Tramming 3d printer

bed leveling - How do you level (or tram) your build surface correctly?

Definition of leveling

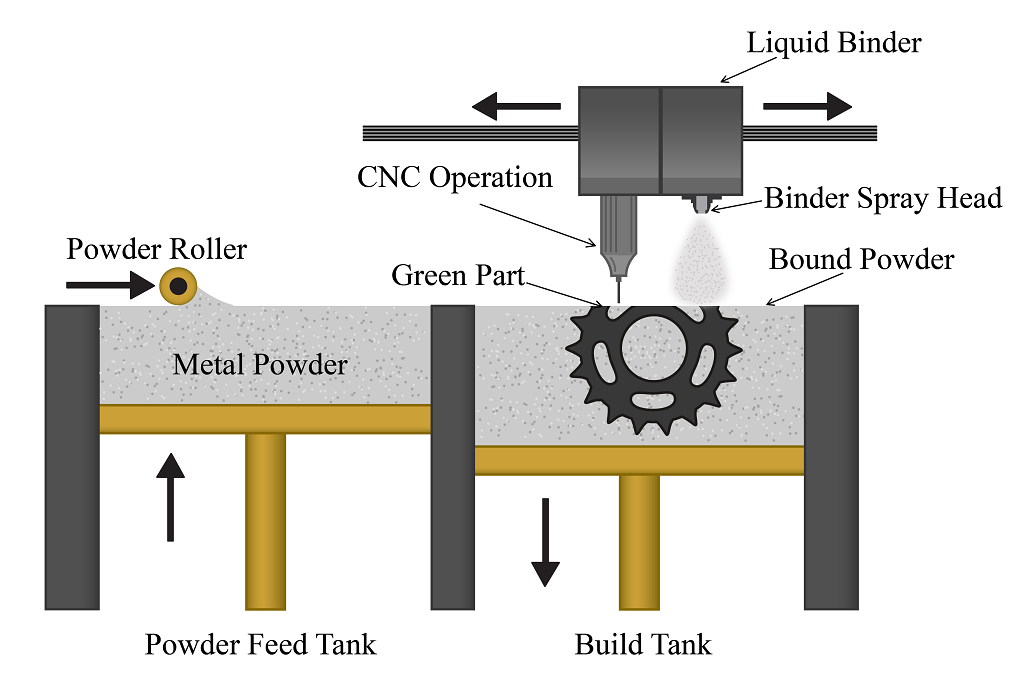

Tramming, often referred to as "leveling" in the 3D printer world ("tramming" and "leveling" is used interchangeably, but "tramming" is the correct nomenclature), is the process of creating a 2D plane of the build surface that is parallel to the nozzle at the whole print area (usually the X-Y plane).

Why tramming?

In order to adhere the hot filament from the nozzle it is essential that the distance between the nozzle and the build surface is as constant as possible. Increase of the gap may cause the filament to not be squished enough and it may be dragged instead of deposited or create an insufficient bond to cause problems later in the print job when e.g. shrinkage of the object comes in play.

How to tram the surface?

To tram the build surface (a build surface comes in many shapes and forms, sheet of glass, bare aluminum plate, some sort of coated heated surface, etc. ) most printers are equipped with at least three so-called "leveling screws". Why at least three? It takes a minimum of three screws to fixate a plane in space, more screws cause the bed to be over-defined or indeterminate, but with a flexible build surface it is quite common to have 4 screws although it is causing a statically indeterminate system. So, these screws need to be adjusted as such that the build surface if parallel to the nozzle.

First step is to home (What is homing? What is the purpose of homing?) the printer, homing from the tag wiki reads:

The process of determining the location of a 3D printer nozzle in three dimensions using a reference point (home location) is referred to as "homing". Homing should occur before every print and involves bringing the X, Y and Z-Axis motors to pre-defined limit locations (usually these are endstops). Pre-recorded homing data offset values determine the position of the build plate origin with respect to the endstop locations.

