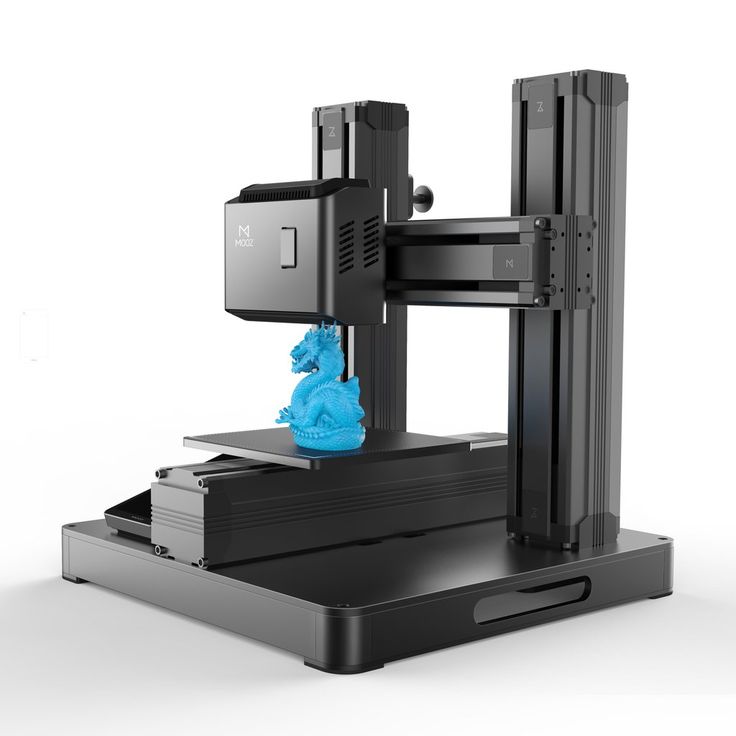

3D printer lower

Hoffman Tactical – Home of the Super Lower !

We design firearms that you can print at home. The AR-15 is the primary focus, though we do lots of other things. You can see some of them below.

Current designs include AR-15, AR-9, and LR-308 lower receivers, as well as stocks and grips. All of our designs can be printed on basic printers from PLA+.

To get started head over to the downloads page and grab your files. Pick up a printer and some filament. Read up on guns and 3D printing as much as you can. Check out our information pages. you can even get some parts from us. And remember, always read the README!

You can find Hoffman Tactical on YouTube, Instagram, Twitter, Rumble, and Odysee. To stay up to date, be sure to subscribe to the email list at the bottom of the page!

New stock system is ergonomically correct and has a positive retention method.

Lazy little follow.

Taulman Glass Fiber Nylon Test Samples. Impact and tensile. Other then it's creep issue, I really like this Nylon.

Nice doggie.

