Tooth 3d printer

Dental 3D Printers - What You Need to Know

Dental 3D Printers - What You Need to Know | Benco DentalAll Products

Search for:

Dental Products

Company Website

Blog Articles

3D Printers

Scan > Design > Print > Prepare

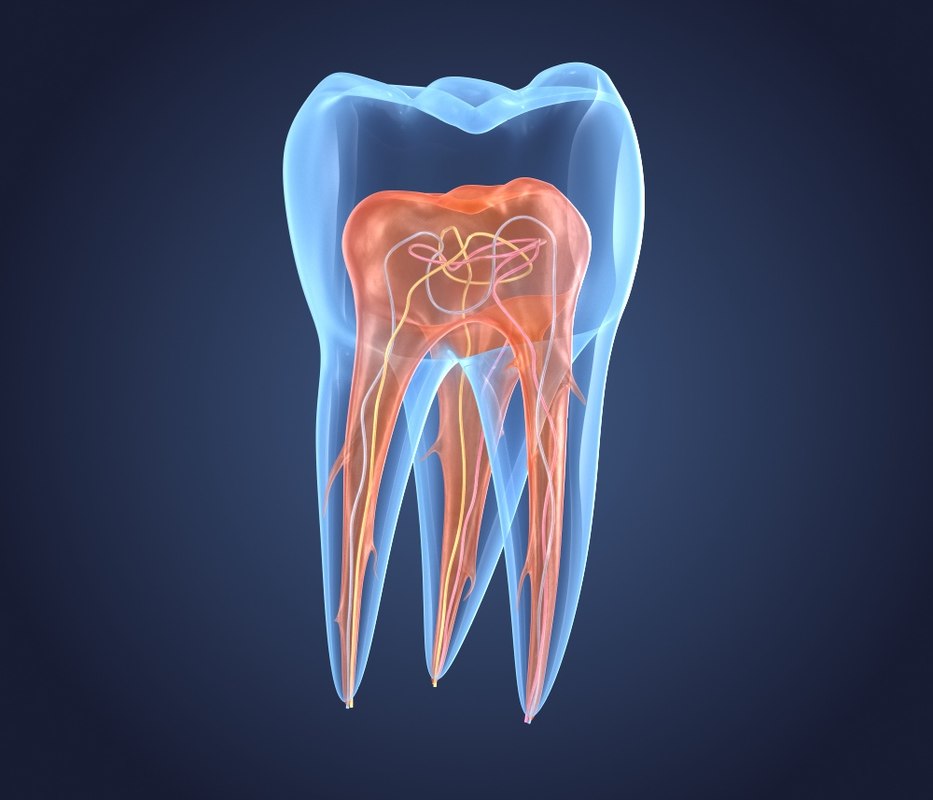

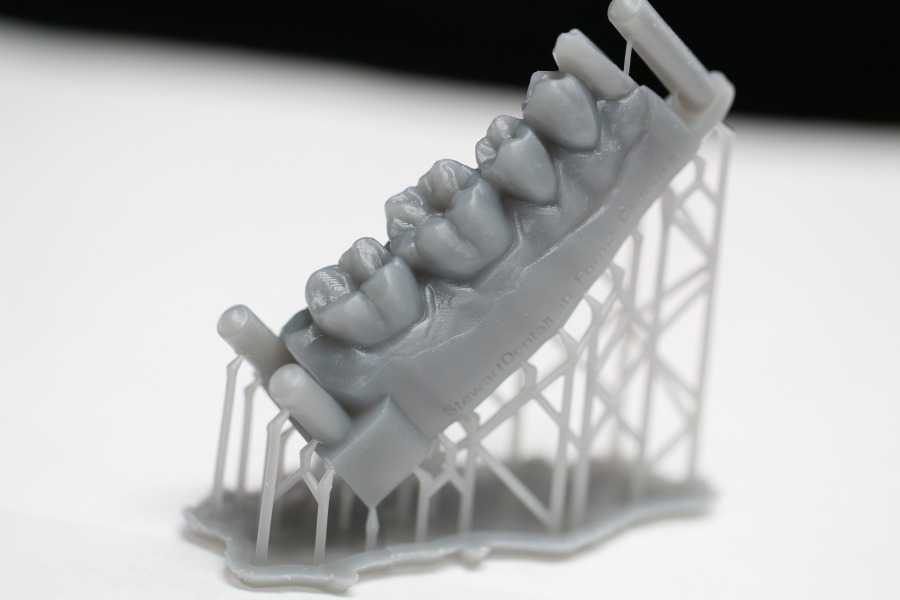

3D printing is the catalyst for digital dentistry. It’s known for reliability and high quality. Much has changed since the first desktop 3D printers became available to the dental industry. A few years ago, 3D printers were only affordable to the largest dental labs, now they are a common sight in labs and practices of any size. Dental 3D printers feature a light or laser that polymerize a liquid with the computer-guided precision required to produce small objects with intricate details.

The dental 3D printing workflow has four-steps:

- Scan – collect a digital impression with an intraoral scanner.

Send the scans to a lab or to a design station.

- Design – import the digital scan into design software (CAD) and design.

- Print – once designing is complete, import the file to print preparation software for print setup.

- Prepare – wash, dry and post-cure printed parts.

WHAT CAN A 3D PRINTER MAKE?

Dental 3D printers can produce applications such as:

- Crown/Bridge Models

- Clear Aligner Models

- Surgical Guides

- Splints/Occlusal Guards

- Patterns for Casting and Pressing

- Hawley Retainers

- Full Dentures

CHOOSING A 3D PRINTER FOR YOUR DENTAL PRACTICE OR LAB

Additive manufacturing is making digital dentistry a no-nonsense business choice, combining high quality and improved patient care with low unit costs and streamlined workflows.

