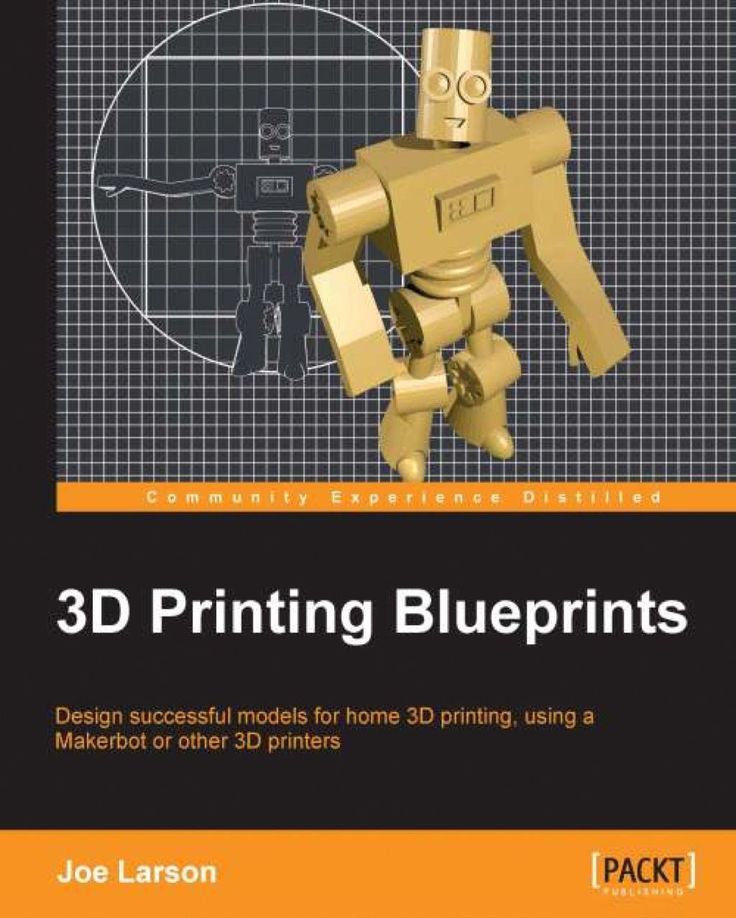

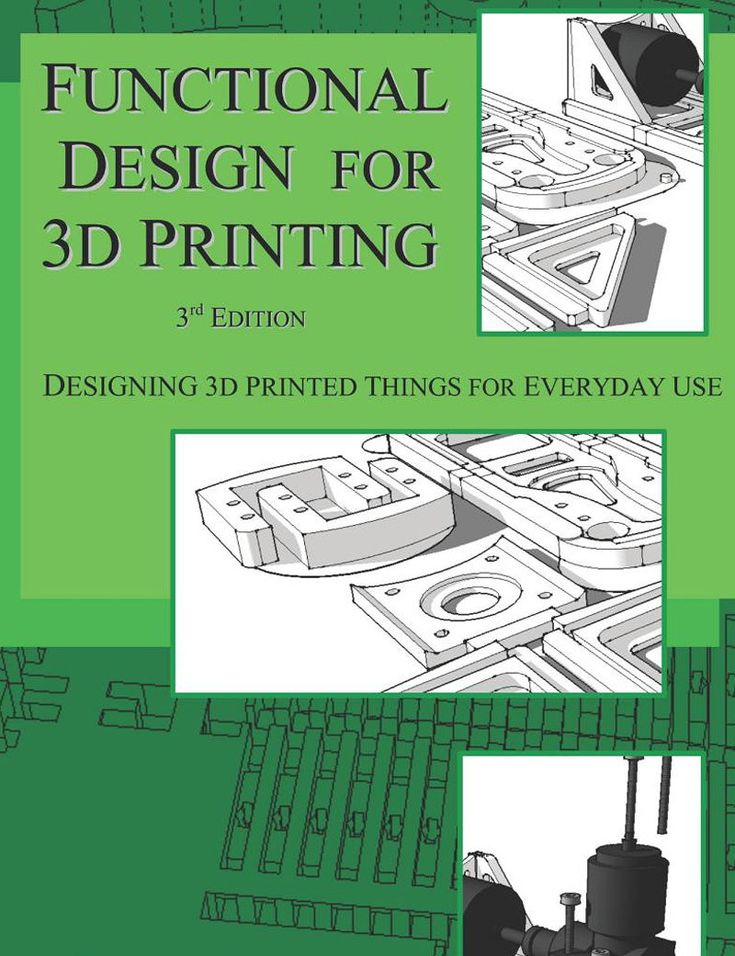

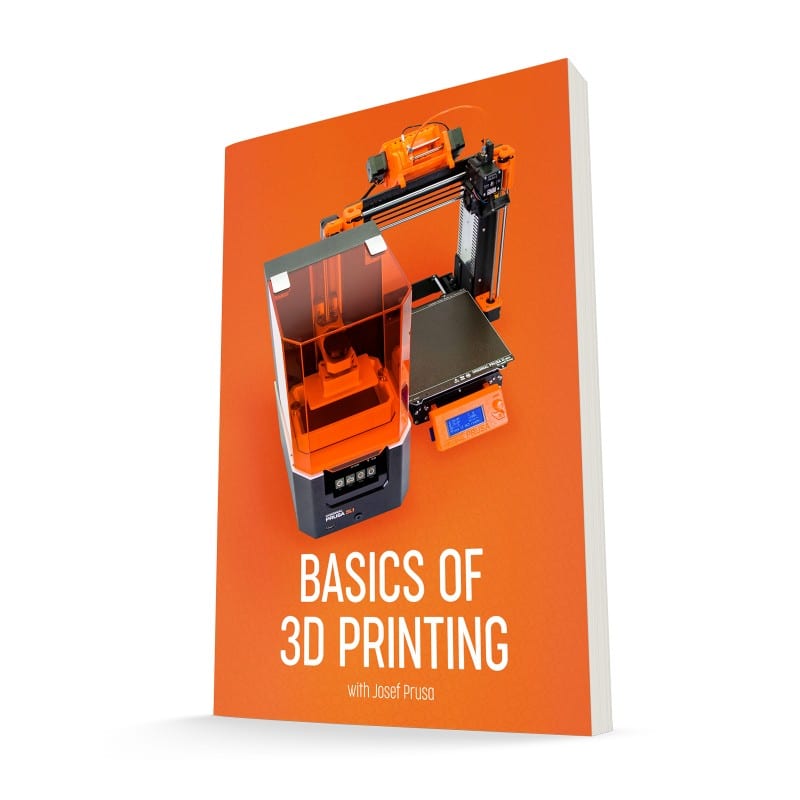

The 3d printing handbook epub

How to design for 3D printing ebook by Bitfab (free 3D printing ebook)

A compact ebook with tips and information on how to learn to design parts that can be 3D printed.

- What is 3D printing?

- What parts can be produced with 3D printing?

- How are 3D printed parts priced?

- Lot of tips and guidelines on how to design 3D printable parts

- How to optimize my design for appearance or strength

Do you want to design 3D printable parts? You don’t have a lot of time? This book is for you

What am I going to learn?

This book is for you if you already can design 3D models or you are currently learning to do 3D design. You can use any 3D design software to apply the information in this book, any 3D modelling or CAD program can export files for 3D printing.

A short introduction to FDM 3D printing will introduce you to the basic concepts of the process so you can understand how your parts will be produced. Then you have a collection of tips, rules and guidelines to help you adapt your designs to be 3D printable.

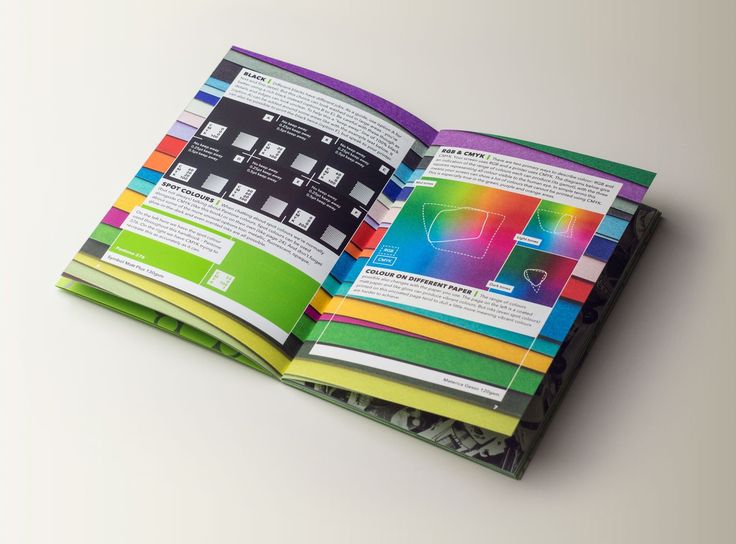

You don’t need a lot of time to learn the content of this book. You’ll find that we have used a lot of images to clarify the concepts and make the content easier to grasp.

This is the perfect source if you need to quickly adapt your 3D modelling skills to start designing 3D printable parts.

