Materials for 3d printing pdf

3D Printer Materials Guide 2022 [Everything You Need To Know]

Want to learn more about the materials used for 3D printing, and the pros and cons of each of them? Here's everything you need to know!

By Justin Evans

Getting into 3D printing can be pretty demanding. There are all kinds of products to choose from and everyone has their own preferences. As a result, any information you’ll find tends to be highly subjective.

Once you’ve purchased and set up your 3D printer, you’ll have to decide which kind of materials to use. Here, we’ve created a wholly factual, objective description of some of the most commonly used 3D printing materials.

Table of ContentsShow

PLA

One of the most-used printing materials, PLA (Poly-Lactic Acid) is highly versatile. It’s made from renewable sources like sugar cane, which helps keep the price low. It’s a very forgiving material with a low chance of warping and good reusability. As a bonus, it produces a sweet, popcorn-like smell when melted.

Because of this material’s low melting point (around 150°F), it’s unsuitable for high heat work. Additionally, while it’s very versatile, the final products tend to be quite brittle, so if you’re building something that’s going to take a few hits, you might want to consider using something else instead.

ABS

ABS (Acrylonitrile Butadiene Styrene) is the second main plastic used in 3D printing. It’s more heat-resistant than PLA, but can be melted down and reused if needed. Its melting point is at about 221°F, so you don’t have to worry about your creations melting in most cases.

This is a more durable plastic too, making it a strong choice for prototyping. You can sand, paint, and polish it without worrying about cracking or warping. It barely shrinks too, so you don’t have to compensate too heavily for that. For the reasons above, ABS is heavily used in manufacturing: it’s what LEGO bricks are made of!

HIPS

HIPS (High Impact Polystyrene) is a rigid, inflexible printing material, often used to create support structures for larger models. It’s water-resistant but can be dissolved in d-Limonene, which prevents the notches left from snap-off supports. It’s a nice, lightweight plastic, which is why it’s usually used for replaceable parts.

It’s water-resistant but can be dissolved in d-Limonene, which prevents the notches left from snap-off supports. It’s a nice, lightweight plastic, which is why it’s usually used for replaceable parts.

Now, there are a couple of limitations. First of all, you’ll need a heated printing bed so that it doesn’t stick. Second, you’ll need a well-ventilated printing area. This is because HIPS fumes can give you a real headache if they’re allowed to build up. With a transition temperature of 212°F, it’s very similar to ABS.

PVA

Like HIPS, PVA (Polyvinyl Alcohol) is most commonly used as a support material. It’s not so great for creating objects since it’s soft and biodegradable. The main difference between PVA and HIPS is that PVA dissolves completely in warm water. This means that you don’t need to obtain any extra solutions or products and can just get on with the job at hand.

The main drawback of this material is that it has a tendency to clog your nozzle if you keep heating it without actually printing. Also, you’ll have to store any extra PVA in an airtight container to prevent any moisture getting in.

Also, you’ll have to store any extra PVA in an airtight container to prevent any moisture getting in.

Nylon

If you want to create objects that can take a beating, nylon is the right material for you. It’s tough, abrasion-resistant, and has a good degree of flexibility to it that most others don’t. For instance, nylon can be used to create cable ties without them snapping.

The main issue is that nylon has a tendency to absorb moisture from its surroundings. This can warp the finished product and compromise its structural integrity. As such, you’ll have to store it in an air-tight container when not in use. Also, its transition temperature is pretty high, at around 250°F, so you might need a special extruder.

Carbon Fiber

Carbon fiber filament is usually PLA or ABS infused with tough fibers that enhance its stability. It’s very light, yet manages to vastly improve the stiffness and rigidity of an object. Further, these fibers help to prevent shrinking as the item cools. The required printing settings barely differ from those of ABS or PLA filament.

The required printing settings barely differ from those of ABS or PLA filament.

There’s a catch, though: carbon fiber filament makes brittle prints and tends to clog easily, and the fibers can scratch your nozzle, changing the way it prints. For this reason, you’ll need to invest in a stronger, ideally steel nozzle before using carbon fiber.

Polycarbonate

Polycarbonate filament (sometimes called PC) is a transparent, tough material that’s suitable for high-temperature applications thanks to its very high transition temperature (around 302°F). PC is naturally flexible, so it can be used in a range of circumstances, including those where the print will be subject to stress.

However, PC filament absorbs moisture from its surroundings. This can cause warping or even layer separation in some cases, so you’ll want to store it in an air-tight container wherever possible. Because of the high temperatures involved, you’ll also need some form of heat protection when printing models with it.

ASA

ASA stands for Acrylic Styrene Acrylonitrile. It’s commonly used in outdoor applications because it’s highly resistant to high temperatures and UV rays. It’s tough too, so you don’t have to worry about it shattering unless you’re really rough with it. So far, so good, but what’s the catch?

Well, ASA is pricey. Also, it gives off fumes that can be hazardous to your health. We’d recommend opening all the windows in your printing room, and perhaps even wearing a mask, just to be safe. With a transition temperature of around 210°F, you’ll also need to run your extruder pretty hot.