Today, three 3D printing technologies are common in dental: stereolithography (SLA), digital light processing (DLP) and material jetting. Each technology can deliver the precision and accuracy needed for dental applications, but quality can vary among different machines and systems.

Each technology can deliver the precision and accuracy needed for dental applications, but quality can vary among different machines and systems.

1. Stereolithography (SLA) – liquid resin is selectively exposed to a laser beam across the print area, solidifying resin in specific areas. Stereolithography is highly accurate and has the best surface finish of the three technologies. SLA printers offer large build volumes and a wide range of materials for various applications. Switching materials is as easy as swapping the resin tank and cartridge. The combination of small footprint, simple workflow and low price make desktop SLA printers well-suited for both dental labs and practices.

2. Digital Light Processing (DLP) – Digital light processing operates with the same chemical process as SLA but uses a digital projector as a light source to solidify the resin, rather than a laser. DLP printers have a small footprint, simple workflow and wide range of material options, but at a substantially higher cost than desktop SLA printers. DLP parts also tend to show voxel lines—layers formed by small rectangular bricks due to digital screen—and have a generally lower quality surface finish.

DLP parts also tend to show voxel lines—layers formed by small rectangular bricks due to digital screen—and have a generally lower quality surface finish.

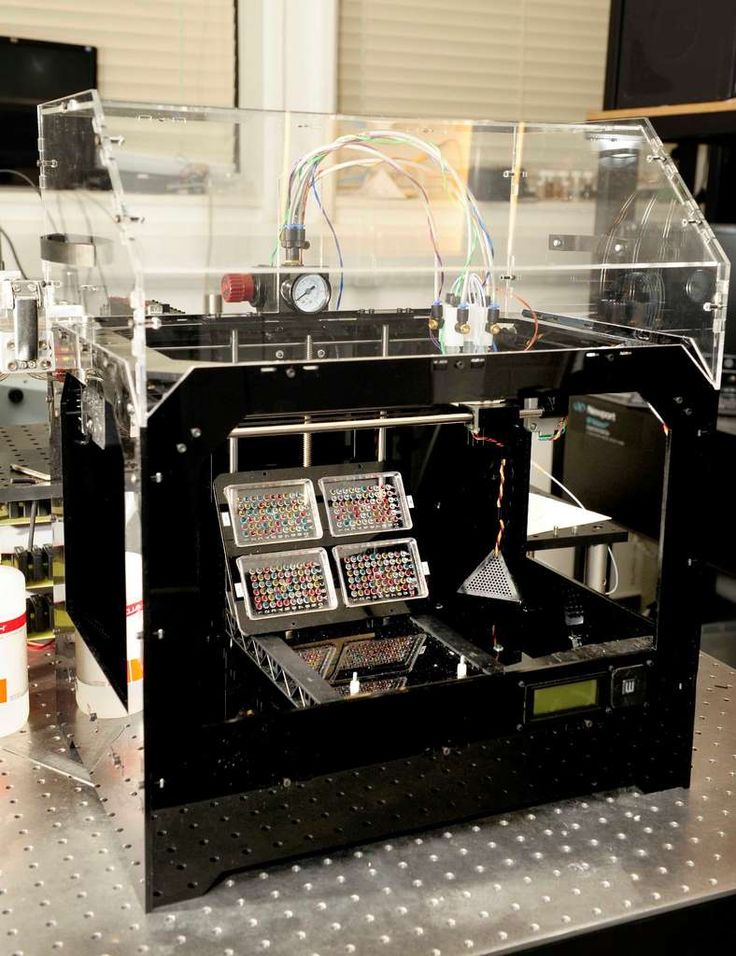

3. Material Jetting – Material jetting (PolyJet and MultiJet Modeling) 3D printers work similarly to inkjet printing, but instead of jetting drops of ink onto paper, they jet layers of liquid resin onto a build tray and cure them instantly using light. Material jetting technologies were the most common in the dental industry a few years ago, but expansion was limited by their high cost and the large size of the machines. They require extensive post-processing and the surface finish of parts produced with this technology is generally inferior to SLA or DLP. Material jetting systems have high throughput but can only be used for a limited range of applications due to the costly, proprietary materials.

KEY FEATURES WHEN EVALUATING 3D PRINTING SOLUTIONS

- Accuracy and Precision

- Ease of Use and Reliability

- Cost and Return on Investment

- Materials and Applications

- Throughput and Scalability

HOW MUCH DO 3D PRINTERS COST

Dental 3D printers can start at a few thousand dollars for resin desktop 3D printers (SLA or DLP) ot up to tens of thousands of dollars for metal 3D printers designed for direct production. Some manufacturers only make dental 3D printers while other have developed specific dental product lines.

Some manufacturers only make dental 3D printers while other have developed specific dental product lines.

Entry-level desktop SLA or DLP 3D printers start around $1,000 and can be used to produce molds using a special casting resin. Industrial-grade dental additive manufacturing systems can cost up to tens of thousands of dollars. Dental 3D printers’ prices vary based on several factors:

- Print quality – the higher the resolution offered by the 3D printer the better, and often the more expensive the 3D printer.

- Build volume – more expensive dental 3D printers usually offer a larger print volume, allowing dental labs to optimize their production flow and increase their ROI.

- Dental 3D software – a special software is required to create custom dental implants based on a 3D scan of the patient’s mouth. The dental 3D software is an important component of the digital dentistry value chain and can be expensive.

- Reliability and repeatability – perhaps the most important factor when it comes to using 3D printing for dental appliances production. Professional dental 3D printers must be able to consistently deliver high quality prints, especially in a dental lab environment where quality controls are frequent, and a high production output is expected. Therefore, some dental 3D printers are more expensive than other because they offer this reliability.

