3D printer rubber material

3D Print Rubber - 3D Printing Gaskets

Rubber and rubber-like materials are everywhere in modern industry. Soft materials like latex, silicone, and thermoplastic elastomer are useful in applications that demand flexibility and durability for industrial parts and consumer goods alike.

While rubber manufacturing has historically been the domain of casting and injection molding, modern advances in 3D printers and 3D printed materials have made additive manufacturing the ideal solution for producing small to medium quantities of rubber-like parts.

Our 3D printed rubber services can manufacture high-quality rubber-like parts in as few as two days―all you need is a 3D model! Start your project by getting a quote or keep reading to learn more.

Get a quote for your project using our quoting tools. Our engineers will review your project and get back to you 24 hours or less. 3D printed rubber parts ship in as few as two days!

3D Printed Rubber Applications, From Prototyping to Production

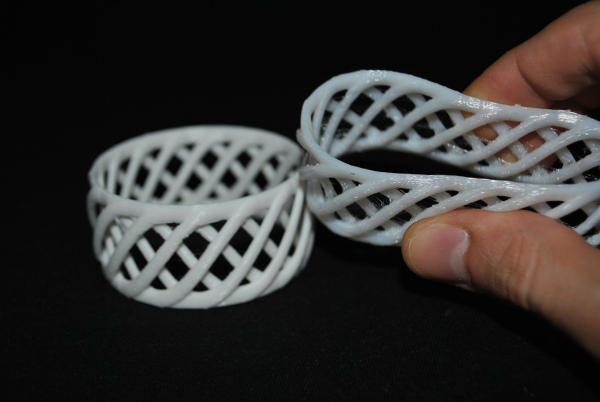

3D printed rubber parts can be used in place of molded rubber for just about any application. Like other methods of 3D printing, rubber prints accurately produce complex internal geometries like lattices and tubes at no extra cost, easily achieving designs that would be impossible with other types of manufacturing.

And because 3D printing doesn’t require any costly molds or tooling, 3D printed rubber parts can be manufactured in just a few days compared to multiple weeks of lead time for injection molding. This combination of high agility and no start-up costs allows rubber 3D printing to excel for both prototyping and small- to medium-sized production runs.

3D printed rubber is ideal for:

Prototypes

Gaskets

Seals

Hoses

Grips

Lids

Plugs

Connectors

Footwear

Tires

Medical Devices

Sporting Goods

Advantages of 3D Printed Rubber vs.

Injection Molding

Injection MoldingTraditionally, rubber manufacturing has required injection molding, casting, or sheet lamination. Rubber-like materials are far too soft to machine, and 3D printing was restricted to harder plastics for most of its development. Now, new developments in 3D printers and materials have opened up a wide range of new possibilities for 3D printed rubber products. So how does 3D printing compare to casting or injection molding for manufacturing rubber?

Short Lead Times and No Setup Costs

Injection molding requires machined metal molds that cost tens of thousands of dollars and take months to produce. Any design changes require new tools, making adjustments extremely expensive and time-consuming.

In contrast, 3D printing requires no tooling or other setup costs and can begin production immediately. This leads to parts that can be manufactured in as little as one day and much greater affordability at low quantities, making 3D printing Moreover, design changes are easy and can be executed at no additional cost.

The Best Choice for Rubber Prototypes

When it comes to product development, 3D printed rubber is a godsend. Even under the most ideal conditions, traditional technologies take weeks of lead time and tens of thousands of dollars for each new design.

Because 3D printing doesn’t require any tooling or setup, 3D printed parts can quickly be designed and redesigned at no additional cost. This agility has made 3D printing an indispensable part of prototyping and product development.

A Question of Quantity

As a result of these differences in lead times and setup costs, 3D printing is much more economical for small- to medium-volume production, while casting and injection molding provide greater value for productions of 1000 parts or more.

Although metal molds are expensive, molded parts become very cheap to produce once the tooling is made. When those initial costs are spread out over thousands of parts, individual part costs plummet, making injection molding the least expensive technology around for high-volume manufacturing.