Conclusion

There are as many different filaments as there are printers, and it’s not always easy to keep up to date with recently released materials. However, we hope that this guide has shed a little light on all the products that are available and given you some fresh ideas for your next prints.

PLA vs ABS – What’s The Difference?

What Materials Are Used in the 3D Printing Process?

The materials used for 3D printing are as diverse as the products that result from the process. As such, 3D printing is flexible enough to allow manufacturers to determine the shape, texture and strength of a product. Best of all, these qualities can be achieved with far fewer steps than what is typically required in traditional means of production. Moreover, these products can be made with various types of 3D printing materials.

As such, 3D printing is flexible enough to allow manufacturers to determine the shape, texture and strength of a product. Best of all, these qualities can be achieved with far fewer steps than what is typically required in traditional means of production. Moreover, these products can be made with various types of 3D printing materials.

In order for a 3D print to be realized in the form of a finished product, a detailed image of the design in question must first be submitted to the printer. The details are rendered in standard triangle language (STL), which conveys the intricacies and dimensions of a given design and allows a computerized 3D printer to see a design from all sides and angles.

Basically, an STL design is the equivalent of multiple flat designs in one computerized file.

The industry for 3D printing is expected to surpass the 10-figure mark in the near future and plastic is set to be the main material to drive this market. As concluded recently in a SmarTech Markets Publishing study, the market for 3D printing is likely to exceed $1. 4 billion before 2020. With an ongoing market expansion, the industry has sought new ways to yield plastics, including the use of organic ingredients like soybean oil and corn. Consequently, plastics are set to become the most environmentally friendly option in 3D printing.

4 billion before 2020. With an ongoing market expansion, the industry has sought new ways to yield plastics, including the use of organic ingredients like soybean oil and corn. Consequently, plastics are set to become the most environmentally friendly option in 3D printing.

