3D laser crystal printer

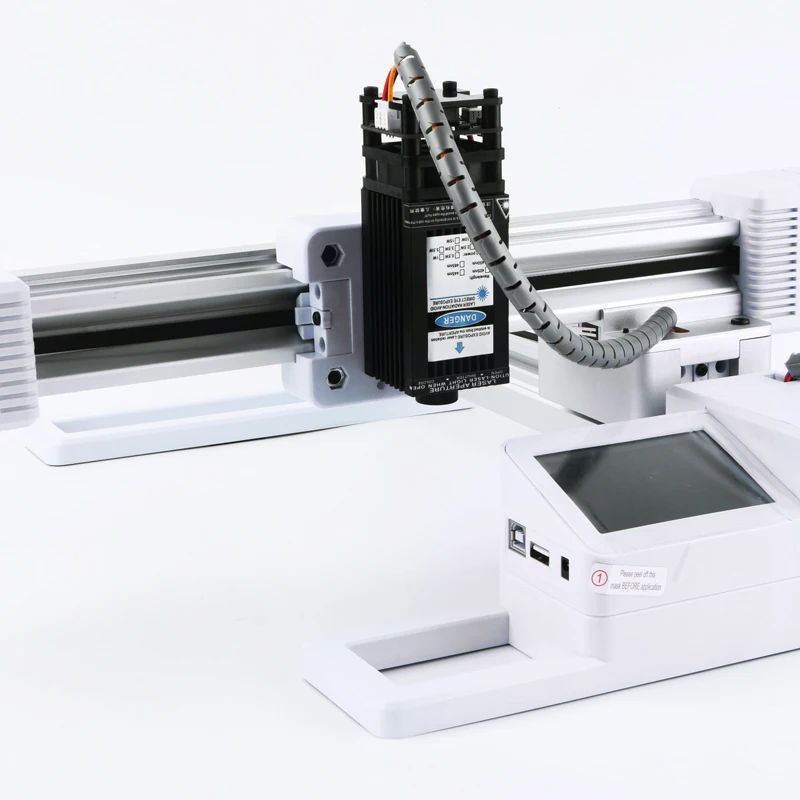

Perfect Laser 3D laser crystal engraving machie for sale

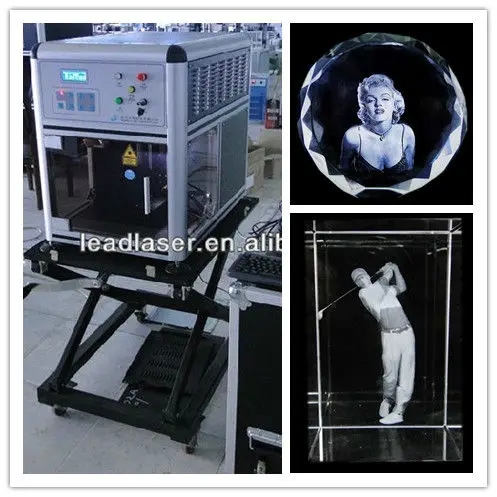

Perfect Laser 3D laser crystal engraving machine is used to engrave 2D or 3D design inside of acrylic, crystal, glass, and other transparent material. 3D laser crystal engraving machine can carve 2D or 3D hand or footprints, portrait, trophy and other personalized souvenirs. The 3D laser crystal engraving machine also can be used for mass production of 2D or 3D plants, animal, cars, buildings and other model products and 3D scenes show. It also can be called laser crystal engraving machine, 3D portrait engraving, trophy engraving machine.

By adding a 3D camera to take the 3D portraits on the human body, and through the laser inner carving technology make beam dots inside of crystal, the 3D laser crystal engraving machine can create many dots to form a 3D human images.

1.Equipment with special designed high power diode pump laser, 3D laser crystal engraving machine have inside laser engraving and material surface engraving function. Carving technology is a world leading level.

2.Using pulse laser power constant technology, the use of special laser mode greatly improve the quality of laser engraving.

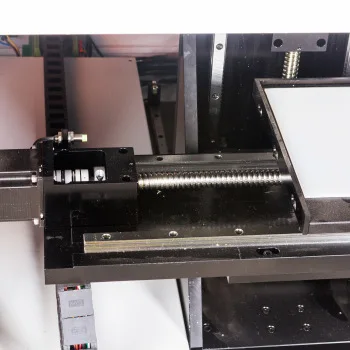

3.The automatic laser positioning system is configured so that the 3D laser crystal engraving machine can track the optical path. And a high-precision motion control system is adopted to ensure the high-quality engraving operation of the finished product.

