Triangulation 3d scanner

The Complete Guide to 3D Scanners using Laser Triangulation

3D printing news News The Complete Guide to 3D Scanners using Laser Triangulation

Published on September 8, 2017 by Alexandrea P.

In line with our files on 3D printing processes, we will be starting today with a new series dedicated to the different techniques of 3D digitization. While the origin of the first 3D scanners dates back to the 1960s, this first portion will be focused on one of the simplest scanning technologies: laser triangulation.

The birth of 3D scanners goes back to the work of the National Research Council Canada, one of the first laboratories that developed a 3D digitization technique based on laser triangulation in 1978.

By definition, a 3D scanner is used to obtain a “digital image” of a physical object. To acquire this digital replica, there are different methods to record the object, which is then analyzed and reprocessed on a computer in order to determine its general shape.

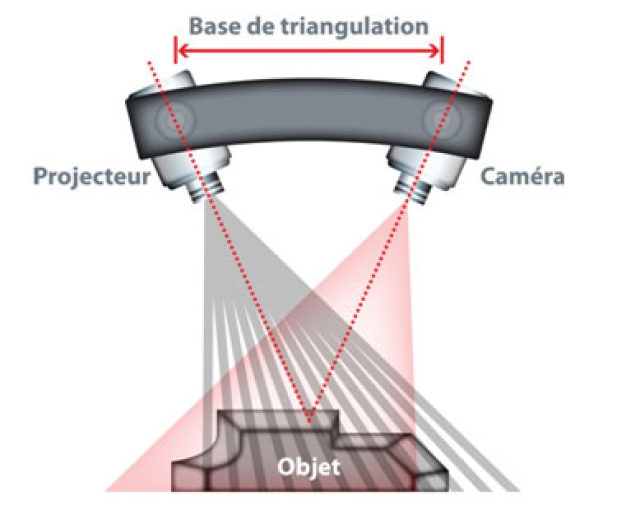

Laser triangulation is based on a trigonometric calculation

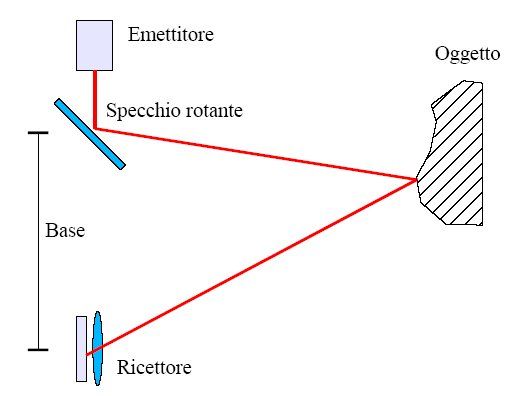

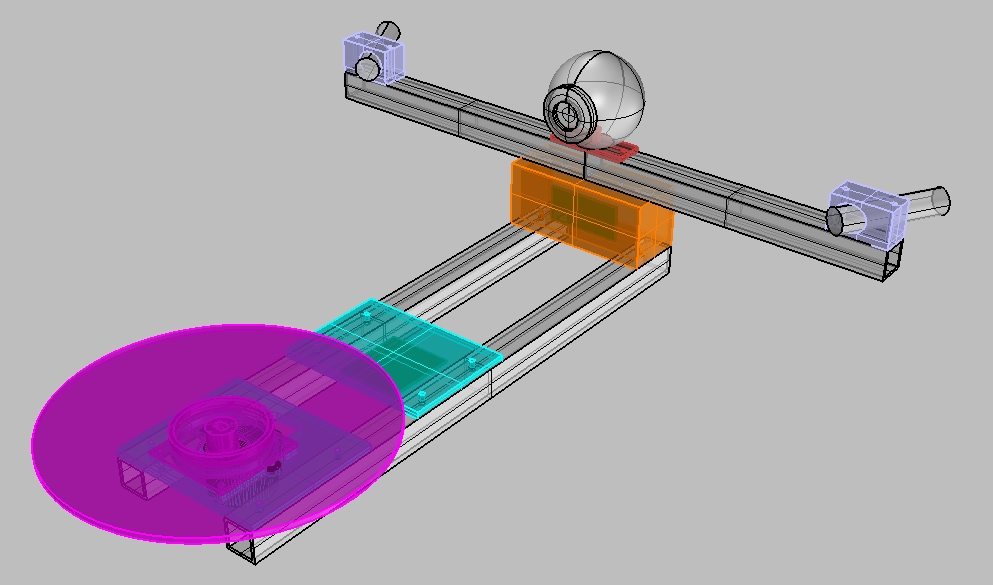

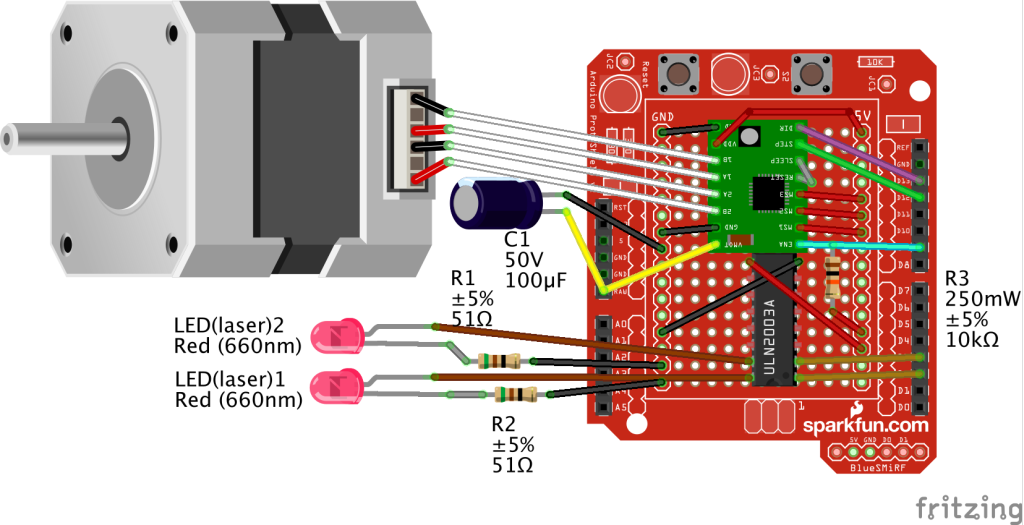

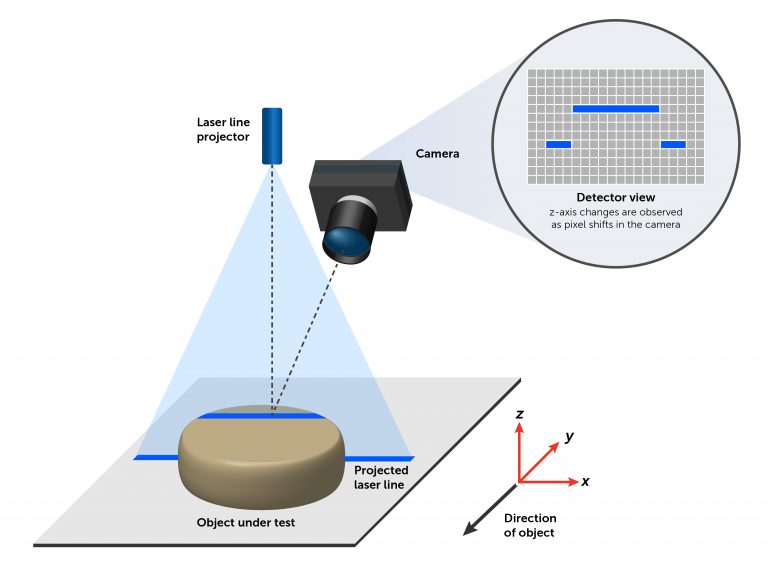

In the case of laser triangulation, the scanners used comprise three main elements (which will form the three vertices of a triangle): a laser transmitter, a camera, and the object to be scanned. A rotating plate is also used to lay the object and obtain its different faces.

Laser triangulation 3D scanners generally use semiconductor lasers in particular because of their low cost and their small size. They are characterized by a red colored beam.

With this method, the digitization begins with the emission of a rectilinear laser beam which deforms on contact with the object. Through the camera, the 3D scanner analyzes the deformation of the line emitted by the laser on the reliefs of the object in order to determine, by means of trigonometric calculations, its position in space.

The angle formed between the camera and the beam of the laser, the distance from the camera to the object and that of the laser source to the object (known by calculating the time taken by the laser to make a round trip), are all parameters which make it possible to determine the spatial coordinates of the object.

Advantages and disadvantages

The main advantage of laser triangulation is its low price, with the first DIY models available for only a few hundred euros. Its acquisition speed (less than 10 minutes on average for an object) and its precision level (of the order of 0.01 mm) also make it a popular technology.