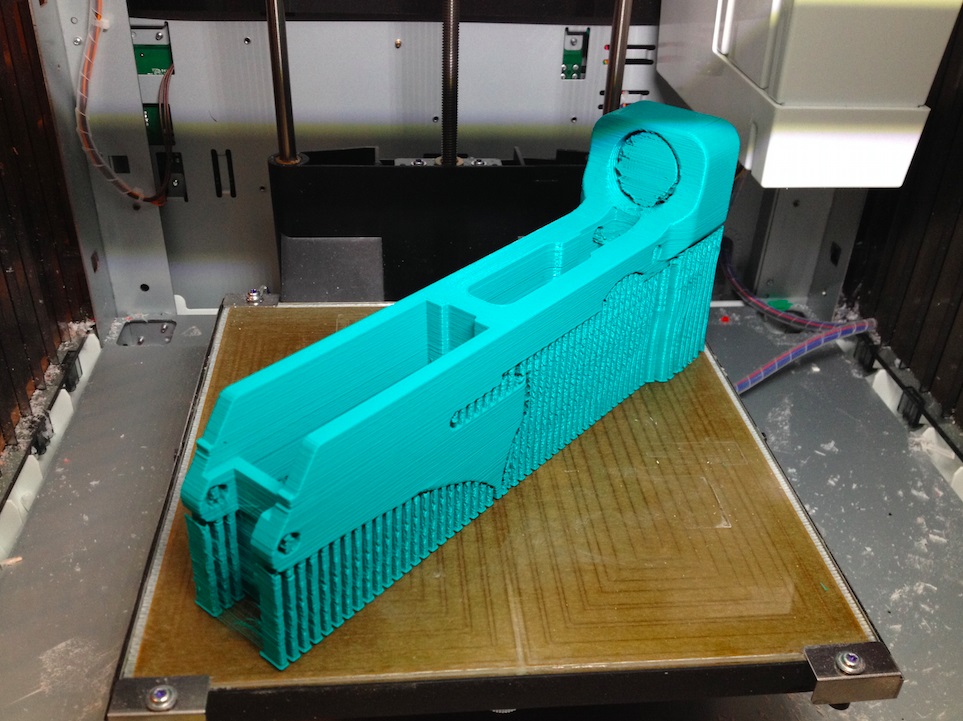

AR-9 Prototype with built in support.

A separated 9 MM case. This is the result of a too light buffer in an AR-9.

Creep test with Overture Easy Nylon. Annealing almost completely eliminated the creep problem.

Buffer Bands fresh from the plating shop.

An LR-308 Prototype. I did not like the VO3D PLA that it was printed from.

Double Rib Lower after a range day. Taulman Glass Fiber Nylon.

Overture Easy Nylon waiting to be creep tested.

PLA test samples used to evaluate the new impact tester.

Test piece for testing different design parameters.

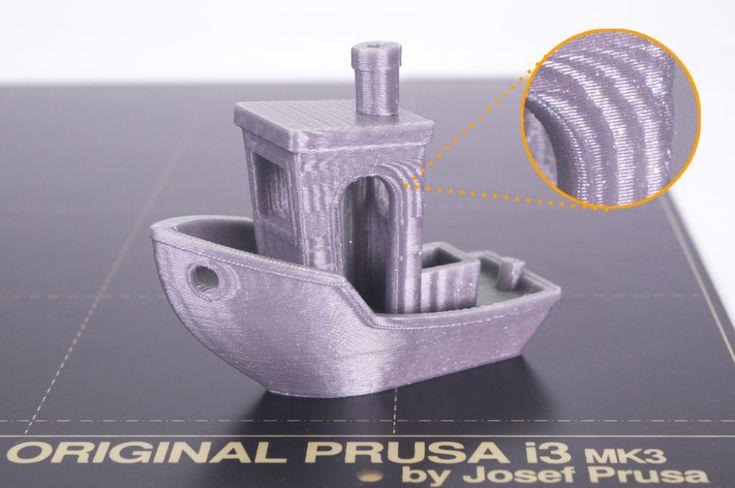

An attempt at more accurate printer calibration.

COEX Nylon. I have actually had a lot of clogging issue with the carbon fiber. I think it has too high of a fiber content.

TPU butt pad prototype for Gen 3 Stocks.

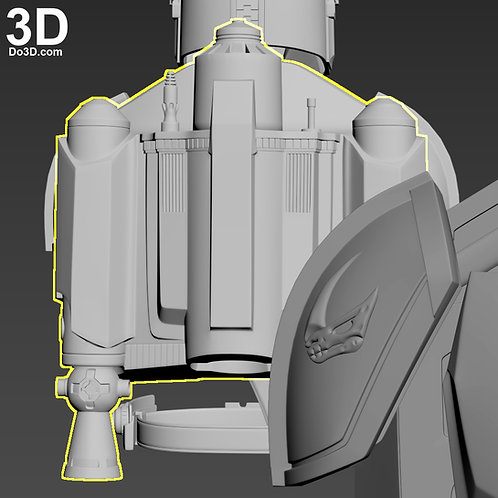

Playing with tree support. I still think built in support is much better, and will design some for a Glock frame sooner then later.

COEX CF Nylon. You can see the results of a nozzle clog on the right.

You can see the results of a nozzle clog on the right.

Printing a TPU butt pad for a Gen 2 Stock.

Old style Gen 1 AR-15 swivel pin plates.