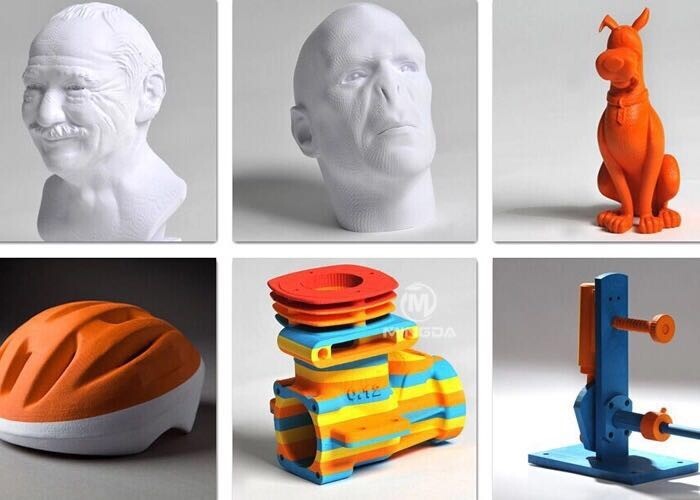

Plastic

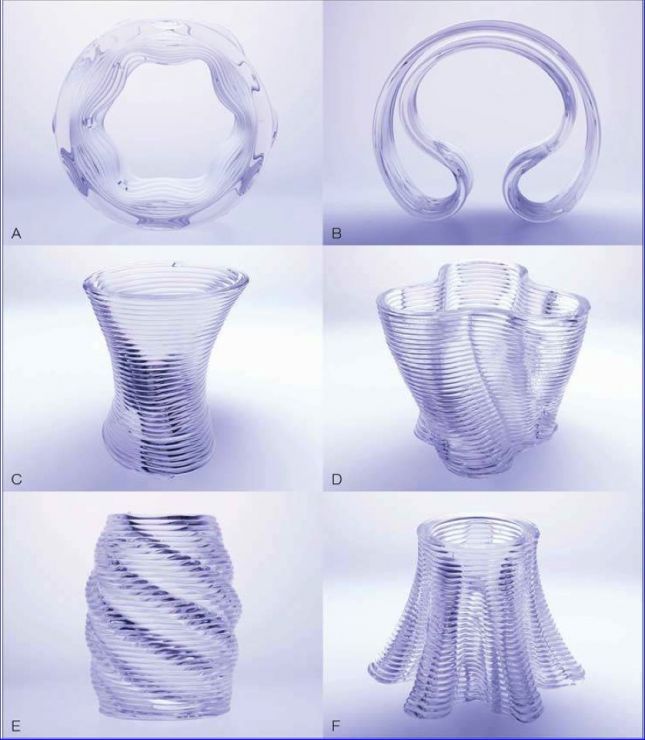

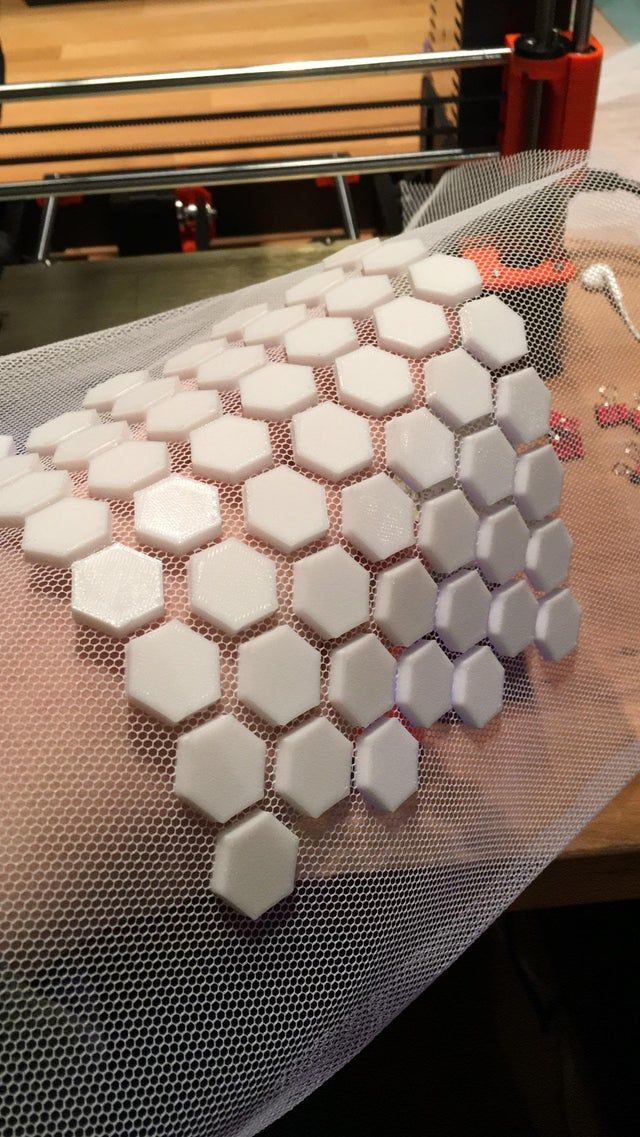

Out of all the raw materials for 3D printing in use today, plastic is the most common. Plastic is one of the most diverse materials for 3D-printed toys and household fixtures. Products made with this technique include desk utensils, vases and action figures. Available in transparent form as well as bright colors — of which red and lime green are particularly popular — plastic filaments are sold on spools and can have either a matte or shiny texture.

With its firmness, flexibility, smoothness and bright range of color options, the appeal of plastic is easy to understand. As a relatively affordable option, plastic is generally light on the pocketbooks of creators and consumers alike.

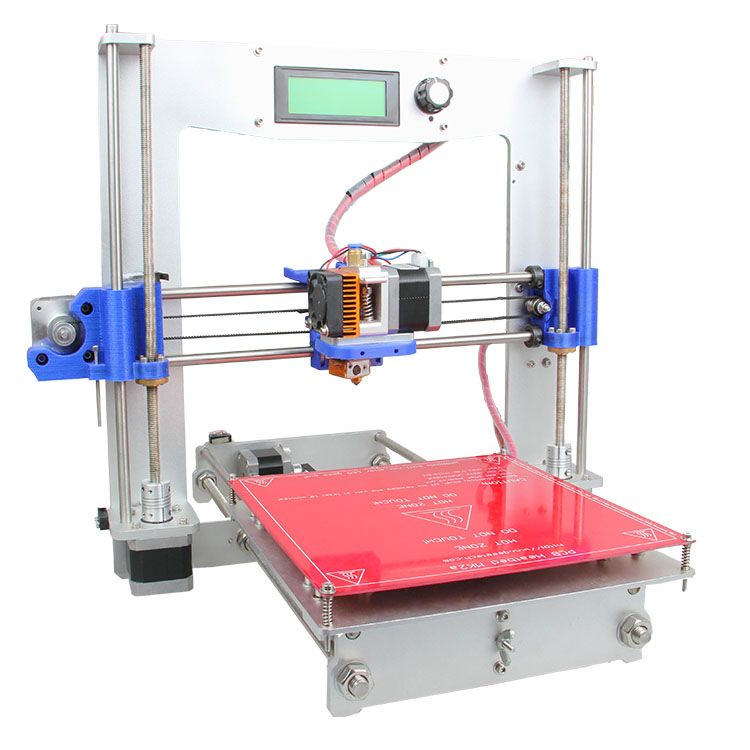

Plastic products are generally made with FDM printers, in which thermoplastic filaments are melted and molded into shape, layer by layer. The types of plastic used in this process are usually made from one of the following materials:

- Polyastic acid (PLA): One of the eco-friendliest options for 3D printers, polyastic acid is sourced from natural products like sugar cane and corn starch and is therefore biodegradable. Available in soft and hard forms, plastics made from polyastic acid are expected to dominate the 3D printing industry in the coming years. Hard PLA is the stronger and therefore more ideal material for a broader range of products.

- Acrylonitrile butadiene styrene (ABS): Valued for its strength and safety, ABS is a popular option for home-based 3D printers. Alternately referred to as “LEGO plastic,” the material consists of pasta-like filaments that give ABS its firmness and flexibility. ABS is available in various colors that make the material suitable for products like stickers and toys.