Please select the CAD/CAM offering you are interested in: (select all that apply)

Same-day Single RestorationsBite Splints/Night GuardsSurgical GuidesDenturesLarge Span BridgesFull Arch RestorationsCustom Titanium Abutments

First Name*:

Last Name*:

Practice Name:

Phone Number*:

Email Address*:

Comments:

* Required Fields

FINANCING OPTIONS AVAILABLE FOR EQUIPMENT & TECHNOLOGY PURCHASES

100% financing means you’ll hit the ground running. Plus, your cash remains untouched and intact for savings, working capital or expenses.

Plus, your cash remains untouched and intact for savings, working capital or expenses.

You’ll get the things you need upfront, with no waiting. Click here to apply for financing.

3D Printers Available

Do you need further assistance?

We’re happy to help you with any additional questions! Please fill in the form below, and a member of our OneVisit team will reach out to you.

I need help with*:

—Please choose an option—Intraoral ScannersSoftwareMilling MachinesBlocks & MaterialsFurnaces3D Printing

First Name*:

Last Name*:

Practice Name:

Phone Number*:

Email Address*:

Comments:

* Required Fields

Larry Cohen

CHIEF CUSTOMER ADVOCATE

Larry Cohen graduated from Wilkes College with a B.S. in Accounting in 1957 and Columbia University Graduate School of Business, earning an M.S. in Management and Finance, 1958. He served in the U. S. Army Reserve from 1958 through 1964.

S. Army Reserve from 1958 through 1964.

He is the second-generation owner of Benco Dental Company, which was founded by his father, Benjamin Cohen in 1930.

Joining Benco Dental in 1959 as manager of the Tooth Department, in 1960, Larry became an outside sales rep, a position he enjoyed full time until 1972. Beginning that year, Larry began reducing his outside sales role and increasing his managerial duties, later becoming the president of Benco Dental from 1965 – 1996.

Larry is the Founder of the American Dental Cooperative; Board, American Dental Trade Associate, plus Various ADTA committees. He sits on the Board of Wilkes University, Board of Visiting Nurses Association and the Board of Jewish Community Center.

x PRF REPORTING ENDLESS SAVINGS PRO-SYS POWER UP

Register and create an account to get started

GET STARTED HERE

3D Printed Teeth Offer Many Benefits for Dental Patients

Skip to contentNew 3D Printed Teeth Comes to the World of Dental Care

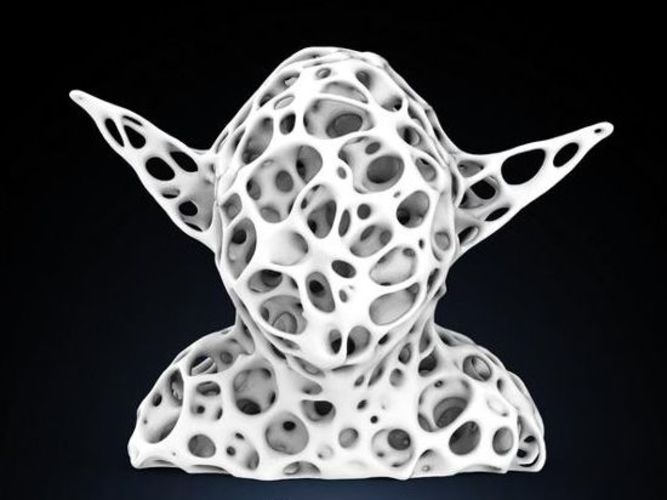

You’ve likely heard a lot of buzz over the last few years about 3D printing technology, and how it is enabling the creation of things that could only be imagined in the past.

3D printing is becoming increasingly more common every day as advancements in the technology continue to expand its use in to a wider range of applications, including many types of healthcare.

3D printing has been used to create such amazing things as a portion of a new skull for a woman in the Netherlands, and a new leg bone for a man in Australia. Truly, the opportunities to improve the world of health care with this amazing technology are nearly limitless.

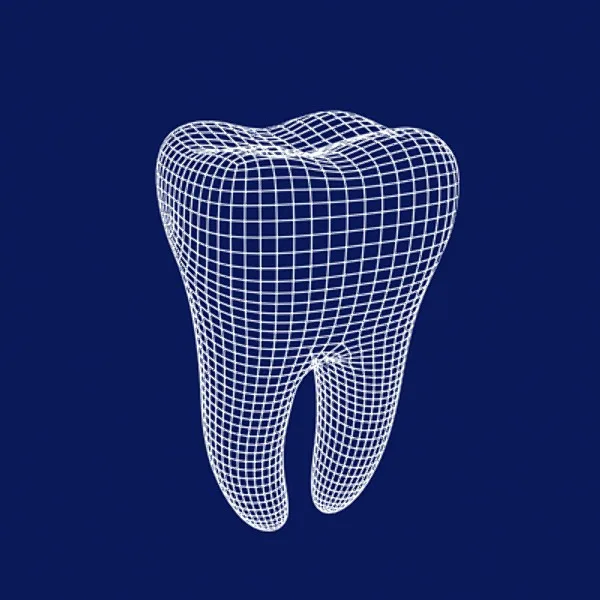

The field of dentistry has also begun realizing the benefits of 3D printing technology, and the advantages that it can bring to a wide variety of dental procedures. In this article, we’re going to take a look at how 3D printing works and examine some of the ways in which 3D printing is being used by dentists, orthodontists and oral surgeons. We will also speculate on just how far this technology may go in the future to bring incredible advancements to the world of dentistry.

First, let’s examine how 3D printers work, and what’s needed in order to create a 3D printed object.