Grip Prototype. I have found that an inverted honeycomb is a better texture then plain honeycomb.

3D printed AR-15 Upper and Lower prototype.

Chilling in the snow with the Double Rib Super Lower.

I bought this nozzle to use with fiber filled Nylon. The larger 0.5 MM orifice should help prevent clogging, but still provide good detail.

5.56 x 45 spent casings after a day at the range.

Triggers waiting to be packed into kits.

Nozzle Temp vs. Layer adhesion eSun PLA+

AR-9 Heavy Buffer. These are a must for a good AR-9 build.

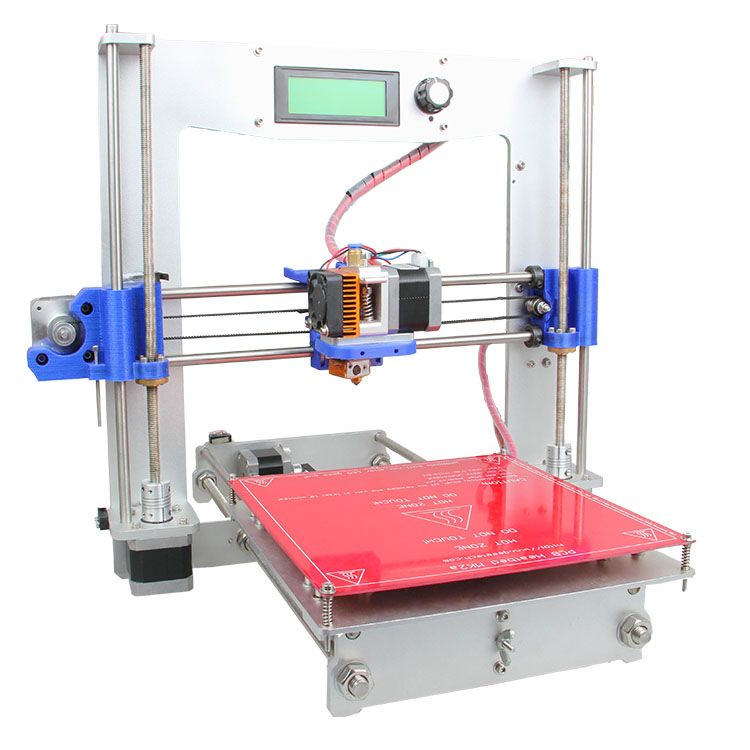

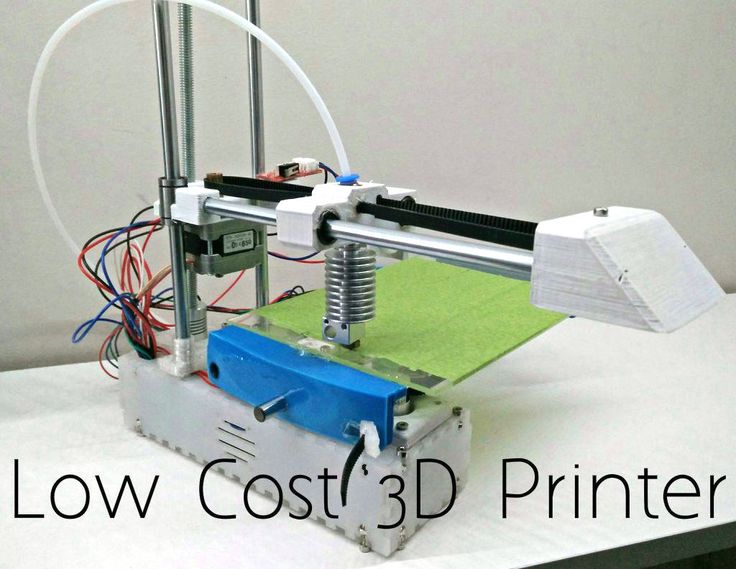

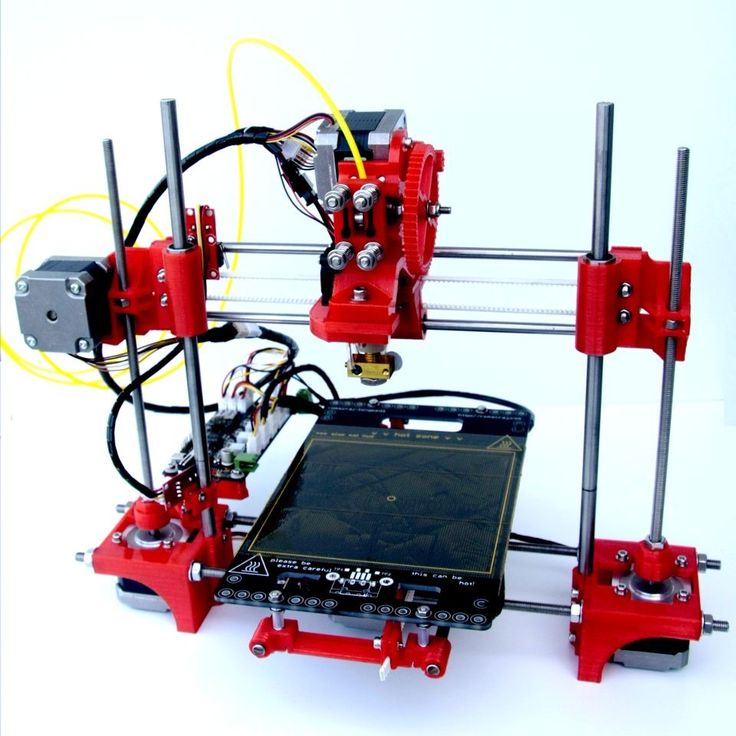

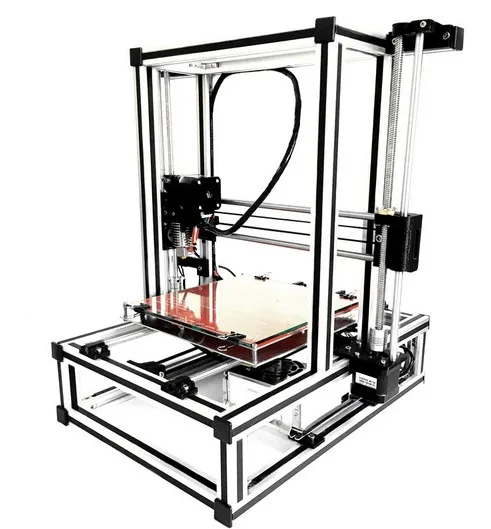

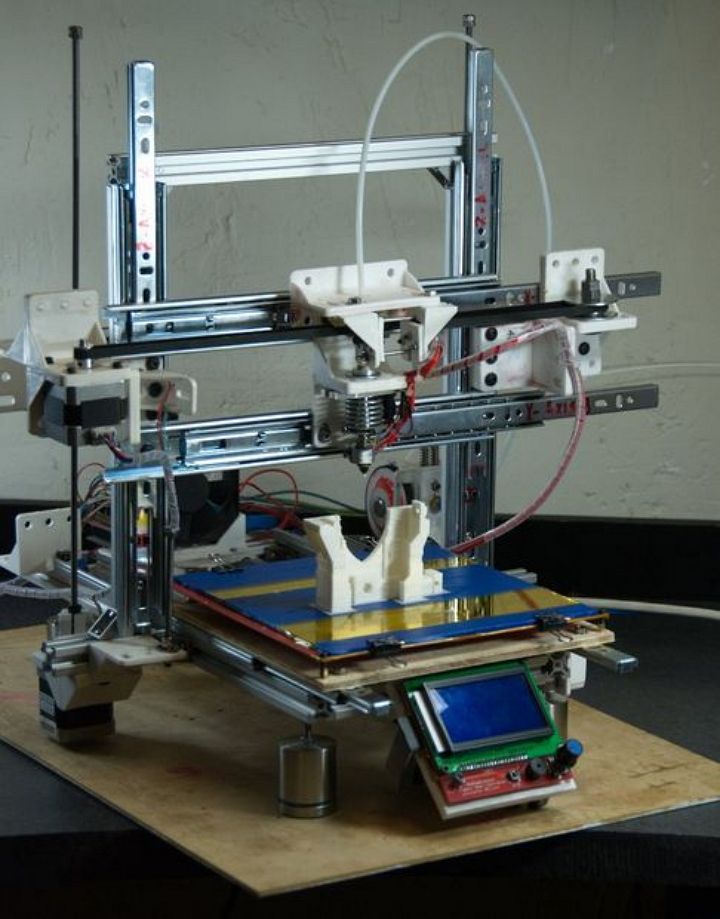

My Ender 3. It's a capable little machine that comes at a ridiculously low cost.

A collection of 3D printed AR lowers. LR-308, Double Rib, AR-15, and AR-9.

A bushing comes to life.

Brass Bushings for the Reinforcement Kits.

V2.5 LR-308 Lower. This is a great lower, the V3.0 grip is nice as well.

This is a great lower, the V3.0 grip is nice as well.

Assembled V2.5 LR-308 Super Lower waiting for it's upper to be built up. KAK bolt and Aero Precision upper and handguard.

Annealing small glass filled Nylon parts in an oil bath.

Number Crunching Gizmo.

V1.4 LR-308 Super Lower with the Gen one stock and grip.

Broken 80% lower.

Cool guy sent me these.

Ghost Guns.