Table of contents

- Basics of FDM 3D printing

- What is FDM 3D printing

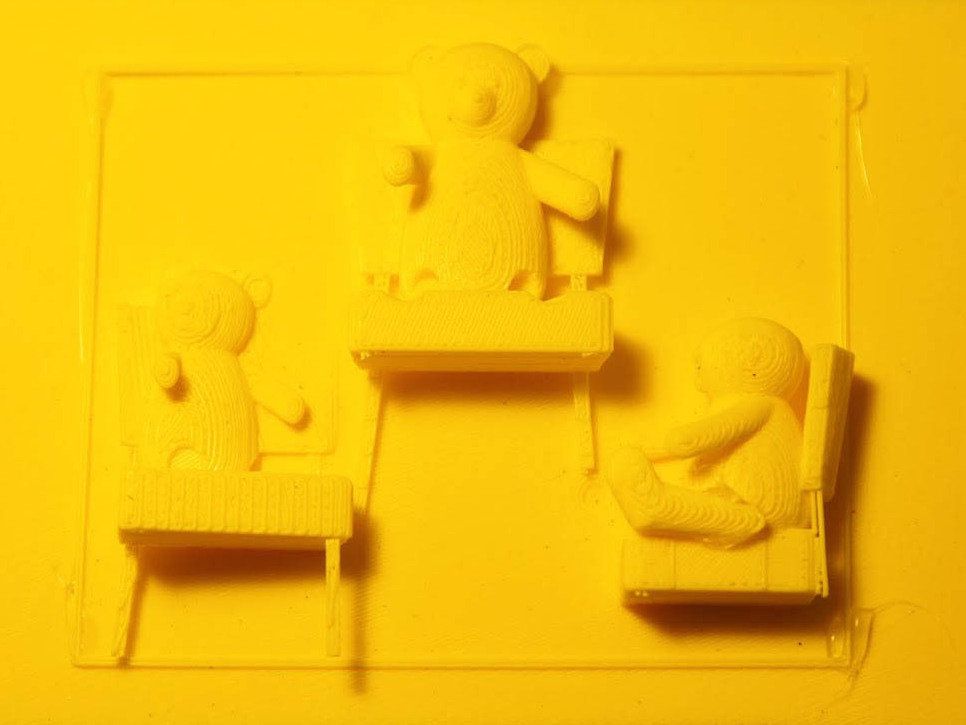

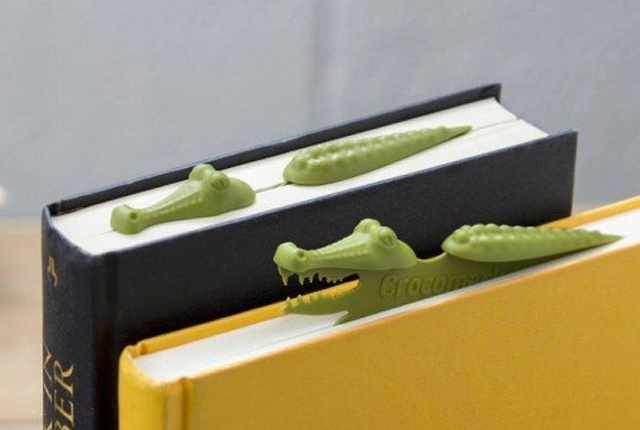

- Applications of 3D printing

- 3D printing for manufacturing

- Understanding the FDM process

- How FDM parts are priced

- Design software

- Design guidelines for FDM 3D printing

- Part size

- Part tolerance

- Walls

- Holes, pins and small sections

- Embossed and engraved details

- Overhangs and bridges

- Printing orientation

- Printing orientation and part finish

- Printing orientation and part strength

Content sample: Part size

Maximum part dimensions: 400 x 300 x 300 millimetres (X, Y, Z axis)

Bigger parts can be printed on demand or spit in several print jobs.

Small parts. Small parts less than 20 x 20 x 20 millimetres can be hard to print with FDM technology.

Such small parts should have simple geometries in order to be printable.

Large parts costs. Since the volume increases rapidly when scaling the part dimensions (volume increases with the cube of the length) very large parts are expensive to produce.

When printing large parts we can offer costs optimizations such as large nozzles, higher layer heights, etc.

80% rule. To reduce the part volume to approximately half, scale the part to 80% of the original dimensions.

This is a measure to reduce costs of parts that can be scaled without affecting functionality (not very common in engineering parts).

More sample pages

You still need your 3D parts printed!

We are Bitfab, a 3D printing service with 6 years experience printing 3D parts. We can produce FDM, SLA and SLS parts for you and help you take advantage of the the benefits of 3D printing for your business.

Leave us a message

This book is open source, like a lot of the work we do at Bitfab. You can use the content, images, 3D models… All of them are published under a Creative Commons Attribution license in the project repo.

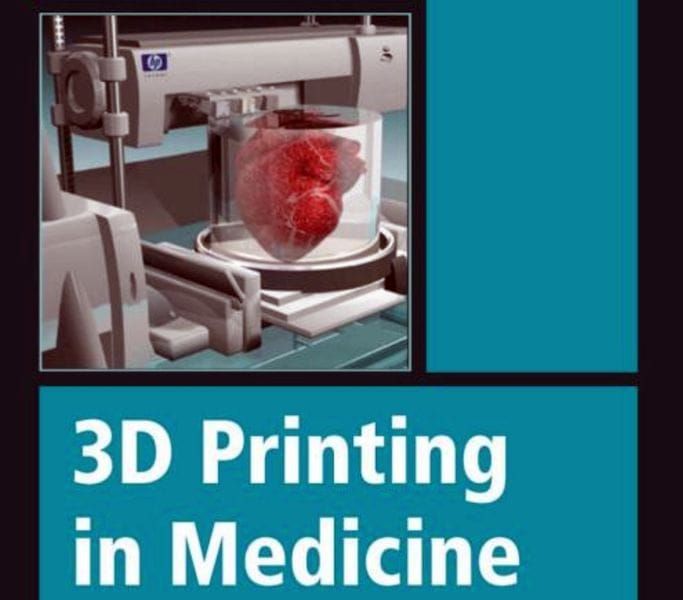

Technologies, design and applications (PDF) PDF

Written by Ben Redwood, Filemon Schöffer & Brian Garret 3D Hubs B.V. Amsterdam, The Netherlands Book design by Multitude Photography by Ken Giang (3D Hubs) unless source is stated Infographics by Tom Debicki (3D Hubs) Book printed by Coers & Roest © 3D Hubs B.V. 2017 3D Hubs is the world’s largest network of manufacturing services. With production facilities connected in over 160 countries, the 3D Hubs online platform helps you find the fastest and most price competitive manufacturing solution near you. Founded in 2013, the network has since produced more than 1,000,000 parts locally, making it the global leader in distributed manufacturing. This work is subject to copyright. All rights are reserved by the 3D Hubs B.V., whether the whole or part of the material is concerned. Specifically the rights of translation, reprinting, reuse of illustrations, recitation, broadcasting, reproduction on microfilms or in any other physical way, and transmission or information storage and retrieval, electronic adaptation, computer software, or by similar or dissimilar methodology now known or hereafter developed. Reproduction of this publication or parts thereof is permitted only under the exemptions as provided for in the Dutch Copyright Act (Auteurswet), in its current version, and permission for use must always be obtained from 3D Hubs B.V. While the advice and information in this book are believed to be true and accurate at the date of publication, neither the authors nor the editors nor the publisher can accept any legal responsibility for any errors or omissions that may be made. 3D Hubs B.V. takes no warranty, express or implied, with respect to the material contained herein.

All rights are reserved by the 3D Hubs B.V., whether the whole or part of the material is concerned. Specifically the rights of translation, reprinting, reuse of illustrations, recitation, broadcasting, reproduction on microfilms or in any other physical way, and transmission or information storage and retrieval, electronic adaptation, computer software, or by similar or dissimilar methodology now known or hereafter developed. Reproduction of this publication or parts thereof is permitted only under the exemptions as provided for in the Dutch Copyright Act (Auteurswet), in its current version, and permission for use must always be obtained from 3D Hubs B.V. While the advice and information in this book are believed to be true and accurate at the date of publication, neither the authors nor the editors nor the publisher can accept any legal responsibility for any errors or omissions that may be made. 3D Hubs B.V. takes no warranty, express or implied, with respect to the material contained herein. 3D Hubs B.V. has made extensive efforts to trace all copyright owners of the images used in this Work, however with respect to a few images the author could not be traced. If you believe that you own the copyrights vested in an image used in this Work, and 3D Hubs B.V. has not yet been in touch with you, please contact 3D Hubs B.V. Credits This book would not be nearly as complete without the dedication and contributions of an incredible amount of industry experts, manufacturers and above all our 3D Hubs community from all around the world. First and foremost, a huge thank you to the people who gave their time to review and provide feedback on the text in this book; Michael Molitch-Hou (Engineering.com), Sarah Goehrke (3Dprint.com), Bill Artley (Print Form), Alan Nguyen (Space Junk Co), Dr. Joshua M. Pearce (Michigan Tech), Richard Smith (Oxford University), Andreas Bastian (Autodesk), Erik de Bruijn (Ultimaker), Florian van der Horst (Oceanz), Chris Mcaloney (Proto3000), Tobias Tuffentsammer (ExOne), and Dr.

3D Hubs B.V. has made extensive efforts to trace all copyright owners of the images used in this Work, however with respect to a few images the author could not be traced. If you believe that you own the copyrights vested in an image used in this Work, and 3D Hubs B.V. has not yet been in touch with you, please contact 3D Hubs B.V. Credits This book would not be nearly as complete without the dedication and contributions of an incredible amount of industry experts, manufacturers and above all our 3D Hubs community from all around the world. First and foremost, a huge thank you to the people who gave their time to review and provide feedback on the text in this book; Michael Molitch-Hou (Engineering.com), Sarah Goehrke (3Dprint.com), Bill Artley (Print Form), Alan Nguyen (Space Junk Co), Dr. Joshua M. Pearce (Michigan Tech), Richard Smith (Oxford University), Andreas Bastian (Autodesk), Erik de Bruijn (Ultimaker), Florian van der Horst (Oceanz), Chris Mcaloney (Proto3000), Tobias Tuffentsammer (ExOne), and Dr. Hisham Alkabie (EQT Aerospace & Defence). For their expert contributions as authors; thanks to Courtney Armstrong on designing for SLA/DLP, Perry Cain on layer height and support for FFF, James Low on snap fit connections, Ben Hudson on designing for FFF, Alkaios Varotsis for his clarifications on the differences between desktop and industrial FFF printing, Diederik van der Steen on post processing and desktop vs. Industrial SLA/DLP, Stefan Holdinga on designing for SLS, Chris McAloney on designing for Material Jetting, Martin Petrak on designing for DMLS/SLM, John Wall on enclosure design, Bill Artley on applications in automotive, Thomas van de Hout on topology optimization, Joris Peelz for his ever available expertize, Jack Davies for his contribution on reverse engineering & CAD software, Robin Brockötter on surface modeling and George Fisher-Wilson for his 3D printing case studies. Many thanks also goes to the following companies who provided us with the world-class case studies for Part 3 of this book; Ultimaker & Volkswagen AutoEuropa and PEAK Industries for applications in FFF.