Increasingly popular among craftspeople, ABC is also used to make jewelry and vases.

Increasingly popular among craftspeople, ABC is also used to make jewelry and vases. - Polyvinyl Alcohol Plastic (PVA): Used in low-end home printers, PVA is a suitable plastic for support materials of the dissolvable variety. Though not suitable for products that require high strength, PVA can be a low-cost option for temporary-use items.

- Polycarbonate (PC): Less frequently used than the aforementioned plastic types, polycarbonate only works in 3D printers that feature nozzle designs and that operate at high temperatures. Among other things, polycarbonate is used to make low-cost plastic fasteners and molding trays.

Plastic items made in 3D printers come in a variety of shapes and consistencies, from flat and round to grooved and meshed. A quick search of Google images will show a novel range of 3D-printed plastic products such as mesh bracelets, cog wheels and Incredible Hulk action figures. For the home craftsperson, polycarbonate spools can now be purchased in bright colors at most supply stores.

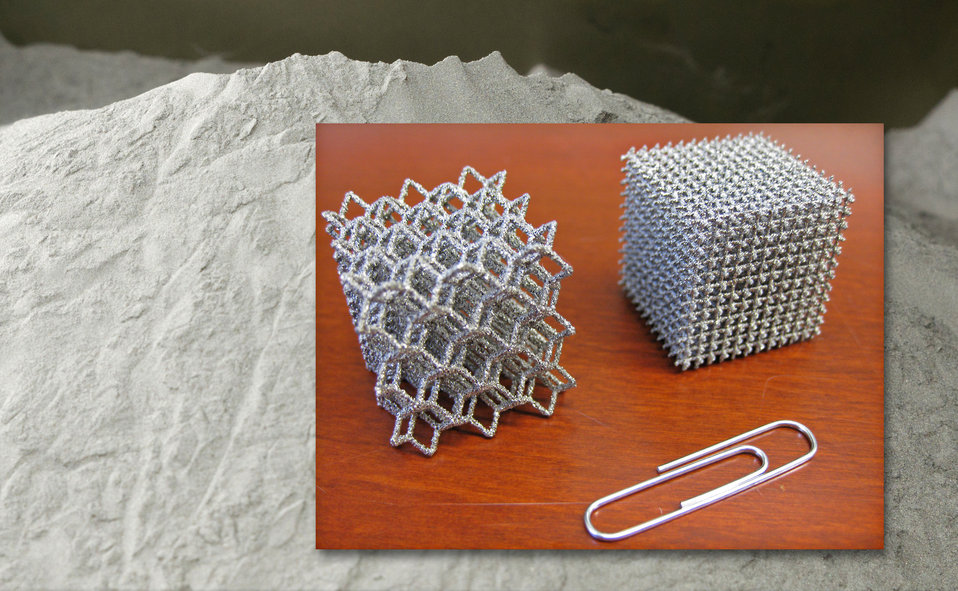

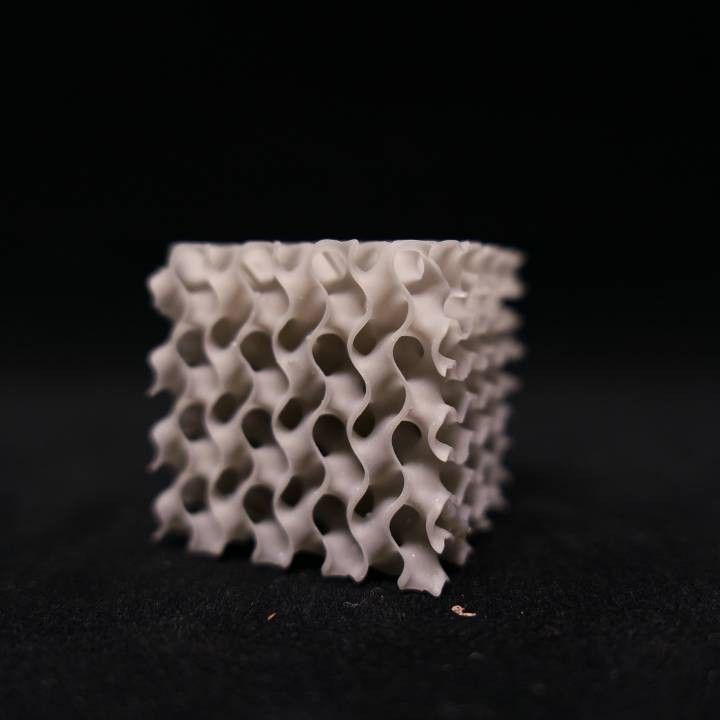

Powders

Today’s more state-of-the-art 3D printers use powdered materials to construct products. Inside the printer, the powder is melted and distributed in layers until the desired thickness, texture and patterns are made. The powders can come from various sources and materials, but the most common are:

- Polyamide (Nylon): With its strength and flexibility, polyamide allows for high levels of detail on a 3D-printed product. The material is especially suited for joining pieces and interlocking parts in a 3D-printed model. Polyamide is used to print everything from fasteners and handles to toy cars and figures.