As for the disadvantages, it should be noted that the digitization of transparent or reflective surfaces can prove difficult, a problem that can be circumvented by using a white powder. Its limited range (only a few meters) also reduces the number of possible applications.

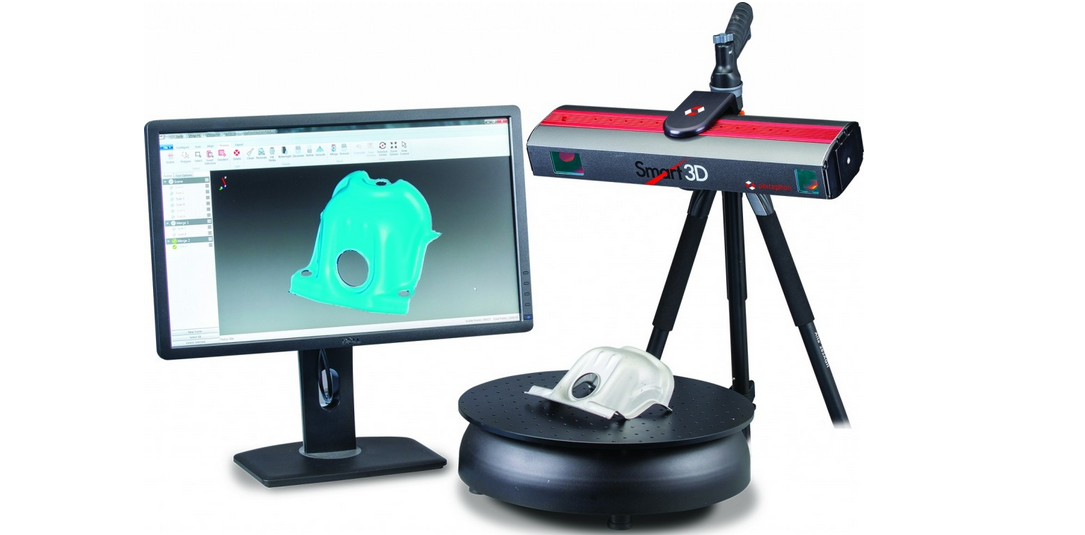

The best-known 3D laser triangulation scanners include the MakerBot Digitizer, the BQ Ciclop, the Matter Form by eponymous, or Faro’s Focus3D professional 3D scanners.

Find all our 3D printer tests here

Types of 3D Scanners and 3D Scanning Technologies

There are many types of 3D scanners and 3D scanning technologies. Some are ideal for short range scanning while others are better suited for mid or long range scanning. The 3D scanner and technology needed to 3D scan a very small object is very different from the best 3D scanner to 3D scan a large aircraft.

The 3D scanner and technology needed to 3D scan a very small object is very different from the best 3D scanner to 3D scan a large aircraft.

EMS uses a wide range of 3D scanners and 3D scanning technologies, which enables us to select the best 3D scanning technology or combination of technologies for every project.

Here is a brief outline of the 3D scanning technologies and types of 3D Scanners.

Short Range 3D Scanners

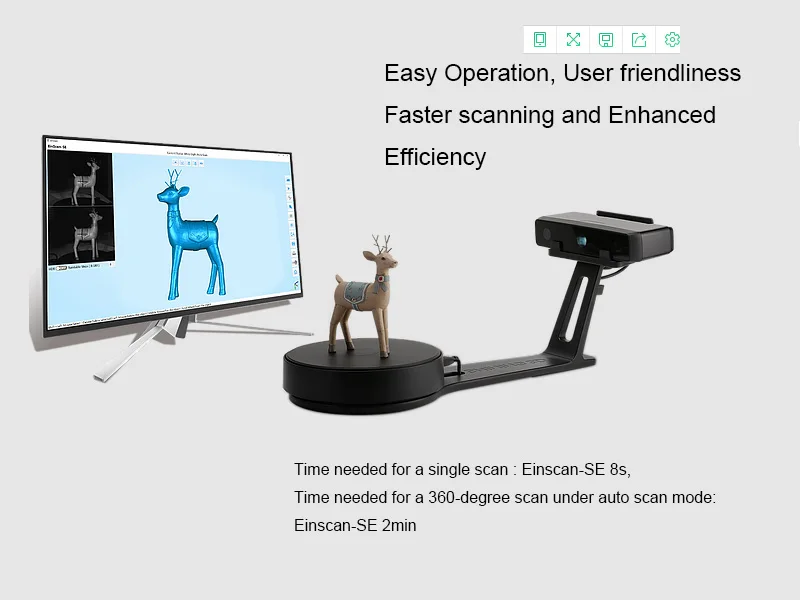

Short Range 3D scanners typically utilize a Laser triangulation or Structured Light technology.

Laser based 3D Scanners

Laser based 3D scanners use a process called trigonometric triangulation to accurately capture a 3D shape as millions of points. Laser scanners work by projecting a laser line or multiple lines onto an object and then capturing its reflection with a single sensor or multiple sensors. The sensors are located at a known distance from the laser's source. Accurate point measurements can then be made by calculating the reflection angle of the laser light.

Accurate point measurements can then be made by calculating the reflection angle of the laser light.

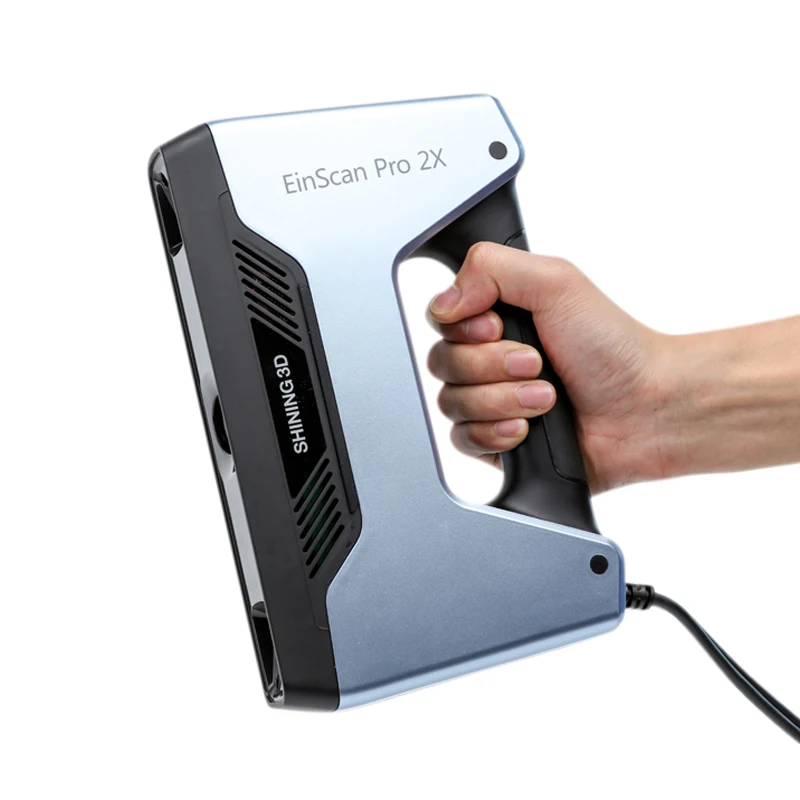

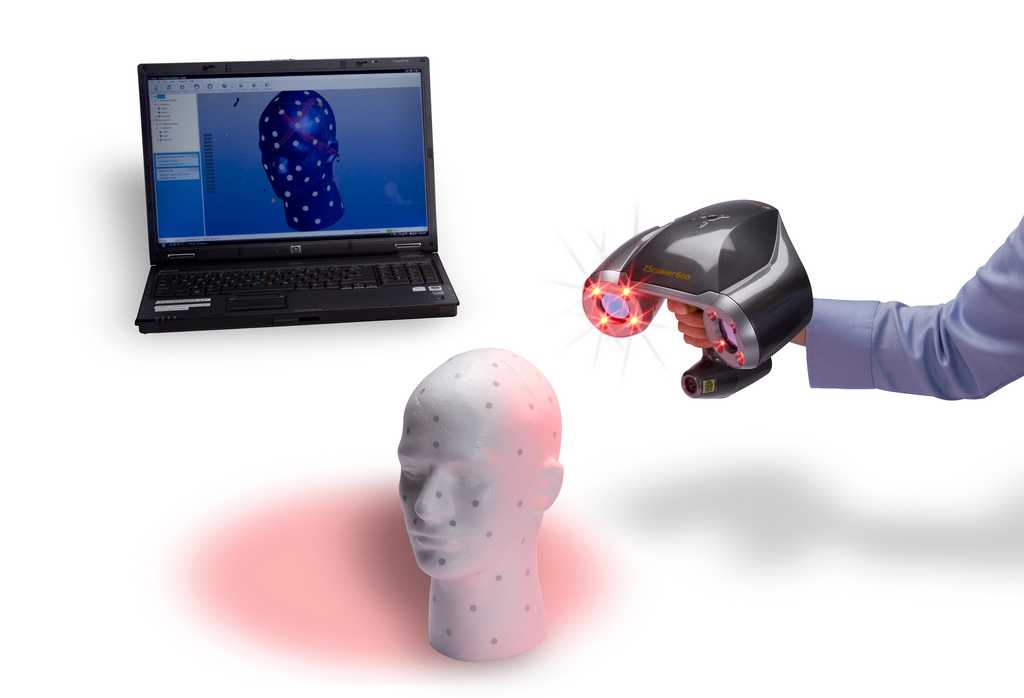

Laser scanners are very popular and come in many designs. They include handheld portable units, arm based, CMM based, long range, and single point long range trackers.

