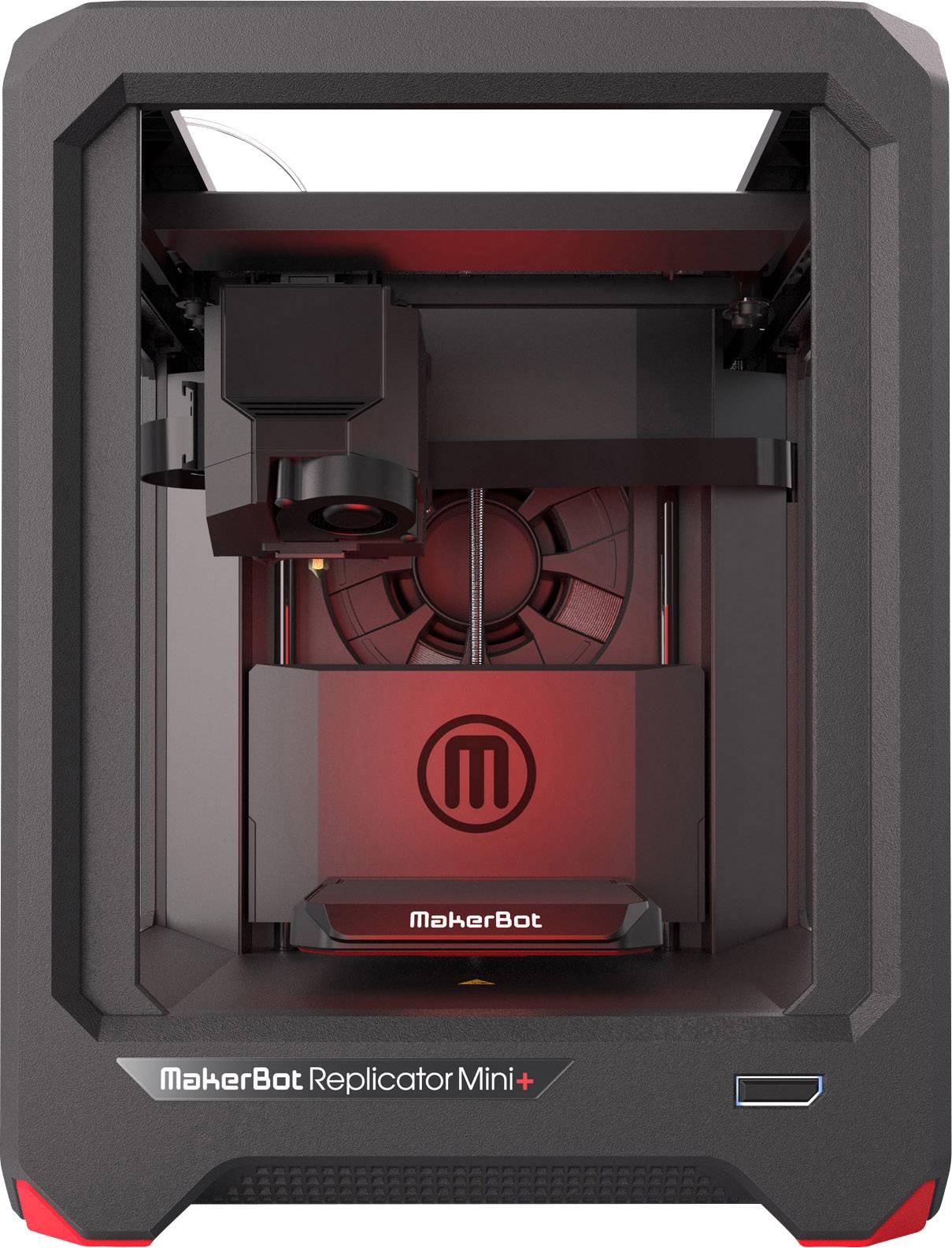

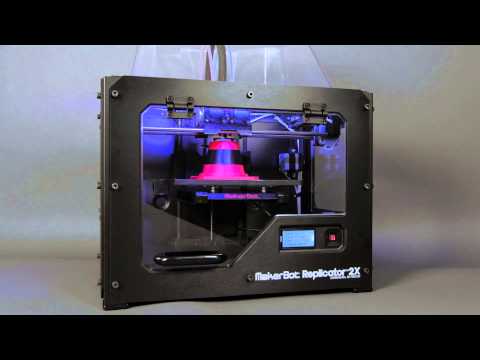

Makerbot replicator 2 desktop 3d printer

MakerBot Replicator 2 Review 2022

3.7

See Price

When you start shopping for a high-end 3D printer, it’s easy to get confused. There are so many different specifications to compare, and it’s not always clear which ones are important. Don’t worry, though – we’re here to help.