- Alumide: Comprised of a mix of polyamide and gray aluminum, alumide powder makes for some of the strongest 3D-printed models. Recognized by its grainy and sandy appearance, the powder is reliable for industrial models and prototypes.

In powder form, materials like steel, copper and other types of metal are easier to transport and mold into desired shapes. As with the various types of plastic used in 3D printing, metal powder must be heated to the point where it can be distributed layer-by-layer to form a completed shape.

As with the various types of plastic used in 3D printing, metal powder must be heated to the point where it can be distributed layer-by-layer to form a completed shape.

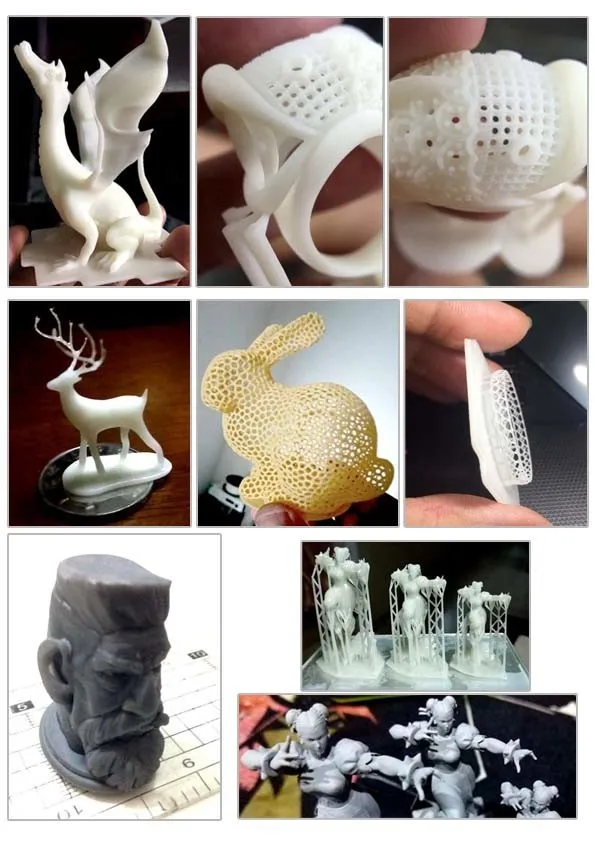

Resins

One of the more limiting and therefore less-used materials in 3D printing is resin. Compared to other 3D-applicable materials, resin offers limited flexibility and strength. Made of liquid polymer, resin reaches its end state with exposure to UV light. Resin is generally found in black, white and transparent varieties, but certain printed items have also been produced in orange, red, blue and green.

The material comes in the following three categories:

- High-detail resins: Generally used for small models that require intricate detail. For example, four-inch figurines with complex wardrobe and facial details are often printed with this grade of resin.

- Paintable resin: Sometimes used in smooth-surface 3D prints, resins in this class are noted for their aesthetic appeal.

Figurines with rendered facial details, such as fairies, are often made of paintable resin.

Figurines with rendered facial details, such as fairies, are often made of paintable resin. - Transparent resin: This is the strongest class of resin and therefore the most suitable for a range of 3D-printed products. Often used for models that must be smother to the touch and transparent in appearance.

Transparent resins of clear and colored varieties are used to make figurines, chess pieces, rings and small household accessories and fixtures.

Metal

The second-most-popular material in the industry of 3D printing is metal, which is used through a process known as direct metal laser sintering or DMLS. This technique has already been embraced by manufacturers of air-travel equipment who have used metal 3D printing to speed up and simplify the construction of component parts.

DMLS printers have also caught on with makers of jewelry products, which can be produced much faster and in larger quantities — all without the long hours of painstakingly detailed work — with 3D printing.

Metal can produce a stronger and arguably more diverse array of everyday items. Jewelers have used steel and copper to produce engraved bracelets on 3D printers. One of the main advantages of this process is that the engraving work is handled by the printer. As such, bracelets can be finished by the box-load in just a few mechanically programmed steps that do not involve the hands-on labor that engraving work once required.

The technology for metal-based 3D printing is also opening doors for machine manufacturers to ultimately use DMLS to produce at speeds and volumes that would be impossible with current assembly equipment. Supporters of these developments believe 3D printing would allow machine-makers to produce metal parts with strength superior to conventional parts that consist of refined metals.

In the meantime, the use of 3D parts is taking flight in the aerospace industry. In what has been the most ambitious push of its kind, GE Aviation plans to print engine injectors at an annual rate of 35,000 units by 2020.![]()

The range of metals that are applicable to the DMLS technique is just as diverse as the various 3D printer plastic types:

- Stainless-steel: Ideal for printing out utensils, cookware and other items that could ultimately come into contact with water.

- Bronze: Can be used to make vases and other fixtures.

- Gold: Ideal for printed rings, earrings, bracelets and necklaces.

- Nickel: Suitable for the printing of coins.