3D Printed AR-15 and LR-308 lowers with the Gen 1 Stocks.

Square nut insert shortly before being imbedded in the print.

V3 Chairmanwon G17 frame. Pretty cool.

Lots of broken samples. Tensile and impact testing.

Fun under white phosphor.

This is an awesome lower. Push Plastic Carbon Fiber Nylon.

New buffer band prototype.

Cleaning the Prusa V6 Hot End.

Hell Fire Lower.

AR-9 Super Lower with a KAK bolt and barrel.

308 Ammo with the V1.4 LR-308 Lower in the background.

The first functional AR-15 Lower printed by Hoffman Tactical.

LR-308 First Print Ever.

I've had a lot of issues printing with the Push Plastic Carbon Fiber Nylon recently, but it makes for great prints when it works.

An interesting experiment. AR-15 Super Lower printed on a resin printer from eSun Hard Tough resin.

The first lower printed with a buffer band.

Gen Two Stock installed on an LR-308 Lower V1.4.

Blog – Hoffman Tactical

6 Comments / Uncategorized / By hoffmantactical

I recently conducted a series of mechanical tests on the Taulman3D Glass Fiber Nylon. The goal was to understand how annealing effected the properties of the Nylon. I also tested how water absorption from the atmosphere effected the mechanical properties, and how soaking in oil and annealing can combat the effects of moisture. These results …

Testing the Taulman Glass FIber Nylon Read More »

9 Comments / Uncategorized / By hoffmantactical