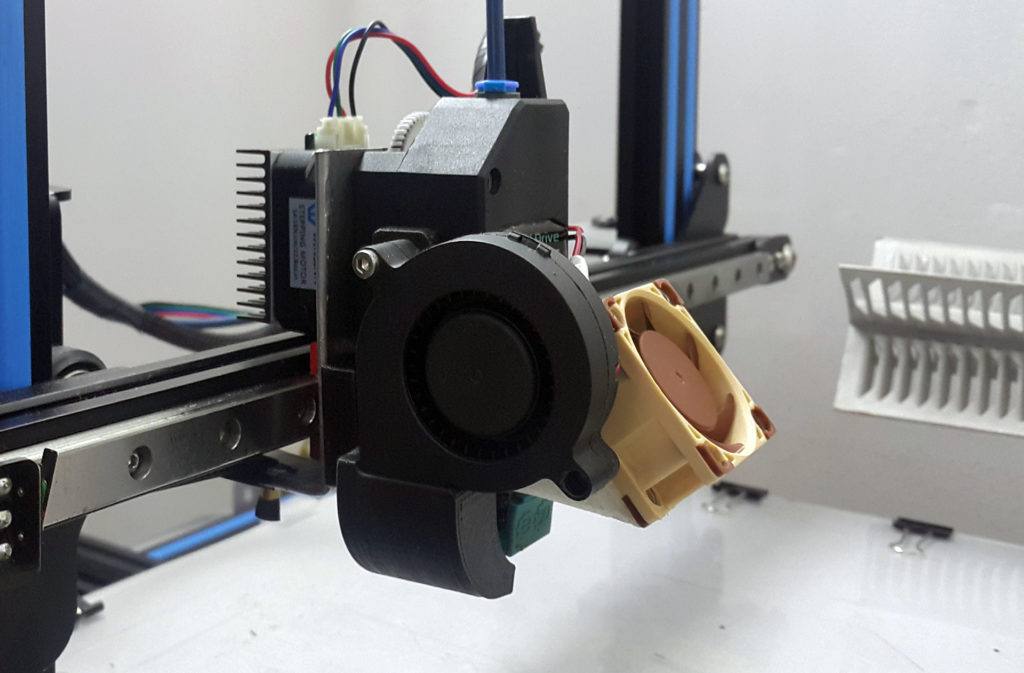

How do 3D printers work?

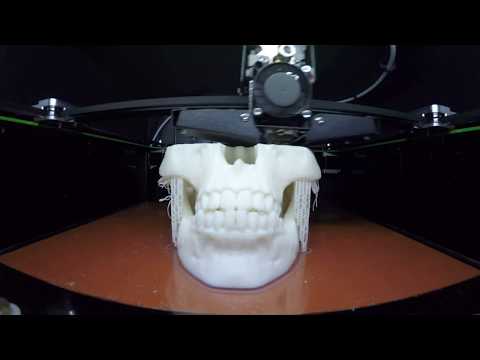

In concept, 3D printers operate in a very similar fashion to the home inkjet printers that you are all familiar with for printing documents and photographs from your computer. Instead of ink, 3D printers use different types of plastics and composites as raw material. While inkjet printers apply a single layer to the paper to produce a printed version of your documents, 3D printers apply layer after layer, one on top of the other, of plastic or composite in a very precise sequence in order to gradually build a 3-dimensional reproduction of the computer-modeled object. This process is known as ‘additive manufacturing’.

Take a look at this quick overview video that shows the steps in the additive 3D printing process, and some examples of things that have been printed using this technology: https://www.youtube.com/watch?v=Vx0Z6LplaMU

Additive manufacturing is just one type of 3D printing. There are other 3D printers that operate with a sculpting process, which is known as ‘reduction printing’. These printers start with a solid mass of raw material and use carving tools controlled by a computer to remove excess material from the raw material, similar to how CNC machining is used to create parts made from solid blocks of metal.

These printers start with a solid mass of raw material and use carving tools controlled by a computer to remove excess material from the raw material, similar to how CNC machining is used to create parts made from solid blocks of metal.