Benefits of 3D Laser Scanners

- Able to scan tough surfaces, such as shiny or dark finishes

- Less sensitive to changing light conditions and ambient light

- Often more portable

- Simpler design – easier to use and lower cost

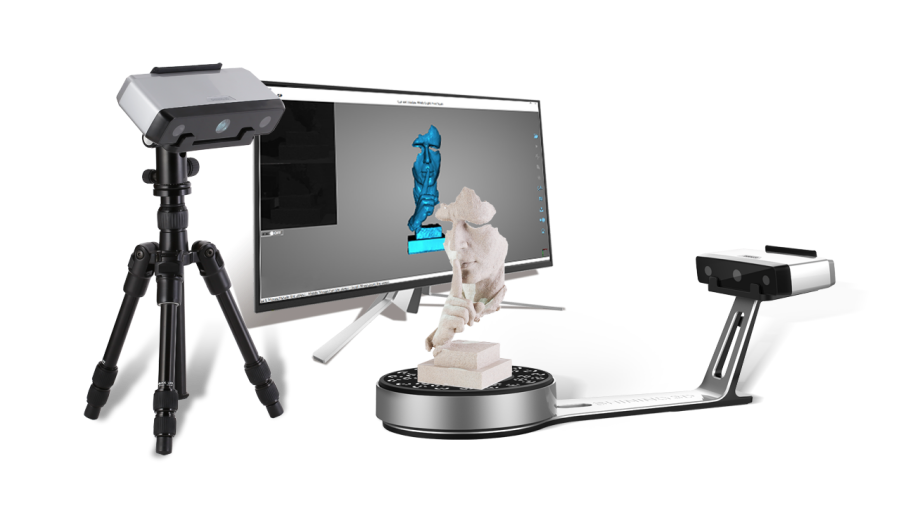

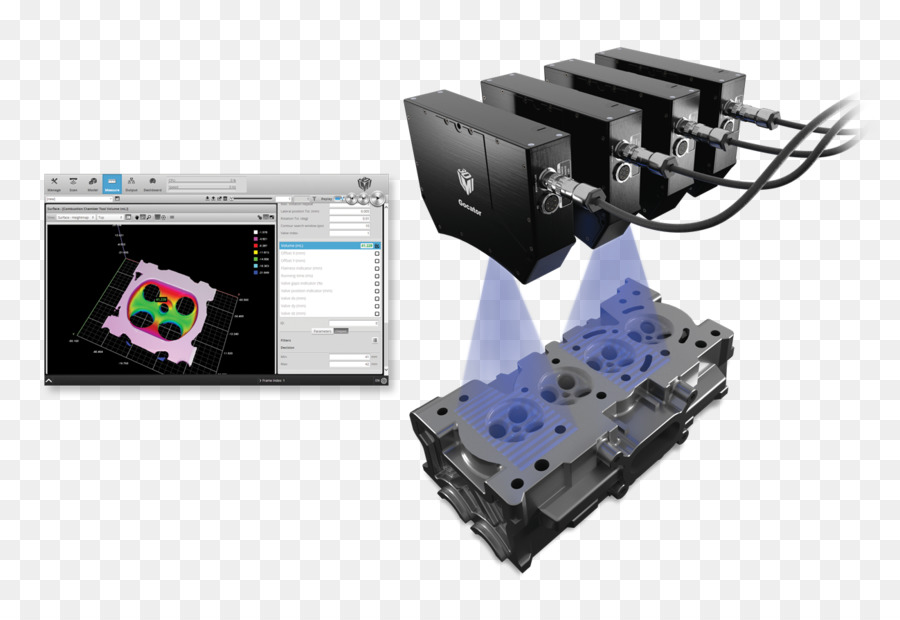

Projected or Structured Light 3D Scanners

Historically known as “white light” 3D scanners, most structured light 3D scanners today use a blue or white LED projected light. These 3D scanners project a light pattern consisting of bars, blocks or other shapes onto an object. The 3D scanner has one or more sensors that look at the edge of those patterns or structure shapes to determine the objects 3D shape. Using the same trigonometric triangulation method as laser scanners the distance from the sensors to the light source is known. Structured light scanners can be tripod mounted or hand held.

Using the same trigonometric triangulation method as laser scanners the distance from the sensors to the light source is known. Structured light scanners can be tripod mounted or hand held.

Benefits of Structured light 3D Scanners

- Very fast scan times – as fast as 2 seconds per scan

- Large scanning area – as large as 48 inches in a single scan

- High resolution – as high as 16 million points per scan and 16 micron (.00062”) point spacing

- Very high accuracy – as high as 10 microns (.00039”)

- Versatile – multiple lenses to scan small to large parts in a single system

- Portable – hand held systems are very portable

- Eye safe for 3D scanning of humans and animals

- Various price points from low cost to expensive depending on resolution and accuracy

Medium and Long Range 3D Scanners

Long range 3D scanners come in two major formats - Pulse based and phase shift – both of which are well suited for large objects such as buildings, structures, aircraft, and military vehicles. Phase shift 3D scanners also work well for medium range scan needs such as automobiles, large pumps and industrial equipment. These scanners capture millions of points by rotating 360 degrees while spinning a mirror the redirects the laser outward towards the object or areas to be 3D scanned.

Phase shift 3D scanners also work well for medium range scan needs such as automobiles, large pumps and industrial equipment. These scanners capture millions of points by rotating 360 degrees while spinning a mirror the redirects the laser outward towards the object or areas to be 3D scanned.

Laser pulse-based 3D scanners

Laser pulse-based scanners, also known as time-of-flight scanners, are based on a very simple concept: the speed of light is known very precisely. Thus, if the length of time a laser takes to reach an object and reflect back to a sensor is known, the distance from sensor to object is known. These systems use circuitry that is accurate to picoseconds to measure the time it takes for millions of pulses of the laser to return to the sensor, and calculates a distance. By rotating the laser and sensor (usually via a mirror), the scanner can scan up to a full 360 degrees around itself.

Laser Phase-shift 3D Scanners

Laser phase-shift systems are another type of time-of-flight 3D scanner technology, and conceptually work similarly to pulse-based systems. In addition to pulsing the laser, these systems also modulate the power of the laser beam, and the scanner compares the phase of the laser sent out and returned to the sensor. Phase shift measurement are typically more accurate and quieter but are not as flexible for long range scanning as pulse-based 3D scanners. Laser pulse based 3D scanners can scan objects up to 1000m away while phase shift scanners are better suited for scanning objects up to 300m or less.

In addition to pulsing the laser, these systems also modulate the power of the laser beam, and the scanner compares the phase of the laser sent out and returned to the sensor. Phase shift measurement are typically more accurate and quieter but are not as flexible for long range scanning as pulse-based 3D scanners. Laser pulse based 3D scanners can scan objects up to 1000m away while phase shift scanners are better suited for scanning objects up to 300m or less.

Benefits Long Range 3D Scanners

- 3D Scan millions of points in a single scan – up to 1 million points per second

- Large scanning area up to 1000 meters

- Good accuracy and resolution based on object size

- Non-contact to safely scan all types of objects

- Portable

Coordinate Measuring Machine (CMM)

A coordinate measuring machine (CMM) is used primarily to inspect parts. The machine can be controlled manually or through controlled offline through software and computers. Measurements are defined by attaching a probe to the machine. The probe typically has a small ball at the end of a shaft of a known diameter. The CMM is then programed to contact the part. When the machine senses contact of the probe tip a measurement value in taken in XYZ space. The most common type of CMM is a bridge type which has 3 axis X, Y & Z. The probing system that is attached many times can rotate providing an additional 3 axis for a total of 6 degrees of freedom (DOF). To very accurately measure parts to a few microns, CMM’s are typically deployed in a very controlled inspection room that includes a reinforced floor, controlled humidity and temperature, and isolation from vibration and other forces that could affect the accuracy. In addition, most CMM’s have a large granite table surface that is perfectly level. Parts are fixtured onto the granite table so that there is no movement during the measuring process.