3D printing, on the other hand, generally stops providing additional per part savings once part quantities exceed the capacity of a single machine. As a result, 3D printing has a much flatter cost curve that makes it a great option for small to medium quantities but significantly less economical for large production runs.

Unlimited Design Possibilities

Rubber 3D printing can easily achieve complicated designs that would simply not be possible with other manufacturing technologies. From interior cavities and lattices to variable wall thicknesses, organic shapes and built-in hoses—all of which are difficult or impossible to create with injection molding—3D printed rubber parts unlock endless new design options. You can even combine multi-part assemblies into single pieces, saving costs and improving functionality.

Plus, 3D printed parts can be highly customized, down to single parts at a time, without additional costs. This is especially useful for industries like medicine or athletics that have a high demand for products customized to each individual user. Needless to say, this would be extraordinarily expensive with casting or injection molding.

Needless to say, this would be extraordinarily expensive with casting or injection molding.

To learn more about the unique design capabilities of 3D printing, check out our Design for Additive Manufacturing (DfAM) Guide.

Is It Really Rubber?

3D Printed Rubber Materials

The answer to whether 3D printed rubber is really rubber depends who you ask. There are a lot of materials that are referred to as rubber: thermoplastic polyurethane, thermoplastic elastomer, silicone, and, of course, natural rubber!

Natural rubber, also known as latex, cannot be liquefied and re-solidified in the manner required by 3D printers. However, thermoplastic elastomers can achieve similar levels of flexibility and softness to rubber and have the thermal properties necessary for 3D printing.

The most effective rubber-like materials for 3D printing are thermoplastic polyurethane (TPU) and thermoplastic elastomer (TPE). It’s important to note, however, that both TPU and TPE refer to multiple materials. In fact, TPU is really a type of TPE―distinguished by its use of polyurethane and increased hardness.

In fact, TPU is really a type of TPE―distinguished by its use of polyurethane and increased hardness.

Thermoplastic Polyurethane (TPU)

Thermoplastic polyurethane (TPU) is valued by engineers for its flexibility and strength. Not only does TPU’s hardness (Shore 85A to 95A) make it easier to print than TPE, but it also provides higher abrasion, chemical and thermal resistance. Moreover, its resistance to oil and grease makes it a great fit for hoses, gaskets and seals. While not as soft as natural rubber, printed TPU can achieve thinner walls than molded parts to create a similar level of flexibility.

TPU can be 3D printed with Multi Jet Fusion or selective laser sintering and is widely used in transportation, medicine, home goods, consumer electronics, and more.

Thermoplastic Elastomer (TPE)

Thermoplastic elastomer (TPE) is softer than TPU―Shore 40A to 70A—and offers moderate abrasion, chemical and thermal resistance. TPE parts can be trickier to print than TPU due to the material’s softness, but it offers a smoother finish.

Nylon TPE is available for selective laser sintering and is used in many of the same industries as TPU. However, because softer TPE materials are not yet available for Multi Jet Fusion, TPE parts are more expensive and slower to produce.

Rubber Printing Services

Multi Jet Fusion (MJF)

Multi Jet Fusion 3D printing is the fastest, most affordable, and most effective option for most 3D printing projects. It is also the newest printing technology to allow rubber printing, with TPU01 options available in black or gray.

MJF prints combine industrial strength, accurate fine details and a high-quality finish to create parts that are equally suited to industrial parts and commercial products. With lead times as little as one day, MJF is the premier printing option for prototypes and small- to medium-sized production runs.

Selective Laser Sintering (SLS)

Selective laser sintering prints nylon TPE parts with excellent mechanical strength but is more expensive and slower than MJF. SLS parts have a medium-quality finish and larger surfaces can warp.

SLS parts have a medium-quality finish and larger surfaces can warp.

This technology scales relatively well at medium volumes and is generally cheaper than FDM at those quantities. SLS can achieve slightly larger part sizes than MJF.

