contrast, the RoboxPro is a little more grassroots showing 3D printed door hinges and parts alongside precision cut CNC panels. 3D printed parts are quite common in production 3D printers and it is great to see these manufacturers leading the way by trusting their own output carbon filled parts.

The RoboxPro is a British made machine, with a large quantity of the parts and manufacture all carried out in the Portishead factory.

While the styling and manufacture of the two machines are quite different, there's no doubting the cross over between the two models. Quality and innovation are at its heart, with the same programmable filament reels, print heads and software being used.

Features

The latest range of printers has taken an enormous leap forward in ease of use and specifications, but many of these innovative features were first seen on the RoboxDual.

The RoboxPro mirrors many of these innovations and adds and improves on them.

Again there's auto bed levelling, tapless PEI and enclosed print platform, interchangeable heads, programmable filament reels, automatic material recognition, fast heating, vast material compatibility, choice of WiFi or ethernet networking and a touch screen display.

So let's take a look at the specifications in depth.

Specifications

Spec Sheet

Build Volume: 210 x 300 x 400mm

Memory: Built-in up to 32GB (For internal use only)

Nozzle size: DualMaterial dual 0. 4mm / QuickFill 0.3mm and 0.8mm / SingleX 0.6mm

4mm / QuickFill 0.3mm and 0.8mm / SingleX 0.6mm

Layer Height: 50 - 500 Microns

Bed: Auto levelling Z-Axis

Print Surface: Heated Polyetherimide (PEI)

Software: AutoMaker

Materials: Extensive material support

Included Material: N / A

Power: AC 100-250V~, 50/60Hz, 3A max

First and foremost the RoboxPro is an FFF machine and takes 1.75mm filament reels. These reels can either be the SmartReels which feedback detailed information about the filament being used, or you can use third-party filaments.

The RoboxPro is all about scale and has a build area of 210 x 300 x 400mm this compares to the Ultimaker S5 at 330 x 240 x 300mm, a machine that cost over a $1000 more.

The print platform is a removable magnetic spring steel sheet laminated with the excellent Robox PEI ThermoSurface print platform, so no glue or adhesive is needed. This surface releases prints as the platform cools. This platform features AutoLevel which is essentially a self-levelling platform.

This surface releases prints as the platform cools. This platform features AutoLevel which is essentially a self-levelling platform.

Like the RoboxDual the Pro is a fully enclosed printer which means that it's better for advanced materials such as ABS, PC, PVOH and Nylon. When printing with PLA based materials, the door is left open.

The large print platform means that the size of the printer is considerably larger than it's smaller sibling at 513 x 508 x 605mm.

(Image credit: Future)One of the unique features of the CEL-UK 3D printers is the quickly interchangeable print heads, HeadLocks, and all three options are included, this gives you the DualMaterial, QuickFill and SingleX.

The DualMaterial enables you to print dual filaments, so for either printing dual colour prints or more practically dual-material models. Using this head allows you to print complex models that would be impossible to print with a traditional standard material head. Dedicated support material can be used such as PVA, PVOH or peel away support. The DualMaterial head offers dual 0.4mm nozzles.

The DualMaterial head offers dual 0.4mm nozzles.

The QuickFill head is the single material option yet still utilises dual nozzles. The first is a 0.3mm for printing the fine detail and outer walls while the second is a 0.8mm for the infill.

This combination of nozzle sizes gives a balance between speed and quality.

The final head is SingleX and has been developed with an Olsson Ruby nozzle for use with specialist materials such as Carbon Fill. This type of material is abrasive and will cause damage to standard heads.

Each head has a maximum temperature of 300ºC well beyond the standard nozzle temperature.

CEL-UK has also developed the needle valve system which cuts off filament flow dead to help reduce stringing, a common issue with retraction systems.

These heads enable layer resolutions with a custom range of between 50 to 500 microns and 100,200 and 300 microns with the presets.

Flexible and specialist materials can be tricky to print with, but the inclusion of the SmartExtruder ensures precise extrusion whatever the material. Finally, there's FastHeatup which ensures fast heating times for the nozzle and ThermoSurface.

Finally, there's FastHeatup which ensures fast heating times for the nozzle and ThermoSurface.

These features are all shared with the CEL-UK RoboxDual; however, the RoboxPro takes things further.

Designed for use in professional outfits, the Pro features extensive networking and scalability options.

(Image credit: Future)Built into the front of the machine is a sizable touch screen panel and this not only displays the current materials but can also be used to navigate settings and print directly from USB or other external drives.

Networking is an important feature and is available as wireless, or a hardwired network connection. Both enable the ability to use the AutoMaker software to connect and control multiple printers from one convenient interface.

(Image credit: Future)One other feature that the Pro has built-in is the HEPA filtration. These filters reduce the effect of smell and contamination to the work area when using specific materials. This meets the recommendations from a 2019 report produced by the Health and Safety Executive (HSE) for UK educational use of 3D printers.

This meets the recommendations from a 2019 report produced by the Health and Safety Executive (HSE) for UK educational use of 3D printers.

Setup overview

When it comes to ease of setup, the RoboxPro is just about as easy as it gets. Unpack, plug in, install the head and feed through the filament and the printer itself is ready to go.

Installing the AutoMaker Software is equally straightforward and once in place, you can then connect to the Pro through a choice of network connections.

If you purchase the AutoMaker Pro upgrade, then you also have the ability for Offline printing through a USB key.

Once everything is powered up, loaded, installed and connected the RoboxPro is ready for its first print, the whole process takes no more than 20 minutes, and that's taking it at a leisurely pace.

Setup in detail

The RoboxPro arrives ready to go, and before you start, you need to choose which of the three heads you want to use and the materials.

I chose the DualMaterial head to start, bolted it in place with the screw on the back, plugged in and switched on the machine. A few flashing lights and about a minute later the RoboxPro had booted.

On the front of the machine, the touch screen panel shows the boot process until it reaches the home screen.

This screen displays the Reels attached and any info you need about the reels such as how much material is left.

It also shows the left and right nozzle, bed and ambient temperatures and when it comes to printing, it will also show details of the print along with any connection info if you're on a network.

At the base of the screen is the menu button, a quick tap, and you're through to the options. These include Control, Print, Calibration, Purge, Maintenance and console.

On pages such as console where you can directly input GCode a small touch screen keypad appears. I found this a little fiddly, but it was handy for shortcode snippets when needed. Anything longer and I found attaching a standard keyboard to the USB port on the front was far more convenient. Of course you can always enter these commands via the AutoMaker software on your computer.

Anything longer and I found attaching a standard keyboard to the USB port on the front was far more convenient. Of course you can always enter these commands via the AutoMaker software on your computer.

After a quick check through the screens, it was time to load the filaments; I went for a black and red ABS. Essentially once I run through the set-up and calibrated, I'll replace one of the ABS filaments with PVOH support material. The PVOH is a water-soluble filament, and I've heard great things about this particular material so it seems like a good place to start.