Once homed (with G-code G28 or through the graphical user interface of the printer display) , the origin (0, 0, 0) of the printer is known, from this origin you can determine the level. Note that the X and Y is usually correct (if not, see How to center my prints on the build platform? (Re-calibrate homing offset)) the Z offset depends on the height of the Z endstop and the leveling screws. For a surface that uses a sensor as endstop (see e.g. Automatic Bed Leveling (ABL) with a sensor (BLTouch, inductive, capacitive), how does it work?) the offset is defined by G-code (M851) or through the user interface of the printer display. Note that automatic bed leveling (ABL) is not magic, you still need to provide a trammed bed that is as level as possible, the sensor merely scans the surface and adjusts for larger imperfections of the build surface. After homing, move the nozzle at a certain Z value to the corner of the origin, which is usually the front left) (0, 0, Z) or close to this corner (10, 10, Z), put a piece of paper (A4/Letter) on the build surface and lower the Z to 0 (or if you hit the build surface before you reach zero height, then lower the build surface) raise the build surface until you can feel the the paper drag slightly when pulled between the nozzle and build surface (alternatively you can use a feeler gauge, A4 paper is 0. 08 to 0.11 mm thick, so a 0.1 mm gauge will do fine). To be sure that the carriage hasn't been moved by the tramming, issue a homing command and move to the corner to the right and repeat the process to crete a slight drag of the paper when pulled between the nozzle and build surface. Note that tramming this point may have influenced the first point. Now repeat the homing and moving (for corners back right and back left) to start over again at the front left corner and repeating the whole process at least one to two times. This iterative process will deliver a trammed bed, the bed should now be parallel to the nozzle.

08 to 0.11 mm thick, so a 0.1 mm gauge will do fine). To be sure that the carriage hasn't been moved by the tramming, issue a homing command and move to the corner to the right and repeat the process to crete a slight drag of the paper when pulled between the nozzle and build surface. Note that tramming this point may have influenced the first point. Now repeat the homing and moving (for corners back right and back left) to start over again at the front left corner and repeating the whole process at least one to two times. This iterative process will deliver a trammed bed, the bed should now be parallel to the nozzle.

Trammed, but filament not adhering...

Once trammed the build surface should be parallel to the nozzle, if the distance (usually paper thickness) is too far or too close, adhesion or first layer deposition may fail or cause surface defects like ripples. If not adhering the initial gap between the nozzle and the build surface (paper thickness) might be too big, making this smaller may help squish the filament more so that it adheres better to the build surface. Alternatively use an adhesive in between the build surface and the first layer, nowadays there are multiple dedicated sprays and liquids available, but some house hold product like wood glue, glue sticks and hair sprays could be used.

Alternatively use an adhesive in between the build surface and the first layer, nowadays there are multiple dedicated sprays and liquids available, but some house hold product like wood glue, glue sticks and hair sprays could be used.

Build surface cannot or is difficult to tram

When the build surface isn't perfectly flat, tramming is a challenge, or doesn't provide a 2D plane at a fixed distance of the nozzle. In such cases, scanning the build surface and adjusting during printing might help to get the filament to adhere properly; this process is called automatic bed leveling or ABL (see Automatic Bed Leveling (ABL) with a sensor (BLTouch, inductive, capacitive), how does it work?). An alternative is UBL (see What is ABL or UBL? Is this the same?).

Tramming frequently?

The frequency of tramming depends on the quality and (mis)use of the printer to maintain the 2D plane parallel to the nozzle. For good quality printers the tramming is performed very seldom.

Tramming | Hackaday

August 30, 2021 by Donald Papp

3D printers have come a long way over the past several years, but the process of bed leveling remains a pain point. Let’s take a look at the different ways the problem has been tackled, and whether recent developments have succeeded in automating away the hassle.

Let’s take a look at the different ways the problem has been tackled, and whether recent developments have succeeded in automating away the hassle.

Bed leveling and first layer calibration tends to trip up novices because getting it right requires experience and judgment calls, and getting it wrong means failed prints. These are things 3D printer operators learn to handle with time and experience, but they are still largely manual processes that are often discussed in ways that sound more like an art than anything else. Little wonder that there have been plenty of attempts to simplify the whole process.

Some consumer 3D printers are taking a new approach to bed leveling and first layer calibration, and one of those printers is the Anycubic Vyper, which offers a one-touch solution for novices and experienced users alike. We accepted Anycubic’s offer of a sample printer specifically to examine this new leveling approach, so let’s take a look at the latest in trying to automate away the sometimes stubborn task of 3D printer bed leveling.