Today we’ll be reviewing the MakerBot Replicator 2 – a premium 3D printer whose fans include the US Army, MIT, and NASA. We’ll identify its strong points, the things that set it apart from the crowd, and of course, the areas that could use some work. Is this the right printer for you? Read on to find out.

| Filament Diameter | 1.75mm |

| Extruders | 1 |

| Supported Materials | PLA |

| Connectivity | USB, SD Card |

| Printing Speed | 100mm/s |

| Build Volume | 11.2 x 6 x 6. |

Table of ContentsShow

Design

This is a nice, compact printer that’ll fit easily on top of your desk. It boasts a fairly large, enclosed build area, as well as a simplistic user interface. Better still, it comes already assembled, so once it arrives, you can start printing as soon as you’ve configured it.

All in all, it’s a pretty sturdy device. The frame is made from powder-coated steel, and even the bearings are wear-resistant. We’ve seen cases where printers struggle to start in cooler climates, but that’s not a problem for the Replicator 2 – as long as your room is 0-32°, you’ll be able to print just fine.

You can import models either directly from your PC, or with a USB stick or SD card. There’s a small LCD screen that can be used to control the unit, although evidently, the functionality here is fairly limited. Still, it’s a nice option to have, and it looks great if nothing else.

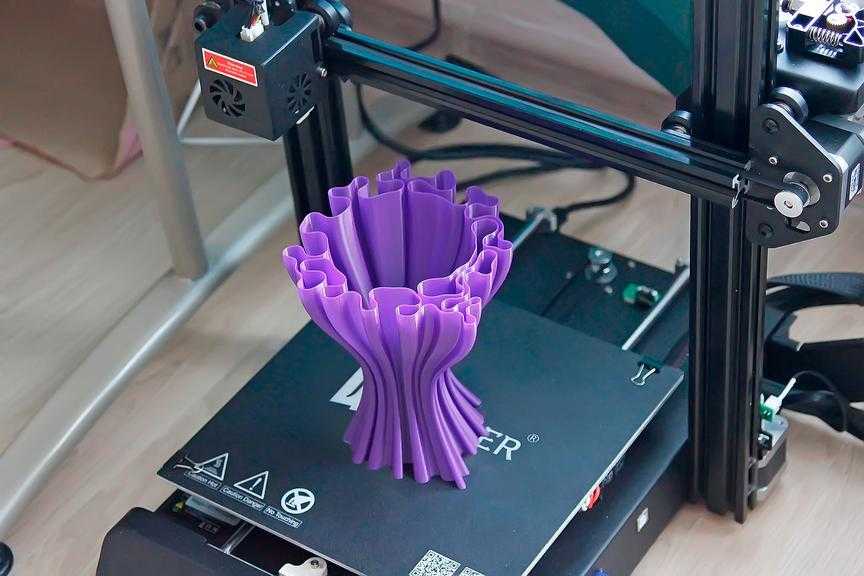

Printing

This printer comes with three print quality options. We found that at its highest resolution, models came out quite well. The edges could be a little sharper, but overall, they were clean enough for most applications. The Replicator 2 excels at creating complex internal structures, and there’s minimal stepping even on sharp curves.

We found that at its highest resolution, models came out quite well. The edges could be a little sharper, but overall, they were clean enough for most applications. The Replicator 2 excels at creating complex internal structures, and there’s minimal stepping even on sharp curves.

There is one fairly major issue, though. The Replicator 2 can only print with PLA. When you consider that even the cheapest printers tend to support ABS at least, this is a bit of a disappointment. If you’d like to create the same object over and over again, this isn’t a problem but hobbyists might find this limitation more than a little restrictive.

Also, while MakerBot boast about the Replicator 2’s speed, it’s nothing to write home about. In fact, we’ve seen considerably faster 3D printers that cost a lot less. However, it’s important to remember that faster printers usually lack the print quality that this model provides.

Features

This printer has one particularly unusual feature: it allows you to add several different models at the same time, so you can effectively queue prints for when you’re away. Admittedly, this would be more useful with a second extruder but it’s still a unique and welcome addition to the printer’s arsenal.

Admittedly, this would be more useful with a second extruder but it’s still a unique and welcome addition to the printer’s arsenal.

MakerBot claims that the Replicator 2 can prepare models for printing up to twenty times faster than its rivals, thanks to its Makerware program. This is compatible with Windows, Mac, and Linux systems, and comes with several handy options such as saving multi-part models into a single file.

Let’s not forget the three-point levelling system. The print bed is locked in place with screws, meaning it’s less likely to wobble or shift. Unfortunately, the bed isn’t heated, though. This is something you really expect from a premium printer, and while one can be added by an experienced modder, it’s a little strange that this wasn’t included as standard.

Cost

Retailing for around $2500, this is far from the cheapest printer around. If you’d like to buy one, you’ll have to find a third-party supplier since MakerBot continually replace their older models and remove them from the store. The new version, the Replicator+, costs about the same price, so unless you’re a die-hard enthusiast, there’s no incentive to choose the Replicator 2.