Hisham Alkabie (EQT Aerospace & Defence). For their expert contributions as authors; thanks to Courtney Armstrong on designing for SLA/DLP, Perry Cain on layer height and support for FFF, James Low on snap fit connections, Ben Hudson on designing for FFF, Alkaios Varotsis for his clarifications on the differences between desktop and industrial FFF printing, Diederik van der Steen on post processing and desktop vs. Industrial SLA/DLP, Stefan Holdinga on designing for SLS, Chris McAloney on designing for Material Jetting, Martin Petrak on designing for DMLS/SLM, John Wall on enclosure design, Bill Artley on applications in automotive, Thomas van de Hout on topology optimization, Joris Peelz for his ever available expertize, Jack Davies for his contribution on reverse engineering & CAD software, Robin Brockötter on surface modeling and George Fisher-Wilson for his 3D printing case studies. Many thanks also goes to the following companies who provided us with the world-class case studies for Part 3 of this book; Ultimaker & Volkswagen AutoEuropa and PEAK Industries for applications in FFF. Formlabs and EnvisionTec for SLA / DLP, Paul Kohlhaussen Design and Rehook for SLS, Mark Thielen & Eindhoven University and Vitaly Bulgarov & Factor 31 for Material Jetting, ExOne for Binder Jetting, Concept Laser and Thomas van de Hout for their DMLS / SLM case studies. Special thanks must go to the awesome 3D Hubs team for tirelessly proofreading version after version and continuously pointing out improvements along the way. Tom Debicki for creating the design concept of the book, creating hundreds of versions of illustrations and all the infographics, and Ken Giang for the world class photography. We couldn’t have done it without you. Also special thank you to Bram de Zwart for creating the space within 3D Hubs to write this book and for supporting us every step of the way. And finally, a big thanks goes to the design team from Multitude for helping us bring this project from a concept into reality and getting this book to production with no compromise on quality. Table of Contents Foreword Introduction Part One: 3D Printing Technologies and Materials Chapter 01: Overview of 3D Printing Chapter 02: Material extrusion — FFF Chapter 03: VAT Polymerization — SLA/DLP Chapter 04: Powder Bed Fusion (Polymers)— SLS Chapter 05: Material Jetting — Material Jetting, DOD Chapter 06: Binder Jetting Chapter 07: Powder Bed Fusion (Metals) — DMLS/SLM, EBM Chapter 08: Decision making tools Part Two: Designing for 3D Printing Chapter 09: General design considerations for 3D printing Chapter 10: Description of 3D printed features Chapter 11: Designing for FFF Chapter 12: Designing for SLA / DLP Chapter 13: Designing for SLS Chapter 14: Designing for Material Jetting Chapter 15: Designing for Binder Jetting Chapter 16: Designing for DMLS/SLM Chapter 17: Design rules summary table Part Three: Applications of 3D Printing Chapter 18: Tools for producing 3D designs Chapter 19: Applications of FFF Chapter 20: Applications of SLA/DLP Chapter 21: Applications of SLS Chapter 22: Applications of Material Jetting Chapter 23: Applications of Binder Jetting Chapter 24: Applications of DMLS/SLM Index Foreword It is the summer of 2001 in Cupertino, California, I stare at a lump of foam, some lego-like mechanical elements and an assortment of electrical components scattered across a desk.

Formlabs and EnvisionTec for SLA / DLP, Paul Kohlhaussen Design and Rehook for SLS, Mark Thielen & Eindhoven University and Vitaly Bulgarov & Factor 31 for Material Jetting, ExOne for Binder Jetting, Concept Laser and Thomas van de Hout for their DMLS / SLM case studies. Special thanks must go to the awesome 3D Hubs team for tirelessly proofreading version after version and continuously pointing out improvements along the way. Tom Debicki for creating the design concept of the book, creating hundreds of versions of illustrations and all the infographics, and Ken Giang for the world class photography. We couldn’t have done it without you. Also special thank you to Bram de Zwart for creating the space within 3D Hubs to write this book and for supporting us every step of the way. And finally, a big thanks goes to the design team from Multitude for helping us bring this project from a concept into reality and getting this book to production with no compromise on quality. Table of Contents Foreword Introduction Part One: 3D Printing Technologies and Materials Chapter 01: Overview of 3D Printing Chapter 02: Material extrusion — FFF Chapter 03: VAT Polymerization — SLA/DLP Chapter 04: Powder Bed Fusion (Polymers)— SLS Chapter 05: Material Jetting — Material Jetting, DOD Chapter 06: Binder Jetting Chapter 07: Powder Bed Fusion (Metals) — DMLS/SLM, EBM Chapter 08: Decision making tools Part Two: Designing for 3D Printing Chapter 09: General design considerations for 3D printing Chapter 10: Description of 3D printed features Chapter 11: Designing for FFF Chapter 12: Designing for SLA / DLP Chapter 13: Designing for SLS Chapter 14: Designing for Material Jetting Chapter 15: Designing for Binder Jetting Chapter 16: Designing for DMLS/SLM Chapter 17: Design rules summary table Part Three: Applications of 3D Printing Chapter 18: Tools for producing 3D designs Chapter 19: Applications of FFF Chapter 20: Applications of SLA/DLP Chapter 21: Applications of SLS Chapter 22: Applications of Material Jetting Chapter 23: Applications of Binder Jetting Chapter 24: Applications of DMLS/SLM Index Foreword It is the summer of 2001 in Cupertino, California, I stare at a lump of foam, some lego-like mechanical elements and an assortment of electrical components scattered across a desk. My task was a tough one; to create the first prototype of a new product I had been contracted to design for Apple. The project brief was to create a device that could be a modern day Sony Walkman for the MP3 generation. It took hard work, dozens of design iterations and lots of foam but it was complete. The creation that would go on to become the first iPod prototype, and a decade of various future iPod incarnations which ultimately grew up to become the iPhone. When creating new products you’re always looking to make something that’s much better, visibly and functionally, than what’s available. Whether it’s hardware or software that you’re designing, at the core of it is the drive to create something new, disruptive, and emotional. With real innovation comes the need to prototype; if it’s not been done before, your first attempt is probably not going to be the one you run to the market with. Iteration is key. The way in which prototypes are designed, produced and modified has come a long way since creating that first iPod at Apple.

My task was a tough one; to create the first prototype of a new product I had been contracted to design for Apple. The project brief was to create a device that could be a modern day Sony Walkman for the MP3 generation. It took hard work, dozens of design iterations and lots of foam but it was complete. The creation that would go on to become the first iPod prototype, and a decade of various future iPod incarnations which ultimately grew up to become the iPhone. When creating new products you’re always looking to make something that’s much better, visibly and functionally, than what’s available. Whether it’s hardware or software that you’re designing, at the core of it is the drive to create something new, disruptive, and emotional. With real innovation comes the need to prototype; if it’s not been done before, your first attempt is probably not going to be the one you run to the market with. Iteration is key. The way in which prototypes are designed, produced and modified has come a long way since creating that first iPod at Apple. Readily available and affordable prototyping via 3D printing is now a reality. The speed in which you can generate ideas into physical objects is now faster than it has ever been. We live in a world full of tools and resources that allow us to create and innovate with ease. The next step is to apply these resources as forces of disruption and change. This really hits home the importance of 3D printing and how it can work for anyone involved in designing or manufacturing physical objects. Innovative and complex product design needs prototyping. It takes time but in the end these are the tools that allow you to make those big decisions. Everything we were doing at Apple, back then, was brand new to the world of technology, which meant we had to continually evolve to find the right path. Part of this evolution set the foundation for others to adopt and improve the technology we developed later on. “The Handbook” will help to guide you on your own path as you look to leverage 3D printing and its potential to create your own breakthrough products, that hopefully will change the world.

Readily available and affordable prototyping via 3D printing is now a reality. The speed in which you can generate ideas into physical objects is now faster than it has ever been. We live in a world full of tools and resources that allow us to create and innovate with ease. The next step is to apply these resources as forces of disruption and change. This really hits home the importance of 3D printing and how it can work for anyone involved in designing or manufacturing physical objects. Innovative and complex product design needs prototyping. It takes time but in the end these are the tools that allow you to make those big decisions. Everything we were doing at Apple, back then, was brand new to the world of technology, which meant we had to continually evolve to find the right path. Part of this evolution set the foundation for others to adopt and improve the technology we developed later on. “The Handbook” will help to guide you on your own path as you look to leverage 3D printing and its potential to create your own breakthrough products, that hopefully will change the world. Every designer and engineer should keep it close as it paves your way into new manufacturing technologies that will spur your creativity and unlock your ideas as they become reality. Creation is changing, manufacturing is changing and design is changing, turn the page it’s time to stay ahead… Tony Fadell Creator of the iPod and founder of Nest Introduction As an engineer, often the most important consideration when designing parts for production is the method of manufacturing. A design can be produced via a range of manufacturing techniques with each having their own associated strengths and weaknesses. The purpose of this introduction is to identify where 3D printing sits as a method of manufacturing relative to more traditional processes, like CNC, injection molding and casting. This section will outline the most common manufacturing methods and conclude with an overview of the general 3D printing process. A detailed explanation of manufacturing technologies other than of 3D printing is outside the scope of this book.