- Aluminum: Ideal for thin metal objects.

- Titanium: The preferred choice for strong, solid fixtures.

In the printing process, metal is utilized in dust form. The metal dust is fired to attain its hardness. This allows printers to bypass casting and make direct use of metal dust in the formation of metal parts. Once the printing has completed, these parts can then be electro-polished and released to the market.

Metal dust is most often used to print prototypes of metal instruments, but it has also been used to produce finished, marketable products such as jewelry. Powderized metal has even been used to make medical devices.

When metal dust is used for 3D printing, the process allows for a reduced number of parts in the finished product. For example, 3D printers have produced rocket injectors that consist of just two parts, whereas a similar device welded in the traditional manner will typically consist of more than 100 individual pieces.

Carbon Fiber

Composites such as carbon fiber are used in 3D printers as a top-coat over plastic materials. The purpose is to make the plastic stronger. The combination of carbon fiber over plastic has been used in the 3D printing industry as a fast, convenient alternative to metal. In the future, 3D carbon fiber printing is expected to replace the much slower process of carbon-fiber layup.

With the use of conductive carbomorph, manufacturers can reduce the number of steps required to assemble electromechanical devices.

Graphite and Graphene

Graphene has become a popular choice for 3D printing because of its strength and conductivity. The material is ideal for device parts that need to be flexible, such as touchscreens. Graphene is also used for solar panels and building parts. Proponents of the graphene option claim it is one of the most flexible of 3D-applicable materials.

The use of graphene in printing received its largest boost through a partnership between the 3D Group and Kibaran Resources, an Australian mining company. The pure carbon, which was first discovered in 2004, has proven to be the most electrically conductive material in laboratory tests. Graphene is light yet strong, which makes it the suitable material for a range of products.

Nitinol

As a common material in medical implants, nitinol is valued in the 3D printing world for its super-elasticity. Made from a mixture of nickel and titanium, nitinol can bend to considerable degrees without breaking. Even if folded in half, the material can be restored to its original shape. As such, nitinol is one of the strongest materials with flexible qualities. For the production of medical products, nitinol allows printers to accomplish things that would otherwise be impossible.

Even if folded in half, the material can be restored to its original shape. As such, nitinol is one of the strongest materials with flexible qualities. For the production of medical products, nitinol allows printers to accomplish things that would otherwise be impossible.

Paper

Designs can be printed on paper with 3D technology to achieve a far more realistic prototype than a flat illustration. When a design is presented for approval, the 3D-printed model allows the presenter to convey the essence of the design with greater detail and accuracy. This makes the presentation far more compelling, as it gives a more vivid sense of the engineering realities should the design be taken to fruition.

Get 3D Plating From Sharretts Plating Company

For more than 90 years, Sharretts Plating Company has offered prompt, affordable, high-quality plating services. Operating from our 70,000-square-foot Pennsylvania production facility, we offer services to customers across North America and abroad. As one of the most globally recognized names in the plating industry, our customizers know they can trust us for plating, metal finishing and other solutions.

As one of the most globally recognized names in the plating industry, our customizers know they can trust us for plating, metal finishing and other solutions.

With each passing decade, SPC has remained at the forefront of innovation in the world of plating. Now, with 3D printing technology approaching maturity, we are determined to meet the demands of this exciting and revolutionary new form of product creation.

At SPC, our extensive background with plating applications has allowed us to apply these capabilities to 3D-printed parts. In recent years, we have applied surface finishing to 3D parts manufactured by electronics and automotive companies as well as in numerous other industries. Regardless of your industry, we can customize a process that will suit your products.

Ultimately, companies that master this technology are bound to have an edge over their competition. Browse our 3D-print plating page to learn more about the options and contact us today for a free quote.

Other pages - Page not found

Ratings and awards Management Expert Council Licenses and accreditations Reviews and thanks Sustainability Management and ESG Cooperation Corporate venture fund

About company >

Accompanying the conclusion of the SPIC Anti-crisis consulting Tax consulting Audit of RAS / IFRS Financial consulting due diligence Investment consulting and valuation HR consulting Management consulting Legal consulting Accounting consulting Transition to FSB Intellectual Property Management Attracting investments

Services and practices ›

Oil and gas Construction and development Mining and exploration Medicine and pharmaceuticals Energy Transport and logistic Food industry and agriculture infrastructure construction mechanical engineering Metallurgy IT industry Retail Light industry Financial sector Science and innovation Management companies Telecommunications and communications Chemical industry Timber industry and woodworking Production

All industries ›

company's news Legislative news Expert Publications Analytical studies

Press Center ›

Jobs Team Internship Alumni

Career >

Send a message and our managers will contact you as soon as possible

We use cookies to improve the site and its user experience. By continuing to use the site, you consent to the use of cookies.

By continuing to use the site, you consent to the use of cookies.

Accept

10 industries that 3D printing is starting to change

3D printing has come a long way from printing small prototype buildings out of plastic. Today, 3D printing is fulfilling its potential in a range of industries, from aerospace to apparel and footwear.