4.The equipment adopts the modular equipment. 3D laser crystal engraving machine is easy to maintain, the laser collimation technology and closed control system can be 24 hours of continuous operation.

5.We kept improving the image processing technology, and make lifelike carving products and an unprecedented engraving effect.

6.The first image sculpture “zero width” splicing technology, can make a wide range of joining together without any trace of carving.

7.Adopt humanized system, with "one-click" control sculpture to complete all the work functions to reduce the loss caused by manual operation errors.

8.The equipment can be plugged and used without special installation, so it is convenient to replace the job site at any time.

9.”Zero width” sculpture of splicing technology makes range up to 120*120*100 mm, meet the demand of personalized customization carving.

10.Inside crystal carving and material surface text’s speed is extremely high.

11.Suitable for any crystal materials carving and the surface of various materials logo engraving.

3D laser crystal engraving machine is widely used in hotel, tourism, photographic studio, advertising, gallery and other consumption activities industry, urban scenic spots, photo print shops, wedding photo, tourist souvenir and personalized gift shop and other forms of consumption and temporary activity places.

Suitable Materials:crystal, glass, acrylic, decoration materials and other apparent materials.

Model | PE-DP-C1 |

Laser | YAG Diode Pump |

Average Life Ld | >20000 Hours |

Max Frequency | 5000HZ |

Max Engraving Area | 100 x 100 x 100mm |

Focal Length(standard) | 120mm |

Accuracy | 20μm~40μm |

Max Speed | 5000 PIONTS / Second |

Repeat Offsite | 10μm |

Power | <400W 100V-120V /50Hz ; 200v - 240V /60Hz |

Net Weight | 95kg |

Cooling | Air cooling |

Environment | Less dust and shock, Temperature 10-35°C, humidity < 85% |

File Format | BMP JPG DXF OBJ WRL 3DS STL |

Applicable Mate | All transparent material, Glass,Crystal, PMMA, etc. |

Package Size | 1010 x1010x 940mm |

Machine Size | 550 x 650 x 850mm |

Laser Marking Machine | Green Laser Marking - 3D Crystal/Glass Engaving

Laser Marking Machine | Green Laser Marking - 3D Crystal/Glass Engaving | Wisely Laser

|

||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3D-printed chicken fried with a laser

American engineers studied in detail the different modes of laser heating of layers of chicken meat printed on a 3D printer. They concluded that the proposed cooking technology has a number of advantages, such as juicier meat and a more uniform texture, compared to traditional oven cooking and can be applied in commercial use. The study is published in npj Science of Food .

The use of 3D printers or laser frying for cooking is a recent development. The first mention of 3D food printing dates back to 2007. Since then, this technology has been tested on a variety of products, such as cryogenic flour or coffee film. Over time, several platforms have emerged that combine both 3D printing and laser cooking. This approach provides penetrating heat and browning of the inner surfaces of the dish, expanding the creativity of chefs.

Over time, several platforms have emerged that combine both 3D printing and laser cooking. This approach provides penetrating heat and browning of the inner surfaces of the dish, expanding the creativity of chefs.

However, not all types of food could be cooked correctly with this combined method. In particular, until recently, no one has studied the possibility of simultaneous printing and laser heat treatment of meat, as well as its organoleptic properties.

A Columbia University team of engineers led by Hod Lipson conducted a large-scale study of various laser cooking modes for 3D printed layers of chicken meat. The samples were triangular and square layers made from chicken puree. The main laser was a blue LED laser with a wavelength of 445 nanometers and a power in the range of five to ten watts. Near-range lasers (980 nanometers) and mid (10.6 microns) IR ranges, as well as a conventional toaster oven. Tests were carried out both for a separated printer and laser, and for a combined platform. In the second case, heating occurred immediately after printing.

In the second case, heating occurred immediately after printing.