Start Rubber 3D Printing Today

If you need rubber manufacturing for your business, RapidMade can help you take your projects from 3D models to high-quality 3D printed rubber parts in as few as two days. When you work with RapidMade, you get a team of 3D printed experts dedicated to helping you succeed.

Learn more about our 3D Printing Services and get started today by requesting a quote. We’ll review your project and get back to you within one day!

3D printing rubber - 3D printing with rubber: is it possible?

Is it possible to print with rubber?The answer is simple: no. Rubber is a type of sticky material that is pressed hot into a mold in which it cools and vulcanizes. When rubber vulcanizes, it becomes solid and holds its shape. However, after vulcanizing, rubber will never become liquid again. If rubber is heated again, it will burn. For 3D printing, you need a material that liquefies in a controlled way. This is not possible with rubber, so rubber is not suitable for printing.

However, after vulcanizing, rubber will never become liquid again. If rubber is heated again, it will burn. For 3D printing, you need a material that liquefies in a controlled way. This is not possible with rubber, so rubber is not suitable for printing.

What is possible, though?

Synthetic materials such as Thermoplastic Elastomers (TPEs) are good replacements for rubber. TPEs are suitable for printing. TPU filament is such a TPE, it has the same flexibility as rubber but it already melts at 60°C. Rubber is an organic material: the properties of rubber cannot be influenced. However, with TPU we can determine, for example, hardness, heat resistance and wear resistance. We imitate the organic material, but we ensure that we get the desired and most optimal properties.

TPEs, including TPU, are used for various applications in industry. You can think of shoe soles, but industrial applications such as sealing rings are also a good example.

What do I need to consider when printing with TPU?