Continue reading “3D Printering: Is Hassle-Free Bed Leveling Finally Here?” →

Posted in 3d Printer hacks, Featured, Hackaday Columns, SliderTagged 3d printer, 3D Printering, bed leveling, first layer calibration, load cell, print bed, strain gauge, trammingDecember 1, 2019 by Al Williams

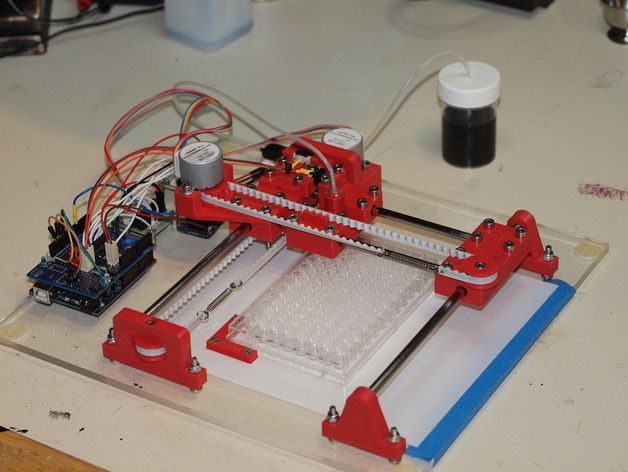

In 3D printing, we often talk about leveling the print bed, although that’s not an accurate term. A bed that is level in our terms presents a flat surface that is parallel to the path of the print head, but within reason we care little about that. Instead we care more about it being parallel to the path of the head than it being perfectly flat. If we had a perfectly flat bed — say a sheet of glass — you’d think it might be pretty easy, but for some other materials it could be convex or concave or even have ripples all over the place. [Teaching Tech] shows you how to manually “level” the bed using a mesh but without using an automatic sensor. You can see the technique in the video below.

You can see the technique in the video below.

When you use adjustments to level the bed, you are tramming it, but only the very pedantic use that term for fine adjustment. But no amount of adjusting bed springs will get rid of bulges and ripples. A common solution is to use a sensor to measure the distance to the bed and form a mesh correction. Then, as the printer head moves in the XY plane, the software will adjust the Z-axis to rise over bumps and go down if there is a concave portion of the bed. What [Teaching Tech] is doing, however, is a manual mapping. You won’t need to add a sensor to your printer to take advantage of the method.

Continue reading “Manual Mesh Bed Levelling For 3D Printers” →

Posted in 3d Printer hacksTagged 3d printing, auto bed leveling, autolevel, level, trammingLarge Area 3D Printer

Create functional plastic items up to 2.5 meters!

Learn more

Discovery 3D Printer is a range of industrial 3D printers made in Spain for creating large-sized products and prototypes using FFF/FDM technology.

Discovery 3D Printer additive machines produce objects from high-strength thermoplastics and are designed for industries ranging from shipbuilding and automotive to architecture and medicine.

Problems solved

Replacement of spare parts or lost parts in engineering, shipbuilding, oil and gas and energy enterprises

Production of small and medium series of products as an alternative to injection or molding of plastic parts automotive, shipbuilding and oil and gas industries

Creation of objects of exterior and interior design and design products for construction, production of facing materials

Production of functional prototypes for R&D and design bureaus in mechanical engineering, shipbuilding and aircraft construction

Production of large-sized wax or burnt master models for metal casting and metallurgy or trolleys)

Looking for a 3D printer for your needs?

Leave a request for a personal consultation!

Solutions catalog

3D printers

3D printer DISCOVERY 3D Printer 2021

Compact solution for 3D printing of large-sized products

Read more

3D printer Super Discovery Compact

Combination of compactness and high performance of the performance

Learn more

Super Discovery 3D Printer Hybrid

Advantages of granule and filament printing in one machine

More details

Super Discovery 3D Printer 3D Printer

Large build chamber and print speed up to 6 kg/h

More details

Super Discovery 3D Printer Workstation 3D Printer

3D large format printer combination: unique 2 in 1 combination and milling systems

More details

Your unique 3D printer

Do you need to print a product larger than 6 meters?

We will develop an individual solution with any build chamber for your needs. tasks - for printing products of any size!

tasks - for printing products of any size!

Choose the right solution for you - compare specifications by model

Compare 3D Printer

Solutions catalog

3D Printing Consumables

Do you have questions about 3D printing media?

Set them to our experts online!

Discovery 3D Printers work with all thermoplastics, including:

- PLA / PLA

- biodegradable polymer provides a smooth and gliding surface products. Designed to obtain detailed and ready-to-use objects

- ABS / acrylonitrile butadiene styrene

- impact-resistant material is able to withstand heavy loads and high temperature, resistant to heat, moisture and various alkalis

- PET / polyethylene terephthalate

- is a hard and strong material with high abrasion resistance.