Loading the filament involves feeding the end through a small funnel on the side of the machine and clipping the filament reel onto the side. Once a length of filament has been manually fed through the system, the extruder then grabs hold and automatically feeds through the rest.

The amount of material that's needed to feed through the system is just under a metre, so the initial manual feed does take a few moments and can be a little fiddly. Once the extruder grabs hold, the machine handles the rest.

Once the extruder grabs hold, the machine handles the rest.

This is where the first part of CEL-UK's real innovation comes in. The SmartReels that hold the filament contain all the information about the material, so there's no need to select what materials you're using through the software before printing. This simple system means anyone can use the printer without needing to know about glass transition points or feed rates.

CEL-UK produce a range of good quality of materials through partnerships with some of the worlds leading filament manufacturers. The SmartReels are an innovative addition and along with the SmartExtruders take much of the hassle out of loading filament.

Third-party materials are compatible and can be spooled onto a spare SmartReel and programmed with the AutoMaker Software.

While the warranty won't cover damage to printer parts caused by third-party materials they are fully compatible and I ran quite a few through the system with no adverse effects.

In this test, I've used the Pro version of AutoMaker which costs an additional £59.90 annually and adds a few additional features such as offline printing.

The standard version of AutoMaker is free and for most people will suffice through a direct connection to the printer through Wifi or network cable.

With AutoMaker Pro installed it's just a case of connecting to the printer. I connected through a standard network cable as this seemed like the easiest solution.

With the cable in place, the IP of the machine appears on the front panel. In AutoMaker, you then click on the Preferences and select Network, type in the IP and click connect. You're then asked for the password; 1111, and that's it. Some networks will allow automatic detection of the available RoboxPro or Root, it depends on the router type.

Connecting through Wifi is equally easy, on the touch screen click the cogwheel, then Wireless Settings and enter the name of the network and password and click OK and you're done.

Once the IP shows on the RoboxPro panel type this into AutoMaker Pro and again click Connect.

If you're printing offline using AutoMaker Pro, then you can save the printable file to a USB stick and push it into the port on the print and use the Print menu to select.

Now with all the software installed and printer connected the final step before printing is to run through calibration sequences. This just ensures everything is working ok, especially seeing as how the printer had a lengthy journey by van and car.

Purge and calibrate

Before starting with the calibration it's advised you purge. This ensures that the system is clear of any previous filaments. This is a feature you don't usually see as a function on machines with the manufacturers simply suggesting you do this manually between each filament swap.

The process here is flawless and takes about five minutes. After the printer had successfully drawn a series of lines across the print platform it was time to run the height and alignment calibration.

The height calibration is especially useful as it ensures that your prints stick to the PEI print platform. The AutoMaker software runs you through the process step-by-step, and this takes around 5-10 minutes.

Through the process, you're asked to remove the PEI print platform which is held magnetically to the movable X-axis and in position by six screw heads.

(Image credit: Future)Removing the platform is easy enough despite the strong pull of the magnetics, but replacing takes a little careful positioning.

The screw head at the back and front help with the positioning but you need to make sure that the platform sits under the lip of the corner screw heads and not on top.

The alignment calibration is again all handled by the AutoMaker software, and after the calibration print has finished, you can dial in any corrections needed.

The entire set-up and calibration process is guided, and there is very little that can go wrong through the process.

With everything set and ready to print, I opted to print the CEL-UK Robot in Orange ABS. The print at medium quality takes about five hours, and the results are superb.

AutoMaker vs AutoMakerPro

The RoboxPro ships with the standard version of the AutoMaker software and to be honest, this is comprehensive and enables you to access almost all the features you could need for printing with the RoboxPro.

However, for an additional $73 (£59.90), and that's annually, there's the AutoMaker Pro software. This is a yearly licence and gives you access to a few more features, including access to the latest Cura4 slicing engine and offline printing.

This may seem like a lot to pay for a few seemingly small features but being able to use the G-Code Visualiser to preview the sliced code and print offline will appeal to those using the printer in a commercial setting.

Either version of the software enables the bulk of functions and features with the ability to load models, adjust print quality settings and print over a network to one or multiple printers.

TODAY'S BEST DEALS

- 1

Current page: Introduction, design and features

Next Page Performance and verdict

Imaging Lab Manager

Ali Jennings is the imaging lab manager for Future Publishing's Photography portfolio. Using Imatest Master and DxO Analyser he produces the image quality tests for all new cameras and lenses review in TechRadar's cameras channel. Ali has been shooting digital since the early nineties and joined Future's Photography portfolio back in 2003.

TechRadar is part of Future US Inc, an international media group and leading digital publisher. Visit our corporate site .

© Future US, Inc. Full 7th Floor, 130 West 42nd Street, New York, NY 10036.

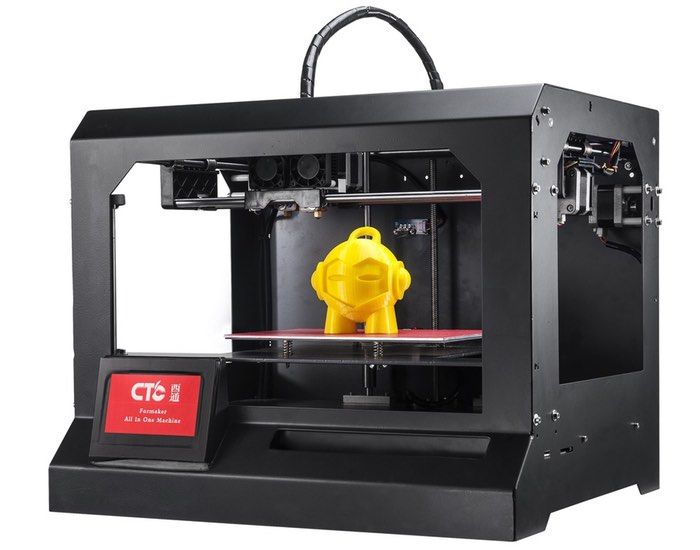

Which 3D printer to choose for business

3D printed business models

3D printing is making its way into more and more areas of life these days. At the same time, the demand for 3D printing remains at a high level and the demand for products produced by additive methods is constantly higher than the supply. In a situation of such a shortage, a far-sighted businessman decides to enter this market in order to earn money by satisfying this request.

At the same time, the demand for 3D printing remains at a high level and the demand for products produced by additive methods is constantly higher than the supply. In a situation of such a shortage, a far-sighted businessman decides to enter this market in order to earn money by satisfying this request.

For new players in the 3D printing market, the choice of niche is closely related to the choice of technology, technique, and, sometimes, even specific models of 3D printers.

It is important that we are talking about business - a sphere of life in which everything can be found at a price expressed in the amount of money, which means that there are general requirements that apply to equipment. Maximum reliability allows you not to spend on repairs, which means it is worth the investment. The presence of all certificates for the equipment is required by the state from the business. The maximum level of after-sales service allows the entrepreneur not to learn 3D printing, but simply to do the business for which he created his business. The cost of the 3D printer itself is not decisive in choosing a particular machine; in various areas, the payback period for investing in such equipment can be both short and almost instantaneous.