Welcome back to Hoffman Tactical! Today, I’ll update you on upcoming products, and what’s been going on here at Hoffman Tactical. Obviously the big thing that has been going down is the situation surrounding the cease and desist letter I received from rare breed. I won’t say much about it here, as it’s not settled …

Obviously the big thing that has been going down is the situation surrounding the cease and desist letter I received from rare breed. I won’t say much about it here, as it’s not settled …

Upcoming Products and Update Read More »

43 Comments / Uncategorized / By hoffmantactical

A “Forced Reset” style trigger allows the operator of the firearm to pull the trigger faster. They are pretty cool, and completely legal. Recently I decided to design a 3D printed conversion kit that would allow a standard “Mil-Spec” trigger group to be converted to forced reset. The mode of operation is actually very simple, …

A Look at the 3D Printed “FRT” Trigger Read More »

21 Comments / Uncategorized / By hoffmantactical

You asked for it. And it has arrived. I released the V1.0 AR-9 Super Lower a few days ago. Here are the details. My goal for the project was to have a 9 MM lower that would work with Glock magazines, use as many standard AR-15 parts as possible, and feature a last round bolt …

Here are the details. My goal for the project was to have a 9 MM lower that would work with Glock magazines, use as many standard AR-15 parts as possible, and feature a last round bolt …