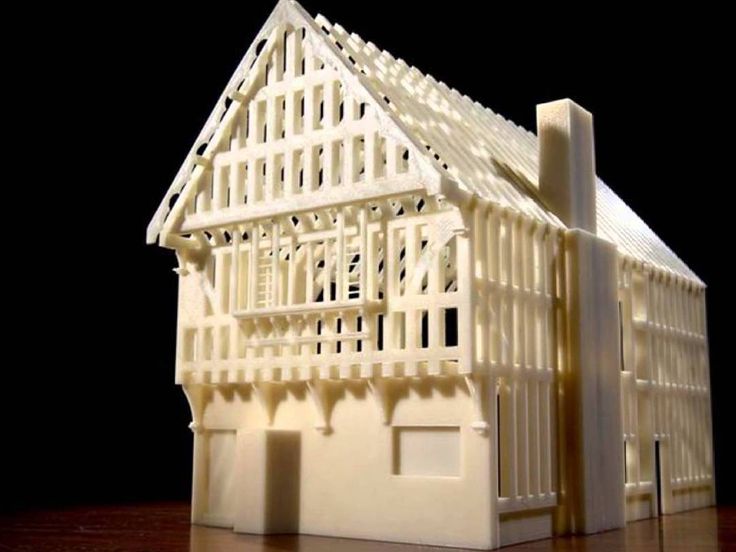

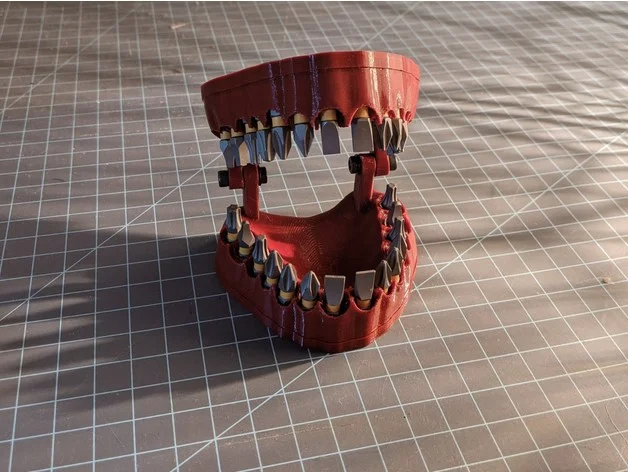

3D printers can create virtually any object that can be rendered using a computer and will fit within the printing chamber of the printer. Some 3D printers are compact enough to fit on a desktop and can create smaller objects, while others are substantially larger and are designed more for industrial or commercial applications.

3D printing has been adopted rapidly by many industries, as the speed and ease with which product prototypes can be produced have been drastically improved. It has also enabled the emergence of a widespread community of amateur 3D modelers and hobbyists that design and produce all kinds of items, including jewelry, artwork, toys, and more.

Check out the vast array of things available on sites like Shapeways.com to get an idea of just how popular and diverse 3D printing has become around the world. You’ll be amazed at the level of precision and detail that can be achieved.

You’ll be amazed at the level of precision and detail that can be achieved.

How have dentists used 3D printers?

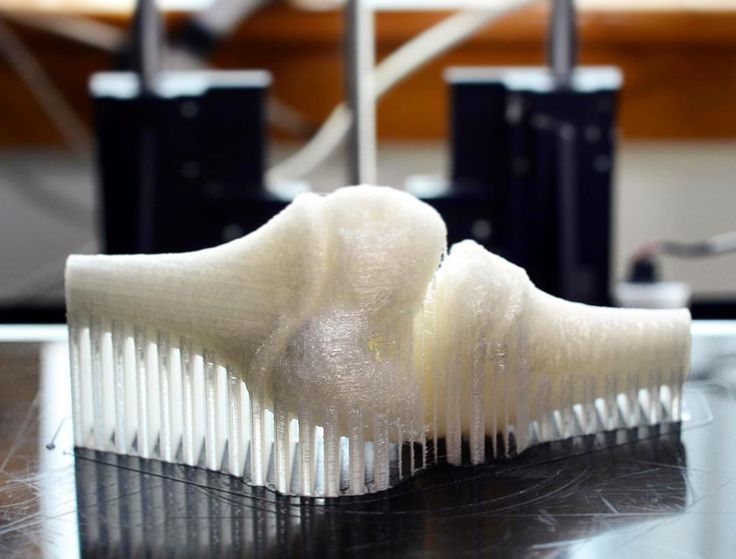

Leveraging this technology for use in the healthcare industry didn’t take long, as innovators in the field were quick to begin experimenting with 3D printing capabilities. Patients around the world have already started receiving 3D printed objects to aid in their healthcare, including prosthetics and bone replacements. Doctors and surgeons are benefitting from the ability to quickly design and create custom and specialized medical tools, enabling them to do their jobs better, faster, and with shorter patient recovery times.