The cost of the 3D printer itself is not decisive in choosing a particular machine; in various areas, the payback period for investing in such equipment can be both short and almost instantaneous.

In general, there are several models for using a 3D printer for profit.

-

The company is introducing 3D printing to help existing processes.

-

The company switches to the production of a product using additive technologies

-

And there are companies that deal exclusively with printing, and the very idea of their business and their product is tied to additive technologies.

Let's see what 3D printing technologies are used in different models of companies on the market, as well as how to choose the right 3D printer for the business in your chosen niche!

Business 3D Printer

Modernization of existing business and technical processes is the key to the success of any enterprise. Not surprisingly, with the advent of new technologies, production strategies can be revised and even radically changed.

Not surprisingly, with the advent of new technologies, production strategies can be revised and even radically changed.

With the cost of additive technologies becoming cheaper, more and more enterprises are looking for ways to optimize their production using 3D printing. Sometimes, the optimization process leads to quite interesting results.

3D printing in production

Machine production is a method that allows you to get the most profit, and therefore the most interesting from a business point of view. Production line machines require constant maintenance and regular replacement of worn out parts. Usually, the process of replacing a part when it breaks down is as follows - a service employee localizes the malfunction, diagnoses the cause of the failure of a particular part, and orders a new part from the manufacturer according to the catalog. It’s good if the supplier has such spare parts in stock, but it happens that you have to wait until the spare part you need is produced.

From the moment of ordering to receipt, it can take from a week to months. All this time the machine is idle, and in our time of widespread use of conveyor chains, this can mean idleness of the whole chain of machines. Moreover, for some machine tools, spare parts cannot be obtained in principle - they can be discontinued, and sometimes it turns out that the company - the manufacturer of the machine has already gone bankrupt and there will be no new parts for the existing machine in principle.

Possible production losses in this case can reach amounts comparable to the value of the enterprise.

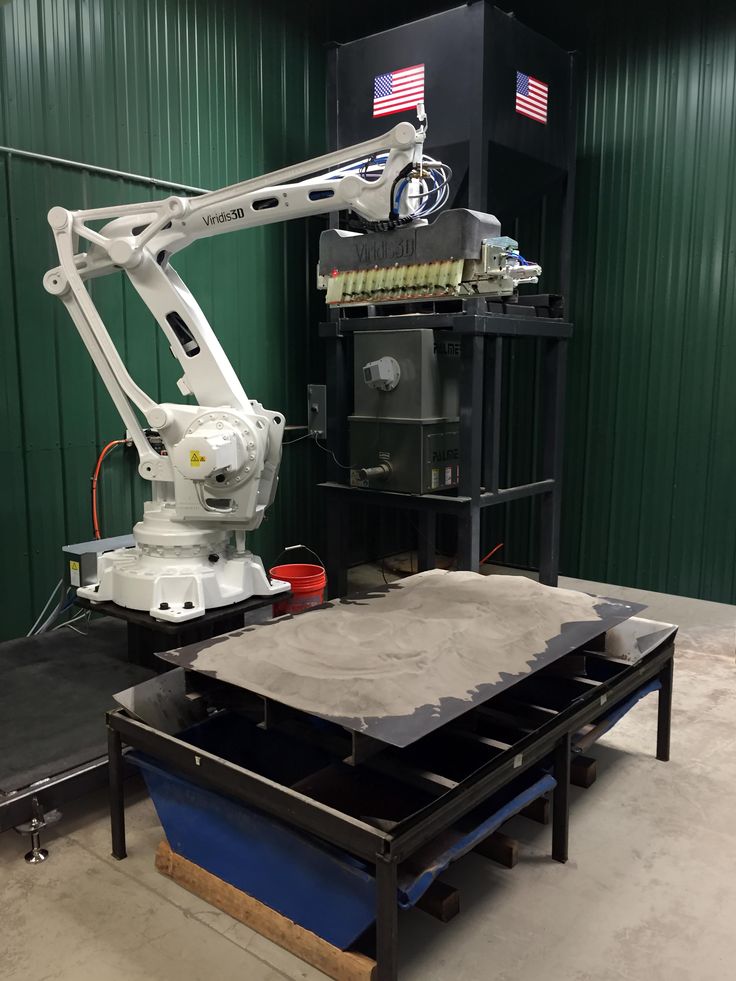

But what if the part you need can be obtained without ordering it from the machine manufacturer? The increase in the availability of 3D printing has led more manufacturers to create 3D printing departments based on their service departments. Such a department consists of several 3D modelers, several 3D printers and several 3D printers.

Such 3D printers must meet several requirements - machine parts must be strong enough, the cost of maintaining a 3D printer fleet must be reasonable, and the 3D printer must be able to produce both the spare part itself and models to obtain parts using more expensive methods.

Such requests are met by 3D printers using FDM and LCD technology.

Picaso 3D Designer X Pro

One of the bestsellers in this category is the Picaso 3D Designer X Pro printer. The defining advantages here are the omnivorousness of this model - you can print both ABS, PLA, PETG, Flex, Nylon, as well as more specific and composite plastics - and the ability to print simultaneously with two materials.

Phrozen Transform Standard

Phrozen Transform Standard is also a good choice. Huge build area - 292x165x400 mm, print speed up to 10mm/hour and high-intensity ParaLED system allow this printer to quickly and accurately print parts, including those from specific polymers.

Architectural 3D printing

In architecture, the ability to present a material model of the proposed project to the customer is of great importance. There is little to promote acceptance; a positive decision, such as the opportunity to inspect and feel live at least a model of a building or apartment. For the production of such models in architectural bureaus and studios, there are large departments. A few years ago, next to the powerful computers of architects, there were workshops for the manual production of models from papier-mâché and other materials that are little associated with modern technology;

For the production of such models in architectural bureaus and studios, there are large departments. A few years ago, next to the powerful computers of architects, there were workshops for the manual production of models from papier-mâché and other materials that are little associated with modern technology;

Affordable 3D printing has taken the manufacturability of the production of architectural models to a whole new level! Moreover, it turned out to be extremely simple to integrate 3D printing technologies into the work of an architectural bureau - engineers in this direction have already specialized in working with one or another software product related to the creation of 3D models, it only remained to bring this work to its logical conclusion - a layout.

The requirements for 3D printers for architectural offices are primarily related to the ability to produce large layouts. Strength here is not as important as the ability to convey the characteristic features of the project as accurately as possible - after all, the layout is a reduced copy, which means all the details will be tiny. These requirements are met by FDM 3D printers.

These requirements are met by FDM 3D printers.

Raise3D Pro2 Plus

A good choice for an architecture studio is the Raise3D Pro2 Plus 3D printer. A large construction area, coupled with precision, through the use of high-quality components and optimal kinematics, allow you to carry out large-scale projects. The ability to print with two materials at the same time makes the implementation of projects easier and allows you to simplify the post-processing of finished models.

BigRep Studio

For particularly demanding architects, BigRep Studio will be a pleasure to work with. Resume printing from the same place after a power outage, remote control and print management make it possible to install this truly large machine in its dedicated room. Well, if necessary, put it in the office, it will pass through the door, since the manufacturer provides the opportunity to disassemble it into 2 halves.