Every designer and engineer should keep it close as it paves your way into new manufacturing technologies that will spur your creativity and unlock your ideas as they become reality. Creation is changing, manufacturing is changing and design is changing, turn the page it’s time to stay ahead… Tony Fadell Creator of the iPod and founder of Nest Introduction As an engineer, often the most important consideration when designing parts for production is the method of manufacturing. A design can be produced via a range of manufacturing techniques with each having their own associated strengths and weaknesses. The purpose of this introduction is to identify where 3D printing sits as a method of manufacturing relative to more traditional processes, like CNC, injection molding and casting. This section will outline the most common manufacturing methods and conclude with an overview of the general 3D printing process. A detailed explanation of manufacturing technologies other than of 3D printing is outside the scope of this book. Classification of manufacturing techniques Most manufacturing techniques can be categorized into 3 groups. At the simplest level these groups can be defined as: · Formative manufacturing: best suited for high volume production of the same part, requiring a large initial investment in tooling (molds) but then being able to produce parts quickly and at a very low unit price. · Subtractive manufacturing: lies in between formative and additive, being best suited for parts with relatively simple geometries, produced at low-mid volumes, that are typically made from functional materials (particularly metal). · Additive manufacturing: best suited for low volume, complex designs that formative or subtractive methods are unable to produce, or when a unique one-off rapid prototype is required. Formative (injection molding, casting, stamping and forging) Formative manufacturing typically forms material into the desired shape via heat and pressure. The raw material can be melted down and extruded under pressure into a mold (injection molding/die casting), melted and then poured into a mold (casting) or pressed or pulled into the desired shape (stamping/vacuum forming/forging).

Classification of manufacturing techniques Most manufacturing techniques can be categorized into 3 groups. At the simplest level these groups can be defined as: · Formative manufacturing: best suited for high volume production of the same part, requiring a large initial investment in tooling (molds) but then being able to produce parts quickly and at a very low unit price. · Subtractive manufacturing: lies in between formative and additive, being best suited for parts with relatively simple geometries, produced at low-mid volumes, that are typically made from functional materials (particularly metal). · Additive manufacturing: best suited for low volume, complex designs that formative or subtractive methods are unable to produce, or when a unique one-off rapid prototype is required. Formative (injection molding, casting, stamping and forging) Formative manufacturing typically forms material into the desired shape via heat and pressure. The raw material can be melted down and extruded under pressure into a mold (injection molding/die casting), melted and then poured into a mold (casting) or pressed or pulled into the desired shape (stamping/vacuum forming/forging). Formative techniques produce parts from a large range of materials (both metals and plastics). For high volume production of parts, formative manufacturing is often unrivaled in cost. The main limitation of formative manufacturing is the need to produce a tool (mold or die) to form the part. Tooling is often expensive and complicated to produce, increasing lead times and delaying the manufacturing of a part. This large upfront investment is why formative manufacturing is generally only cost effective at high volumes. The design of formative tooling is also complex with the need for mold features like spurs or runners to assist in the formation of parts. Parts that are produced via formative manufacturing also have design constraints like draft angles and uniform wall thickness to aid in the forming process. Subtractive (CNC, turning, drilling) Subtractive manufacturing begins with a block of solid material (blank), and utilizes cutting tools to remove (machine) material to achieve a final shape.

Formative techniques produce parts from a large range of materials (both metals and plastics). For high volume production of parts, formative manufacturing is often unrivaled in cost. The main limitation of formative manufacturing is the need to produce a tool (mold or die) to form the part. Tooling is often expensive and complicated to produce, increasing lead times and delaying the manufacturing of a part. This large upfront investment is why formative manufacturing is generally only cost effective at high volumes. The design of formative tooling is also complex with the need for mold features like spurs or runners to assist in the formation of parts. Parts that are produced via formative manufacturing also have design constraints like draft angles and uniform wall thickness to aid in the forming process. Subtractive (CNC, turning, drilling) Subtractive manufacturing begins with a block of solid material (blank), and utilizes cutting tools to remove (machine) material to achieve a final shape. CNC milling, turning (lathe) and machine operations like drilling and cutting are all examples of subtractive techniques. Subtractive manufacturing is capable of producing highly accurate parts with excellent surface finish. Almost every material is able to be machined in some way. For majority of designs, subtractive manufacturing is the most cost effective method of production. Subtractive manufacturing is limited by a number of factors. Most designs require Computer Aided Manufacturing (CAM) to plot tool paths and efficient material removal. This adds time and cost to the overall process. Tool access must also be considered when designing parts for subtractive manufacturing as the cutting tool must be able to reach all surfaces to remove material. While machines like 5-axis CNC eliminate some of these restrictions, complex parts will need to be re-orientated during the machining process, further increasing cost and lead time. Subtractive manufacturing is also generally considered a wasteful process, due to the large amounts of material that is often removed to produce the final part geometry.

CNC milling, turning (lathe) and machine operations like drilling and cutting are all examples of subtractive techniques. Subtractive manufacturing is capable of producing highly accurate parts with excellent surface finish. Almost every material is able to be machined in some way. For majority of designs, subtractive manufacturing is the most cost effective method of production. Subtractive manufacturing is limited by a number of factors. Most designs require Computer Aided Manufacturing (CAM) to plot tool paths and efficient material removal. This adds time and cost to the overall process. Tool access must also be considered when designing parts for subtractive manufacturing as the cutting tool must be able to reach all surfaces to remove material. While machines like 5-axis CNC eliminate some of these restrictions, complex parts will need to be re-orientated during the machining process, further increasing cost and lead time. Subtractive manufacturing is also generally considered a wasteful process, due to the large amounts of material that is often removed to produce the final part geometry. Additive (3D printing) Additive manufacturing (more commonly known as 3D printing) is the process of additively building up a part one layer at a time. There are a range of 3D printing technologies with each having their own benefits and limitations and each being able to print parts from different materials. Parts can be produced in almost any geometry, which is one of the core strengths of 3D printing (even though there are still rules that must be followed per technology). Also, 3D printing does not rely on expensive tooling having essentially no start up costs. The advantage of this is the rapid verification and development of prototypes and low- volume production parts. One of the biggest limitations of 3D printing is the inability to produce parts with material properties equivalent to those made via subtractive or formative techniques. Most 3D printing technologies produce parts that are inherently anisotropic or not fully dense. 3D printing also has limitations on repeatability, meaning parts will often have slight variations due to differential cooling or warping during curing.

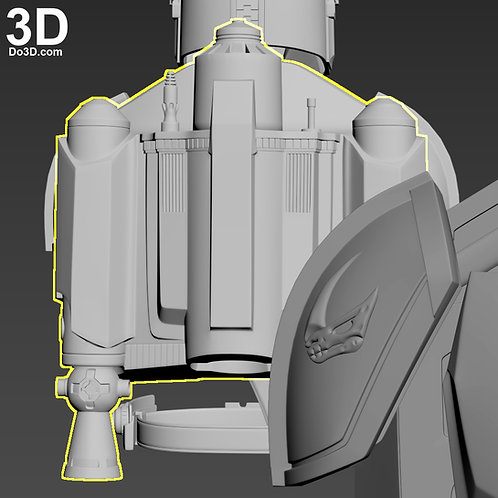

Additive (3D printing) Additive manufacturing (more commonly known as 3D printing) is the process of additively building up a part one layer at a time. There are a range of 3D printing technologies with each having their own benefits and limitations and each being able to print parts from different materials. Parts can be produced in almost any geometry, which is one of the core strengths of 3D printing (even though there are still rules that must be followed per technology). Also, 3D printing does not rely on expensive tooling having essentially no start up costs. The advantage of this is the rapid verification and development of prototypes and low- volume production parts. One of the biggest limitations of 3D printing is the inability to produce parts with material properties equivalent to those made via subtractive or formative techniques. Most 3D printing technologies produce parts that are inherently anisotropic or not fully dense. 3D printing also has limitations on repeatability, meaning parts will often have slight variations due to differential cooling or warping during curing. Cost comparison Cost is often the governing factor behind how a part will be manufactured. Figure 0.2 gives a general insight into how the cost of manufacturing (cost per part) varies based on the amount of parts being produced. The 3D printing process While there are many different 3D printing technologies, the following section will focus on the general process from design to final part. Although each method of 3D printing produces parts in a different way, these 5 core steps are constant across all technologies. 1. Producing a 3D file Producing a digital model is the first step in the 3D printing process. The most common method for producing a digital model (Figure 0.3) is Computer Aided Design (CAD). Reverse engineering can also be used to generate a digital model via 3D scanning. Both CAD modeling and reverse engineering are discussed in Chapter 18 of this book.There are several design considerations that must be evaluated when designing for 3D printing. These generally focus on feature geometry limitations, support material and escape hole requirements.

Cost comparison Cost is often the governing factor behind how a part will be manufactured. Figure 0.2 gives a general insight into how the cost of manufacturing (cost per part) varies based on the amount of parts being produced. The 3D printing process While there are many different 3D printing technologies, the following section will focus on the general process from design to final part. Although each method of 3D printing produces parts in a different way, these 5 core steps are constant across all technologies. 1. Producing a 3D file Producing a digital model is the first step in the 3D printing process. The most common method for producing a digital model (Figure 0.3) is Computer Aided Design (CAD). Reverse engineering can also be used to generate a digital model via 3D scanning. Both CAD modeling and reverse engineering are discussed in Chapter 18 of this book.There are several design considerations that must be evaluated when designing for 3D printing. These generally focus on feature geometry limitations, support material and escape hole requirements. Designing parts for 3D printing is discussed in Part 2 of this book.