Measurements are defined by attaching a probe to the machine. The probe typically has a small ball at the end of a shaft of a known diameter. The CMM is then programed to contact the part. When the machine senses contact of the probe tip a measurement value in taken in XYZ space. The most common type of CMM is a bridge type which has 3 axis X, Y & Z. The probing system that is attached many times can rotate providing an additional 3 axis for a total of 6 degrees of freedom (DOF). To very accurately measure parts to a few microns, CMM’s are typically deployed in a very controlled inspection room that includes a reinforced floor, controlled humidity and temperature, and isolation from vibration and other forces that could affect the accuracy. In addition, most CMM’s have a large granite table surface that is perfectly level. Parts are fixtured onto the granite table so that there is no movement during the measuring process.

Benefits of CMM’s

- One of the most accurate ways of measuring an object

- Small to large parts can be measured with the proper machine

- Industry standards and certifications for measurements and software exist

- Many styles and sizes of machines exist from many manufactures

Arm based 3D Scanners and Probe systems

An armed based 3D scanning or probing system is similar to a coordinate measuring machine (CMM) in the fact it can use a touch probe to measure a part. In addition to the probe, many arm based systems also have an attachable 3D laser scanner for collecting large amount of points. Software keeps track of the joint movements of the arm to know where it is in 3D space at all time. Arm based systems work by attaching the articulated arm to either a table or sturdy base. Then the arm is held by a hand grip at the end and moved around to probe or scan. The main advantage of these systems is they are much more portable then a CMM and can be used in a shop floor environment.

In addition to the probe, many arm based systems also have an attachable 3D laser scanner for collecting large amount of points. Software keeps track of the joint movements of the arm to know where it is in 3D space at all time. Arm based systems work by attaching the articulated arm to either a table or sturdy base. Then the arm is held by a hand grip at the end and moved around to probe or scan. The main advantage of these systems is they are much more portable then a CMM and can be used in a shop floor environment.

Benefits of Arm based 3D Scanners and Probe systems

- Portable system

- Good accuracy on small to medium size parts

- Ability to probe and scan a single part

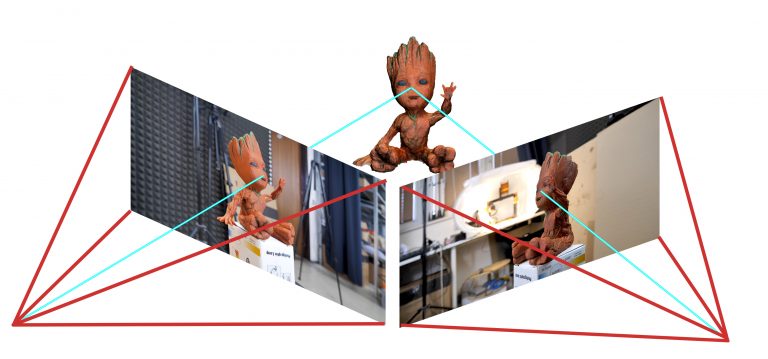

Optically tracked 3D Scanners and Probe Systems

Optically tracked 3D scanning and probing systems use a set of cameras to track the location of the 3D scan head or probe in 3D space. These systems offer advantages over arm based systems including freedom of movement, better accuracy over distance, and the ability to include “dynamic referencing”. Dynamic referencing systems work by attaching targets or led lights to the object you are scanning or probing. This allows the camera system to track the part and scan or probe head separately from each other. The net result is the part can be moving even while scanning and no loss of accuracy or data quality occurs. In addition, the camera system can also be moved around allowing you to scan large parts in one setup.

Dynamic referencing systems work by attaching targets or led lights to the object you are scanning or probing. This allows the camera system to track the part and scan or probe head separately from each other. The net result is the part can be moving even while scanning and no loss of accuracy or data quality occurs. In addition, the camera system can also be moved around allowing you to scan large parts in one setup.

Benefits of optically tracked 3D scanning and probing systems

- 3D scanning and probing in the same system

- Freedom of movement

- Large 3D scanning volume

- Ability to probe and scan even while the part is moving with no loss of accuracy

- Very portable

All about 3D scanners: from varieties to applications

The 3D scanner is a special device that analyzes a specific physical object or space in order to obtain data on the shape of an object and, if possible, its appearance (for example , about color). The collected data is then used to create a digital three-dimensional model of this object.

The collected data is then used to create a digital three-dimensional model of this object.

To create 3D-scanner allows several technologies at once, differing from each other in certain advantages, disadvantages, as well as cost. In addition, there are some restrictions on the objects that can be digitized. In particular, there are difficulties with objects that are shiny, transparent or have mirror surfaces. nine0005

Don't forget that 3D data collection is also important for other applications. So, they are needed in the entertainment industry to create films and video games. Also, this technology is in demand in industrial design, orthopedics and prosthetics, reverse engineering, prototyping, as well as for quality control, inspection and documentation of cultural artifacts.

Functionality

The purpose of the 3D Scanner is to create a point cloud of geometric patterns on the surface of an object. These points can then be extrapolated to recreate the shape of the object (a process called reconstruction). If color data were obtained, then the color of the reconstructed surface can also be determined. nine0005

If color data were obtained, then the color of the reconstructed surface can also be determined. nine0005

3D scanners are a bit like regular cameras. In particular, they have a cone-shaped field of view, and they can only receive information from surfaces that have not been darkened. The difference between these two devices is that the camera transmits only information about the color of the surface that fell into its field of view, but the 3D scanner collects information about the distances on the surface, which is also in its field of view. Thus the "picture" obtained with of the 3D scanner, describes the distance to the surface at each point in the image. This allows you to determine the position of each point in the picture in 3 planes at once.

In most cases, one scan is not enough to create a complete model of the object. Several such operations are required. As a rule, a decent number of scans from different directions will be needed in order to obtain information about all sides of the object. All scan results must be normalized to a common coordinate system, a process called image referencing or alignment, before a complete model is created. This whole procedure from a simple map with distances to a full-fledged model is called a 3D scanning pipeline. nine0005

All scan results must be normalized to a common coordinate system, a process called image referencing or alignment, before a complete model is created. This whole procedure from a simple map with distances to a full-fledged model is called a 3D scanning pipeline. nine0005

Technology

There are several technologies for digitally scanning a mold and creating a 3D model of an object. However, a special classification has been developed that divides 3D scanners into 2 types: contact and non-contact. In turn, non-contact 3D scanners can be further divided into 2 groups - active and passive. Several technologies can fall under these categories of scanning devices.

Coordinated-measuring machine with two fixed mutually perpendicular measuring hands

Contact 3D scanners

Contact 3D-scanners Explore (probes) the object directly through physical contact, while the subject itself is expected to explode itself on a precision surface plate, ground and polished to a certain degree of surface roughness. If the scanned object is uneven or cannot lie stably on a horizontal surface, then a special vise will hold it. nine0005

If the scanned object is uneven or cannot lie stably on a horizontal surface, then a special vise will hold it. nine0005

The scanner mechanism comes in three different forms:

- Carriage with a fixed measuring arm positioned perpendicularly, and measurement along the axes occurs while the arm slides along the carriage. This system is optimal for flat or regular convex curved surfaces.

- Fixed component manipulator with high precision angle sensors. The location of the end of the measuring arm entails complex mathematical calculations regarding the angle of rotation of the wrist joint, as well as the angle of rotation of each of the joints of the arm. This mechanism is ideal for probing recesses or interior spaces with a small inlet. nine0072

- Simultaneous use of the previous two methods. For example, a manipulator can be combined with a carriage, which allows you to get 3D data from large objects that have internal cavities or overlapping surfaces.

The

The

CMM (coordinate measuring machine) is a prime example of the contact 3D scanner . They are used mainly in manufacturing and can be ultra-precise. The disadvantages of CMM include the need for direct contact with the surface of the object. Therefore, it is possible to change the object or even damage it. This is very important if thin or valuable items such as historical artifacts are being scanned. Another disadvantage of CMM over other scanning methods is slowness. Moving the measuring arm with the probe in place can be very slow. The fastest result of CMM operation does not exceed a few hundred hertz. At the same time, optical systems, for example, a laser scanner, can operate from 10 to 500 kHz. nine0005

Another example is hand-held measuring probes used to digitize clay models for computer animation.