This technology not only allows you to create items with incredible precision, but also saves money.

Today, there are many materials that allow you to make a wide variety of objects using 3D printing.

Below we will talk about the industries in which this technology is applied.

1. Aerospace

In the aerospace industry, everything must be made with high precision. Precision plays a very important role here in the execution of every space mission, and the industry itself is extremely important for the development of mankind.

3D printing has already begun to change the industry, it is used to replace many parts that have become too expensive to produce. In addition, the technology is used to test prototypes.

In addition, the technology is used to test prototypes.

ULTEM 9085 is a thermoplastic commonly used in aircraft construction that can be melted down and used in 3D printing.

2. Architecture

3D printing technology saves time in building construction.

With this technology, printing houses is as fast as printing documents.

And when creating a design, you can share it with other users by placing an object in the database.

3. Food

While 3D printing doesn't save lives, it could change the way we think about food.

Nevertheless, experts note that in the future humanity will face a shortage of food, it is already becoming increasingly difficult to feed the growing population of the planet.

However, science is looking for ways to grow meat and use alternative materials to produce food.

4. Product design

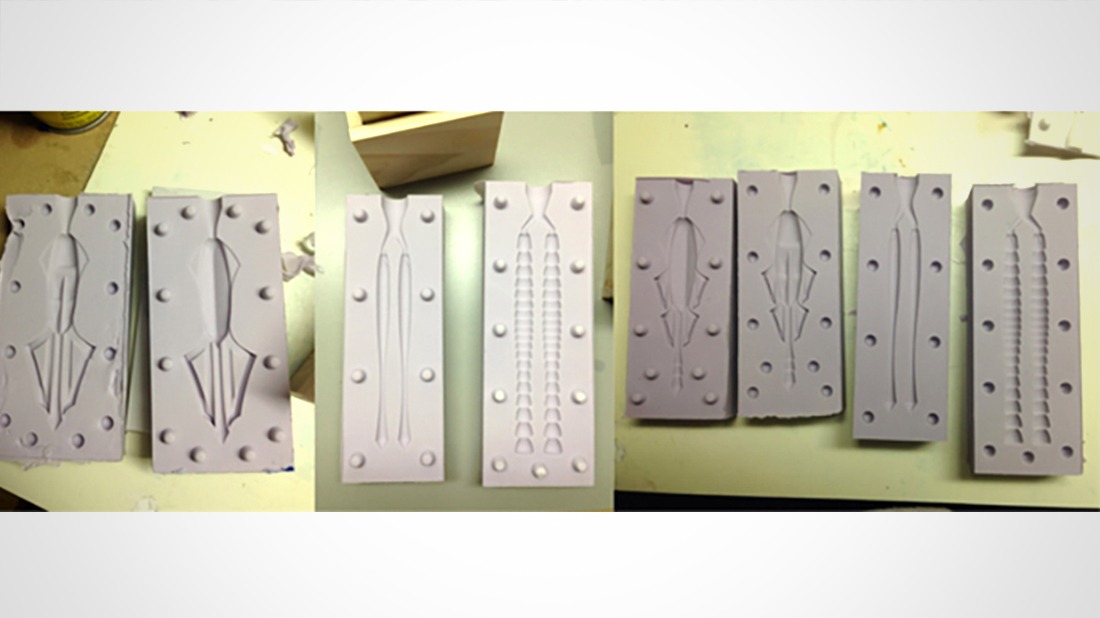

Technology allows you to design something on a computer, then print it in an hour, test it, find flaws, redesign, print a second prototype - and all this takes only half a day.

Previously, concepts were produced, but now 3D printing technology makes it possible to get closer to an almost identical representation of products in a very short amount of time.

5. Medicine

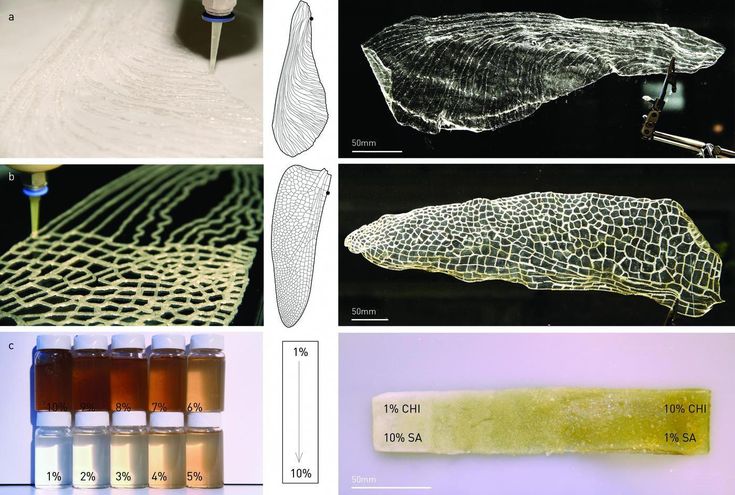

3D printing plays an important role in almost every aspect of medicine. When it comes to prototyping, technology allows you to create ready-made models that will cost less and take less time to create, and these will be ready-made models that are completely usable.