Excellent suitable for making gears, carriages and guides

Excellent suitable for making gears, carriages and guides - PA / polyamide

- hard engineering plastic with excellent mechanical properties characteristics. Widely used in various industries

- ASA / acrylonitrile styrene acrylate plastic

- analogue of ABS, characterized by increased weather resistance, minimal shrinkage and high impact strength

- Nylon

- is elastic, wear-resistant and remarkably durable. Good suitable for printing functional parts and mechanisms

- HIPS / polystyrene

- Lightweight, alkali and acid resistant polymer. deserved popular in traditional manufacturing due to its impact resistance

Advantages of Discovery 3D Printer Solutions

ISO 9001 certified products

3D printers with the largest build chamber in the world

Ability to design a custom printer

The only 3D printer on the market with an integrated CNC system for finishing milling a part after printing

Accelerate the creation of new products thanks to the dual extrusion system

Repair and replacement of products faster and more economically than contractors

Ability to use a large number of third-party materials

Self-leveling platform function for automatic compensation of irregularities

Case Studies

FDM Airbus Spare Parts 3D Printing

| Industry: | Aircraft industry |

| Equipment: | Super Discovery 3D Printer |

| Material: | CFRP SABIC LNP™ THERMOCOMP™ AM EZ006EXAR1 |

Created a strong mold for autoclave forming parts with a sealed surface and a low thermal expansion coefficient.

3D printed car bumper

| Industry: | Automotive |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with carbon fiber |

Prototype car bumper printed, measuring 1800 x 600 x 4500 mm and weighing 12 kg.

Large format 3D printed chair

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer |

| Material: | 3D850 |

Printed design armchair measuring 45 x 50 x 95 cm and weighing 18 kg.

3D printed architectural statue

| Industry: | Architecture |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with cellulose fiber |

The solid statue is printed and is 1. 87 m high and 45 kg in weight.

87 m high and 45 kg in weight.

3D printing of railway components

| Industry: | Railway industry |

| Equipment: | Super Discovery 3D Printer |

| Material: | plastic |

The front part of a tram for CAF was made in one printing session.

Helicopter seat 3D printing

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with carbon fiber |

Printed helicopter seat measuring 120 x 70 x 45 cm and weighing 20 kg.

3D printed internal combustion engine

| Industry: | Engineering |

| Equipment: | Discovery 3D Printer 2021 |

| Material: | Premium PLA |

Prototype of an internal combustion engine was created, the dimensions of which were 100 x 60 x 50 cm and the weight was 5. 5 kg.

5 kg.

3D printed exclusive piece of furniture

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | ABS |

A custom and exclusive chair created without the need for any further finishing.

Architectural 3D printed in durable ABS with cellulose

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | ABS |

A street sculpture has been made that fully implements the initial decorative idea of the project.

Dior boutique window dressing

| Industry: | Advertising |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | plastic |

Huge bottles 3D printed for exclusive display at Dior's flagship stores.

FDM Cap Prototype

| Industry: | Design |

| Equipment: | Discovery 3D Printer 2021 |

| Material: | 3D850 |

Prototype cap printed at 29 x 19 x 4.5 cm and weighing 146 g.

A prototype of a modular toilet has been printed, measuring 2200 x 1700 x 1200 mm and weighing 250 kg. At the same time, the weight of the product was reduced by almost 50%.

3D printed marine ventilation grille

| Industry: | Shipbuilding |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with carbon fiber |

Ventilation grill printed 59 x 89 x 4. 5 cm and weight 3500 g.

5 cm and weight 3500 g.

Printed motorcycle part measuring 42.5 x 16.5 x 4.5 cm and weighing 165 g.

Prototype printed with support measuring 10 x 9 x 2.5 cm and weighing 18 g.

Created a square mold that measures 10 x 10 x 2 cm and weighs 67 g.

Printed fender for a wheel measuring 55 x 16 x 20 cm and weighing 645 g.

3D printed and post-processed a high-strength mold for wind turbine blades.

3D printed car wheel

| Industry: | Automotive |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with carbon fiber |

A wheel for a car was made, the diameter of which was 440 mm, and the weight of the product was 5 kg.

3D printed designer vase

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | ABS with carbon fiber |

Printed vase in ABS for excellent interlayer adhesion and minimal warping.

Geometric 3D printing

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | ABS with carbon fiber |

Pyramid printed with an 8mm extruder with a smooth surface thanks to the built-in milling system.