The Lidar device is used to scan buildings, rocks, etc., which makes it possible to create 3D models of them. The Lidar laser beam can be used in a wide range: its head rotates horizontally, and the mirror moves vertically. The laser beam itself is used to measure the distance to the first object in its path. nine0004

The laser beam itself is used to measure the distance to the first object in its path. nine0004

Non-contact active scanners

Active scanners use certain types of radiation or just light and scan an object through the reflection of light or the passage of radiation through an object or medium. These devices use light, ultrasound, or x-rays.

Time-of-Flight Scanners

Time-of-Flight Laser Scanner The 3D scanner is an active scanner that uses a laser beam to examine an object. This type of scanner is based on a time-of-flight laser range finder. In turn, the laser rangefinder determines the distance to the surface of the object, based on the time of flight of the laser back and forth. The laser itself is used to create a pulse of light, while the detector measures the time until the light is reflected. Given that the speed of light (c) is a constant value, knowing the time of flight of the beam back and forth, you can determine the distance over which the light has moved, it will be twice the distance between the scanner and the surface of the object. If (t) is the round-trip flight time of the laser beam, then the distance will be (c*t\2). Laser beam time-of-flight accuracy of the 3D scanner depends on how accurately we can measure time (t) itself: 3.3 picoseconds (approximately) is needed for the laser to travel 1 millimeter.

If (t) is the round-trip flight time of the laser beam, then the distance will be (c*t\2). Laser beam time-of-flight accuracy of the 3D scanner depends on how accurately we can measure time (t) itself: 3.3 picoseconds (approximately) is needed for the laser to travel 1 millimeter.

The laser distance meter determines the distance of only one point in a given direction. Therefore, the device scans its entire field of view in separate points at a time, while changing the direction of scanning. You can change the direction of the laser rangefinder either by rotating the device itself, or using a system of rotating mirrors. The latter method is often used, because it is much faster, more accurate, and also easier to handle. For example, time-of-flight 3D scanners can measure distance from 10,000 to 100,000 points in one second.

TOF devices are also available in 2D configuration. Basically, this applies to time-of-flight cameras. Triangulation scanners Two positions of the object are shown.

A point cloud is generated by triangulation and a laser stripe. nine0004

Triangulation laser scanners The 3D scanners are also active scanners that use a laser beam to probe an object. Like the time-of-flight 3D scanners, triangulation devices send a laser to the scanned object, and a separate camera captures the location of the point where the laser hit. Depending on how far the laser travels across the surface, the dot appears at different locations in the camera's field of view. This technology is called triangulation because the laser dot, the camera and the laser emitter itself form a kind of triangle. The length of one side of this triangle is known - the distance between the camera and the laser emitter. The angle of the laser emitter is also known. But the camera angle can be determined by the location of the laser dot in the field of view of the camera. These 3 indicators completely determine the shape and size of the triangle and indicate the location of the corner of the laser point. In most cases, to speed up the process of obtaining data, a laser strip is used instead of a laser dot. Thus, the National Research Council of Canada was among the first scientific organizations that developed the basics of triangulation laser scanning technology back in 1978 year.

In most cases, to speed up the process of obtaining data, a laser strip is used instead of a laser dot. Thus, the National Research Council of Canada was among the first scientific organizations that developed the basics of triangulation laser scanning technology back in 1978 year.

Advantages and disadvantages of

scanners Both time-of-flight and triangulation scanners have their own strengths and weaknesses, which determines their choice for each specific situation. The advantage of time-of-flight devices is that they are optimally suited for operation over very long distances up to several kilometers. They are ideal for scanning buildings or geographic features. At the same time, their disadvantages include measurement accuracy. After all, the speed of light is quite high, so when calculating the time it takes for the beam to overcome the distance to and from the object, some flaws (up to 1 mm) are possible. And this makes the scan results approximate. nine0005

nine0005

As for triangulation rangefinders, the situation is exactly the opposite. Their range is only a few meters, but the accuracy is relatively high. Such devices can measure distance with an accuracy of tens of micrometers.

The study of the edge of an object negatively affects the accuracy of the TOF scanners. The laser pulse is sent one, and is reflected from two places at once. The coordinates are calculated based on the position of the scanner itself, and the average value of the two reflections of the laser beam is taken. This causes the point to be defined in the wrong place. When using scanners with high resolution, the chances that the laser beam hits the exact edge of the object increase, but noise will appear behind the edge, which will negatively affect the scan results. Scanners with a small beam can solve the edge scanning problem, but they have limited range, so the beam width will exceed the distance. There is also special software that allows the scanner to perceive only the first reflection of the beam, while ignoring the second. nine0005

nine0005

At 10,000 dots per second, low resolution scanners can do the job within seconds. But for scanners with high resolution, you need to do several million operations, which will take minutes. It should be borne in mind that the data may be distorted if the object or the scanner moves. So, each point is fixed at a certain point in time in a certain place. If the object or scanner moves in space, then the scan results will be false. That's why it's so important to mount both the object and the scanner on a fixed platform and keep the possibility of vibration to a minimum. Therefore, scanning objects in motion is practically impossible. Recently, however, there has been active research on how to compensate for the effect of vibration on data corruption. nine0005

It is also worth considering that when scanning in one position for a long time, a slight movement of the scanner may occur due to temperature changes. If the scanner is mounted on a tripod and one side of the scanner is exposed to strong sunlight, then the tripod will expand and the scan data will gradually distort from one side to the other. However, some laser scanners have built-in compensators that counteract any movement of the scanner during operation. nine0005

However, some laser scanners have built-in compensators that counteract any movement of the scanner during operation. nine0005

Conoscopic holography

In the conoscopic system, a laser beam is projected onto the surface of an object, after which the beam is reflected along the same path, but through a conoscopic crystal, and is projected onto a CCD (charge-coupled device). The result is a diffraction pattern from which frequency analysis can be used to determine the distance to the surface of an object. The main advantage of conoscopic holography is that only one beam path is needed to measure the distance, which makes it possible to determine, for example, the depth of a small hole. nine0005

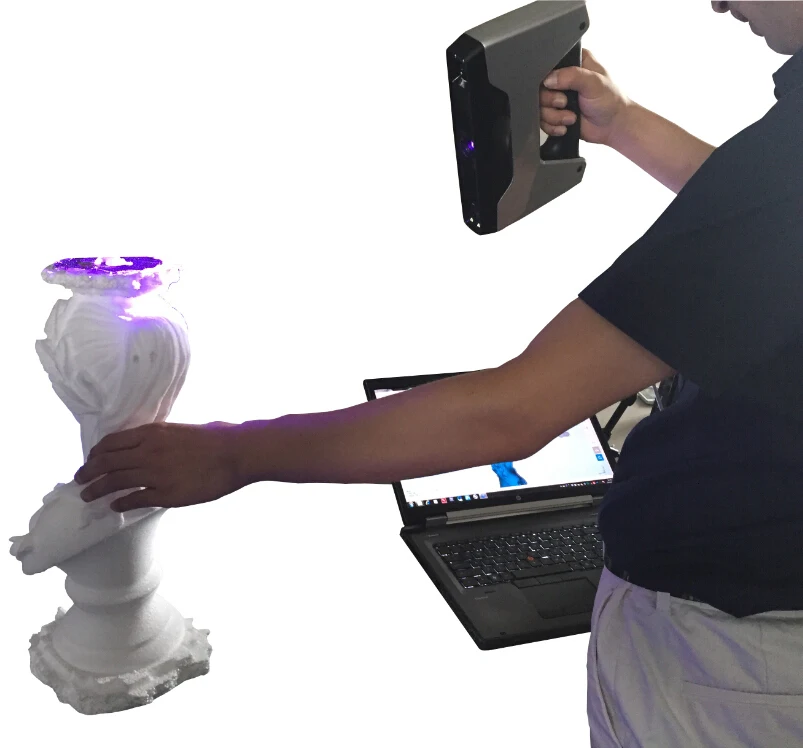

Handheld laser scanners

Handheld laser scanners create a 3D image using the triangulation principle described above. A laser beam or stripe is projected onto an object from a hand-held emitter, and a sensor (often a CCD or position-sensitive detector) measures the distance to the surface of the object. The data is collected relative to the internal coordinate system and therefore, to obtain results, if the scanner is in motion, the position of the device must be accurately determined. This can be done using basic features on the scanned surface (adhesive reflective elements or natural features) or using the external tracking method. The latter method often takes the form of a laser tracker (providing a position sensor) with a built-in camera (to determine the orientation of the scanner). You can also use photogrammetry, provided by 3 cameras, which gives the scanner six degrees of freedom (the ability to make geometric movements in three-dimensional space). Both techniques typically use infrared LEDs connected to the scanner. They are observed by cameras through filters that ensure the stability of ambient lighting (reflecting light from different surfaces). nine0005

The data is collected relative to the internal coordinate system and therefore, to obtain results, if the scanner is in motion, the position of the device must be accurately determined. This can be done using basic features on the scanned surface (adhesive reflective elements or natural features) or using the external tracking method. The latter method often takes the form of a laser tracker (providing a position sensor) with a built-in camera (to determine the orientation of the scanner). You can also use photogrammetry, provided by 3 cameras, which gives the scanner six degrees of freedom (the ability to make geometric movements in three-dimensional space). Both techniques typically use infrared LEDs connected to the scanner. They are observed by cameras through filters that ensure the stability of ambient lighting (reflecting light from different surfaces). nine0005

Scan data is collected by a computer and recorded as points in 3D space, which after processing are converted into a triangulated grid. The computer-aided design system then creates a model using a non-uniform rational B-spline, NURBS (a special mathematical form for creating curves and surfaces). Handheld laser scanners can combine this data with passive visible light sensors that capture surface texture and color to create or reverse engineer a complete 3D Models .