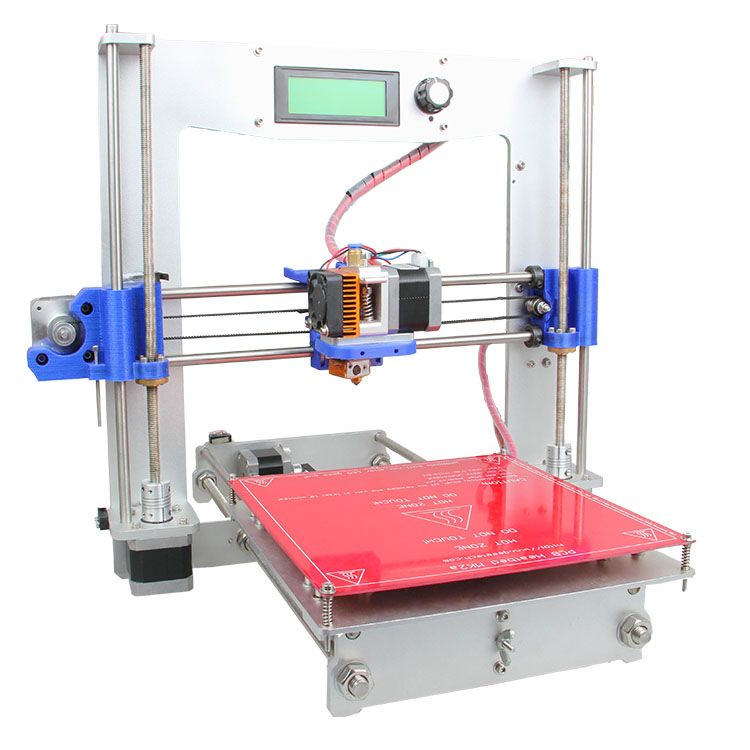

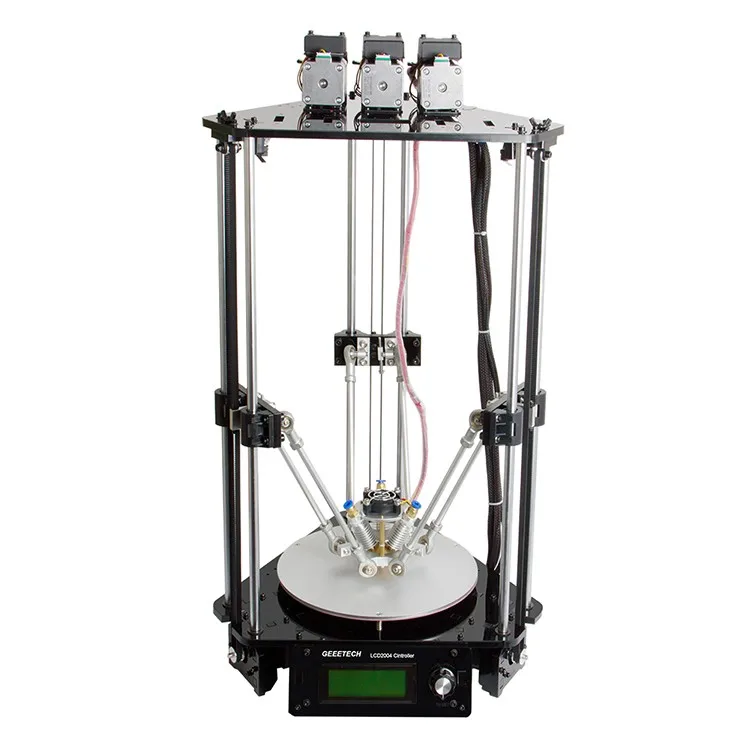

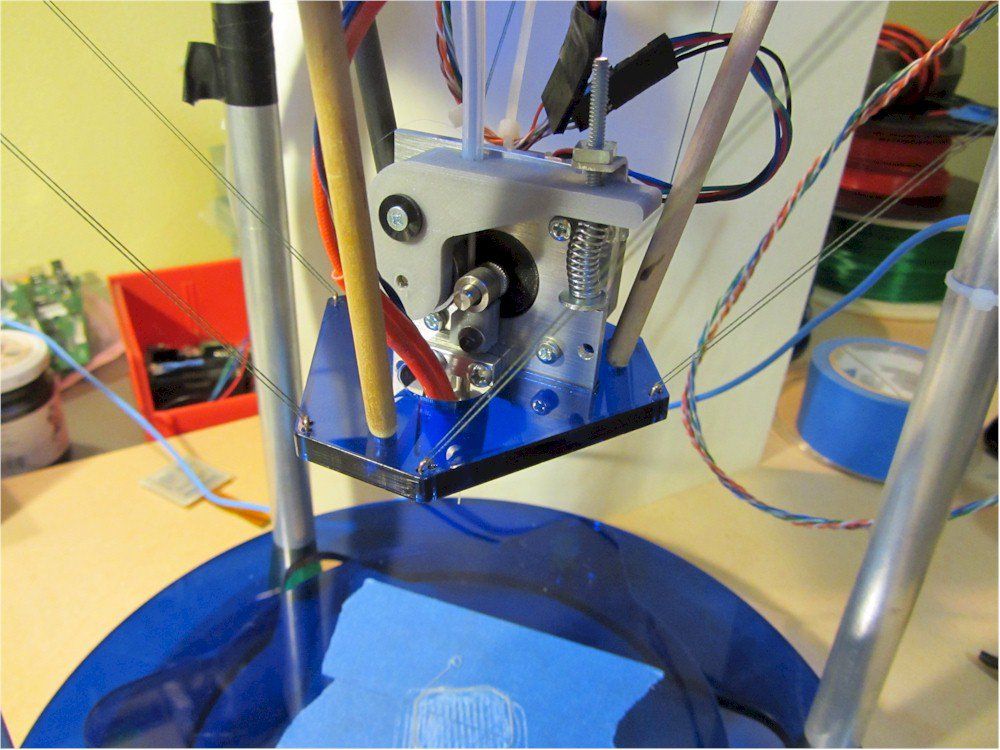

Printing with TPU is difficult. Therefore, it is necessary to practice with PLA first before printing with TPU. TPU needs more time to melt and flow. If you print too fast, the material will collapse. Therefore, it is important to reduce the printing speed. The type of printer you use is also relevant to printing TPU. If the drive motor is at the back of the printer, the material is pushed through the extruder to eventually melt into the print head. With direct-drive printers, where the motor is located in the print head, the filament does not have to be pushed through the entire extruder. It only has to travel a short distance until it is melted. Imagine pushing a rubber band through a pipe, the rubber band will accumulate: the greater the distance, the harder it gets. If the drive motor is in the print head, the filament has to travel a shorter distance. So you need a printer with a direct drive to print well with TPU filament.

Therefore, it is necessary to practice with PLA first before printing with TPU. TPU needs more time to melt and flow. If you print too fast, the material will collapse. Therefore, it is important to reduce the printing speed. The type of printer you use is also relevant to printing TPU. If the drive motor is at the back of the printer, the material is pushed through the extruder to eventually melt into the print head. With direct-drive printers, where the motor is located in the print head, the filament does not have to be pushed through the entire extruder. It only has to travel a short distance until it is melted. Imagine pushing a rubber band through a pipe, the rubber band will accumulate: the greater the distance, the harder it gets. If the drive motor is in the print head, the filament has to travel a shorter distance. So you need a printer with a direct drive to print well with TPU filament.

How do you affect flexibility?

There are different TPEs available: the ones that are really stiff and others that are really elastic. However, the elasticity of the final product is not only influenced by the filament used. The printing technique also affects the elasticity. The thinner you print, the more elastic your product becomes. For example: printing a honeycomb structure creates thin layers with air in between. In this way you can determine which part is more flexible than the other. Thanks to the printing technique, you can achieve different levels of flexibility. When rubber is vulcanized, the end product is always solid. So it is not possible to play with the elasticity of rubber.