Advertising and exhibitions

The advertising business is probably one of the most demanding of novelty. The new attracts attention, and that's what advertisers do. The media that conveys the advertising message is of high importance. Today, any new way to attract a potential client is in demand.

The new attracts attention, and that's what advertisers do. The media that conveys the advertising message is of high importance. Today, any new way to attract a potential client is in demand.

A special area of this business is the organization of stands for exhibitions and similar events. It often happens that there is very little time to implement an idea, and success is achieved due to the possibility of implementing the maximum range of such ideas.

So in advertising, 3D printing is in demand in a huge number of its manifestations. Here the creation of handouts, and layouts of future projects, and noticeable signs of pylons and posters. Different 3D printing methods are suitable for different areas of the advertising business, FDM and LCD are very much in demand. One of the fastest growing areas of advertising using 3D printing is signage. A 3D printer creates an almost finished product - all that remains is to connect the backlight and electronics. This allows, firstly, to implement ideas that are too costly to implement by other methods, and secondly, to significantly simplify the tailor made approach to the customer - each customer wants his own, unique sign. The requirements for such equipment are special. The size is of course very important, the sign must be highly visible, which means the print area must be suitable - wide and long, but not too high. Printing speed is more important than quality, you can't see small inaccuracies from afar. Signs are most often placed on the street, which means that it is important that the products are resistant to use in different weather conditions, which means that it is necessary to be able to print with suitable plastics.

The requirements for such equipment are special. The size is of course very important, the sign must be highly visible, which means the print area must be suitable - wide and long, but not too high. Printing speed is more important than quality, you can't see small inaccuracies from afar. Signs are most often placed on the street, which means that it is important that the products are resistant to use in different weather conditions, which means that it is necessary to be able to print with suitable plastics.

Flashforge AD1 Channel Letter

The Flashforge AD1 Channel Letter 3D printer is perfect for solving such problems. Its huge printable area allows you to print signs that will be visible from a great distance. The high-speed extrusion system will make this process relatively fast, and the ability to print in multiple colors makes the need for post-processing much lower. The use of such a machine allows not only to meet the requirements of the most fastidious customers, but also to significantly reduce the cost of production.

Jewelry 3D Printer

Since ancient times, jewelry has been considered one of the most profitable. The history of jewelry creation dates back many centuries and goes back to the time of the birth of the Homo Sapiens species. Many techniques in this area of production have been preserved for decades, and are in many ways an art. But even in this area, we see that additive technologies help to realize more and more projects and ideas.

The meaning of the word “jewelry” itself is associated with miniature, precision and painstaking work. A lot of time and effort is spent on creating each piece of jewelry, which as a result can easily turn out to be a masterpiece of art. 3D printing helps to facilitate the production of highly detailed blanks, making the work of the craftsman easier. Most often, models are printed, according to which such semi-finished products are subsequently smelted. The achievements of modern technologies bring their quality to the level of an almost finished product. For this, of course, the SLA 3D printing method is used - with its help you can create the most detailed models. The requirements for such 3D printers are related to the maximum resolution of finished models, as well as the ability to use materials created for subsequent transformation into metal, for example, by direct casting.

For this, of course, the SLA 3D printing method is used - with its help you can create the most detailed models. The requirements for such 3D printers are related to the maximum resolution of finished models, as well as the ability to use materials created for subsequent transformation into metal, for example, by direct casting.

Phrozen Sonic XL 4K

A good example of a suitable 3D printer for jewelry is the Phrozen Sonic XL 4K LCD technology. The maximum resolution of 4K allows you to create the most detailed models, and the ParaLED system significantly reduces the time of their production.

Phrozen Sonic Mighty 4K

For workshops dealing with more miniature production, the Phrozen Sonic Mighty 4K may be sufficient. Although the build area is smaller and the ergonomics of the machine are not as well thought out, this printer performs well enough to be a rational choice when looking for a 3D printer for a small workshop.

Sculpture

A striking example of a paradigm shift in production in our time is sculpture. Many people remember the saying of the great Michelangelo Buonarroti “I take a stone and cut off all that is superfluous.” How exactly the master defines the fundamental principle of subtractive technologies! Modern developments help to make the process of creating masterpieces more connected with working with the head than with the hands.

In our time, the sculptor has the opportunity not only to work with material objects, but to almost completely rid himself of such work. A chisel and hammer can replace a computer and a 3D printer. The requirements for the machine in this bundle are mainly related to the area of \u200b\u200bconstruction - sculptures can often be large. There is also a need for printing with different materials to implement projects that are complex in terms of 3D printing. It is important that the finished model can be processed by classical methods. Suitable 3D printing methods are FDM and SLA.

Suitable 3D printing methods are FDM and SLA.

CreatBot D600 Pro

The CreateBot D600 Pro 3D printer becomes a frequent inhabitant of the studios of successful architects. A huge build area, the ability to print with two materials at the same time make this machine ready for the implementation of projects of increased complexity. The presence of a special table cover, as well as a special compartment for drying plastics, makes the process as comfortable as possible and does not require extra space.

Peopoly Phenom XXL

For more detailed sculpting tasks, it will be useful to look at the Peopoly Phenom XXL 3D printer. The gigantic build area, coupled with the use of MSLA technology, makes this machine stand out from other printers in this price range.

Business converted to use a 3D printer

There are several periods of the so-called “breakthrough development of production” in history. One of the last can be called the Great Industrial Revolution in England. This revolution was made possible and resulted from the invention of a new method of production - production with an improved steam engine. Living during even such a revolution, it is difficult to realize the significance of a single invention or new technology for future generations. But even these difficulties do not prevent us from reasonably calling modern additive manufacturing methods revolutionary, of great importance, and changing entire business sectors.

This revolution was made possible and resulted from the invention of a new method of production - production with an improved steam engine. Living during even such a revolution, it is difficult to realize the significance of a single invention or new technology for future generations. But even these difficulties do not prevent us from reasonably calling modern additive manufacturing methods revolutionary, of great importance, and changing entire business sectors.

Today we see a huge number of companies that, while remaining fundamentally in the same area, are changing the entire production line of their product, based on the new opportunities that 3D printing provides.

Dental 3D printers

For me personally, going to the dentist is always stressful. Despite the fact that in our time, sitting in the dentist's chair and not feel real negative sensations, memories of visits to doctors in childhood encourage us to think less about the existence of problems with teeth. Perhaps you do the same. It is also possible that for this reason, you, like me, do not notice strong changes in this area of \u200b\u200bmedicine. And they are really huge and, in my opinion, even a little magical.

Perhaps you do the same. It is also possible that for this reason, you, like me, do not notice strong changes in this area of \u200b\u200bmedicine. And they are really huge and, in my opinion, even a little magical.