Designing parts for 3D printing is discussed in Part 2 of this book.

347 Pages·2017·31.16 MB·English

by Ben Redwood, Filemon Schöffer, Brian Garret

#3d printing #3d print

Checking for file health...

Preview

The 3D Printing Handbook: Technologies, design and applications (PDF)Written by Ben Redwood, Filemon Schöffer & Brian Garret 3D Hubs B.V. Amsterdam, The Netherlands Book design by Multitude Photography by Ken Giang (3D Hubs) unless source is stated Infographics by Tom Debicki (3D Hubs) Book printed by Coers & Roest © 3D Hubs B.V. 2017 3D Hubs is the world’s largest network of manufacturing services. With production facilities connected in over 160 countries, the 3D Hubs online platform helps you find the fastest and most price competitive manufacturing solution near you. Founded in 2013, the network has since produced more than 1,000,000 parts locally, making it the global leader in distributed manufacturing. This work is subject to copyright. All rights are reserved by the 3D Hubs B.V., whether the whole or part of the material is concerned. Specifically the rights of translation, reprinting, reuse of illustrations, recitation, broadcasting, reproduction on microfilms or in any other physical way, and transmission or information storage and retrieval, electronic adaptation, computer software, or by similar or dissimilar methodology now known or hereafter developed. Reproduction of this publication or parts thereof is permitted only under the exemptions as provided for in the Dutch Copyright Act (Auteurswet), in its current version, and permission for use must always be obtained from 3D Hubs B.V. While the advice and information in this book are believed to be true and accurate at the date of publication, neither the authors nor the editors nor the publisher can accept any legal responsibility for any errors or omissions that may be made. 3D Hubs B.V. takes no warranty, express or implied, with respect to the material contained herein.

All rights are reserved by the 3D Hubs B.V., whether the whole or part of the material is concerned. Specifically the rights of translation, reprinting, reuse of illustrations, recitation, broadcasting, reproduction on microfilms or in any other physical way, and transmission or information storage and retrieval, electronic adaptation, computer software, or by similar or dissimilar methodology now known or hereafter developed. Reproduction of this publication or parts thereof is permitted only under the exemptions as provided for in the Dutch Copyright Act (Auteurswet), in its current version, and permission for use must always be obtained from 3D Hubs B.V. While the advice and information in this book are believed to be true and accurate at the date of publication, neither the authors nor the editors nor the publisher can accept any legal responsibility for any errors or omissions that may be made. 3D Hubs B.V. takes no warranty, express or implied, with respect to the material contained herein. 3D Hubs B.V. has made extensive efforts to trace all copyright owners of the images used in this Work, however with respect to a few images the author could not be traced. If you believe that you own the copyrights vested in an image used in this Work, and 3D Hubs B.V. has not yet been in touch with you, please contact 3D Hubs B.V. Credits This book would not be nearly as complete without the dedication and contributions of an incredible amount of industry experts, manufacturers and above all our 3D Hubs community from all around the world. First and foremost, a huge thank you to the people who gave their time to review and provide feedback on the text in this book; Michael Molitch-Hou (Engineering.com), Sarah Goehrke (3Dprint.com), Bill Artley (Print Form), Alan Nguyen (Space Junk Co), Dr. Joshua M. Pearce (Michigan Tech), Richard Smith (Oxford University), Andreas Bastian (Autodesk), Erik de Bruijn (Ultimaker), Florian van der Horst (Oceanz), Chris Mcaloney (Proto3000), Tobias Tuffentsammer (ExOne), and Dr.

3D Hubs B.V. has made extensive efforts to trace all copyright owners of the images used in this Work, however with respect to a few images the author could not be traced. If you believe that you own the copyrights vested in an image used in this Work, and 3D Hubs B.V. has not yet been in touch with you, please contact 3D Hubs B.V. Credits This book would not be nearly as complete without the dedication and contributions of an incredible amount of industry experts, manufacturers and above all our 3D Hubs community from all around the world. First and foremost, a huge thank you to the people who gave their time to review and provide feedback on the text in this book; Michael Molitch-Hou (Engineering.com), Sarah Goehrke (3Dprint.com), Bill Artley (Print Form), Alan Nguyen (Space Junk Co), Dr. Joshua M. Pearce (Michigan Tech), Richard Smith (Oxford University), Andreas Bastian (Autodesk), Erik de Bruijn (Ultimaker), Florian van der Horst (Oceanz), Chris Mcaloney (Proto3000), Tobias Tuffentsammer (ExOne), and Dr. Hisham Alkabie (EQT Aerospace & Defence). For their expert contributions as authors; thanks to Courtney Armstrong on designing for SLA/DLP, Perry Cain on layer height and support for FFF, James Low on snap fit connections, Ben Hudson on designing for FFF, Alkaios Varotsis for his clarifications on the differences between desktop and industrial FFF printing, Diederik van der Steen on post processing and desktop vs. Industrial SLA/DLP, Stefan Holdinga on designing for SLS, Chris McAloney on designing for Material Jetting, Martin Petrak on designing for DMLS/SLM, John Wall on enclosure design, Bill Artley on applications in automotive, Thomas van de Hout on topology optimization, Joris Peelz for his ever available expertize, Jack Davies for his contribution on reverse engineering & CAD software, Robin Brockötter on surface modeling and George Fisher-Wilson for his 3D printing case studies. Many thanks also goes to the following companies who provided us with the world-class case studies for Part 3 of this book; Ultimaker & Volkswagen AutoEuropa and PEAK Industries for applications in FFF.

Hisham Alkabie (EQT Aerospace & Defence). For their expert contributions as authors; thanks to Courtney Armstrong on designing for SLA/DLP, Perry Cain on layer height and support for FFF, James Low on snap fit connections, Ben Hudson on designing for FFF, Alkaios Varotsis for his clarifications on the differences between desktop and industrial FFF printing, Diederik van der Steen on post processing and desktop vs. Industrial SLA/DLP, Stefan Holdinga on designing for SLS, Chris McAloney on designing for Material Jetting, Martin Petrak on designing for DMLS/SLM, John Wall on enclosure design, Bill Artley on applications in automotive, Thomas van de Hout on topology optimization, Joris Peelz for his ever available expertize, Jack Davies for his contribution on reverse engineering & CAD software, Robin Brockötter on surface modeling and George Fisher-Wilson for his 3D printing case studies. Many thanks also goes to the following companies who provided us with the world-class case studies for Part 3 of this book; Ultimaker & Volkswagen AutoEuropa and PEAK Industries for applications in FFF. Formlabs and EnvisionTec for SLA / DLP, Paul Kohlhaussen Design and Rehook for SLS, Mark Thielen & Eindhoven University and Vitaly Bulgarov & Factor 31 for Material Jetting, ExOne for Binder Jetting, Concept Laser and Thomas van de Hout for their DMLS / SLM case studies. Special thanks must go to the awesome 3D Hubs team for tirelessly proofreading version after version and continuously pointing out improvements along the way. Tom Debicki for creating the design concept of the book, creating hundreds of versions of illustrations and all the infographics, and Ken Giang for the world class photography. We couldn’t have done it without you. Also special thank you to Bram de Zwart for creating the space within 3D Hubs to write this book and for supporting us every step of the way. And finally, a big thanks goes to the design team from Multitude for helping us bring this project from a concept into reality and getting this book to production with no compromise on quality. Table of Contents Foreword Introduction Part One: 3D Printing Technologies and Materials Chapter 01: Overview of 3D Printing Chapter 02: Material extrusion — FFF Chapter 03: VAT Polymerization — SLA/DLP Chapter 04: Powder Bed Fusion (Polymers)— SLS Chapter 05: Material Jetting — Material Jetting, DOD Chapter 06: Binder Jetting Chapter 07: Powder Bed Fusion (Metals) — DMLS/SLM, EBM Chapter 08: Decision making tools Part Two: Designing for 3D Printing Chapter 09: General design considerations for 3D printing Chapter 10: Description of 3D printed features Chapter 11: Designing for FFF Chapter 12: Designing for SLA / DLP Chapter 13: Designing for SLS Chapter 14: Designing for Material Jetting Chapter 15: Designing for Binder Jetting Chapter 16: Designing for DMLS/SLM Chapter 17: Design rules summary table Part Three: Applications of 3D Printing Chapter 18: Tools for producing 3D designs Chapter 19: Applications of FFF Chapter 20: Applications of SLA/DLP Chapter 21: Applications of SLS Chapter 22: Applications of Material Jetting Chapter 23: Applications of Binder Jetting Chapter 24: Applications of DMLS/SLM Index Foreword It is the summer of 2001 in Cupertino, California, I stare at a lump of foam, some lego-like mechanical elements and an assortment of electrical components scattered across a desk.