However, the elasticity of the final product is not only influenced by the filament used. The printing technique also affects the elasticity. The thinner you print, the more elastic your product becomes. For example: printing a honeycomb structure creates thin layers with air in between. In this way you can determine which part is more flexible than the other. Thanks to the printing technique, you can achieve different levels of flexibility. When rubber is vulcanized, the end product is always solid. So it is not possible to play with the elasticity of rubber.

Can I combine support material with TPU?

When you use support material, you have to pay attention to the print and bed temperatures. These should be about the same temperature as the filament being used. PVA needs about the same temperature as TPU and therefore PVA is the best option to combine with this filament. Is it possible to combine TPU with a material other than the carrier material? Yes, but in this case both must also have the same print and bed temperature. ABS needs a higher temperature than TPU. Therefore, this would not be a good combination because the TPU filament will melt on the print bed. We also recommend that when printing with two materials, the parts should be mechanically joined. That way, the parts will stick together even if the print adhesion does not. More information on printing with support materials can be found here.

ABS needs a higher temperature than TPU. Therefore, this would not be a good combination because the TPU filament will melt on the print bed. We also recommend that when printing with two materials, the parts should be mechanically joined. That way, the parts will stick together even if the print adhesion does not. More information on printing with support materials can be found here.

Our dddrop RAPID ONE features a direct drive, so it’s suitable for printing TPU. Furthermore, for optimum print quality, we offer our own dddrop TPU filament. In case you have any questions, please feel free to contact us: [email protected]. We would love to help you.

All dddrop administrator content is written and edited by the dddrop marketing team.

FlexibelPolyEster (FPE 3D plastic) - rubber plastic for 3D printing

Description

FlexibelPolyEster 3D plastic for 3D printing

The use of flexible materials in 3D printing can be considered a huge step for production. Due to this, the range of possible applications of the technology is greatly expanded. Rubber plastic FlexibelPolyEster is one of the materials that allows you to create flexible products on an ordinary desktop 3D printer. It combines strength, elasticity and heat resistance, giving users access to a range of creative and engineering applications. Moreover, FlexibelPolyEster is compatible with other types of materials, which, in the presence of a 3D printer with two extruders, allows you to combine plastics in a single structure.