The AR-9 Super Lower V1.0 Read More »

27 Comments / Uncategorized / By hoffmantactical

The most distinct and unique feature of the Super Lower is the large support rib on the left side of the lower. This greatly increases the strength and stiffness of the buffer tower. Unfortunately another large rib cannot be added to the right side of the lower because it would interfere with the forward assist …

V3.0 – A significant improvment in the Super Lower Read More »

3 Comments / Uncategorized / By hoffmantactical

The original stock worked quite well. But it had one mortal flaw – It was not modular. The new Gen 2 Stock System fixes this problem. The new stock has three Neck types and four Butt types as well as a TPU rubber pad. The parts are interchangeable and can be set up to the …

The new stock has three Neck types and four Butt types as well as a TPU rubber pad. The parts are interchangeable and can be set up to the …

Gen 2 Stock has been Released! Read More »

20 Comments / Uncategorized / By hoffmantactical

I’d like to let you know that V2.8 is out, though it’s not that exciting of a release. The primary improvement is that the support rib has been redesigned to allow the use of Bear Creak Armory slick side uppers. V2.7 had a small amount of interference between these oversized uppers and the rib, this …

V2.8 AR-15 Super Lower and other designs in the works. Read More »

4 Comments / Uncategorized / By hoffmantactical

With the deadline looming only a few days away, time to comment on the two proposed rules that the ATF has published grows short. In the past comments from the public have been effective at deterring the ATF from enacting new antigun rules. And yes, that was a redundant statement. This time around the ATF …

And yes, that was a redundant statement. This time around the ATF …

Commenting on the proposed ATF rule(s) Read More »

15 Comments / Uncategorized / By hoffmantactical

If you head over to the Downloads page you will find that V2.7 of the AR-15 Super Lower is now available. V2.7 is very similar to V2.6 with a few minor improvements. The more important ones are: The profile of the left side has been widened so that a three position selector switch can be …

V2.7 Released and a general update Read More »

2 Comments / Uncategorized / By hoffmantactical

The downloads and products are added and working. I will be adding more info under the “learn” pages. A top priority now is getting instructional material done so that users know how to use the Bushing Installation Tool, print settings, and other important info. I am working on impact tester as well. Still in the …

I am working on impact tester as well. Still in the …

Site is ready! Read More »

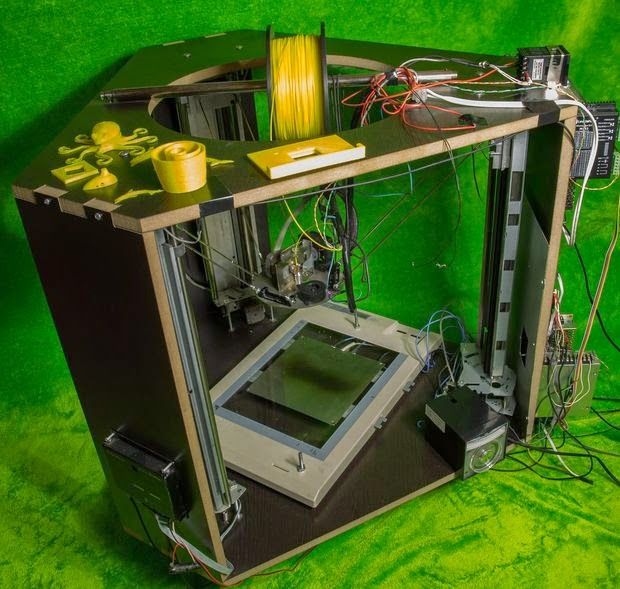

3D printing to order in Nizhny Novgorod, the cost of services

The cost of printing on a 3d printer allows you to use the service not only for commercial and state enterprises, but also for individuals - innovative production technologies have become widely available. Prototyping of 3d models is the reading of information from a computer program by special equipment and translation into a real object by successive building up layer by layer until the formation of a finished product. ProPlast-NN LLC carries out 3d printing to order - the price of is calculated individually depending on the size of the object, the number of samples ordered, the material from which they will be made and the method of prototyping.