Formlabs and EnvisionTec for SLA / DLP, Paul Kohlhaussen Design and Rehook for SLS, Mark Thielen & Eindhoven University and Vitaly Bulgarov & Factor 31 for Material Jetting, ExOne for Binder Jetting, Concept Laser and Thomas van de Hout for their DMLS / SLM case studies. Special thanks must go to the awesome 3D Hubs team for tirelessly proofreading version after version and continuously pointing out improvements along the way. Tom Debicki for creating the design concept of the book, creating hundreds of versions of illustrations and all the infographics, and Ken Giang for the world class photography. We couldn’t have done it without you. Also special thank you to Bram de Zwart for creating the space within 3D Hubs to write this book and for supporting us every step of the way. And finally, a big thanks goes to the design team from Multitude for helping us bring this project from a concept into reality and getting this book to production with no compromise on quality. Table of Contents Foreword Introduction Part One: 3D Printing Technologies and Materials Chapter 01: Overview of 3D Printing Chapter 02: Material extrusion — FFF Chapter 03: VAT Polymerization — SLA/DLP Chapter 04: Powder Bed Fusion (Polymers)— SLS Chapter 05: Material Jetting — Material Jetting, DOD Chapter 06: Binder Jetting Chapter 07: Powder Bed Fusion (Metals) — DMLS/SLM, EBM Chapter 08: Decision making tools Part Two: Designing for 3D Printing Chapter 09: General design considerations for 3D printing Chapter 10: Description of 3D printed features Chapter 11: Designing for FFF Chapter 12: Designing for SLA / DLP Chapter 13: Designing for SLS Chapter 14: Designing for Material Jetting Chapter 15: Designing for Binder Jetting Chapter 16: Designing for DMLS/SLM Chapter 17: Design rules summary table Part Three: Applications of 3D Printing Chapter 18: Tools for producing 3D designs Chapter 19: Applications of FFF Chapter 20: Applications of SLA/DLP Chapter 21: Applications of SLS Chapter 22: Applications of Material Jetting Chapter 23: Applications of Binder Jetting Chapter 24: Applications of DMLS/SLM Index Foreword It is the summer of 2001 in Cupertino, California, I stare at a lump of foam, some lego-like mechanical elements and an assortment of electrical components scattered across a desk. My task was a tough one; to create the first prototype of a new product I had been contracted to design for Apple. The project brief was to create a device that could be a modern day Sony Walkman for the MP3 generation. It took hard work, dozens of design iterations and lots of foam but it was complete. The creation that would go on to become the first iPod prototype, and a decade of various future iPod incarnations which ultimately grew up to become the iPhone. When creating new products you’re always looking to make something that’s much better, visibly and functionally, than what’s available. Whether it’s hardware or software that you’re designing, at the core of it is the drive to create something new, disruptive, and emotional. With real innovation comes the need to prototype; if it’s not been done before, your first attempt is probably not going to be the one you run to the market with. Iteration is key. The way in which prototypes are designed, produced and modified has come a long way since creating that first iPod at Apple.

My task was a tough one; to create the first prototype of a new product I had been contracted to design for Apple. The project brief was to create a device that could be a modern day Sony Walkman for the MP3 generation. It took hard work, dozens of design iterations and lots of foam but it was complete. The creation that would go on to become the first iPod prototype, and a decade of various future iPod incarnations which ultimately grew up to become the iPhone. When creating new products you’re always looking to make something that’s much better, visibly and functionally, than what’s available. Whether it’s hardware or software that you’re designing, at the core of it is the drive to create something new, disruptive, and emotional. With real innovation comes the need to prototype; if it’s not been done before, your first attempt is probably not going to be the one you run to the market with. Iteration is key. The way in which prototypes are designed, produced and modified has come a long way since creating that first iPod at Apple. Readily available and affordable prototyping via 3D printing is now a reality. The speed in which you can generate ideas into physical objects is now faster than it has ever been. We live in a world full of tools and resources that allow us to create and innovate with ease. The next step is to apply these resources as forces of disruption and change. This really hits home the importance of 3D printing and how it can work for anyone involved in designing or manufacturing physical objects. Innovative and complex product design needs prototyping. It takes time but in the end these are the tools that allow you to make those big decisions. Everything we were doing at Apple, back then, was brand new to the world of technology, which meant we had to continually evolve to find the right path. Part of this evolution set the foundation for others to adopt and improve the technology we developed later on. “The Handbook” will help to guide you on your own path as you look to leverage 3D printing and its potential to create your own breakthrough products, that hopefully will change the world.

Readily available and affordable prototyping via 3D printing is now a reality. The speed in which you can generate ideas into physical objects is now faster than it has ever been. We live in a world full of tools and resources that allow us to create and innovate with ease. The next step is to apply these resources as forces of disruption and change. This really hits home the importance of 3D printing and how it can work for anyone involved in designing or manufacturing physical objects. Innovative and complex product design needs prototyping. It takes time but in the end these are the tools that allow you to make those big decisions. Everything we were doing at Apple, back then, was brand new to the world of technology, which meant we had to continually evolve to find the right path. Part of this evolution set the foundation for others to adopt and improve the technology we developed later on. “The Handbook” will help to guide you on your own path as you look to leverage 3D printing and its potential to create your own breakthrough products, that hopefully will change the world. Every designer and engineer should keep it close as it paves your way into new manufacturing technologies that will spur your creativity and unlock your ideas as they become reality. Creation is changing, manufacturing is changing and design is changing, turn the page it’s time to stay ahead… Tony Fadell Creator of the iPod and founder of Nest Introduction As an engineer, often the most important consideration when designing parts for production is the method of manufacturing. A design can be produced via a range of manufacturing techniques with each having their own associated strengths and weaknesses. The purpose of this introduction is to identify where 3D printing sits as a method of manufacturing relative to more traditional processes, like CNC, injection molding and casting. This section will outline the most common manufacturing methods and conclude with an overview of the general 3D printing process. A detailed explanation of manufacturing technologies other than of 3D printing is outside the scope of this book.

Every designer and engineer should keep it close as it paves your way into new manufacturing technologies that will spur your creativity and unlock your ideas as they become reality. Creation is changing, manufacturing is changing and design is changing, turn the page it’s time to stay ahead… Tony Fadell Creator of the iPod and founder of Nest Introduction As an engineer, often the most important consideration when designing parts for production is the method of manufacturing. A design can be produced via a range of manufacturing techniques with each having their own associated strengths and weaknesses. The purpose of this introduction is to identify where 3D printing sits as a method of manufacturing relative to more traditional processes, like CNC, injection molding and casting. This section will outline the most common manufacturing methods and conclude with an overview of the general 3D printing process. A detailed explanation of manufacturing technologies other than of 3D printing is outside the scope of this book. Classification of manufacturing techniques Most manufacturing techniques can be categorized into 3 groups. At the simplest level these groups can be defined as: · Formative manufacturing: best suited for high volume production of the same part, requiring a large initial investment in tooling (molds) but then being able to produce parts quickly and at a very low unit price. · Subtractive manufacturing: lies in between formative and additive, being best suited for parts with relatively simple geometries, produced at low-mid volumes, that are typically made from functional materials (particularly metal). · Additive manufacturing: best suited for low volume, complex designs that formative or subtractive methods are unable to produce, or when a unique one-off rapid prototype is required. Formative (injection molding, casting, stamping and forging) Formative manufacturing typically forms material into the desired shape via heat and pressure. The raw material can be melted down and extruded under pressure into a mold (injection molding/die casting), melted and then poured into a mold (casting) or pressed or pulled into the desired shape (stamping/vacuum forming/forging).

Classification of manufacturing techniques Most manufacturing techniques can be categorized into 3 groups. At the simplest level these groups can be defined as: · Formative manufacturing: best suited for high volume production of the same part, requiring a large initial investment in tooling (molds) but then being able to produce parts quickly and at a very low unit price. · Subtractive manufacturing: lies in between formative and additive, being best suited for parts with relatively simple geometries, produced at low-mid volumes, that are typically made from functional materials (particularly metal). · Additive manufacturing: best suited for low volume, complex designs that formative or subtractive methods are unable to produce, or when a unique one-off rapid prototype is required. Formative (injection molding, casting, stamping and forging) Formative manufacturing typically forms material into the desired shape via heat and pressure. The raw material can be melted down and extruded under pressure into a mold (injection molding/die casting), melted and then poured into a mold (casting) or pressed or pulled into the desired shape (stamping/vacuum forming/forging). Formative techniques produce parts from a large range of materials (both metals and plastics). For high volume production of parts, formative manufacturing is often unrivaled in cost. The main limitation of formative manufacturing is the need to produce a tool (mold or die) to form the part. Tooling is often expensive and complicated to produce, increasing lead times and delaying the manufacturing of a part. This large upfront investment is why formative manufacturing is generally only cost effective at high volumes. The design of formative tooling is also complex with the need for mold features like spurs or runners to assist in the formation of parts. Parts that are produced via formative manufacturing also have design constraints like draft angles and uniform wall thickness to aid in the forming process. Subtractive (CNC, turning, drilling) Subtractive manufacturing begins with a block of solid material (blank), and utilizes cutting tools to remove (machine) material to achieve a final shape.

Formative techniques produce parts from a large range of materials (both metals and plastics). For high volume production of parts, formative manufacturing is often unrivaled in cost. The main limitation of formative manufacturing is the need to produce a tool (mold or die) to form the part. Tooling is often expensive and complicated to produce, increasing lead times and delaying the manufacturing of a part. This large upfront investment is why formative manufacturing is generally only cost effective at high volumes. The design of formative tooling is also complex with the need for mold features like spurs or runners to assist in the formation of parts. Parts that are produced via formative manufacturing also have design constraints like draft angles and uniform wall thickness to aid in the forming process. Subtractive (CNC, turning, drilling) Subtractive manufacturing begins with a block of solid material (blank), and utilizes cutting tools to remove (machine) material to achieve a final shape. CNC milling, turning (lathe) and machine operations like drilling and cutting are all examples of subtractive techniques. Subtractive manufacturing is capable of producing highly accurate parts with excellent surface finish. Almost every material is able to be machined in some way. For majority of designs, subtractive manufacturing is the most cost effective method of production. Subtractive manufacturing is limited by a number of factors. Most designs require Computer Aided Manufacturing (CAM) to plot tool paths and efficient material removal. This adds time and cost to the overall process. Tool access must also be considered when designing parts for subtractive manufacturing as the cutting tool must be able to reach all surfaces to remove material. While machines like 5-axis CNC eliminate some of these restrictions, complex parts will need to be re-orientated during the machining process, further increasing cost and lead time. Subtractive manufacturing is also generally considered a wasteful process, due to the large amounts of material that is often removed to produce the final part geometry.