The new version, the Replicator+, costs about the same price, so unless you’re a die-hard enthusiast, there’s no incentive to choose the Replicator 2.

On the other hand, PLA is among the least expensive materials to buy. You are limited to MakerBot filament, however. As you might expect, this costs a little more than usual, at around $18 for a small 200g spool. There are bulk deals on offer, though, which is something.

Obviously, this printer isn’t intended to be your first 3D printer. Its price range puts it outside of the budget for most people. However, it works wonderfully and its price is reasonable enough for small-scale commercial applications.

Support

Although it’s no longer available on the store, MakerBot have extensive technical support for the Replicator 2. There’s everything from tutorials to maintenance guides here, and you can even search for a specific error code if need be.

Even if you buy from a third-party, once you register the printer, you become eligible for a 60-day support service called MakerCare. This provides faster response times, additional support methods, and premium plans last for up to three years. You can’t order online, though – all MakerCare enquiries have to be made over the phone.

This provides faster response times, additional support methods, and premium plans last for up to three years. You can’t order online, though – all MakerCare enquiries have to be made over the phone.

If you’re not covered by MakerCare, you can expect to wait about three days before hearing back about any issues. You should note that the warranty only lasts six months, after which point, you’re on your own. This is shorter than we’d have liked, especially considering the high initial investment this printer requires.

Are you looking for another MakerBot product? Check our review about the MakerBot Replicator 5th Generation, this may the one for you.

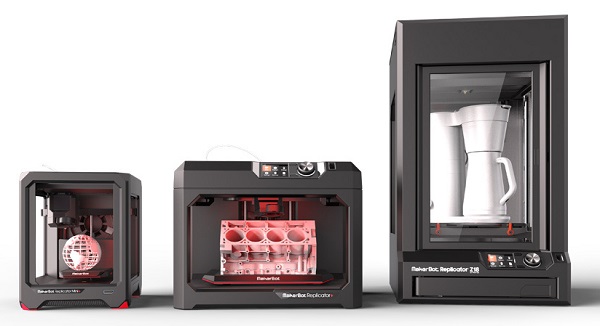

Professional 3D Printer Comparison | MakerBot

METHOD | REPLICATOR+ | REPLICATOR Z18 | |

|---|---|---|---|

CATEGORY | Performance | Desktop | Desktop Large Volume |

USES | Prototypes, manufacturing aids, and other parts that require complex assemblies, extreme geometries, and commercial precision. | Classroom lesson plans, STEM projects, design thinking exercises, and facilitation of 21st-century career skills. | Oversized models, housings, and structures that require a massive build volume. |

PRICE | $4,999 | $2,799 | $5,499 |

LAYER HEIGHTThe range of thicknesses of each printed layer measured in microns. | 20 - 400 microns Print Modes: | 100 - 400 microns Print Modes: | 100 - 400 microns Print Modes: |

COMPATIBLE EXTRUDERSMakerBot 3D printers utilize swappable extruders for flexibility of print options and convenience of maintainance. | Model 1 Performance Extruder, Model 2 Performance Extruder | Smart Extruder+ Tough Smart Extruder+ Experimental Extruder | Smart Extruder+ Tough Smart Extruder+ Experimental Extruder |

BUILD SPEEDMax Material Flow rate is the maximum speed material can be extruded. Print Head Travel Speed is the speed that extruder moves on the xy axis. | Max Material Flow Rate: ~50mm3/sec Print Head Travel Speed: 500 mm/sec | Max Material Flow Rate: ~15mm3/sec Print Head Travel Speed: Up to 175 mm/sec | Max Material Flow Rate: ~15mm3/sec Print Head Travel Speed: Up to 175 mm/sec |

PRINTER FRAME CONSTRUCTIONThe printer's frame connects the xy gantry to the z stage making it the essential structural component of the printer. | Ultra-Rigid Metal Frame | Injection Molded ABS with aluminum gantry-reinforcement | Injection Molded ABS with aluminum gantry-reinforcement |

BUILD VOLUMEThe maximum space available for 3D printing either your complete object or a component of your final, assembled object. | 19 L x 19 W x 19.6 H cm / 7.5 x 7.5 x 7.75 in single extrusion 15.2 L x 19 W x 19.6 H cm / 6.0 x 7.5 x 7.75 in dual extrusion | 29.5 L x 19.5 W x 16.0 H cm / 11.6 L x 7.  6 W x 6.5 H in 6 W x 6.5 H in | 30.0 L x 30.5 W x 45.7 H cm / 11.8 L x 12.0 W x 18.0 H in |

MATERIAL STORAGEMaterial storage location can improve the user experience, and a sealed storage compartment can significantly increase the "pristine" lifetime of material allowing for high print accuracy. | Dry-Sealed Material Bay | Open back loaded material drawer | Open bottom loaded material drawer |