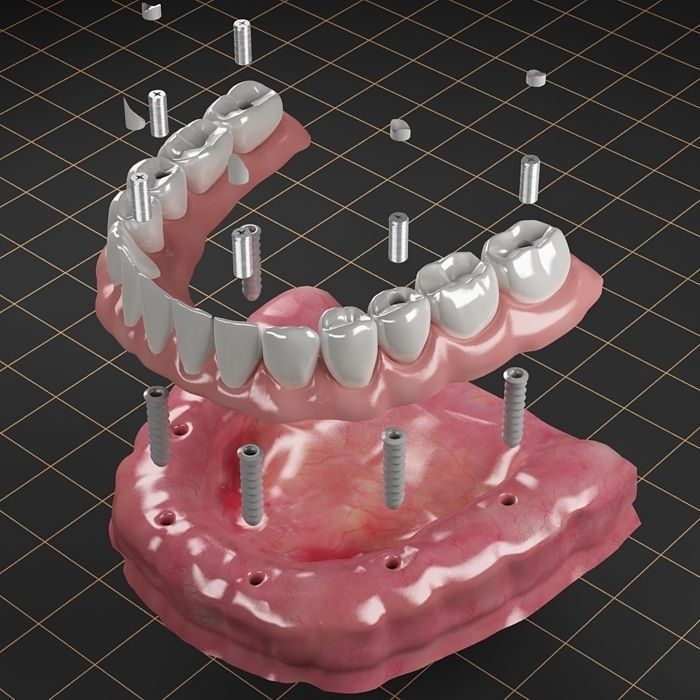

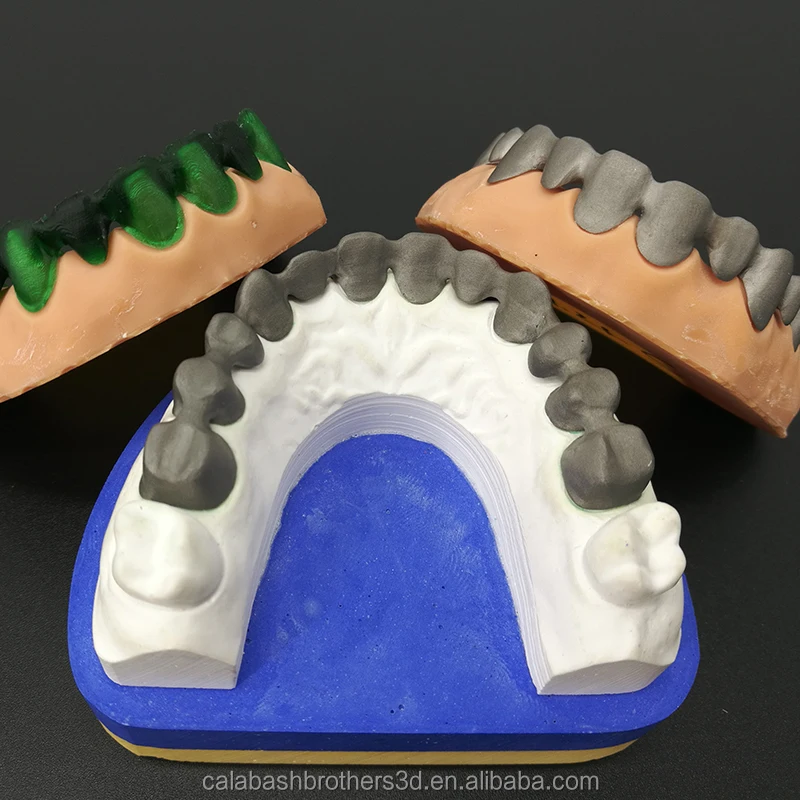

Dentists, orthodontists, and oral surgeons are using 3D printing technology in patient care as well as in research and testing. Using advanced scanning technology, exact replicas can be made of virtually any part of the human body, including the jaw and teeth. By having such precise replicas to work with, dental implants and corrective appliances can be designed to fit better, look better, and work better than ever before for each individual patient.

The materials that can be used to create 3D printed objects are advancing just as quickly. While the majority of objects are printed using plastics, there are now a wider variety of composite materials being used. These composites are blends of materials to produce characteristics that are best suited to the application where the 3D printed object will be used. For example, some include metallic elements, while others are more like ceramics. In dental applications, materials are being developed that will be exceptionally hard and tough, just like real tooth enamel, and can also be infused with anti-bacterial properties.

3D printing is most commonly used in the creation of dental implants and crowns. The process yields a final product that is indistinguishable from your natural teeth. The shape, size, colour, and position of the artificial tooth or crown are all precisely crafted to ensure a perfect match for your smile. Using the reduction printing method, dentists can use solid blocks of hard ceramic to create the strongest possible crowns and implants for your dental restoration.

What’s next for 3D printing in dental care?

As amazing as this technology is, we are really just starting to scratch the surface of its possibilities. As it continues to advance, and more applications are discovered for 3D printing, the ability to solve problems using these types of processes will increase. New designs will be developed, faster manufacturing methods will be discovered, and results will continually get better. Materials will become stronger and more durable and will be designed to provide even better adhesion and fusion to natural bone and gum tissue.

It’s likely that at some point in the not-so-distant-future that you may see a 3D printer alongside all the other tools at every dentist office, ready to print anything the dentist may need to give you the perfect smile you’ve always wanted.

3D Dental Printing Summary

3D printing is the most exciting technological development to emerge in the world of healthcare in recent years, and the promise that it holds is immeasurable. Dental patients can look forward to faster treatments, quicker recovery time, and superior results due to the fact that each 3D printed object has been precisely crafted and specially engineered for the unique needs of each individual patient.

Dental patients can look forward to faster treatments, quicker recovery time, and superior results due to the fact that each 3D printed object has been precisely crafted and specially engineered for the unique needs of each individual patient.

This level of flexibility and customization has never been so easy to achieve in such a short amount of time, and things are only going to get better.

As pioneers in 3D printing for dental health, we have the experience and knowledge to ensure you get the best quality treatment and exceptional results from this technology.

If you’d like to learn more about 3D printed teeth and the advantages that they may offer you, contact the team at Georgian Dental® today.

We will be glad to answer all of your questions as part of a free no-obligation consultation and guide you through the different treatment options that 3D printing can offer you.

Blog Categories

Free Consultations

Free consults for braces, implants, bridges & crowns, gum recession and full mouth reconstructions ($300 Value). Call now and book your appointment!

Call now and book your appointment!

705-710-2525

Recent Posts

- How to Correct an Underbite

- Dental Abscesses

- Understanding Toothpaste Ingredients

- Dental Mouthguards & Nightguards

- Get Cleaner, Healthier Teeth

Newsletter Signup

Want more great, useful dental content delivered directly to your inbox?

Subscribe Now

Free Initial Consultation

Free consultations for all braces, implants, bridges & crowns, gum recession and full mouth reconstructions ($300 Value). Contact us now for all the details.

705-710-2525

Related Articles

View All Posts

Page load linkGo to Top

All about a 3D printer in dentistry: features, applications, technologies

The first attempts to use 3D printing in dentistry were made by specialists from Align Technology in the 1990s. Using a 3D printer, mouth guards were made, which served as a start for the development of this technology in the dental industry. The process of making teeth was looked at from a radically new point of view.

Using a 3D printer, mouth guards were made, which served as a start for the development of this technology in the dental industry. The process of making teeth was looked at from a radically new point of view.

But development did not progress as fast as we would like: it took almost 20 years to achieve satisfactory print quality and optimize performance. The first implant was printed by Layer Wise in 2012. In the same year, for the first time, it was possible to implant a patient with a titanium lower jaw, which was made using a 3D printer. Since then, the technology has evolved and raised the quality bar.

The advantages of using a 3D printer in a short time to solve almost any problem. With a dental 3D printer, a significant number of required instances can be modeled in a single session. All projects are saved in files, so in the future you can re-make the same model if necessary.