Modern technologies have made it possible to change the correction of such a frequent feature of dental clinic clients as malocclusion. In the days before 3D printing, overbite was corrected with braces or braces. This process was very pleasant, required a lot of attention from the client, and also forced to replace the usual tools, such as a toothbrush, with specific and inconvenient ones. For many, wearing braces was also unpleasant from an aesthetic point of view.

Why did people make such sacrifices? A metal brace attached to the teeth puts pressure on them in a certain direction, forcing them to shift towards the medically correct position. After a few months of wearing, the braces literally push the teeth where the dentist has determined.

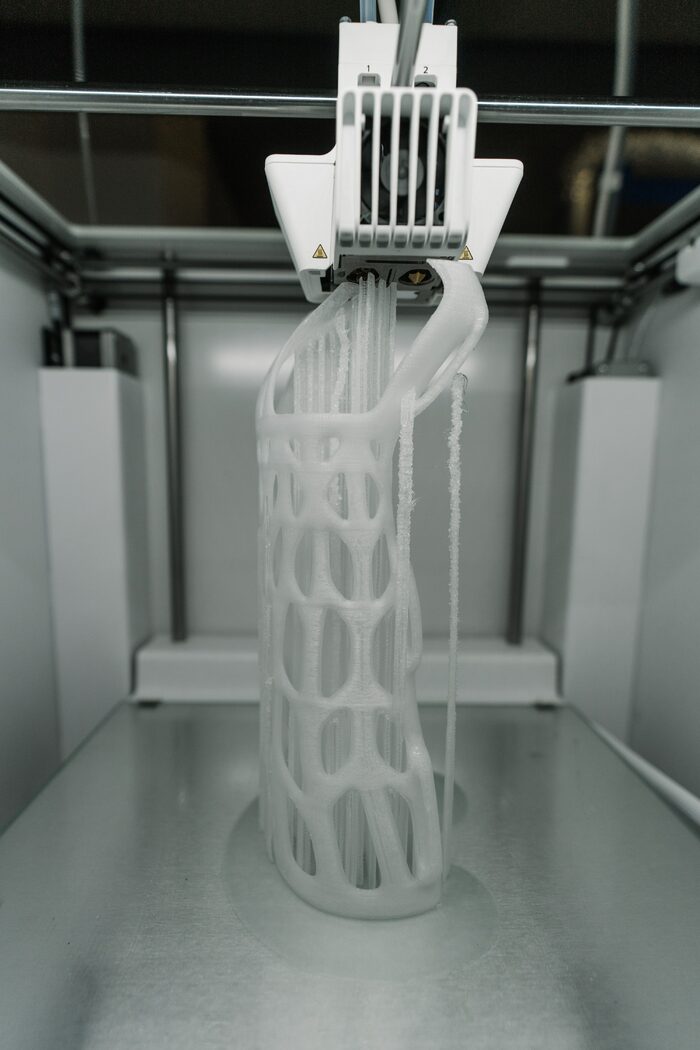

This is what the aligners look like

3D printing has changed the approach to the process itself so much that a patient undergoing a course of bite changes practically does not change his habits and lifestyle! This technology is called aligners (from the English allign, align). Now the dentist takes a 3D map of your teeth, a special program calculates the necessary changes and creates 3D images of special onlays for teeth, which are subsequently cast from special materials according to 3D printed models. The patient puts on such linings before going to bed and takes them off in the morning. The accuracy of manufacturing is so high that it allows the maximum dosage of pressure on certain teeth, forcing them to move into place in the most natural and imperceptible way. The absence of the need to specially maintain such pads, the invisibility of the process to others, and the comfort make this technique very popular. The purchase of what kind of 3D printers will allow you to enter the dental services market? The main requirement is medical neutrality, the machine itself, plastics, production quality must be such that use in medical institutions is justified. An important issue is the availability of the necessary specific certificates. Mandatory ability to produce high-precision models.

Now the dentist takes a 3D map of your teeth, a special program calculates the necessary changes and creates 3D images of special onlays for teeth, which are subsequently cast from special materials according to 3D printed models. The patient puts on such linings before going to bed and takes them off in the morning. The accuracy of manufacturing is so high that it allows the maximum dosage of pressure on certain teeth, forcing them to move into place in the most natural and imperceptible way. The absence of the need to specially maintain such pads, the invisibility of the process to others, and the comfort make this technique very popular. The purchase of what kind of 3D printers will allow you to enter the dental services market? The main requirement is medical neutrality, the machine itself, plastics, production quality must be such that use in medical institutions is justified. An important issue is the availability of the necessary specific certificates. Mandatory ability to produce high-precision models.

One of the leading printer manufacturers for this market segment is Formlabs.

Formlabs Form 3

The Formlabs Form 3 3D printer allows you to create high-quality models using a wide range of plastics. Particular attention to issues related to the possibility of using printers from this company in medical institutions allows you to be sure of their safety. Ergonomics and ease of use make it possible to concentrate even more on the really important things - helping the patient.

Formlabs Form 3L

For dental clinics that have already increased their production volumes and the need for even more advanced equipment is clearly overdue, the Formlabs Form 3L 3D printer will be a rational choice. The advantages of this machine will not only be an increased build area, but also closed-loop calibration and simplified component replacement.

3D printing in modern orthotics

Will it be news to you that the left and right legs of each of us are of different lengths? And will it be news to you that this can affect your life much more than just complications with the choice of trousers? It turns out that the individual characteristics of a person associated with the length of the legs can be the cause of many diseases, including mental ones, such as depression. Orthopedists help to get rid of problems associated with the peculiarities of the bones, muscles and joints of the patient. Quite often, the healing technique of interaction is based on the principle that we discussed in the previous part of the article - gentle movement and maintenance of body parts in a medically correct place in the body. For example, if the disease is due to the fact that leaning on legs of different lengths, you have a curvature of the spine, the orthopedist prescribes insoles of different thicknesses for you, thereby leveling the difference in the length of your body supports. And here 3D printing helps a lot with its accuracy, and most importantly, the ability to manufacture to individual sizes. Basically, in this area of medicine, solutions based on FDM technology are used. Machines capable of printing with various plastics, including elastic and hypoallergenic, are required. The ability to print products immediately in pairs is welcome.

Orthopedists help to get rid of problems associated with the peculiarities of the bones, muscles and joints of the patient. Quite often, the healing technique of interaction is based on the principle that we discussed in the previous part of the article - gentle movement and maintenance of body parts in a medically correct place in the body. For example, if the disease is due to the fact that leaning on legs of different lengths, you have a curvature of the spine, the orthopedist prescribes insoles of different thicknesses for you, thereby leveling the difference in the length of your body supports. And here 3D printing helps a lot with its accuracy, and most importantly, the ability to manufacture to individual sizes. Basically, in this area of medicine, solutions based on FDM technology are used. Machines capable of printing with various plastics, including elastic and hypoallergenic, are required. The ability to print products immediately in pairs is welcome.

Raise3D E2

These requirements are met by the Raise3D E2 3D printer. Automatic printing of products in pairs, the ability to use elastic materials for printing, convenient operation, and a filter make this model a good choice for an orthopedic clinic.