More projects and examples of 3D printing in production - in the blog 3D experts

Go to blog

Useful materials

Webinar on 3D printing large objects with complex geometry

- How can 3D printing help you optimize production?

- Features FDM-technology for printing products up to 2.

5 meters

5 meters - Benefits of using 3D plastic printing

- Real cases

Large Format Plastic 3D Industrial Printing Brochure

Benefits of FDM Technology, Overview of Equipment and Consumables, industries and implementation examples - this and much more in one material!

About the manufacturer

CNC Barcenas / Spain

is one of the leaders in the European market for large format 3D printing.

The company specializes in the production of industrial 3D printers Discovery 3D Printer for printing large-sized products and prototypes based on FFF/FDM technology.

discovery3dprinter.com

Take a closer look at Discovery 3D Printer solutions - take a virtual tour of companies!

3D TOUR OF COMPANY

About us

iQB Technologies is a Russian distributor of 3D printers, consumables, 3D scanners and software from the world's leading manufacturers.

We develop complete 3D solutions, provide printing services and scanning, as well as training specialists in the use of 3D technologies in their work.

iQB Technologies is the exclusive distributor of Discovery 3D Printer solutions in Russia.

3D printers are available for order

in this section .

iqb.ru

Why order a 3D printer from iQB Technology?

The best prices for this class of equipment

Training on how to use 3D printers

A wide range of integrated solutions: 3D printer + 3D scanner + software

Provision of services for the implementation, maintenance and repair of 3D equipment throughout Russia

Participation in public procurement and tenders

Still have questions?

Our experts will advise you free of charge on Discovery 3D Printer solutions

Frequently Asked Questions

Which technology to choose: the method of fusing granules (FGF) or polymer filaments (FFF / FDM)?

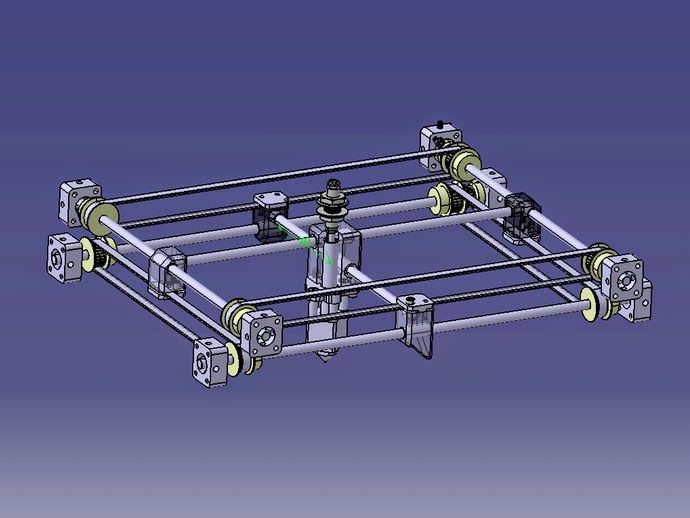

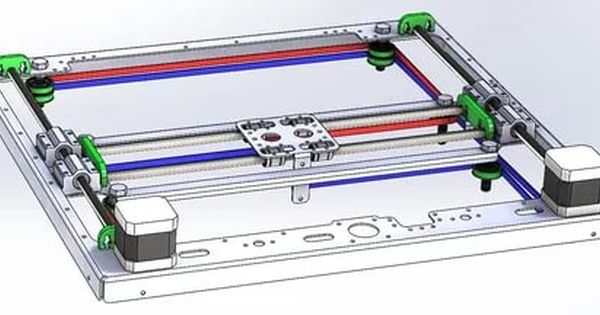

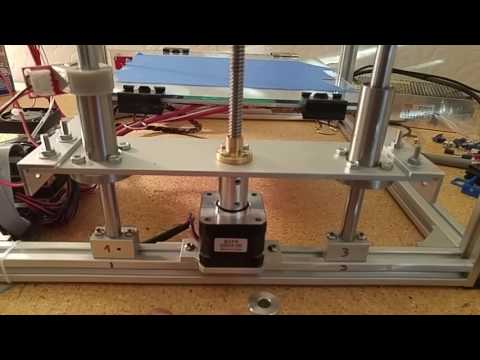

What are the kinematics and mechanics of the Discovery equipment?

In this respect, all Discovery equipment differs from budget additive solutions. The products are based on the kinematic diagram of a CNC machine. Gears, pulleys, lead screws, no belts. HIVIN rail guides are used. The entire structure is made with European quality from advanced products in the machine tool industry.