COMPATIBLE MATERIALDifferent materials can be used for different applications. | MakerBot Precision PLA, MakerBot Precision Tough, MakerBot Precision PVA, MakerBot Specialty PETG | MakerBot PLA, Smart Extruder+. MakerBot Tough, Tough Smart Extruder+. Additional materials such as bronzeFill, copperFill, and woodFill, Experimental Extruder. MakerBot Tough, Tough Smart Extruder+. Additional materials such as bronzeFill, copperFill, and woodFill, Experimental Extruder. | MakerBot PLA, Smart Extruder+. MakerBot Tough, Tough Smart Extruder+. Additional materials such as bronzeFill, copperFill, and woodFill, Experimental Extruder. |

BUILD PLATFORMBuild surface and platform type | Factory-Leveled Spring Steel Build Plate with Reusable Grip Surface | Factory-Leveled Flex Build Plate with Reusable Grip Surface | Factory-Leveled ABS Build Plate with Reusable Grip Surface |

MEASURABLE DIMENSIONAL ACCURACY3D printed parts that consistently match CAD dimensions to within a published tolerance. | |||

DUAL EXTRUSIONTwo extruders provide the added ability to print with soluble support material alongside model material. | |||

ENCLOSED HEATED BUILD CHAMBERAn elevated 3D printing environmental temperature improves layer adhesion, reduces warping, and improves dimensional accuracy. | |||

SMART ASSIST MATERIAL LOADINGAn extra sensor and drive motor designed to automate the loading process from spool to extruder. | |||

SMART SPOOL COMPATIBILITYRFID Tag equipped spool providing real-time information on material type, color, and amount remaining. | |||

CAMERAOnboard camera for monitoring your print jobs and sharing pictures of your 3D prints. | |||

INTERFACEProvides easy, computer-free access to printing menus, commands, and your cloud storage library. | 5" Capacitive Touch Screen | 3.5" LCD Screen | 3.5" LCD Screen |

CONNECTIVITYOptions for connecting directly or remotely to the printer for from launching and monitoring prints, to adjusting settings and updating firmware. | WI-FI Ethernet USB Stick USB Cable | WI-FI Ethernet USB Stick USB Cable | WI-FI Ethernet USB Stick USB Cable |

| Shop Method | Shop Replicator+ | Shop Replicator Z18 |

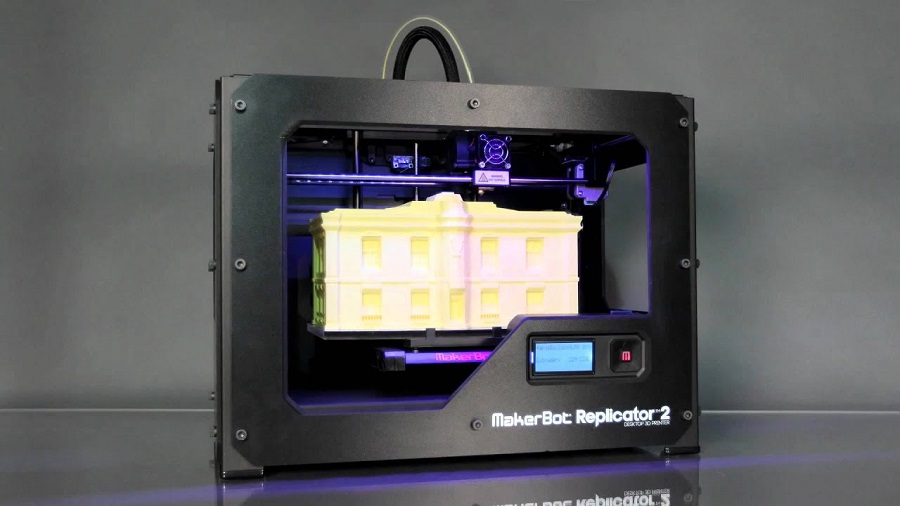

from MakerBot Industries, LLC The MakerBot Replicator 2 personal 3D printer has a high print resolution of 100 microns, which puts it in line with expensive professional 3D printers.

The device can create 3D models with dimensions of 285x153x155 mm with high print speed: 50 mm/s without losing the quality of printed objects. The printer is equipped with a heated platform, which eliminates plastic slip and layer deformation. nine0003

The device can create 3D models with dimensions of 285x153x155 mm with high print speed: 50 mm/s without losing the quality of printed objects. The printer is equipped with a heated platform, which eliminates plastic slip and layer deformation. nine0003 About the MakerBot Replicator 2

Rugged steel housing ensures high durability.