Automatic printing of products in pairs, the ability to use elastic materials for printing, convenient operation, and a filter make this model a good choice for an orthopedic clinic.

Cosplay

Many of us love masquerades. Probably one of the most exaggerated ways to dress up is cosplay (from the English costume play - costume play). Changing clothes, applying make-up, using additional accessories, cosplayers sometimes become almost like a copy of the heroes of movies, cartoons or comics. And if a pipe and a bowler hat can be enough to become Commissioner Maigret, then in order to turn into Iron Man or Wonder Woman, you need to create many elements of the costume from scratch. 3D printing helps with this. Cosplayers create such impressive costumes on a 3D printer that it is very difficult to guess about the use of 3D printing in their production. At the same time, if earlier costumes were created mainly with the help of papier mache and similar technologies, today most of the cosplay costumes are made using additive technologies. FDM is more commonly used, but LCD methods are also in demand.

FDM is more commonly used, but LCD methods are also in demand.

A cosplay 3D printer should be able to print large models as quickly as possible. Plastics used are different, but mostly inexpensive, accessible, and easy to process.

Anycubic Chiron

Cosplayers starting to print costume details often look at the Anycubic Chiron 3D printer. This is an inexpensive machine that allows you to print with affordable plastics and create models that fit into a large print area of 400x400x450mm. An additional advantage of the model is its high maintainability and unpretentiousness in maintenance.

Anycubic Photon Mono

To create accessories and details requiring more detail, purchase the Anycubic Photon Mono. The main advantage of this machine, of course, is its price. At the same time, the print resolution, although it does not reach the height of professional models, is at a level more than sufficient for use in cosplay.

Pure 3D printing business

Speaking about the various niches in the market that have been created by new technological opportunities, one cannot fail to mention those companies whose business appeared as a result of the advent of 3D printing and cannot exist without it. It happens that such companies were initially engaged in something else, but then they saw the economic feasibility of switching to a new business model. There are many companies that were originally created and designed for entrepreneurship based on 3D printing. Due to the fact that additive technologies literally burst into all areas of our lives like an avalanche, it may seem that they are indistinguishable from the companies described in the previous parts of this article. Looking closely, you can see that they make a profit exclusively by doing 3D printing.

Prototyping

Personally, 3D printing has always seemed to me to be a way to create some kind of device or device parts. Moreover, it was important that if I made a mistake in calculations or taking measurements, I could always quickly correct the computer model and get a new version of the required component in the shortest possible time. Abroad for a long time, and now in our country, there are companies on the market that are engaged exclusively in the production of prototypes. Quite often it turns out that this is a subsidiary of some kind of laboratory or research center. Depending on the area in which these prototypes are used, 3D printing techniques and requirements for 3D printers can be different. Most often this is FDM printing, which must be accurate. A prototyping 3D printer should be easy to operate and maintain.

Moreover, it was important that if I made a mistake in calculations or taking measurements, I could always quickly correct the computer model and get a new version of the required component in the shortest possible time. Abroad for a long time, and now in our country, there are companies on the market that are engaged exclusively in the production of prototypes. Quite often it turns out that this is a subsidiary of some kind of laboratory or research center. Depending on the area in which these prototypes are used, 3D printing techniques and requirements for 3D printers can be different. Most often this is FDM printing, which must be accurate. A prototyping 3D printer should be easy to operate and maintain.

PICASO 3D Designer X

In our country, the PICASO 3D Designer X 3D printer is in great demand. The high printing accuracy of this printer is combined with a compact body with the ability to dry plastic in the process. Working with various plastics is facilitated by the system of profiling print parameters for each plastic - if you don’t like how the model was printed, you can print it with another plastic without using a computer, it’s enough to have a profile for it. Ergonomics, ease of monitoring the printing process, a high degree of automation add significant advantages to the scales of this printer.

Ergonomics, ease of monitoring the printing process, a high degree of automation add significant advantages to the scales of this printer.

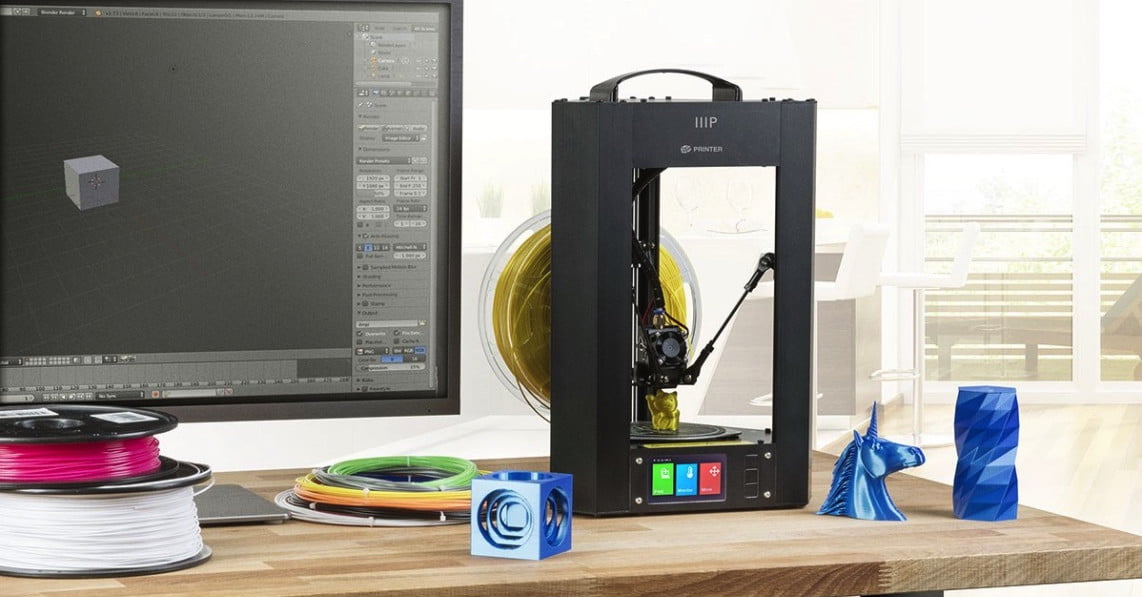

Flash Forge Finder

The FlashForge Finder 3D printer is used to create low-level prototypes and to teach the 3D printing process. Also, the low cost and bright appearance make this printer an attractive purchase for studios and circles, where children get acquainted with additive technologies.