The products are based on the kinematic diagram of a CNC machine. Gears, pulleys, lead screws, no belts. HIVIN rail guides are used. The entire structure is made with European quality from advanced products in the machine tool industry.

What consumables can be used with Discovery products?

Any material (other than PEEK and PEKK) sold in bars or pellets. First of all, thanks to the heating of the table to 175 ° C and vacuum fixation, as well as due to the installed nozzles made of hardened steel.

How is such a large print platform heated?

A matrix of separate equidistant heaters is built into the platform from the bottom side; these modules provide uniform heating of the surface of the printing platform. The maximum recorded temperature difference over the entire area is 3°C.

How to speed up printing on such large dimensions?

There is a special method for properly emptying the internal volume, which you can learn more about from our technical experts. This procedure will have very little effect on the strength and elasticity of the print object, but will still reduce the time by up to 60%.

This procedure will have very little effect on the strength and elasticity of the print object, but will still reduce the time by up to 60%.

It is important to consider that with a large range of large-sized products, it is better to consider Super Discovery 3D Printer or Super Discovery 3D Printer Workstation with a capacity of up to 11 kg / h (depending on the material used).

Is it possible to upgrade this equipment for a specific enterprise?

Yes. Most of the Discovery machines can be upgraded for a specific production project. This is possible, since the equipment was designed for the tasks of Production 4.0, and our specialists will help to integrate it correctly.

What is the warranty for this equipment?

24 months, which is 1.5 - 2 times more than analogues from Europe, Russia and China. Permanent customer support is provided directly by the vendor or iQB Technologies specialists.

How to get a high quality product so that it can be handed over as a final product?

3D printing is basically a high quality preform process. If you need to get the final product, it is suggested to use milling or turning equipment, manual machining, priming, painting or varnishing.

If you need to get the final product, it is suggested to use milling or turning equipment, manual machining, priming, painting or varnishing.

This is often not necessary as the product is not visible.

full name *

Company *

E-mail *

Telephone *

Message

STL file Flowers on tram tracks・3D printer model for download・Cults

Wallace and Smash Bunny Guru

3 €

WALLACE AND GROMIT Valentine's Day

3 €

VAN AND TRAILER

2 €

VAN IMPERIAL

2,50 €

Throne of bones

2. 08 €

08 €

peugeot 106

2 €

Rainbow dash

1.25 €

Complete Christmas crib carved in the style of terracotta

0,83 €

Renault twingo

2 €

Volkswagen lupo

2 €

Son Gohan, Piccolo cape

1.67 €

SMURFETTE SMURFETTE SCHLUMPFINE POLLY POCKET

2,60 €

Best Files for 3D Printers in the Art Category

Figurine "Among Us" SUS

2.38 €

SkatBoard

Free

Creepy Tree

2 €

Captain America

1. 42 €

42 €

PALPATINE

€7.27

Lowpoly Moai remix

Free

Catacombs Skull of bones, creepy skull of a skeleton, skull of a pile of bones

3,79 €

Bansky rebel STL Statue for 3D printing

19.20 € -fifty% 9.60 €

Art category bestsellers

Cute sloth with flexi print

2,80 €

Cute T-Rex dinosaur with flexi print

2,80 €

CUTE CROCODILE WITH FLEXIBLE PRINT IN PLACE

€2.80

Stitch Love (easy printing without support)

1,50 €

Cute little fox with flexi print

2. 38 €

38 €

FLEXIBLE STANDING STANDING YETI

2,80 €

Articulated Python Snake Toy, Imprint Body, Snap Head, Cute Flexi

3.75 €

Skeleton hand with flexi print

1.89 €

Adorable articulated axolotl, imprinted body, snap head, cute flexi

3.31 €

Articulated bat toy, body with prints, head with latches, cute flexi

3,31 €

GHOST ZU - GHOST WITH FEET

2,80 €

Crystal Dragon, Articulating Animal Flexi Wiggle Pet, Print on the Spot, Fantasy

3,80 €

Cute elf with flexi print

1,85 €

Cute circus baby elephant with flexi print

2,80 €

Leopard gecko articulated toy, imprinted body, snap head, cute flexi

3,31 €

Bearded Dragon Articulated Toy, imprinted body, snap head, cute flexi

3,31 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people , so supporting us in maintaining activities and creating future developments is very easy.