Due to this, the range of possible applications of the technology is greatly expanded. Rubber plastic FlexibelPolyEster is one of the materials that allows you to create flexible products on an ordinary desktop 3D printer. It combines strength, elasticity and heat resistance, giving users access to a range of creative and engineering applications. Moreover, FlexibelPolyEster is compatible with other types of materials, which, in the presence of a 3D printer with two extruders, allows you to combine plastics in a single structure.

Features of printing with FlexibelPolyEster plastic

If you want to print with FlexibelPolyEster rubber plastic, do not forget that the method of working with flexible materials differs from printing with conventional plastics. The reason for this lies in the design of the extruder and clamping mechanism of modern desktop 3D printers. Therefore, when printing with flexible materials, it is worth remembering the following rules:

Do not put pressure on the plastic thread when feeding, it is pointless. The filament will simply bend inside the extruder;

The filament will simply bend inside the extruder;

Do not set the print speed to high: print at low (20 - 40 mm/s) speeds. Otherwise, bending and slipping of the thread between the clamping mechanism and the extruder wheel cannot be avoided;

There must be no free space between the extruder wheel and the thermal barrier (the tube into which the plastic filament enters after the extruder wheel). Otherwise, the plastic thread is likely to bend and fill the voids. If there is a similar design in a 3D printer, a Teflon tube should be placed in the free space. Thus, at the exit from the extruder motor, it will immediately fall into the tube, bypassing the void.

Specifications

| Country of origin | China |

| Tensile Strength | more than 35 MPa |

| Stretch | 500% |

| Density | 1200 kg/m 3 |

| Extruder temperature | 220 - 250 °C |

| Platform temperature | 100 - 110 °C |

| Layer thickness | 0. 1 – Ø 0.3 mm 1 – Ø 0.3 mm |

| Wall thickness | 0.03 mm larger than |

| Plastic feed speed | 20 – 50 mm/s |

| Weight | 0.5, 0.8, 1.0 kg |

| 3D printing technology | FDM |

| Plastic thread diameter | 1.75 mm |

| Color | in assortment |

| Reel inner diameter | 32 mm |

Back to Home

Creative materials for 3D printing. The most incredible materials for 3D printer

Today, the main materials for printing on a 3D printer are PLA and ABS plastic. Both materials have long established themselves on the market and are used for printing on a 3D printer using layer-by-layer material build-up technology.

ABS plastic is a plastic formed by the polymerization process of substances , such as acrylonitrile (A) with butadiene (B) and styrene (S).

PLA plastic , or as it is also called - biodegradable plastic is an aliphatic polyester with a monomer in the form of lactic acid. The materials for the production of such plastic are rapidly renewable resources - corn or sugar cane, that is, starch or cellulose.

PVA-plastic has recently appeared on the market. The well-known PVA glue is transferred from a dry state to a liquid of the desired consistency, then melted using special equipment and formed into PVA threads or special granules that are used for 3D printing. An even newer material - Nylon (nylon) - is resistant to a wide range of chemicals and solvents.

The materials discussed above are known to everyone involved in the 3D technology market. But this is not all materials. Manufacturers have stepped far ahead, and are already using for printing on a 3D printer a wide variety of materials - clay, resin, seaweed and more.

Formlabs White Resin :

3D printing equipment manufacturer Formlabs introduces a new material - White Resin . A year ago, the company already launched two new 3D printing materials, Clear Resin and Gray Resin.

The main feature of White Resin is its striking white and opaque color , as well as the exceptional surface smoothness of the printed object . In addition, the new material is ideal for subsequent staining.

White Resin will soon be available in the Formlabs online store at a price of $149 per liter, while (as of the end of summer 2014) it can only be bought in a kit with the company's 3D printer (the relevance of the offer and prices, just in case, check the manufacturer's website).

Titanium Powder for 3D Printing Auto Parts :

English metalworking company Metalysis announced new low cost titanium powder suitable for 3D printing auto parts and parts .