Custom 3D printing

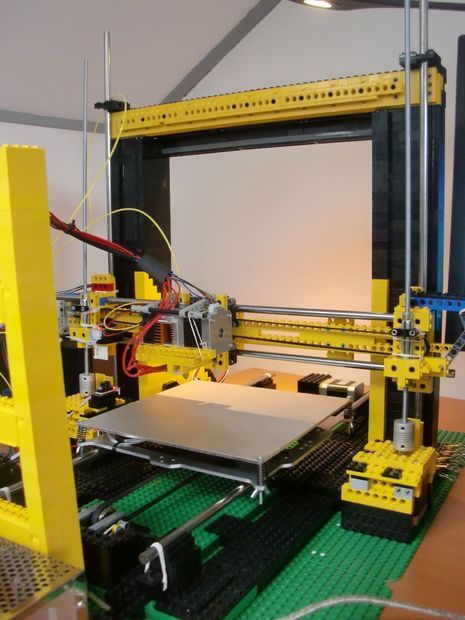

You can print on a 3D printer a huge, almost infinite number of types of things. And some of them need to be printed in one copy and that's it. Someone needs 3D printing not constantly, but not often or even very rarely. Custom 3D printing companies are helping to meet the needs of these potential customers. Usually a full service is provided - model development, 3D printing and processing. Often these companies have many 3D printers, and they are located in the same room. Such assemblies are called 3D printed trusses. The technologies that are presented on such farms are FDM and LCD. The fact is that the requirements for printers here are formed mainly in terms of the price of the printer, the cost of maintenance and reliability. For the fastest return on investment in a 3D-printed farm, inexpensive printers are purchased for it in batches - the more unification, the easier it is to work.

The technologies that are presented on such farms are FDM and LCD. The fact is that the requirements for printers here are formed mainly in terms of the price of the printer, the cost of maintenance and reliability. For the fastest return on investment in a 3D-printed farm, inexpensive printers are purchased for it in batches - the more unification, the easier it is to work.

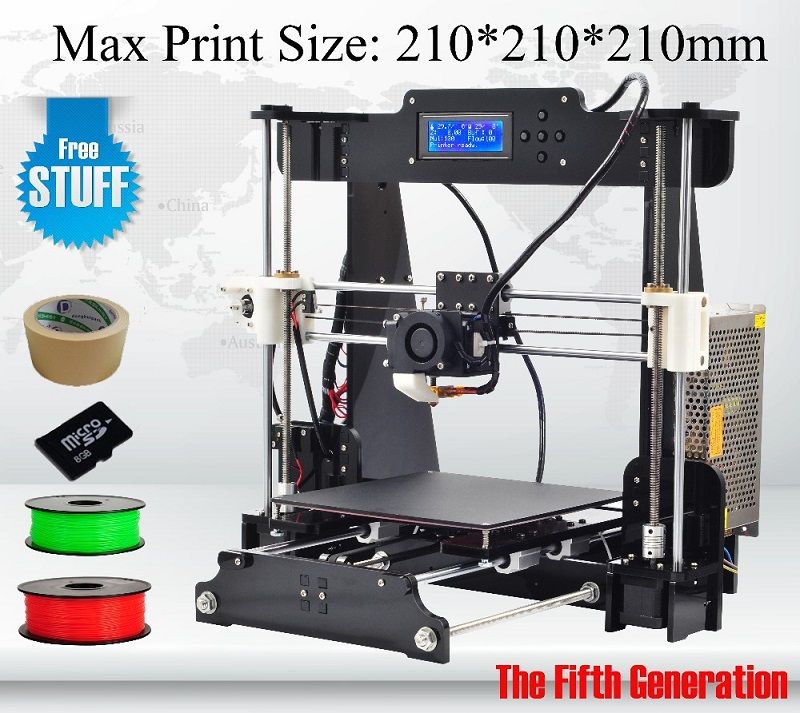

Creality3D Ender 3

The Creality3D Ender 3 3D printer holds the undisputed leader in terms of affordability/quality ratio in this market segment. Its cost, decent print quality, acceptable reliability and high maintainability make it possible to recoup investments in creating a farm based on such machines in the shortest possible time. Without a doubt, this is one of the best 3D printers for 3D printed farm!

Anycubic Photon Mono X

It is not uncommon for 3D printed trusses to purchase multiple Anycubic Photon Mono X 3D printers to enable collaboration with customers who require a radically different level of detail. The reliable linear guides, high level of consumables unitization, and low maintenance seem to be a strong point. arguments in his favor.

The reliable linear guides, high level of consumables unitization, and low maintenance seem to be a strong point. arguments in his favor.

Multiple cases

It's always interesting to hear success stories. Let me give you a few real cases as an example.

3D printer - creator of scarce spare parts

There is an AUCHAN plant in the Tambov region. On the production lines of this enterprise, most of the machines are foreign. The machines use a huge amount of plastic parts, some of which are considered consumables and are ordered from the manufacturer with a margin.

In particular, there is a line for the production and processing of plastic containers. For the washing machine on this line, the plant regularly ordered washer nozzles in Europe.

One terrible day for the manufacturer, on another machine of this line, a plastic part failed, without which the line stood up. After contacting the supplier, it turned out that this particular part was out of stock. We would have to wait for a new delivery for at least 2 months, and during this time the line would be idle. In such a case, the production would suffer big losses.

We would have to wait for a new delivery for at least 2 months, and during this time the line would be idle. In such a case, the production would suffer big losses.

The management decided to turn to a 3D printing studio to urgently create a scarce part based on a failed one. The part was created in the shortest possible time, production resumed its work, although there was a loss, it turned out to be completely incomparable with what it could have been.

Seems like a success story. But it was not all success!

In the process of negotiations with the contractor, it turned out that it is possible to quickly produce a large range of parts for this line, in particular, washer nozzles. At the same time, with the same quality of parts, the cost of these consumables turned out to be much lower. Such production made it possible to abandon logistics costs, free up storage space, and the cost of the part itself turned out to be corny lower. As a result, prototypes were presented, and then finished parts. The company was incorporated into UK Bekar and now this small 3D printed farm is doing contracts on a full-time basis for a large manufacturer. Everyone was a winner!

The company was incorporated into UK Bekar and now this small 3D printed farm is doing contracts on a full-time basis for a large manufacturer. Everyone was a winner!

Legs of different lengths and what does 3D printing have to do with it

I had a terrible boss at one of my previous jobs. He always found fault with no reason, voiced conflicting demands, in general, it was uncomfortable to work, and I thought about quitting.

But I didn't quit, and here's why.

It turned out that the boss was such a radish simply because he was haunted by constant headaches. He went to different doctors, to no avail. He made a visit to the next doctor when I was just starting work in the company. It was a turning point, he went to the orthopedist. In Germany. There, in a few days, they determined that he had headaches from the fact that the pelvis was displaced. And the pelvis is displaced because one leg is longer. Special insoles were prescribed and produced right in the clinic.

I remember that Thursday when he returned from his trip. I was shocked that he gave the bonus to our entire department, including me. Yes, and in person, it seemed that he had been replaced. Completely different, better person!

This story led him to invest in the creation of a laboratory for the production of such insoles in Russia based on the existing center of orthopedics. So to speak, I bought myself personal manufacturers of insoles. On this technological base, it was possible to produce, among other things, shoes designed taking into account the individual characteristics of the customer's foot. Subsequently, he sold this business, some of the specialists work in the Perseus Ortho center.

How the desire to help his wife turned into a business

And finally, a description of the case in which I took a personal part.