The computer-aided design system then creates a model using a non-uniform rational B-spline, NURBS (a special mathematical form for creating curves and surfaces). Handheld laser scanners can combine this data with passive visible light sensors that capture surface texture and color to create or reverse engineer a complete 3D Models .

Structured light

3D scanners, working on structured light technology, represent a projection of a light grid directly onto an object, deformation of this pattern and is a model of the scanned object. The grid is projected onto the object using a liquid crystal projector or other constant light source. A camera positioned just to the side of the projector captures the shape of the network and calculates the distance to each point in the field of view. nine0113 Structured light scanning is still an active area of research, with quite a few research papers devoted to it each year. Ideal maps are also recognized as useful as structured light patterns that can solve matching problems and allow errors to be corrected as well as detected.

Ideal maps are also recognized as useful as structured light patterns that can solve matching problems and allow errors to be corrected as well as detected.

The advantage of the Structured Light 3D Scanners is their speed and accuracy. Instead of scanning one point at a time, structured scanners scan several points at the same time or the entire field of view at once. Scanning the entire field of view takes a fraction of a second, and the generated profiles are more accurate than laser triangulations. This completely solves the problem of data corruption caused by motion. In addition, some existing systems are capable of scanning even moving objects in real time. For example, the VisionMaster, a 3D scanning system, has a 5-megapixel camera, so each frame contains 5 million dots. nine0005

Real-time scanners use digital edge projection and a phase-shifting technique (one of the techniques for using structured light) to capture, reconstruct and create a high-density computer model of dynamically changing objects (such as facial expressions) at 40 frames per second. A new type of scanner has recently been created. Various models can be used in this system. The frame rate for capturing and processing data reaches 120 frames per second. This scanner can also process individual surfaces. For example, 2 moving hands. Using the binary defocusing method, the shooting speed can reach hundreds or even thousands of frames per second. nine0005

A new type of scanner has recently been created. Various models can be used in this system. The frame rate for capturing and processing data reaches 120 frames per second. This scanner can also process individual surfaces. For example, 2 moving hands. Using the binary defocusing method, the shooting speed can reach hundreds or even thousands of frames per second. nine0005

Modulated light

When using the 3D scanners based on modulated light, the light beam directed at the object is constantly changing. Often the change of light passes along a sinusoid. The camera captures the reflected light and determines the distance to the object, taking into account the path that the light beam has traveled. Modulated light allows the scanner to ignore light from sources other than the laser, thus avoiding interference. nine0005

Volumetric techniques

Medical

Computed tomography (CT) is a special medical imaging technique that creates a series of two-dimensional images of an object, a large three-dimensional image of the internal space. Magnetic resonance imaging works on a similar principle - another imaging technique in medicine, which is distinguished by a more contrast image of the soft tissues of the body than CT. Therefore, MRI is used to scan the brain, the musculoskeletal system, the cardiovascular system, and to search for oncology. These techniques produce volumetric voxel models that can be rendered, modified, and transformed into a traditional 3D surface using isosurface extraction algorithms. nine0005

Magnetic resonance imaging works on a similar principle - another imaging technique in medicine, which is distinguished by a more contrast image of the soft tissues of the body than CT. Therefore, MRI is used to scan the brain, the musculoskeletal system, the cardiovascular system, and to search for oncology. These techniques produce volumetric voxel models that can be rendered, modified, and transformed into a traditional 3D surface using isosurface extraction algorithms. nine0005

Production

Although MRI, CT or microtomography are more widely used in medicine, they are also actively used in other areas to obtain a digital model of an object and its environment. This is important, for example, for non-destructive testing of materials, reverse engineering or the study of biological and paleontological samples.

Non-contact passive scanners

Passive scanners do not emit light, instead they use reflected light from the environment. Most scanners of this type are designed to detect visible light, which is the most accessible form of ambient radiation. Other types of radiation, such as infrared, may also be involved. Passive scanning methods are relatively cheap, because in most cases they do not need special equipment, a conventional digital camera is enough. nine0113 Stereoscopic systems involve the use of 2 video cameras located in different places, but in the same direction. By analyzing the differences in the images of each camera, you can determine the distance to each point in the image. This method is similar in principle to human stereoscopic vision.

Most scanners of this type are designed to detect visible light, which is the most accessible form of ambient radiation. Other types of radiation, such as infrared, may also be involved. Passive scanning methods are relatively cheap, because in most cases they do not need special equipment, a conventional digital camera is enough. nine0113 Stereoscopic systems involve the use of 2 video cameras located in different places, but in the same direction. By analyzing the differences in the images of each camera, you can determine the distance to each point in the image. This method is similar in principle to human stereoscopic vision.

Photometric systems typically use a single camera that captures multiple frames in all lighting conditions. These methods attempt to transform the object model in order to reconstruct the surface for each pixel. nine0005

Silhouette techniques use contours from successive photographs of a three-dimensional object against a contrasting background. These silhouettes are extruded and transformed to get the visible skin of the object. However, this method does not allow you to scan the recesses in the object (for example, the inner cavity of the bowl).

However, this method does not allow you to scan the recesses in the object (for example, the inner cavity of the bowl).

There are other methods that are based on the fact that the user himself discovers and identifies some features and shapes of the object, based on many different images of the object, which allow you to create an approximate model of this object. Such methods can be used to quickly create a three-dimensional model of objects of simple shapes, for example, a building. You can do this using one of the software applications: D-Sculptor, iModeller, Autodesk ImageModeler or PhotoModeler. nine0005

This 3D scan is based on the principles of photogrammetry. In addition, this technique is in some ways similar to panoramic photography, except that the photographs of the object are taken in three-dimensional space. Thus, it is possible to copy the object itself, rather than taking a series of photos from one point in three-dimensional space, which would lead to the reconstruction of the object's environment.

Reconstruction

From point clouds

The point clouds generated by the 3D Scanners can be directly used for measurement or visualization in architecture and engineering.

However, most applications use non-homogeneous rational B-spline, NURBS, or editable CAD models (also known as solid models) instead of polygonal 3D models.

- Polygon mesh models: In polygon representation shapes curved surfaces consist of many small flat surfaces with edges (a striking example is a ball in discotheques). Polygonal models are very in demand for visualization in the field of CAM - an automated system for technological preparation of production (for example, mechanical processing). At the same time, such models are quite « heavy" (accommodate a large amount of data) and are quite difficult to edit in this format. Reconstruction into a polygonal model involves searching and combining neighboring points with straight lines until a continuous surface is formed.

For this, you can use a number of paid and free programs (MeshLab, Kubit PointCloud for Au toCAD, 3D JRC Reconstructor, ImageModel, PolyWorks, Rapidform, Geomagic, Imageware, Rhino 3D, etc.). nine0072

For this, you can use a number of paid and free programs (MeshLab, Kubit PointCloud for Au toCAD, 3D JRC Reconstructor, ImageModel, PolyWorks, Rapidform, Geomagic, Imageware, Rhino 3D, etc.). nine0072 - Surface models: This method represents the next level of sophistication in the field of modeling. It applies a set of curved surfaces that give your object its shape. It can be NURBS, T-Spline or other curved objects from the topology. Using NURBS converts, for example, a sphere to its mathematical equivalent. Some applications require manual processing of the model, but more advanced programs also offer automatic mode. This option is not only easier to use, but also provides the ability to modify the model when exporting to a computer-aided design system (CAD). Surface models are editable, but only in a sculptural way. Organic and artistic forms lend themselves well to modeling. Surface modeling is available in Rapidform, Geomagic, Rhino 3D, Maya, T Splines. nine0072

- 3D CAD Models: From an engineering and manufacturing perspective, this type of simulation is a full digitized form of a parametric CAD model.