Clarity and precision allows you to print ultra-fine lines that allow you to create the smallest tools.

In addition, 3D printing technology allows you to recreate parts of the human body using various materials. Scientists are constantly working to create new materials and textures.

6. Dentistry

Making dental models is very useful, but it is not always possible to make them taking into account the individual characteristics of a person.

3D printing technology allows you to make exact copies of a patient's teeth to replace them, or crowns that can last longer.

Objet Digital is a dedicated 3D printer designed for use in the field of dentistry.

He uses materials that are very similar in structure to bone to print teeth.

7. Construction

In Dubai, 3D printing is an increasingly common way to construct buildings. Cazza, a 3D printed construction company, plans to build the world's first 3D printed skyscraper.

They created special machines that can build buildings from the bottom up.

Companies around the world have expressed interest in such machines.

In addition, this method of building construction leaves less debris. During construction, environmentally friendly materials can be used.

8. Agriculture

It may seem strange to use this technology in agriculture, but it is true. Many farms need specialized tools, which cost between $8,000 and $12,000 and can take months to complete.

Many farms need specialized tools, which cost between $8,000 and $12,000 and can take months to complete.

PLA, or polylactic acid, is a material that is used for 3D printing and costs $0.25 per 1.5 cu. m. This can significantly save money and time for farmers who are looking to upgrade their machines.

9. Making clothes and shoes

So far, 3D printed clothes have not entered the mass market, but the idea of such clothes has been developed since 2013.

The idea is that in the future, customers can print clothes, which suits their individual sizes.

10. Organ printing

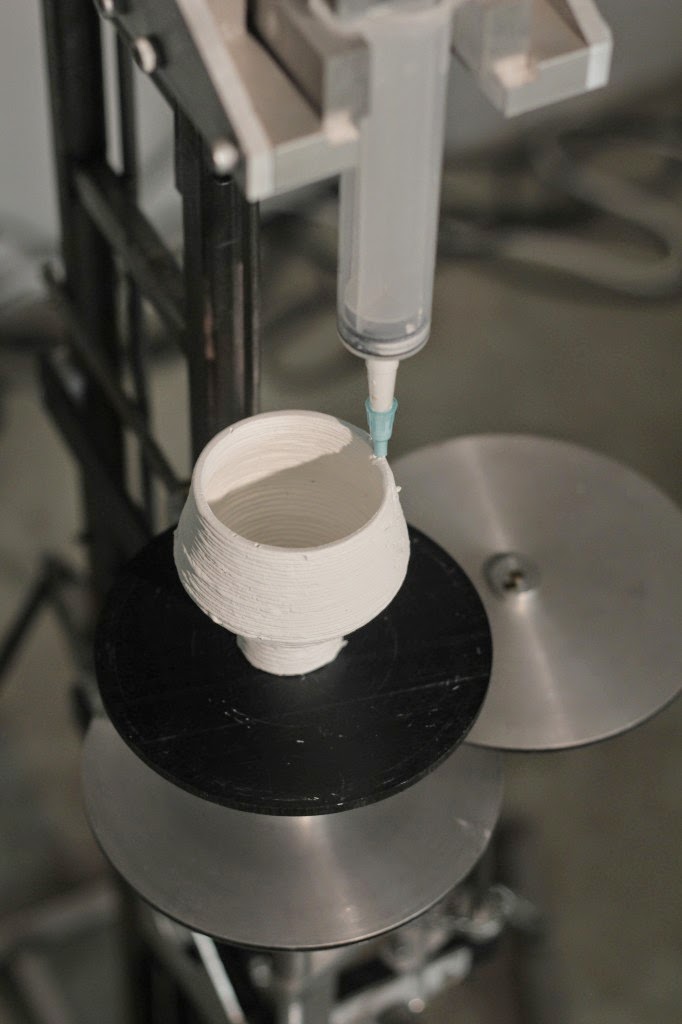

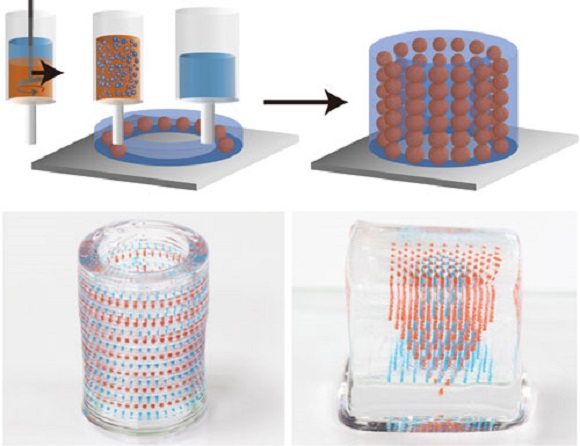

3D bioprinting is a new application that is developing at a rapid pace.

Scientists have made great progress in printing ribs, but they also believe that in the future it will be possible to print hearts, kidneys, livers and other organs.

Cell Link is a company that works with products of this kind, donor organs will soon become mostly artificial.