Until now, the most popular materials for 3D printing have been plastics, due to the high cost of the titanium powder production process. But recently Metalysis found a new cheap way to get titanium powder , which can become the most demanded in the manufacture of equipment and machines for the aerospace , defense and automotive industries.

To produce titanium powder, Metalysis uses rutile, which is electrolyzed directly into titanium powder. This method of obtaining a powder makes it possible to change, if necessary, the size of the powder granules, its purity, morphology and the proportion of the content of alloying elements in the composition.

The most amazing material of our time - graphene :

Graphene is a material suitable for three-dimensional printing, which has incredible potential for applications in various fields (molecular programming, solar energy, etc. ), a material that can change the lives of many people. In this regard, the Canadian research company Lomiko Metals Inc. announced the opening of a new special laboratory Graphene 3D Labs Inc., which will focus on the development of high-performance materials based on graphene.

), a material that can change the lives of many people. In this regard, the Canadian research company Lomiko Metals Inc. announced the opening of a new special laboratory Graphene 3D Labs Inc., which will focus on the development of high-performance materials based on graphene.

Material reference: graphite or graphene is composed entirely of carbon atoms, but 1 mm of graphite contains about 3 million layers of graphene. Graphite has a three-dimensional crystal structure, while graphene is a two-dimensional crystal 1 atom thick.

3D Printer Wood Filament :

Dutch 3D printing materials company colorFabb has released a new material, WoodFill wood filament.

WoodFill wood threads are available in two types - Fine (Delicate) and Coarse (Coarse). The main difference between these threads is the quality of processing of wood fibers. WoodFill Fine uses finely ground wood particles, WoodFill Coarse is thicker - based on coarsely ground wood particles.

Wood threads allow you to print beautiful and original vases, decorations and interior items. Finished objects are highly durable and produced in a short time. WoodFill threads consist of 30% pine wood fibers and 70% PLA plastic. Coils with wooden threads are already on sale at a price of 40 euros for a 750-gram spool.

Seaweed 3D Printer Filament :

Le Fabshop has introduced the world's first SWF filament, a "green" filament based on seaweed , , for 3D printing applications.

The manufacturer estimates that the SWF material will be released to the market in the spring of 2014.

Three new materials from Proto-Pasta :

Recently, scientist Aaron Cram and mechanical engineer Dustin Cram launched the Proto-Pasta project, which developed three new materials for use in a desktop 3D printer: Carbon Fiber Reinforced PLA (PLA reinforced with carbon fiber), High Temperature PLA (high temperature PLA) and Polycarbonate-ABS (ABS with polycarbonate alloy).

Compared to all known plastics - ABS and PLA, the new materials have improved performance and are affordable.

Carbon Fiber Reinforced PLA is more heat resistant than regular PLA.

Polycarbonate-ABS (PC-ABS) has high elasticity and bending strength.

Stereolithography rubber material , easy to clean, affordable.

Silk based 3D printing material :

The new material was created from raw silk. Raw silk has been sourced from sustainable sources and treated with epoxy resin. Silk-based material is flexible and strong, thin and light, ideal for 3D printing applications.

Polished and raw brass as material for 3D printer :

Shapeways has introduced two new materials to the world at once - Polished Brass and Raw Brass.

Polished Brass is a material with a smooth, glossy bright yellow surface. Products printed with its help, then covered with 22 carat gold, are almost indistinguishable from real gold jewelry.

Raw Brass is ideal for 3D printing antique or antique style objects, it is also useful for jewelry prototyping and functional parts.

Shapeways soft plastic :

Shapeways has developed a new soft plastic, Elasto Plastics, for use in summer footwear. Elasto Plastics has a milky white color, the material is very flexible, has an uneven grainy surface, and is quite strong.

Clear resin for 3D printer :

Clear resin was developed by specially for stereolithography , based on the technology of layering transparent resin and strengthening the layers with a special laser. This resin is used by to make detailed and fairly complex models.

Learn more