CNC milling, turning (lathe) and machine operations like drilling and cutting are all examples of subtractive techniques. Subtractive manufacturing is capable of producing highly accurate parts with excellent surface finish. Almost every material is able to be machined in some way. For majority of designs, subtractive manufacturing is the most cost effective method of production. Subtractive manufacturing is limited by a number of factors. Most designs require Computer Aided Manufacturing (CAM) to plot tool paths and efficient material removal. This adds time and cost to the overall process. Tool access must also be considered when designing parts for subtractive manufacturing as the cutting tool must be able to reach all surfaces to remove material. While machines like 5-axis CNC eliminate some of these restrictions, complex parts will need to be re-orientated during the machining process, further increasing cost and lead time. Subtractive manufacturing is also generally considered a wasteful process, due to the large amounts of material that is often removed to produce the final part geometry. Additive (3D printing) Additive manufacturing (more commonly known as 3D printing) is the process of additively building up a part one layer at a time. There are a range of 3D printing technologies with each having their own benefits and limitations and each being able to print parts from different materials. Parts can be produced in almost any geometry, which is one of the core strengths of 3D printing (even though there are still rules that must be followed per technology). Also, 3D printing does not rely on expensive tooling having essentially no start up costs. The advantage of this is the rapid verification and development of prototypes and low- volume production parts. One of the biggest limitations of 3D printing is the inability to produce parts with material properties equivalent to those made via subtractive or formative techniques. Most 3D printing technologies produce parts that are inherently anisotropic or not fully dense. 3D printing also has limitations on repeatability, meaning parts will often have slight variations due to differential cooling or warping during curing.

Additive (3D printing) Additive manufacturing (more commonly known as 3D printing) is the process of additively building up a part one layer at a time. There are a range of 3D printing technologies with each having their own benefits and limitations and each being able to print parts from different materials. Parts can be produced in almost any geometry, which is one of the core strengths of 3D printing (even though there are still rules that must be followed per technology). Also, 3D printing does not rely on expensive tooling having essentially no start up costs. The advantage of this is the rapid verification and development of prototypes and low- volume production parts. One of the biggest limitations of 3D printing is the inability to produce parts with material properties equivalent to those made via subtractive or formative techniques. Most 3D printing technologies produce parts that are inherently anisotropic or not fully dense. 3D printing also has limitations on repeatability, meaning parts will often have slight variations due to differential cooling or warping during curing. Cost comparison Cost is often the governing factor behind how a part will be manufactured. Figure 0.2 gives a general insight into how the cost of manufacturing (cost per part) varies based on the amount of parts being produced. The 3D printing process While there are many different 3D printing technologies, the following section will focus on the general process from design to final part. Although each method of 3D printing produces parts in a different way, these 5 core steps are constant across all technologies. 1. Producing a 3D file Producing a digital model is the first step in the 3D printing process. The most common method for producing a digital model (Figure 0.3) is Computer Aided Design (CAD). Reverse engineering can also be used to generate a digital model via 3D scanning. Both CAD modeling and reverse engineering are discussed in Chapter 18 of this book.There are several design considerations that must be evaluated when designing for 3D printing. These generally focus on feature geometry limitations, support material and escape hole requirements.

Cost comparison Cost is often the governing factor behind how a part will be manufactured. Figure 0.2 gives a general insight into how the cost of manufacturing (cost per part) varies based on the amount of parts being produced. The 3D printing process While there are many different 3D printing technologies, the following section will focus on the general process from design to final part. Although each method of 3D printing produces parts in a different way, these 5 core steps are constant across all technologies. 1. Producing a 3D file Producing a digital model is the first step in the 3D printing process. The most common method for producing a digital model (Figure 0.3) is Computer Aided Design (CAD). Reverse engineering can also be used to generate a digital model via 3D scanning. Both CAD modeling and reverse engineering are discussed in Chapter 18 of this book.There are several design considerations that must be evaluated when designing for 3D printing. These generally focus on feature geometry limitations, support material and escape hole requirements. Designing parts for 3D printing is discussed in Part 2 of this book.

Designing parts for 3D printing is discussed in Part 2 of this book.

See more

Similar The 3D Printing Handbook: Technologies, design and applications (PDF)

Most Popular

Latest upload

Read Free Book “3D-Primet in Small Business” Dmitry Gorky completely online-MyBook

3D-Plot

In the Small Business

Examples of Practical Application ,0002 9000 3D-PRIVE 9000 9000

Gorkov Dmitry

2015

About the author

My name is Dmitry Gorkov and I will tell you a little about

myself. I have been actively working in the field of 3D printing since 2013.

Initially started doing 3D printing on order.

As a result, I built a system on how to start this business from scratch.

At the moment I am developing and

conducting various training programs, both for working on a

3D printer, and building my own business in this area.

You can find a list of training programs

in the appendix to this book.

I cooperate with a large number of manufacturers

and sellers of equipment and consumables, and I can learn from

first hand and convey all the information to you.

I publish articles in the magazine for professionals

publishing activities Publish.

Acted as an invited expert at

conference 3D Print Expo 2015 in Moscow.

All methods of printing and working on 3D printers

this is my personal experience passed through myself, my

rake, my discoveries. In this book, I even more

rethought some points so that more

it is accessible and with a great end result to transfer my knowledge

9. This is not a retelling of other people's articles from the Internet

and you understand the value and uniqueness of

our country similar knowledge and skills.

Introduction

Have you heard that 3D printing is

the technology of the new millennium and promises huge benefits

to those who use it?

Is it true?

In what areas is its use justified, and where

is not? Is it true that this technology can replace

classical manufacturing techniques?

Find answers to these and other questions in this

book.

In order not to be unfounded, I will give you examples

of practical use in the work of many small businesses

.

I would really like 3D printing in Russia

to develop rapidly. I believe that thanks to

to us, this will happen faster and better.

Opportunities and niches for 3D printing

More and more information is coming in about the introduction of 3D printing into all areas of our

life.

Is everything so simple and easy?

How can we apply 3D printing to reality?

Let's start with the fact that this technology is not a magic wand

for all problems.

No, is a VERSATILE tool.

In

first

for

manufacturing

non-standard/small series

products

made of

plastic/resin/plaster etc. The

technology itself is of interest to a not very large group of people,

present here.

Other people are interested in solving their problems.

Can we solve their problems with 3D printing?

Many yes!

Everything that we will tell further will be

refers to the use of a printer that prints using FDM-

technology. Technology of layer-by-layer deposition of plastic.

This is the most versatile and budget option for

starting a business. The main thing is to come to an understanding that a 3D printer

is a universal machine for manufacturing

small non-standard plastic parts.

And you have to “dance” from this.

The main areas of application in which

3D printing is mainly used are:

Modeling of architectural, engineering projects.

Design.

Manufacture of various artistic creations

Decoration, bijouterie.

If you are engaged in one of these areas,

you still yesterday needed to purchase a printer and bring your work to a new level

.

In addition to the customers in the above areas, there are

many more niches for 3D printing applications.

In the CIS countries, a unique situation has developed due to

which the use of 3D printing can be used in

many areas.

What are these factors?

1. The exchange rate of local currencies to world currencies, resulting in

the price of the printer, positions it as equipment ,

and not a toy for printing gnomes.

2. The same exchange rate makes many plastic

things/parts vehicles/equipment from abroad

have a fairly high cost , which allows

much more expensive 3D printing technology

compete with cast parts.

3. Destroyed or built inefficiently

economic relations of enterprises of the former USSR

led to the fact that there is a demand for the manufacture of

plastic parts. Production of parts by casting

is theoretically cheaper, but it is economically justified for large batches

. In the field of small business

injection molding technology ultimately fails

justify.

4. At

West

Problems

small

companies-

manufacturers

decides

large

number

engineering companies . In the countries of the former USSR

this niche is practically not developed . For various

reasons.

What do we get? 3D printing services are in demand. This,

is exactly the niche of engineering firms that

are needed in the field of small-scale production of

plastic parts.

They are also in demand in the public services sector . But

But

here I have to warn you that it is very difficult to promote such services

directly against the backdrop of the current informational

noise.

It is much easier to communicate this to future customers through

companies that already provide services or

sell consumer goods. For it to be

economically justified, it is necessary to focus on

the execution of small-scale orders from various organizations

. Such as car repair shops, household appliances repair shops or clubs

for people who are engaged in some kind of hobby.

In general, at the moment there is still

the opportunity to enter the market from scratch with the offer of 3D printing services and

work on third-party orders.

Many do not yet see 3D printing in their workflow

or are not financially ready to implement this

equipment. The purpose of this book is to convey the full benefits of

3D printers in the manufacturing and service industries.

Some misconceptions

Unfortunately, one of the factors hindering the introduction of

3D printing into business is the incorrect positioning of equipment

. That is, we all hear

that the scope of application is huge, but in fact at exhibitions and from

TV screens we see only "gnomes".

Yes, they can look spectacular, but a person, unfortunately,

does not perceive such presentation of information. He

does not want to think out how he can implement this

technology into his work.

A person does not want to draw an analogy between a

printed dog with an engine on its back and a banal

plastic gear that he uses in his

equipment.

You can understand the manufacturers and sellers - such

products look quite impressive at exhibitions, but they

attract a limited audience of designers and

artists.

Such pictures are empty words for an engineer. I'm not

I'm not

trying to prove here that the artistic use of 3D printing is not correct

. It's just one of the many

facets of technology application.

And just a huge mistake would be to drive all the 3D-

Printing in narrow frames for the production of decorative items.