MakerBot is the benchmark for desktop 3D printers. The main model of the company has undergone many changes, constantly undergoing modernization of both functional features and appearance. MakerBot Replicator 2 should not be considered a household printer, because it is not. This device is aimed at the more advanced users, or at least those who are willing to delve into the intricacies of the 3D printing process and be rewarded with high quality prints and rich functionality. nine0003

Design

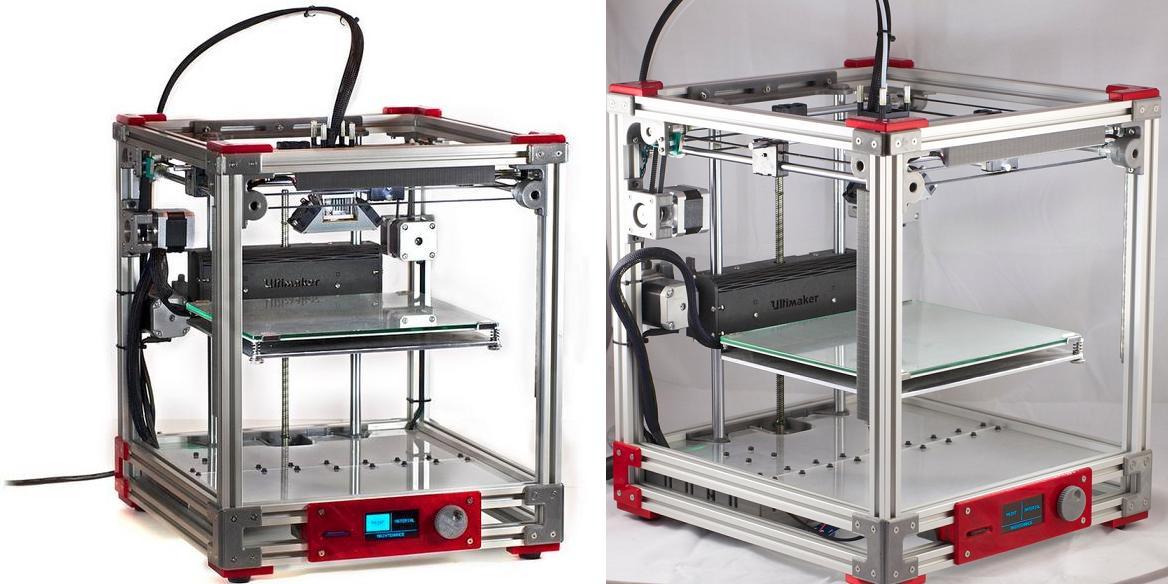

MakerBot Replicator 2 3D Printer

The exterior design of the Replicator 2 is hardly classic. It would be more correct to be “original”, because it was the “replicators” (including their heterogeneous predecessors, the MakerBot Thing-O-Matic and MakerBot Cupcake printers) that made the open case with cutouts in the facing panels a kind of standard that gave rise to a myriad of imitations and outright clones. The cutouts serve a strictly practical purpose, facilitating access to the build platform from all sides and, last but not least, providing good ventilation and fast cooling when printing with PLA. nine0003

It would be more correct to be “original”, because it was the “replicators” (including their heterogeneous predecessors, the MakerBot Thing-O-Matic and MakerBot Cupcake printers) that made the open case with cutouts in the facing panels a kind of standard that gave rise to a myriad of imitations and outright clones. The cutouts serve a strictly practical purpose, facilitating access to the build platform from all sides and, last but not least, providing good ventilation and fast cooling when printing with PLA. nine0003

Printer frame made of powder-coated steel with PVC cladding panels. The guides are made of aluminium, while the bearings are made of cermet based on oil-impregnated bronze. In general, the developers have put a lot of effort into ensuring the durability of the device. True, the metal frame is not to everyone's taste, because the wood used in the early models of the printer tends to absorb vibrations more effectively.

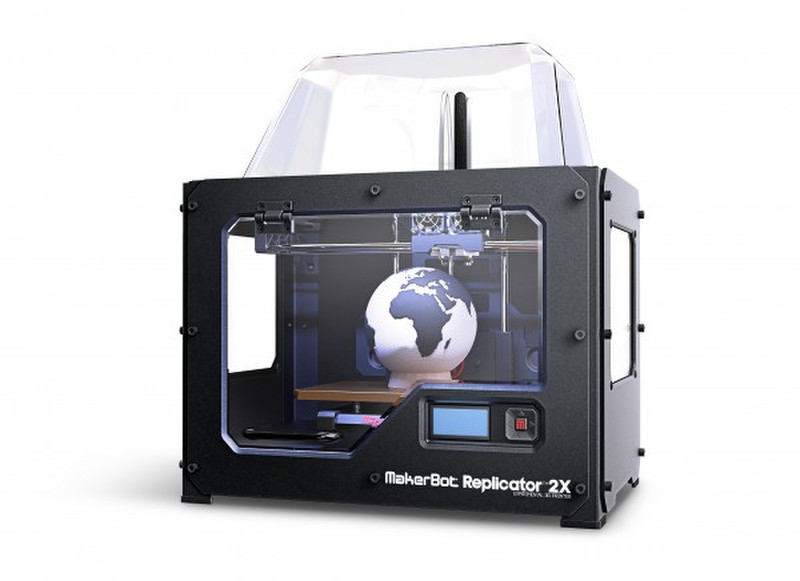

Unlike some earlier versions, the Replicator 2 uses only one extruder, but the size of the working area has been significantly increased and is 285x153x155mm. Note that some confusion is possible: the latest model of the fifth generation is again called the Replicator. This device can be considered a further development of the described Replicator 2 model, which, according to the new nomenclature, should be attributed to the fourth generation. At the moment, the fourth and fifth generation models are sold in parallel, having certain differences in the configurations of the build areas, electronic filling, and some other points. nine0003