After all, CAD is the industry's common "language" for describing, editing, and preserving the shape of an enterprise's assets. For example, in CAD, a sphere can be described by parametric functions that are easy to edit by changing their value (say, radius or center point).

After all, CAD is the industry's common "language" for describing, editing, and preserving the shape of an enterprise's assets. For example, in CAD, a sphere can be described by parametric functions that are easy to edit by changing their value (say, radius or center point).

These CAD models don't just describe the shell or shape of an object, but they also enable design intent (ie, critical features and their relationship to other features). An example of design intent that is not expressed in form would be the ribbed bolts of a brake drum, which should be concentric with the hole in the center of the drum. This nuance determines the sequence and method of creating a CAD model, so the engineer, taking into account these features, will develop bolts tied not to the outer diameter, but, on the contrary, to the center. Thus, to create such a CAD model, you need to correlate the shape of the object with the design intent. nine0005

There are several approaches to get a parametric CAD model./cdn.vox-cdn.com/uploads/chorus_asset/file/12803133/IMG_4902.1419979924.jpg) Some involve only exporting a NURBS surface, leaving the CAD engineer to complete the modeling (Geomagic, Imageware, Rhino 3D). Others use the scan data to create an editable and verifiable function model that can be fully imported into CAD with an intact fully functional tree, providing a complete fusion of shape and design intent of the CAD model (Geomagic, Rapidform). However, other CAD applications are powerful enough to manipulate a limited number of points or polygonal models in a CAD environment (CATIA, AutoCAD, Revit). nine0005

Some involve only exporting a NURBS surface, leaving the CAD engineer to complete the modeling (Geomagic, Imageware, Rhino 3D). Others use the scan data to create an editable and verifiable function model that can be fully imported into CAD with an intact fully functional tree, providing a complete fusion of shape and design intent of the CAD model (Geomagic, Rapidform). However, other CAD applications are powerful enough to manipulate a limited number of points or polygonal models in a CAD environment (CATIA, AutoCAD, Revit). nine0005

From the 2D slice set

3D reconstruction of the brain or eyeballs based on CT results is performed using DICOM images. Their peculiarity is that the areas on which air is displayed, or bones with a high density are made transparent, and the sections are superimposed in a free alignment interval. The outer ring of biomaterial surrounding the brain is made up of the soft tissues of the skin and muscles on the outside of the skull. All sections are made on a black background. Since they are simple 2D images, when added one-to-one when viewed, the borders of each slice disappear due to their zero thickness. Each DICOM image is a slice about 5 mm thick. nine0004

All sections are made on a black background. Since they are simple 2D images, when added one-to-one when viewed, the borders of each slice disappear due to their zero thickness. Each DICOM image is a slice about 5 mm thick. nine0004

CT, industrial CT, MRI or microCT scanners do not create a point cloud, but 2D slices (referred to as a “tomogram”) that are superimposed on each other, resulting in a kind of 3D model. There are several ways to do this, depending on the desired result:

- Volume rendering: Different parts of an object usually have different thresholds and grayscale densities. Based on this, a three-dimensional model can be freely designed and displayed on the screen. Several models can be made from different thresholds, allowing different colors to represent a specific part of an object. Volumetric rendering is most often used to render a scanned object. nine0072

- Image segmentation: When different structures have similar threshold or midtone values, it may not be possible to separate them simply by changing volume rendering parameters.

The solution to the problem will be segmentation - a manual or automatic procedure that will remove unnecessary structures from the image. Special programs that support image segmentation allow you to export segmented structures to CAD or STL format, which will allow you to continue working with them. nine0072

The solution to the problem will be segmentation - a manual or automatic procedure that will remove unnecessary structures from the image. Special programs that support image segmentation allow you to export segmented structures to CAD or STL format, which will allow you to continue working with them. nine0072 - Meshing based on image analysis: When 3D image data (CFD and FEA) is used for computer analysis, simple data segmentation and meshing from a CAD file can be quite time consuming. In addition, some typical image data may not be inherently suitable for a complex topology. The solution lies in image analysis meshing, which is an automated process for generating an accurate and realistic geometric description of the scanned data. nine0072

Application

Material Handling and Manufacturing

3D Laser Scanning describes a general way to measure or scan a surface using laser technology. It is used in several areas at once, differing mainly in the power of the lasers that are used and the results of the scan itself. Low laser power is needed when the scanned surface should not be influenced, for example, if it only needs to be digitized. Confocal or 3D laser scanning are methods that provide information about the scanned surface. Another low power application involves a projection system that uses structured light. It is applied to solar panel plane metrology involving voltage calculation with a throughput of more than 2,000 plates per hour. nine0005

Low laser power is needed when the scanned surface should not be influenced, for example, if it only needs to be digitized. Confocal or 3D laser scanning are methods that provide information about the scanned surface. Another low power application involves a projection system that uses structured light. It is applied to solar panel plane metrology involving voltage calculation with a throughput of more than 2,000 plates per hour. nine0005

The laser power used for laser scanning of industrial equipment is 1W. The power level is typically 200mW or less.

Construction industry

- Robot control: laser scanner acts as the eye of the robot

- Executive drawings of bridges, industrial plants, monuments

- Documentation of Historic Sites

- Site modeling and layout

- Quality control

- Measurement of works

- Reconstruction of highways

- Marking an existing shape/state to identify structural changes after extreme events - earthquake, ship or truck impact, fire.

- Creation of GIS (Geographic Information System), maps and geomatics

- Scanning of subsurface in mines and karst voids

- Court records

Benefits of 3D scanning

Creating a 3D model by scanning has the following benefits:

- Makes working with complex parts and shapes more efficient

- Encourages product design when needed to add a part created by someone else.

- If CAD models become outdated, 3D scanning will provide an updated version

- Replaces missing or missing parts of

Entertainment

3D scanners are widely used in the entertainment industry to create 3D digital models in film and video games. If the model being created has a counterpart in the real world, then scanning will allow you to create a three-dimensional model much faster than developing the same model through 3D modeling. Quite often, artists first sculpt a physical model, which is then scanned to get a digital equivalent, instead of creating such a model on a computer. nine0005

nine0005

Reverse engineering

Reverse engineering of mechanical components requires a very accurate digital model of the objects to be recreated. This is a good alternative to converting many points of a digital model to a polygon mesh, using a set of NURBS flat and curved surfaces, or, ideally for mechanical components, creating a 3D CAD model. A 3D scanner can be used to digitize objects that freely change shape. As well as the prismatic configuration, for which a coordinate measuring machine is usually used. This will allow you to determine the simple dimensions of the prismatic model. This data is further processed by special programs for reverse engineering. nine0005

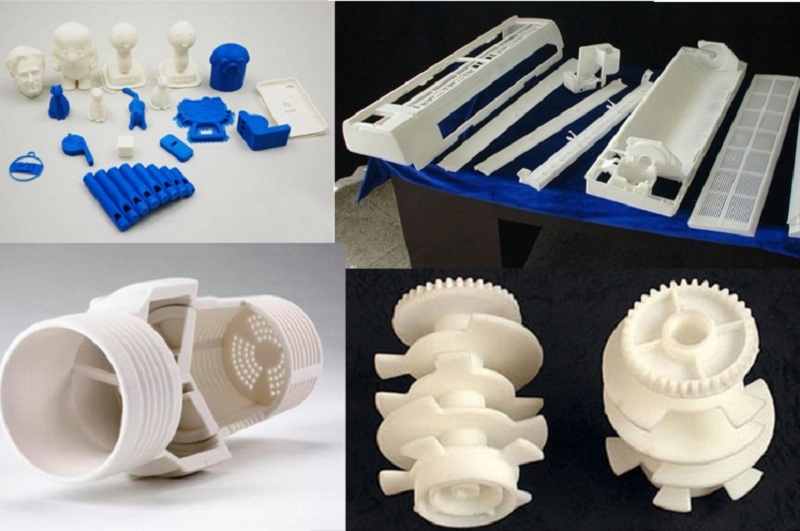

3D printing

3D scanners are also actively used in the field of 3D printing, as they allow you to create fairly accurate 3D models of various objects and surfaces in a short time, suitable for further refinement and printing. In this area, both contact and non-contact scanning methods are used, both methods have certain advantages.