In the book you will learn about some practical niches

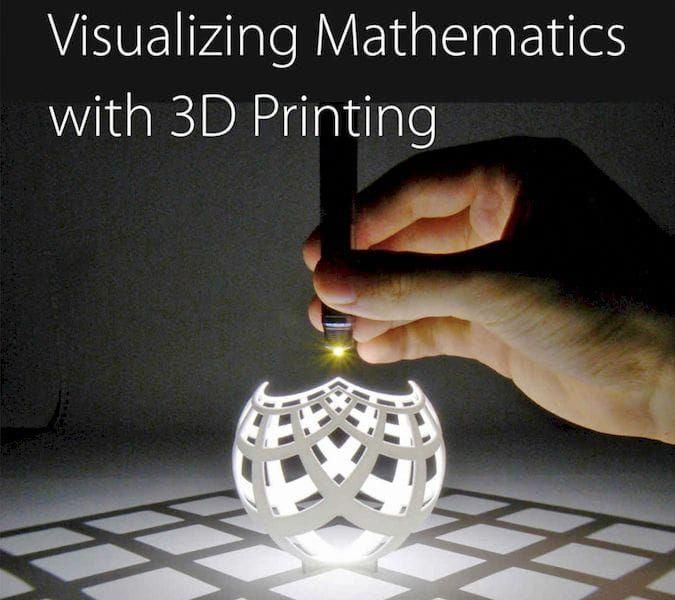

Read a guide to 3D printing with high-strength PEEK material on the Tsvetnoy Mir website

If you're planning to 3D print with PEEK material, which is stronger than metal, then in our guide you will find everything you need to know about PEEK and the best 3D printers to work with this material.

What is PEEK and where is it used?

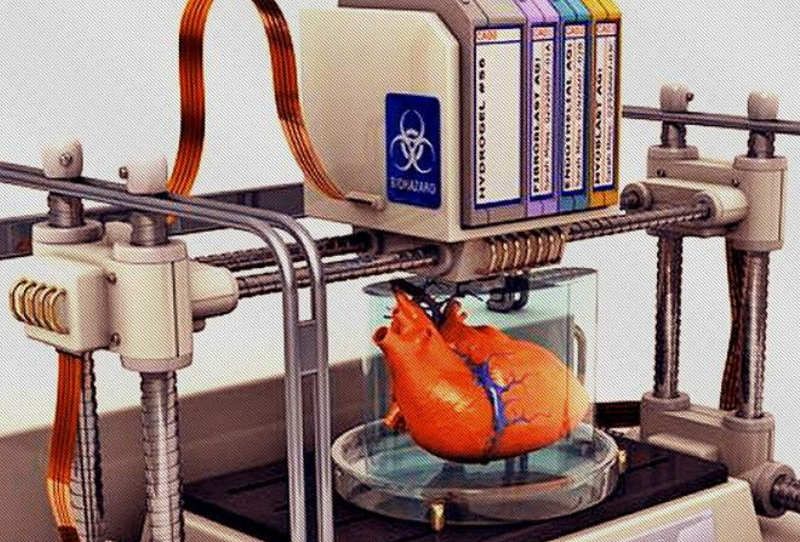

PEEK (polyetheretherketone) is one of the most common thermoplastics in manufacturing, and with good reason. PEEK can produce parts that are stronger and lighter than stainless steel and aluminum, with extremely high thermal, chemical and physical wear resistance. Parts made from this engineering material can be found in almost every industry.

Parts made from this engineering material can be found in almost every industry.

The British company Imperial Chemical Industries (today known as Victrex) introduced polyetheretherketone (PEEK) back in the 1980s. In its basic form, this material is a high purity semi-crystalline polymer containing repeating monomers of two ester groups and a ketone group.

PEEK belongs to the Polyaryletherketone (PAEK) family of polymers, which also includes PEKK (Polyetherketone ketone), but is superior because it can operate at higher temperatures and retain its excellent mechanical properties at continuous use temperatures up to 240°C (464°F) , which allows it to replace metal in harsh operating conditions.

PEEK is one of the few plastics that is compatible with UHV applications, making it suitable for the aerospace, automotive, and chemical industries.

PEEK is also ideal for electrical parts due to its electrical insulating properties and is widely used in applications requiring long-term pressure and wear resistance, such as in the oil and gas industry.

Combine the qualities of this plastic with the power of 3D printing, and you'll be able to create virtually any custom shape and intricate detail in a material that can withstand the harshest environments. It's no surprise that we're seeing more and more printed PEEK parts replacing metal in spacecraft, orthopedic implants, and even engine parts.

The demand for 3D printers that can work with this material is growing, prompting 3D equipment manufacturers to produce more affordable, large and easy-to-use industrial PEEK printers.

While PEEK is still one of the most expensive additive manufacturing polymers (but cheaper than most metals) and not easy to work with, it is now more affordable than ever.

PEEK 3D printer parameters

A spool of PEEK filament may look like any other 3D printing plastic, but not every printer is capable of printing with this material. The main condition for PEEK printing is the high operating temperatures of the printer.

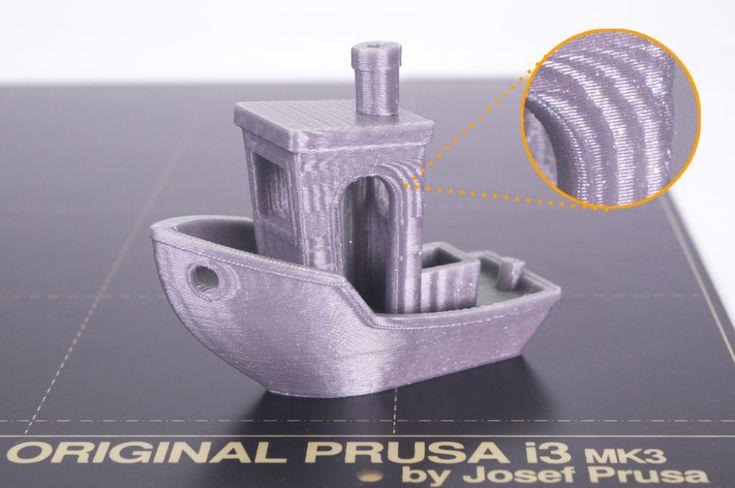

It is required not only to extrude PEEK with a high temperature extruder heating block (380+ ºC), but also to keep it hot with a heated table and a heated chamber. Heating the model during printing improves interlayer adhesion. Also, the heat must be constant and controlled, as how quickly you cool the part after printing also affects quality.

Here are a few more parameters that are important when choosing a 3D printer for PEEK printing:

- HEPA air filter for harmful vapors and particles

- Sealed chamber to keep heat from heating up your room and reducing temperatures in the print chamber

- Quick warm-up chamber for faster print preparation

- The dual extruder printer will print PEEK with dissolvable supports from another material, making it possible to print parts with complex geometries

- Built-in filament dryer keeps media ready to print at all times

- Controlled cooling to prevent deformation

- High print speed

- Built-in video camera for continuous print monitoring

- Power failure protection that resumes printing where you left off

- Filament End Sensor

PEEK 3D printers

We will talk about the most affordable 3D printers in Russia that print with high-temperature materials, which include PEEK.

CreatBot F430

The CreatBot F430 is a versatile industrial printer designed to print on a wide range of materials including PEEK.

CreatBot F430 is equipped with a dual extruder: the left heating block, designed for printing solvent supports, supports heating up to 260 ºC, and the right heating block up to 420 ºC, it ensures a stable supply of high-temperature materials such as PEEK and ULTEM. The construction area is 400x300x300 mm, which is suitable for most production tasks.

The all-metal housing with sealed doors ensures that there are no unplanned temperature changes, and the built-in convector allows you to maintain a constant temperature of the entire volume of the print chamber up to 70 ºC.

It is also worth noting that CreatBot F430 has modern rich functionality, which significantly improves the quality and comfort of working with the printer: resuming printing, filament end sensor, automatic power off, BL-Touch table auto-calibration sensor, air filtration system, intuitive printer interface and others

CreatBot PEEK-300

CreatBot PEEK-300 is CreatBot's more advanced printing solution for PEEK and PEEK-based materials: PEKK, CF-PEEK (carbon fiber), GF-PEEK (glass fiber), and more.

CreatBot PEEK-300 also has a dual extruder, the maximum temperature of each heating block is 500 ºC. The printing table supports heating up to 200 ºC, and the convector is able to provide constant heating of the entire volume of the print chamber up to 120 ºC. The construction area is 300x300x400 mm.

Especially for the CreatBot PEEK-300, Direct Annealing Technology (DAS) was developed and patented, which heats the part during the printing process up to 400 ºC. This system eliminates the need to additionally bake the part after printing to obtain high strength characteristics. After printing is completed, the CreatBot PEEK-300 provides a fully finished part.

Due to the elevated operating temperatures, the CreatBot PEEK-300 uses an improved thermal insulation system using advanced insulation materials and vacuum boards. Also, for long-term operation at extreme temperatures, a liquid cooling system was built into the extruder, and stepper motors are air-cooled.

PICASO 3D Designer X and Designer XL printer series

PICASO 3D's Designer X and Designer XL professional 3D printers use heating blocks with a maximum operating temperature of 410 ºC, and the maximum bed temperature in both cases is 150 ºC, which is suitable for printing most engineering materials, including PEEK. The main difference between the two printers is in the construction area: Designer X has 200x200x210mm, Designer XL has 360x360x610mm.

The all-metal housings of the printers are made of composite aluminum with doors made of heat-resistant plastic, so that a constant temperature is maintained in the print chamber during the printing process. Another significant plus of PICASO 3D printers for printing PEEK and engineering materials is the built-in filament dryer, so the material can be stored directly in the printer in a ready-to-print state. However, Designer X and Designer XL do not have chamber heaters, so consistent PEEK print results can only be obtained when printing small flat parts.