Note that some confusion is possible: the latest model of the fifth generation is again called the Replicator. This device can be considered a further development of the described Replicator 2 model, which, according to the new nomenclature, should be attributed to the fourth generation. At the moment, the fourth and fifth generation models are sold in parallel, having certain differences in the configurations of the build areas, electronic filling, and some other points. nine0003

Acrylic worktable excellent for PLA printing

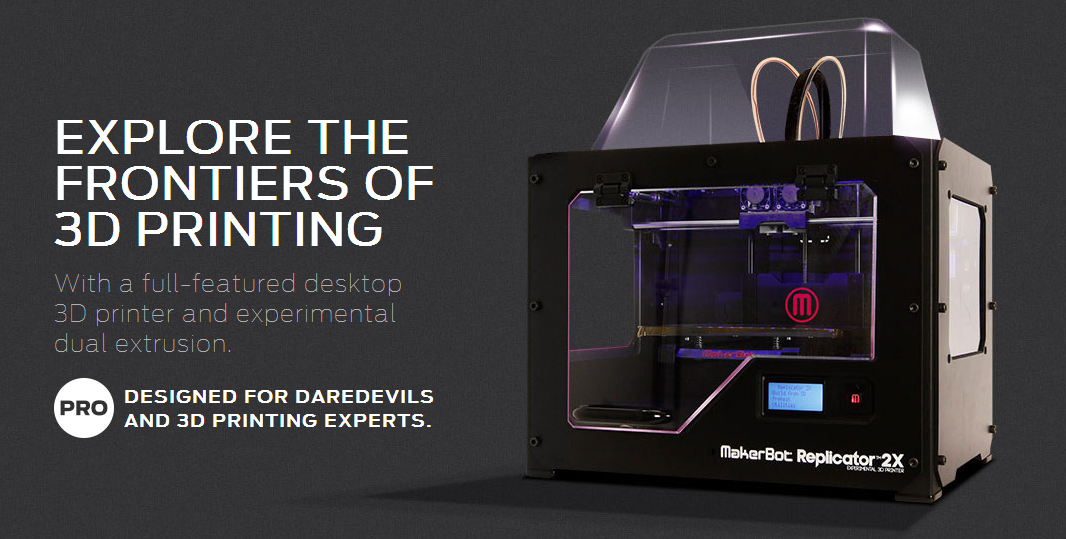

Since “replicators” have traditionally been designed primarily for PLA printing, the Replicator 2 does not have a heated bed. Actually, polylactide is the only type of consumable that is officially supported by this device. By the way, there is a printer variant called the Replicator 2X (“X” stands for “experimental”), in which MakerBot re-tested printing with ABS plastic, including a heated platform in the design, removable panels that cover openings in the cladding panels, and returning printing with two extruders . This option is also on sale, but is intended for professional users. The removable table of the Replicator 2 is made of acrylic, which is an excellent base for models made of PLA plastic. nine0003

This option is also on sale, but is intended for professional users. The removable table of the Replicator 2 is made of acrylic, which is an excellent base for models made of PLA plastic. nine0003

Printing

Replicator 2 3D printer extruder

Printing is done using a single extruder and a 0.4mm nozzle. With a minimum layer thickness of 100 µm and a positioning accuracy of 11 µm along the X and Y axes and 2.5 µm along the Z axis, very high-quality models are obtained, allowing the Replicator 2 to be put in the class of semi-professional printers.

As already mentioned, the detachable work table is made of acrylic. This option has been so successful that most users do not even resort to additional means of holding the model in place, such as duct tape. On the contrary, the addition of tape can worsen the adhesion of the polylactide compared to printing on a bare bed. You just need to make sure that the platform is free of dust and grease before printing. nine0003

nine0003

The choice of colors of the branded plastic thread is quite rich, including 26 options, of which 7 are translucent. In addition, the Replicator 2 uses quite standard spools and the usual 1.75mm filament diameter, which allows you to use "non-native" materials, although at your own risk.