It is no longer necessary to send the patient for 2-3 days to wait for the production of plaster models. Now everything happens much faster: the doctor builds a 3D model in a few minutes using an intraoral scanner and instantly transfers the data to the laboratory, where printing also does not take much time. Speed and maximum precision increase the level of treatment and really save resources and time.

Now everything happens much faster: the doctor builds a 3D model in a few minutes using an intraoral scanner and instantly transfers the data to the laboratory, where printing also does not take much time. Speed and maximum precision increase the level of treatment and really save resources and time.

What you can print

Let's highlight the most common uses of 3D printing in dentistry. Using the printer, you can create:

- demonstration and collapsible models of the jaw, sectoral reproduction of the upper and lower jaws in the occlusion;

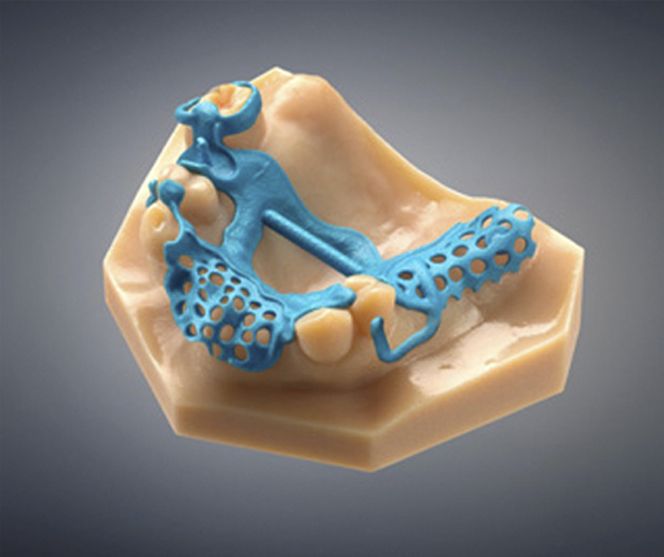

- ashless constructions, caps, bases for crowns and bridges, clasp prostheses;

- surgical guides for implantation, individual trays, guides for maxillofacial surgery.

Such a promising direction as the printing of permanent and temporary orthopedic structures, removable denture bases is actively developing.

About the types of printing

As we have already found out, the main task of a 3D printer for dentistry is to reduce the time of manufacturing restorations and reduce the cost of production without loss of quality and accuracy. We will understand the printing technologies and their features.

We will understand the printing technologies and their features.

Stereolithography (SLA or SL). With this technology, a laser beam selectively impacts a container of liquid resin through the printable area. Thus, the resin hardens in layers in specific places and forms a three-dimensional figure.

Stereolithography gives the best surface finish on parts and is most commonly used in today's 3D printer models. SLA machines provide a large area of restoration construction and work with a wide range of materials designed for a variety of tasks.

To switch from one material to another, it is enough to change the cartridge and the resin bottle. Relatively compact dimensions, ease of workflow and affordable price make SLA printers the best choice for dental laboratories. An example of SLA models - Form 2 and Form 3 from Formlabs, SLASH PLUS from Uniz Technology, Basic Dental from Omaker, Asiga PICO2.

Digital LED projection (DLP). Here, the chemical process is similar to SLA, but a digital projector is used instead of a laser as a light source to cure the resin. DLP printers have a simple interaction process, a fairly modest footprint, and a good selection of material options, but at a higher price compared to SLA.

Here, the chemical process is similar to SLA, but a digital projector is used instead of a laser as a light source to cure the resin. DLP printers have a simple interaction process, a fairly modest footprint, and a good selection of material options, but at a higher price compared to SLA.

Due to the nature of the illumination of the LED projector, there is a tendency for voxel lines-layers formed by small rectangular bricks of material. Models made by DLP have inferior surface quality to SLA models. But it is worth noting that DLP printers print much faster than laser ones. Examples of DLP printers include Varseo S by Bego, AccuFab-D1 by Shining 3D, D2-150 by Veltz 3D, Versus by Microlay.

PolyJet technology. The process is similar to that of a regular inkjet printer, but instead of inkjet drops on paper, the 3D printer blows layers of liquid resin onto the printable area. The layers harden when exposed to light.

Once upon a time PolyJet gained popularity in the dental industry, but its development was slowed down by two factors: the high cost of equipment and the impressive dimensions of the devices. Models made using PolyJet technology require long post-processing and are again inferior to SLA in terms of surface quality.

Models made using PolyJet technology require long post-processing and are again inferior to SLA in terms of surface quality.

PolyJet systems produce parts very quickly, but are limited in scope due to expensive proprietary consumables. Therefore, in the context of our industry, it is better to buy a dental 3D printer with SLA technology.

SLS and EBM. Allows titanium printing of ready-made elements for replacement of jaw parts. These technologies work on the principle of laser sintering of metal clay, a special metal powder for dentistry. So, the SLS and EBM systems allow you to work with a biocompatible titanium alloy. Since pure metal powder does not require a binder filler, the finished models do not differ in porosity. To achieve the required mechanical strength, the products do not require additional firing. An example of a printer capable of printing with metals is the EP-M150T from Shining 3D.

Filament printing. Technology is not relevant in dentistry and now we will explain why.

Technology is not relevant in dentistry and now we will explain why.

Printed with filament, a material similar to fine garden trimmer wire. The wound filament is charged directly into the 3D printer head, which moves on three axes.

Compared to other materials for 3D printing, this filament is quite inexpensive, but gives low accuracy compared to powders. The most popular types of filament are ABS and PLA plastic.