Alexander is my neighbor. Worked in a company that was engaged in deliveries abroad. We crossed paths with him on the topic of 3D printing, he bought himself an Ender 3 and printed all sorts of toys, trinkets and useful details. His wife Marina, as a hobby, baked various cookies, and sold them a little through Instagram. After 2018, the company went bankrupt and Alexander found himself out of a job. He was looking for a new job via the Internet, and Marina asked him to find on the Internet and buy a form for cutting cookies - the goddaughter asked her to bake cookies in the form of a unicorn for her birthday. After a long search, Sasha decided that it was easier for him to model this form himself and print it on a 3D printer than to find the right one. Within one day, the work was done, the cookies were baked, the goddaughter was happy, the photos of the cookies were posted on Instagram.

His wife Marina, as a hobby, baked various cookies, and sold them a little through Instagram. After 2018, the company went bankrupt and Alexander found himself out of a job. He was looking for a new job via the Internet, and Marina asked him to find on the Internet and buy a form for cutting cookies - the goddaughter asked her to bake cookies in the form of a unicorn for her birthday. After a long search, Sasha decided that it was easier for him to model this form himself and print it on a 3D printer than to find the right one. Within one day, the work was done, the cookies were baked, the goddaughter was happy, the photos of the cookies were posted on Instagram.

I heard this story some time later, when Alexander asked me to help him complete an order for 3D printing. It turned out that Marina was literally inundated with questions about cookies, and subsequently, with orders for cutting molds. In just a couple of weeks, the number of orders for modeling and printing exceeded the capabilities of Sasha's printer, and he turned to me.

The ending of this story is good, Sasha has been creating and printing forms to order for some time. For this, a powerful computer and 6 printers were purchased. A year later, the business was sold and Alexander left for Canada for permanent residence.

Finalizing

3D printing helps companies of a completely different profile occupy a variety of niches in the market. At the same time, there are many free niches, and often the prospect of using 3D printing in a certain area is not so obvious.

The success stories associated with the use of additive technologies are numerous, from the aerospace industries to the creation of toys.

The presented cases help you look at the existing order of things a little differently. It makes economic sense to check how 3D printing can help the business you run. It may be profitable to enter a new sector of the market with the help of 3D printing. In any case, the ability to understand the choice of 3D printers for business can be an additional benefit.

Good luck in building your successful business using a 3D printer and good adhesion!

Small Business 3D Printers: Using

Contents

- What are the features of home 3d printers

- Selection of premises for business organization

- What kind of business can you start with a 3d printer?

- Purchase of equipment

- Marketing promotion

- Calculation of expenses and income

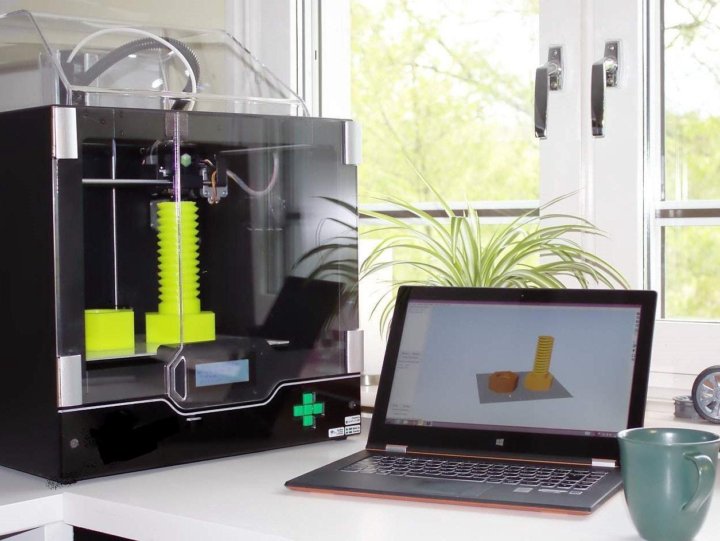

One of the modern small business options is based on a 3D printer. By purchasing this device, you can organize a small but profitable business at home.

The3D printers have a number of incredible features that are found in even the most basic desktop devices. In the future, under the words home printers, we mean devices of the smallest price categories, that is, the most inexpensive 3d printers for a small workshop or office, at home, which can be easily purchased in domestic stores.

Currently, you can find suitable business ideas that require the use of a home 3d printer. But first of all, it is necessary to draw up a detailed business plan, no matter how interesting and in demand the idea among consumers.

But first of all, it is necessary to draw up a detailed business plan, no matter how interesting and in demand the idea among consumers.

A business plan usually consists of items such as:

- Room selection;

- Purchase of equipment;

- Marketing promotion of business;

- Calculation of expenses and profits.

What are the features of home 3d printers

First of all, I would like to talk about the possibilities of a new technology device, with which you can start your own business and earn good money.

Today, any 3D printer is able to print a multi-dimensional shape from plastic, while having an accuracy of 100 microns. This applies to even the most inexpensive and ordinary home printer purchased at a discount due to a malfunction. But at the same time, a person using a new-technological device takes part only as a controller of an electronic computer, and the resulting object will become an exact copy of a 3d drawing.

Selection of premises for business organization

Such a business does not require the mandatory rental or purchase of premises. The best option is to start your own small production at home. But you can also install a printer, for example, in a cafe or in an entertainment center, where everyone can use the device for a fee and print whatever they want. Then you will need to sign an agreement with the owner of the premises.

What kind of business can you start with a 3d printer?

To start a small business, you will need to purchase a 3D printer, and at first, a home printer is enough. And of course, choose your favorite ideas for the production of something.

Some ideas you can use to organize your business:

- The first idea of using a 3D printer in business is the production and sale of small models of various buildings. You can be sure that there are many people who want to buy the Eiffel Tower or the Colosseum in miniature.

Or you can use this feature to print layouts for construction companies.

Or you can use this feature to print layouts for construction companies. - Using a 3d printer, you can make a variety of original items for interior decoration. Such an idea will bring income thanks to the hostesses who want their apartment to always be comfortable.

- Another interesting idea that will allow you to make money on a 3D printer is the production of toys and construction sets for children.

- Manufacture of souvenirs.

- Well-established seal for sculptors or painters. If there are any in your city, then they will be happy to cooperate with you on an ongoing basis.

- If you buy an expensive 3D printer, then the best option in this case would be the production of unique prostheses in the field of dentistry.

- In addition, you can produce original jewelry, which will also be in great demand among fashionistas.

- Manufacture of phone cases. A very popular item in today's world.

- Printing false nails.

But for this you need to understand the female style.

But for this you need to understand the female style. - Printing unique tableware. Here you can realize any requirements of the client to create plates or mugs.

- And finally, the best option for those with a sweet tooth. Now there are already such printers that use sugar in consumables, with which you can easily prepare sweets.

Purchase of equipment

Once you have decided on your production idea, you can choose the right printer. It all depends on financial capabilities and desires. Of course, a home printer is not suitable for creating complex goods, and it is necessary to choose equipment among expensive high-tech models.

To create the same toys, designer, nails, souvenirs, a simple inexpensive option is quite suitable. But over time, no one forbids you to buy another, more powerful device.

Marketing promotion

This type of business currently has not so many competitors. Therefore, it is not necessary to resort to complex marketing moves.