Inexpensive variants from the same Chinese manufacturers often suffer from rather poor performance. It is not uncommon for a filament to have an oval cross section, which, coupled with a frankly rather weak pulling mechanism, can lead to loss of adhesion and clogging of the extruder. A particularly unpleasant surprise can be the instability of the filament shape - printing can start quite normally, but end up crashing in the middle of the process with the loss of an unfinished model. It is worth paying attention to the packaging: coils sold without vacuum packaging inevitably collect dust, whose accumulation in the extruder again does not promise anything good. nine0003

The Replicator 2 has been successfully used to print sandstone and wood simulants

In addition to potential savings, the use of standard spools provides the ability to print materials not originally intended by the printer's designers. For example, the Replicator 2 prints quite successfully with resin wood and sandstone simulants, known as LAYWOO-D3 and Laybrick, from the German manufacturer Orbi-Tech. True, to print with these materials, you will have to make some changes to the printer settings. For example, LAYWOO-D3 is preferably printed at a nozzle temperature of about 215-210°C (standard temperature for PLA printing is 230°C) and with the fan turned off, usually cooling freshly applied PLA layers. In the case of Laybrick, an extrusion temperature of 165-190°C for smooth surfaces and 210°C with fan running for a rough outer layer.

For example, the Replicator 2 prints quite successfully with resin wood and sandstone simulants, known as LAYWOO-D3 and Laybrick, from the German manufacturer Orbi-Tech. True, to print with these materials, you will have to make some changes to the printer settings. For example, LAYWOO-D3 is preferably printed at a nozzle temperature of about 215-210°C (standard temperature for PLA printing is 230°C) and with the fan turned off, usually cooling freshly applied PLA layers. In the case of Laybrick, an extrusion temperature of 165-190°C for smooth surfaces and 210°C with fan running for a rough outer layer.

Printing with ABS is theoretically impractical due to the lack of platform heating, but there is evidence of successful printing of small models. The greatest difficulty is preventing ABS plastic from slipping, but the savvy of 3D craftsmen suggested the option of replacing the desktop with a glass one and using hairspray as glue. However, the printing of large models is doomed to twisting of the deposited layers and deformation of the model during shrinkage. nine0003

nine0003

Fairly good results can be achieved with nylon printing, although the lack of a heated bed also makes the process much more difficult. Specially designed options such as Taulman 618 and 645 are recommended.

All in all, the Replicator 2 allows you to let your imagination run wild and experiment with many materials beyond the standard PLA.

Software

The Replicator 2 software caused quite a stir. The fact is that the company used a closed code. The proprietary program was called MakerWare. Actually, "closeness" touched the design of the entire printer, for the first time since the founding of the company, which built its business on the use of designs and developments in the public domain. Most outraged was the legendary founder of the open source printer project, called RepRap, Josef Prusa, who caught MakerBot in the commercial use of his ideas. Traditionally, RepRap developments are intended for use by enthusiasts, and if for commercial use, then with the concomitant provision of improvements to the public domain. But to some extent, MakerBot can be understood: the latest models have undergone such significant changes that their manufacture by improvised means is unlikely. The addition of proprietary software was only the final touch in the "closing" of design features. nine0003

But to some extent, MakerBot can be understood: the latest models have undergone such significant changes that their manufacture by improvised means is unlikely. The addition of proprietary software was only the final touch in the "closing" of design features. nine0003

MakerWare - MakerBot Replicator 2 Proprietary Software

In terms of functionality, MakerWare is practically the same as the previously used open source programs Skeinforge and Repetier-Host, except that the interface has changed. The program is compatible with Windows 7 and 8, Mac OS X and Linux and is able to work with STL, OBJ and THING files.

What is alarming is the lack of full control of the printer via a computer connection. The Replicator 2 is equipped with a very user-friendly LCD control module that exclusively performs operations such as platform calibration or plastic loading. If the module breaks, the user can use the remaining plastic on the spool, but then the printer will have to be returned for repair. One computer is not enough. On the other hand, while the module is working, you can use the SD card reader to print offline, without fear of print failures due to a computer freeze or a cable break due to a toothy pet. nine0003

One computer is not enough. On the other hand, while the module is working, you can use the SD card reader to print offline, without fear of print failures due to a computer freeze or a cable break due to a toothy pet. nine0003

Summary

Replicator 2 with Heated Bed by BC Technological Solutions

One of the most successful and sought-after 3D printers on the market. The model has undergone many changes aimed at optimizing performance and increasing durability, and at the same time received a stylish and strict exterior design, befitting a high-tech gadget. Perhaps the only serious drawback of the printer can be considered a fairly high cost compared to competitors or previous models. As for the theoretical inability to print with ABS plastic, let's not reproach a device that performs its tasks well. If you want to print in ABS and are interested in MakerBot products, we recommend that you take a look at the specially modified version of the Replicator 2X, or purchase an upgrade of the working platform from a third-party company, such as BC Technological Solutions. nine0003

nine0003

Features

- Stylish design

- High print quality

- Handy control module

- Flexible software

- Printable from SD memory card

Disadvantages

- Relatively high cost

MakerBot Replicator 2 3D printer

Out of production

Add to compare

Item added to compare Go nine0003

Free shipping within Russia

Official distributor

We work directly with manufacturers.