Comparison of the main 3D printing technologies used in dentistry

To clearly show the main pros and cons of each technology, we compare them in a table format.

| Stereolithography (SLA) | Digital Light Processing (DLP) | PolyJet technology | SLS and EBM technologies | |

| Precision | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★★ |

| Surface finish | ★★★★★ | ★★★★☆ | ★★★☆☆ | ★★★★☆ |

| Print speed | ★★★★☆ | ★★★★★ | ★★★★★ | ★★★☆☆ |

| Availability of materials | ★★★★★ | ★★★★★ | ★★★★☆ | ★★☆☆☆ |

| Metal printing | ||||

| Benefits |

|

|

|

|

| Drawbacks | Slow single print speed |

|

|

|

Our CV

PolyJet technology is becoming a thing of the past due to high cost and imperfect print results. SLS and EBM are more relevant for large laboratories than ordinary clinics. Therefore, it is worth considering SLA and DLP printers for everyday tasks. For example, take a closer look at Bego Varseo S, Formlabs Form 2. These devices have already proven themselves in the dental market and provide guaranteed high-quality results. You can see all 3D printers presented in StomShop.pro here.

SLS and EBM are more relevant for large laboratories than ordinary clinics. Therefore, it is worth considering SLA and DLP printers for everyday tasks. For example, take a closer look at Bego Varseo S, Formlabs Form 2. These devices have already proven themselves in the dental market and provide guaranteed high-quality results. You can see all 3D printers presented in StomShop.pro here.

← General requirements for the placement of portable X-ray machines | TOP 5 Illuminated Physiodispensers →

3D Printing in Dentistry for Dental Prostheses

Modern additive printing technologies enable the production of a wide variety of products for an incredible range of applications. Medicine, in particular the field of dentistry, has long been no exception and is using the achievements of technological progress for the benefit of its patients with might and main, becoming digital.

Benefits of using a 3D printer

Clinics everywhere are moving to intraoral scanning, abandoning analog, uncomfortable for the patient methods of impression making. Some are not limited to diagnostic manipulations at all, transferring the stages of modeling and manufacturing of single works under their own roof and partially refusing laboratory services. In this case, a 3D printer for dentistry is indispensable in the manufacture of orthodontic and temporary orthopedic structures. Mouth guards, night guards, surgical templates for operations and even the printing of dentures, whether they be single crowns, bridges or even removable basic dentures - all this is under the power of dental 3D printing.

Some are not limited to diagnostic manipulations at all, transferring the stages of modeling and manufacturing of single works under their own roof and partially refusing laboratory services. In this case, a 3D printer for dentistry is indispensable in the manufacture of orthodontic and temporary orthopedic structures. Mouth guards, night guards, surgical templates for operations and even the printing of dentures, whether they be single crowns, bridges or even removable basic dentures - all this is under the power of dental 3D printing.

Comparison of the main 3D printing technologies used in dentistry

Laboratories are not left behind and are improving the manufacturing methods and range of dental products and services. The use of laboratory scanning eliminates the error that may occur during the manufacture of a plaster model. If desired, the model can be produced on a dental printer from a photopolymer, which is always less troublesome and faster. Gingival masks, individual trays, and any orthopedic constructions - the 3D printer opens up new horizons for dental laboratories.

If desired, the model can be produced on a dental printer from a photopolymer, which is always less troublesome and faster. Gingival masks, individual trays, and any orthopedic constructions - the 3D printer opens up new horizons for dental laboratories.

If we talk about the main methods of manufacturing dental products on a 3D printer, then these will be:

- SLA, or the so-called stereolithography, in which the laser beam polymerizes the material, quickly passing through each point of the object;

- DLP, or layer-by-layer illumination process, in which the projector illuminates the photopolymer layer by layer using ultraviolet radiation, transforming it into a future product.

Regardless of the printing method, the final properties of the work will depend on the material from which it is made, the very "resin".

Speaking of photopolymers, one cannot but mention NextDent. The company is a subsidiary of the Dutch manufacturer of plastics for prosthetics Vertex. NextDent pioneered the field of biocompatible 3D printing resins and was soon bought out by global additive technology giant 3D Systems.

NextDent pioneered the field of biocompatible 3D printing resins and was soon bought out by global additive technology giant 3D Systems.

With 30 unique NextDent photopolymers, the widest range of any dental material supplier. A range of aesthetically accurate colors enable dental labs and clinics to achieve a close match of finished products to the patient's teeth and gums. 3D printing materials from NextDent are biocompatible and certified in accordance with the requirements of the European Union, which makes them widely used. Photopolymers meet the requirements of the European Medical Device Directive (93/42/EEC), approved by the Food and Drug Administration (USA) and certified in many other countries.

With such a promising line of dental resins in its portfolio, 3D Systems, as the inventor of 3D printing and a recognized industry leader, could not do without using its own revolutionary technologies in a new field for itself. This is how the first 3D printer for dentists NextDent 5100 appeared, specially designed for the manufacture of products from biocompatible photopolymers.

Its hallmarks are speed and ease of use. Incredibly fast in the production of dental work of any complexity, the NextDent 5100 will allow you to print more than 70 temporary crowns in 25 minutes. Or to make a whole prosthesis in front of the patient in just an hour.

NextDent Denture 3D+, a class IIa biocompatible material, was created for the fabrication of removable denture bases. This material has significantly less shrinkage than the already used, standard PMMA materials. Shrinkage can be avoided using software, resulting in a perfectly suitable base for a removable denture. Excellent mechanical properties make it possible to surpass the quality of traditional methods of manufacturing removable dentures. Available in the following shades: dark pink, light pink, opaque, reddish pink and transparent pink. Biocompatible, non-cytotoxic, non-mutagenic, does not cause redness and swelling, does not have sensitizing properties, does not cause systemic toxicity.

NextDent C&B Micro Filled Hybrid is a class IIa biocompatible material designed for the production of single crowns and bridges.