3d printing and prototyping - the latest technologies in practice

The combination of computer technology with production allows you to multiply the speed of production, reduce the cost of creating the necessary items. Volumetric printing is developing at a rapid pace, from the realm of fantasy, it has become a familiar production process, which can be carried out using various methods. Order 3d printing in Nizhny Novgorod for one model or batch of products, just call Pro Plast-NN LLC at the numbers listed on the site. The customer will receive a three-dimensional plastic part, made with a high degree of accuracy according to the drawings or based on a real analogue. Small-scale production of products by 3D printing and prototyping is possible.

Volumetric printing is developing at a rapid pace, from the realm of fantasy, it has become a familiar production process, which can be carried out using various methods. Order 3d printing in Nizhny Novgorod for one model or batch of products, just call Pro Plast-NN LLC at the numbers listed on the site. The customer will receive a three-dimensional plastic part, made with a high degree of accuracy according to the drawings or based on a real analogue. Small-scale production of products by 3D printing and prototyping is possible.

Where the created 3d models and prototypes are used

Prototyping on 3d printers allows you to quickly and at low cost get a sample of the desired part from a polymer material, made with a high degree of accuracy, without roughness or distortion. Depending on the technology used and the material from which the sample is made, the product acquires high-tech properties: ideal shape, strength, plasticity, temperature stability. Models have found application in many areas, so they make custom 3d printing companies of different specializations:

Models have found application in many areas, so they make custom 3d printing companies of different specializations:

- medicine;

- automotive;

- serial industrial production: mechanical engineering, instrumentation, metallurgy;

- architecture - when creating models of buildings and complexes;

- design;

- souvenir production.

How 3d prototyping is carried out

The basis for prototyping is a 3d image of an object, compiled by a computer program with three-dimensional modeling functions. 3d custom prototyping is performed with high accuracy of transferring an image into a physical object using one of several possible methods:

- FDM (Fused Deposition Modeling). A moving molten polymer thread forms an object of complex geometric shape in layers, which can subsequently withstand high mechanical and thermal loads.

- SLS (Eng. Selective Laser Sintering).

This is the sintering of a powder in a container under the targeted action of a laser beam.

This is the sintering of a powder in a container under the targeted action of a laser beam. - MJM (from the English. Multi Jet Modeling - modeling with many nozzles). Multi-nozzle 3d printer prototyping , applying molten material with multiple inkjet heads, based on the principle of laser printer.

- LOM (from the English Laminated Object Manufacturing - the production of an object by lamination). Bonding layer by layer of thin films, as is done with lamination. After reaching the desired volume with a laser tool, an object of the desired shape is cut out of the mass.

- SLM (from English Selective Laser Melting - selective laser melting). Selective fusion of metal with a targeted laser beam, resulting in a solid object.

- EBM (from the English Electron Beam Melting - electron beam melting). Creation of a product from a powder that is melted by a directed electron beam.

- STL (from English stereolithography - stereolithography).

Purposeful formation of a solid object by a laser beam directed into a container with liquid polymer rubber.

Purposeful formation of a solid object by a laser beam directed into a container with liquid polymer rubber.

Benefits of 3d printing and prototyping

What are the advantages and benefits for a customer who decides to order 3D printing with printer?

Before launching a new product into mass production, an enterprise can purchase a prototype, test it, make changes to avoid errors in the design development of the product, and reduce the cost of production.

If a private or public enterprise needs to produce a small batch of products, it is more profitable for him to apply for a small-scale prototyping service than to carry out design and engineering development and testing of prototypes, reconfigure production, use labor resources and equipment. Printing on a 3D printer at affordable prices will save businesses a significant amount, reduce production costs.

The desired samples can be obtained in a short period, regardless of the degree of complexity of the object being created. Typically, the prototyping process lasts from one to ten days, depending on the specifics of the chosen manufacturing method. You can place an order for 3D printing at Pro Plast-NN LLC - we will answer your questions, calculate the cost, conclude an agreement and print products in a short time.