Any form of payment

An opportunity to see the 3D printer in action in our demo room.

Own warranty service

Warranty and post-warranty service for equipment purchased from us. nine0003

nine0003

Permanent 10% discount on consumables

When you buy a 3D printer from us,

, you get a 10% discount on all consumables.

MakerBot Replicator 2

MakerBot has unveiled one of the best 3D printers, the desktop Replicator 2. The objects that the device creates can reach dimensions of 28.44 x 15.49 x 15.24 cm. The design of the printer is designed to withstand heavy loads. The body material of the device has high impact resistance and wear resistance, due to which the equipment is rightfully considered reliable. When printing, MAKERBOT REPLICATOR 2 uses environmentally friendly PLA plastic, which has excellent adhesion to the materials used. It allows you to print even on fairly flexible products. nine0003

The MAKERBOT REPLICATOR 2 3D printer allows you to achieve the highest quality of the product. In a technique designed for printing three-dimensional objects, the quality and accuracy is determined by the thickness of the coating layer. More specifically, the thinner the layer, the better the result. This is due to the high resolution used for the best print quality. For MAKERBOT REPLICATOR 2, the following modes are defined: 340 microns - fast printing, 270 microns - normal, 100 microns - high. In the latter case, the thickness of the plastic applied to the product is comparable to the thickness of a standard sheet of paper. Environmentally friendly PLA plastic perfectly fits on a perfectly smooth surface, while there is no need for its processing. The products that are obtained at the output have a realistic bright appearance and are quite pleasant to the touch. Thanks to the use of high technology, the printer is able to work even incredibly small parts, while achieving the highest quality of the finished product. nine0003

More specifically, the thinner the layer, the better the result. This is due to the high resolution used for the best print quality. For MAKERBOT REPLICATOR 2, the following modes are defined: 340 microns - fast printing, 270 microns - normal, 100 microns - high. In the latter case, the thickness of the plastic applied to the product is comparable to the thickness of a standard sheet of paper. Environmentally friendly PLA plastic perfectly fits on a perfectly smooth surface, while there is no need for its processing. The products that are obtained at the output have a realistic bright appearance and are quite pleasant to the touch. Thanks to the use of high technology, the printer is able to work even incredibly small parts, while achieving the highest quality of the finished product. nine0003

In order to know how high-quality a product you are getting, you need to understand what PLA plastic is. This material is widely used due to its physical and chemical properties. Plastic is applied to the product in a heated molten state. Firstly, it absolutely does not emit any odor or vapors - it is harmless to health and the environment. Thanks to this, MAKERBOT REPLICATOR 2 can be used in any room, even at home. Secondly, PLA plastic is economical in processing and has perfect adhesion to the material being processed. When compared to ABS plastic, energy costs are reduced by 32%. This is a significant indicator for maximizing profits. Thirdly, the finished product is perfectly smooth and pleasant to the touch, and the range of plastic colors is constantly expanding. nine0003

Firstly, it absolutely does not emit any odor or vapors - it is harmless to health and the environment. Thanks to this, MAKERBOT REPLICATOR 2 can be used in any room, even at home. Secondly, PLA plastic is economical in processing and has perfect adhesion to the material being processed. When compared to ABS plastic, energy costs are reduced by 32%. This is a significant indicator for maximizing profits. Thirdly, the finished product is perfectly smooth and pleasant to the touch, and the range of plastic colors is constantly expanding. nine0003

The MAKERBOT REPLICATOR 2 has significantly increased the volume of the working chamber. In comparison with its predecessor - by 37%. The camera is now 410 cubic inches in size, which allows you to work with objects up to 28.44 x 15.49 x 15.24 cm. With this improvement, the 3D printer is able to create quite large objects, as well as process many small objects in one pass. By doing this, you can save time that was used to perform tasks one by one.

The printer is controlled by proprietary MakerWare software. Thanks to a simple and understandable shell of the program, everyone can work with the device - you do not need additional training. The developers managed to reduce the printing time by software optimization of the process. Using this software, you will speed up your work by 30%. The program can run on various operating systems such as Linux, Windows and Mac. Object details are considered in the most common formats - .stl and .obj. nine0003

MakerBot Replicator 2 Key Features:

- Handles objects up to 28.44 x 15.49 x 15.24 cm.

- Printing material - environmentally friendly PLA-plastic.

- Specialized software - MakerWare.

- High resolution printing - 100 micron layer thickness.

- Works on Linux, Windows and Mac.

- Economical printing with high quality.

- Minimum power consumption. nine0078

- Printing speed has been improved by optimizing the software.

Learn more

Increased rigidity will lead to better print quality.

Increased rigidity will lead to better print quality.