The authors conducted a series of experiments to determine the effect of laser beam trajectories on the speed of cooking and meat safety, to study the cooling rate of different parts of the dish, to investigate weight loss during cooking, to compare the penetration of different lasers, and to investigate the possibility of cooking through plastic packaging. In particular, they found that samples cooked in a conventional oven lost almost twice as much weight and volume as those prepared with a laser, due to the longer thermal exposure time to the entire volume. In addition, laser cooking has avoided burning from the edges, which often occurs when cooking in ovens. Comparison of lasers of different ranges revealed a greater penetrating power of the blue laser, while infrared lasers are better suited for browning the surface or cooking thin samples.

The authors also report that they blindly tested the palatability of samples prepared by laser and conventional heating using two tasters. They both preferred laser-cooked food because of its greater juiciness and more uniform texture. In conclusion, the researchers note that the precisions available with the combined technique can improve not only the organoleptic properties of food, but also their aesthetic appearance due to the possibility of applying patterns or drawings using software settings for the laser operation mode.

They both preferred laser-cooked food because of its greater juiciness and more uniform texture. In conclusion, the researchers note that the precisions available with the combined technique can improve not only the organoleptic properties of food, but also their aesthetic appearance due to the possibility of applying patterns or drawings using software settings for the laser operation mode.

3D printers are not just for chefs. We already wrote how the first 3D printed concrete bridge was built in Italy, and the 3D bioprinter printed an ear through the skin of a mouse.

Marat Khamadeev

Found a typo? Select the fragment and press Ctrl+Enter.

90,000 laser photopolymer Drygostol, or how to stick everything in the worldNews

Subscribe to the author

Subscribe

I do not want

14

Dutch home-made Yon Sheyon, author of YouTube channel Proper Printing, laid out a funny project on the forefront FDM 3D printer into a system that prints photopolymer resins using lasers. Why? Because lasers are cool.

Why? Because lasers are cool.

Let's say right away that the idea is not new. Jon himself admits that the video of another well-known video blogger, Joel Telling from the 3D Printing Nerd channel, about the large-format additive systems of the Israeli company Massivit served as inspiration. These 3D printers work with photopolymer gels, laying the material through a nozzle and immediately curing it with ultraviolet emitters. Jon decided to do something similar at home.

Joe Telling learns the basics of "massivization"

In Jon's project, the peristaltic pump is responsible for supplying the photopolymer, since such pumps are just designed for cases where contact of the pumped liquid with moving mechanisms is undesirable. In addition, with the help of such a pump, you can try to implement a retract. Of course, Jon made the pump himself, printing the necessary parts on the same 3D printer that was to be converted into a photopolymer system. RepRap, what do you want?

RepRap, what do you want?

At the same time, Jon was able to demonstrate the concept of rapid prototyping in all its glory: the first version of the pump was not very successful due to uneven delivery, so Jon quickly redesigned the body and reprinted it, changing the shape of the internal channel and the diameter of the rollers to stabilize the flow.

The next step is curing. Instead of LED lamps, Jon decided to use a laser module like those used on laser engravers. The wave range of the diode laser, by a lucky coincidence, turned out to be in the range of 400-450 nm, and ideally, ultraviolet with a wavelength of 405 nm is needed for polymerization of the resin, so just right.

Jon printed the head already on a stereolithographic 3D printer. The idea is this: in the center of the nozzle there is a dispenser with a photopolymer connected to a pump, and along the perimeter there are channels with optical fibers that transmit laser radiation to the resin application zone. But that's in theory.

But that's in theory.

In practice, the design proved to be too complex and inefficient. Then Jon got rid of the nozzle by simply wrapping the dispenser and waveguides with adhesive tape, but this already led to parasitic light with resin polymerization right in the tube supplying the photopolymer.

Having suffered enough, Jon prevailed over the craving for overengineering, threw out the fiber winding, installed the laser at an angle on the side and screwed a lens with a round piece of electrical tape in the center of the lens onto the emitter - this way he managed to get ring illumination without irradiating the dispenser itself. In the final iteration, instead of a tricky nozzle, our hero simply used a regular hot end with a nozzle from an FDM 3D printer, and at the same time screwed on a second laser.

To some extent, all this even prints. You can enjoy the suffering of Jon and learn a couple of dirty words in Dutch in the video below:

Its products can give person crystal-clear and fine noble visual image, that' s elaboration for your home decoration.

Its products can give person crystal-clear and fine noble visual image, that' s elaboration for your home decoration.

02mm

02mm hk.

hk.