Typically, the prototyping process lasts from one to ten days, depending on the specifics of the chosen manufacturing method. You can place an order for 3D printing at Pro Plast-NN LLC - we will answer your questions, calculate the cost, conclude an agreement and print products in a short time.

The cost of 3d printing on the printer is low, which allows customers to reduce their own costs for design development, testing and sample production. LLC "Pro Plast-NN" makes high-quality 3D printing - the price is calculated by managers individually, depending on the volume, complexity of the work, the chosen manufacturing method and the material from which the sample is printed.

The cost of prototyping and creating 3d models

Answer to question how much it costs to print on a 3d printer depends primarily on the number of ordered products, the material from which the product is made, the size of the object, and the technology of its manufacture.

The company "Pro Plast-NN" has the possibility of small-scale production of parts - we can produce a whole batch of products. The cost of a single sample is higher than products produced in batches.

Pro Plast-NN LLC offers 3D printing in Nizhny Novgorod at prices below market prices. Many businesses and individuals who once applied for the service prints on a 3d printer to order become our regular customers - we guarantee the quality of the resulting products, fast production speed, meeting deadlines.

Repair of 3d printers in Nizhny Novgorod, prices, reviews

Found 5 service centers for repair of 3d printers in Nizhny Novgorod. Choose the service that suits you from the list below or just leave a request for repair and the master will contact you.

Quick repair request

BQ Anycubic Creality3D FlashForge Picaso 3D Tianfour Tiertime wanhao XINKEBOT XYZprinting 3D Systems Anet

st. Vaneeva 23

Vaneeva 23

Today 09:00-20:00, no break

+7 (8312) 81-39-33

5 pictures

WE REPAIR FAST AND FOR LONG !!! Association of Private Masters. Ours is cheaper. Call!

Maxim Gorky 184

Today 09:00-20:00, break 09:00-20:00

+7 (960) 172-00-64

4 certificates

Lenin Avenue 65 (and 1 more address)

Today 10:00-19:00, non-stop

+7 (8312) 91-18-95

st. Maslyakova, 14

Today 10:00-20:00, no break

+7 (8312) 60-10-74

4 reviews

Lenina, 1

Today 09:00-18:00, no break

+7 (939) 802-77-18

Sergey rated 5 stars

Good tradesmen, good service. The washing machine was repaired quickly and at a fair price. Thank you

The washing machine was repaired quickly and at a fair price. Thank you

Leave a request for repair of a 3d printer or just ask a question to the masters and representatives of service centers will contact you to fix the problem.

How does it work?

Find a service center

Useful manuals

Can't contact a service center? Then try to fix it yourself with the help of step-by-step instructions, guides and manuals that we have collected in one place.

Random instructions

UP! Nozzle Replacement Plus 2

Often the nozzle on a 3D printer becomes clogged or broken and needs to be replaced.

M3D Micro Fan Replacement

The M3D fan is a critical component of the M3D and if it is defective or broken your printer will not work perfectly.

02 | Z Frame complete

03 | Y axis assembly

All manuals

Frequently asked questions about 3d printer repair

Where can I repair a 3d printer in Nizhny Novgorod?

We advise you to contact one of the following service centers: Spectrum-Service, RosTechService, RMOBi SERVICE CENTER.

Are there services with free diagnostics?

Yes, for example, Spectrum-Service, RMOBi SERVICE CENTER, Foton. You can get a complete list of service centers with this service by applying the filter.

How many 3d printer repair shops in Nizhny Novgorod have good reviews?

According to users of Nizhny Novgorod, there is 1 3d printer repair service center in the city with positive reviews: LenService and 0 more service centers.

I need an urgent repair of a 3d printer in Nizhny Novgorod

Urgent repair is available from 4 service centers, here are some of them: Spectrum-Service, RosTechService, RMOBi SERVICE CENTER. Use the filter to find urgent repairs.

Can I pay for repairs with a card?

You can pay for the repair of a 3d printer with a card in 3 services, for example here: Spectrum-Service, RosTechService, Photon.

Is there delivery for repairs?

3 service centers are ready to come and pick up your 3d printer for repair, and then bring it back.