Cultural heritage

An example of copying a real object through 3D scanning and 3D printing. There are many research projects that have been carried out using the scanning of historical sites and artifacts to document and analyze them. The combined use of 3D scanning and 3D printing makes it possible to replicate real objects without the use of a traditional plaster cast, which in many cases can damage a valuable or delicate cultural heritage artifact. The sculpture of the figure on the left was digitized using a 3D scanner, and the resulting data was converted in the MeshLab program. The resulting digital 3D model was printed using a rapid prototyping machine that allows you to create a real copy of the original object. nine0004

Michelangelo

There are many research projects that have been carried out using scanning of historical sites and artifacts to document and analyze them.

In 1999, 2 different research groups started scanning Michelangelo's statues. Stanford University, along with a team led by Mark Levoy, used a conventional laser triangulation scanner built by Cyberware specifically to scan Michelangelo's statues in Florence. In particular, the famous David, "Slaves" and 4 more statues from the Medici chapel. Scanning is performed with a dot density of 0.25 mm, sufficient to see the traces of Michelangelo's chisel. Such a detailed scan involves obtaining a huge amount of data (about 32 gigabytes). It took about 5 months to process them. nine0005

Around the same time, a research group from IBM was working, led by H. Raschmeyer and F. Bernardini. They were tasked with scanning the Florentine Pieta sculpture to obtain both geometric data and color information. The digital model obtained from a Stanford University scan was fully used in 2004 to further restore the statue.

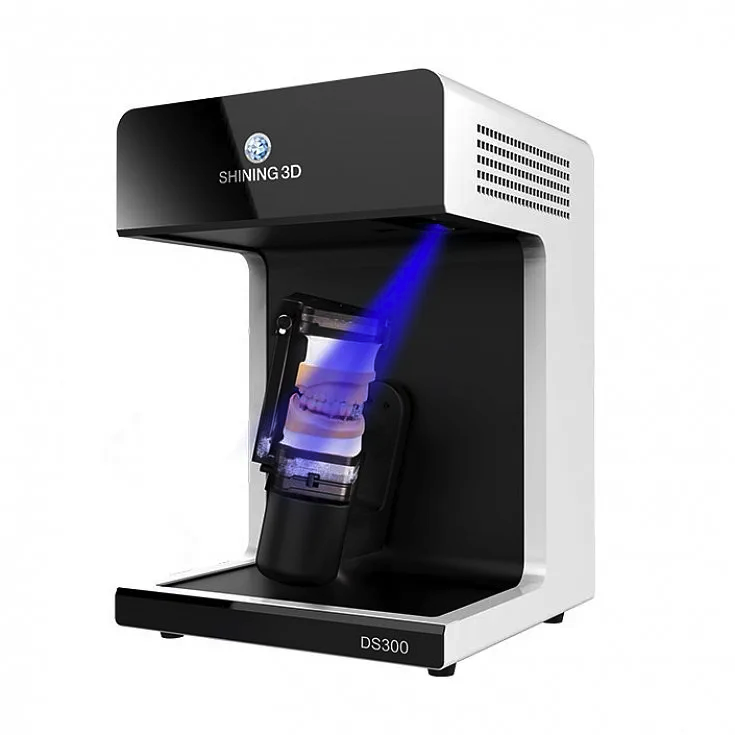

Medical applications CAD/CAM

3D scanners are widely used in orthopedics and dentistry to create a 3D patient shape. Gradually, they replace the outdated gypsum technology. CAD/CAM software is used to create prostheses and implants.

Gradually, they replace the outdated gypsum technology. CAD/CAM software is used to create prostheses and implants.

Many dentistry uses CAD/CAM as well as 3D scanners to capture the 3D surface of a dentifrice (in vivo or in vitro) in order to create a digital model using CAD or CAM techniques (e.g. , for a CNC milling machine (computer numerical control), as well as a 3D printer). Such systems are designed to facilitate the process of 3D scanning of the drug in vivo with its further modeling (for example, for a crown, filling or inlay). nine0005

Quality assurance and industrial metrology

The digitization of real world objects is of great importance in various fields of application. 3D scanning is very actively used in industry to ensure product quality, for example, to measure geometric accuracy. Predominantly all industrial processes such as assembly are quite complex, they are also highly automated and are usually based on CAD (computer-aided design data). The problem is that the same degree of automation is required for quality assurance. A striking example is the automated assembly of modern cars, because they consist of many parts that must match exactly with each other. nine0113 Optimum performance levels are guaranteed by quality assurance systems. Geometrical metal parts need special checking, because they must be of the correct size, fit together to ensure reliable operation.

The problem is that the same degree of automation is required for quality assurance. A striking example is the automated assembly of modern cars, because they consist of many parts that must match exactly with each other. nine0113 Optimum performance levels are guaranteed by quality assurance systems. Geometrical metal parts need special checking, because they must be of the correct size, fit together to ensure reliable operation.

In highly automated processes, the results of geometric measurements are transferred to machines that produce the corresponding objects. Due to friction and other mechanical processes, the digital model may differ slightly from the real object. In order to automatically capture and evaluate these deviations, the manufactured parts must be rescanned. For this, 3D scanners are used, which create a reference model with which the received data are compared. nine0113 The process of comparing 3D data and CAD model is called CAD comparison, and can be a useful method for determining mold and machine wear, final assembly accuracy, gap analysis, and the volumetric surface of a disassembled part. Currently laser triangulation scanners, structured light devices and contact scanning are the leading technologies used in industrial applications. Contact scanning methods, although they are the slowest, but the most accurate option. nine0005

Currently laser triangulation scanners, structured light devices and contact scanning are the leading technologies used in industrial applications. Contact scanning methods, although they are the slowest, but the most accurate option. nine0005

If you have a need for 3D scanning services and / or subsequent reverse engineering, please contact us at [email protected].

LS2D laser triangulation 2-D probe manufacturer

Home / LS2D - laser triangulation 2-D probe

LS2D - laser triangulation 2-D sensor

LS2D – laser triangulation 2-D sensor (scanner) with built-in microprocessor control system. nine0005

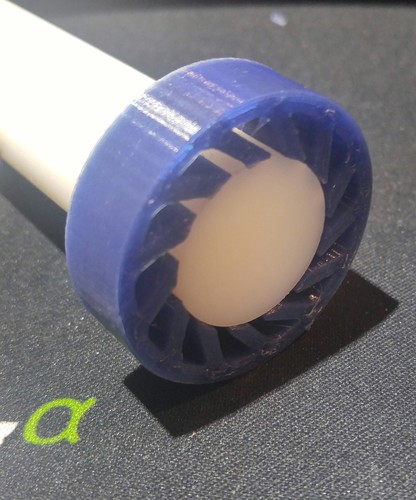

Model LS2D scanners designed for non-contact measurement of the profile of an object with a scattering surface, width, thickness of rolled metal, internal and external diameters, thread parameters, detection of local product defects, control of gaps, welds, object recognition, building 3-D models, as well as for use in various measuring systems.

|

| nine0475 | ||||||||

| Principle of operation |

| Application |

| Links |

| Enclosure options |

Working principle of LS2D – laser triangulation 2-D sensor

| The beam emitted by the laser, unfolded into an ideal straight line, is projected onto the surface of the controlled object. The light line repeats the shape of the profile of an object in a section. The image of the light line reflected from the object is projected by means of a lens onto a CMOS photomatrix. According to the image coordinates on the photodetector, the microprocessor calculates the real coordinates of the light line. nine0005 Scanner measurements are transferred to a computer via the Ethernet interface. To obtain a 3D model of the shape or surface of an object, you can use the movement of the LS2D sensor, taking into account the exact amount of this movement. | |

| Depending on the task, the scanners use blue lasers in addition to red ones. The use of such lasers makes it possible to use scanners under strong illumination with a large predominance of the red spectrum (welding, daylight, etc.). The use of scanners with different wavelengths in one system makes it possible to eliminate the mutual influence of sensors on each other. Scanners can be equipped with window ventilation and air (or water) cooling systems. The window blowing system is used to remove dust and other contaminants from the surface of protective glass. The water/air cooling system is used to increase the operating temperature range of the scanner. Model LS2DB binocular scanners are two scanners in one housing (see figure 1). The laser beam reflected from object 1 is projected onto two photomatrices 2 at once. Based on the information received from these photomatrices, the microprocessor calculates the distance to the object. nine0005

Figure 1 - Device binocular scanner LS2DB: 1 - controlled surface; 2 - CMOS photomatrix; 3 - laser board; 4 - laser lens; 5 - photomatrix lens The use of binocular scanners improves the accuracy of measurements of deep objects and surfaces with complex relief (see Figure 2). | |

| | |

| Figure 2 - Comparison of measurement results with a conventional laser scanner (a) and binocular (b) When measuring such objects with a conventional triangulation laser scanner (see Figure 2, a), there may be dark zones in which the radiation reflected from the object does not fall on the photodetector of the device. | |

nine0005

nine0005

_Angle_View.jpg)